Abstract

Traditional printed products have to some extent affected the development of smart structures and their application in multiple fields, especially in harsh environments, due to their complex mechanisms and control principles. The 4D printing technology based on magnetically controlled smart materials exploits the advantages of magnetically controlled smart materials with good operability and security, and its printed smart structures can be obtained under magnetic field drive for unfettered remote manipulation and wireless motion control, which expands the application of printed products in complex environments, such as sealed and narrow, and has broad development prospects. At present, magnetically controlled smart material 4D printing technology is still in its infancy, and its theory and application need further in–depth study. To this end, this paper introduces the current status of research on magnetically controlled smart material 4D printing, discusses the printing process, and provides an outlook on its application prospects.

1. Introduction

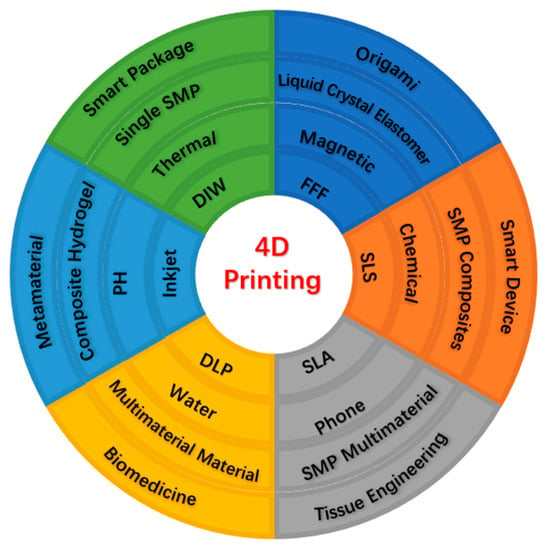

4D printing technology, developed from 3D printing, enables 3D technology to print structures that change shape or structure under external stimuli, directly building smart materials and deformation design of structures into materials, simplifying the process of building objects from design concepts to physical objects, enabling objects to automatically assemble conformations, and realizing the integration of product design, manufacturing, and assembly by adding dimensions that change over time on top of 3D printing [1]. The shape, properties, or function of the printed structure can change over time in response to external environmental stimuli (e.g., water [2], light [3], heat [4], electric current [5], magnetic fields [6], acidic and alkaline environments [7], etc.), as shown in Figure 1. Magnetically controlled 4D printing is a method of 4D printing that uses magnetic fields as a driving method. It can be classified as a magnetic thermal deformation based on the deformation mechanism of shape memory, which uses the characteristics of shape memory polymer (SMP) materials and, thus, has the characteristics of warming up and shaping, cooling down, and deforming again using the magnetic field due to power loss and thermal drive, which can change from a temporary shape to the initial shape [8,9]. In addition, the drive can be designed, it is lightweight, and it is inexpensive, and coupled with the unique shape memory effect and deformation capability, it has great potential and practical value in many fields, but the traditional preparation of SMP limits the application and development of SMP deformable structures. Products based on the magnetic response properties of the material are realized by doping the printing material with iron particles, which are driven by the force in the magnetic field to change the overall structure, and in order to make the printed products with a large deformation, the printing material is generally selected from graphene and polydimethylsiloxane (PDMS).

Figure 1.

4D printing development status.

Magnetic 4D printing has the advantages of a rapid response, higher security, remote manipulation, greater controllability, and predictability. Compared to a thermal drive, a magnetic drive is instantaneous and has a fast response; compared to a water drive, a magnetic drive can be manipulated remotely to achieve non–contact control; and compared to an electric drive, a magnetic drive is more secure, and the power of a magnetic drive comes from the internal magnetic domain, which is stored more inside the printed product. However, due to the limitations of the current 4D printing technology and the limited variety of printing materials, there are still many shortcomings of magnetically controlled 4D printing, such as the lack of reprogramming ability of the materials; the possibility of a slow response or deformation of the printed components to meet the design specifications over a long period of time; the inability to program at the micron level for fine printing and non–light–cured voxel printing; and the rheological properties of the materials. Insufficient research, single printing structure, few available printing materials, the urgent need to study the innovative combination of formulations; and 4D printing integrating materials, structure, and function are limitations in the specific application areas. In order to play the maximum role of 4D printing, printed materials, 3D printer types, printing methods, design methods, and programming methods are needed to have a certain combination of design.

As a 4D printing technology, the research related to magnetically controlled 4D printing is still in its infancy, and the research mainly includes the development of magnetically controlled smart materials, a smart material additive manufacturing process and performance, a 4D smart structure design, and a smart structure driving mechanism [10,11]. In recent years, research on additive manufacturing for smart materials has shown a continuous growth trend and is now widely used in medicine [12], assisted rehabilitation [13], fragile body sorting [14], non–structural environment detection [15,16], underwater operations [17,18], and other fields with high flexibility requirements for human–machine–environment interaction. Magnetically controlled 4D printing has received wide attention because of its good manipulability and safety.

2. Research Status

2.1. Magnetically Controlled Materials

In the 4D printing process, two aspects are required of the material: printability and intelligence. Printability is a prerequisite for 4D structures to be realized in the process [19]. In the printing process of extrusion, rheology modifiers can be used to provide the proper material viscosity. Photoinitiators, crosslinkers, and sacrificial agents are also important factors to consider for printability. Smart materials for 4D printing can be classified into shape change materials (SCM) and shape memory materials (SMM). Magnetically controlled 4D printed smart materials can undergo a deformation response under the action of alternating the magnetic field, rotating the magnetic field, and oscillating the magnetic field and gradient magnetic field. Magnetically controlled smart materials are characterized by a large deformation rate, easy control, fast dynamic response, high power density, high electromechanical energy conversion efficiency, and the ability to realize contactless control. With the development of magnetically controlled 4D printing technology, the research and development of magnetically controlled smart materials that can be used for this technology is also in progress, and the variety is increasing.

Currently, magnetically smart materials can be divided into magnetothermally deformable shape memory polymers (SMP) and composite elastomers driven by magnetic particles encapsulated within a matrix material according to indirect and direct responses [20]. The direct response method fixes a substrate mixed with magnetic particles into a temporary shape and places it in a magnetic field. The magnetic field changes the magnetic domains in the magnetic particles, and when the same magnetic field is applied again, the magnetic field of the magnetic particles in the substrate responds to the applied magnetic field, thus achieving shape memory. The indirect response method is based on the magneto–thermal interaction of the magnetic particles in the magnetic field and uses a thermally driven method to achieve shape memory, which is a variation of the thermally driven method. According to the composition, they can be divided into two categories: magnetic shape memory composite hydrogels and magnetic shape memory polymers and their composites [21].

2.1.1. Ferromagnetic Droplets

Liquid magnets [22] are reconfigurable ferromagnetic droplets that can be obtained with the adsorption of superparamagnetic nanoparticles at the liquid/liquid interface under ambient conditions, enabling the controlled preparation of arbitrary droplet shapes and the paramagnetic fluid–ferromagnetic fluid transition. Conventional ferromagnetic solid materials are rigid and cannot be configured. Although ferromagnetic fluids can be configured at a later stage, they must be continuously magnetized under the action of an applied magnetic field to exhibit specific magnetic properties. In contrast, ferromagnetic droplets have the fluidic properties of a liquid and the magnetic properties of a solid, they can be reconfigured while maintaining their magnetic properties, and the attractive/repulsive interactions between ferromagnetic droplets can be manipulated. Separation and patterning of ferromagnetic droplets is easily achieved and can be reconfigured in different shapes with relative ease; with their ability to deform according to their surroundings, spherical droplets can become the shape of a column, a pancake, a hair–thin tube, or even an octopus, and their magnetic characteristics do not disappear. Moreover, ferromagnetic droplets can precisely control the motion of the printed object with less energy dissipation through an external magnetic field.

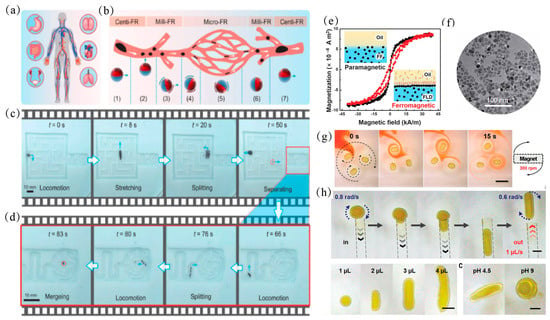

Ferromagnetic droplets have excellent characteristics on which research breakthroughs have been made. Fan et al. [23] prepared a scale–reconfigurable magnetic droplet robot using magneto–fluid droplets, which can not only freely travel through extreme transformational environments, but can also achieve an on–demand adjustment of its own scale by splitting or fusion under necessary conditions to adapt to extreme environments as well as specific tasks, which is currently used in targeted medical–related applications (Figure 2a–d,f). However, robotic locomotion is characterized by a number of challenges. For example, the scales of blood vessels and tissue interstitials within the human body often span several orders of magnitude, and it is impossible to match such complex environments with only certain fixed–scale micro–robots; compatible motion control of micro–robots at different scales has also been a challenge due to the fact that the forces that dominate the motion behavior of micro–robots at different scales vary with the scale.

Figure 2.

(a–d) Controlled motion, deformation, and scale scaling of a scale reconfigurable magnetic droplet robot in a live dramatic environment (simulation). (e) Schematic representation of magnetic nanoparticles in the water phase and ligands in the oil phase self–assembling at the water–oil interface to form dense two–dimensional nanofilms and ferromagnetic droplets. (f) Transmission electron micrograph of magnetic nanoparticles undergoing blocking phase transition at the water–oil interface. (g) A ferromagnetic droplet suspended in the oil phase rotates under the action of an external magnetic field, and the turbulent trajectory of the liquid around the droplet is recorded with the red dye. (h) Schematic representation of the magnetic nanoparticles in the aqueous phase and the ligands in the oil phase self–assembling at the water–oil interface to form dense two–dimensional nanofilms and ferromagnetic droplets (adapted from with the permission from Ref. [23], 2022, Science Advance. Ref. [24], 2019, Science).

In order to expand the application of ferromagnetic droplets, further research on their principles is needed. Research on soft robots has been very hot in the past few years, but their power systems still face a big challenge: small soft robots yet require huge pneumatic equipment. If this magnetic droplet is embedded in a soft robot, it can move with only a magnetic field, thus greatly simplifying its power system. Liu et al. [24] have demonstrated the conversion of ferromagnetic fluids into ferromagnetic droplets by interfacial interference and magnetization of MNP surfactants. The self–assembly of magnetic nanoparticles at the water–oil interface can be controlled to eventually guide the conversion of ferromagnetic fluids from paramagnetic to ferromagnetic. Hysteresis loops of iron 3O4–carbon monoxide 2H ferromagnetic fluid droplets (Figure 2e) show the same ferromagnetic fluid droplets with and without magnetic nanoparticle (MNP) surfactants jamming the interfacial assembly. When the magnetic field is removed, the moment of the ferromagnetic droplet remains constant until the droplet is exposed to a magnetic field that exceeds the switching field, and then, the droplet is re–magnetized. Reshaping the droplet with other external fields or reducing the binding energy of the MNP surfactant also causes the MNP surfactant (Mr and Hc) to disappear, providing a further way to control magnetization. This ability to manipulate magnetization further distinguishes ferromagnetic droplets from ferromagnetic fluids and common ferromagnetic materials. Combined with the latest all–liquid–phase 3D printing and microfluidic molding techniques, researchers can fabricate magnetic liquid devices with arbitrary morphologies under all–liquid conditions. Figure 2g shows the visualization of hydrodynamic vortices in FLD collections using oil–soluble dyes in a rotating magnetic field. The bar magnet attracts ferromagnetic droplets, and using a rotating magnet, the ferromagnetic droplets are attracted to the center of the magnet and form a dynamically stable pattern that balances hydrodynamic repulsion and magnetic attraction. Furthermore, the self–assembly of interfacial magnetic nanoparticles is reversible and can be reconfigured by changing the aqueous phase acid–base environment (Figure 2h) where an increase in pH from 4.5 to 9 loosens the MNP surfactant, and the droplet shape returns to a spherical shape. The magnetization strength is lost, but by decreasing the pH, the MNP surfactant is re–clogged, and the droplet changes back to a ferromagnetic droplet. Thus, the shape and magnetic state of the ferromagnetic droplet are responsive. It changes the physical experience that ferromagnetic substances can only be composed of hard materials by studying their properties, and it has a wide range of potential applications from an application point of view.

The new ferromagnetic droplets have many peculiar properties and are expected to be used in the future for magnetically controlled liquid robots, programmable liquid microreactors, and driving new liquid magnetic material characterization techniques, such as polarized neutron magnetic field imaging, forward, and researchers will continue to investigate more complex 3D printed magnetic liquid structures, such as artificial cells printed with liquid, small propeller–motioned micro–robots, and deliveries to diseased cells as a targeted non–invasive drug delivery.

2.1.2. Magnetic Shape Memory Composite Hydrogel

Magnetic hydrogels are compounded by magnetic particles and a hydrogel matrix, which not only have excellent porosity and no killing effect on fibroblasts, but also have good mechanical stability and special magnetic responsiveness. The development around magnetic hydrogels has been very rapid in recent years, and they show good prospects for applications in drug release, photonic crystals, actuators, and artificial muscles. Shape–memory hydrogels (SMH) are a class of special shape–memory polymers containing large amounts of water consisting of a permanent cross–linked network and a molecular switch whose initial shape is determined by the permanent cross–linked network, and the temporary shape is fixed by the molecular switch [25]. It has been shown that magnetic nanoparticles in hydrogels and their precursors (inks) have an effect on their rheological and mechanical stability, and magnetic nanoparticles can react with the polymer backbone, thus changing its physical and chemical properties and also making the bio–nanocomposites magnetic.

In recent years, magnetic hydrogels have been widely used in 4D printing. It has promising applications in soft electronics, flexible robotics, biomedical devices, wastewater treatment, etc. Gang et al. [26] developed a novel self–healing magnetic double mesh gel using multiple interactions between magnetic Fe3O4 and chitosan–polyolefin groups, which showed excellent performance in magnetoacoustic effect and magnetic resonance imaging, further revealing the hydrogel 3D printing potential. Magnetic self–repairing hydrogels show excellent biosafety properties in animal experiments, demonstrating their potential as injectable implantable materials for biological and medical applications. In addition, 4D printing technology can maintain the morphology and strength of hydrogels for a certain period of time. Hydrogels, such as poly(N–isopropylacrylamide–co–acrylic acid) (pNIPAM–AAc), can be photopatterned to create a wide range of actuatable and self–folding microstructures; Breger et al. [27] designed, manufactured, and characterized photopatterned, self–folding microclamps based on this hydrogel. Conventional hydrogel grippers have low modulus and limited gripping ability, but the self–folding micro–fixtures obtained through experiments and modeling have good gripping ability and can be responsive and remotely guided according to the magnetic field. It is better used in soft robotics and surgical applications.

Magnetic hydrogels are not only used in our daily lives, but also in bionic technology. Chen et al. [28] proposed a new method of 3D printing with rheological modifiers and produced a magnetic hydrogel octopus using ink direct printing technique where the magnetic hydrogel octopus structure was printed directly without any structural processing and its motion and deformation could be controlled by a program. Hydrogels are very biocompatible and can be used to develop soft robots for biomedical applications, bioactuators, and so on. Simińska–Stanny et al. [29] introduce a printable magnetic hydrogel that can be effectively applied to multi–material soft bodies for direct printing and allows for a non–contact aerial control of hydrogel motion. This magnetic hydrogel can be successfully used for multi–material direct ink printing of soft actuators.

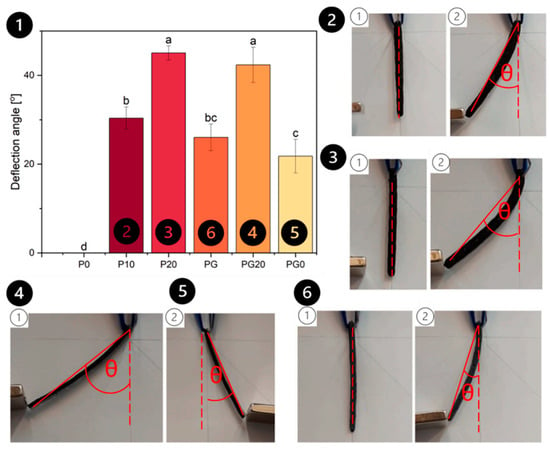

The assembly of non–magnetic and magnetic hydrogels into a single structure by additive manufacturing provides excellent adhesion between the magnetic and non–magnetic hydrogel layers, and the interaction between the magnetic nanoparticles and the precursor network of the hydrogel gives the ink a good shear thinning capability. By testing the deflection angle for different content of magnetic nanoparticle content, it was found that the deflection angle was strongly related to the magnetic nanoparticle content, 4D mode, and exposure surface. When a magnetic field is applied, the magnetic cantilever shows instantaneous bending. The average bending angles of the 4D printed cantilever beams with different 3D patterns are shown in Figure 3. The multi–material direct printing based on this structural hydrogel is well able to obtain high resolution, high shape fidelity, adjustable distribution of magnetic nanoparticles, and an induction of macroscopic anisotropy of the 3D structure.

Figure 3.

Average bending angles of 3D printed cantilever beams with different 3D patterns and their corresponding magnetic response photos. P0, nonmagnetic hydrogel consisting of one-type ink (contains 0% magnetic nanoparticles); P10, magnetic hydrogel consisting of one-type ink (contains 10% magnetic nanoparticles); P20, magnetic hydrogel consisting of one-type ink (contains 20% magnetic nanoparticles); PAA, polyacrylic acid; PG, hydrogel assembled from 3 inks (thirteen layers of 0% MNPs, thirteen layers of 10% MNPs and fourteen layers of 20% MNPs); PG0, hydrogel assembled from 3 inks, measuring the bending angle for the cantilever where the magnet was on the side of the layers with 0% MNPs; PG20, hydrogel assembled from 3 inks, measuring the bending angle for the cantilever where the magnet was on the side of the layers with 20% MNPs (adapted from with the permission from Ref. [29], 2021, Additive Manufacturing).

2.1.3. Magneto–Thermally Deformable Shape Memory Polymers

Magneto–thermally deformable shape memory polymer is usually a ferromagnetic material incorporated into a thermally deformable SMP and thermally driven in a magnetic field due to power loss. The laboratory of Xi’an Jiaotong University chose temperature–sensitive PNIPAm hydrogels as a matrix and added oleic acid–coated Fe3O4 magnetic nanoparticles to prepare magnetic temperature–sensitive hydrogels, which were printed by extrusion to fabricate integrated structures of magnetic hydrogels and elastomers [30]. The integrated structures were fabricated by curing the elastomeric ink by heating and curing the hydrogel ink with UV irradiation.

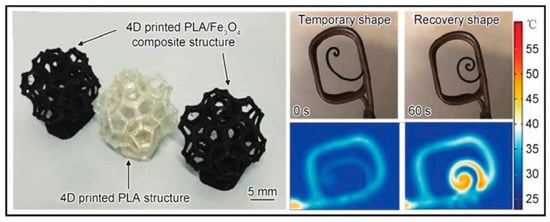

As shown in Figure 4, Zhang et al. [31] printed Fe3O4/PLA composite scaffolds using FDM technology, the printed scaffolds can be uniformly heated to 40 °C, driven by an alternating magnetic field at a frequency of 27.5 kHz, which leads to morphology changes, and the prepared scaffolds have a promising application in the field of bone tissue repair.

Figure 4.

FDM printing magneto–thermal effect driven deformation structure (adapted from with the permission from Ref. [31], 2019, Composites: PartA).

2.1.4. Magnetic Particle–Driven Composite Elastomers

A composite elastomer driven by magnetic particles encased in a matrix material is usually a polymer grid using magnetic nanoparticles (MNP) physically or chemically. Compared to magnetothermally deformable SMP, the use of magnetic nanoparticles to directly drive the elastic matrix for reversible deformation results in fast response, large deformation, and rapid deformation.

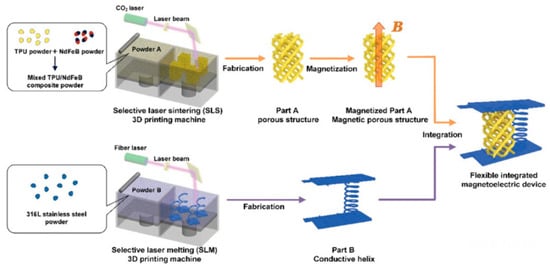

The research group of Prof. Yusheng Shi at Huazhong University of Science and Technology adopted the idea of material compounding [32] to combine additively fabricated magnetoelectric materials, thus realizing a new type of flexible magnetoelectric device. The flexible magnetoelectric device consists of a highly homogeneous porous structure that generates a magnetic field due to its permanent magnetism and a conductive spiral structure (equivalent to a conductive coil) in this magnetic field. It consists of a highly identical porous structure with a helical structure. It can be compressed or recovered periodically under the influence of external pressure, during which the magnetic flux through the coil changes, and it is known from Faraday’s principle of electromagnetic induction that a voltage will appear between two parallel plates. Therefore, additive manufacturing of magnetic composites, i.e., 4D printing of magnetic smart materials, produces components with piezoelectric properties and the ability to sense external pressure. The properties and functions above are not present in the original magnetic porous and conductive structures. This work has enriched the 4D printing research ideas.

2.1.5. Magnetic Inorganic Composites

Magnetic inorganic composites are also a theme for future development, using the properties of the material to provide new possibilities in many fields. Current studies on magnetic inorganic composites focus on magnetic memory metals, magnetic ceramics, and magnetic concrete.

4D printed shape memory alloys (SMAs) are a class of special metal alloys capable of shape memory effects (SME) when stimulated by temperature or magnetic fields. SMAs can be used in applications such as temperature control systems, actuators, biomedicine, and aerospace. The driving mechanism of magnetically responsive shape memory alloys is twin grain boundary motion, also known as magnetically induced reorientation (MIR) or magnetoplasticity [33]. MIR leads to an increase in magnetization intensity, which results in shape change. Caputo et al. [34] investigated an additive manufacturing route to produce functional net–shape parts from pre–alloyed magnetic shape memory Ni–Mn–Ga powder using binder jetting technology to print Ni–Mn–Ga magnetic shape memory alloys with various porosities. The printed Ni–Mn–Ga parts undergo reversible martensitic transformation during heating and cooling, which is a prerequisite for the shape–memory behavior. Under the action of applied magnetic field, Ni–Mn–Ga magnetically responsive shape memory alloy has a magnetic field–induced strain of about 0.01%. The additive manufacturing is a viable technology in solving the design issues of functional parts made of Ni–Mn–Ga magnetic shape–memory alloys (MSMA).

At present, although metal implantable tissue engineering scaffolds have been widely used in clinical practice, they still have many problems, such as non–degradability, migration, embolization, corrosion, and nickel allergy. Lin [35] designed and prepared novel blockers and intestinal scaffolds based on 4D printed biocomposite wires. A variety of 4D printed biocomposite wires with controllability and functionality were designed and prepared with the introduction of plasticizer polyethylene glycol, which enabled them to move at near body temperature (42.5–43.1 °C). In addition, the photothermal agent graphene oxide and magnetic nanoparticles of ferric tetroxide were introduced to enable the biocomposite wire to be optically and magnetically driven for remote and precisely controlled unfolding of tissue engineering scaffolds. The magnetically driven biocomposite enables remote and controlled deployment of the blocker.

The introduction of magnetic elements into bioglass ceramics to prepare magnetic bioglass ceramics to obtain biomaterials with structure and properties similar to those of human tissues, making them both magnetic and biologically active and allowing their functions to be regulated and controlled by changing their composition to suit different requirements, has become one of the most active fields in the development and research of biomaterials [36]. Ceramics have high mechanical strength and hardness, good chemical stability, and excellent acousto–optic–electromagnetic thermal properties, and they are widely used in chemical, mechanical, electronic, aerospace, and biomedical fields. In the 1990s, Marcus et al. [37] and Sachs et al. [38] proposed the concept of 3D printed ceramics, which provided a new possibility to solve the problems and challenges of traditional ceramic manufacturing processes. By implanting magnetic bioactive glass ceramics into the lesion site, the material can generate heat at the site under an applied alternating magnetic field, killing tumor cells without harming normal tissues and promoting tissue repair by forming a chemical bond with the tissue through the bone–like apatite layer. He et al. [39] used NH4HCO3 as a pore–forming agent to produce porous lithium–iron–phosphorus magnetic ceramics with a biological coating by sintering. The fabricated ceramics have good magnetic properties, and the porous structure is necessary as a carrier of chemotherapeutic drugs so that the combination of chemotherapy and thermotherapy can be achieved through the ceramics to improve the efficacy of cancer treatment. Martin et al. [40] used oriented anisotropic reinforcement particles during magnetic field printing of composites to produce bionic reinforced structures with ceramic particles of 90 μm characteristic size. These architectures resulted in composites with higher stiffness, strength, and hardness properties. This approach is robust, low–cost, scalable, sustainable, and will enable a new class of robust, lightweight composite prototypes with programmable properties. Based on the current research status and new developments of ferrite magnetic materials, their development will move from monolithic ferrite materials to composite ferrite materials, large particle materials to nanoparticle level materials, and a wider range of applications.

In recent years, concrete 3D printing technology has achieved rapid development and application in civil engineering, construction, etc. In the 1990s, Pegna [41], an American scholar, was the first to use cement–based materials for 3D printing, printing concrete (mortar) structures by accumulating mortar layer by layer and using steam curing for rapid curing. After nearly 30 years of development, concrete 3D printing technology has been able to complete the printing of concrete products and structures and print low–rise houses. Concrete printing currently has two methods, adding additives to the initial concrete mix and the print head to improve buildability through pre (on–demand settings), the former method is the most widely studied; however, it can affect pumping capabilities. The latter includes mixing accelerators, heating, ultrasound, or magneto–rheological control, forming in the print head and rapidly increasing the yield strength of the material immediately before extrusion [42].

As one of the most used construction materials, the performance and quality of concrete construction also have higher requirements with the continuous development and progress of civil construction. Based on its characteristics, people continue to innovate it, Jin et al. [43] studied a 3D printed magnetically oriented steel fiber reinforced cementitious composite material, which significantly improved the tensile strength, ductility properties, and crack resistance of concrete, making it with good deformation capacity. It was found that the higher the steel fiber admixture in the same cementitious material, the higher the required magnetic induction strength of steel fiber orientation. In the same cementitious material, the smaller the length–to–diameter ratio, the smaller the required magnetic induction strength of fiber orientation and the better the orientation effect.

2.1.6. Overview of This Section

As the number of programming cycles increases, the responsiveness and accuracy of the printed component will be greatly affected. Currently the most widely used are unidirectional shape memory materials, i.e., when reprogramming, an external load often needs to be applied to accomplish temporary shape fixation. However, bidirectional memory materials can achieve bidirectional conversion between the original shape and the temporary shape without any external load [44]. In order to make the printing material with better reprogramming ability and the determined pattern of the magnet not be completely fixed, researchers need to keep focusing on the research of reprogramming lifetime and reversible programming of memory materials and focusing on the development of what kind of materials can break the current dilemma.

In order to solve the problem of 4D printing accuracy and more flexible control of printed components, some scholars proposed the use of structural voxelization [45], which defines 4D printed materials as digital materials and defines the parts with the same properties and structure as a voxel. Each voxel contains only one material and has its own unique properties. The collection of different voxels can achieve a multi–material deformable structures. In order to find good digital materials for 4D printing, it is necessary for researchers to invest in deeper rheological research of materials to study the properties and structure of materials to improve the response rate of print builds; to obtain better shape memory properties, strength, and stiffness; to discover new physical mechanisms; and to create innovative combinations of material formulations.

However, in practice, the choice of printing materials is often matched to the type of printer and printing method. For example, in 4D printing with SLA technology, the material used should be a photosensitive liquid material with fast curing, low viscosity, and suitable depth of throw; in printing with SLM technology, the material used should be a powder with good flowability, high sphericity, high bulk density, small particle size, and uniform distribution; and in printing with FDM technology, the filament used should have a uniform and moderate filament diameter, low melting point, low fluidity, low viscosity, low shrinkage, and good adhesion.

4D printing achieves the structural and functional integration of its printed objects. The effect of magnetically controlled 4D printing can be influenced by various aspects, including: printing materials, types of 3D printers, printing methods, design methods, and programming methods. A certain combination of design is needed to make 4D printing work to its maximum effect, so designing a good 4D printing model is a comprehensive problem.

3. Magnetically Controlled 4D Printing Process

3.1. Direct Ink Writing Magnetically Control 4D Printing

Direct ink writing is one of the main methods of magnetically controlled 4D printing. The magnetization of the uncured elastomeric compound containing magnetic particles during the printing process is treated as a small permanent magnet, and when it is magnetized to saturation, its shear yield stress prevents the dispersed magnetic particles from coalescing in the composite ink. During the printing process, due to mechanical properties such as shear deformation and shear yielding, the composite ink can be extruded by the micro–nozzle, and the deposited ink can form multiple stacks without changing its shape. The magnetic poles of the deposited ink can be adjusted by changing the applied magnetic field or the printing direction. At the end of printing, the shear yield stress in the uncured ink keeps the programmed ferromagnetic domains from being thermally randomized by the aligned particles.

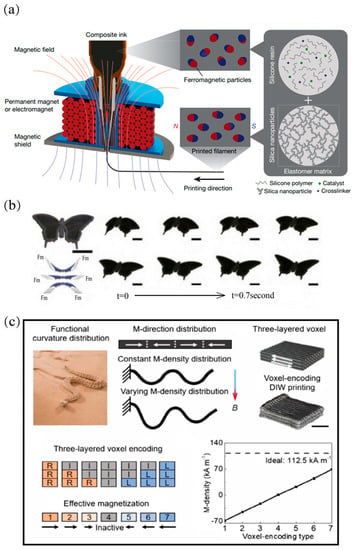

Yoonho Kim [46] proposed a method for printing soft materials with direct inks writing based on uncured elastomer composites. The process involves applying a magnetic field to the dispensing nozzle (as in Figure 5a), thereby repositioning the magnetic particles along the direction of the applied magnetic field, i.e., printing the magnetic domains directly on the 4D printed soft body, creating a magnetic pole pattern. The composite ink used for 4D printing was composed of neodymium–iron–boron (NdFeB) particles and silica nanoparticles embedded in a silicone rubber matrix with a silicon catalyst and cross–linker, and it was subjected to a pulsed field of approximately 2.7 T for magnetization. A permanent magnet or electromagnetic coil is placed on the printer nozzle during printing to apply a magnetic field along (or in the reverse direction of) the flow of the printed material. To prevent the magnetic field applied to the nozzle from affecting the structure of the print, a magnetic shield is placed under the tip of the nozzle to attenuate the magnetic flux density. After printing, the printed structure is cured at 120 °C for 1 h. After the solidification process, the ferromagnetic soft body was able to rapidly transform into a complex three–dimensional figure under the action of a magnetic field and took on different morphologies with the direction and intensity of the applied magnetic field.

Based on Kim’s research, the researchers have developed a variety of composite inks for 4D printing, whose structures are enhanced in different directions by an external magnetic field, depending on their application requirements. Zhu et al. [47] mixed iron nanoparticles with PDMS to make a printable composite ink, the printed structure changed shape under the action of an alternating magnetic field, and the response time is shortened by this external magnetic field. Due to the low magnetic force and high magnetic permittivity of the soft magnetic iron particles in this composite ink, the printed structures can gain or lose high magnetization immediately when the external magnetic field is switched on or off. As an example of a 3D butterfly with rapidly flapping wings under an applied magnetic field, as shown in Figure 5b, the butterfly structure printed with PDMS/Fe ink deformed under magnetic stimulation and the butterfly wings flapped from the lowest to the highest position in only 0.7 s; Podstawczyk [48] formulated a bio–nanocomplex synthesized from alginate, methylcellulose, and magnetic nanoparticles as a novel 4D printing ink to print predefined 3D structures that can retain their shape for a long time after printing and have high mechanical stability. The thixotropic inks developed in this study are expected to be ideal for direct printing of high–fidelity, magnetically–activated, stimulus–responsive hydrogel structures, whereas conventional DIW printing techniques can only achieve programmable magnetic orientation and constant magnetic density. Wu et al. [49] introduced a method for DIW printing using voxel–encoded hard magnetic soft active materials (hmSAMs) and combined it with an evolutionary algorithm (EA)–based design strategy to achieve the desired magnetic drive as well as complex geometry and curvature distribution. Magnetization density and magnetization direction distribution can be programmed simultaneously during hmSAMs. Using the novel voxel–encoded DIW printing technique, hmSAM functions with the required curvature distribution were obtained, such as the bionic motion function of a rattlesnake performing a side–to–side motion. In this printing method, each voxel includes multiple hmSAM layers with high aspect ratio DIW printing, as shown in the actual DIW printed voxel elements in 5c. By controlling the printing direction of each voxel, the overall magnetization intensity can be achieved. Greater adjustability of magnetic flux density and magnetic field direction distribution in DIW printing is achieved by increasing the number of layers of DIW voxels. This printing method greatly broadens the application potential of hmSAMs.

Figure 5.

(a) Direct ink printing process, (b) Magnetoparticle–filled magnetotactic SMPCs printed on butterflies. (c) hmSAM voxel–coded DIW print (adapted from with the permission from Ref. [46], 2018, Massachusetts Institute of Technology. Ref. [47], 2018, ACS Applied Materials & Interfaces. Ref. [49], 2020, Advanced Intelligent Systems).

3.2. Laser–Selected Sintered Magnetically Controlled 4D Printing

Laser–selective sintering (SLS) is a promising technique for powder–based additive manufacturing that uses an infrared laser as the emission energy source, and the laser beam is computer–controlled to selectively sinter based on the layered cross–sectional information to melt adjacent powders, cool and solidify them into a pre–defined forming surface after the irradiation stops, and sinter the layers to obtain pre–defined parts. It is used to manufacture polymer composites with high mechanical strength [50,51,52], which can be magnetically controlled 4D printing.

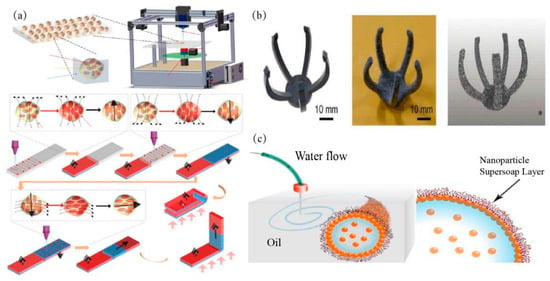

Deng [53] developed a laser rewritable magnetic composite film whose deformation in response to a magnetic field can be digitally programmed with simple direct laser writing and with transient laser heating to temporarily melt the phase change polymer so that the orientation of the magnetic particles can be rearranged when the programmed magnetic field changes. The NdFeB@PCL MPs were randomly oriented on the prepared MRSM film using NdFeB@PCL MPs so that they were not fully magnetized. On the melting of the polycaprolactone (PCL) shell due to local laser heating, the magnetic orientation of the magnetic particles was re–adjusted to the programmable magnetic field orientation (e.g., Figure 6a). PCL was chosen because its melting temperature is much lower than that of silicone, allowing for the effective control of the laser power and minimizing its damage. When the laser is moved out of the exposure zone, the PCL cures quickly, and the programmed magnetic field direction of the NdFeB MPs is fixed. Depending on the digitally controlled laser scan and dynamically changing the programmed magnetic field direction, magnetic domains with complex magnetic field anisotropy can be formed on the MRSM film. Because the phase transition of PCL is reversible, the magnetic field that was rewritten according to the same program has anisotropy and can be constructed in the same MRSM film with different shape transformations. Using this printing method, polymorphic electronic switches for electronic devices can be fabricated, and reconfigurable magnetic soft robots with motion modes, such as creeping, crawling, and moving, can be constructed, which is promising in the field of adaptive and reconfigurable soft robots. Wu et al. [54] developed a new gripper using SLS–based 4D printing technology, discussed the 2D/3D distribution of magnetic induction intensity and scalar magnetic potential of the gripper, conducted an in–depth analysis of its deformation mechanism by adjusting its magnetic composition and distance from the external magnet, and established a quantitative relationship between the magnetic excitation and the gripper, which provides guidance for future 4D printing controlled deformation, and driving force calculation research provides guidance, as shown in Figure 6b. Future research is required to optimize the structure of the gripper for more effective controls. The energy consumption in the driving process should also be considered.

Figure 6.

(a) System design and mechanism for DLW reprogramming MRSM thin film magnetic anisotropy. (b) Gripper. (c) Printing water in oil using nanoparticle super soap (adapted from with the permission from Ref. [53], 2020, Nature Communications. Ref. [54], 2020, ACS Applied Materials & Interfaces. Ref. [55], 2018, Advanced Materials).

3.3. All–Liquid Printing

All–liquid printing is a new printing technology that uses a special 3D printer to deposit “water lines” into a silicone oil substrate that can be used to build liquid electronics and chemical synthesis. Berkeley Lab scientists lock the water in a special nanoparticle surfactant that prevents pipes from breaking into droplets and call the surfactant a super soap. The super soap is achieved by dispersing gold nanoparticles into water and polymer ligands into oil. The gold nanoparticles and polymer ligands are interconnected and remain in their respective water and oil media, and shortly after the water is injected into the oil, the resulting super soap has glass–like properties that stabilize the water–oil interface and keep the liquid structure in place. So far, the researchers have printed water droplets between 10 microns and 1 mm in diameter, each containing a large number of iron oxide nanoparticles with a diameter of 20 nanometers. Magnetometry shows that about a billion nanoparticles are “packed together” and that they exhibit magnetic properties when excited by a magnetic coil. These external nanoparticles transfer the magnetic orientation to the nanoparticles at the core of the droplet, giving the entire droplet permanent magnetic properties. The process of printing water in oil is accomplished by nanoparticles binding to polymer ligands in the oil to form an elastic film (Figure 6c), and based on this principle, scientists have created several different types of structures, including complex spiral and branched patterns up to several meters long. The Chinese and American research team [55] used all–liquid–phase 3D printing technology to prepare a new type of droplet with permanent magnetic properties. This ferromagnetic fluid droplet is about 1 mm in diameter and consists of a large number of iron oxide nanoparticles with a diameter of 20 nm. The clustered nanoparticles exhibit magnetic properties under the action of magnetic coils. When the nanoparticles on the surface are magnetized, they transfer the magnetism to the nanoparticles in the center, and the entire droplet becomes permanently magnetic. Using all–liquid–phase 3D printing and microfluidic molding, the researchers were able to create magnetic droplets of arbitrary shapes, they remain magnetic after being divided into smaller droplets, and the molded liquid can also be reversibly magnetized or demagnetized by changing the acid–base environment. This technology can be applied to provide artificial cells for targeted cancer therapy, deformable liquid robots, etc.

3.4. Light–Curing Molding Magnetically Controlled 4D Printing

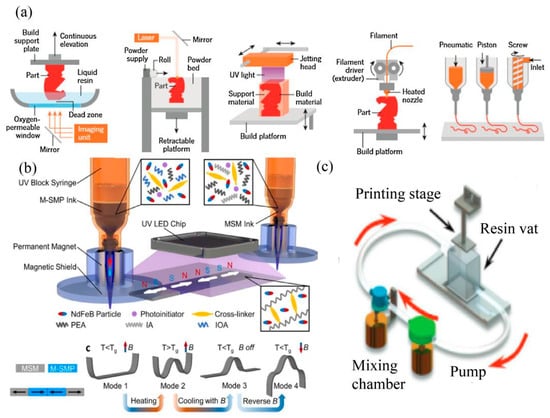

Light curing molding technology is divided into stereo light curing (SLA) and digital light processing technology (DLP). Light curing molding is the use of a specific wavelength and intensity of light focused on the surface of photosensitive materials so that they are sequentially cured from point to line and line to surface, completing a level of molding operations, after which the lifting table moves a level of height in the vertical direction, thus constituting a three–dimensional entity. SLA manufactures workpieces with high dimensional accuracy (e.g., Figure 7a) [56] and was the first commercialized 3D printing technology. DLP technology [57] differs from SLA’s laser progressive scanning by curing the entire input slice layer at once, and the surface of the resin used in the printing process is in constant contact with the platform, which ensures the accuracy, resolution, and quality (e.g., smoothness) of the print.

DIW and fused filament fabrication (FFF) have been used to manufacture fast response drives, inks with highly loaded magnetic fillers [58], and the folding and extension of 2D planar structures [59], but DIW and FFF currently still have some shortcomings in terms of resolution, filler dispersion, and compatibility of temperature and filler. The alternative is DLP. DLP has the following advantages: the print resolution of DLP is of pixel size, which is usually higher than DIW and FFF [60,61]; the use of liquid formulations in DLP allows for better control of filler dispersion; and it can be prepared directly at room temperature. This reduced polymerization 3D printing technique involves the use of photosensitive (liquid) resins, and the resins can be cured under appropriate light conditions. In DLP, a digital light projector (digital microscope device) illuminates the light–curable resin with a 2D pixel pattern to cure individual slices of a 3D object [62,63]. Lantean et al. [64] investigated the use of DLP for printing magnetically responsive polymers with tunable mechanical and magnetic properties by mixing butyl acrylate and polyurethane–acrylic resins, which can be adjusted as needed for the magnetic response mechanical properties of the polymer to achieve a 6% loading of Fe3O4 nanoparticles to regulate the magnetic response of the printed samples. Following this strategy, magnetoresponsive active components are fabricated with programmable complex functions using external magnetic fields.

Ma et al. [65] developed a magnetic multi–material DIW (M3DIW) technique for the integration of complex structures with light–cured M–SMP and MSM. The technique is based on the complex structural integration of magnetic soft materials and magnetic shape memory polymers (M–SMPs) for composite printing, which is synergistically thermally and magnetically driven to obtain various morphological variations and further improve the tunability of the active material. As an example, the magnetization distribution and four morphology types are shown in Figure 7b. The success or failure of DIW printing of M–SMP/MSM composites is determined by the ink’s print suitability, curing efficiency, and curing quality. The two main properties of the ink, i.e., ink rheology and curing depth, influence the printing and curing process. The former can be adjusted by adjusting the rheology of silica nanoparticles; the latter mainly depends on the size, loading, UV irradiation time, and intensity of NdFeB particles. Magnetic multi–material printing technology is a powerful method of fabricating magnetic materials with integrated multi–physics fields and multifunctional response, offering further possibilities for the development of deformable structures, soft robotic systems, and biomedical devices.

Figure 7.

(a) Traditional light and ink–based 3D printing methods. (b) Magnetic multi–material DIW (M3 DIW) system and its working mechanism. (c) CVP system schematic (adapted from with the permission from Ref. [56], 2020, Applied Materials Today. Ref. [65], 2021, ACS Applied Materials & Interfaces. Ref. [66], 2022, Advanced Materials).

3.5. Reduced Photopolymerization Magnetically Controlled 4D Printing

Reduced photopolymerization (VP) is also a popular 4D printing method for making magnetic miniature robots. VP is used to generate 3D structures by curing the resin layer by layer using an ultraviolet (UV) photonic energy source. A major advantage of the printing technology is the ability to achieve high quality prints on a smaller scale. Two–photon multimerization is a VP–based printing technique that is now widely used to produce magnetic soft micro–robots (MSMR) with complex 3D structures [67,68,69,70]. However, these magnetic robots cannot be actively deformed to achieve complex mechanical functions. While obtaining realistic 3D initial geometry and deformation, the fabrication of MSMRs with homogeneous, highly magnetic materials using VP 3D printing remains a problem worth exploring. Zhou proposed a new cyclic reduction photopolymerization (CVP) technique to print MSMRs [66]. The unique cyclic system of CVP allows the magnetic composite resin to remain homogeneous (Figure 7c), such that parts with high homogeneity, high particle loading, and strong magnetic response can be printed using relatively large micron–sized particles.

3.6. Other Magnetically Controlled 4D Printing Processes

As magnetically controlled 4D printing technology continues to develop, more and more new materials are being developed and applied, requiring corresponding printing processes to accompany them, and multidisciplinary research in multiple fields needs to be further strengthened.

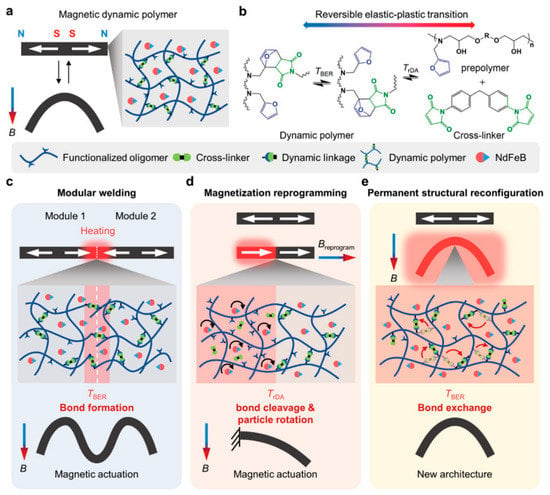

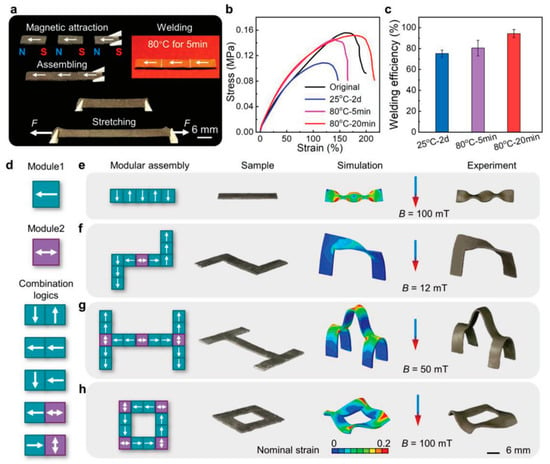

Positively influenced by covalent dynamic polymers (DPs) in the welding and remanufacturing of materials, Kuang et al. [71] designed a reprogrammable and reconfigurable deformable magnetic dynamic polymer (MDP) composite. This MDP includes hard magnetic particles (NdFeB) and a reversible cross–linked DP matrix (e.g., Figure 8). MDPs have excellent properties, such as flexible, fast, and reversible transmission as well as welding, reprogramming, reconstitution, and recycling, providing a new process for the production of functionalized unstressed 3D structures.

Figure 8.

Schematic diagram of the working mechanism and function of magnetodynamic polymers (MDPs). (a) Schematic diagram of MDP assembly. (b) Reversible elasto–plastic transformation scheme. (c) Schematic diagram of MDP modular welding (d) Schematic diagram of magnetization reprogramming. (e) Schematic diagram of MDP structural reconfiguration (adapted from with the permission from Ref. [71], 2020, Advanced Materials).

Kuang et al. [71] used a combination of both bending and bending–folding into a closed shape at a magnetic field of 100 mT (as in Figure 9) and verified the validity of the structure and response of the finite element method under magnetic force by comparing numerical simulations with experimental data; at a heating temperature of 110 °C and a magnetic field of 35 mT, it was verified that the magnetization strength of the 45° oriented reprogrammed MDP film was sufficient to achieve magnetization. In addition, the reprogramming intensity of the remanent magnetization can reach 100% when the applied magnetic field reaches 140 mT. Using the synergistic effect of temperature and magnetic field to adjust the DP network and magnetic dipole rearrangement, the functional features and applications of MDP are demonstrated, which include seamless welding of modular components based on objective functions, magnetization reprogramming for reconfigurable drive methods, and structural reorganization for remote control. Magnetic modular components are based on a combination of magnetized reprogramming and permanent shaping functions for programmable and reconfigurable architectures and deformed structures. The investigated MDPs will provide new directions for the design and fabrication of future multifunctional components and reconfigurable deformable architectures and devices.

Figure 9.

Magnetically assisted seamless welding modular assembly. (a) Elongated assembly consisting of three MDP modules. (b) Tensile stress–strain curves for original and welded MDP specimens. (c) Effect of process conditions on the welding efficiency of processed MDPs. (d) Schematic diagram of square unidirectional and bidirectional magnetization modules. (e–h) Complex deformation of two–dimensional planar structures (adapted from with the permission from Ref. [71], 2020, Advanced Materials).

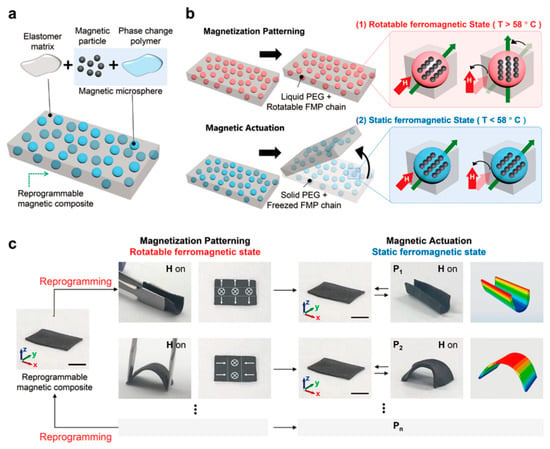

Soft magnetic materials show promise in a variety of applications because of their fast response, remote driveability, and wide penetration range. Song et al. [72] prepared a new soft magnetic composite and proposed a new printing method that reprograms the magnetization without affecting the intrinsic magnetic properties of the embedded magnetic particles and the molecular properties of the matrix. The reprogrammable magnetic composites consist of spatially separated magnetic microspheres embedded in an elastic matrix, each of which consists of magnetizable NdFeB particles with an average particle size of 5 μm (e.g., Figure 10). The solid–liquid phase transformation allows the magnetic particles within the microspheres to be rearranged, thus changing their magnetization direction, and the structure can also be heated to induce a transformation of the microspheres; an applied magnetic field can also be applied during the cooling process to program the elastomeric substrate with non–uniform magnetization into the desired programmed structure.

Figure 10.

Design and mechanism of a reconfigurable magnetic composite. (a) Composition of a reconfigurable magnetic composite. (b) Rotatable and static ferromagnetic state of magnetic microspheres. (c) Process for reconfiguring a programmable magnetic composite (adapted from with the permission from Ref. [72], 2020, Advanced Materials, Nano letters).

4. The Application of 4D Printing for Magnetically Controlled Smart Materials

Nowadays, 4D printing has played an irreplaceable role in many fields. Printing time can be greatly saved through the evolution of the shape and function of the smart materials and structures in manufacturing smart devices. It is confirmed that self–folding can accelerate rapid prototyping of 3D objects by saving 60–87% of printing time and material consumption. In addition, the storage space can be saved by taking advantage of stimulus–responsive shape change features. The application space for 4D printing is increasing. With the development of 4D printing technology and magnetically controlled smart materials, the new magnetically controlled smart materials have been widely used in many fields and show good application prospects.

4.1. Biomedical Applications

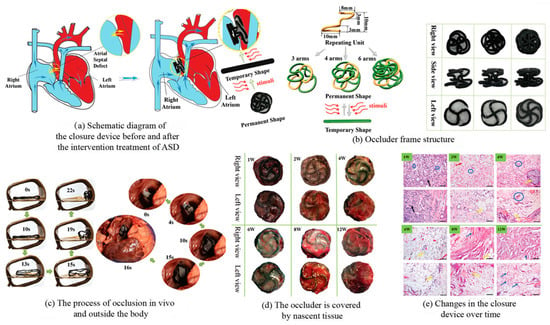

Due to the need for the development of personalized implantable devices and drug delivery devices, magnetically controlled 4D printed SMP structures with biocompatible, programmable, and reversible properties are now proven for potential applications in many targeted drug delivery in the biomedical field, where they offer minimally invasive, locally effective, and controlled therapeutic approaches [73,74,75,76]. The biodegradability, low invasiveness and remote intervention, and non–contact control of 4D printed bioimplantable devices with magnetically controlled smart materials offer significant advantages in clinical operations. Traditional drug delivery can have undesirable consequences due to drug overdose and off–target delivery, and the introduction of magnetized microrobots allows for access to hard–to–reach lesions through a minimally invasive approach. In recent years, magnetized microrobots have played an increasingly important role in the field of targeted therapy. Lin et al. [77] designed and prepared a personalizable and biodegradable SMP composite blocker by doping Fe3O4 magnetic particles into a shape–memory polylactic acid matrix, which was able to achieve remote controlled deployment under a magnetic field of certain strength. As shown in Figure 11, for the therapeutic procedure of shape memory heart blockers, the blocker can be packaged, delivered, and released smoothly through the catheter and can be deployed in less than 16 s with cellular adhesion and granulation tissue growth into the occlusion, thus promoting rapid endothelialization. In addition, the 4D printed shape memory occluder allows for a perfect fit and provides adequate support for the defect. Thus, 4D printed shape memory occluders can be used as a potential alternative to metal occlusion devices.

Figure 11.

Biomedical applications. (a) Blocker intervention ASD schematic. (b) Blocker frame structure. (c) Blocker structure. (d) Blocker deployment process in the body. (e) Blocker covered by new tissue (adapted from with the permission from Ref. [77], 2019, Advanced Functional Materials).

From a tissue process perspective, manipulation of the orientation and intensity of the magnetic field will lead to specific changes in the morphology and any shape of the scaffold, which can be used for certain tissues that require structural regeneration [78,79,80], mechanical stimulation [81], and dry cell differentiation [82]. Tracheal stents designed based on biological SMPs materials have excellent performance of being actuated without contact, showing great potential to replace conventional tracheal stents. Zhao et al. [83] designed a 4D printed tracheal scaffold with the ability to adapt to the complex environment in the patient’s soft tissue based on the microstructure of a glass sponge, which can be implanted in a programmed form and controlled by alternating magnetic fields to change its morphology. The shape memory properties of bio–inspired 4D printed scaffolds help to match the geometry of the trachea and allow it to exhibit better support and stability compared to conventional scaffolds [84].

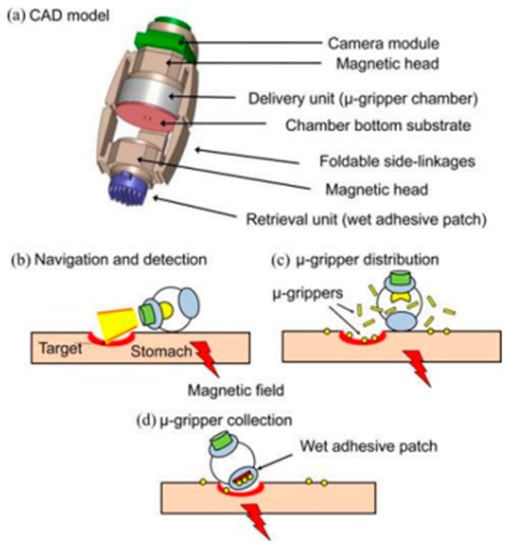

Yim et al. [85] developed a magnetically driven untethered soft capsule robot for wireless biopsy, which comes with an endoscope that carries and releases a large number of thermal sensitizers to grasp the sample by micro gripping jaws after the desired location in the stomach, as shown in Figure 12.

Figure 12.

Magnetically driven unbound softgel (adapted from with the permission from Ref. [85], 2014, IEEE Transactions on Bio–medical Engineering).

Micro–bio–printing technology in medicine is still in its infancy, with limited print speed, resolution, and complexity of print patterns. The use of MNP in the life support system requires consideration of biocompatibility, the type of MNP, and its strategy for incorporation into polymers.

4.2. Applications in the Field of Robotics

The field of robotics requires a high degree of structural complexity and structural automation. There has long been a commitment to create untethered, intelligent robots capable of performing tasks on a small scale. The use of magnetic control is of great importance for robot actuation because the driving magnetic field can easily and harmlessly penetrate most synthetic and biological materials [86,87,88].

There are many such robots: small, untethered robots that can noninvasively enter confined spaces can be used in bioengineering, such as single–cell manipulation and biosensing, and microfactories, such as building tissue scaffolds via robotic assembly, and in healthcare, such as targeted drug delivery and minimally invasive surgery. However, existing small robots are unable to recognize changes in texture or material in unstructured environments or autonomously bypass obstacles, and they have limited mobility. Xu et al. [89] designed a spiral miniature swimming robot driven by a magnetic field that can achieve three states of forward, dynamic stationary and backward, and can accomplish movement in complex environments (Figure 13a). It is expected that the dynamic swimming phenomenon found in soft–tailed swimmers can be used for agile and fine motion control of soft micro–robots; soft robots have higher degrees of freedom compared to rigid machines and can achieve high maneuverability through multimodal motion. Hu et al. [90] designed a small soft robot that can accomplish multimodal movement by controlling a magnetic field to accomplish control of its movement, and the robot can not only swim inside and on the surface of liquid, but also roll and walk on solid surfaces, jump over obstacles, and crawl in narrow tunnels.

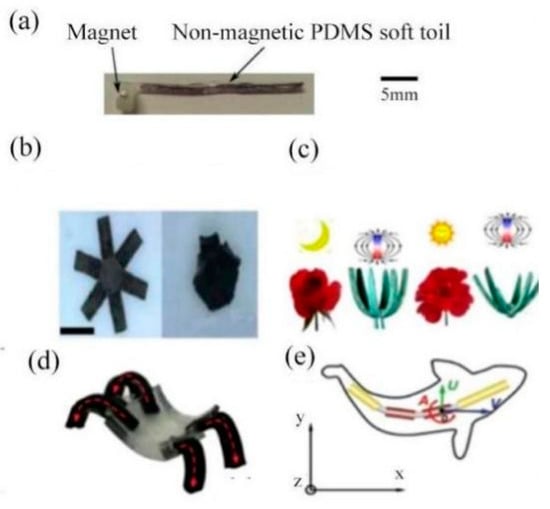

Figure 13.

Magnetically controlled robot. (a) Spiral microswimming robot. (b) Six–armed soft microgripper. (c) Flower robot. (d) Quadruped soft rRobot. (e) Nanosoft robot fish (adapted from with the permission from Ref. [89], 2019, IEEE ASME Transactions on Mechatronics. Ref. [91], 2021,ACS Applied Materials & Interfaces. Ref. [92], 2016, ACS Applied Materials & Interfaces. Ref. [93], 2021, IEEE Robotics and Automation Letters. Ref. [94], 2016, Small).

As analyzed in the above studies, flexible magnetic mini–robots utilize patterned magnetization to achieve rapid transformation of complex three–dimensional (3D) shapes, solving current problems faced by micro–robots in drug delivery, object manipulation, and minimally invasive surgery. However, micro–robot design is limited by existing methods for patterning magnetic particles of flexible materials. To address this problem, Xu et al. [91] developed a UV lithography–based method for conforming permanent magnetic particles in planar composites, resulting in a six–armed soft microgripper with complex geometry that can perform translation in three directions: yaw, pitch, and transverse rocking rotation (Figure 13b). UV lithography–based methods allow for the fabrication of multiple planar micro–robots with different sizes, different geometries, and arbitrary magnetization profiles in a single precursor. In addition, 3D magnetization profiles allow for multiple combinations of bending and torsion on a single piece of polymer, enabling previously unattainable shape variations and micro–robotic motions, such as multi–arm force grasping and multi–legged paddle crawling.

Nature–inspired actuators that can be driven by various stimuli are an emerging application in mobile microrobotics and microfluidics. Gao et al. [92] used ferromagnetic particles and silicon–based polymers to fabricate a flower–like magnetically controlled soft robot (Figure 13c); Venkiteswaran et al. [93] developed an untethered magnetically controlled quadruped soft robot with a rotating magnetic field as the driving field to deform the legs to move perpendicular to the body plane (Figure 13d); and Li et al. [94] developed a magnetically–controlled nanosoft robotic fish with a maximum velocity of 30.9 um/s by applying an oscillating magnetic field to drive its lateral displacement with a backward traveling wave generated by the interaction between the body and the tail fin (Figure 13e).

4.3. Applications in the Field of Intelligent Device Manufacturing

Magnetically controlled 4D printing opens a new door for the field of smart sensor devices as well. In recent years, there has been a strong demand for flexible electronic devices and wearable electronic devices, and magnetically controlled 4D printing technology for smart materials has given new ideas and approaches to this research field. For example, the polymer–based substrates of deformable RF devices reported by Fu et al. [95] are expected to be prepared with the aid of 4D printing devices [96]. Fundamental studies of multistable flexural modes and associated probabilistic geometric transformations underlie robust and reproducible engineering behavior. These concepts have the potential for a wide range of applications compatible with state–of–the–art planar thin–film materials and microsystems technologies; Wu et al. [32] proposed a material combination concept to build 4D printed devices whose properties and functions can be changed in a controlled manner. 4D printed devices consist of conductive and magnetic components that enable the integrated devices to display piezoelectric properties, even though neither component is a separate piezoelectric device, using a composite material consisting of PU powder and NdFeB particles to print devices that can perform piezoelectric conversion functions under external magnetic field excitation, which can be used as a manometer, as shown in Figure 14. This work opens a new manufacturing method of flexible magnetoelectric devices and provides a new material combination concept for the property–changed and functionality–changed 4D printing. As the research and development of magnetron 4D printing technology continues to advance, the application of this technology in the above fields will continue to deepen and, at the same time, will expand the application space in more fields.

Figure 14.

Piezoelectric conversion devices based on composite prints made of thermoplastics and magnetically induced particles (adapted from with the permission from Ref. [32], 2020, Advanced science).

5. Conclusions

This paper presents a systematic study of the current status of research on magnetically controlled 4D printing technology, the process, and its applications. Magnetically controlled 4D printing fully applies magnetic smart materials on the basis of 3D printing to achieve controllability of shape, performance, and function of components under the action of controlled magnetic fields.

Magnetically controlled 4D printing technology has made great progress in the past few years, but it is still in its infancy. Printing methods have significant limitations; DIW printing is currently the most likely practical application of the technology, with low equipment requirements, low manufacturing costs, a wide range of raw materials, high molding accuracy, manufacturing flexibility, and other advantages, but curing, sintering, and other processing are needed after direct writing, and the accuracy of its molding components are influenced by a variety of factors. Existing 4D printing equipment does not have specific standards, and the functionality is limited. The future development of 4D printing requires the participation of multiple fields to create 4D printing devices with more comprehensive functions. Nowadays, there are few types of existing printing materials, and printing products have great limitations. Researchers should pay attention to the innovation of new materials, printing schemes, and printing processes; otherwise, there will be stagnation. 4D printing is a disruptive new manufacturing technology that will have broad applications in many fields. People are already using 4D printing technology to achieve organ printing and minimally invasive printing in situ [97]. With technological innovation, we expect to achieve 4D printing of human organs, 4D printing of autonomous detection in outer space, etc.

New magnetically controlled printing technologies, new smart materials, new structural design, and development of modeling tools and software will continue to drive the progress of magnetically controlled 4D printing technology, and its application areas will be more extensive. A great deal of research and application development work will be needed for magnetically controlled 4D printing technology in the future.

In order to develop and improve magnetically controlled 4D printing technology, the following aspects need attention.

- (1)

- There is an urgent need to standardize experimental equipment and develop high–precision printers. The current equipment on printing is all developed by the laboratory itself, which has limited capacity, and there will be a more rapid development with the participation of professional manufacturers in the research.

- (2)

- There is a need to focus on the original innovation of 4D printing materials, encourage more systematic research on original solutions, increase the research on the transformation mechanism of 4D printing materials, explore more optimal design and methods of 4D printing controllable deformation components, and innovate 4D printing processes. There is also a need to develop more highly sensitive materials to improve the dynamic characteristics of the device and to reduce the impact of the required shape, property, or function transformation on the component itself during the printing process.

Author Contributions

Conceptualization, H.W.; methodology, H.W.; investigation, J.Z. and Z.L. (Zhuo Luo); resources, Z.L. (Zhenkun Li); writing—original draft preparation, J.Z. and Z.L. (Zhuo Luo); writing—review and editing, H.W.; J.Z. and Z.L. (Zhuo Luo); supervision, Z.L. (Zhenkun Li); project administration, H.W.; funding acquisition, H.W. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by Education and teaching reform project of China University of Labor Relations, with grant number JG22085; Student research project of China University of Labor Relations, with grant number 23xjx095; Beijing higher education undergraduate teaching reform and innovation project(2022), with grant number 36; Second Batch of New Engineering Research and Practice Projects of the Ministry of Education, with grant number E-XTYR20200608.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ma, S.; Jiang, Z.; Wang, M.; Jiang, Z.; Zhang, L.; Liang, Y.; Zhang, Z.; Ren, L.; Ren, L. 4D printing of PLA/PCL shape memory composites with controllable sequential deformation. Bio-Des. Manuf. 2021, 4, 867–878. [Google Scholar] [CrossRef]

- Mao, Y.; Ding, Z.; Yuan, C.; Ai, S.; Michael, L.; Wu, J.; Wang, T.; Qi, H.J. 3D Printed reversible shape changing components with stimuli responsive materials. Sci. Rep. 2016, 6, 24761. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Shaw, B.; Dickey, M.D.; Genzer, J. Sequential self-folding of polymer sheets. Sci. Adv. 2017, 3, e1602417. [Google Scholar] [CrossRef]

- Ding, Z.; Yuan, C.; Peng, X.; Wang, T.; Qi, H.J.; Dunn, M.L. Direct 4D printing via active composite materials. Sci. Adv. 2017, 3, e1602890. [Google Scholar] [CrossRef] [PubMed]

- Wei, H.; Cauchy, X.; Navas, I.O.; Abderrafai, Y.; Chizari, K.; Sundararaj, U.; Liu, Y.; Leng, J.; Therriault, D. Direct 3D printing of hybrid nanofiber-based nanocomposites for highly conductive and shape memory applications. ACS Appl. Mater. Interfaces 2017, 3, 1602417. [Google Scholar] [CrossRef]

- Hu, X.; Ge, Z.; Wang, X.; Jiao, N.; Tung, S.; Liu, L. Multifunctional thermo-magnetically actuated hybrid soft millirobot based on 4D printing. Compos. Part B Eng. 2022, 228, 109451. [Google Scholar] [CrossRef]

- Nadgorny, M.; Xiao, Z.; Chen, C.; Connal, L.A. Three-dimensional printing of pH-responsive and functional polymers on an affordable desktop printer. ACS Appl. Mater. Interfaces 2016, 8, 28946–28954. [Google Scholar] [CrossRef]

- Hu, J.; Zhu, Y.; Huang, H.; Zhu, Y.; Lu, J. Recent advances in shape-memory polymers: Structure, mechanism, functionality, modeling and applications. Prog. Polym. Sci. 2012, 37, 1720–1763. [Google Scholar] [CrossRef]

- Zhao, Q.; Qi, H.J.; Xie, T. Recent progress in shape memory polymer: New behavior, enabling materials, and mechanistic understanding. Prog. Polym. Sci. 2015, 49–50, 79–120. [Google Scholar] [CrossRef]

- Tibbits, S.; Mcknelly, C.; Olguin, C.; Dikovsky, D.; Hirsch, S. 4D printing and universal transformation. In Proceedings of the 34th Annual Conference of the Association-for-Computer-Aided-Design-in-Architecture, Los Angeles, CA, USA, 23–25 October 2014; pp. 539–548. [Google Scholar]

- Sonatkar, J.; Kandasubramanian, B.; Ismail, S. 4D printing: Pragmatic progression in biofabrication. Eur. Polym. J. 2022, 169, 111–128. [Google Scholar] [CrossRef]

- Khan, M.S.; Khan, S.A.; Shabbir, S.; Umar, M.; Mohapatra, S.; Khuroo, T.; Naseef, P.P.; Kuruniyan, M.S.; Lqbal, Z.; Mirza, M.A. Raw materials, technology, healthcare applications, patent repository and clinical trials on 4D printing technology: An updated review. Pharmaceutics 2022, 15, 116. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, A.; Nag, S.; Gomes, A.; Gosavi, A.; Ghule, G.; Kundu, A.; Purohit, B.; Srivastava, R. Applications of smart material sensors and soft electronics in healthcare wearables for better user compliance. Micromachines 2023, 14, 121. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Wang, H.; Tang, J.; Guo, H.; Hong, J. Modeling and design of a soft pneumatic finger for hand rehabilitation. In Proceedings of the 2015 IEEE International Conference on Information and Automation, Lijiang, China, 8–10 August 2015; pp. 2460–2465. [Google Scholar]

- Tolley, M.T.; Shepherd, R.F.; Mosadegh, B.; Galloway, K.C.; Wehner, M.; Karpelson, M.; Wood, R.J.; Whitesides, G.M. A resilient, untethered soft robot. Soft Robot. 2014, 1, 213–223. [Google Scholar] [CrossRef]

- Methenitis, G.; Hennes, D.; Lzzo, D.; Visser, A. Novelty search for soft robotic space exploration. In Proceedings of the Genetic and Evolutionary Computation Conference, ACM, Madrid, Spain, 11–15 July 2015; pp. 193–200. [Google Scholar]

- Galloway, K.; Becker, K.; Phillips, B.; Kirby, J.; Licht, S.; Tchernov, D.; Wood, R. Soft robotic grippers for biological sampling on deep reefs. Soft Robot. 2016, 3, 23–33. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yang, X.; Chen, Y.; Wainwright, D.K.; Kenaley, C.P.; Gong, Z.; Liu, Z.; Liu, H.; Guan, J.; Wang, T.; et al. A biorobotic adhesive disc for underwater hitchhiking inspired by the remora suckerfish. Sci. Robot. 2017, 2, eaan8072. [Google Scholar] [CrossRef] [PubMed]

- Alshahrani, H. Review of 4D printing materials and reinforced composites: Behaviors, applications, and challenges. J. Sci. Adv. Mater. Devices 2021, 6, 167–185. [Google Scholar] [CrossRef]

- Bai, J.; Bu, G. Progress in 4D printing technology. J. Adv. Manuf. Sci. Technol. 2022, 2, 2022001. [Google Scholar] [CrossRef]

- Liang, X.; Jiang, X.; Gu, J.; Bai, J.; Guan, Z.; Li, Z.; Yan, H.; Zhang, Y.; Esling, C.; Zhao, X.; et al. 5M and 7M martensitic stability and associated physical properties in Ni50Mn35In15 alloy: First-principles calculations and experimental verification. Scr. Mater. 2021, 204, 114140. [Google Scholar] [CrossRef]

- Streubel, R.; Liu, X.; Wu, X.; Russell, T.P. Perspective: Ferromagnetic liquids. Materials 2020, 13, 2712. [Google Scholar] [CrossRef]

- Fan, X.; Jiang, Y.; Li, M.; Zhang, Y.; Tian, C.; Mao, L.; Xie, H.; Sun, L.; Yang, Z.; Sitti, M. Scale-reconfigurable miniature ferrofluidic robots for negotiating sharply variable spaces. Sci. Adv. 2022, 8, eabq1677. [Google Scholar] [CrossRef]

- Liu, X.; Noah, K.; Alejandro, C.; Robert, S.; Jiang, Y.; Chai, Y.; Kim, P.Y.; Joe, F.; Frances, H.; Shi, S. Reconfigurable ferromagnetic liquid droplets. Science 2019, 365, 264–267. [Google Scholar] [CrossRef]

- Korde, J.; Kandasubramanian, B. Naturally biomimicked smart shape memory hydrogels for biomedical functions. Chem. Eng. J. 2020, 379, 122430. [Google Scholar] [CrossRef]

- Gang, F.; Yan, H.; Ma, C.; Jiang, L.; Gu, Y.; Liu, Z.; Zhao, L.; Wang, X.; Zhang, J.; Sun, X. Robust magnetic double-network hydrogels with self-healing, MR imaging, cytocompatibility and 3D printability. Chem. Commun. 2019, 55, 9801–9804. [Google Scholar] [CrossRef] [PubMed]

- Breger, J.C.; Yoon, C.; Xiao, R.; Kwag, H.R.; Wang, M.O.; Fisher, J.P.; Nguyen, T.D.; Gracias, D.H. Self-folding thermo-magnetically responsive soft microgrippers. ACS Appl. Mater. Interfaces 2016, 7, 3398–3405. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Zhao, D.; Liu, B.; Nian, G.; Li, X.; Yin, J.; Qu, S.; Yang, W. 3D printing of multifunctional hydrogels. Adv. Funct. Mater. 2019, 29, 1900971. [Google Scholar] [CrossRef]

- Simińska-Stanny, J.; Nizioł, M.; Szymczyk-Ziółkowska, P.; Brozyna, M.; Adam, J.; Shavandi, A.; Podstawczyk, D. 4D printing of patterned multimaterial magnetic hydrogel actuators. Addit. Manuf. 2021, 49, 102506. [Google Scholar] [CrossRef]

- Tang, J.; Tong, Z.; Xia, Y.; Liu, M.; Lv, Z.; Gao, Y.; Lu, T.; Xie, S.; Pei, Y.; Fang, D.; et al. Super tough magnetic hydrogels for remotely triggered shapemorphing. Mater. Chem. B 2018, 6, 2713–2722. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Wang, L.; Zheng, Z.; Liu, Y.; Leng, J. Magnetic programming of 4D printed shape memory composite structures. Compos. Part A 2019, 125, 105571. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, X.; Ma, Z.; Zhang, C.; Ai, J.; Chen, P.; Yan, C.; Su, B.; Shi, Y. A material combination concept to realize 4D printed products with newly emerging property/functionality. Adv. Sci. 2020, 7, 1903208. [Google Scholar] [CrossRef]

- Paul, D.I.; McGehee, W.; O’Handley, R.C.; Richard, M. Ferromagnetic shape memory alloys: A theoretical approach. J. Appl. Phys. 2007, 101, 123917. [Google Scholar] [CrossRef]

- Caputo, M.P.; Berkowitz, A.E.; Armstrong, A.; Müllner, P.; Solomon, C.V. 4D printing of net shape parts made from Ni-Mn-Ga magnetic shape memory alloys. Addit. Manuf. 2018, 21, 579–588. [Google Scholar] [CrossRef]

- Lin, C. Design and Mechanical Properties of 4D Printed Shape Memory Polymer Tissue Engineering Scaffold. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2022. [Google Scholar]

- Kawashita, M. Ceramic microspheres for biomedical applications. Int. J. Appl. Ceram. Technol. 2005, 2, 173–183. [Google Scholar] [CrossRef]

- Marcus, H.L.; Beaman, J.J.; Barlow, J.W.; Bourell, D. Solid freeform fabrication-powder processing. Am. Ceram. Soc. Bull. 1990, 69, 1030–1031. [Google Scholar]

- Sachs, E.; Cima, M.; Williams, P.; Brancazio, J.; Cornie, J. Three-dimensional printing: Rapid tooling and prototypes directly from a CAD model. CIRP Ann.-Manuf. Technol. 1990, 39, 201–204. [Google Scholar] [CrossRef]

- He, B.; Yang, J.; Zhou, M. Development of bioceramics as heat seeds and drug carriers at the same time. Glass Enamel 2007, 35, 15–18. [Google Scholar]

- Martin, J.J.; Fiore, B.E.; Erb, R.M. Designing bioinspired composite reinforcement architectures via 3D magnetic printing. Nat. Commun. 2015, 6, 8641. [Google Scholar] [CrossRef]

- Pegna, J. Exploratory investigation of solid freeform construction. Autom. Constr. 1997, 5, 427–437. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Ramakrishnan, S.; Sanjayan, J. Technologies for improving buildability in 3D concrete printing. Cem. Concr. Compos. 2021, 122, 104144. [Google Scholar] [CrossRef]

- Jin, X. Preparation of Magnetically Oriented Steel Fiber Reinforced Cementitious Composites Based on 3D Printing and Study on Mechanical Properties of Beams. Master’s Thesis, Beijing University of Technology, Beijing, China, 2019. [Google Scholar] [CrossRef]

- Lee, Y.A.; An, J.; Chua, K.C. Two-way 4D printing: A review on the reversibility of 3D-printed shape memory materials. Engineering 2017, 3, 663–674. [Google Scholar] [CrossRef]