Linear Regression-Based Procedures for Extraction of Li-Ion Battery Equivalent Circuit Model Parameters

Abstract

1. Introduction

1.1. Motivation and Challenges

1.2. Literature Review

1.3. Main Contribution

1.4. Article Organization

2. Materials and Methods

2.1. Model Structure

2.2. Parameter Extraction Procedures

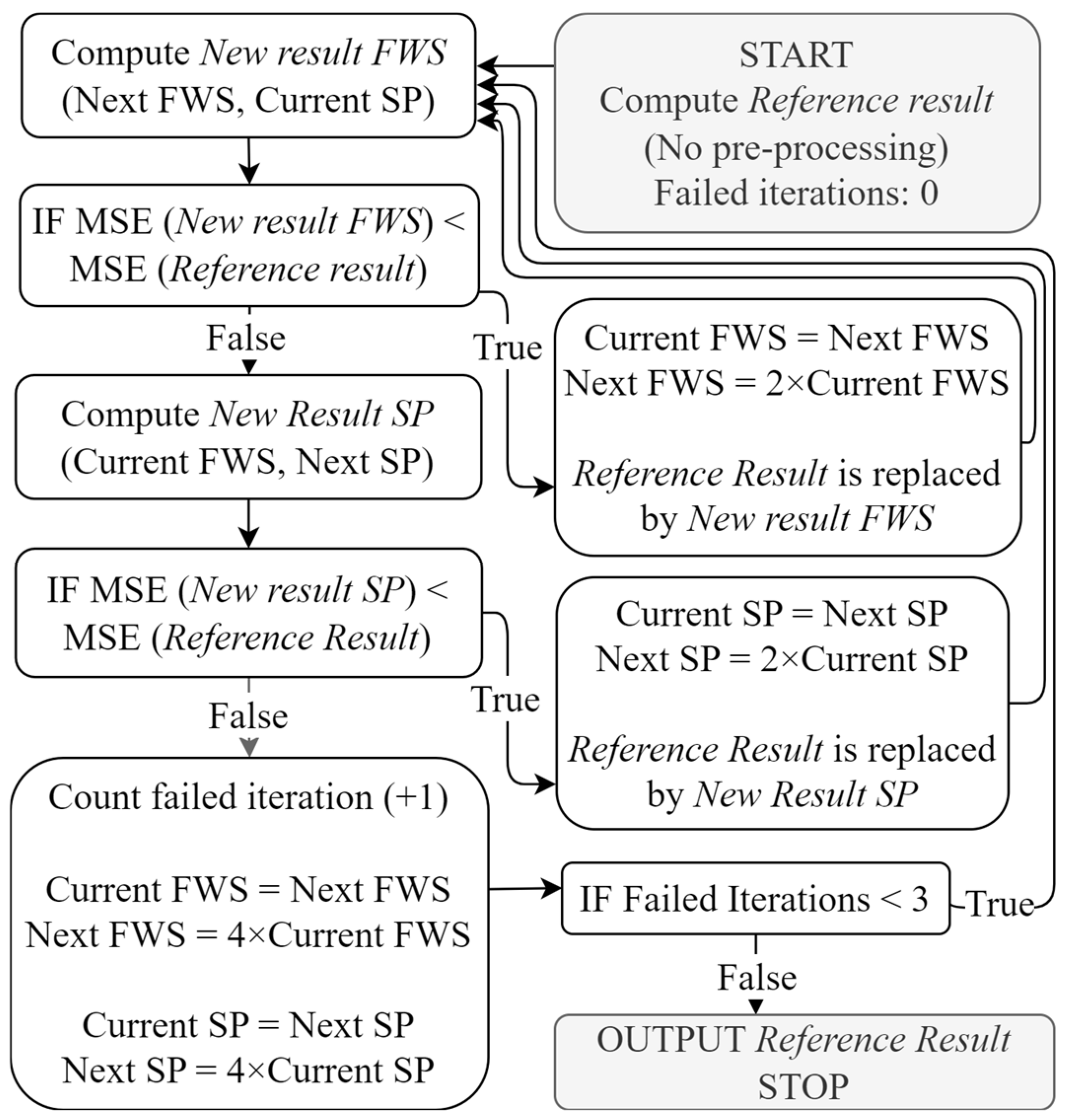

2.2.1. Parameter Extraction Using the ARX Model Format and Least Squares Linear Regression (LS-ARX)

2.2.2. Parameter Extraction Based on Linearization and Least Squares Linear Regression (LS-ECM)

- Step 1

- Step 2

2.2.3. Extraction Based on Differential Evolution (DE-ECM)

2.3. Experimental

3. Results

4. Discussion

4.1. Analysis of LS-ARX Procedure

4.2. Analysis of LS-ECM Procedure

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

- Kirchhoff’s First Law applied to an RC element (Equation (A1))

- Kirchhoff’s Second Law applied to an RC element (Equation (A2))

- Capacitive current definition (Equation (A3))

Appendix B

Appendix C

References

- Kalogiannis, T.; Hosen, M.S.; Sokkeh, M.A.; Goutam, S.; Jaguemont, J.; Jin, L.; Qiao, G.; Berecibar, M.; Van Mierlo, J. Comparative Study on Parameter Identification Methods for Dual-Polarization Lithium-Ion Equivalent Circuit Model. Energies 2019, 12, 4031. [Google Scholar] [CrossRef]

- Li, J.; Peng, Y.; Wang, Q.; Liu, H. Status and Prospects of Research on Lithium-Ion Battery Parameter Identification. Batteries 2024, 10, 194. [Google Scholar] [CrossRef]

- Ljung, L. System Identification; Webster, J.G., Ed.; Wiley Encyclopedia of Electrical and Electronics Engineering: Hoboken, NJ, USA, 1999. [Google Scholar] [CrossRef]

- Zhang, T.; Guo, N.; Sun, X.; Fan, J.; Yang, N.; Song, J.; Zou, Y. A Systematic Framework for State of Charge, State of Health and State of Power Co-Estimation of Lithium-Ion Battery in Electric Vehicles. Sustainability 2021, 13, 5166. [Google Scholar] [CrossRef]

- Huang, C.-S. Online Parameter Identification for Lithium-Ion Batteries: An Adaptive Moving Window Size Design Methodology for Least Square Fitting. IEEE Trans. Veh. Technol. 2023, 72, 5824. [Google Scholar] [CrossRef]

- Raihan, S.A.; Balasingam, B. Recursive Least Square Estimation Approach to Real-Time Parameter Identification in Li-ion Batteries. In Proceedings of the 2019 IEEE Electrical Power and Energy Conference (EPEC), Montreal, QC, Canada, 16–18 October 2019. [Google Scholar] [CrossRef]

- Kim, M.; Kim, K.; Han, S. Reliable Online Parameter Identification of Li-Ion Batteries in Battery Management Systems Using the Condition Number of the Error Covariance Matrix. IEEE Access 2020, 8, 189106. [Google Scholar] [CrossRef]

- Fan, Y.; Shi, H.; Wang, S.; Fernandez, C.; Cao, W.; Huang, J. A Novel Adaptive Function—Dual Kalman Filtering Strategy for Online Battery Model Parameters and State of Charge Co-Estimation. Energies 2021, 14, 2268. [Google Scholar] [CrossRef]

- Xia, B.; Huang, R.; Lao, Z.; Zhang, R.; Lai, Y.; Zheng, W.; Wang, H.; Wang, W.; Wang, M. Online Parameter Identification of Lithium-Ion Batteries Using a Novel Multiple Forgetting Factor Recursive Least Square Algorithm. Energies 2018, 11, 3180. [Google Scholar] [CrossRef]

- Sun, X.; Ji, J.; Ren, B.; Xie, C.; Yan, D. Adaptive Forgetting Factor Recursive Least Square Algorithm for Online Identification of Equivalent Circuit Model Parameters of a Lithium-Ion Battery. Energies 2019, 12, 2242. [Google Scholar] [CrossRef]

- Sun, C.; Lin, H.; Cai, H.; Gao, M.; Zhu, C.; He, Z. Improved parameter identification and state-of-charge estimation for lithium-ion battery with fixed memory recursive least squares and sigma-point Kalman filter. Electrochim. Acta 2021, 387, 138501. [Google Scholar] [CrossRef]

- Li, C.; Kim, G.-W. Improved State-of-Charge Estimation of Lithium-Ion Battery for Electric Vehicles Using Parameter Estimation and Multi-Innovation Adaptive Robust Unscented Kalman Filter. Energies 2024, 17, 272. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, X.; Zhang, H.; Yang, F.; Tong, L.; Yang, Y.; Yan, D.; Yang, A.; Yu, M.; Liu, Z.; et al. Online identification of battery model parameters and joint state of charge and state of health estimation using dual particle filter algorithms. Int. J. Energy Res. 2022, 46, 19615–19652. [Google Scholar] [CrossRef]

- Tian, N.; Wang, Y.; Chen, J.; Fang, H. On parameter identification of an equivalent circuit model for lithium-ion batteries. In Proceedings of the IEEE Conference on Control Technology and Applications (CCTA), Maui, HI, USA, 27–30 August 2017. [Google Scholar] [CrossRef]

- Tran, M.-K.; DaCosta, A.; Mevawalla, A.; Panchal, S.; Fowler, M. Comparative Study of Equivalent Circuit Models Performance in Four Common Lithium-Ion Batteries: LFP, NMC, LMO, NCA. Batteries 2021, 7, 51. [Google Scholar] [CrossRef]

- Chen, C. Parameter Determination for the Battery Equivalent Circuit Model Using a Numerical Integro-Differential Method; SAE Technical Paper 2020-01-1179; SAE International: Warrendale, PA, USA, 2020. [Google Scholar] [CrossRef]

- Al Rafei, T.; Yousfi Steiner, N.; Chrenko, D. Genetic Algorithm and Taguchi Method: An Approach for Better Li-Ion Cell Model Parameter Identification. Batteries 2023, 9, 72. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, X.; Hua, Y.; Zhou, X.; Yang, S. Adaptive model parameter identification for lithium-ion batteries based on improved coupling hybrid adaptive particle swarm optimization- simulated annealing method. J. Power Sources 2021, 482, 228951. [Google Scholar] [CrossRef]

- Ghoulam, Y.; Mesbahi, T.; Wilson, P.; Durand, S.; Lewis, A.; Lallement, C.; Vagg, C. Lithium-Ion Battery Parameter Identification for Hybrid and Electric Vehicles Using Drive Cycle Data. Energies 2022, 15, 4005. [Google Scholar] [CrossRef]

- Cheng, Y.S. Identification of Parameters for Equivalent Circuit Model of Li-Ion Battery Cell with Population Based Optimization Algorithms. Available online: https://ssrn.com/abstract=4229575 (accessed on 14 September 2024).

- Hou, J.; Wang, X.; Su, Y.; Yang, Y.; Gao, T. Parameter Identification of Lithium Battery Model Based on Chaotic Quantum Sparrow Search Algorithm. Appl. Sci. 2022, 12, 7332. [Google Scholar] [CrossRef]

- Lee, S.; Lee, D. A Novel Battery State of Charge Estimation Based on Voltage Relaxation Curve. Batteries 2023, 9, 517. [Google Scholar] [CrossRef]

- Lee, J.; Sun, H.; Liu, Y.; Li, X. A machine learning framework for remaining useful lifetime prediction of li-ion batteries using diverse neural networks. Energy AI 2024, 15, 100319. [Google Scholar] [CrossRef]

- Cleary, T.; Nozarijouybari, Z.; Wang, D.; Wang, D.; Rahn, C.; Fathy, H.K. An Experimentally Parameterized Equivalent Circuit Model of a Solid-State Lithium-Sulfur Battery. Batteries 2022, 8, 269. [Google Scholar] [CrossRef]

- Zeigler, B.; Muzy, A.; Kofman, E. Chapter 3—Modeling Formalisms and Their Simulators. In Theory of Modeling and Simulation, 3rd ed.; Zeigler, B., Muzy, A., Kofman, E., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 43–91. [Google Scholar]

- Cheever, E. The Z Transform. 2022. Available online: https://lpsa.swarthmore.edu/ZXform/FwdZXform/FwdZXform.html (accessed on 14 September 2024).

- Cheever, E. Transformation: Transfer Function ↔ State Space. 2022. Available online: https://lpsa.swarthmore.edu/Representations/SysRepTransformations/TF2SS.html (accessed on 14 September 2024).

- SciPy. Scipy.optimize.lsq_linear—SciPy v1.10.1 Manual. 2023. Available online: https://docs.scipy.org/doc/scipy/reference/generated/scipy.optimize.lsq_linear.html (accessed on 14 September 2024).

- SciPy. Scipy.optimize.differential_evolution—SciPy v1.10.1 Manual. 2023. Available online: https://docs.scipy.org/doc/scipy/reference/generated/scipy.optimize.differential_evolution.html (accessed on 14 September 2024).

- PyVisa Authors. PyVISA—Control Your Instruments with Python, PyVISA. 2023. Available online: https://pyvisa.readthedocs.io/en/latest/index.html (accessed on 14 September 2024).

| ARX Parameter | Equation |

|---|---|

| Sample No. | SOC Range | Discharge Time (s) | LS-ARX | LS-ECM | DE-ECM (Average) |

|---|---|---|---|---|---|

| Sample 1 | 24.6–24.3% | 10 s | 5.349 × 10−7 | 5.900 × 10−8 | 5.890 × 10−8 |

| Sample 2 | 64.8–64.5% | 10 s | 4.164 × 10−7 | 4.661 × 10−8 | 4.660 × 10−8 |

| Sample 3 | 95.0–94.7% | 10 s | 5.971 × 10−7 | 3.798 × 10−7 | 3.794 × 10−7 |

| Sample 4 | 24.3–14.6% | ~334 s | 1.082 × 10−4 | 4.825 × 10−6 | 4.826 × 10−6 |

| Sample 5 | 64.5–54.8% | ~334 s | 2.120 × 10−5 | 8.061 × 10−7 | 8.058 × 10−7 |

| Sample 6 | 94.7–84.9% | ~334 s | 2.391 × 10−5 | 7.069 × 10−6 | 7.073 × 10−6 |

| Parameter | LS-ARX | LS-ECM | DE-ECM (Average) |

|---|---|---|---|

| (V) | 4.103 | 4.108 | 4.108 |

| (V) | 4.075 | 4.076 | 4.076 |

| (Ω) | 2.513 × 10−2 | 2.666 × 10−2 | 2.670 × 10−2 |

| (Ω) | 1.011 × 10−2 | 1.434 × 10−2 | 1.437 × 10−2 |

| (s) | 3.850 | 13.788 | 13.938 |

| (Ω) | 2.240 × 10−2 | 1.668 × 10−2 | 1.664 × 10−2 |

| (s) | 95.961 | 183.044 | 184.345 |

| Sample No. | LS-ARX (% of DE-ECM) | LS-ECM (% of DE-ECM) | DE-ECM (Average) |

|---|---|---|---|

| Sample 1 | 19 (0.15%) | 311 (2.42%) | 12,836 (100%) |

| Sample 2 | 25 (0.17%) | 161 (1.12%) | 14,398 (100%) |

| Sample 3 | 20 (0.13%) | 223 (1.48%) | 15,107 (100%) |

| Sample 4 | 9 (0.08%) | 121 (1.10%) | 10,983 (100%) |

| Sample 5 | 7 (0.05%) | 163 (1.15%) | 14,129 (100%) |

| Sample 6 | 18 (0.16%) | 77 (0.67%) | 11,367 (100%) |

| Sample No. | Default MSE | Best Result MSE | Filter Window Size | DS Factor | Global Minimum MSE |

|---|---|---|---|---|---|

| Sample 1 | 1.611 × 10−6 | 5.349 × 10−7 | 2048 | 2 | 5.316 × 10−7 |

| Sample 2 | 2.334 × 10−6 | 4.164 × 10−7 | 2048 | 16 | 4.043 × 10−7 |

| Sample 3 | 2.994 × 10−6 | 5.971 × 10−7 | 1024 | 4 | 5.971 × 10−7 |

| Sample 4 | 1.085 × 10−4 | 1.082 × 10−4 | 1 | 2 | 1.082 × 10−4 |

| Sample 5 | 2.120 × 10−5 | 2.120 × 10−5 | 1 | 1 | 1.705 × 10−5 |

| Sample 6 | 3.150 × 10−5 | 2.391 × 10−5 | 64 | 8 | 2.226 × 10−5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Savu, V.-I.; Brace, C.; Engel, G.; Didcock, N.; Wilson, P.; Kural, E.; Zhang, N. Linear Regression-Based Procedures for Extraction of Li-Ion Battery Equivalent Circuit Model Parameters. Batteries 2024, 10, 343. https://doi.org/10.3390/batteries10100343

Savu V-I, Brace C, Engel G, Didcock N, Wilson P, Kural E, Zhang N. Linear Regression-Based Procedures for Extraction of Li-Ion Battery Equivalent Circuit Model Parameters. Batteries. 2024; 10(10):343. https://doi.org/10.3390/batteries10100343

Chicago/Turabian StyleSavu, Vicentiu-Iulian, Chris Brace, Georg Engel, Nico Didcock, Peter Wilson, Emre Kural, and Nic Zhang. 2024. "Linear Regression-Based Procedures for Extraction of Li-Ion Battery Equivalent Circuit Model Parameters" Batteries 10, no. 10: 343. https://doi.org/10.3390/batteries10100343

APA StyleSavu, V.-I., Brace, C., Engel, G., Didcock, N., Wilson, P., Kural, E., & Zhang, N. (2024). Linear Regression-Based Procedures for Extraction of Li-Ion Battery Equivalent Circuit Model Parameters. Batteries, 10(10), 343. https://doi.org/10.3390/batteries10100343