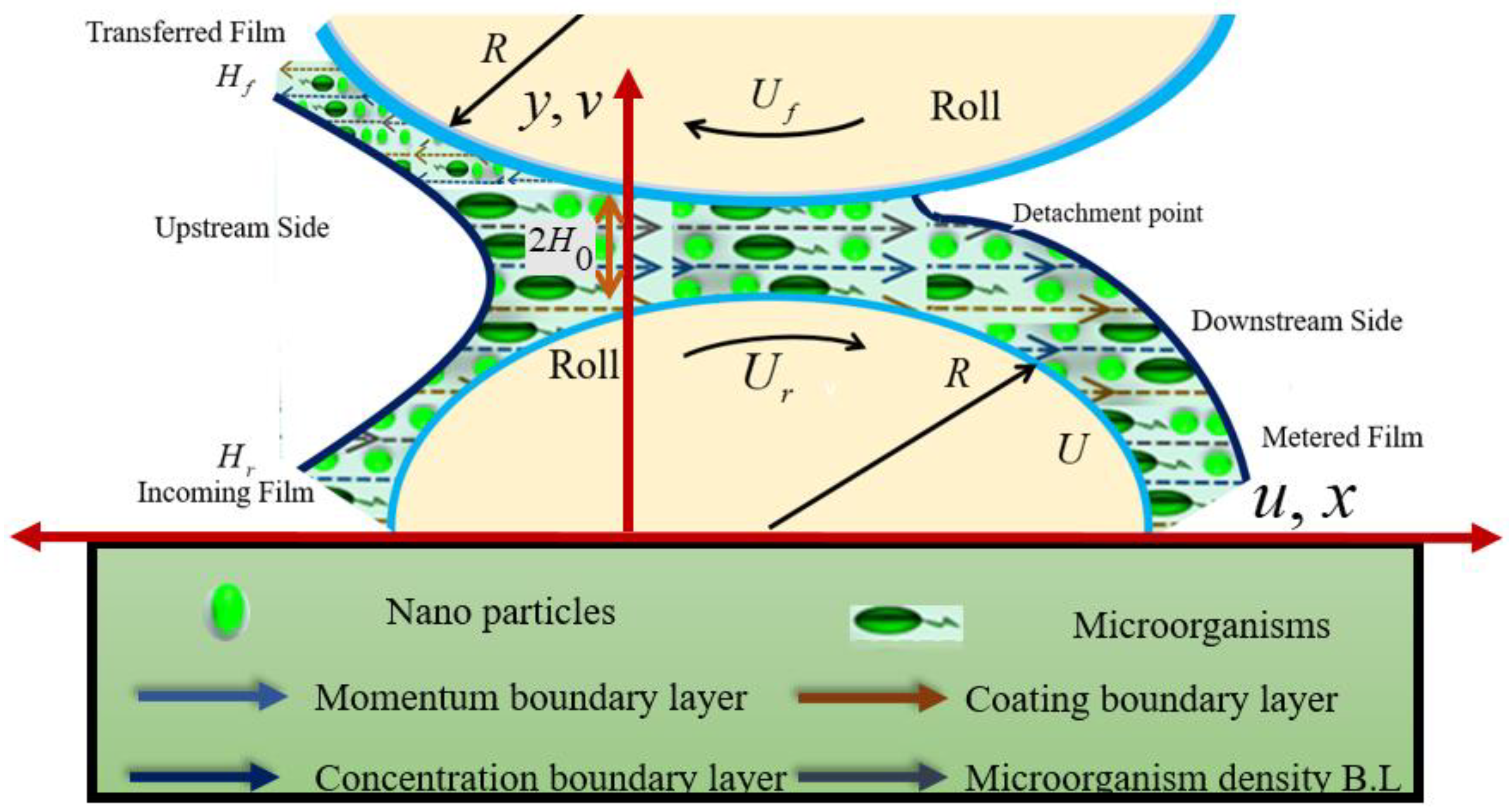

The discussion is based on the numerical results obtained for the Sutterby MHD nanofluid flowing in a thin channel formed by two counter-rotating rolls. The variations in velocity, temperature, concentration, and microorganism distributions are examined with respect to numerous governing parameters, and the outcomes are illustrated and interpreted through graphical representations.

Figure 9,

Figure 10 and

Figure 11 provide valuable insights into the variations in dimensionless velocity, temperature, concentration, and microorganism distribution at the nip position

.

Figure 9a presents the velocity profiles

for different values of the velocity ratio parameter

and

. As

increases, the fluid velocity within the channel also increases, which is physically consistent since larger velocity ratios correspond to faster roll speeds and greater momentum transfer. The most significant variations occur in the near-wall regions, particularly close to the upper boundary. For smaller values of

(e.g.,

), the velocity decays more gradually, indicating weaker acceleration. In contrast, for higher values of

(e.g.,

), the profile shifts upward, demonstrating higher velocity magnitudes across most of the channel. Importantly, the maximum velocity is attained near the roll surfaces, where direct interaction with the moving rolls exerts the strongest influence on the fluid motion.

Figure 9b illustrates the outcome of the magnetic parameter

on the velocity profile

for

and 1.2. It is observed that as

increases, the fluid velocity decreases throughout the channel. This trend is expected because a stronger magnetic field induces a Lorentz force, which acts as a resistive drag force opposing the motion of the electrically conducting nanofluid. Consequently, momentum transfer is suppressed, leading to a reduction in velocity. Similarly,

Figure 9c shows the effect of the bioconvection parameter

on the velocity profile u(y) for

and 0.9. It can be observed that increasing

causes a rise in the fluid velocity across the channel.

Figure 9e–g illustrates the nanoparticle concentration and micro-organism profiles under the influence of key flow parameters, namely the Brownian motion parameter, the velocity ratio parameter, and the Schmidt number.

Figure 9e shows the outcome of the velocity ratio parameter

on the nanoparticle concentration distribution

across the channel. It is observed that as

increases from 0.1 to 0.5, the concentration profile gradually shifts upward, leading to higher nanoparticle concentrations throughout the domain. Physically, a higher velocity ratio corresponds to stronger counter-rotating roll motion, which enhances fluid mixing and intensifies convective transport.

Figure 9g demonstrates the impact of the Brownian motion parameter

on the nanoparticle concentration profile

. As

increases from 0.2 to 1.2, the concentration curves shift downward, indicating a reduction in nanoparticle concentration throughout the channel. This occurs because increased random motion causes nanoparticles to disperse more widely within the fluid, thereby lowering the concentration profiles.

In the context of Sutterby nanofluid flow through reverse roll coating, microorganisms are important as their collective movement induces bioconvective effects that alter the fluid structure and flow characteristics. Their presence introduces additional dynamics into the system, making them a valuable factor to consider in analyzing coating processes.

Figure 9h and

Figure 10a,b demonstrates the sensitivity of the Micro-Organisms profile

to variations in key dimensionless parameters, namely the velocity ratio parameter

, the Schmidt number

, the Brownian motion parameter

and Peclet number

.

Figure 10a highlights the role of the velocity ratio parameter

on the microorganism distribution profile. The concentration profiles have decreasing trend for

and 0.5.

Figure 10b illustrates the impact of the Schmidt number

, on the Micro-Organisms profile

. As

increases from 0.2 to 0.9, the microorganism concentration rises across the channel, with the profiles shifting upward.

Figure 10b shows the impact of the Brownian motion parameter

on the microorganism profile

. It is observed that increasing

from 0.2 to 0.9 elevates the microorganism profile. The trend suggests that enhanced nanoparticle random motion indirectly promotes microorganism distribution.

Skin friction is a fundamental engineering quantity in analyzing non-Newtonian nanofluid flow through the reverse roll coating process. It quantifies the shear stress exerted by the fluid at the roll surfaces, which directly governs the energy required to drive the rolls and plays a vital role in maintaining the stability and uniformity of the coating layer. The impact of various parameters on the skin friction coefficient is presented in

Figure 11a–e. The influence of the

is shown in

Figure 11a. As

increases from 0.1 to 0.9, the skin friction coefficient decreases significantly, with the profiles shifting downward.

Figure 11b illustrates the effect of the magnetic field parameter

, where an increase in

reduces the magnitude of skin friction due to the Lorentz forces opposing the fluid motion and thereby enhancing resistance near the wall. The variation with the Brownian motion parameter

is shown in

Figure 11c, where increasing

from 0.2 to 1.2, results in a slight reduction in skin friction. A similar trend is observed for the bioconvection number

in

Figure 11d, indicating a modest decrease in skin friction with increasing microorganism activity. Finally,

Figure 11e depicts the effect of the Schmidt number

, where increasing Sc from 0.2 to 1.0 produces a gradual decline in the skin friction coefficient. In the next phase, we extend the analysis to heat transfer characteristics, where the predictive capabilities of the ANN-LMA framework are discussed in detail.

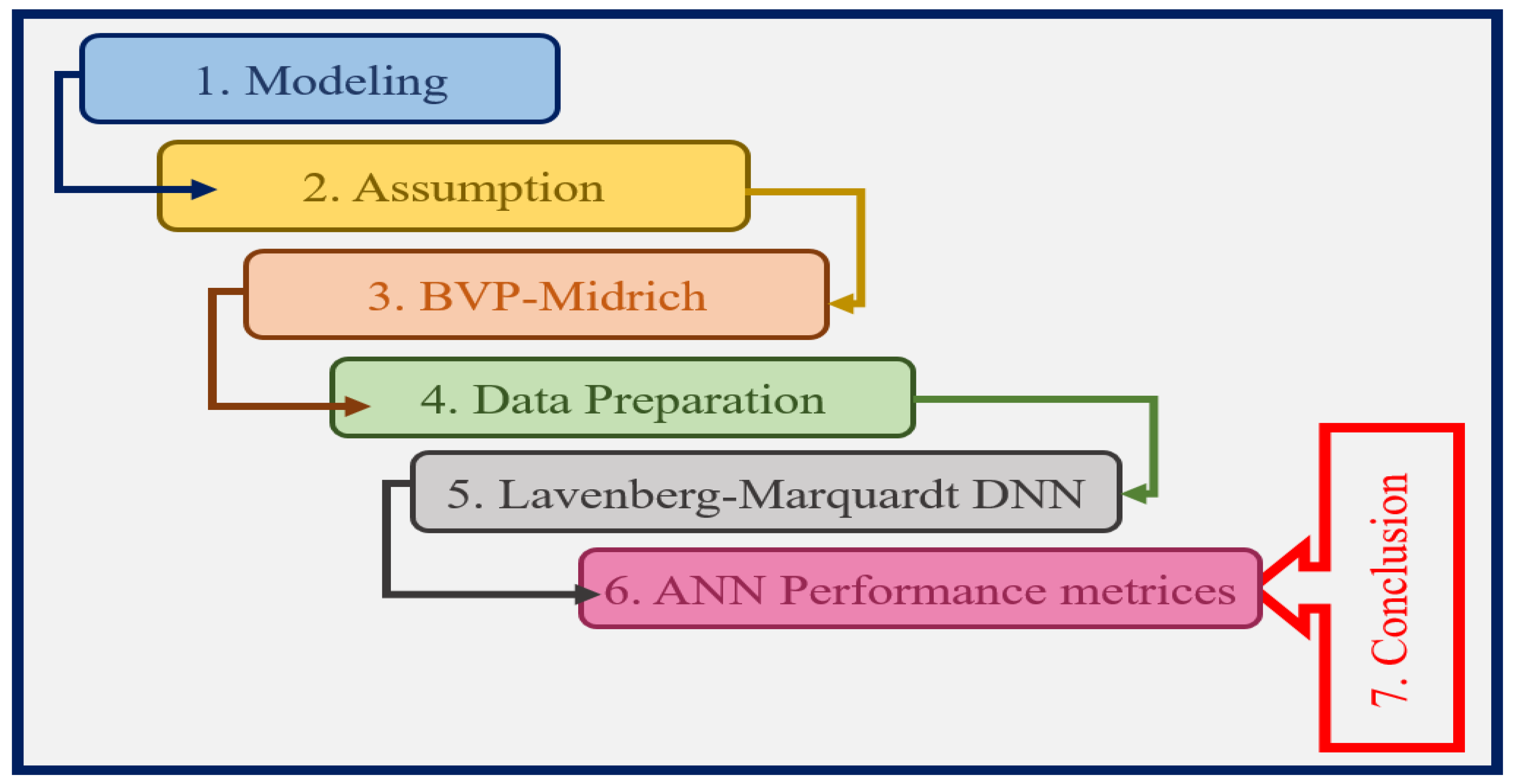

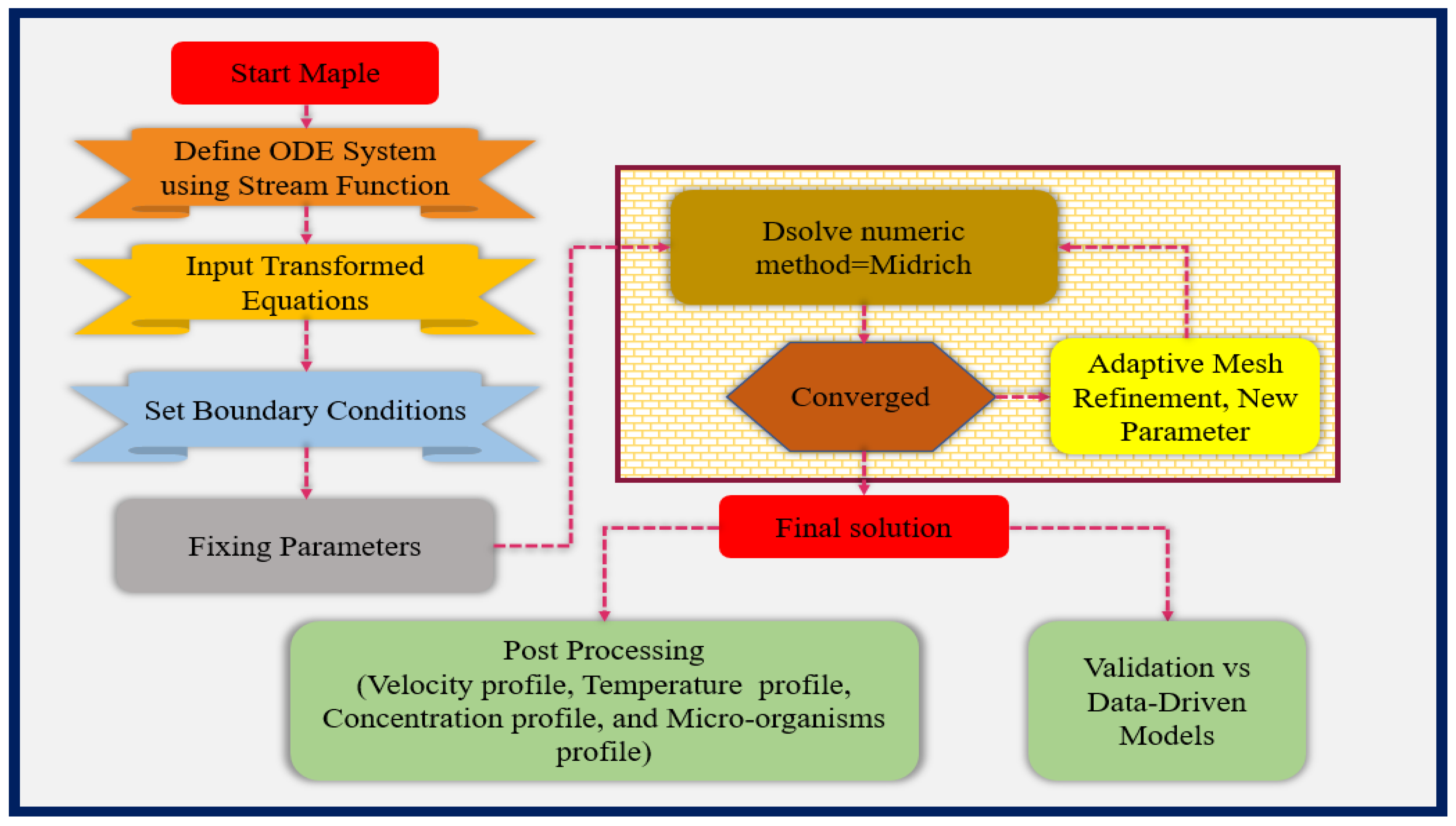

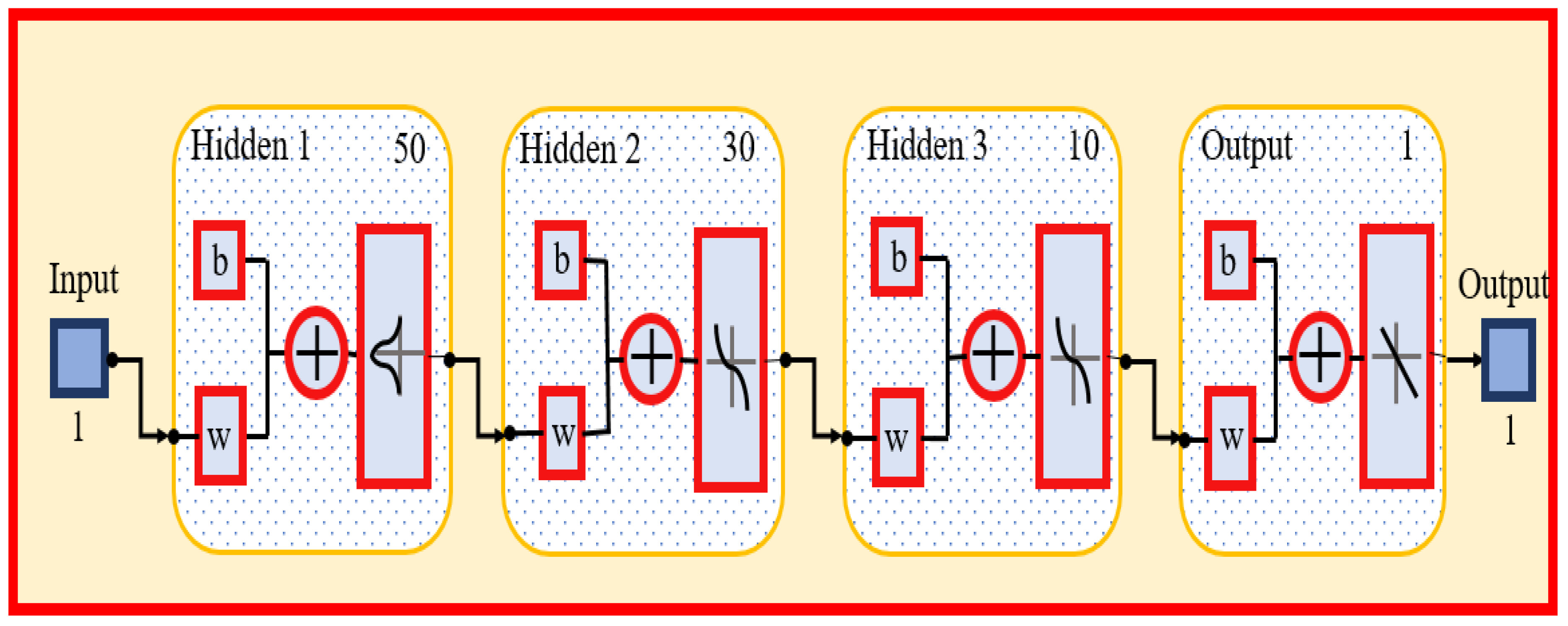

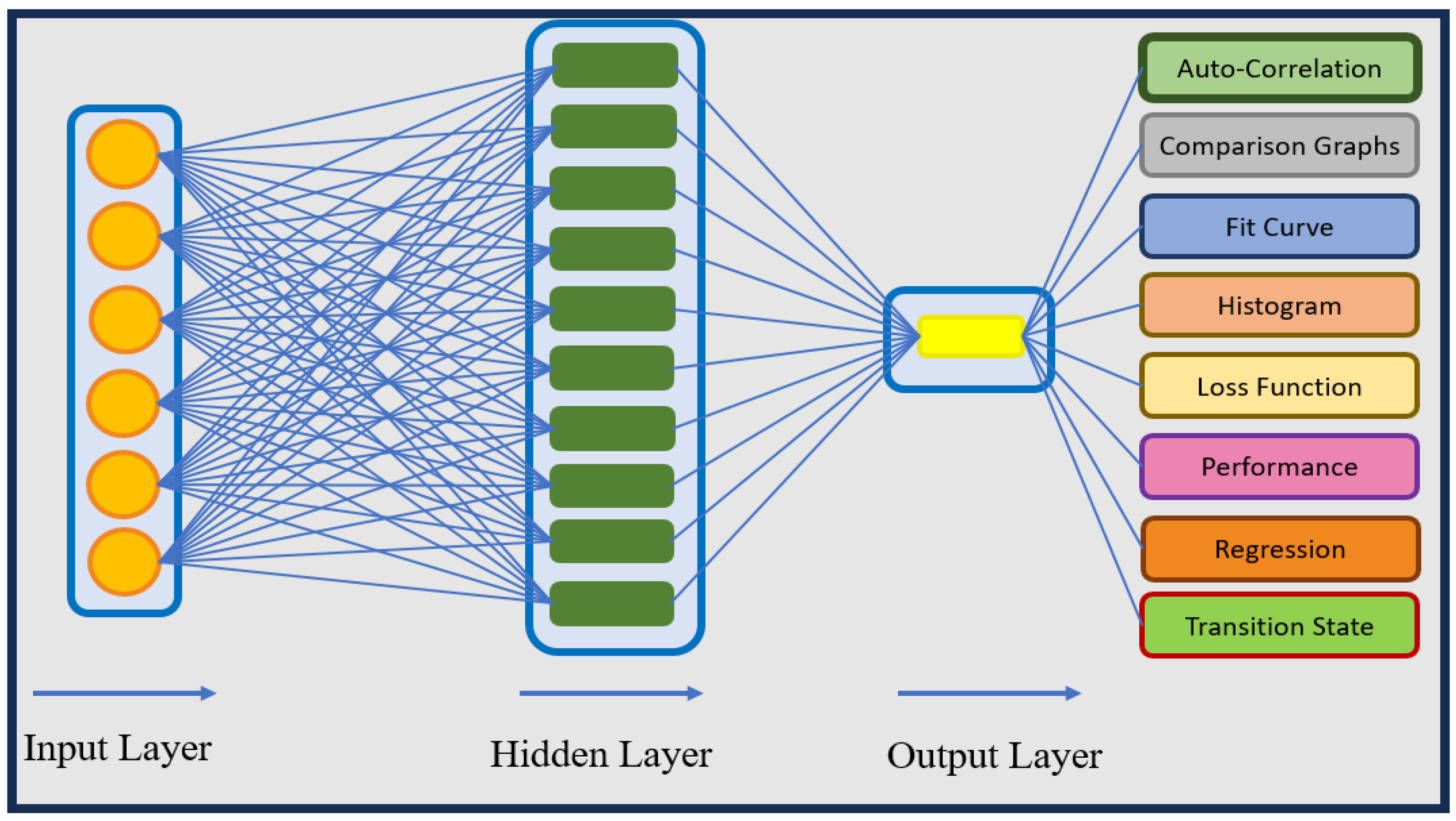

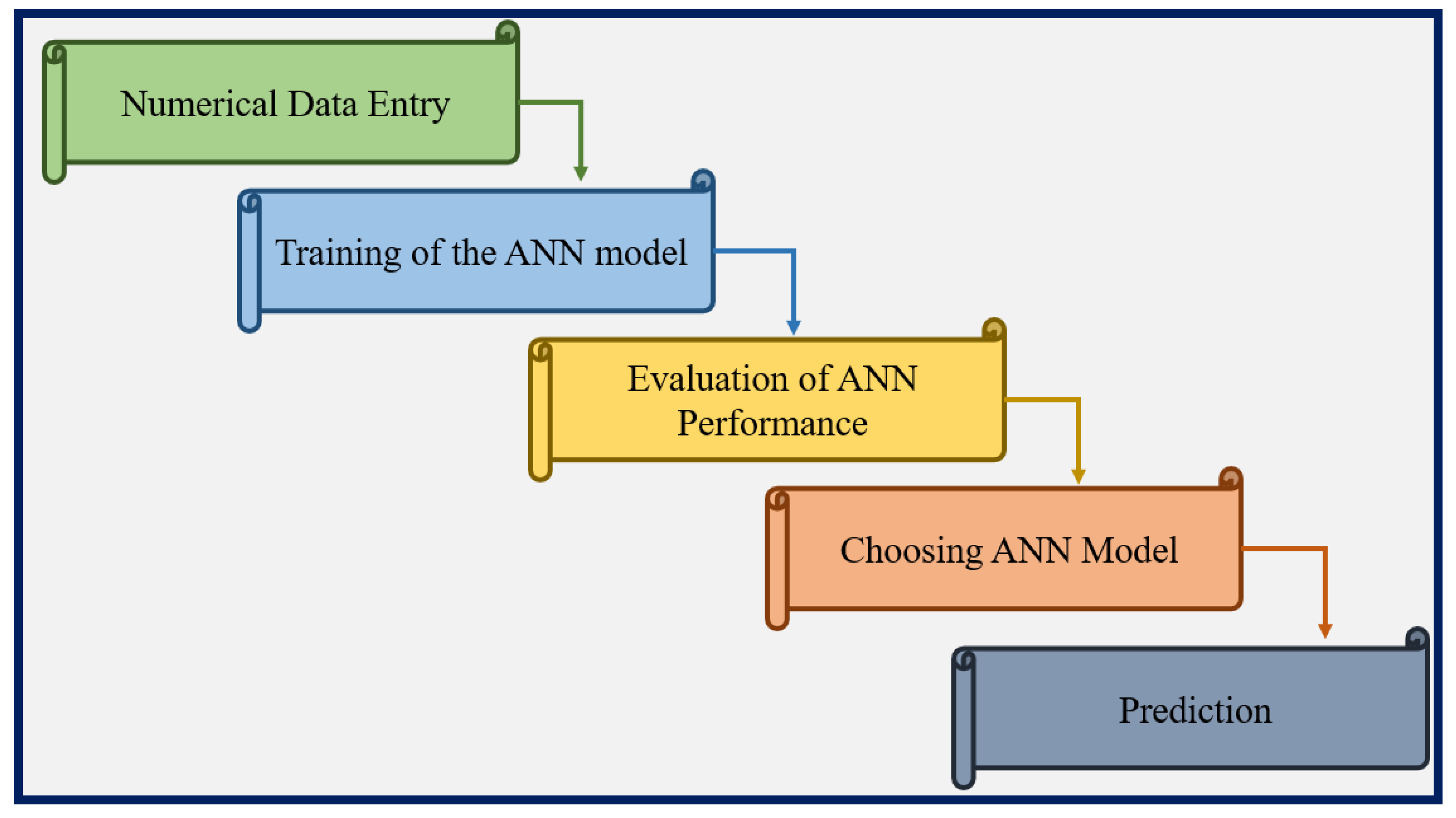

ANNs-LMA Discussion

Now we will discuss the output of the ANNs-LMB for heat transfer in the Sutterby MHD nanofluid within a thin channel.

Figure 12,

Figure 13,

Figure 14,

Figure 15,

Figure 16,

Figure 17,

Figure 18 and

Figure 19 present the outcomes of ANNs-LMB, including performance, histogram, MSE, loss function, and comparisons across training, validation, and testing under different scenarios.

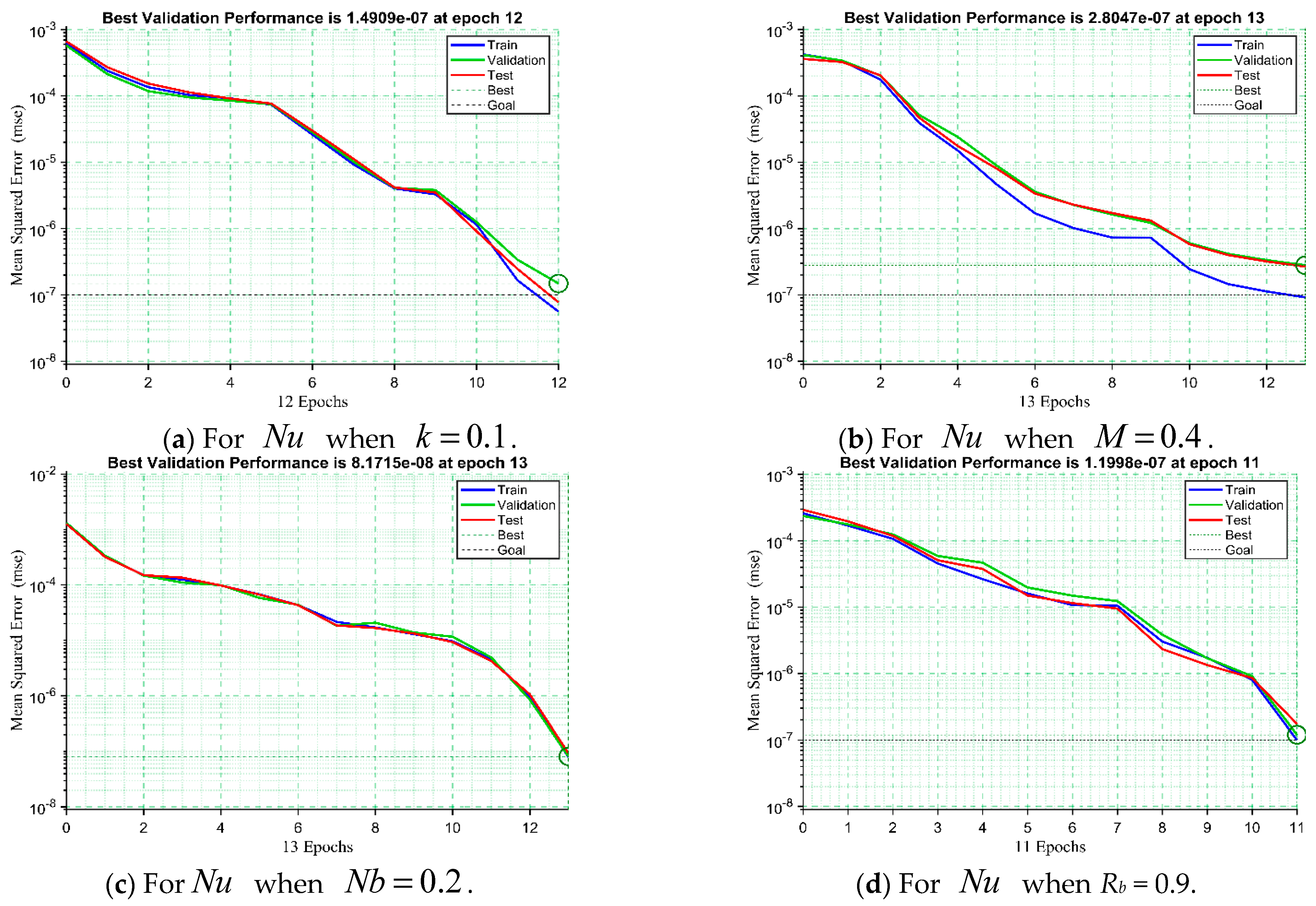

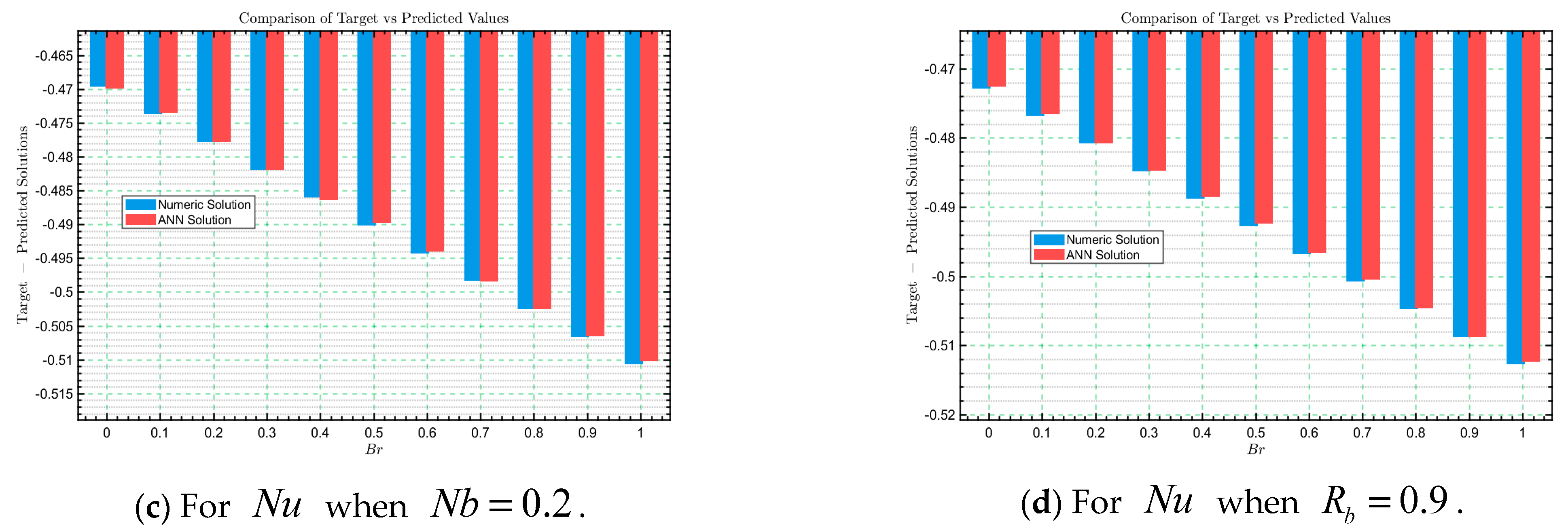

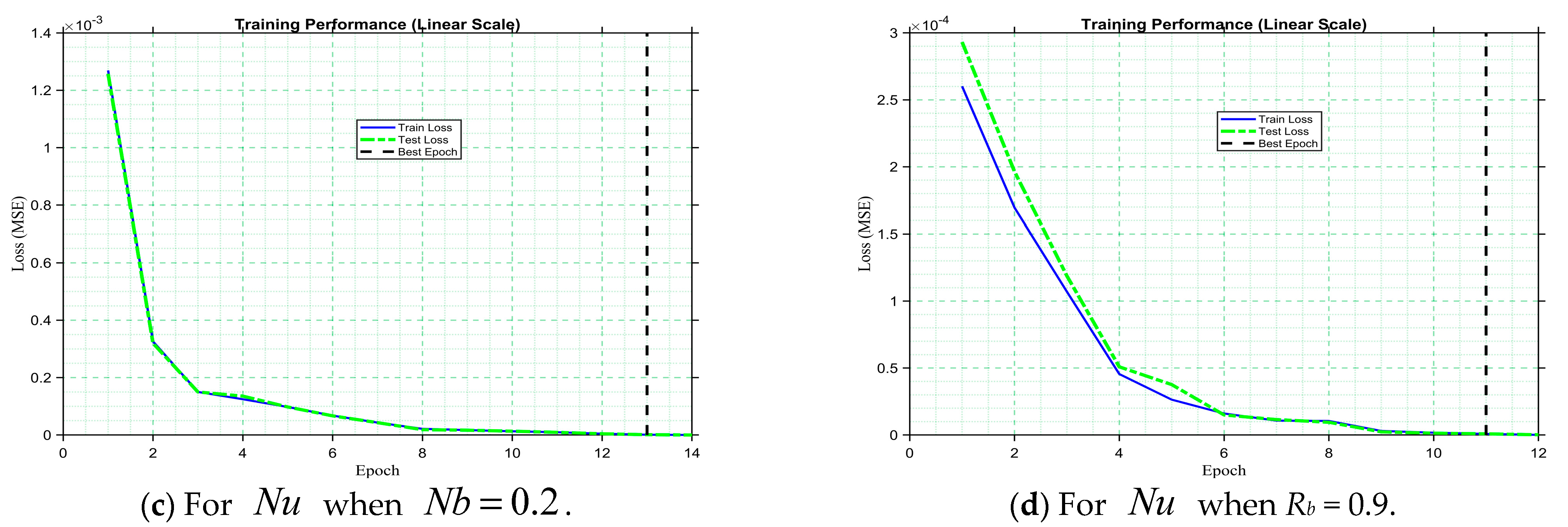

Figure 12a–d demonstrates the performance of the ANNs-LMB models through the MSE trajectories obtained during training, validation, and testing across different scenarios. As observed, all models demonstrate rapid convergence toward very low error values, with the optimal validation performance attained at specific epochs. In particular, the MSE curves highlight the convergence patterns of the trained datasets, where the best validation performances are recorded as

epoch 12,

at epoch 13,

at epoch 13, and

at epoch 11. The smooth decline and close alignment of the training, validation, and testing curves confirm the efficient learning capability of the models and their robustness in generalization, with minimal signs of overfitting. These results emphasize the reliability and adaptability of ANNs-LMA in capturing the highly nonlinear interactions governing the nanofluid system.

Figure 13a–d presents the error histograms for various scenarios of Nusselt number prediction in the thin channel using the ANNs-LMA model. The horizontal axis represents the error values, calculated as the difference between targets and outputs (Errors = Targets − Outputs), while the vertical axis shows the number of instances (frequency) corresponding to each error bin. Each histogram is divided into 20 bins, with blue, green, and red bars denoting the training, validation, and testing datasets, respectively. The vertical orange line indicates the position of zero error, serving as the reference for perfect prediction. From the figure, it can be observed that most of the errors are concentrated close to zero, representing strong model accuracy and only slight deviation from the actual values. The symmetry distribution reveals the absence of significant bias, suggesting that the models perform consistently well across all datasets. This consistency highlights their robust ability to simplify with minimal risk of overfitting. Across all scenarios, the majority of errors are distributed tightly around the zero line, confirming that the model has achieved highly accurate predictions with minimal deviation. In the first case, the maximum concentration of instances is centered between approximately

and

, with the highest frequency exceeding 300 instances. Similarly, in the second scenario, the errors cluster within the range of about

and

, with the tallest bin reaching nearly 200 instances. Based on these outcomes, it can be concluded that the ANNs-LMA model maintains stable and reliable performance across validation, training, and testing phases.

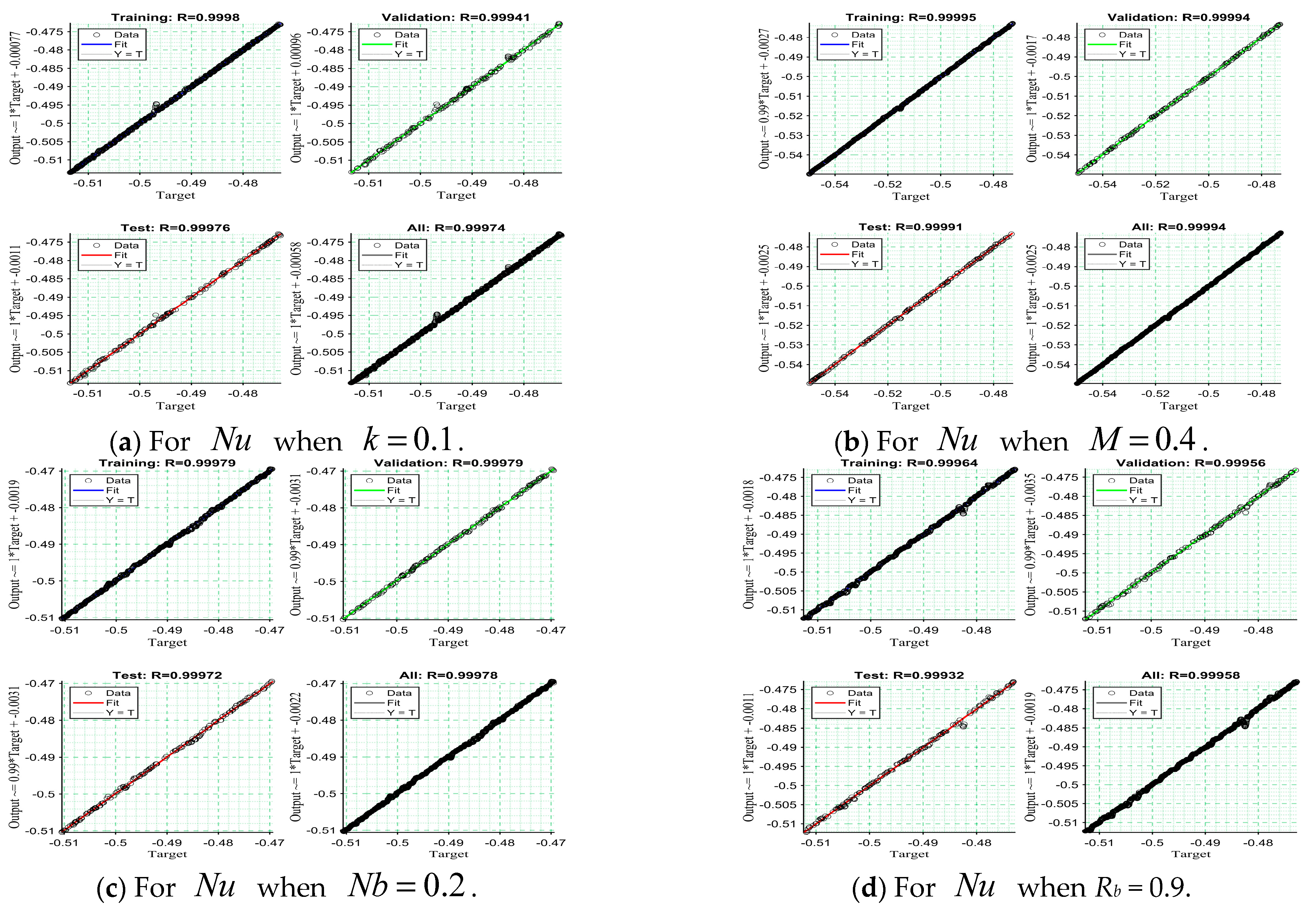

Figure 14a–d presents the regression plots of the ANN models for the training, validation, and testing phases, highlighting the correlation between the actual and predicted outputs. In all cases, the data points lie very close to the best-fit line (Y = T), with correlation coefficients

exceeding 0.999, which reflects a near-perfect agreement between predictions and targets. Such consistently high

-values demonstrate the reliability of the model in capturing the underlying nonlinear dynamics of the system. The strong linear alignment observed across all phases further confirms the absence of overfitting, emphasizing the model’s capability to generalize effectively across different datasets.

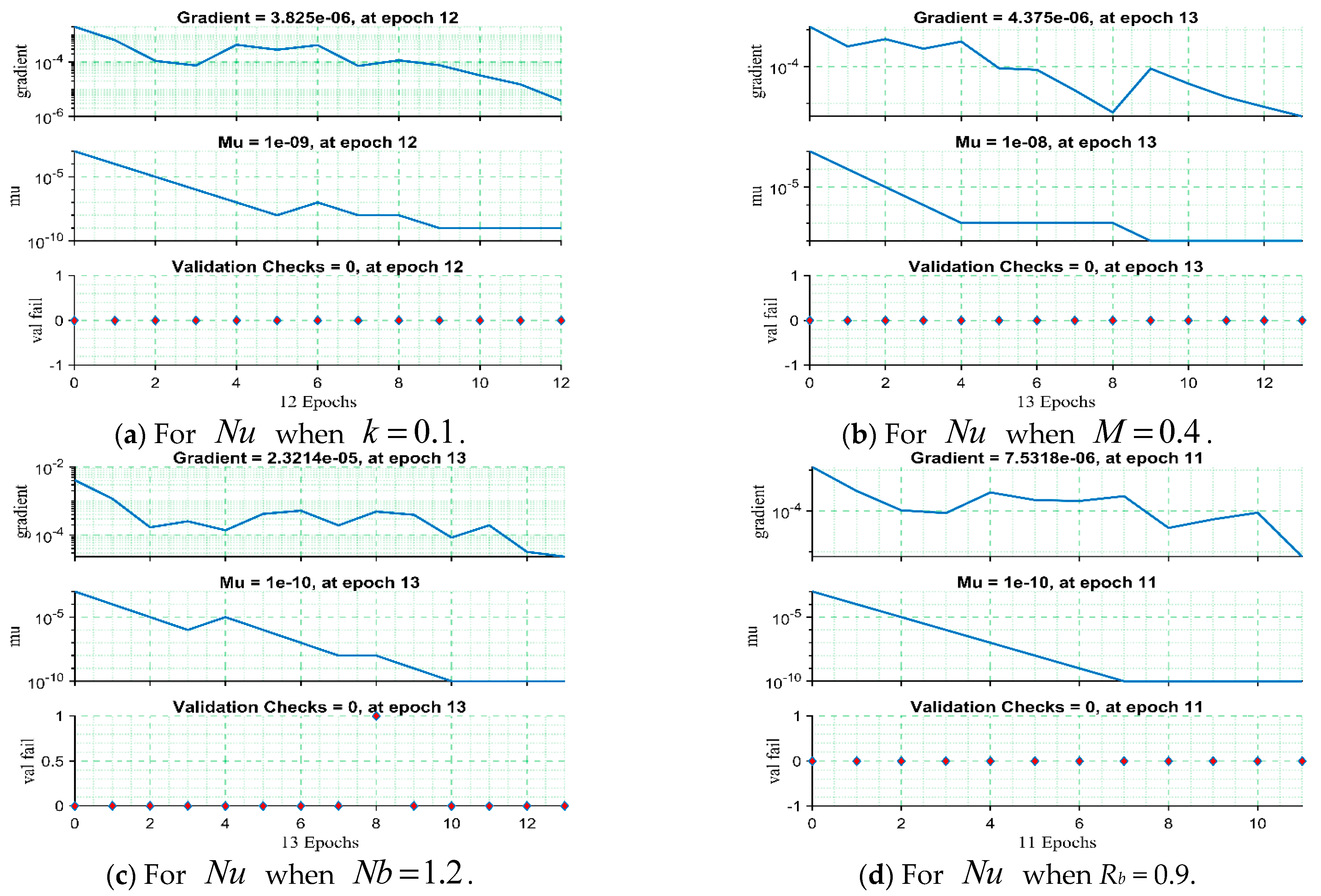

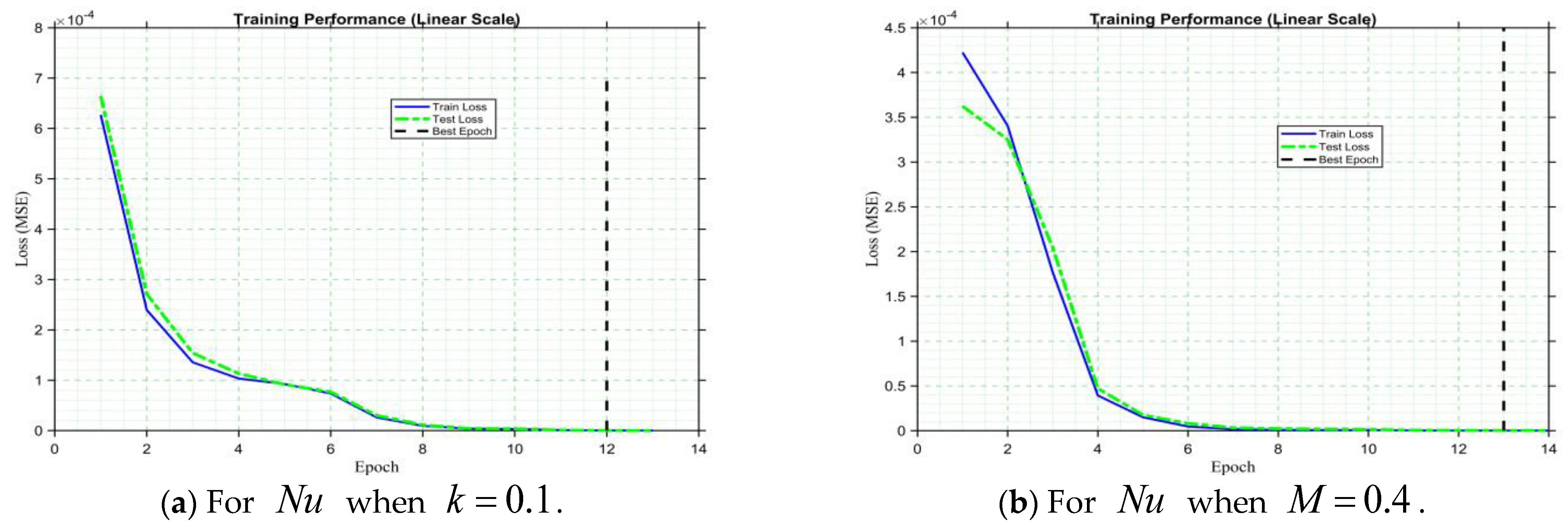

The training performance of ANNs-LMA models for multiple output parameters across distinct physical scenarios is presented in

Figure 15a–d. The figures highlight significant training characteristics such as gradient values,

parameter variation, and validation tests. In all cases, the gradient values decrease steadily with training, reaching very small magnitudes, which indicates effective convergence and error minimization. The

parameters also decline consistently, reflecting stable adjustments of the learning process and consistent improvements in training. Notably, the validation checks remain at zero throughout, confirming that no validation failures occurred and demonstrating the model’s strong ability to avoid overfitting. These observations jointly validate the efficiency, accuracy, and dependability of the ANNs-LMA models in capturing the nonlinear system behavior, while the rapid convergence within 11–13 epochs further emphasizes the robustness and reliability of the training process. Furthermore,

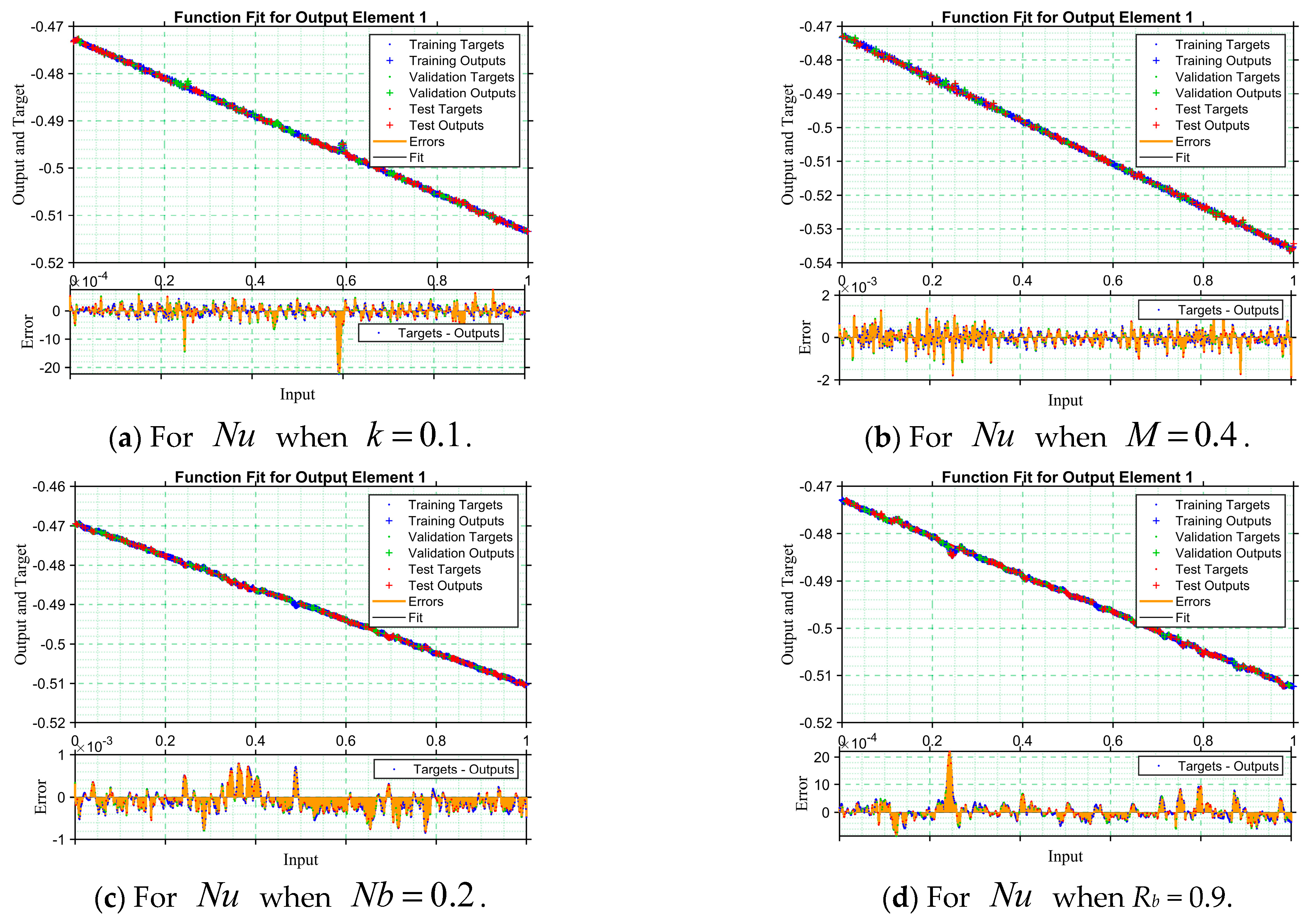

Figure 16a–d presents the function fit plots for the trained ANNs-LMA models, where training, validation, and testing datasets are represented by blue, green, and red points, respectively. The black line represents the best-fit curve, whereas the orange line demonstrates the prediction error. In all cases, the predicted outputs align very closely with the target values, demonstrating strong model accuracy. The error plots below each fit confirm this performance, with most errors concentrated around zero. In

Figure 16a, errors fluctuate within a narrow range of approximately -0.001 to 0.001, indicating negligible deviation. In

Figure 16b, the errors spread slightly wider, ranging between −0.002 and 0.002. Similarly,

Figure 16c, d shows minimal deviations, with error values confined to small magnitudes without large outliers.

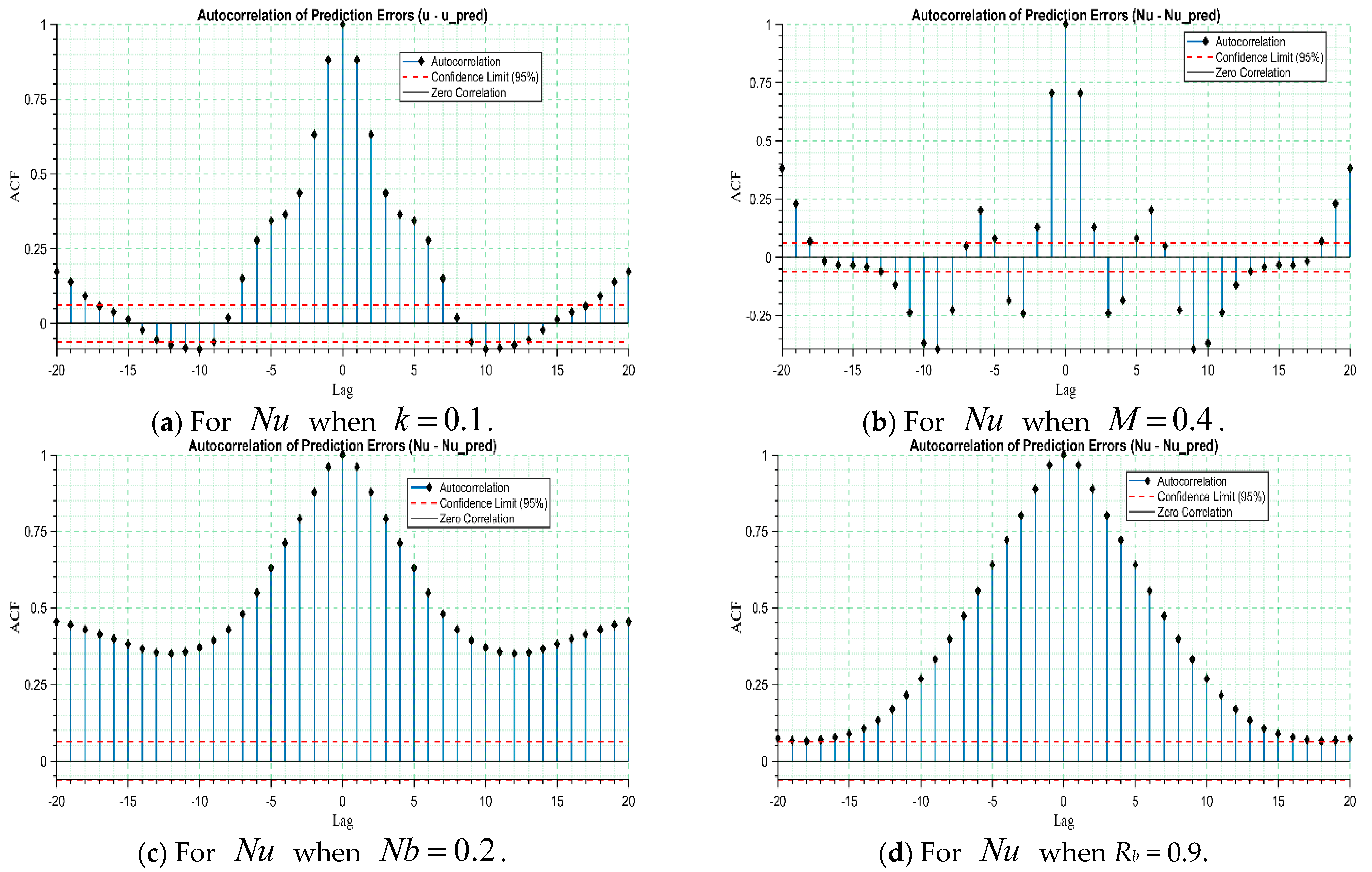

Next, we present the autocorrelation error plots for different scenarios, which are used to evaluate the independence of residual errors in the ANNs-LM model. Ideally, prediction errors should be uncorrelated and lie within the 95% confidence bounds, indicating that the model has efficiently captured the underlying data patterns without leaving systematic dependencies. The autocorrelation error analysis for each scenario of the proposed model trained using the solver is shown in

Figure 17a–d. In these cases, most spikes remain within or close to the confidence limits, suggesting that the residuals are largely uncorrelated and that the ANN provides reliable predictions.

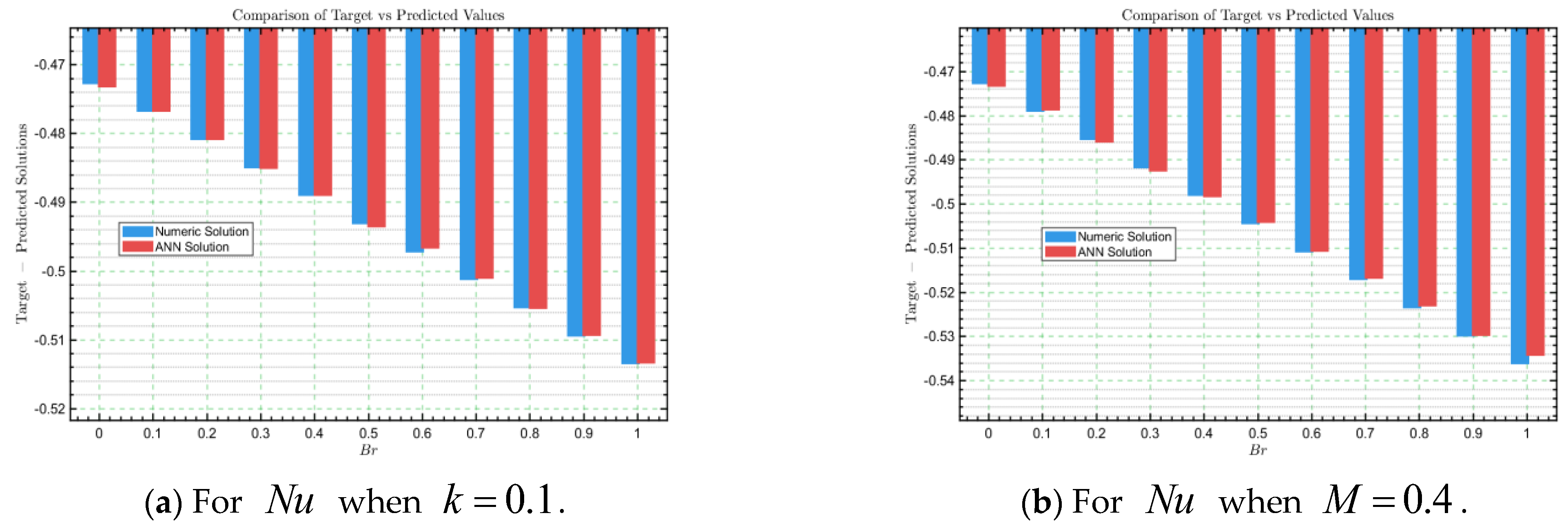

The comparison between numerical solutions and ANNs-LMA predicted solutions is essential for validating the reliability of the trained model.

Figure 18a–d presents bar plots that compare the target (numeric) and predicted (ANNs-LMA) solutions versus the Brinkman number (Br) on the horizontal axis and the predicted solution on the vertical axis. In each case, the ANNs-predicted values closely follow the numeric solutions with only minor deviations, demonstrating excellent agreement. This strong alignment confirms that the ANNs-LMA model successfully captures the underlying physical behavior of the system and can serve as a dependable surrogate to traditional numerical methods. Such comparison is important as it not only verifies prediction accuracy but also establishes the ANN model’s potential for computational efficiency in complex fluid dynamic problems. Moreover, the evaluation of the training and testing loss functions is equally important to assess the stability and convergence of the ANNs-LMA model.

Figure 19a–d displays the loss (MSE) versus epochs, showing a rapid decrease in error during the initial iterations followed by stabilization at very low values

. The close overlap of training and testing loss curves indicates that the model has converged efficiently without signs of overfitting or underfitting. This behavior highlights the robustness of the ANNs-LMA in generalizing across unseen data and achieving reliable predictive performance. The consistent minimization of the loss function demonstrates that the ANNs-LMA model not only reproduces the numerical results accurately but also ensures long-term stability and efficiency in practical prediction tasks.

The convergence performance of the developed ANNs-LMA model has been evaluated using statistical measures such as performance, MSE, gradient, mu, validation, and epochs under varying parametric conditions (

and

). The results summarized in

Table 2,

Table 3,

Table 4 and

Table 5 highlight that the model consistently achieves low MSE values across both training and testing datasets. For example, at

, the training and testing MSE values are

and

, respectively, with a performance value of

and a gradient of

within 12 epochs. Similarly, at

, the model converges with training and testing MSE values of

and

, achieving performance of

and a gradient of

after only 11 epochs. For the case of

, the ANN-LMA demonstrates training and testing MSE values of

and

, with a performance of 7.2229 × 10

−8 and a gradient of

over 15 epochs. Similarly, the results for the bioconvection number

can be observed from

Table 5, where the ANN-LMA model again exhibits stable convergence behavior with low training and testing MSE values, controlled gradients, and efficient epochs. Across all cases, the gradients gradually reduce to the order of

, while the mu parameter remains stable between

and

, reflecting robust convergence. The validation values remain close to the training accuracy, and the required epochs (ranging between 10 and 16) further confirm efficient convergence without excessive iterations. These outcomes demonstrate that the ANN-LMA model not only reproduces the numerical solutions with high accuracy but also ensures computational efficiency and strong adaptability to capture the nonlinear dynamics of the system under diverse fluid flow scenarios.

Assessing multiple statistical error metrics is important to validate the reliability and robustness of the ANNs-LMB model under varying physical parameters. The outcomes presented in

Table 6,

Table 7,

Table 8 and

Table 9 demonstrate that the model consistently maintains high accuracy across changes in

and

. Across all cases, the error indicators like MAE, MSE, RMSE, ME, MAD, and MRE, remain very small, typically in the range of

, while the coefficient of determination

remains close to 0.99. For instance, at

, the ANN achieves MAE of

, MSE of

, and

, confirming strong predictive accuracy. Similarly, at

, the model yields MAE of

, RMSE of

, and

. For

, one of the lowest error levels is recorded with MSE of

and RMSE of

, while maintaining

. The analysis for

further supports these trends, with

ranging between 0.9914 and 0.99 and MAE values remaining in the order of

. The stability of additional measures, such as SSR and SST, further validates the model’s balance between explained and unexplained variations. Moreover, the mean absolute error (MAE), which remains below 0.001 in most cases, provides strong evidence of the model’s reliability and its close alignment with numerical solutions. These statistical validations complement the regression, performance, and error histogram analyses, together confirming the robustness, accuracy, and generalization ability of the ANNs-LMB model.

The Nusselt number

is an important dimensionless parameter in heat transfer analysis, as it represents the ratio of convective to conductive heat transfer across a boundary. Its evaluation is critical for understanding the effectiveness of thermal transport in fluid flow systems and for optimizing coating and cooling processes.

Table 10 presents the effect of varying parameters

, and

on the

. The results indicate that

decreases slightly with increasing values of these parameters, showing the sensitivity of thermal transport to fluid dynamic conditions. For instance, at

and

, the

is

, which further decreases to

when

is increased to 1.2. Overall, these results highlight that the

is strongly dependent on flow and thermal parameters. The analysis demonstrates the importance of carefully selecting these parameters to control convective heat transfer. Likewise, the impact of the other parameters can also be witnessed from the same table, where their respective variations further illustrate the sensitivity of

to fluid and thermal conditions.