Assessing Biodegradable Mulch Duration and Nutsedge Suppression during Late Summer Cucumber Production in Mississippi and Louisiana

Abstract

:1. Introduction

2. Materials and Methods

2.1. Description of Location and Mulch Treatments

2.2. Field Preparation and Planting Descriptions

2.3. Experimental Design and Statistics

3. Results

3.1. Baton Rouge, Louisiana Results

3.1.1. Louisiana Mulch Coverage

3.1.2. Louisiana Weed Prevention

3.1.3. Louisiana Yields by Mulch Treatment

3.2. Beaumont, Mississippi Location Results

3.2.1. Mississippi Mulch Coverage

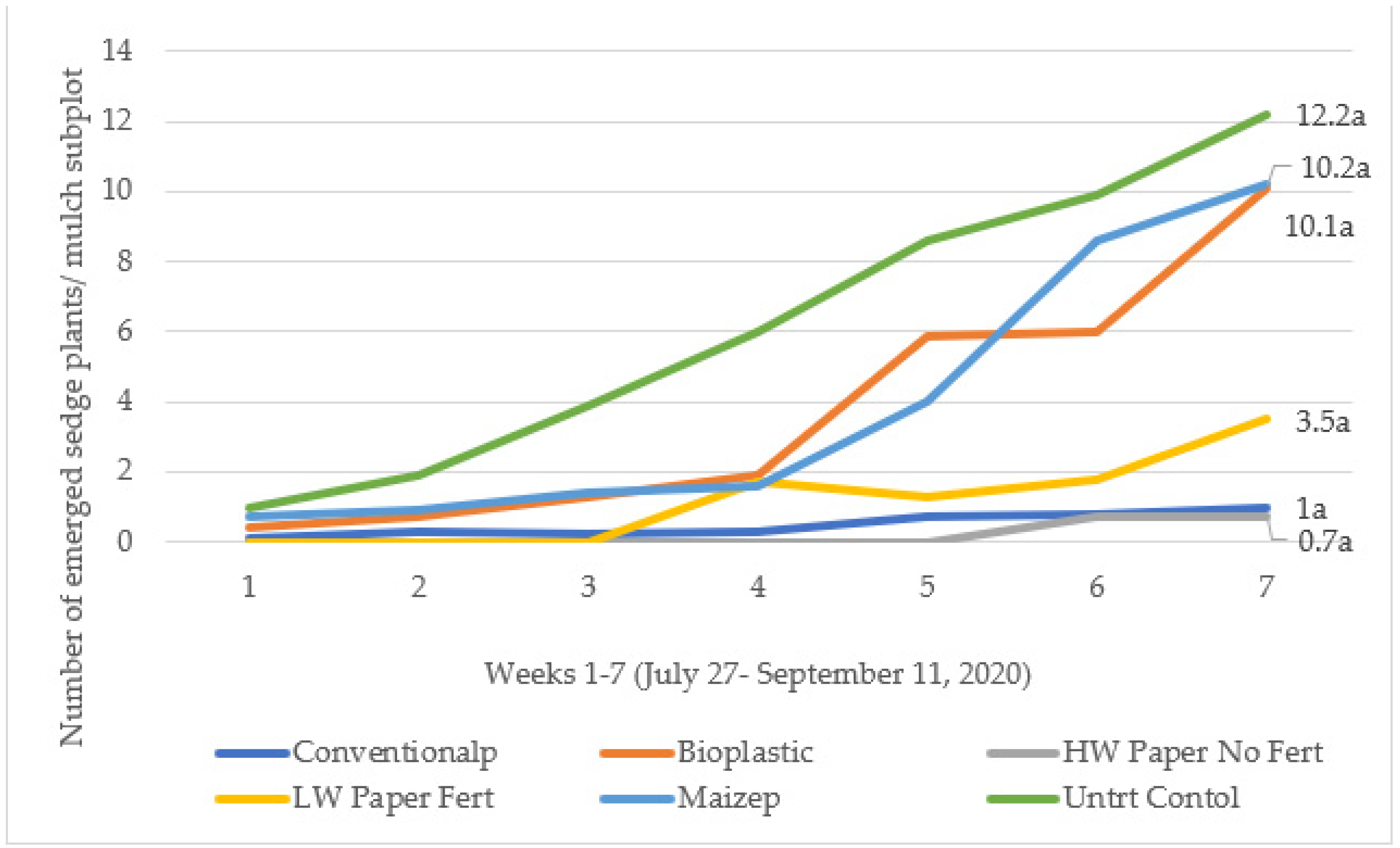

3.2.2. Mississippi Weed Prevention

3.2.3. Mississippi Yield by Mulch Treatment

3.3. Overall Yield Data (States Combined)

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Peerzada, A.M. Biology, agricultural impact, and management of Cyperus rotundus L.: The world’s most tenacious weed. Acta Physiol. Plant. 2017, 39, 270. [Google Scholar] [CrossRef]

- Jones, H.; Black, A.; Jassal, P. Effects of Various Plastic Mulches on Soil Temperature and Surface Energy Balance. Climate Action Initiative. (climateagriculturebc.ca). Available online: FI07-2018-factsheet-Plastic-Mulches.pdf (accessed on 10 December 2020).

- Moore, J.; Wszelaki, A. Paper Mulch for Nutsedge Control in Vegetable Production. Report No. FA-2019-02. Available online: https://ag.tennessee.edu/biodegradablemulch/Documents/Paper%20Mulch%20for%20Nutsedge%20Control%20in%20Vegetable%20Production_FINAL.pdf (accessed on 10 June 2021).

- Shah, F.; Wu, W. Chapter 5—Use of plastic mulch in agriculture and strategies to mitigate the associated environmental concerns. In Advances in Agronomy; Sparks, D.L., Ed.; Elsevier Inc.: Cambridge, MA, USA, 2020; Volume 164, pp. 231–287. [Google Scholar]

- Mansl, K. Agricultural Plastic in the U.S. and China: A Blessing or a Curse? Ohio’s Country Journal. Available online: https://ocj.com/2020/11/agricultural-plastic-in-the-u-s-and-china-a-blessing-or-a-curse/ (accessed on 10 December 2020).

- Levitan, L.; Barros, A. Recycling agricultural plastics in New York State. In Environmental Risk Analysis Program; Cornell University: Ithaca, NY, USA, 2003. [Google Scholar]

- Kasirajan, S.; Ngouajio, M. Polyethylene and biodegradable mulches for agricultural applications: A review. Agron. Sustain. Dev. 2012, 32, 501–529. [Google Scholar] [CrossRef]

- Valavanidis, A.; Iliopoulos, N.; Gotsis, G.; Fiotakis, K. Persistent free radicals, heavy metals and PAHs generated in particulate soot emissions and residue ash from controlled combustion of common types of plastic. J. Hazard. Mater. 2008, 156, 277–284. [Google Scholar] [CrossRef] [PubMed]

- Hahladakis, J.N.; Velis, C.A.; Weber, R.; Iacovidou, E.; Purnell, P. An overview of chemical additives present in plastics: Migration, release, fate and environmental impact during their use, disposal, and recycling. J. Hazard. Mater. 2018, 344, 179–199. [Google Scholar] [CrossRef] [PubMed]

- Galinato, S.P.; Walters, T.W. Cost Estimates of Producing Strawberries in a High Tunnel in Western Washington; Ext. Publ. FS093E; Washington State University: Pullman, WA, USA, 2012. [Google Scholar]

- Environmental Protection Agency (EPA). Advancing Sustainable Materials Management: 2017 Fact Sheet. Available online: https://www.epa.gov/sites/production/files/2019-11/documents/2017_facts_and_figures_fact_sheet_final.pdf (accessed on 11 November 2020).

- Fonsah, E.G.; Shealey, J. Estimated Cost Per Acre of Removing and Replacing Plastic Mulch Damaged by Hurricane Michael in Georgia. FARE Food, Agriculture and Resource Economics Blog. 2019. Available online: https://site.extension.uga.edu/aaecext/2019/09/estimated-cost-per-acre-of-removing-and-replacing-plastic-mulch-damaged-by-hurricane-michael-in-georgia/ (accessed on 10 December 2020).

- Cowan, J.S.; Miles, C.A.; Andrews, P.K.; Inglis, D.A. Biodegradable mulch performed comparable to polyethylene in high tunnel tomato (Solanum lycopersicum L.) production. J. Sci. Food Agric. 2014, 94, 1854–1864. [Google Scholar] [CrossRef] [PubMed]

- Ghimire, S.A.; Wszelaki, J.; Moore, D.; Inglis, D.A.; Miles, C. The Use of Biodegradable Mulches in Pie Pumpkin Crop Production in Two Diverse Climates. HortScience 2018, 53, 288–294. [Google Scholar] [CrossRef] [Green Version]

- Wortman, S.E.; Kadoma, I.; Crandall, M.D. Biodegradable plastic and fabric mulch performance in field and high tunnel cucumber production. HortTechnology 2016, 26, 148–155. [Google Scholar] [CrossRef] [Green Version]

- Martin-Closas, L.; Pelacho, A.M.; Picuno, P.; Rodriguez, D. Properties of new biodegradable plastics for mulching, and characterization of their degradation in the laboratory and in the field. Acta Hort. 2008, 801, 275–282. [Google Scholar] [CrossRef]

- Miles, C.; Wallace, R.; Wszelaki, A.; Martin, J.; Cowan, J.; Walters, T.; Inglis, D. Deterioration of potentially biodegradable alternatives to black plastic mulch in three tomato production regions. HortScience 2012, 47, 1270–1277. [Google Scholar] [CrossRef]

- Moreno, M.M.; Moreno, A. Effect of different biodegradable and polyethylene mulches on soil properties and production in a tomato crop. Sci. Hort. 2008, 116, 256–263. [Google Scholar] [CrossRef]

- Li, C.; Moore-Kucera, J.; Lee, J.; Corbin, A.; Brodhagen, M.; Miles, C.; Inglis, D. Effects of biodegradable mulch on soil quality. Appl. Soil Ecol. 2014, 79, 59–69. [Google Scholar] [CrossRef]

- Fontenot, K.; Ivey, M.; Singh, R.; Heafner, K.; Koske, T. Louisiana Vegetable Planting Guide. Louisiana Cooperative Extension Service Pub 1980. Available online: https://www.lsuagcenter.com/profiles/bneely/articles/page1481835882715 (accessed on 10 December 2020).

- Synder, R. Planting Guide. Mississippi State University Extension Planting Dates. Available online: http://extension.msstate.edu/vegetable-gardening-mississippi/planting%20guide (accessed on 10 December 2020).

- Kemble, J.; Jennings, K.; Walgenbach, J. Southeastern Vegetable Crop Handbook; Meister Media Worldwide: Willoughby, OH, USA, 2019. [Google Scholar]

| Mulch Type | Manufacturer | Plastic/ Paper | Polymer | Thickness (mil.) | Cost Per Linear Meter | Color |

|---|---|---|---|---|---|---|

| Weed Guard Plus with 3–3-3 fertilizer | Sunshine Paper Co. | Paper | Cellulose | 9 | $0.63 | Brown |

| Heavy weight Weed Guard | Sunshine Paper Co. | Paper | Cellulose | 13 | $0.82 | Brown |

| Bio 360 | Dubois Agrinovation | Plastic | Mater-Bi (corn starch) | 0.6 | $0.17 | Black |

| Maize Mulch | Sunshine Paper Co. | Plastic | Corn starch | 6 | $0.79 | Black |

| Conventional Plastic Mulch | Berry Plastics Corp. | Plastic | Black embossed non-degradable | 1.0 | $0.11 | Black |

| Date | Baton Rouge, LA Weekly Rainfall (cm) | Baton Rouge, LA Weekly Temperature °C Range | Beaumont, MSWeekly Rainfall (cm) | Beaumont, MS Weekly Average Temperature °C Range |

|---|---|---|---|---|

| 1–4 July | 13.5 | 29–34 | Trial not begun | Trial not begun |

| 5–11 July | 2.7 | 24–32 | Trial not begun | Trial not begun |

| 12–18 July | 2.4 | 30–35 | Trial not begun | Trial not begun |

| 19–25 July | 6.0 | 27–34 | Trial not begun | Trial not begun |

| 26 July–1 Aug | 4.5 | 22–34 | 2.8 | 23–31 |

| 2–8 Aug | 0.7 | 27–35 | 0.05 | 21–33 |

| 9–15 Aug | 4.4 | 27–36 | 9.6 | 23–33 |

| 16–22 Aug 16–22 | 0.08 | 28–36 | 4.0 | 21–32 |

| 23–29 Aug | 1.7 | 22–33 | 6.7 | 23–81 |

| 30 Aug–5 Sept | 2.9 | 23–36 | 0.13 | 24–34 |

| 6–11 Sept | 1.9 | 20–35 | 0.3 | 21–33 |

| Location | Mulch Type | Avg. Number of Fruit Harvested at Each Harvest Date | Total Weight (lb) of Fruit Harvested at Each Harvest Date |

|---|---|---|---|

| Louisiana | Heavy weight paper | 9.0a | 5.9a |

| Louisiana | Polyethylene black plastic | 8.4ab | 5.1ab |

| Louisiana | Bioplastic mulch | 5.9ab | 3.3bc |

| Louisiana | Maize mulch | 4.8bc | 2.5cd |

| Louisiana | Light weight paper mulch | 1.8cd | 0.8de |

| Louisiana | Un-mulched control | 0d | 0e |

| Mississippi | Heavy weight paper | 8.3AB | 4.4AB |

| Mississippi | Polyethylene black plastic | 0.5C | 0.2C |

| Mississippi | Bioplastic mulch | 10.2AB | 5.0AB |

| Mississippi | Maize mulch | 9AB | 5.0AB |

| Mississippi | Light weight paper mulch | 11.1A | 6.2A |

| Mississippi | Un-mulched control | 5.2BC | 2.4BC |

| Mulch Type | Avg. Number of Fruit Harvested at Each Harvest Date | Total Weight (lb) of Fruit Harvested at Each Harvest Date |

|---|---|---|

| Heavy Weight Paper | 8.7a | 5.3a |

| Bioplastic Mulch | 7.6ab | 4.0ab |

| Maize Mulch | 6.5ab | 3.5ab |

| Polyethylene Black Plastic | 5.8ab | 3.5ab |

| Light Weight Paper Mulch | 4.7bc | 2.5bc |

| Un-mulched Control | 2.0c | 0.9c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fontenot, K.; Kirk-Ballard, H.; Coker, C.E.H.; Strahan, R.; Bacas, I.; Ely, R.M. Assessing Biodegradable Mulch Duration and Nutsedge Suppression during Late Summer Cucumber Production in Mississippi and Louisiana. Horticulturae 2021, 7, 290. https://doi.org/10.3390/horticulturae7090290

Fontenot K, Kirk-Ballard H, Coker CEH, Strahan R, Bacas I, Ely RM. Assessing Biodegradable Mulch Duration and Nutsedge Suppression during Late Summer Cucumber Production in Mississippi and Louisiana. Horticulturae. 2021; 7(9):290. https://doi.org/10.3390/horticulturae7090290

Chicago/Turabian StyleFontenot, Kathryn, Heather Kirk-Ballard, Christine Elizabeth Harris Coker, Ronald Strahan, Isabel Bacas, and Robert Michael Ely. 2021. "Assessing Biodegradable Mulch Duration and Nutsedge Suppression during Late Summer Cucumber Production in Mississippi and Louisiana" Horticulturae 7, no. 9: 290. https://doi.org/10.3390/horticulturae7090290

APA StyleFontenot, K., Kirk-Ballard, H., Coker, C. E. H., Strahan, R., Bacas, I., & Ely, R. M. (2021). Assessing Biodegradable Mulch Duration and Nutsedge Suppression during Late Summer Cucumber Production in Mississippi and Louisiana. Horticulturae, 7(9), 290. https://doi.org/10.3390/horticulturae7090290