Controlled Atmosphere Storage Alleviates Hass Avocado Black Spot Disorder

Abstract

:1. Introduction

2. Materials and Methods

2.1. Selection of Orchards and Plant Material

2.2. Postharvest Treatments

2.3. Quality Parameters

2.4. Analysis of Epicarp Non-Enzymatic Defense System

Total Phenolic Compounds and Antioxidant Capacity

2.5. Analysis of Epicarp Enzymatic Defense System

2.5.1. Enzyme Extraction

2.5.2. Catalase (CAT) Activity

2.5.3. Polyphenol Oxidase (PPO) Activity

2.5.4. Superoxide Dismutase (SOD) Activity

2.5.5. Peroxidase (POD) Activity

2.5.6. Phenylalanine Ammonia Lyase (PAL) Activity

2.6. Statistical Analysis

3. Results and Discussion

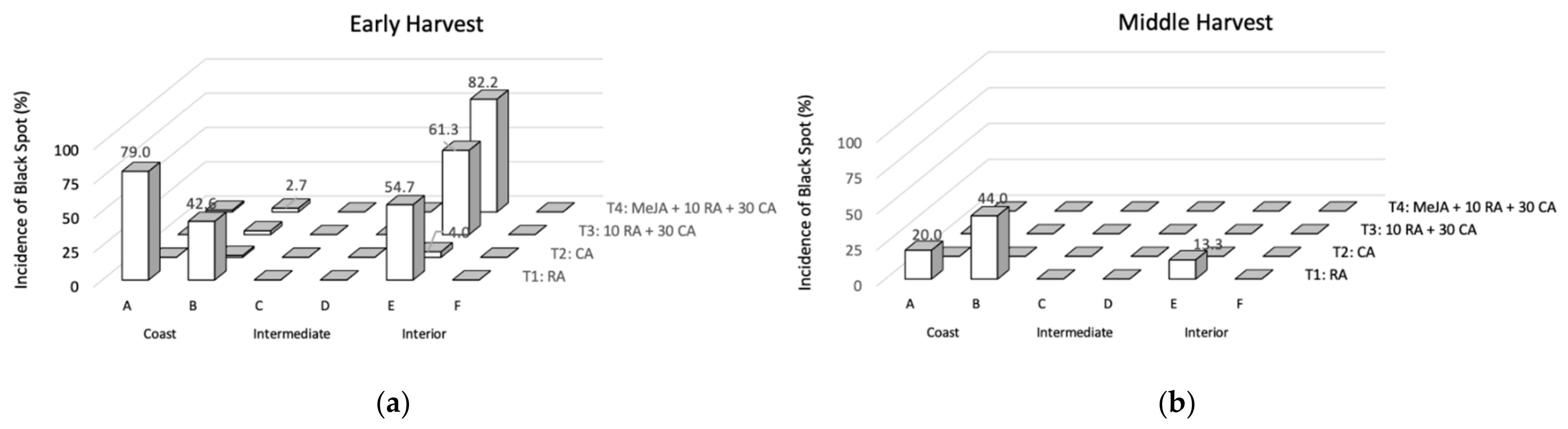

3.1. Incidence of Black Spot

3.2. Quality Parameters

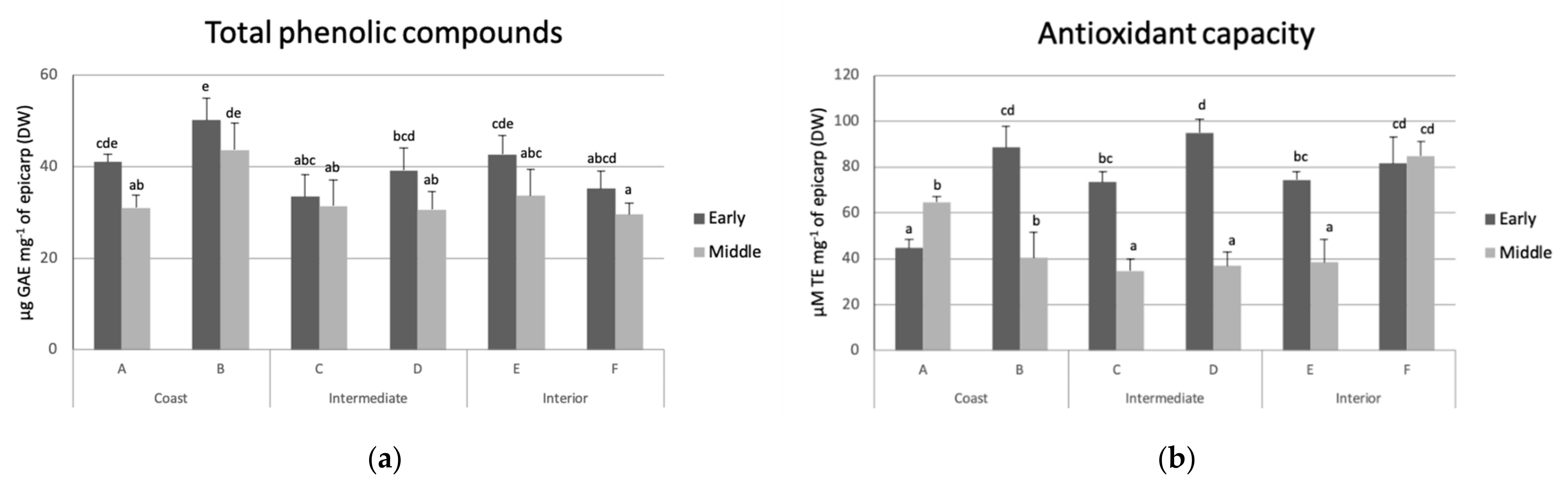

3.3. Total Phenolic Compounds (TPC) and Antioxidant Capacity (AC)

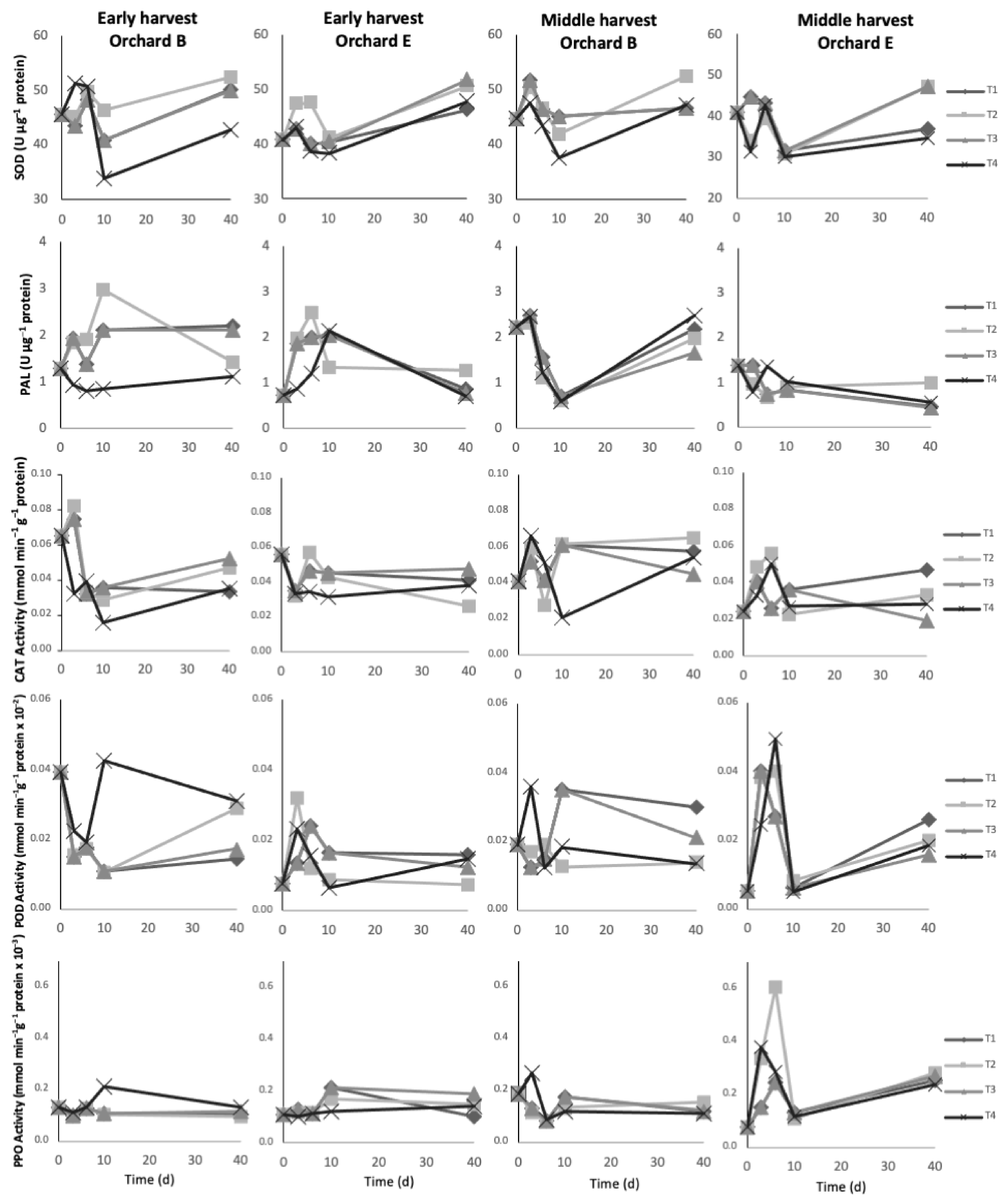

3.4. Analysis of Epicarp Enzymatic Defense System

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chil, I.; Molina, S.; Ortiz, L.; Dutok, C.; Souto, R. Estado del Arte de la especie Persea americana Mill (aguacate). Rev. Amaz. Investig. 2019, 8, 73–86. [Google Scholar]

- Melgar, B.; Dias, M.J.; Ciric, A.; Sokovic, M.; Garcia-Castello, E.; Rodriguez-Lopez, A.; Barros, L.; Ferreira, I. Bioactive characterization of Persea americana Mill. by-products: A rich source of inherent antioxidants. Ind. Crops Prod. 2018, 111, 212–218. [Google Scholar] [CrossRef] [Green Version]

- FAOSTAT. Food and Agriculture Statistical Division. Crops and Livestock Products. 2020. Available online: https://www.fao.org/faostat/en/#data/QCL/visualize (accessed on 5 January 2022).

- ODEPA. Oficina de Estudios y Políticas Agrarias. Ministerio de Agricultura. La palta Chilena en los Mercados Internacionales. 2018. Available online: https://www.odepa.gob.cl/wp-content/uploads/2018/12/palta2018rev1.pdf (accessed on 5 January 2022).

- Uarrota, V.; Hernandez, I.; Ponce, E.; Vidal, J.; Fuentealba, C.; Defilippi, B.; Lindh, V.; Zulueta, C.; Chirinos, R.; Campos, D.; et al. Unravelling factors associated with ‘blackspot’ disorder in stored Hass avocado (Persea americana Mill) fruit. J. Hortic. Sci. 2020, 95, 804–815. [Google Scholar] [CrossRef]

- Lindh, V.; Uarrota, V.; Zulueta, C.; Alvaro, J.E.; Valdenegro, M.; Cuneo, I.F.; Mery, D.; Pedreschi, R. Image analysis reveals that lenticel damage does not result in black spot development but enhances dehydration in Persea americana Mill. cv. Hass during prolonged storage. Agronomy 2021, 11, 1699. [Google Scholar] [CrossRef]

- Hernández, I.; Uarrota, V.; Paredes, D.; Fuentealba, C.; Defilippi, B.G.; Campos-Vargas, R.; Meneses, C.; Hertog, M.; Pedreschi, R. Can metabolites at harvest be used as physiological markers for modelling the softening behaviour of Chilean “Hass” avocados destined to local and distant markets? Postharvest Biol. Technol. 2021, 174, 111457. [Google Scholar] [CrossRef]

- Glowacz, M.; Roets, N.; Sivakumar, D. Control of anthracnose disease via increased activity of defence related enzymes in ‘Hass’ avocado fruit treated with methyl jasmonate and methyl salicylate. Food Chem. 2017, 234, 163–167. [Google Scholar] [CrossRef]

- Silvankalyani, V.; Feygenberg, O.; Maorer, D.; Zaaroor, M.; Fallik, E.; Alkan, N. Combined treatments reduce chilling injury and maintain fruit quality in avocado fruit during cold quarantine. PLoS ONE 2015, 10, e0140522. [Google Scholar]

- Munhuweyi, K.; Mpai, S.; Sivakumar, D. Extension of avocado fruit postharvest quality using non-chemical treatments. Agronomy 2020, 10, 212. [Google Scholar] [CrossRef] [Green Version]

- Ochoa-Ascencio, S.; Hertog, M.; Nicolaï, B. Modelling the transient effect of 1-MCP on ‘Hass’ avocado softening: A Mexican comparative study. Postharvest Biol. Technol. 2009, 51, 62–72. [Google Scholar] [CrossRef]

- Saavedra, J.; Córdova, A.; Navarro, R.; Díaz-Calderón, P.; Fuentealba, C.; Astudillo-Castro, C.; Toledo, L.; Enrione, J.; Galvez, L. Industrial avocado waste: Functional compounds preservation by convective drying process. J. Food Eng. 2017, 198, 81–90. [Google Scholar] [CrossRef]

- Bradford, M. A Rapid and Sensitive Method for the Quantitation of Microgram Quantities of Protein Utilizing the Principle of Protein-Dye Binding. Anal. Biochem. 1976, 72, 248–254. [Google Scholar]

- Bi, X.; Hemar, Y.; Balaban, M.; Liao, X. The effect of ultrasound on particle size, color, viscosity and polyphenol oxidase activity of diluted avocado puree. Ultrason. Sonochem. 2015, 27, 567–575. [Google Scholar] [CrossRef]

- Olivares, D.; Alvarez, E.; Véliz, D.; García-Rojas, M.; Díaz, C.; Defilippi, B. Effects of 1-methylcyclopropane and controlled atmosphere on ethylene synthesis and quality attributes of avocado cvs Edranol and Fuerte. J. Food Qual. 2020, 2020, 5075218. [Google Scholar] [CrossRef]

- López, J.; Valverde, F.; Mejía, S.; López, G.; Vega, M. Effect of controlled atmosphere storage on the postharvest and nutritional quality of tomato fruit. Rev. Chapingo Ser. Hortic. 2011, 17, 115–128. [Google Scholar] [CrossRef]

- Medina-Carrillo, R.; Salazar-García, S.; Bonilla-Cárdenas, J.; Herrera-González, J.; Ibarra-Estrada, M.; Alvarez-Bravo, A. Secondary metabolites and lignin in “Hass” avocado fruit skin during fruit development in three producing regions. HortScience 2017, 52, 852–858. [Google Scholar] [CrossRef]

- Bower, J.; Cutting, J. Avocado fruit development and ripening physiology. Hortic. Rev. 1988, 10, 229–271. [Google Scholar]

- Silveira, A. Fisiología y Bioquímica de los Productos MPF. V Congreso Iberoamericano de Tecnología Postcosecha y Agroexportaciones, Cartagena, España, 2007th ed.; Universidad Politécnica de Cartagena: Cartagena, Spain, 1655. [Google Scholar]

- Goulao, L.; Oliveira, C. Cell wall modifications during fruit ripening. When a fruit is not the fruit. Trends Food Sci. Technol. 2008, 19, 4–25. [Google Scholar] [CrossRef] [Green Version]

- Escobar, J.; Rodriguez, P.; Cortes, M.; Correa, G. Influence of dry matter as a harvest index and cold storage time on cv. Hass avocado quality produced in high tropic region. Inf. Technol. 2019, 30, 199–210. [Google Scholar]

- Saxena, A.; Saxena, T.M.; Raju, P.S.; Bawa, A.S. Effect of controlled atmosphere storage and chitosan coating on quality of fresh-cut jackfruit bulbs. Food Bioproc. Technol. 2013, 6, 2182–2189. [Google Scholar]

- Chirinos, R.; Campos, D.; Martínez, S.; Llanos, S.; Betalleluz-Pallardel, I.; García-Ríos, D.; Pedreschi, R. The effect of hydrothermal treatment on metabolite composition of Hass avocados stored in a controlled atmosphere. Plants 2021, 10, 2427. [Google Scholar] [CrossRef]

- Fukai, T.; Ushio-Fukai, M. Superoxide dismutases: Role in redox signaling, vascular function and diseases. Antioxid. Redox Signal. 2011, 15, 1583–1606. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.; Wu, C.; Wang, G.; He, J.; Zhu, S. Transcriptomic analysis reveals a role of phenylpropanoid pathway in the enhancement of chilling tolerance by pre-storage cold acclimation in cucumber fruit. Sci. Hortic. 2021, 288, 110282. [Google Scholar] [CrossRef]

- Sanchez-Ballesta, M.T.; Romero, I.; Jiménez, J.B.; Orea, J.M.; González-Ureña, A.; Escribano, M.I.; Merodio, C. Involvement of the phenylpropanoid pathway in the response of table grapes to low temperature and high CO2 levels. Postharvest Biol. Technol. 2007, 46, 29–35. [Google Scholar] [CrossRef] [Green Version]

- Christopoulos, M.V.; Tsantili, E. Participation of phenylalanine ammonia-lyase (PAL) in increased phenolic compounds in fresh cold stressed walnut (Juglans regia L.) kernels. Postharvest Biol. Technol. 2015, 104, 17–25. [Google Scholar] [CrossRef]

- Tesfay, S.; Bertling, I.; Bower, J. Antioxidant levels in various tissues during the maturation of Hass avocado (Persea americana Mill.). J. Hortic. Sci. Biotechnol. 2010, 85, 106–112. [Google Scholar] [CrossRef]

| Harvest | Agroclimatic Zone | Orchard | Dry Matter (%) Epicarp | Dry Matter (%) Mesocarp | Firmness (N) |

|---|---|---|---|---|---|

| Early | Coast | A | 22.1 ± 2.1 ab | 23.3 ± 3.1 a,A | 241 ± 14 b,A |

| B | 21.1 ± 1.2 a | 23.9 ± 2.4 a | 241 ± 28 b | ||

| Intermediate | C | 26.1 ± 1.2 c | 27.9 ± 2.2 b | 286 ± 9.3 c,B | |

| D | 25.9 ± 2.8 c | 26.6 ± 2.7 b | 249 ± 11 b | ||

| Interior | E | 22.4 ± 2.1 a | 22.3 ± 2.8 a,A | 241 ± 14 a,B | |

| F | 23.4 ± 1.2 b | 23.5 ± 1.7 a | 239 ± 12 b | ||

| Middle | Coast | A | 21.9 ± 1.0 a | 26.5 ± 1.8 B | 221 ± 9.4 a,B |

| B | 21.8 ± 1.5 a | 25.6 ± 2.8 | 248 ± 21 cd | ||

| Intermediate | C | 24.9 ± 1.5 b | 26.0 ± 1.9 | 229 ± 8.1 ab,A | |

| D | 25.6 ± 1.7 b | 24.9 ± 1.4 | 251 ± 11 d | ||

| Interior | E | 21.9 ± 1.2 a | 24.7 ± 2.4 B | 238 ± 9.4 bc,A | |

| F | 24.3 ± 1.1 b | 25.6 ± 2.5 | 249 ± 12 cd |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fuentealba, C.; Vidal, J.; Zulueta, C.; Ponce, E.; Uarrota, V.; Defilippi, B.G.; Pedreschi, R. Controlled Atmosphere Storage Alleviates Hass Avocado Black Spot Disorder. Horticulturae 2022, 8, 369. https://doi.org/10.3390/horticulturae8050369

Fuentealba C, Vidal J, Zulueta C, Ponce E, Uarrota V, Defilippi BG, Pedreschi R. Controlled Atmosphere Storage Alleviates Hass Avocado Black Spot Disorder. Horticulturae. 2022; 8(5):369. https://doi.org/10.3390/horticulturae8050369

Chicago/Turabian StyleFuentealba, Claudia, Juan Vidal, Claudio Zulueta, Excequel Ponce, Virgilio Uarrota, Bruno G. Defilippi, and Romina Pedreschi. 2022. "Controlled Atmosphere Storage Alleviates Hass Avocado Black Spot Disorder" Horticulturae 8, no. 5: 369. https://doi.org/10.3390/horticulturae8050369

APA StyleFuentealba, C., Vidal, J., Zulueta, C., Ponce, E., Uarrota, V., Defilippi, B. G., & Pedreschi, R. (2022). Controlled Atmosphere Storage Alleviates Hass Avocado Black Spot Disorder. Horticulturae, 8(5), 369. https://doi.org/10.3390/horticulturae8050369