Delay of 1-MCP Treatment on Post-Harvest Quality of ‘Bosc Kobak’ Pear

Abstract

:1. Introduction

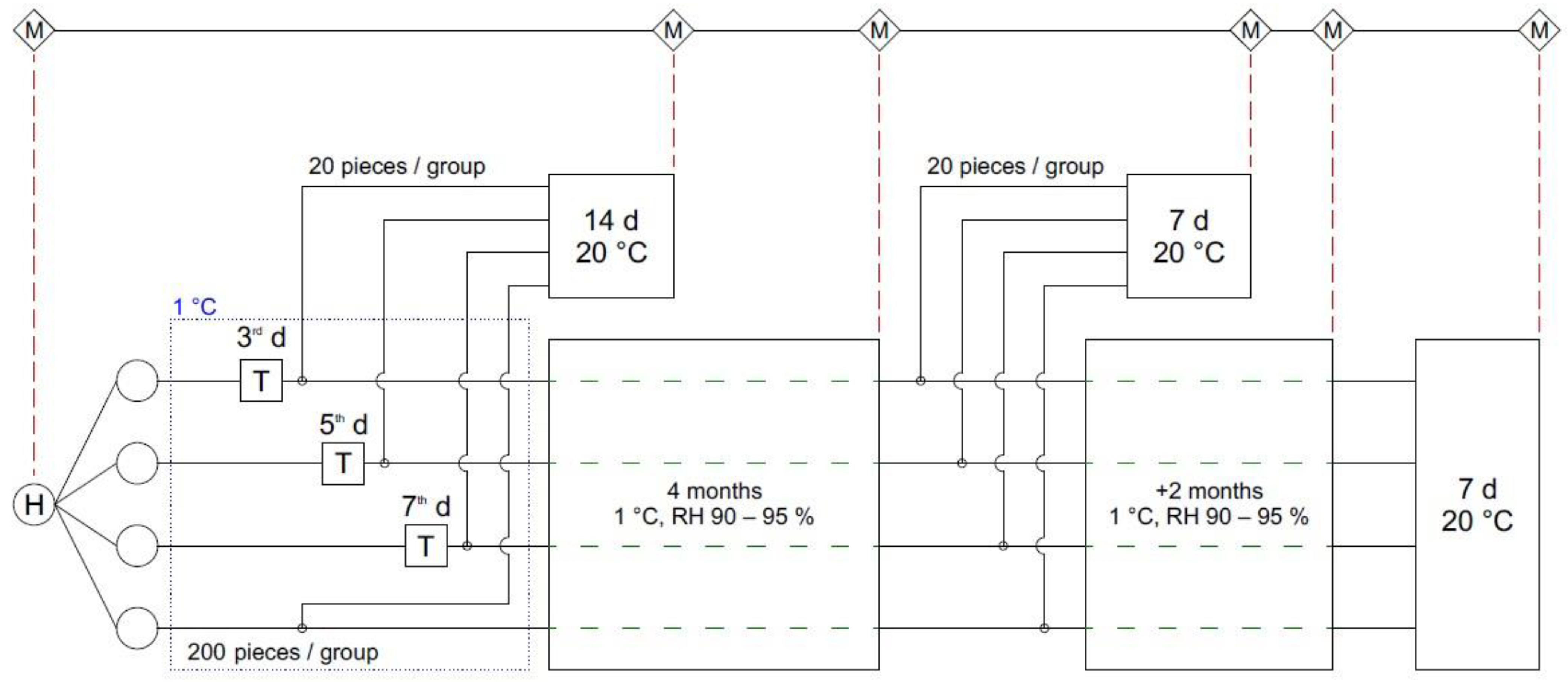

2. Materials and Methods

2.1. Materials and Experimental Design

2.2. Measurements

2.2.1. Starch Index

2.2.2. Fruit Firmness

2.2.3. Storage Disorder

2.2.4. Soluble Solids Content

2.2.5. Rate of Black Seeds

2.2.6. Ethylene Production

2.2.7. Respiration Rate

2.2.8. Surface Color

2.3. Statistical Analysis

3. Results

3.1. Initial Quality of Pear

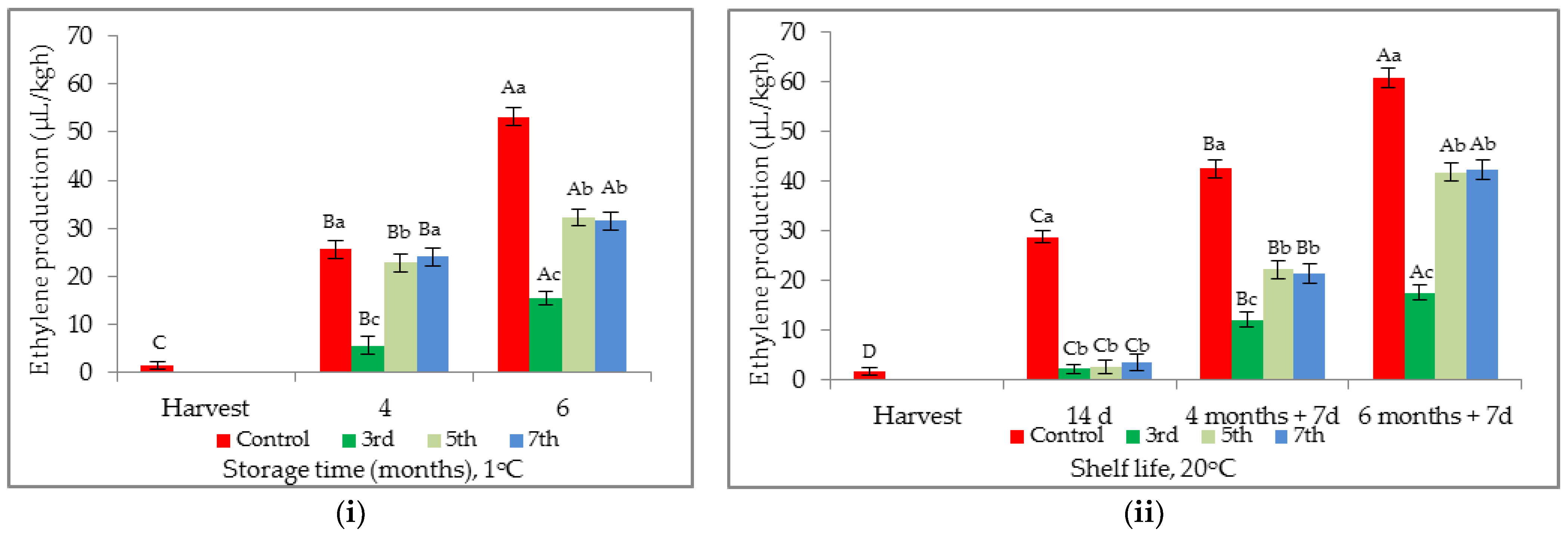

3.2. Ethylene Production

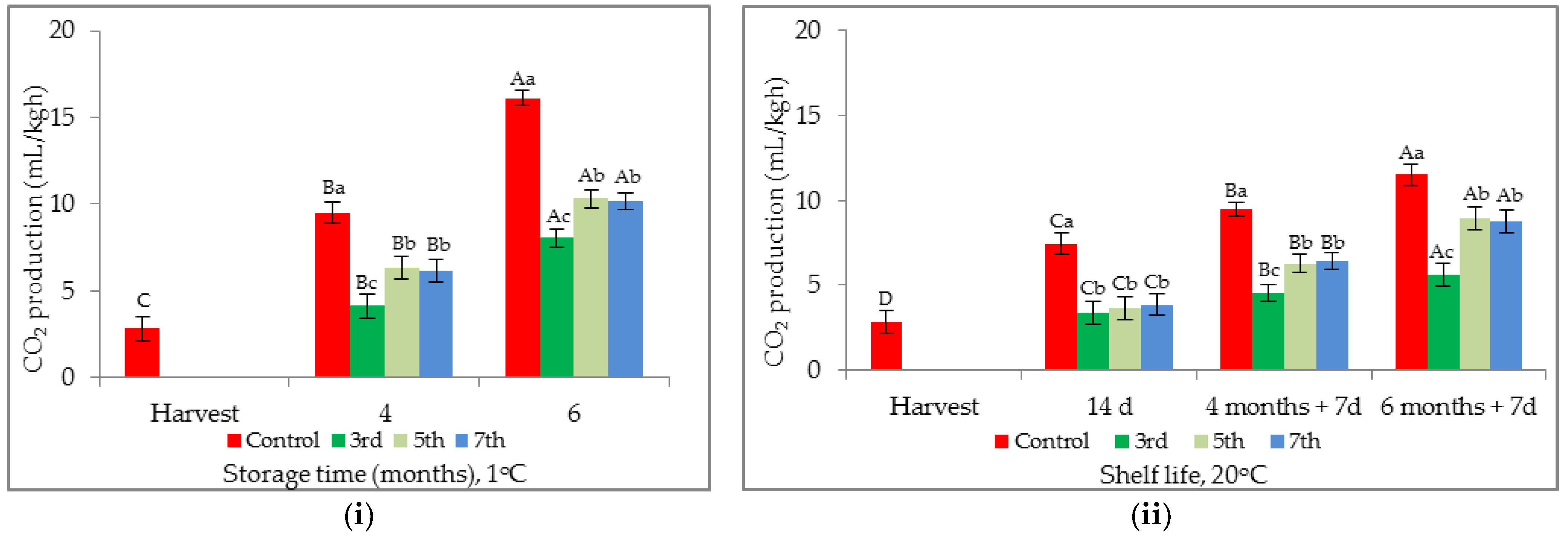

3.3. Respiration

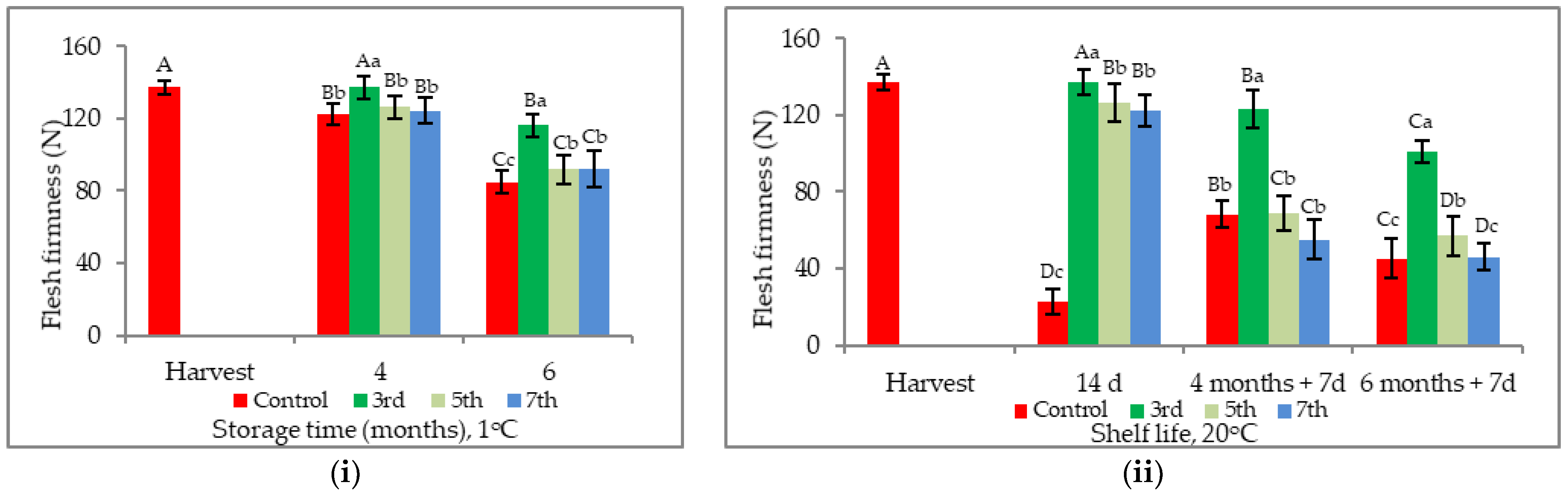

3.4. Firmness

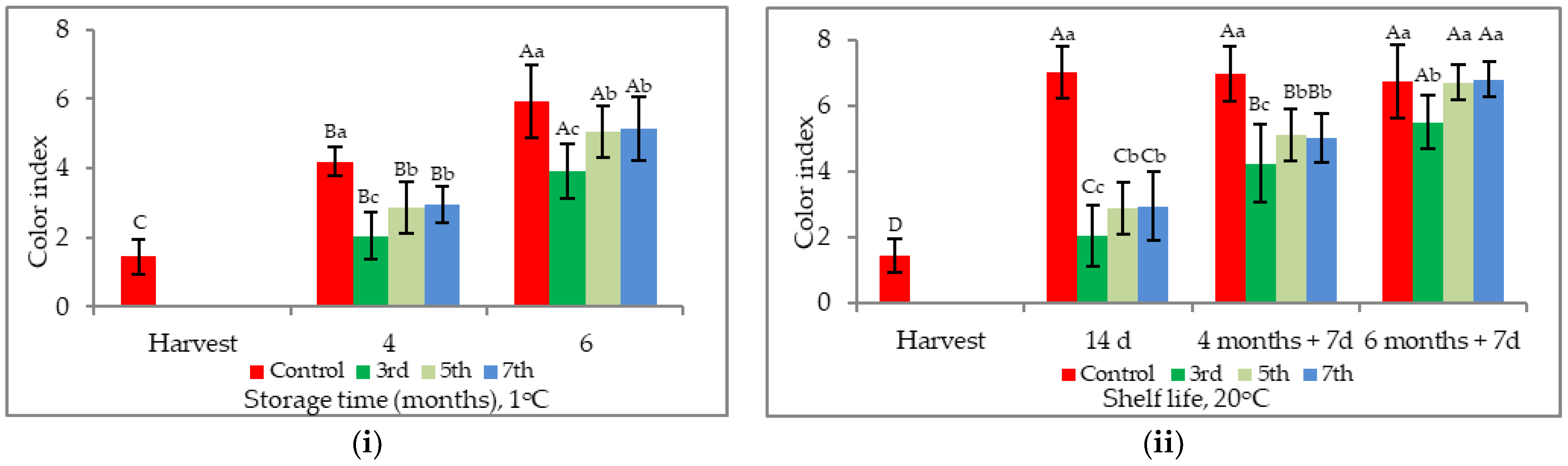

3.5. Color

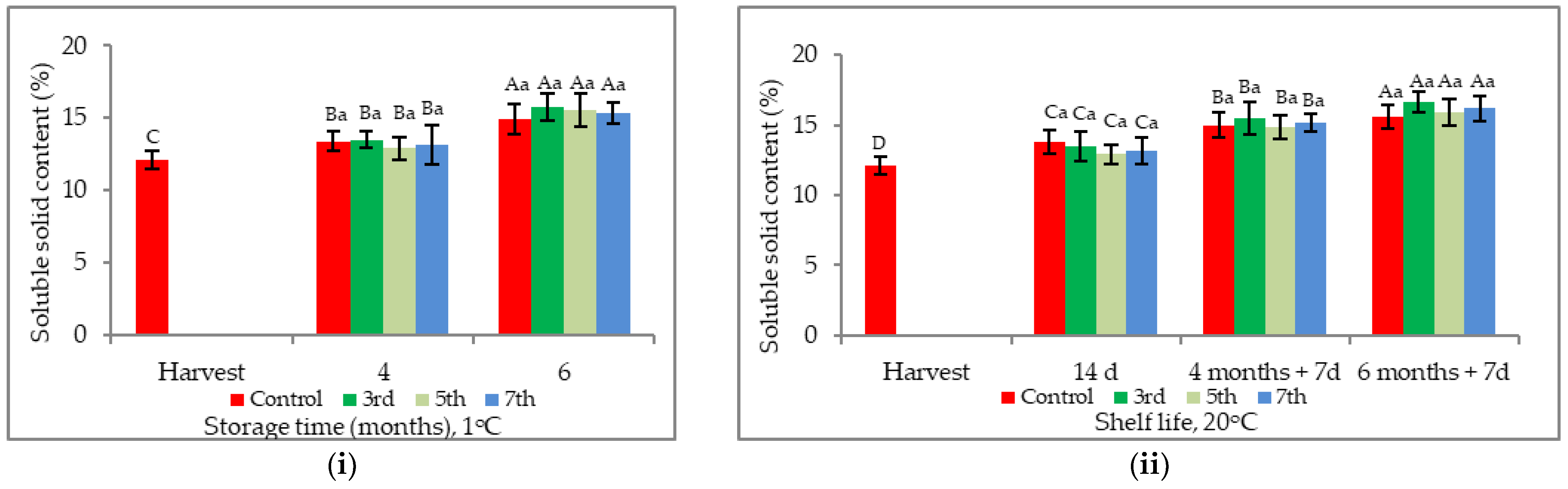

3.6. Soluble Solid Content

3.7. Storage Disorder

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hitka, G.; Zsom, T.; Nguyen, L.; Balla, C. Effect of 1-methylcyclopropene on ‘Bosc Kobak’ pears. Acta Aliment. 2014, 43, 73–77. [Google Scholar] [CrossRef] [Green Version]

- Blankenship, S.M.; Dole, J.M. 1-Methylcyclopropene: A review. Postharvest Biol. Technol. 2003, 28, 1–25. [Google Scholar] [CrossRef]

- Ekman, J.H.; Clayton, M.; Biasi, W.V.; Mitcham, E.J. Interactions between 1-MCP concentration, treatment interval and storage time for ‘Bartlett’ pears. Postharvest Biol. Technol. 2004, 31, 127–136. [Google Scholar] [CrossRef]

- Zhao, J.; Xie, X.; Wang, S.; Zhu, H.; Dun, W.; Zhang, L.; Wang, Y.; Fang, C. 1-Methylcyclopropene affects ethylene synthesis and chlorophyll degradation during cold storage of ‘Comice’pears. Sci. Hortic. 2020, 260, 108865. [Google Scholar] [CrossRef]

- Nguyen, L.P.L.; Zsom, T.; Sao Dam, M.; Baranyai, L.; Hitka, G. Comparison of 1-MCP treatment on four melon cultivars using different temperatures. J. Appl. Bot. Food Qual. 2020, 93, 122–129. [Google Scholar]

- Watkins, C.B.; Nock, J.F. Effects of delays between harvest and 1-methylcyclopropene treatment, and temperature during treatment, on ripening of air-stored and controlled-atmosphere-stored apples. HortScience 2005, 40, 2096–2101. [Google Scholar] [CrossRef] [Green Version]

- Charoenchongsuk, N.; Matsumoto, D.; Itai, A.; Murayama, H. Ripening characteristics and pigment changes in russeted pear fruit in response to ethylene and 1-MCP. Horticulturae 2018, 4, 22. [Google Scholar] [CrossRef] [Green Version]

- Nock, J.F.; Watkins, C.B. Repeated treatment of apple fruit with 1-methylcyclopropene (1-MCP) prior to controlled atmosphere storage. Postharvest Biol. Technol. 2013, 79, 73–79. [Google Scholar] [CrossRef]

- Jung, S.K.; Watkins, C.B. Superficial scald control after delayed treatment of apple fruit with diphenylamine (DPA) and 1-methylcyclopropene (1-MCP). Postharvest Biol. Technol. 2008, 50, 45–52. [Google Scholar] [CrossRef]

- Kubo, Y.; Hiwasa, K.; Owino, W.O.; Nakano, R.; Inaba, A. Influence of Time and Concentration of 1-MCP Application on the Shelf Life of PearLa France’Fruit. HortScience 2003, 38, 1414–1416. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Sugar, D. 1-MCP efficacy in extending storage life of ‘Bartlett’ pears is affected by harvest maturity, production elevation, and holding temperature during treatment delay. Postharvest Biol. Technol. 2015, 103, 1–8. [Google Scholar] [CrossRef]

- Kwon, J.G.; Yoo, J.; Win, N.M.; Naing, A.H.; Kang, I.K. Fruit Quality Attributes of ‘Arisoo’ and ‘Picnic’ Apples as Influenced by 1-Methylcyclopropene Concentration and Its Application Frequency during Cold Storage. Horticulturae 2021, 7, 477. [Google Scholar] [CrossRef]

- Poirier, B.C.; Mattheis, J.P.; Rudell, D.R. Extending ‘Granny Smith’ apple superficial scald control following long-term ultra-low oxygen controlled atmosphere storage. Postharvest Biol. Technol. 2020, 161, 111062. [Google Scholar] [CrossRef]

- DeEll, J.R.; Ayres, J.T.; Murr, D.P. 1-Methylcyclopropene concentration and timing of postharvest application alters the ripening of ‘McIntosh’apples during storage. HortTechnology 2008, 18, 624–630. [Google Scholar] [CrossRef]

- Baranyai, L.; Nguyen, L.L.P.; Sao Dam, M.; Zsom, T.; Hitka, G. Evaluation of precooling temperature and 1-MCP treatment on quality of ‘Golden Delicious’ apple. J. Appl. Bot. Food Qual. 2020, 93, 130–135. [Google Scholar]

- Le Lezec, M.; Belouin, A. Test de regression de l’ amidon des poires. Arboric.-Fruit. 1994, 474, 34–35. [Google Scholar]

- OECD. Pears, International Standards for Fruit and Vegetables; OECD Publishing: Paris, France, 2021. [Google Scholar] [CrossRef]

- Chiriboga, M.A.; Schotsmans, W.C.; Larrigaudiere, C.; Dupille, E.; Recasens, I. How to prevent ripening blockage in 1-MCP-treated ‘Conference’pears. J. Sci. Food Agric. 2011, 91, 1781–1788. [Google Scholar] [CrossRef]

- Dias, C.; Ribeiro, T.; Rodrigues, A.C.; Ferrante, A.; Vasconcelos, M.W.; Pintado, M. Improving the ripening process after 1-MCP application: Implications and strategies. Trends Food Sci. Technol. 2021, 113, 382–396. [Google Scholar] [CrossRef]

- Brandes, N.; Zude-Sasse, M. Respiratory patterns of European pear (Pyrus communis L. ‘Conference’) throughout pre-and post-harvest fruit development. Heliyon 2019, 5, e01160. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, L.L.P.; Baranyai, L.; Nagy, D.; Mahajan, P.V.; Zsom-Muha, V.; Zsom, T. Color analysis of horticultural produces using hue spectra fingerprinting. MethodsX 2021, 8, 101594. [Google Scholar] [CrossRef] [PubMed]

- Xie, X.; Zhao, J.; Wang, Y. Initiation of ripening capacity in 1-MCP treated green and red ‘Anjou’pears and associated expression of genes related to ethylene biosynthesis and perception following cold storage and post-storage ethylene conditioning. Postharvest Biol. Technol. 2016, 111, 140–149. [Google Scholar] [CrossRef]

- Gago, C.M.L.; Guerreiro, A.C.; Miguel, G.; Panagopoulos, T.; Sanchez, C.; Antunes, M.D.C. Effect of harvest date and 1-MCP (SmartFreshTM) treatment on ‘Golden Delicious’ apple cold storage physiological disorders. Postharvest Biol. Technol. 2015, 110, 77–85. [Google Scholar] [CrossRef]

- Argenta, L.C.; Fan, X.; Mattheis, J.P. Influence of 1-methylcyclopropene on ripening, storage life, and volatile production by d’Anjou cv. Pear fruit. J. Agric. Food Chem. 2003, 51, 3858–3864. [Google Scholar] [CrossRef] [PubMed]

- Watkins, C.B. Overview of 1-methylcyclopropene trials and uses for edible horticultural crops. HortScience 2008, 43, 86–94. [Google Scholar] [CrossRef]

- Nguyen, L.P.L.; Hitka, G.; Zsom, T.; Kókai, Z. Application of 1-MCP on apricots at different temperatures and days after harvest. Acta Aliment. 2016, 45, 542–550. [Google Scholar] [CrossRef] [Green Version]

| Flesh Firmness (N) | Soluble Solid Content (%) | Black Seed (%) | Ethylene Production (μL kg−1 h−1) | Carbon Dioxide Production (mL kg−1 h−1) | Starch Index | Color Index | |

|---|---|---|---|---|---|---|---|

| Initial fruit | 137.4 ± 3.90 | 12.12 ± 0.66 | 96.00 ± 5.28 | 1.56 ± 0.87 | 2.82 ± 0.67 | 3.27 ± 0.88 | 1.47 ± 0.52 |

| 14 d Shelf-Life | 4 Months Cold Storage | 4 Months Cold Storage Plus 7 d Shelf Life | 6 Months Cold Storage | 6 Months Cold Storage Plus 7 d Shelf Life | |

|---|---|---|---|---|---|

| Senescence scald | |||||

| Control | 0 | 0 | 0 | 10.00 | 30.00 |

| 1-MCP3rd | 0 | 0 | 0 | 0 | 0 |

| 1-MCP5th | 0 | 0 | 0 | 6.00 | 14.00 |

| 1-MCP7th | 0 | 0 | 0 | 6.00 | 14.00 |

| Internal browning | |||||

| Control | 0 | 0 | 0 | 8.00 | 34.00 |

| 1-MCP3rd | 0 | 0 | 0 | 0 | 0 |

| 1-MCP5th | 0 | 0 | 0 | 4.00 | 16.00 |

| 1-MCP7th | 0 | 0 | 0 | 4.00 | 20.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, L.L.P.; Pham, T.T.; Syium, Z.H.; Zsom-Muha, V.; Baranyai, L.; Zsom, T.; Hitka, G. Delay of 1-MCP Treatment on Post-Harvest Quality of ‘Bosc Kobak’ Pear. Horticulturae 2022, 8, 89. https://doi.org/10.3390/horticulturae8020089

Nguyen LLP, Pham TT, Syium ZH, Zsom-Muha V, Baranyai L, Zsom T, Hitka G. Delay of 1-MCP Treatment on Post-Harvest Quality of ‘Bosc Kobak’ Pear. Horticulturae. 2022; 8(2):89. https://doi.org/10.3390/horticulturae8020089

Chicago/Turabian StyleNguyen, Lien Le Phuong, Tung Thanh Pham, Zinabu Hailu Syium, Viktória Zsom-Muha, László Baranyai, Tamás Zsom, and Géza Hitka. 2022. "Delay of 1-MCP Treatment on Post-Harvest Quality of ‘Bosc Kobak’ Pear" Horticulturae 8, no. 2: 89. https://doi.org/10.3390/horticulturae8020089

APA StyleNguyen, L. L. P., Pham, T. T., Syium, Z. H., Zsom-Muha, V., Baranyai, L., Zsom, T., & Hitka, G. (2022). Delay of 1-MCP Treatment on Post-Harvest Quality of ‘Bosc Kobak’ Pear. Horticulturae, 8(2), 89. https://doi.org/10.3390/horticulturae8020089