Abstract

Capacitors exhibit exceptional power density, a vast operational temperature range, remarkable reliability, lightweight construction, and high efficiency, making them extensively utilized in the realm of energy storage. There exist two primary categories of energy storage capacitors: dielectric capacitors and supercapacitors. Dielectric capacitors encompass film capacitors, ceramic dielectric capacitors, and electrolytic capacitors, whereas supercapacitors can be further categorized into double-layer capacitors, pseudocapacitors, and hybrid capacitors. These capacitors exhibit diverse operational principles and performance characteristics, subsequently dictating their specific application scenarios. To make informed decisions in selecting capacitors for practical applications, a comprehensive knowledge of their structure and operational principles is imperative. Consequently, this review delved into the structure, working principles, and unique characteristics of the aforementioned capacitors, aiming to clarify the distinctions between dielectric capacitors, supercapacitors, and lithium-ion capacitors.

1. Introduction

Due to global economic growth and expanding population, there has been a consistent and unwavering increase in the demand for energy [1]. The extensive exploitation of fossil fuels, however, has resulted in numerous challenges, including global warming and environmental pollution [2]. These issues not only pose a direct threat to human health but also inflict significant damage on our ecosystems. Furthermore, given the limited reserves of fossil fuels, the issue of energy scarcity is rapidly escalating [3]. Consequently, there is an urgent need to move away from traditional fossil fuels and explore renewable energy sources. However, renewable energy sources such as solar energy, wind energy, tidal energy, and geothermal energy are inherently intermittent and unstable, posing challenges to their utilization [4,5]. To enhance the utilization of renewable energy, it is imperative to transform it into other forms, primarily electricity, for storage. Consequently, the advancement of energy storage technology holds immense significance in optimizing energy structures, enhancing energy efficiency, safeguarding energy security, and fostering sustainable energy development.

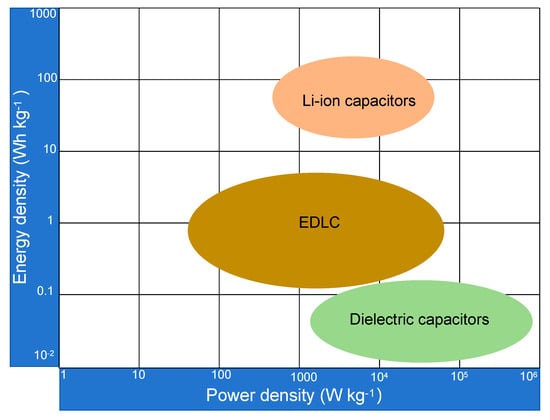

For over two centuries, batteries have been extensively utilized for energy storage purposes and continue to be so today. In recent years, lithium-ion batteries with polymer solid-state electrolytes have received increasing attention due to their inherent safety and excellent thermal stability, promising large-scale applications [6]. Furthermore, various other technologies such as solid oxide fuel cells (SOFCs), electrochemical capacitors (ECs), superconducting magnetic energy storage (SMES) systems, flywheel energy storage systems, and dielectric capacitors are also commonly employed for storing energy [7]. Capacitors possess higher charging/discharging rates and faster response times compared with other energy storage technologies, effectively addressing issues related to discontinuous and uncontrollable renewable energy sources like wind and solar [3]. Furthermore, they can tackle challenges such as peak shaving, frequency regulation, and intelligent power supply within the power grid, thereby enhancing the efficiency of multi-energy coupling and promoting energy conservation and emission reduction [8]. With the rapid development of the electronics industry, capacitors have undergone an evolution from relatively primitive forms such as air-dielectric capacitors, mica-dielectric capacitors, and paper-dielectric capacitors to ceramic-dielectric capacitors and electrolytic capacitors [9]. The advent of diverse dielectric materials, especially organic media, combined with sophisticated manufacturing techniques, has led to a significant reduction in capacitors’ overall size and a remarkable boost in performance. In recent years, the emergence of the double-layer theory has fueled the rise of supercapacitors, with double-layer supercapacitors and hybrid supercapacitors experiencing rapid growth and exhibiting promising applications [10]. The performance of different capacitors is shown in Table 1, and the comparison chart of energy density and power density for different capacitors is shown in Figure 1.

Table 1.

Performance comparison of different capacitors.

Figure 1.

The comparison chart of energy density and power density for different capacitors. Reproduced from Ref. [11] with permission.

As new energy technology and capacitor energy storage continue to evolve, users may encounter numerous questions related to capacitors. To make informed decisions about their selection and usage, it is imperative to gain a comprehensive understanding of capacitors’ structure and operating principles. Furthermore, there are some new researchers in the realm of capacitor energy storage who lack a thorough comprehension of capacitors’ classification, structure, and operational mechanisms, which can readily lead to confusion regarding the various types of capacitors. Hence, this review endeavors to offer a comprehensive overview of the structures and operational principles of various capacitor types. Its objective is to illuminate the distinctions between dielectric capacitors, supercapacitors, and lithium-ion capacitors, thereby facilitating a thorough understanding of these capacitor categories among the readership.

2. Dielectric Capacitor

The development of commercial dielectric capacitors can be traced back to 1876 when Fitzgerald invented the wax-impregnated paper dielectric capacitor equipped with foil electrodes [12]. This innovation was swiftly adopted in early radio-receiving equipment, significantly advancing radio communication technology. Subsequently, in 1909, William Dubilier introduced the mica dielectric capacitor, injecting new vitality into the field of radio transmission. Around 1926, capacitors based on titanium dioxide hit the market, further diversifying the types and enhancing the performance of capacitors. Then, in 1936, Cornell-Dubilier successfully commercialized aluminum electrolytic capacitors, launching a series of commercial products that marked a new era in the development of aluminum electrolytic capacitor technology. With the discovery of barium titanate in 1941, researchers embarked on the study of barium titanate-based dielectric capacitors, further advancing capacitor technology. During World War II, significant breakthroughs were made in capacitor manufacturing technology. Bosch leveraged lacquered paper and vacuum metallization techniques to mature the metalized paper capacitor, significantly enhancing its performance [13]. In 1954, Bell Labs successfully developed the first metalized polymer film capacitor, rejuvenating the capacitor industry [14]. From the 1970s to the 1980s, significant progress was made in the manufacture of multilayer ceramic capacitors (MLCCs) through the adoption of tape-casting technology and co-firing of ceramic electrodes. This resulted in a substantial increase in capacitance values and voltage withstand capabilities, vastly expanding the application areas of ceramic capacitors and making them indispensable components in numerous electronic devices. Currently, the primary types of dielectric capacitors include film capacitors, electrolytic capacitors, and ceramic capacitors [15].

The capacitance value of a capacitor is typically determined using Equation (1) [16]:

where εr is the dielectric constant with respect to the electrolyte utilized, ε0 is the permittivity of the vacuum, A is the surface area of the electrode material accessible to the electrolyte ions, and D is the effective thickness (charge separation distance) between the electrodes.

Therefore, the capacitance value can be increased by increasing the surface area of the electrodes and decreasing the distance between them.

In comparison to various electrical storage devices like batteries, dielectric capacitors possess the capability to discharge stored energy in an extremely brief timeframe (microseconds), resulting in the generation of substantial power pulses [17]. Their rapid charging and discharging rates render them ideally suited for high-power/pulse power systems, including medical defibrillators, pulsed lasers, power conditioning systems, and advanced electromagnetic emission systems [18,19,20,21]. Additionally, they are effective in harnessing energy from intermittent renewable sources [22]. However, the relatively low energy density of dielectric capacitors poses significant constraints on the miniaturization and lightweighting of equipment [23]. If the energy density of dielectric capacitors could be enhanced, it would lead to a substantial broadening of their application scope in the realm of energy storage.

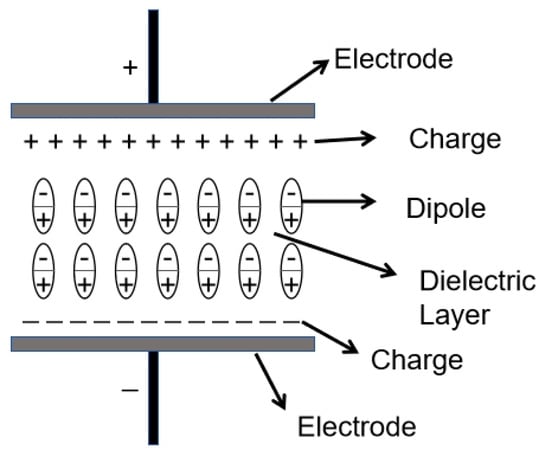

The energy storage mechanism of a dielectric relies on its polarization process triggered by an electric field [24]. When an electric field is applied, the dielectric becomes polarized, leading to the accumulation of equal amounts of positive and negative charges on its surface. Consequently, energy is stored within the dielectric in the form of an electric field, as shown in Figure 2. The mechanism behind energy storage and release in dielectrics is elucidated through the electric displacement (D)-electric field (E) loop. As an electric field is applied, dielectrics become polarized due to the relative displacement of oppositely charged particles within their dipoles. Conversely, upon the removal of the electric field, depolarization occurs, causing the oppositely charged centers to tend toward overlap [25].

Figure 2.

A schematic depiction of an electrically charged dielectric capacitor reveals how the charges of oriented electric dipoles, under the influence of a bias, contribute to binding the opposite charges at their respective electrode interfaces.

Dielectric capacitors can be categorized into several types, including film capacitors without electrolytes, electrolytic capacitors that utilize electrolytes, and ceramic capacitors. Film capacitors are made by depositing metal layers with different patterns on both sides of a thin film. While they can achieve voltages of tens of thousands of volts per unit, their capacitance is relatively small, necessitating parallel connection for high-power applications. Electrolytic capacitors can be classified into aluminum electrolytic capacitors (with an anode made of aluminum oxide, a separator of fibrous paper for insulation and electrolyte absorption, and an electrolyte typically composed of boric acid, ammonia water, and ethylene glycol) and tantalum electrolytic capacitors (with an anode made of tantalum pentoxide and a separator of fibrous paper). Typically, the voltage rating of a single unit is ≤100 V (low-voltage electrolytic capacitor) or ≥100 V (high-voltage electrolytic capacitor). Under high voltage conditions, they need to be used in series. Ceramic capacitors can be categorized into ceramic disc capacitors and multilayer ceramic capacitors. These capacitors are compact and cost-effective and possess excellent electrical properties, leading to their widespread application. In particular, high-capacity multilayer ceramic capacitors have been used to replace more expensive tantalum capacitors.

2.1. Film Capacitor

Film capacitors, alternatively known as plastic film capacitors, frequently employ metal foil as electrodes and plastic film as the dielectric. These capacitors often incorporate artificially synthesized polymer materials as dielectrics, enabling the selection of appropriate dielectric materials based on specific requirements, thereby exhibiting immense development potential. Recently, research in the field of film capacitors has focused on optimizing their dielectric properties. Meng et al. [26] proposed a hierarchical structural design approach to enhance the dielectric properties of metalized polypropylene (PP) film capacitors by utilizing terephthalaldehyde. This method offers insights into improving the dielectric properties of PP films by regulating charge transport behavior. Hu et al. [27] developed an ultra-high-temperature capacitor with relaxor ferroelectric (RFE) films by controlling polarization behavior. They further suggested that adjusting the intrinsic/extrinsic polarization ratio can enhance energy storage performance, providing a feasible approach to improving the high-temperature performance and dielectric strength of capacitors.

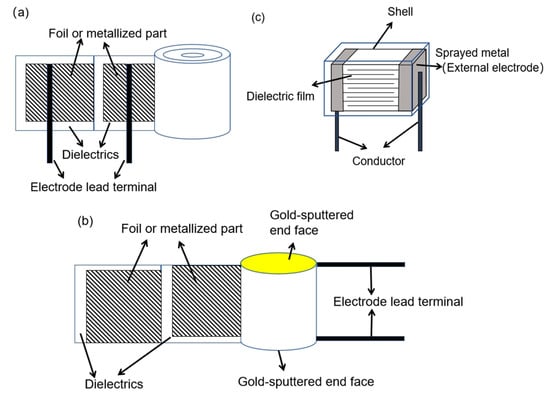

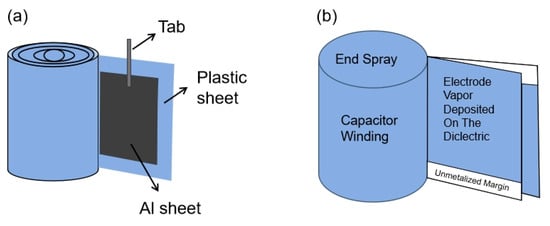

Film capacitors can be classified based on their structure, type of dielectric, and electrode formation method. To begin with, film capacitors are produced either in the form of winding utilizing a capacitor winding machine or as stacks of dielectric films [28]. These two distinct manufacturing methods are commonly referred to as coil technology and the stacking technique, respectively [29,30]. Therefore, based on their structure, film capacitors can be broadly classified into two types: “wound type” and “stacked type”. The digital images are shown in Figure 3. The wound type involves winding and stamping polymer films and then inserting them into a shell. This type can further be divided into two winding methods: inductive (Figure 4a) and non-inductive (Figure 4b). The stacked type, on the other hand, involves stacking multiple layers of polymer films together and then inserting the stacked body into a shell (Figure 4c). Currently, wound-type film capacitors are more commonly used due to their ease of manufacturing.

Figure 3.

The digital images of film capacitors. (a) Wound-type film capacitors. (b) Stacked-type film capacitors. The capacitor on the left is used for DC circuits, while the one on the right is used for AC circuits.

Figure 4.

The structural diagram of film capacitors. (a) Inductive winding method. (b) Non-inductive winding method. (c) Stacked film capacitor.

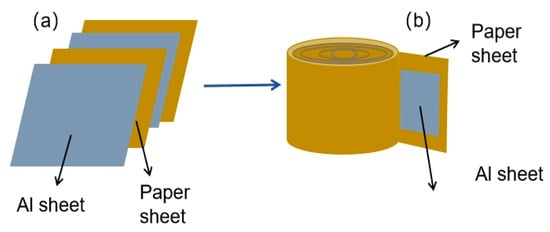

Furthermore, film capacitors can be categorized into paper media and organic media based on their insulation materials. Paper dielectric capacitors are a type of wound capacitor that employs capacitor paper as the insulating medium and aluminum foil as the electrode. These capacitors consist of two or more layers of aluminum sheets interspersed with paper sheets. The paper sheets serve as the dielectric, whereas the aluminum sheets function as the capacitor electrodes, as shown in Figure 5a [31]. During the manufacturing process, paper and aluminum sheets are typically rolled into cylindrical shapes, with leads attached to both ends of the aluminum sheet, as depicted in Figure 5b. Subsequently, the entire cylindrical structure is coated with a protective layer of wax or plastic resin to safeguard it from exposure to moisture in the air.

Figure 5.

(a) Assembly of a paper sheet capacitor. (b) The process of rolling up a paper sheet capacitor into a cylinder. Reproduced from Ref. [31] with permission.

Compared with traditional paper dielectric capacitors, the manufacturing process of metalized paper capacitors is more distinctive. It employs vacuum evaporation technology to deposit an ultra-thin and even layer of zinc or aluminum film onto the surface of the paper. Following this, the paper coated with this metal film is wound into a cylindrical structure, completing the overall fabrication of the metalized capacitor. Metalized paper capacitors feature a direct and thin coating of aluminum on paper, resulting in a thinner aluminum layer compared with traditional paper capacitors. This thinner layer contributes to a smaller capacitor size. Paper dielectric capacitors offer a diverse range of capacitance and operating voltage, along with a straightforward manufacturing process, low cost, and ease of metallization. Owing to these attributes, they are commonly utilized in high-voltage and high-current applications.

Organic dielectric capacitors primarily consist of synthetic organic thin films serving as dielectric materials and are typically constructed in a wound structure. Common dielectric materials employed in these capacitors include polypropylene (PP), polyethylene terephthalate (PET), polyethylene naphthalate (PEN), polyphenylene sulfide (PPS), and polycarbonate (PC) [28,32,33,34]. Ran et al. [35] improved the micro-morphology of PP films by utilizing an organic crystallization accelerator with good dispersion. The film capacitors produced using this method exhibit excellent breakdown strength. Ping et al. [36] prepared a double-layer polymer film by solution casting on the surface of PET film and coating it with boron nitride nanosheets. The resulting film capacitor exhibits excellent breakdown strength (736 MV m−1) and high energy density (8.77 J cm−3). Zou et al. [37] developed a high-performance thin-film capacitor through the controlled deposition of Si3N4 on PEN. This capacitor film possesses excellent mechanical properties, making it a promising candidate for power converters in electric vehicles. Zhang et al. [38] designed and prepared a P-3-P sandwich structured film with PC as the outer insulation layer and 3 wt% TiO2–PC/polyvinylidene fluoride as the middle polarization layer using solution casting and hot-pressing processes. This film exhibits excellent charge-discharge characteristics, offering a promising possibility for the construction of high-energy storage film capacitors.

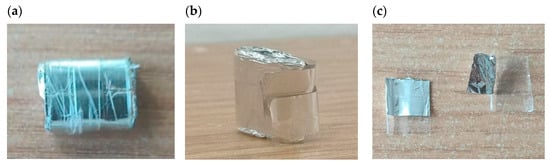

In comparison to inorganic dielectric capacitors, organic dielectric capacitors primarily utilize polymer materials as dielectrics, benefiting from the abundance of raw materials available. Additionally, the thickness of the films can be made exceptionally thin. Nevertheless, organic media are susceptible to aging and exhibit limited heat resistance, potentially compromising the capacitors’ performance [39,40]. The characteristics of film capacitors vary significantly depending on the type of dielectric medium used, resulting in diverse application fields. Organic dielectric capacitors can be classified into two electrode types: metal foil electrodes (the foils are typically on the order of 6 μm in thickness) and metalized electrodes (the metalized layers are <100 nm thick) [41]. The organic dielectric capacitor of a metal foil electrode is made of two layers of plastic film or sheet. Each layer is interspersed with thin aluminum metal foil or sheet, serving as the electrode. Subsequently, the plastic sheets and aluminum sheets are rolled into a cylindrical jelly roll structure. To establish electrical connections, wire leads are attached to both ends of the aluminum sheets, typically through soldering or metal spraying techniques. The thickness of the plastic film determines the separation distance within the capacitor, while the operating area is dictated by the size of the electrodes. In metalized film organic dielectric capacitors, the aluminum sheets or foils are superseded by metal layers that are vacuum-deposited onto the thin film layer. These metal layers possess a thickness of approximately 1/100 of that of the metal foil, making them significantly thinner and more conducive to space conservation [31]. The most frequently utilized metal layer is composed of ultra-thin aluminum. The dielectric is typically formed by a plastic film layer made of synthetic materials, while the electrode is comprised of an aluminum layer [42]. The schematic diagram of the structure of organic dielectric capacitors is shown in Figure 6.

Figure 6.

(a) Foil-type organic dielectric capacitor. (b) The capacitor with metalized electrodes, in which the electrodes are typically very thin aluminum layers deposited by vapor deposition onto an organic dielectric.

Finally, film capacitors can be categorized into two types: foil-type film capacitors and metalized film capacitors, depending on their distinct electrode formation techniques. The foil-type film capacitors represent the earliest incarnation of wound capacitors. Typically, they are crafted with clamping aluminum foil, which possesses exceptional ductility, within an insulating medium and then winding it, as shown in Figure 7. Conversely, the electrode of a metalized film capacitor eschews the use of metal foil. Instead, an ultra-thin metal film is deposited onto the capacitor through the process of vacuum evaporation, as shown in Figure 8. Compared with metal foil electrode film capacitors, metalized film capacitors have the obvious advantage of self-healing. Self-healing refers to the phenomenon that when a metalized capacitor experiences breakdown due to defects in the dielectric, an arc current is immediately generated at the breakdown point, and this current density is concentrated at the center of the breakdown point [43,44]. Due to the thin metallization film (less than 0.1 μm), the heat generated by this current is sufficient to melt and evaporate the metal near the breakdown point, forming a metal-free zone around the breakdown area, restoring insulation between the two electrodes of the capacitor, thus restoring normal operation of the capacitor. The self-healing properties of metalized film capacitors enable them to be applied in more complex situations.

Figure 7.

(a,b) Overall structural diagram of a disassembled foil-type film capacitor. (c) The aluminum foil is sandwiched between the plastic films.

Figure 8.

(a,b) Disassembled metalized film capacitor. (c) Placing the dismantled metalized film under a scanning electron microscope (SEM) reveals the deposition of aluminum on the film. (d) Single-sided metallization structure. (e) Double-sided metallization structure. (f) Series metallization structure.

2.2. Electrolytic Capacitor

Electrolytic capacitors are capacitors that exist in two forms: non-polar and polar. The anode of these capacitors typically comprises metal foil, such as aluminum or tantalum, with an oxide film, often aluminum oxide or tantalum pentoxide, serving as the dielectric and adhering closely to the anode. The cathode, on the other hand, consists of a combination of conductive materials, electrolytes (which can be either liquid or solid), and additional materials. The naming of electrolytic capacitors is derived from the electrolyte, which forms the principal component of the cathode. Notably, most electrolytic capacitors exhibit polarity, necessitating the application of voltage with the appropriate polarity. In the event of a reversed connection or incorrect polarity, the capacitor can undergo a short circuit, leading to a significant current flow that may result in permanent damage to the capacitor [31]. Electrolytic capacitors feature a thin dielectric layer, an extensive positive electrode area, and, consequently, a high capacitance per unit volume. This allows them to often boast higher capacitance values compared with other dielectric capacitors. However, they also exhibit a significant leakage current and a relatively short lifespan. When utilizing electrolytic capacitors, it is crucial to adhere to polarity requirements, ensuring that the positive and negative poles are connected correctly to avoid any mishaps.

In recent years, research on electrolytic capacitors has primarily concentrated on electrode materials and production processes. Bai et al. [45] utilized a protective atmosphere sintering process to produce sintered foils with added starch, evaluating the impact of starch addition within the range of 0–50 volume percent on the specific capacitance and anti-buckling performance of the sintered foils. This work unveiled the potential of starch addition in optimizing the properties of sintered foils, providing a valuable reference for developing an advanced powder metallurgy preparation process. Zeng et al. [46] employed additive manufacturing technology to produce anode foils, systematically investigating the influence of aluminum particle size and sintering temperature on the electrical properties of the anode foils. They also discussed the reaction mechanisms during sintering and the inherent relationship between the microstructure and electrical properties of the anode foils. Chen et al. [47] utilized metallic glass (MG) as a binder to adhere Ta powder at low temperatures (513 K), yielding MG-Ta composites. When applied in tantalum electrolytic capacitors, these composites exhibited a 57% increase in specific capacitance compared with pure Ta materials, accompanied by a 32% enhancement in mechanical properties.

2.2.1. Aluminum Electrolytic Capacitors

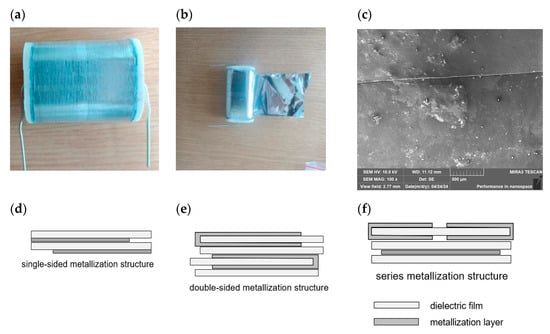

Aluminum electrolytic capacitors (AECs) offer a superior cost-to-energy ratio and volume efficiency compared with various other capacitor types [48]. As a result, they are frequently employed at the dc-link of power electronic converters (PECs) to serve as an energy buffer [49]. The physical structure and detailed structure of AEC are shown in Figure 9a. It comprises two aluminum electrodes, with a thin oxide film layer (known as alumina) serving as the dielectric [50]. Additionally, it includes a paper separator and an electrolyte, which is a blend of solvents and additives (shown in Figure 9b) [51].

Figure 9.

(a) Physical structure of ACE. Reproduced from Ref. [48] with permission. (b) A detailed structural diagram of the AEC, which consists of etched aluminum electrodes, alumina dielectrics, electrolyte carriers, and paper sheets impregnated with the electrolyte. Reproduced from Ref. [50] with permission. (c) Digital images of aluminum electrolytic capacitors. (d) The dismantled aluminum electrolytic capacitor. (e) The image of the anode aluminum foil of the aluminum electrolytic capacitor under a scanning electron microscope reveals that the anode aluminum foil is coated with aluminum oxide. (f) The image of the cathode aluminum foil of the aluminum electrolytic capacitor under a scanning electron microscope reveals that it is an etched aluminum foil.

In aluminum electrolytic capacitors, both the anode and cathode consist of pure aluminum foil. The anode foil is coated with a thin layer of aluminum oxide, electrically insulating in nature, serving as the dielectric. This oxide coating, along with the cathodes, is separated by electrolytic paper soaked in an electrolyte solution. This paper, possessing high porosity, can absorb and hold the maximum amount of electrolyte. While the cathode aluminum foil also possesses a naturally formed, very thin insulating oxide layer due to exposure to air, its thickness is significantly thinner compared with the oxide layer on the anode foil [52]. The electrolyte serves as the actual cathode of the capacitor when compared to the anode foil, while the cathode foil merely collects current from the electrolyte [48]. Figure 9c shows digital images of aluminum electrolytic capacitors, and the disassembled structure of one of the aluminum electrolytic capacitors is depicted in Figure 9d. After soaking the anode and cathode aluminum foils of the disassembled aluminum electrolytic capacitor in ionized water and allowing them to dry, they were observed under a scanning electron microscope. It can be observed that the anode aluminum foil is coated with aluminum oxide (as shown in Figure 9e), while the cathode aluminum foil is etched aluminum foil (as shown in Figure 9f).

Before forming a layer, the anode foil needs to undergo other processing. Initially, it is etched to enlarge its surface area, enabling better performance [53]. Subsequently, anodization is performed by applying a direct current voltage, resulting in the formation of a thin layer of aluminum oxide on the anode foil’s surface. This oxide layer functions as the dielectric in AEC. Conversely, the thin layer of Al2O3 present on the cathode results from the natural oxidation of aluminum, which effectively mitigates corrosion.

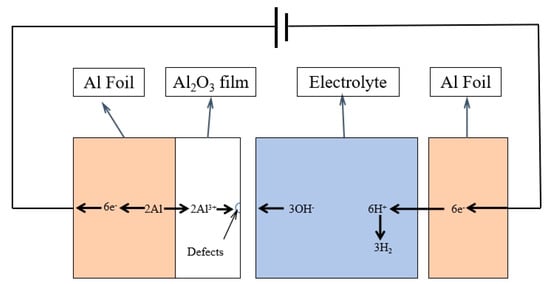

AEC is a type of polarized capacitor that can only be subjected to a DC bias in one direction. Its electrochemical structure is shown in Figure 10 [48]. The dissociation of water molecules in the electrolyte produces proton (H+) and hydroxyl (OH−) ions, which can freely exist in the electrolyte. When a positive electric field is applied to the AEC terminal, staying within the rated voltage, the OH− ions are drawn toward the aluminum anode foil. However, they encounter a dense dielectric barrier that prevents their passage. Conversely, if the applied negative voltage surpasses the potential hurdle posed by the aluminum oxide formed during passivation, the H+ ions are drawn toward the anode foil. Given their significantly smaller size compared with OH− ions, the H+ ions can effortlessly penetrate the dielectric and arrive at the anode, resulting in the production of hydrogen gas. Meanwhile, the OH− ions migrate toward the cathode and unite with aluminum (Al3+) ions, leading to the formation of aluminum oxide on the cathode foil. In this case, the cathode capacitance will decrease, thereby reducing the total capacitance. If voltage is applied for a long time, it will damage the capacitor, so the polarity of ACE cannot be reversed.

Figure 10.

Electrochemical structure of AEC. Reproduced from Ref. [48] with permission.

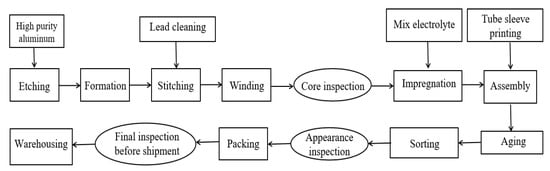

The manufacturing process of aluminum electrolytic capacitors primarily comprises the following steps, as depicted in Figure 11 [50,54]:

Figure 11.

Manufacturing process diagram of aluminum electrolytic capacitors.

- (1)

- Etching: High-purity aluminum foil undergoes an etching process through an electrochemical method in a chloride solution, utilizing either direct or alternating current. The anode and cathode foils are crafted from virtually pure aluminum foil. To enhance their effective surface area and minimize the size of the capacitor, anode foils ranging from 0.05 to 0.11 mm in thickness and cathode foils measuring 0.02 to 0.05 mm thick are continuously subjected to electrochemical etching in a chloride solution, utilizing either alternating current or direct current. Typically, AC electrolysis is employed for the production of low-voltage capacitors, whereas DC electrolysis is utilized for the fabrication of medium- and high-voltage capacitors.

- (2)

- Formation: Through electrolysis, a continuous voltage exceeding the nominal value is applied, resulting in the formation of an aluminum oxide layer on the surface of the aluminum foil. The thickness of the alumina dielectric film can be controlled.

- (3)

- Slitting: After etching and anodizing the aluminum foil roll, the foil is cut into a specified width according to the size of the capacitor shell.

- (4)

- Winding: Secure the lead-out wires of the anode and cathode foils using rivets or welding and position the foils between isolation plates. Employ a winding machine to neatly wind them together, creating a capacitor core package.

- (5)

- Impregnation: Soak the capacitor core with electrolyte to saturate the paper isolation layer and all parts of the corroded aluminum foil to ensure good contact between the oxide layer and the true cathode. This method requires the removal of gas from the core package and vacuum immersion of the electrolyte.

- (6)

- Assembly: To prevent evaporation or moisture absorption of the electrolyte, which can lead to deterioration, it is imperative to insert the capacitor core into a metal casing and securely seal it. Furthermore, to safeguard against the potential for electrolytic capacitor explosion due to excessive gas pressure during faults, a pressure relief device must be integrated.

- (7)

- Aging: Repair the oxide film that may be damaged during the manufacturing process, especially during cutting and assembly, by applying a DC voltage.

- (8)

- Inspection: After sealing, inspect the product for capacitance, leakage current, appearance, and performance as required, and then proceed with packaging.

2.2.2. Tantalum Electrolytic Capacitor

After aluminum electrolytic capacitors gained widespread use, issues such as limited lifespan and inadequate high-temperature resistance became apparent, prompting the development of tantalum electrolytic capacitors. These capacitors, similar to other electrolytic types, consist of an anode, electrolyte, and cathode. The cathode can be either solid or liquid, but currently, the majority of tantalum electrolytic capacitors available on the market are of the solid variety.

Solid tantalum electrolytic capacitors are composed exclusively of stable, inorganic, and nonvolatile materials devoid of any water or other liquids. This composition endows them with numerous advantages, including compact size, excellent temperature characteristics, the elimination of sealing requirements, and an extended service life [55,56]. However, solid electrolytes have poor productivity and high costs, and the capacity achievement rate during use is generally poor [57].

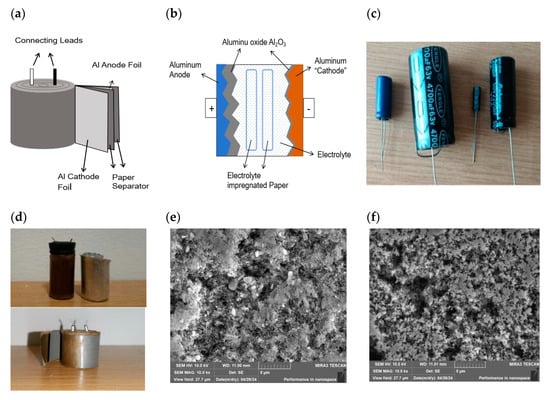

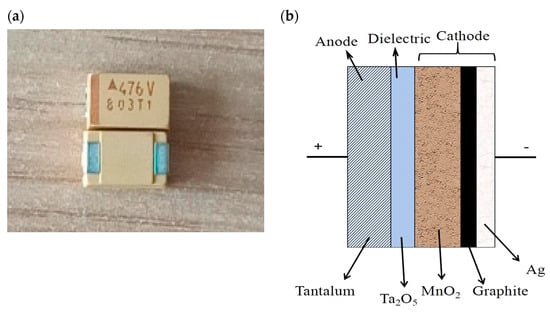

Distinct from aluminum electrolytic capacitors, solid tantalum electrolytic capacitors employ tantalum powder sintered into porous tantalum blocks as the anode. The surface of these porous tantalum blocks is then oxidized to create an insulating medium composed of tantalum pentoxide [58]. The cathode, on the other hand, consists of manganese dioxide, which is in intimate contact with the tantalum pentoxide. The tantalum electrolytic capacitor is completed by drawing out the electrode. Notably, solid tantalum electrolytic capacitors are polarized capacitors, necessitating their use in a unipolar state; reverse polarity is strictly prohibited. The digital image and structure of this capacitor are illustrated in Figure 12.

Figure 12.

(a) Digital images of tantalum electrolytic capacitors. (b) Schematic diagram of tantalum electrolytic capacitor structure.

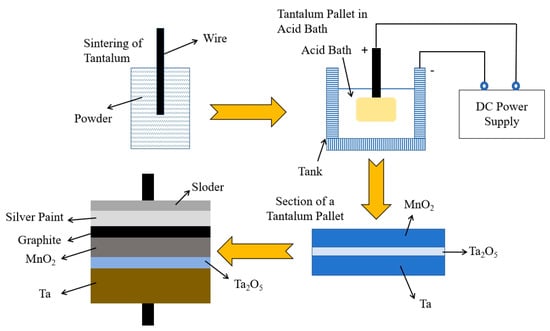

The production of solid tantalum electrolytic capacitors mainly involves the following steps (Figure 13) [31,59,60]:

Figure 13.

Fabrication process of solid electrolyte capacitor. Reproduced from Ref. [31] with permission.

- (1)

- The tantalum metal is crushed into a fine powder and thoroughly mixed with organic solvents. This mixture is then pressed into a desired shape under pressure, with tantalum leads embedded within. Subsequently, the assembly is sintered in a vacuum high-temperature environment, transforming it into a sponge-like structure. This process creates a highly porous metal anode, which significantly enhances its capacitance value. At the same time, it is truly integrated with the lead wire.

- (2)

- The sponge-like tantalum is submerged in a phosphoric acid solution for electrolysis. Through the process of oxidation, tantalum pentoxide is formed on its surface. This anode is then further coated with an insulating oxide layer, specifically tantalum pentoxide, serving as the dielectric layer. This comprehensive treatment process is referred to as anodizing.

- (3)

- Liquid manganese nitrate is added to the tantalum blocks, followed by thermally decomposing them in an environment containing water vapor and a catalyst. This process results in the production of manganese dioxide. Due to the excellent adsorption properties of manganese nitrate, the generated manganese dioxide is able to be fully adsorbed into the numerous tiny pores within the sponge-like tantalum block. Alternatively, if a solid polymer with a lower melting point is utilized, it can be melted and directly placed into the small pores.

- (4)

- Finally, silver powder and graphite are coated on the surface of manganese dioxide to reduce its equivalent resistance and enhance its conductivity. At the same time, external leads are added and packaged with epoxy resin.

In addition, there is another type of tantalum capacitor called a wet tantalum electrolytic capacitor, which uses a liquid electrolyte (usually sulfuric acid) instead of a solid electrolyte. The initial steps of anode production and dielectric deposition for wet tantalum electrolytic capacitors mirror those employed for solid tantalum capacitors. Subsequently, the dielectric-coated anode is submerged in a cage filled with the electrolyte solution. This cage, along with the electrolyte solution, collectively fulfills the role of the cathode in wet tantalum capacitors [31]. Wet tantalum electrolytic capacitors can be used at high temperatures and high ripple currents and are generally used in military and aerospace fields [61].

Although electrolytic capacitors share the self-healing ability with metalized thin film capacitors, the underlying mechanisms differ. In non-solid electrolytic capacitors, if the anodic oxide film sustains partial damage during operation or storage, the electrolyte serving as the cathode comes into play. Under the influence of the applied voltage, the non-solid electrolyte releases oxygen, which regenerates the oxide film at the damaged spot, thereby restoring its functionality. On the other hand, solid tantalum electrolytic capacitors may encounter cracks or metal impurities in the tantalum pentoxide film, resulting in an elevated leakage current. In this case, due to the high current density and temperature in the defective region, MnO2 can locally transform into manganese oxides with high resistance, such as Mn2O3 and Mn3O4, thereby isolating the breakdown point and preventing capacitor failure [62]. This process effectively repairs the defect, exhibiting the self-healing property of these capacitors.

2.3. Ceramic Capacitors

In ceramic capacitors, ceramic materials serve as dielectrics, while conductive metals function as electrodes. These capacitors are extensively employed in electronic devices because of their abundant raw materials, uncomplicated design, affordable price, and vast range of electrical capacity. Ceramic capacitors come in diverse types, primarily categorized as Class I and Class II, based on the characteristics of the dielectric materials employed [63]. Class I ceramic capacitors, commonly referred to as high-frequency ceramic capacitors, exhibit low dielectric loss, high insulation resistance, and a linear variation in dielectric constant with temperature. These capacitors are ideal for resonant circuits, filters, and temperature compensation. On the other hand, Class II ceramic capacitors, also known as low-frequency ceramic capacitors or ferroelectric ceramic capacitors, utilize ferroelectric ceramics as their dielectric. They offer higher specific capacitance, non-linear capacitance changes with temperature, and increased losses. Therefore, they are commonly utilized for bypass or coupling applications in electronic devices [64]. In addition, according to their shape and structure, they can be divided into ceramic disk capacitors and multilayer ceramic capacitors (MLCCs).

Recently, research on ceramic capacitors has primarily focused on enhancing the performance of MLCC. Yong et al. [65] proposed a method of applying polydopamine (PDA) as a robust coating layer for MLCC. The barium titanate particles treated with PDA exhibited improved dispersion stability, preventing particle reagglomeration and contributing to the enhancement of the mechanical properties of MLCC. Lv et al. [66] developed a novel lead-free MLCC composed of NaNbO3–(Bi0.5Na0.5)TiO3–Bi(Mg0.5Hf0.5)O3, which demonstrated exceptional performance, including a recoverable energy density of up to 12.65 J cm−3 and an energy efficiency of 88.5%.

2.3.1. Ceramic Disc Capacitors

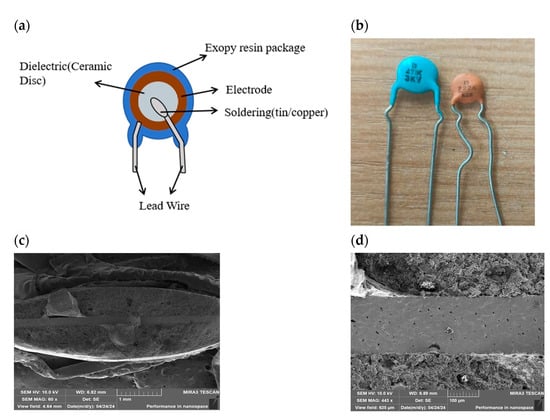

Ceramic disc capacitors are constructed by applying silver contacts to both faces of a ceramic disc (shown in Figure 14a). Here, the ceramic disc serves as the dielectric material, while the silver coating on both sides functions as the electrodes of the capacitor. The leads, made of copper, are welded to the ceramic disc to establish electrical connections. Figure 14b shows actual images of ceramic disc capacitors. When its cross-section is placed under a scanning electron microscope, the observed images are shown in Figure 14c,d.

Figure 14.

(a) Ceramic disc-type capacitor. (b) The actual images of ceramic disc capacitors. (c) The cross-section of the ceramic disc capacitor observed under a scanning electron microscope, which shows that the leads are bonded to the electrodes coated on both sides of the ceramic. (d) Enlarged cross-sectional view of a ceramic capacitor. In the middle is the ceramic dielectric, with electrodes coated on both sides and an outer layer of protective material.

Ceramic disc capacitors are extensively utilized in general electronic circuits due to their cost-effectiveness and ease of soldering. The capacitance of these capacitors is determined by the area of the ceramic disk or dielectric, as well as the spacing between the silver electrodes. For disc capacitors with lower capacitance, a single ceramic disc coated with silver contacts is sufficient, while for high capacitance ceramic disc capacitors, multilayer ceramic discs are required [64]. The preparation of ceramic discs is similar to traditional ceramic processing. Initially, the dielectric powder undergoes ball milling to disaggregate it. Subsequently, an organic binder is added to prepare the powder for the forming process. After spray drying, the powder is fed into an automatic granulator to shape it into a raw disk. Next, two firing processes are carried out: the first to burn out the binder at a temperature below 550 °C, removing organic components, and the second sintering process at over 1000 °C to consolidate the ceramic particles into a solid body. Then, electrodes are applied to both sides of the disc using a paste containing metal particles (such as silver) and glass frit, followed by heat treatment. During this treatment, the glass material melts, ensuring strong adhesion of the metal electrode to the ceramic surface at a relatively low processing temperature. Finally, after attaching the leads to the electrodes, an epoxy or phenolic coating is applied to safeguard the ceramics from environmental contaminants [64].

2.3.2. Multilayer Ceramic Capacitor

The multilayer ceramic capacitor (MLCC) stands as a pivotal passive surface mount component in contemporary electronic devices. Its genesis dates back to the 1960s when American companies pioneered its successful development. Subsequently, Japanese companies like Murata, TDK, and Sunpower spearheaded its rapid industrialization and refinement. These companies continue to uphold their global supremacy in the MLCC industry, exemplified by their proficiency in manufacturing MLCCs that boast high reliability, precision, integration, and frequency, along with intelligence, low power consumption, immense capacity, miniaturization, and cost-effectiveness.

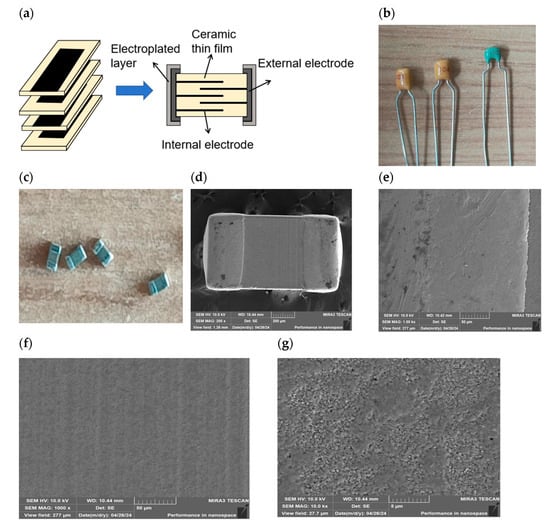

The MLCC is fabricated by stacking multiple layers of ceramic material interspersed with conductive electrodes [67,68]. Each layer of ceramic material sandwiches the electrodes, serving as the dielectric for the capacitor. These multilayer ceramic media and electrodes are interconnected through the terminal’s surface, creating a compact and efficient structure. In other words, the MLCC is constructed by alternately layering ceramic dielectric membranes (commonly rutile titanium dioxide or barium titanate) with printed electrodes (inner electrodes) in a staggered configuration. This assembly is then consolidated into a ceramic chip through a single high-temperature sintering process. Subsequently, a metal layer (outer electrode) is applied to both ends of the chip, completing the manufacturing process. Its structure is shown in Figure 15a. The MLCC boasts not only the benefits of standard ceramic dielectric capacitors but also exhibits a range of exceptional characteristics. These include compact size, substantial capacity, high mechanical strength, excellent moisture resistance, outstanding high-frequency performance, and remarkable reliability [69,70]. Given its versatility and superior performance, the MLCC finds widespread application in various electronic information fields, encompassing mobile phones, computers, the military industry, aerospace, and beyond [71,72]. The packaging forms of MLCC mainly include wire-bonded and surface-mount types. The wire-bonded type was previously known as the monolithic capacitor (shown in Figure 15b). Its name originated from the fact that the ceramic dielectric body coated with metal electrodes is sintered with the electrodes into a single unit, resembling a stone block, hence the name “monolithic capacitor.” Removing the leads from the monolithic capacitor results in the surface-mount packaging form (shown in Figure 15c). The observed images of the surface-mount type MLCC placed under a scanning electron microscope are shown in Figure 15d–g.

Figure 15.

(a) Schematic diagram of MLCC structure. (b) The actual image of the monolithic ceramic capacitor. (c) The actual image of the surface-mount packaging form. (d) The overall structural diagram of the surface-mount type MLCC under a scanning electron microscope, which shows that MLCC is constructed by stacking ceramic dielectric sheets with printed electrodes in a staggered manner to form a layered structure. (e) The external electrode of MLCC, which is composed of an electroplated metal layer. (f) The internal electrode of MLCC, which is composed of metallic materials. (g) The dielectric of MLCC, which is composed of ceramic materials.

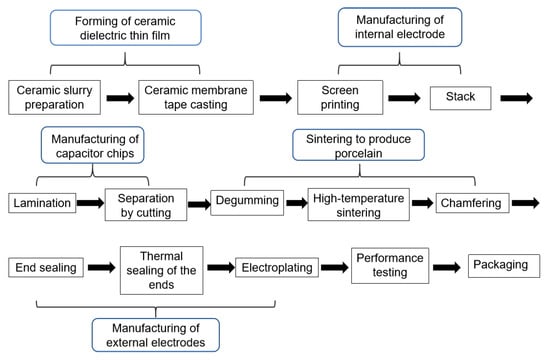

The production of surface-mount MLCC encompasses multiple processes, including the formation of ceramic dielectric films, the fabrication of inner electrodes, the creation of capacitor chips, sintering them into ceramics, the construction of outer electrodes, performance testing, and packaging, among others [64,73,74]. The specific process diagram is shown in Figure 16. Firstly, the dielectric powder is mixed with solvents, dispersants, binders, and plasticizers to form a homogeneous suspension. This slurry is then transferred to a casting machine, where a scraper evenly applies it onto a tape. The tape, coated with the mixed slurry, is sent to a tape-casting machine where a doctor blade precisely scrapes the slurry onto it. The resulting wet sheet is subsequently dried, transforming into a flexible tape. Next, an electrode paste is applied to the tape in a designed pattern through screen printing. During the lamination process, the printed tapes are stacked layer by layer with precision alignment. After cutting and separation, each green MLCC undergoes high-temperature sintering to eliminate the adhesive and organic matter. This sintering process also solidifies the layers of dielectric tape and electrodes, creating a dense structure. Additionally, the sintered ceramic is chamfered to fully expose the inner electrodes.

Figure 16.

MLCC manufacturing process flowchart.

To form the outer electrode, electrode paste is applied to the exposed inner electrodes, connecting the inner electrodes on the same side. Notably, the surface-mount MLCC achieves electrical connection through three consecutive layers of termination electrodes [75]. The first layer, in contact with the inner electrode, is copper. Nickel serves as an intermediate layer, electroplated onto the copper, acting as a thermal barrier to safeguard the capacitor during welding. Finally, a layer of tin is applied to the nickel to enhance solderability. After the completion of outer electrode production, rigorous performance testing and packaging procedures are conducted to eliminate any defective products.

2.3.3. Others

In recent years, researchers have been paying attention to a new type of capacitor, namely, the multilayer polymer capacitor (MLPC), which has a similar design as MLCC and exhibits extremely high application value. Different from traditional solid capacitors, MLPC adopts a unique chip-type multilayer structure. Its production process is elaborately designed. Firstly, the aluminum foil is etched to form a porous oxide layer, and then a conductive polymer is deposited on the oxide layer as the cathode. After that, these treated aluminum foils are stacked into a multilayer structure, and then carbon paste is applied on them to form a carbon coating, followed by the application of silver paste to form a silver coating. Finally, the entire structure is completely sealed and fixed with epoxy resin, which can effectively protect its internal structure and prevent local overheating.

Compared with MLCC, MLPC has a higher capacity, which can significantly reduce the number of capacitors required in applications, thus reducing the overall cost. Moreover, MLPC exhibits excellent performance in high and low-temperature environments, overcoming the cracking issues that MLCC may encounter due to temperature or mechanical shock, thereby improving the reliability and stability of the product. Compared with solid tantalum capacitors, MLPC has a lower equivalent series resistance and higher safety. Currently, the conductive polymer of MLPC is mainly based on poly(3,4-ethylenedioxythiophene) (PEDOT), and the deposition technology often adopts in situ polymerization. The development of new conductive polymers and the optimization of polymer deposition technology have become research hotspots in recent years.

3. Electrochemical Capacitor

Electrochemical capacitors, commonly referred to as supercapacitors (SCs), possess remarkable charge and discharge efficiency, an outstanding cycle life, and exceptional power performance while being capable of operating across a broad temperature spectrum [76,77]. In comparison to batteries, supercapacitors exhibit a superior power density and the ability to rapidly store or discharge energy [78]. Nevertheless, their energy density is lower due to the constraints associated with electrode surface charge storage. When compared to traditional capacitors, they possess a lower power density but a higher energy density [79]. Supercapacitors can serve as rapid starting power sources for electric vehicles, as well as balancing power supplies for lifting equipment. Furthermore, they can be utilized as traction energy sources for hybrid electric vehicles, internal combustion engines, and trackless vehicles [80,81,82].

The history of supercapacitors can be traced back to 1853. In 1853, Helmholtz pioneered the exploration of electrical storage mechanisms within capacitors and introduced the concept of the double-layer model in the context of colloidal suspension research. In 1957, Becker filed the first patent for an electrochemical capacitor, which incorporated porous carbon electrodes immersed in an H2SO4 solution [83]. Advancing further, in 1971, Trasatti and his colleagues reported for the first time on the charge storage behavior of ruthenium oxide films in sulfuric acid, revealing the pseudocapacitance phenomenon in transition metal oxides. Subsequently, Shirakawa et al. garnered attention for the pseudocapacitive charge storage properties they developed in conductive polymer materials, thus propelling the interest in pseudocapacitors [84]. In 1978, NEC Corporation of Japan commercialized electrochemical capacitors, branding them “supercapacitors.” A decade and a half later, in 1989, the U.S. Department of Energy initiated long-term research support for high-energy-density supercapacitors intended for use in electric drive systems as part of their electric and hybrid vehicle initiatives. Presently, leading global supercapacitor companies such as Maxwell (USA), Nesscap (South Korea), ELTON (Russia), and Nippon Chemicon (Japan) have developed and offered a diverse range of supercapacitors for commercial applications [85].

In recent years, researchers have proposed numerous approaches to improve the performance of supercapacitors. Zan et al. [86] employed a self-template biomimetic method to synthesize a novel mesoporous Ni(OH)2 structure, which comprises house-of-cards-like cubic nanocages assembled from monolayer Ni(OH)2 coupled with an exceptionally large interlayer spacing of approximately 1 nm. Tests have shown that it provides a specific capacity close to 100% of the theoretical value and exhibits an excellent cycling performance of over 10,000 cycles. Shwetha et al. [87] synthesized Co3O4 nanoparticles using a mixture of cobalt nitrate and ascorbic acid. Electrochemical data indicate that the Co3O4 nanoparticles exhibit good capacitive behavior, with the highest electrochemical performance observed when the cobalt nitrate/ascorbic acid ratio equals 1. Specifically, these nanoparticles deliver a specific capacitance of 166 F g−1 at a current density of 0.5 A g−1 and retain 90% of their capacitance after 5000 cycles. Luo et al. [88] reported a method for synthesizing heterogeneous Ni3N-Co2N0.67/nitrogen-doped carbon (Ni3N-Co2N0.67/NC) hollow nanoflowers by pyrolyzing a NiCo-TEOA (triethanolamine) complex precursor and employing urea as a nitrogen source. The assembled Ni3N-Co2N0.67/NC//AC battery achieves a peak energy density of 32.4 W h kg−1 at a power density of 851.3 W kg−1. Wang et al. [89] proposed an effective method for activating Ni-Co oxide nanosheet arrays (NiCoO NSAs) grown on carbon fiber cloths. The resulting ac-NiCoO NSA exhibits a high specific capacity (206.5 mAh g−1 at 0.5 A g−1). The assembled capacitor demonstrates high energy density (45.4 Wh kg−1), high power density (17.3 kW kg−1), and ultra-long cycling stability, with a retention rate of 77.4% after 20,000 cycles (20 A g−1).

Furthermore, in recent years, flexible supercapacitors, which exhibit both bendability and stretchability coupled with their high electrochemical performance retention, have garnered extensive and intensive research attention. Song et al. [90] have developed a self-wrinkled polyaniline (PANI)-based composite hydrogel (SPCH), featuring an electrolyte hydrogel and PANI composite hydrogel as its core and shell, respectively, through a stretching, low-temperature polymerization/release strategy. This SPCH exhibits remarkable stretchability (approximately 970%) and high fatigue resistance. Remarkably, upon cutting and reconnecting the edges, it can directly function as an intrinsically stretchable all-solid-state supercapacitor (A-SC), maintaining highly stable output with a capacitance retention rate of 92% even after 1000 stretching and releasing cycles at 100% strain. Huai et al. [91] synthesized cobalt-doped NiMoO4 nanosheets via a hydrothermal method, which exhibited a specific capacitance of 906 C g−1 at a current density of 1 A g−1. The assembled flexible supercapacitor delivered an energy density of 64 Wh kg−1 at a power density of 2880 W kg−1. Notably, the device retained 78% of its initial capacitance after 10,000 cycles. Liu et al. [92] prepared graphene/MnO2 composites by growing MnO2 nanosheets on single-layer graphene via a water bath method and introducing two-dimensional black phosphorus during the pulping process. These composites were used to fabricate micro-supercapacitors that can be integrated with flexible film pressure sensors, holding promise for wearable electronic devices. Zhu et al. [93] provided an overview of solid-state flexible supercapacitors, reviewed the current research status of vanadium-based electrode materials in solid-state flexible SC, and proposed strategies to address the challenges associated with these materials. Wang et al. [94] introduced a fully biomass-based colloidal gel composed of a mononuclear anthraquinone derivative and porous lignin-based graphene oxide fabricated through a self-assembly process. This gel was successfully used to produce biomass-based flexible micro-supercapacitors via screen printing. Upon testing, these capacitors demonstrated significant areal capacitance (43.6 mF cm−2), energy and power densities (6.1 μWh cm−2 and 50 μW cm−2, respectively), and cyclic stability (>10,000 cycles).

In recent years, numerous review articles have outlined the research progress in supercapacitor electrode materials and electrolytes. Li et al. [95] comprehensively summarized the research advancements in nickel-based composites for supercapacitors, encompassing the properties of novel materials, preparation methods, and application potentials, offering insights into the research prospects and future trends of nickel-based composites. Troschke et al. [96] introduced the general chemical properties of Schiff bases and reviewed several nanomaterials and their carbonized derivatives obtained through Schiff-base formation, along with an outlook on the major obstacles and future prospects in this research field. Shi et al. [97] overviewed the research progress in redox electrolyte-enhanced carbon-based supercapacitors, analyzing the causes of self-discharge and corresponding suppression strategies from aspects such as separator modification, electrolyte formulation, and electrode design while outlining their development prospects. Wu et al. [98] reviewed the research progress of various spatially dimensional carbon materials in recent years, discussing their advantages and disadvantages as supercapacitor electrode materials, examining the key factors influencing their electrochemical performance, and proposing new development trends for carbon materials. Kong et al. [99] introduced the concept of superstructured carbons with customized functionality, comprehensively outlining their designs tailored to different energy storage mechanisms and prospectively pointing out potential challenges in their future development. Although these reviews have thoroughly explored supercapacitor electrode materials or electrolytes, a comprehensive overview of their structures and energy storage principles remains lacking. Thus, the present review focuses on elucidating the classification, fine structures, and unique energy storage mechanisms of supercapacitors, aiming to provide readers with a more complete and in-depth understanding of the framework.

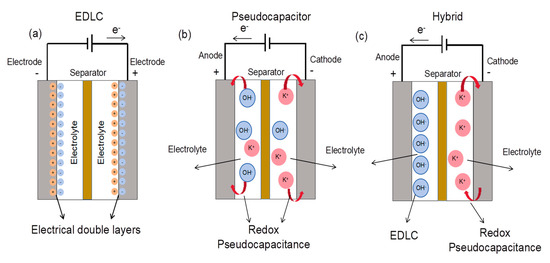

The structure of a supercapacitor comprises four main components: two electrodes, an electrolyte, a separator, and current collectors. The function of current collectors is to collect the current generated by the active material in the capacitor and facilitate the formation of a larger current for external output. Typically, copper foil is used as the current collector for the negative electrode, while aluminum foil is employed for the positive electrode. Depending on the energy storage principle, SC can be categorized into three types, namely electrochemical double-layer capacitors (EDLCs), pseudocapacitors, and hybrid capacitors, as illustrated in Figure 17 [100,101]. Their respective energy storage mechanisms are based on non-Faradaic, Faradaic, and a blend of both processes [102]. In the non-Faradaic process, charges are distributed across the surface through physical means without the formation or breakdown of chemical bonds [103]. Conversely, the Faradaic process involves the transfer of charges between electrodes and electrolytes. Double-layer capacitors store energy through non-Faradaic reactions, commonly utilizing carbon-based materials with a high surface area and porosity as electrode materials. On the other hand, pseudocapacitors store energy through Faradaic reactions, typically employing transition metal oxides (like RuOx) and conductive polymers (such as polyaniline) as electrode materials [104]. In hybrid capacitors, both Faradaic and non-Faradaic reactions occur for energy storage, combining the benefits of EDLC and pseudocapacitors [105].

Figure 17.

Types of supercapacitors. (a) EDLC. (b) Pseudocapacitors. (c) Hybrid supercapacitors. Reproduced from Ref. [106] with permission.

Supercapacitors and electrolytic capacitors seem superficially similar due to their shared electrolyte component. Both aim to enhance capacitance by increasing electrode area and reducing electrode distance. However, a deeper exploration reveals significant differences. The electrolyte in aluminum electrolytic capacitors is the actual cathode, while the electrolyte in supercapacitors is the dielectric, with porous activated carbon comprising the actual electrode. Traditional electrolytic capacitors utilize valve metal as the electrode and its oxide as the dielectric, resulting in polarity and intolerance to reverse voltage. Conversely, supercapacitors exhibit identical electrode structures, classifying them as non-polar capacitors.

3.1. Electrochemical Double-Layer Capacitors

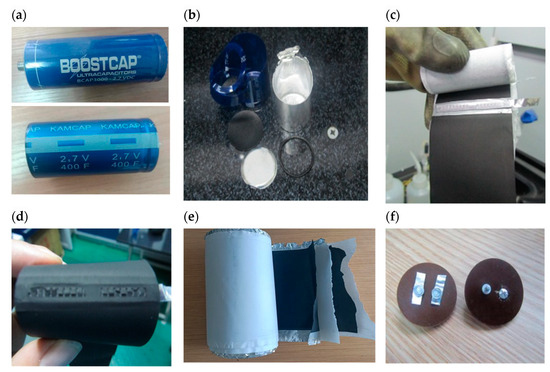

The concept of the double layer was originally introduced and formulated by von Helmholtz in the 19th century, with subsequent modifications and enhancements made by Gouy, Chapman, and Stern [107]. EDLC comprises two carbon-based electrodes, a separator, and an electrolyte [108]. Charge storage is achieved by the formation of a double layer at the interface between the electrode and the electrolyte [109]. The physical image and the dismantled structural diagram of EDLC are shown in Figure 18. During the operation of an EDLC, charge accumulation occurs through a non-Faradaic process, meaning that there is no ion exchange between the electrode material and the electrolyte solution, and electrons do not transfer across the electrode interface [110]. When charging, electrons are driven by an external electric field to move from the positive electrode to the negative electrode through an external circuit, resulting in the formation of a layer of charge electrons on the surface lattice structure of the electrode material [110]. In electrolytes, anions are attracted toward the positive electrode, while cations migrate toward the negative electrode. These oppositely charged ions migrate toward the respective electrodes and accumulate on their surfaces, creating a double layer. Upon removal of the external electric field, the double layer persists, stabilizing the voltage due to the attractive forces between the opposing charges [80]. During discharge, the process reverses. The charged ions adsorbed on the electrode migrate in a directional manner, generating a current in the external circuit until the electrolyte returns to its electrically neutral state. This charge storage mechanism is fully reversible, and since it lacks chemical reactions, the electrode structure of the EDLC remains virtually unchanged. This attribute confers EDLC capacitors with a prolonged cycle life and exceptional power density [109,111].

Figure 18.

(a) The physical image of an EDLC. (b) The bottom gasket, insulating sheet, top sealing ring, outer aluminum case, and packaging plastic film of the EDLC. (c) Lead-out welding spot. (d) The back of the welding spot. (e) The overall structure of the EDLC. (f) Top rivet.

The electrode materials of EDLC commonly consist of carbon-based substances, encompassing activated carbon (AC) [112,113,114], carbon nanotubes (CNTs) [115], graphene [116,117], and various other carbon-based composite materials. These materials are deemed suitable for double-layer capacitors, attributed to their expansive specific surface area, robust thermal and electrochemical stability, and superior conductivity [107]. Currently, research in the field of EDLC is focused on two major directions: optimizing the performance of existing electrode materials and developing new materials. Fu et al. [118] obtained nitrogen and sulfur dual-doped activated carbon with a hierarchical pore structure by directly carbonizing/activating polymer-based monolithic materials. The EDLC assembled with this material exhibits favorable energy density and power density in a 6 mol·L−1 KOH aqueous electrolyte. Lv et al. [119] utilized dopamine and copper chloride precursors to form carbon flocculates embedded with ultrafine copper nanoparticles on carbon cloth through pyrolysis and electrochemical oxidation reactions. The results indicated that the obtained electrode possessed a large surface area of 55.5 m2·g−1 and a high conductivity of 48.7 S·mm−1. When the prepared material was applied in an EDLC, the EDLC exhibited outstanding performance with a power density as high as 179 mW·cm−³ and an energy density reaching 23 mWh·cm−³, demonstrating promising application prospects. Yoo et al. [120] successfully prepared cost-effective carbon xerogels with large surface areas by substituting phenol for resorcinol and controlling the amount of catalyst, further confirming their excellent electrochemical performance as active materials for EDLC electrodes.

The performance of EDLC is also influenced by the compatibility between the pore size of the electrode material and the size of the electrolyte ions, as well as the ionic mobility. Consequently, the performance of EDLC can be altered by utilizing diverse electrolytes, including aqueous and organic electrolytes. Although aqueous electrolytes offer lower series resistance compared with organic electrolytes, their narrower potential window range restricts the energy density of EDLC [121]. During the production process, it is crucial to select an electrolyte solution that suitably adapts to the pore size of the electrode material.

3.2. Pseudocapacitors

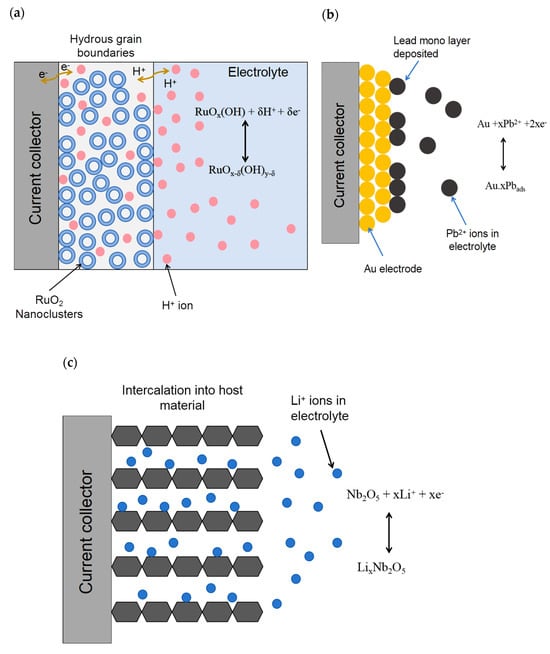

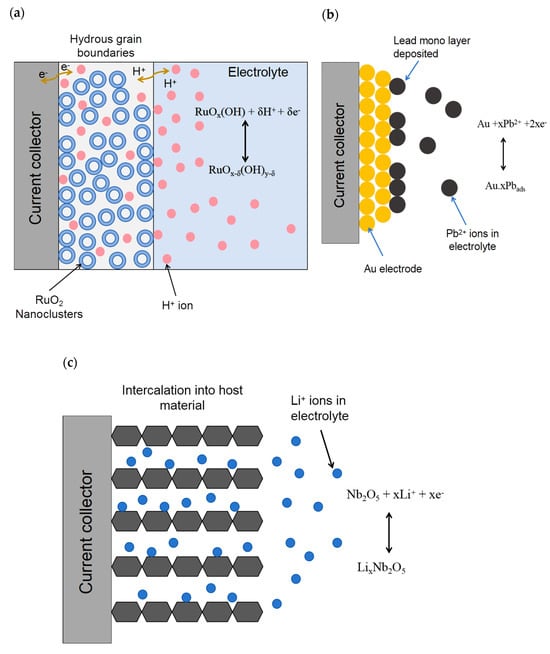

In contrast to EDLC, a pseudocapacitor exhibits charge transfer at the electrode-electrolyte interface, enabling energy storage through a rapid and reversible Faradaic reaction. This mechanism enhances the energy density within the electrode [122]. Generally speaking, pseudocapacitance can be divided into three different types based on its reaction mechanism, including redox pseudocapacitance, under potential deposition (adsorption) pseudocapacitance, and intercalation pseudocapacitance [123]. The schematic diagrams of the three processes are shown in Figure 19.

3.2.1. Redox Pseudocapacitance

Redox pseudocapacitance (Figure 19a) is the most prevalent form of pseudocapacitance. Its working principle involves the electrochemical adsorption of active ions in the electrolyte onto or near the electrode surface when a potential is applied [124]. Simultaneously, the electrode material undergoes a rapid and reversible oxidation-reduction reaction, generating charges and facilitating Faraday currents to flow through the supercapacitor (Figure 19a) [125].

3.2.2. Underpotential Deposition Pseudocapacitance

Underpotential deposition pseudocapacitance (Figure 19b), alternatively known as adsorption pseudocapacitance, occurs when an external potential is applied. This process involves the surface adsorption and reduction of metal ions, resulting in the deposition of a monolayer on the metal surface. This deposition causes a minor change in potential relative to its equilibrium potential. An example of underpotential deposition pseudocapacitance is the adsorption of lead onto the surface of an Au electrode (Figure 19b) [126].

3.2.3. Intercalation Pseudocapacitance

The principle of intercalated pseudocapacitors (Figure 19c) involves the embedding of ions from the electrolyte into the layered or tunnel-like structure of redox-active materials. This embedding process triggers rapid charge transfer, which occurrs without altering the crystal structure of the electrode material [125]. One example is the insertion of lithium ions into the lattice of niobium oxide (Figure 19c) [127].

Pseudocapacitors possess distinct electrochemical characteristics, allowing for high charge storage capacity and a boost in energy density through efficient charge transfer channels [128]. Typically, pseudocapacitors exhibit superior specific capacitance and energy density when compared to EDLCs [129]. However, redox reactions, particularly those occurring on the electrode surface, can alter the bulk phase or electrolyte composition of the electrode material. Consequently, over extended charging and discharging cycles, materials are prone to fatigue damage, resulting in a shorter cycling life [80]. While their lifespan is still longer than that of batteries, it falls short of that of double-layer capacitors.

During the early stages of pseudocapacitive electrode research, researchers primarily focused on transition metal oxides (TMOs) [130]. Nevertheless, their practical applications have been unsatisfactory due to low conductivity and relatively limited charge storage capacity, thus limiting their widespread use in pseudocapacitive electrodes. Currently, electrode materials for pseudocapacitors that are widely studied include carbon materials doped with heteroatoms (such as N, P, S) [131], transition metal oxides/hydroxides (like MnO2, NiOOH) [132,133], two-dimensional transition metal carbides, and nitrides (MXene) [134]. Compared with pure carbon materials, carbon materials doped with heteroatoms possess characteristics such as low cost and excellent electrochemical performance. Commonly, N atoms, P atoms, and others are selected for doping. For instance, Cao et al. [135] prepared nitrogen-doped biomass-derived hierarchical porous carbon materials (HPC) using different nitrogen-containing compounds (NH4Cl, (NH4)2CO3, and urea) simultaneously as activators and dopants. When the three materials were used in pseudocapacitors, the pseudocapacitor based on HPC-urea exhibited the highest specific capacitance (300 F·g−1 at 1 A·g−1) and energy density (14.3 Wh·kg−1). As a transition metal oxide, MnO2 boasts low cost and superior electrochemical performance, achieving a specific capacitance as high as 1100 F·g−1 within a potential window of 1.0 V. In recent years, MnO2 has emerged as a research hotspot in the field of pseudocapacitive materials. The reversible transformation between MnO2 and MnOONa in sodium sulfate electrolyte is the primary reason for the pseudocapacitive behavior exhibited by MnO2 electrodes [136]. Currently, research on MnO2 primarily focuses on enhancing its specific capacitance. For instance, Zhou et al. [137] successfully synthesized mesoporous manganese dioxide with a semicrystalline spinodal structure using mesoporous silica KIT-6 as a robust hard template. Within the potential range of −0.1 V to 0.55 V, this material exhibited stable and reversible electrochemical behavior, achieving an excellent capacitance performance of 220 F·g−1. Nayak et al. [138] obtained mesoporous manganese dioxide with an average pore diameter of 2–20 nm from potassium permanganate through a sonochemical method using triblock copolymers as soft templates. These materials possess a high specific capacitance of 265 F·g−1. MXene is a novel class of two-dimensional transition metal carbides, carbonitrides, or nitrides. Its interlayer structure is flexible, allowing various ions to be inserted between MXene sheets. Additionally, due to its abundant interlayer ion diffusion pathways and ion storage sites, combined with the conductive carbide/nitride core within the material, MXene has emerged as an important candidate for pseudocapacitive energy storage materials [139]. Cao et al. [140] have developed highly stretchable micro-pseudocapacitor electrodes composed of MXene nanosheets and in situ reconstructed silver nanoparticles (Ag-NP-MXene). These electrodes exhibit high energy density, a stable operating voltage of approximately 1 V, and rapid charging capabilities. Kim et al. [141] immersed carbon nanofibers (CNFs) into a colloidal solution of MXene (Ti3C2) to form a composite material through a dip-coating process. Subsequently, they constructed a three-electrode system using an aqueous solution of 1 M sodium sulfate as the electrolyte. Experimental results showed that this MXene-coated CNF exhibited remarkable performance, achieving a maximum specific capacitance of 514 F·g−1 at a current density of 0.5 A·g−1. Additionally, the energy density and power density reached 71.4 Wh·kg−1 at 0.5 A·g−1 and 2.3 kW·kg−1 at 5 A·g−1, respectively.

Figure 19.

The schematic diagrams of pseudocapacitance. (a) A redox pseudocapacitance in RuO2 schematics. (b) Underpotential deposition pseudocapacitance, Pb coating on Au electrode. (c) Intercalation pseudocapacitance, lithium ions embedded in the lattice of niobium oxide. Reproduced from Ref. [125] with permission.

3.3. Hybrid Capacitors

As implied by its name, a hybrid capacitor is essentially a type of supercapacitor that consists of two electrode parts and a separator. The electrodes of a hybrid capacitor can be made from dissimilar materials, and the separator typically has a microporous structure. The diversity in hybrid capacitors is achieved through the combination of various redox and EDLC materials. The storage mechanism of hybrid supercapacitors integrates the principles of both EDLC and pseudocapacitors. This unique combination results in a significantly higher capacitance, often reaching levels two to three times greater than those of traditional capacitors, standalone EDLCs, or pseudocapacitors. Additionally, it exhibits a higher working potential, further enhancing its overall performance [142]. The electrodes of hybrid supercapacitors are usually asymmetric, with one electrode being a carbon electrode that charges and discharges based on the double-layer capacitance process and the other electrode being a pseudocapacitive electrode material or battery electrode material that undergoes Faradaic redox reactions during charging and discharging.

The positive electrode of a hybrid capacitor is a crucial component that supports its high-current discharge and high-power density capabilities. Carbon-based materials, known for their high electrical conductivity and large specific surface area, are commonly used as positive materials in hybrid capacitors. The reaction mechanism of carbon-based positive materials is primarily based on the electric double-layer principle, where energy is stored and released through the adsorption and desorption of ions from the electrolyte onto the surface of the carbon electrode. Common carbon-based positive materials include activated carbon and graphene. Activated carbon features a porous structure, a large specific surface area (approximately 1000–1500 m2·g−1), and strong adsorption capabilities [143]. However, its relatively low specific capacity (around 40–80 mAh·g−1) and electrical conductivity (approximately 1–5 S·cm−1) limit its applications to some extent. Currently, research on activated carbon materials focuses on optimizing their porous structure, morphology control, and surface modification to achieve higher specific capacitance. For example, Lu et al. [144] utilized corn stalks to prepare mesoporous activated carbon for use in high-performance supercapacitors. The activated carbon based on corn stalks exhibited a high specific capacitance of 188 F·g−1 at a current density of 1 A·g−1 in both organic and ionic liquid electrolytes. Piao et al. [145] reported an activated multi-hierarchical mesoporous carbon (MHPC). When tested in a three-electrode system using a 6 M KOH aqueous solution at a current density of 1 A·g−1, the assembled supercapacitor with the MHPC electrode achieved a specific capacitance of 318 F·g−1. Graphene is a two-dimensional monolayer material composed of carbon atoms arranged in a honeycomb lattice. It possesses a theoretical specific surface area of 2360 m2·g−1, a theoretical specific capacitance of 550 F·g−1, and high electrical conductivity (approximately 50–150 S·cm−1). However, irreversible stacking tends to occur between graphene sheets, reducing their surface area [113]. Currently, researchers have employed various methods to address the aforementioned issues. For instance, Gao et al. [146] synthesized a three-dimensional oriented graphene framework that resembles paper but possesses a directed surface, macropores, and interconnected parts through ordered assembly guided by hard templates. This framework exhibits a high specific surface area of up to 402.5 m2·g−1 and excellent mechanical flexibility, making it suitable for use as an electrode in hybrid capacitors. Yan et al. [147] prepared hollow graphene nanospheres through a combination of template separation, microwave heating, and graphitization of carbon layers. The synthesized graphene exhibits a specific surface area of 2794 m2·g−1, a capacitance exceeding 529 F·g−1 at a current density of 1 A·g−1, and a capacitance retention rate of 62.5% during continuous power supply.

For the negative electrode of hybrid capacitors, materials with rapid charge-discharge capabilities are often employed to compensate for the kinetic differences between the positive and negative electrodes. Transition metal oxides, with their high theoretical specific capacities, abundant sources, and low costs, are commonly used as negative electrode materials in hybrid capacitors. The reaction mechanism of transition metal oxide negative electrode materials is primarily based on Faraday redox reactions. When the hybrid capacitor is charged, ions in the electrolyte (such as sodium ions, lithium ions, etc.) diffuse to the surface of the transition metal oxide negative electrode material and undergo electrochemical reactions with it, storing charge. During this process, one or more redox pairs form on the surface of the transition metal oxide, which can reversibly convert during charging and discharging, thereby enabling the storage and release of charge. Common transition metal oxide materials include MnO and Co3O4. When MnO is used as a negative electrode material, its theoretical capacity ratio can reach 756 mAh·g−1, but pure MnO has poor electronic conductivity (approximately 10−8–10−6 S·m−1), leading to easy capacity decay. Therefore, it is typically combined with highly conductive carbon materials. For example, Yang et al. [148] utilized graphene oxide (GO) and nanospherical KxMnO2 precursors to prepare a one-dimensional graphene nanoscroll-wrapped MnO nanoparticle (GNS@MnO) material through a simple liquid nitrogen quenching followed by atmospheric annealing process. The obtained material exhibited a high reversible capacity of 766 mA·h·g−1 at a current density of 100 mA·g−1, high rate performance (437 mA·h·g−1 at 5.0 A·g−1), and good cycling stability. Chen et al. [149] designed and synthesized one-dimensional graphene nanoscrolls wrapped with MnO nanoparticles featuring a unique nanocomposite structure. The constructed composite negative electrode material exhibits rapid ion and electron transport kinetics, as well as strong durability. When used as a negative electrode material, Co3O4 boasts a theoretical specific capacity of up to 890 mA·h·g−1 and a low redox potential (<1 V). However, the volume expansion that occurs during charging and discharging can lead to the shedding of active materials and rapid capacity decay. To address this issue, researchers have taken various measures. For instance, Wang et al. [150] synthesized Co3O4 cryogels using a triblock polymer/ice crystal dual-template sol-gel method. These cryogels exhibited a specific capacitance of up to 742.3 F·g–1 and maintained 86.2% of their capacity after 2000 cycles. Liu et al. [151] successfully obtained uniformly sized and highly crystalline Co3O4 nanocubes with the assistance of mesoporous carbon nanorods. After heat treatment, mesoporous Co3O4 nanocubes were formed. Electrochemical tests revealed that the specific capacitance of the Co3O4 nanocube electrode was approximately 350 F·g−1 at a current density of 0.2 A·g−1.