Abstract

Red drupelet reversion (RDR) is a physiological disorder in which blackberry drupelets revert from black to red, losing their commercial value. RDR has been associated with mechanical damage caused by vibrations during transport. The goal of the present study was to construct a portable vibration system to quantify RDR progression in different blackberry cultivars. The system was integrated with an electrical signal generator, a monoaural amplifier, a subwoofer type speaker, and an oscilloscope. This system generates vibration intensities reached during fruit commercial transport (10 Hz and 0.5 g’s). To induce RDR, blackberry clamshells cv. ‘Tupi’ were placed in the portable system and subjected to different vibration times. RDR was observed immediately after fruit was subjected to 5 min vibration. To evaluate RDR progression in different cultivars, blackberry clamshells ‘Ak234′, ‘Am151′, and ‘Tupi’ were subjected to vibration during different times; and analyzed after storage (0 to 5 d). ‘Tupi’ blackberries reverted more rapidly than ‘Am151′ and ‘Ak234′ cultivars, suggesting that ‘Tupi’ was more susceptible to RDR. These results highlight that portable vibration system could be a useful and fast tool to evaluate resistance to RDR in blackberries.

1. Introduction

Red drupelet reversion (RDR) is a physiological disorder in which black blackberry drupelets turn red losing their quality and commercial value. It has been estimated that ~5% of commercial blackberries could be affected by RDR [1], and that, in export markets, ~95% of fruit rejections are caused by this defect [1,2].

Mechanical damage, caused by vibrations during transport, is one of the main factors that induce RDR [2,3]. It has been reported that vibrations provoke cell damage, which causes an increase in enzymatic activity, generating browning reactions in different fruits [4,5,6]. In blackberries, it has been shown that vibrations at 10–15 Hz. and 0.5 g’s, induce fruit damage, causing rupture of anthocyanin agglomerates (containing cyanidin 3-O-glucoside, the main pigment in blackberry fruit), which has been associated with RDR incidence [2,3].

In addition to mechanical damage, other factors increase blackberry susceptibility to RDR. For example, a high N fertilization rate (212 kg N ha−1) increased RDR incidence compared with medium (106 kg N ha−1) and low (53 kg N ha−1) N fertilization rates; due to nitrogen over application reduced firmness increasing the susceptibility to mechanical injury [7]. Also, high temperature of fruit skin during harvest and handling significantly increased the severity of the RDR [7,8,9,10]; this effect was most notable when skin temperatures exceeding 25 °C. Others blackberry cultivars, such as ‘Osage’, ‘Tupi’, ‘Triple Crown’, and ‘Natchez’, have shown an increased susceptibility to RDR [9,11,12] due to their low firmness [1].

Importantly, in commercial production, there is a pressing need to establish an affordable, simple, robust, and systematic approach to assess the contribution of different blackberry harvest seasons, fruit cultivars, pre- and postharvest management conditions to RDR disorder progression. For this reason, different vibration devices such as an electro-hydraulic vibration system conformed by a hydraulic bomb, platform, a sine-wave generator connected to an amplifier [13]; a vibration table with a frequency generator by percussion (5–20 Hz) (Euro Percussion, Lempdes, France, CT 38/31) [14,15]; an electro-dynamic vibration simulator driven by a power amplifier, a signal-conditioning amplifier and two piezoelectric accelerometers [16]; a simulator of vibration with two components: a vibration generating system made up of an inverter-controlled motor; and an integrated parameter control system [17] have been designed to simulate the vibratory movement in transport of different fruit. In this work, we propose the use of a simple and portable vibration system as a method to induce and quantify RDR progression in different blackberry cultivars.

2. Materials and Methods

2.1. Portable Vibrator System

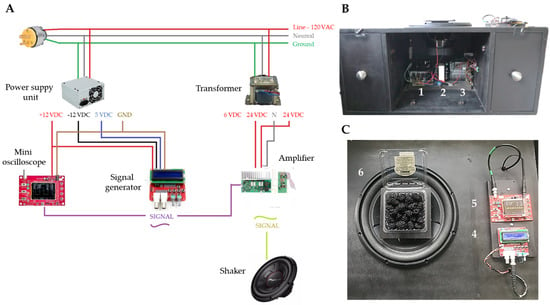

A portable system was built to reproduce, under laboratory conditions, vibration levels reached during commercial transport. The system is integrated by an electrical signal generator module DDS HS signal frequency (1 Hz to 8 MHz; frequency adjusting steps: 1, 10, 1000, 10,000 Hz; waveform type: sine, square, triangular, saw, rev saw, electrocardiogram or ECG and noise; power: +5 V/+12 V/−12 V); a monoaural amplifier (working voltage: double 24–32 VAC; output power: 350 W; channel type: mono), a subwoofer type speaker (Max. Music power: 1300 W; nominal power: 350 W; speaker size: 30 cm; impedance: 4 Ω; sensitivity: 96 dB ± 1.5 dB (in car, input: 1 W); frequency response 20 Hz to 125 Hz; gross weight: 3.60 kg), and an oscilloscope DS0138 (maximum real-time sampling rate: 1 Msps, accuracy: 12 bits; sampling buffer depth: 1024 bytes; analog bandwidth: 0–200 kHz; vertical sensitivity: 10 mV/grid–5 V/grid (1–2–5 gradual way); input impedance: 1 MΩ; maximum input voltage: 50 Vpp (1:1 probe); 400 Vpp (10:1 probe); coupling modes include DC/AC/GND).

In this system, the signal generator produces a low voltage sinusoidal signal, with frequencies from 0 to 100 Hz; then it is increased and converted by the amplifier to an electrical signal that is received by the subwoofer which produces vibration motion. Amplitude level and vibration frequency generated are displayed by the oscilloscope to monitor them. To vibrate the fruits at the frequency and acceleration required (e.g., 10 Hz and 0.5 g’s), commercial clamshells containing fresh blackberries (170 g) are placed on the subwoofer (Figure 1) [2,3].

Figure 1.

Elements of portable vibration system. (A) System operations diagram with its main components. Front view (B) and upper view (C) of the system. 1: amplifier; 2: transformer; 3: power supply unit; 4: signal generator; 5: mini oscilloscope; and 6: subwoofer (shaker). VDC: volts of direct current; VAC: volts of alternating current; GND: ground; N: neutral.

2.2. Blackberry Fruit

The experiments were carried out using three blackberry cultivars (Rubus sp. ‘Ak234′, ‘Am151′, and ‘Tupi’) provided by a commercial orchard located in Zamora Michoacan, Mexico (19°35′00″ N, 102°28′00″ O). Commercial clamshells (n = 12 for each cultivar) containing ~170 g of full ripe and shiny black fruits (Tupi: L* = 16.1, a* = 0.22, b* = −0.35, C* = 0.42, h° = 302.4; Am151: L* = 14.6, a* = 0.01, b* = −0.68, C* = 0.68, h° = 271.1; Ak234: L* = 17.6, a* = 0.88, b* = 0.002, C* = 1.26, h° = 0.15) were transported (within 4.5 h) in a cooler filled with ice packs to the laboratory. Immediately at arrival, fruits without defects were selected and stored at 1 °C and 95% relative humidity (RH) during 24 h prior vibration.

2.3. Laboratory Test to Induce RDR

To standardize laboratory conditions that reproduce RDR defect as observed in commercial situations, clamshells containing blackberries cv. ‘Tupi’ were placed on portable system and vibrated during 0, 1, 3, and 5 min. After vibration, fruits inside the clamshell were immediately photographed and then, individual fruits (n = 15) were subjected to visual inspection and color analysis.

2.4. Analysis of RDR Susceptibility in Blackberry Cultivars

To evaluate the potential use of the portable vibration system to distinguish susceptibility to RDR among different blackberries cultivars, a proof-of-concept test was performed using blackberry cultivars ‘Ak234′, ‘Am151′, and ‘Tupi’. Clamshells containing ~170 g of fruit were vibrated during 0, 1, 3, and 5 min; and then, immediately placed in a commercial cool room (1 °C and 95% RH). At d 0, 1, 2, 3, 4, and 5; fruits were randomly selected and subjected to visual inspection and color analysis (see Section 2.5 and Section 2.6).

2.5. Fruit Visual Inspection

Clamshells were visually inspected to estimate percentage of fruits showing RDR defect. Fruits (n = 15) were randomly collected to estimate RDR prevalence. Presence of RDR was considered when at least five drupelets per berry were completely fully red [18]. A fully red drupelet had all visible skin a red color as was described by elsewhere [19].

2.6. Objective Color Analysis

Objective evaluation of RDR was realized using color CIELa*b* values. Values of CIELa*b* color space were measured, on three different points along the equatorial zone of each fruit, using a reflectance spectrophotometer CM-600D (Konica Minolta, Japan) with an observer of 10° and illuminant D65 as equipment set point. Chroma (C*) and hue (h°) values were estimated as described elsewhere [19] based on previous color analysis in fruits [20].

2.7. Statistical Analyses

Results of CIELa*b* color analyses were subjected to one-way ANOVA test using a completely random model; then, multiple comparisons of means were conducted using Tukey pos hoc test. These statistical analyses were carried out using the JMP 6 Software (SAS Institute Inc., Cary, NC, USA); level of significance was established at p ≤ 0.05. All of the experiments were performed in triplicate.

3. Results

3.1. Portable Vibration System Induce RDR

This system reached vibration levels such as those of commercial transport of blackberry fruits. The analysis of vibration profile revealed that setting at 10 Hz, the system produces an acceleration of 0.53 g’s when a clamshell with 200 g of blackberries is placed on the device.

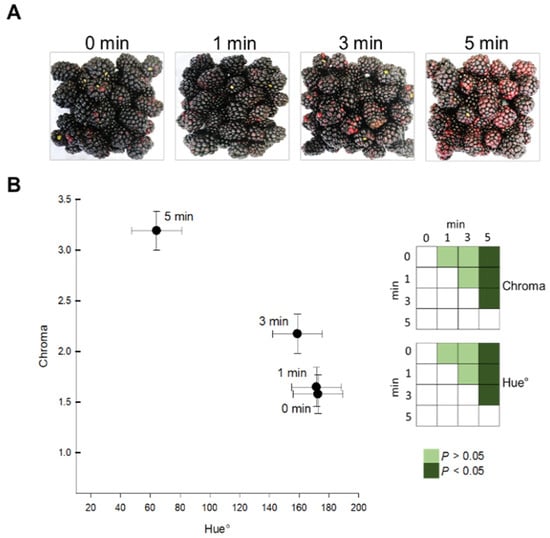

To verify that this portable vibration system induces RDR, blackberry fruits were collected from a commercial orchard and subjected to 0, 1, 3, and 5 min of vibration (10 Hz and 0.5 g’s). Visual inspection, immediately after treatment, revealed that blackberries vibrated for 0, 1, and 3 min did not show signs of RDR. In contrast, fruits vibrated for 5 min reverted to red color (Figure 2A). These results were corroborated by chroma and hue° analyses showing that fruits vibrated for 5 min, exhibited an intense red color (C* = 3.2, h° = 70) compared to the vibrated berries for 0, 1, and 3 min (C* = 1.6–2.2, h° = 155–170; p < 0.05. Figure 2B). Together, these results confirmed that the portable vibration system could induce RDR under laboratory conditions.

Figure 2.

Vibration generated by portable vibrator system induce RDR in blackberry fruit. (A) Color change induced by different vibration times (10 Hz and 0.5 g’s). (B) Hue° and chroma parameters in blackberries vibrated at different times. Left panel depicts mean values ± SE (n = 15). Right panel depicts pairwise comparisons for statistical analysis (Tukey test).

3.2. Analysis of RDR Susceptibility in Blackberry Cultivars

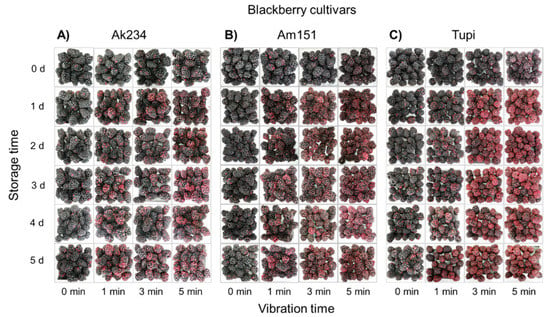

To evaluate the potential use of the portable vibration system to assess susceptibility to RDR in different blackberry cultivars, three cultivars were subjected to different vibration times (0, 1, 3, and 5 min) and storage periods (0, 1, 2, 3, 4 and 5 d). For cultivar ‘Ak234′, vibration for 0, 1, 3 and, 5 min induced 0%, 20%, 10%, and 40% RDR, respectively, immediately after treatment. ‘Ak234′ fruit subjected to same vibration times and stored during 5 d reached up to 15%, 75%, 70%, and 80% RDR, respectively (Figure 3A and Figure 4A). For cultivar ‘Am151′, no signs of RDR were observed after 0, 1, and 3 min of vibration; however, vibration for 5 min induced 15% RDR; immediately after treatment. ‘Am151′ blackberries vibrated for these four vibration times and stored during 5 d reached up to 30%, 85%, 90%, and 100% RDR, respectively (Figure 3B and Figure 4A). Moreover, these four vibration times in cultivar ‘Tupi’ induced 0%, 15%, 45%, and 60% RDR, respectively, immediately after treatment. Vibration for 0, 1, 3, and 5 min and storage during 5 d caused up to 15%, 30%, 100%, and 100% RDR, respectively (Figure 3C and Figure 4A).

Figure 3.

Vibration produces by the portable vibrator system induces RDR in different blackberry fruit cultivars. Color changes in (A) ‘Ak234′, (B) ‘Am151′, and (C) ‘Tupi’ cultivars induced by different vibration (10 Hz and 0.5 g’s) times (0, 1, 3, and 5 min) during 5 d of storage at 1 °C.

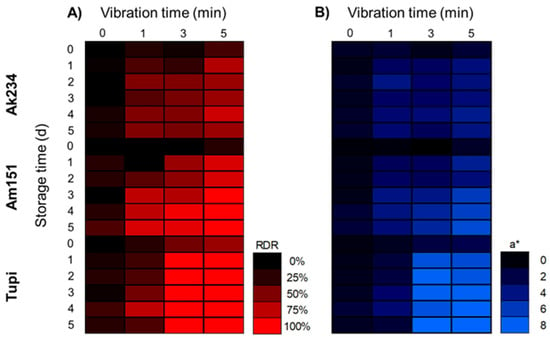

Figure 4.

Portable vibration system allows to assess susceptibility of three blackberry cultivars to RDR. Heat map depicts average of (A) % of RDR and (B) a* color CIELab parameter in ‘Ak234′, ‘Am151′ and ‘Tupi’ cultivars induced by different vibration (10 Hz and 0.5 g’s) times (0, 1, 3 and 5 min) during 5 d of storage at 1 °C (n = 15).

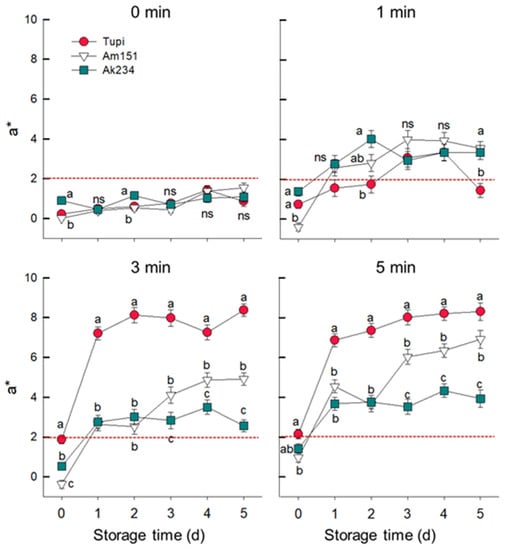

To corroborate these color changes, from blackish (a* ≤ 2.0) to reddish (a* > 2.0), in the three blackberry cultivars, CIELab colorimetry analysis was performed. ‘AK234′ fruit, stored from 0 to 5 d, changed color from a* = 0.90 to 1.08; 1.38 to 3.34; 0.53 to 2.56; 1.42 to 3.93; after 0, 1, 3, and 5 min of vibration treatment; respectively (Figure 4B). ‘Am151′ fruit, stored from 0 to 5 d, changed color from a* = 0.01 to 1.54; 0.04 to 3.93; −0.36 to 4.86; 0.97 to 6.34; after 0, 1, 3, and 5 min of vibration treatment; respectively (Figure 4B). Interestingly, it was confirmed that berries from ‘Tupi’ cultivar were more susceptible to RDR induction, fruit from this cultivar stored from 0 to 5 d, changed color from a* = 0.22 to 0.87; 0.74 to 1.44; 1.87 to 8.37; 2.15 to 8.31; after 0, 1, 3, and 5 min of vibration treatment, respectively (Figure 4B).

Also, differences in the RDR progression of the three blackberry cultivars evaluated were observed (Figure 5). For example, fruits subjected to 0 min of vibration showed blackish color (a* > 2.0) after 5 d of storage. ‘Ak234′ and ‘Am151′ berries subjected for 1 min vibration suffered loss of blackish color after 1 d of storage. Blackberry fruits of the three cultivars vibrated for 3 or 5 min lost blackish color after 1 d of storage. Importantly, vibration for 3 or 5 min showed significant susceptibility patterns among the three different cultivars; specifically, it was revealed that ‘Tupi’, followed by ‘Am151′ and ‘Ak234′ blackberries, changed more rapidly to different intensities of red color during storage; suggesting that RDR prevalence and progression is more apparent in ‘Tupi’ fruit (Figure 5).

Figure 5.

Portable vibrator system could be used as a tool to evaluate color progression in different blackberry fruit. Bottom graph depicts mean value ± SE of a* color CIELAB parameter in ‘Ak234′, ‘Am151′ and ‘Tupi’ cultivars induced by different vibration (10 Hz and 0.5 g’s) times (0, 1, 3 and 5 min) during 5 d of storage at 1 °C (n = 15). Red line specifies limit between blackish (a* ≤ 2.0) and reddish (a* > 2.0) color. Different letters indicate statistical differences (p < 0.05) using one-way ANOVA and Tukey test.

4. Discussion

The portable system designed can generate vibration frequencies and accelerations comparable to laboratory vibration tables used to induce mechanical damage in berries and other fruits [2,4,14,21]; importantly, various studies using vibration tables have confirmed that 10 Hz and 0.5 g’s vibrations could induce mechanical damage in strawberries and apples [14,21], and RDR in blackberries [2]. This evidence results highlights the value of the postable vibration systems as a tool to assess mechanical damage in blackberry fruit under commercial conditions.

Use of the portable vibration system allowed the assessment of RDR susceptibility and progression among different blackberry cultivars. In terms of susceptibility, herein, it was shown that ‘Tupi’ was more susceptible to RDR than ‘Ak234′ and ‘Am151′ cultivars. This result is in agreement with previous studies showing different manifestation of RDR among cultivars [1]. In terms of RDR progression, we observed that RDR could be occurring with less vibration time (1 min) and 1 d of storage in comparison to previous studies which tested 5 min of vibration [2,3].

Previous studies have explored the notion that fruit storage at cool temperatures (1–5 °C) could be a key factor linked to RDR induction in blackberries [9,11,18,22,23,24]. However, herein, we provide evidence suggesting that fruit vibration could be an important exacerbating factor for RDR development. Specifically, it was shown that fruit vibration followed by cool storage increased considerably the presence of RDR. For example, vibrated blackberries showed between 10 and 100% of RDR after 5 d storage at 1 °C; in contrast, non-vibrated berries exhibited between 5 and 30% of RDR at similar storage conditions. Based on these results, it is possible to consider that higher prevalence (50–98%) of RDR reported in previous studies [9,18,24] could be linked to fruit damage caused by vibration. Studies are in progress to confirm this hypothesis.

5. Conclusions

A portable vibrator system was design and constructed to simulate the mechanical damage produced during the transport that generate RDR in blackberries. Importantly, the present study confirmed that vibrations generated by this system can induce RDR in blackberries under experimental conditions. Moreover, this vibration system could allow for the analyses of RDR progression in different blackberry cultivars and storage conditions; enabling the possibility of ranking blackberries based on RDR susceptibility before and after storage. These results highlight the potential use of the portable vibration system as a tool to objectively evaluate RDR resistance in different breeding nutrition and plant managing programs for blackberry commercial production.

Author Contributions

A.R.F.-S., G.M.N. and E.M.M.-S. conceptualized the study; A.R.F.-S., M.J.F.-G., M.E.C.-A., and D.M.R.-P. performed experiments, analyzed, and validated the data; A.R.F.-S., D.M.R.-P., G.M.N., and E.M.M.-S. interpreted the results and wrote the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the Universidad Autonoma de Queretaro (Projects FOPER-2021-FQU02504, FOPES-2021-FQST2021-17, and FOMIC-2021-FCQ202124).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

We thank to CONACYT-Mexico for the scholarship given to A.R.F.-S. (grant 785569), and to Mexican Institute of Transportation; Coordination of Vehicle Engineering and Structural Integrity, Division of Laboratories of Vehicle and Materials Performance, for the technical support to development the vibration system.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Edgley, M.; Close, D.C.; Measham, P.F. Red drupelet reversion in blackberries: A complex of genetic and environmental factors. Sci. Hortic. 2020, 272, 109555. [Google Scholar] [CrossRef]

- Pérez-Pérez, G.; Fabela-Gallegos, M.; Vázquez-Barrios, M.; Rivera-Pastrana, D.; Palma-Tirado, L.; Mercado-Silva, E.; Escalona, V. Effect of the transport vibration on the generation of the color reversion in blackberry fruit. In Proceedings of the VIII International Postharvest Symposium: Enhancing Supply Chain and Consumer Benefits-Ethical and Technological Issues 1194, Cartagena, Spain, 21–24 June 2016; pp. 1329–1336. [Google Scholar]

- Flores-Sosa, A.R.; Soto-Magaña, D.; Gonzalez-de la Vara, L.E.; Sanchez-Segura, L.; Bah, M.; Rivera-Pastrana, D.M.; Nava, G.M.; Mercado-Silva, E.M. Red drupelet reversion in blackberries caused by mechanical damage is not linked to a reduction in anthocyanin content. Postharvest Biol. Technol. 2021, 180, 111618. [Google Scholar] [CrossRef]

- Dagdelen, C.; Aday, M.S. The effect of simulated vibration frequency on the physico-mechanical and physicochemical properties of peach during transportation. LWT 2021, 137, 110497. [Google Scholar] [CrossRef]

- Wei, X.; Xie, D.; Mao, L.; Xu, C.; Luo, Z.; Xia, M.; Zhao, X.; Han, X.; Lu, W. Excess water loss induced by simulated transport vibration in postharvest kiwifruit. Sci. Hortic. 2019, 250, 113–120. [Google Scholar] [CrossRef]

- Zhou, R.; Su, S.; Yan, L.; Li, Y. Effect of transport vibration levels on mechanical damage and physiological responses of Huanghua pears (Pyrus pyrifolia Nakai, cv. Huanghua). Postharvest Biol. Technol. 2007, 46, 20–28. [Google Scholar] [CrossRef]

- Edgley, M.; Close, D.; Measham, P. Nitrogen application rate and harvest date affect red drupelet reversion and postharvest quality in ‘Ouachita’blackberries. Sci. Hortic. 2019, 256, 108543. [Google Scholar] [CrossRef]

- Edgley, M.; Close, D.C.; Measham, P.F. Effects of climatic conditions during harvest and handling on the postharvest expression of red drupelet reversion in blackberries. Sci. Hortic. 2019, 253, 399–404. [Google Scholar] [CrossRef]

- McCoy, J.E.; Clarke, J.R.; Salgado, A.A.; Jecmen, A. Evaluation of harvest time/temperature and storage temperature on postharvest incidence of red drupelet reversion development and firmness of blackberry (Rubus L. subgenus Rubus Watson). Discov. Stud. J. Dale Bump. Coll. Agric. Food Life Sci. 2016, 17, 59–65. [Google Scholar]

- Yin, M.H. Studies in Blackberry: Development and Implementation of a Phenotyping Protocol for Blackberry Seedling Populations and Impact of Time of Day of Harvest on Red Drupelet Reversion for University of Arkansas Blackberry Genotypes; University of Arkansas: Fayetteville, AR, USA, 2017. [Google Scholar]

- Salgado, A.A.; Clark, J.R. “Crispy” blackberry genotypes: A breeding innovation of the University of Arkansas blackberry breeding program. HortScience 2016, 51, 468–471. [Google Scholar] [CrossRef] [Green Version]

- Kim, M.J.; Lee, M.Y.; Shon, J.C.; Kwon, Y.S.; Liu, K.-H.; Lee, C.H.; Ku, K.-M. Untargeted and targeted metabolomics analyses of blackberries–Understanding postharvest red drupelet disorder. Food Chem. 2019, 300, 125169. [Google Scholar] [CrossRef]

- Fischer, D.; Craig, W.; Watada, A.; Douglas, W.; Ashby, B. Simulated in-transit vibration damage to packaged fresh market grapes and strawberries. Appl. Eng. Agric. 1992, 8, 363–366. [Google Scholar] [CrossRef] [Green Version]

- La Scalia, G.; Aiello, G.; Miceli, A.; Nasca, A.; Alfonzo, A.; Settanni, L. Effect of Vibration on the Quality of Strawberry Fruits Caused by Simulated Transport. J. Food Process Eng. 2016, 39, 140–156. [Google Scholar] [CrossRef]

- La Scalia, G.; Enea, M.; Micale, R.; Corona, O.; Settanni, L. Damage to strawberries caused by simulated transport. Int. J. Biol. Biomol. Agric. Food Biotechnol. Eng. 2015, 9, 480–485. [Google Scholar]

- Khodaei, M.; Seiiedlou, S.; Sadeghi, M. The evaluation of vibration damage in fresh apricots during simulated transport. Res. Agric. Eng. 2019, 65, 112–122. [Google Scholar] [CrossRef]

- Walkowiak-Tomczak, D.; Idaszewska, N.; Łysiak, G.P.; Bieńczak, K. The effect of mechanical vibration during transport under model conditions on the shelf-life, quality and physico-chemical parameters of four apple cultivars. Agronomy 2021, 11, 81. [Google Scholar] [CrossRef]

- Lawrence, B.; Melgar, J.C. Harvest, handling, and storage recommendations for improving postharvest quality of blackberry cultivars. HortTechnology 2018, 28, 578–583. [Google Scholar] [CrossRef]

- Edgley, M.; Close, D.C.; Measham, P.F.; Nichols, D.S. Physiochemistry of blackberries (Rubus L. subgenus Rubus Watson) affected by red drupelet reversion. Postharvest Biol. Technol. 2019, 153, 183–190. [Google Scholar] [CrossRef]

- McGuire, R.G. Reporting of objective color measurements. HortScience 1992, 27, 1254–1255. [Google Scholar] [CrossRef] [Green Version]

- Acıcan, T.; Alibaş, K.; Özelkök, I. Mechanical damage to apples during transport in wooden crates. Biosyst. Eng. 2007, 96, 239–248. [Google Scholar] [CrossRef]

- Segantini, D.M.; Threlfall, R.; Clark, J.R.; Brownmiller, C.R.; Howard, L.R.; Lawless, L.J. Changes in fresh-market and sensory attributes of blackberry genotypes after postharvest storage. J. Berry Res. 2017, 7, 129–145. [Google Scholar] [CrossRef]

- Armour, M.E.; Worthington, M.; Clark, J.R.; Threlfall, R.T.; Howard, L. Effect of Harvest Time and Fruit Firmness on Red Drupelet Reversion in Blackberry. HortScience 2021, 56, 889–896. [Google Scholar] [CrossRef]

- Worthington, M.; Clark, J.; Threlfall, R.; Sebesta, B. Evaluation of Red Drupelet Reversion in Blackberries Using High-Throughput Digital Image Analysis. Available online: file:///C:/Users/MDPI/Downloads/2017R-02.pdf (accessed on 6 July 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).