Dry Matter, Starch Content, Reducing Sugar, Color and Crispiness Are Key Parameters of Potatoes Required for Chip Processing

Abstract

1. Introduction

2. Materials and Methods

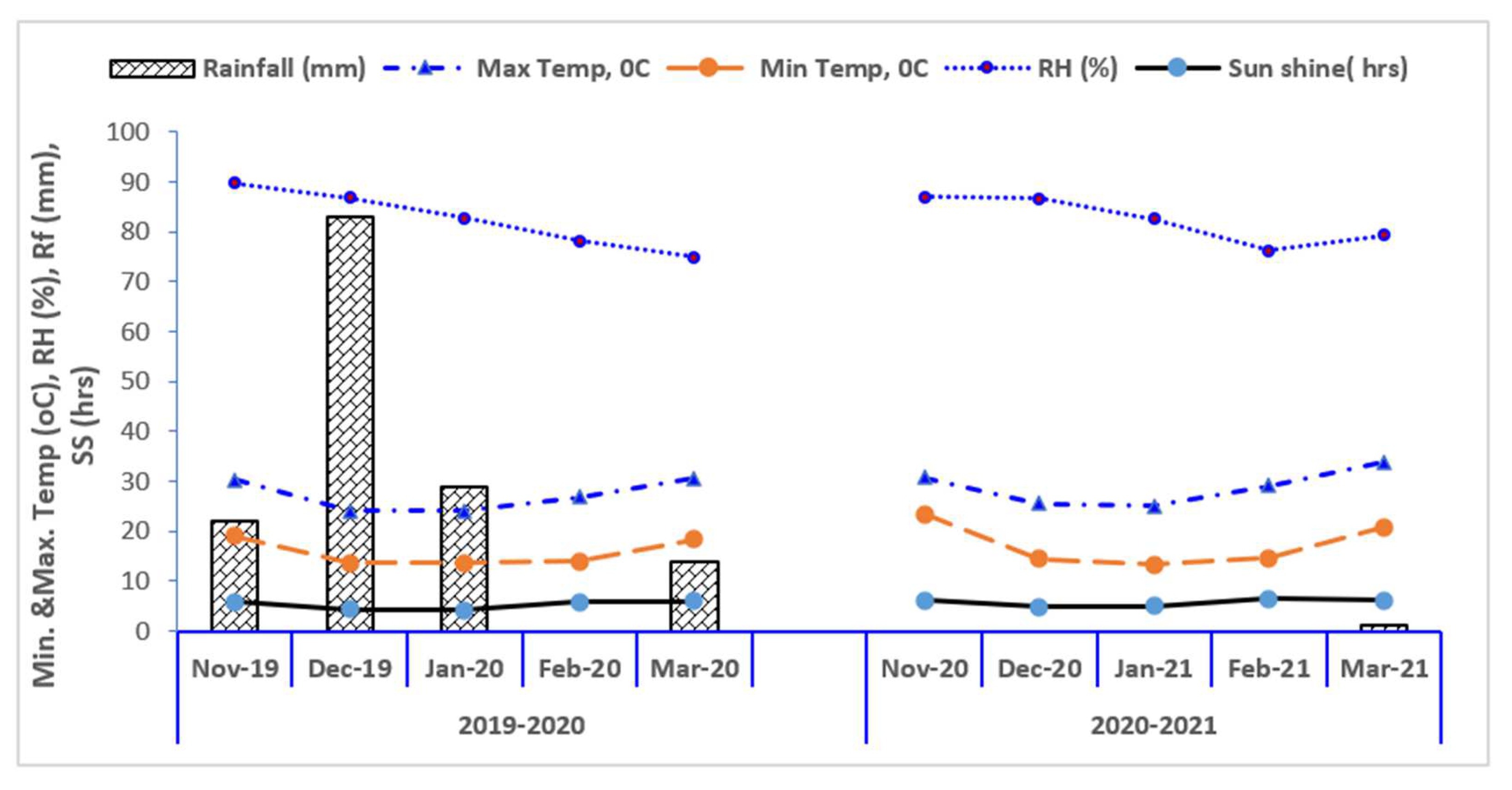

2.1. Location and Agro-Climatic Situations

2.2. Experimental Materials and Design

2.3. Experimental Procedures and Management

2.4. Data Collection and Parameters Estimation

2.4.1. Specific Gravity

2.4.2. Determination of Dry Matter Content

2.4.3. Extraction of Sugar and Starch

2.4.4. Reducing Sugar Content Determination

2.4.5. Starch Content Determination

2.4.6. Blanching and Potato Chip Preparation

2.4.7. Assessment of Potato Chips Color

2.4.8. Measurement of Chips Crispiness

2.4.9. Sensory Evaluation of Chips

2.5. Statistical Data Analysis

3. Results and Discussion

3.1. Specific Gravity and Dry Matter Content

3.2. Starch Content of Different Processing Varieties

3.3. Reducing Sugar Content of Different Processing Varieties

3.4. Chips Crispiness and Color

3.5. Sensory Evaluation of Chips

3.6. Correlations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- De Haan, S.; Rodriguez, F. Advances in Potato Chemistry and Technology; Academic Press: Cambridge, MA, USA, 2016; pp. 1–32. [Google Scholar] [CrossRef]

- Scott, G.J.; Rosegrant, M.W.; Ringler, C. Global Projections for Root and Tuber Crops to the Year 2020. Food Policy 2000, 25, 561–597. [Google Scholar] [CrossRef]

- Thiele, G.; Theisen, K.; Bonierbale, M.; Walker, T. Targeting the poor and hungry with potato science. Potato J. 2010, 37, 75–86. [Google Scholar]

- Galdón, B.R.; Rodríguez, L.H.; Mesa, D.R.; León, H.L.; Pérez, N.L.; Rodríguez Rodríguez, E.M.; Romero, C.D. Differentiation of Potato Cultivars Experimentally Cultivated Based on Their Chemical Composition and by Applying Linear Discriminant Analysis. Food Chem. 2012, 133, 1241–1248. [Google Scholar] [CrossRef]

- Gibson, S.; Kurilich, A.C. The Nutritional Value of Potatoes and Potato Products in the UK Diet. Nutr. Bull. 2013, 38, 389–399. [Google Scholar] [CrossRef]

- Navarre, D.A.; Pillai, S.S.; Shakya, R.; Holden, M.J. HPLC Profiling of Phenolics in Diverse Potato Genotypes. Food Chem. 2011, 127, 34–41. [Google Scholar] [CrossRef]

- Zarzecka, K.; Gugala, M. The effect of herbicides and soil tillage systems on the content of polyphenols in potato tubers. Pol. J. Environ. Stud. 2011, 20, 513–517. [Google Scholar]

- Liu, R.H. Health-Promoting Components of Fruits and Vegetables in the Diet. Adv. Nutr. 2013, 4, 384S–392S. [Google Scholar] [CrossRef]

- FAOSTAT. Food and Agriculture Data; Food and Agricultural Organization of United Nations: Rome, Italy, 2020; Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 28 December 2021).

- Nawaz, A.; Danish, A.; Waseem, A.S.; Shahbaz, H.M.; Khalifa, I.; Ahmed, A.; Irshad, S.; Ahmad, S.; Ahmed, W. Evaluation and storage stability of potato chips made from different varieties of potatoes cultivated in Pakistan. J. Food Process. Preserv. 2021, 45, e15437. [Google Scholar] [CrossRef]

- Abong, G.O.; Okoth, M.W.; Karuri, E.G.; Kabira, J.N.; Mathooko, F.M. Evaluation of selected Kenyan potato cultivars for processing into french fries. J. Anim. Plant Sci. 2009, 2, 141–147. [Google Scholar]

- Das, S.; Mitra, B.; Saha, A.; Mandal, S.; Paul, P.K.; El-Sharnouby, M.; Hassan, M.M.; Maitra, S.; Hossain, A. Evaluation of Quality Parameters of Seven Processing Type Potato (Solanum tuberosum L.) Cultivars in the Eastern Sub-Himalayan Plains. Foods 2021, 10, 1138. [Google Scholar] [CrossRef]

- BARI (Bangladesh Agricultural Research Institute). Developed Crop Varieties of Potato. 2021. Available online: https://baritechnology.org/m/categories/index. (accessed on 28 December 2021).

- Wiltshire, J.J.J.; Cobb, A.H.A. Review of the Physiology of Potato Tuber Dormancy. Ann. Appl. Biol. 1996, 129, 553–569. [Google Scholar] [CrossRef]

- Pandey, S.K.; Singh, S.V.; Marwaha, R.S.; Pattanayak, D. Indian potato processing varieties: Their impact and future priorities. Potato J. 2009, 36, 95–114. [Google Scholar]

- Kumar, D.; Singh, B.P.; Kumar, P. An Overview of the Factors Affecting Sugar Content of Potatoes. Ann. Appl. Biol. 2004, 145, 247–256. [Google Scholar] [CrossRef]

- Ahmmed, S.; Jahiruddin, M.; Razia., M.; Begum., R.A.; Biswas, J.C.; Rahman, A.S.M.M.; Ali, M.M.; Islam, M.K.M.S.; Hossain, M.M.; Gani, M.N.; et al. Fertilizer Recommendation Guide; Bangladesh Agricultural Research Council (BARC): Dhaka, Bangladesh, 2018. [Google Scholar]

- Kundu, B.C.; Islam, M.S.; Kawochar, M.A.; Rashid, M.H. Potato (Solanum tuberosum L.) Variety Development through Hybridization: A New Era in Bangladesh. Bangladesh J. Agric. Res. 2013, 38, 637–646. [Google Scholar] [CrossRef]

- Kleinkopf, G.E.; Westermann, D.T.; Wille, M.J.; Kleinschmidt, G.D. Specific Gravity of Russet Burbank Potatoes. Am. Potato J. 1987, 64, 579–587. [Google Scholar] [CrossRef]

- Mostofa, M.; Roy, T.S.; Chakraborty, R.; Modak, S.; Kundu, P.K.; Zaman, M.S.; Rahman, M.; Shamsuzzoha, M. Effect of vermicompost and tuber size on processing quality of potato during ambient storage condition. Int. J. Plant Soil Sci. 2019, 26, 1–18. [Google Scholar] [CrossRef][Green Version]

- Nelson, N. A photometric adaptation of the Somogyi method for the determination of glucose. J. Biol. Chem. 1944, 153, 375–380. [Google Scholar] [CrossRef]

- Liu, E.Z.; Scanlon, M.G. Modeling the Effect of Blanching Conditions on the Texture of Potato Strips. J. Food Eng. 2007, 81, 292–297. [Google Scholar] [CrossRef]

- Mariotti, M.; Cortés, P.; Fromberg, A.; Bysted, A.; Pedreschi, F.; Granby, K. Heat Toxicant Contaminant Mitigation in Potato Chips. LWT-Food Sci. Technol. 2015, 60, 860–866. [Google Scholar] [CrossRef]

- Kaymak, F.; Kincal, N.S. Apparent Diffusivities of Reducing Sugars in Potato Strips Blanched in Water. Int. J. Food Sci. Technol. 1994, 29, 63–70. [Google Scholar] [CrossRef]

- Kita, A.; Bąkowska-Barczak, A.; Lisińska, G.; Hamouz, K.; Kułakowska, K. Antioxidant Activity and Quality of Red and Purple Flesh Potato Chips. LWT-Food Sci. Technol. 2015, 62, 525–531. [Google Scholar] [CrossRef]

- Dervisi, P.; Lamb, J.; Zabetakis, I. High Pressure Processing in Jam Manufacture: Effects on Textural and Colour Properties. Food Chem. 2001, 73, 85–91. [Google Scholar] [CrossRef]

- Ezekiel, R.; Singh, B.; Kumar, D. A reference chart for potato chip colour for use in India. Potato J. 2003, 30, 259–265. [Google Scholar]

- Joshi, V.K. Sensory Science: Principles and Application in Food Evaluation; Agrotech-Publishing Academy: Udaipur, India, 2006; p. 527. [Google Scholar]

- R Core Team. R. A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2013; Available online: http://www.R-project.org/ (accessed on 20 December 2021).

- Marwaha, R.S.; Pandey, S.K.; Singh, S.V.; Khurana, S.M.P. Processing and nutritional qualities of Indian and exotic potato cultivars as influenced by harvest date, tuber curing, pre-storage holding period, storage and reconditioning under short days. Adv. Hortic. Sci. 2005, 19, 130–140. [Google Scholar]

- Wayumba, B.O.; Choi, H.S.; Seok, L.Y. Selection and Evaluation of 21 Potato (Solanum tuberosum) Breeding Clones for Cold Chip Processing. Foods 2019, 8, 98. [Google Scholar] [CrossRef] [PubMed]

- Uppal, D.S. Quality traits and chipping performance of newly released potato varieties. J. Indian Potato Assoc. 1999, 26, 139–142. [Google Scholar]

- Flis, B.; Tatarowska, B.; Milczarek, D.; Plich, J. Effect of location on starch content and tuber texture characteristics in potato breeding lines and cultivars. Acta Agric. Scand. Sect. B Soil Plant Sci. 2017, 67, 453–461. [Google Scholar] [CrossRef]

- Freitas, S.T.; Pereira, E.I.P.; Gomez, A.C.S.; Brackmann, A.; Nicoloco, F.; Bisognin, D.A. Processing quality of potato tubers produced during autumn and spring and stored at different temperatures. Hortic. Bras. 2012, 30, 91–98. [Google Scholar] [CrossRef]

- Vaitkevičienė, N.; Jarienė, E.; Kulaitienė, J.; Levickienė, D. The Physico-Chemical and Sensory Characteristics of Coloured-Flesh Potato Chips: Influence of Cultivar, Slice Thickness and Frying Temperature. Appl. Sci. 2022, 12, 1211. [Google Scholar] [CrossRef]

- Sharkar, M.; Ahmed, J.; Hoque, M.; Mohi-Ud-Din, M. Influence of Harvesting Date on Chemical Maturity for Processing Quality of Potatoes. Ann. Bangladesh Agric. 2019, 23, 89–103. [Google Scholar] [CrossRef]

- Meena, R.; Manivel, P.; Bharadwaj, V.; Gopal, J. Screening potato wild species for low accumulation of reducing sugars during cold storage. Electron. J. Plant Breed. 2009, 56, 89–92. [Google Scholar]

- Manivel, P.; Pandey, S.K.; Singh, S.V.; Kumar, D. Pattern of chip colour segregation in some crosses of potato. Potato J. 2007, 34, 49–50. [Google Scholar]

- Kita, A. The Influence of Potato Chemical Composition on Crisp Texture. Food Chem. 2002, 76, 173–179. [Google Scholar] [CrossRef]

- Abbas, G.; Hafiz, I.A.; Abbasi, N.A.; Hussain, A. Determination of processing and nutritional quality attributes of potato genotypes in Pakistan. Pak. J. Bot. 2012, 44, 201–208. [Google Scholar]

- Ooko, G.A.; Kabira, J.N. Suitability of three newly released Kenyan potato varieties for processing into crisps and French fries. Afr. J. Food Agric. Nutr. Dev. 2011, 11. [Google Scholar] [CrossRef]

- Rahman, M.M.; Roy, T.S.; Chowdhury, I.F.; Nishizawa, T.; Afroj, M. Colour and crispness assessment of forty potato varieties for processing industry of Bangladesh. Potato J. 2016, 43, 78–85. [Google Scholar]

- Kaur, A.; Singh, N.; Ezekiel, R. Quality parameters of potato chips from different potato cultivars: Effect of prior storage and frying temperatures. Int. J. Food Prop. 2008, 11, 791–803. [Google Scholar] [CrossRef]

- Salvador, A.; Varela, P.; Sanz, T.; Fiszman, S.M. Understanding potato chips crispy texture by simultaneous fracture and acoustic measurements, and sensory analysis. LWT Food Sci. Technol. 2009, 42, 763–767. [Google Scholar] [CrossRef]

- Kraus, A. Factors Influencing the Decisions to Buy and Consume Functional Food. Br. Food J. 2015, 117, 1622–1636. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, Y. Sensory Profiles and Hedonic Perception of Commercial Potato Chips under Blind and Informed Consumer Tests. Emir. J. Food Agric. 2020, 32, 543–549. [Google Scholar] [CrossRef]

- Killick, R.J.; Simmonds, N.W. Specific gravity of potato tubers as a character showing small genotype-environment interactions. Heredity 1974, 32, 109–112. [Google Scholar] [CrossRef]

- Grewal, S.S.; Uppal, D.S. Effect of dry matter and specific gravity on yield, color and oil content of potato chips. Indian Food Pack. 1989, 43, 17–20. [Google Scholar]

| Soil Texture | pH | OM (%) | Total N (%) | K (meq100g–1 Soil) | P | S | Z | B |

|---|---|---|---|---|---|---|---|---|

| ppm | ||||||||

| Silty clay | 6.3 | 0.62 | 0.07 | 0.11 | 20 | 10 | 0.70 | 0.2 |

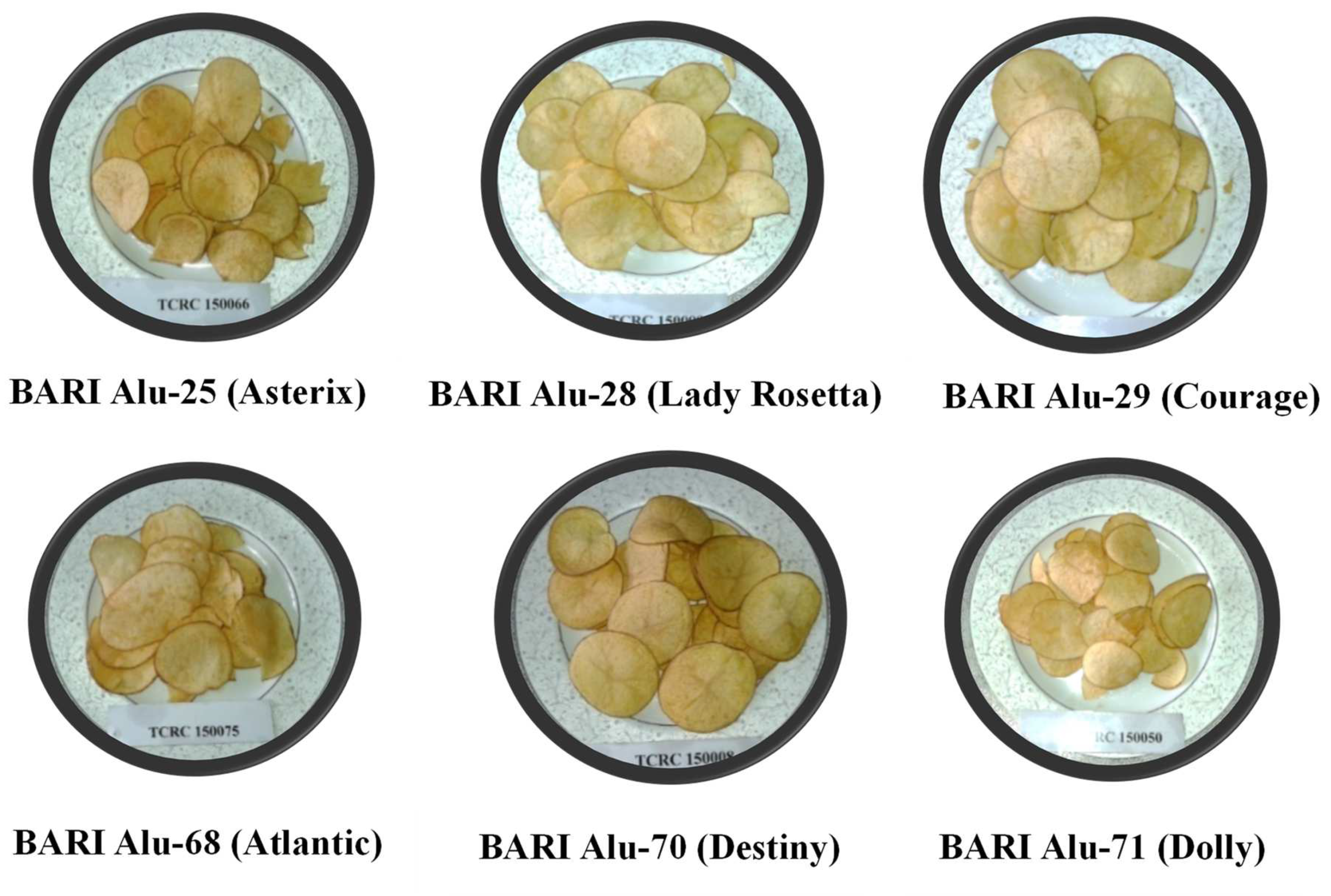

| Variety Name | Origin | Shape | Size | Skin Color | Smoothness of Skin | Flesh Color | Eye Base Color | Eye Depth | Eye Distribution | Image |

|---|---|---|---|---|---|---|---|---|---|---|

| BARI Alu-25 (Asterix) | The Netherlands | Oval to long oval | Medium to large | Red | Smooth | Light yellow | Red | Shallow | Even |  |

| BARI Alu-28 (Lady Rosetta) | The Netherlands | Round to oval | Medium | Red | Rough | Light yellow | Red | Medium | Predominant |  |

| BARI Alu-29 (Courage) | The Netherlands | Round to oval | Medium | Red | Rough | Cream | Red | Deep | Predominant |  |

| BARI Alu-68 (Atlantic) | America | Round (compressed) | Medium | Yellow | Medium | White | Yellow | Medium | Predominant |  |

| BARI Alu-70 (Destiny) | The Netherlands | Round to short oval | Medium | Yellow | Medium | Yellow | Red | Medium | Predominant |  |

| BARI Alu-71 (Dolly) | France | Round (compressed) | Medium | Red | Rough | Light yellow | Red | Medium | Predominant |  |

| Varieties | Specific Gravity | Dry Matter (%) (Oven Dry Method) | Dry Matter (%) (Digital Hydrometer Method) | Starch (mg/g Fresh wt.) | Reducing Sugar (mg/g Fresh wt.) | Crispiness (mm) |

|---|---|---|---|---|---|---|

| BARI Alu-25 (Asterix) | 1.074 bc | 19.88 d | 18.72 b | 21.15 c | 0.724 b | 0.880 b |

| BARI Alu-28 (Lady Rosetta) | 1.085 a | 22.61 a | 21.42 a | 26.06 a | 0.591 c | 0.723 c |

| BARI Alu-29 (Courage) | 1.084 a | 21.72 ab | 20.29 ab | 24.66 b | 0.619 c | 0.731 c |

| BARI Alu-68 (Atlantic) | 1.079 ab | 20.89 bc | 20.73 a | 21.36 c | 0.787 ab | 0.947 a |

| BARI Alu-70 (Destiny) | 1.068 c | 20.63 cd | 19.04 b | 21.47 c | 0.809 a | 0.748 c |

| BARI Alu-71 (Dolly) | 1.083 a | 21.38 bc | 21.11 a | 22.26 c | 0.645 c | 0.902 ab |

| CV (%) | 0.396 | 2.495 | 4.277 | 2.760 | 5.994 | 4.238 |

| Significance Level | ** | ** | * | *** | *** | *** |

| Varieties | Chips Color | |||

|---|---|---|---|---|

| Lightness (L*) | Chroma (C*) | Hue Angle (H*) | Sensory Evaluation Score | |

| BARI Alu-25 (Asterix) | 60.77 ± 2.00 c | 20.02 ± 0.40 b | 83.38 ± 1.28 bc | 3.27 ± 0.05 b |

| BARI Alu-28 (Lady Rosetta) | 71.77 ± 3.16 a | 28.96 ± 0.66 a | 88.62 ± 0.98 a | 1.38 ± 0.07 e |

| BARI Alu-29 (Courage) | 70.88 ± 3.71 a | 27.24 ± 0.56 a | 87.50 ± 0.65 a | 1.82 ± 0.07 d |

| BARI Alu-68 (Atlantic) | 59.59 ± 3.17 c | 19.07 ± 1.07 b | 82.17 ± 3.58 bc | 3.17 ± 0.15 b |

| BARI Alu-70 (Destiny) | 65.29 ± 2.65 b | 27.21 ± 1.78 a | 79.68 ± 2.44 c | 3.82 ± 0.10 a |

| BARI Alu-71 (Dolly) | 69.35 ± 1.37 a | 28.69 ± 1.94 a | 85.95 ± 1.70 ab | 2.83 ± 0.11 c |

| CV (%) | 3.276 | 4.647 | 2.621 | 3.679 |

| Significance Level | *** | *** | ** | *** |

| Varieties | Sensory Attributes | |||

|---|---|---|---|---|

| Appearance | Taste | Aroma | Overall Acceptability | |

| BARI Alu-25 (Asterix) | 7.07 ± 0.25 cd | 8.77 ± 0.21 ab | 7.23 ± 0.25 a | 7.97 ± 0.15 ab |

| BARI Alu-28 (Lady Rosetta) | 8.67 ± 0.12 a | 8.97 ± 0.06 a | 7.47 ± 0.32 a | 8.40 ± 0.40 a |

| BARI Alu-29 (Courage) | 8.70 ± 0.10 a | 8.83 ± 0.15 ab | 7.33 ± 0.29 a | 8.30 ± 0.26 a |

| BARI Alu-68 (Atlantic) | 8.27 ± 0.15 b | 7.87 ± 0.21 c | 7.20 ± 0.30 ab | 7.87 ± 0.38 ab |

| BARI Alu-70 (Destiny) | 7.37 ± 0.15 c | 8.60 ± 0.26 b | 6.90 ± 0.30 b | 7.50 ± 0.30 b |

| BARI Alu-71 (Dolly) | 6.73 ± 0.32 d | 8.63 ± 0.15 ab | 7.37 ± 0.21 a | 7.60 ± 0.26 b |

| CV (%) | 2.375 | 2.240 | 2.427 | 3.770 |

| Significance Level | *** | *** | * | * |

| Parameters | Dry Matter | Starch | Reducing Sugar | Chips Color | Crispiness |

|---|---|---|---|---|---|

| Specific gravity | 0.67 ** | 0.68 ** | −0.69 ** | −0.75 *** | −0.09 |

| Dry Matter | 0.84 *** | −0.63 ** | −0.77 *** | −0.50 * | |

| Starch | −0.76 *** | −0.92 *** | −0.69 ** | ||

| Reducing Sugar | 0.83 *** | 0.35 | |||

| Chips Color | 0.48 * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Islam, M.M.; Naznin, S.; Naznin, A.; Uddin, M.N.; Amin, M.N.; Rahman, M.M.; Tipu, M.M.H.; Alsuhaibani, A.M.; Gaber, A.; Ahmed, S. Dry Matter, Starch Content, Reducing Sugar, Color and Crispiness Are Key Parameters of Potatoes Required for Chip Processing. Horticulturae 2022, 8, 362. https://doi.org/10.3390/horticulturae8050362

Islam MM, Naznin S, Naznin A, Uddin MN, Amin MN, Rahman MM, Tipu MMH, Alsuhaibani AM, Gaber A, Ahmed S. Dry Matter, Starch Content, Reducing Sugar, Color and Crispiness Are Key Parameters of Potatoes Required for Chip Processing. Horticulturae. 2022; 8(5):362. https://doi.org/10.3390/horticulturae8050362

Chicago/Turabian StyleIslam, Md Mazadul, Sauda Naznin, Afroz Naznin, Md Nasir Uddin, Md Nurul Amin, Md Mushfiqur Rahman, Mohammad Monirul Hasan Tipu, Amnah Mohammed Alsuhaibani, Ahmed Gaber, and Sharif Ahmed. 2022. "Dry Matter, Starch Content, Reducing Sugar, Color and Crispiness Are Key Parameters of Potatoes Required for Chip Processing" Horticulturae 8, no. 5: 362. https://doi.org/10.3390/horticulturae8050362

APA StyleIslam, M. M., Naznin, S., Naznin, A., Uddin, M. N., Amin, M. N., Rahman, M. M., Tipu, M. M. H., Alsuhaibani, A. M., Gaber, A., & Ahmed, S. (2022). Dry Matter, Starch Content, Reducing Sugar, Color and Crispiness Are Key Parameters of Potatoes Required for Chip Processing. Horticulturae, 8(5), 362. https://doi.org/10.3390/horticulturae8050362