Abstract

Postharvest deterioration remains a major challenge for blackberries, particularly in warm climates where shelf life is limited. This study evaluated the postharvest performance of three thornless cultivars grown under subtropical conditions: ‘Prime-Ark® Freedom’, ‘Osage’, and ‘Sweet-Ark™ Ponca’ using a two-phase cold storage regime (0 °C for 7 days, then 5 °C for 9 days). Over two seasons (2023–2024), fruit quality was assessed at days 0, 7, 12, and 16, focusing on weight loss, leakiness, red drupelet reversion (RDR), soluble solids content (SSC), titratable acidity (TTA), SSC/TTA ratio, and ascorbic acid. Cultivar responses varied: ‘Prime-Ark® Freedom’ showed strong storage resilience with minimal weight loss and fewer disorders, although SSC and ascorbic acid levels were lower. ‘Osage’ maintained high SSC, SSC/TTA, and ascorbic acid, favoring shorter storage for fresh markets. ‘Sweet-Ark™ Ponca’ had high SSC/TTA ratios but was prone to leakiness and RDR. Ascorbic acid declined during storage in 2023 but was better preserved in 2024, especially with ‘Prime-Ark® Freedom’. Our results provide actionable insights for cultivar selection in postharvest strategies that are critical to preserving fruit quality and extending shelf life in blackberries.

1. Introduction

Blackberry (Rubus L. subgenus Rubus Watson), a member of the Rosaceae family, is classified as an aggregate fruit composed of numerous drupelets tightly clustered into a single berry structure [1]. Blackberries have been cultivated for centuries across Europe and North America and are now widely grown through temperate and subtropical regions, including South America, Asia, Africa, and Oceania. With the availability of numerous improved cultivars [2,3], the crop has gained increasing economic importance, particularly in the fresh-market sector.

Historically, the commercialization of blackberries was confined to local markets due to their poor postharvest durability, which restricted long-distance transportation [4]. Among small fruits, blackberries are considered one of the most perishable due to their extreme susceptibility to softening and leakage during storage and transport [4]. Nevertheless, rising consumer demand has driven a global increase in blackberry production. Between 2000 and 2019, the global blackberry harvested area increased by 64.1%, from 78,000 to 128,000 hectares. During the same period, production rose by 75.0%, from 527,000 to 922,000 t. Both the harvested area and production grew at an average annual rate of 2.7% and 3.4%. Current estimates suggest the harvested area now exceeds 157,000 hectares [5,6]. This expansion has been supported by the adoption of protected cultivation methods, such as high tunnels, which has extended the growing season, enabled harvesting during unfavorable weather, and enhanced fruit quality [7,8,9].

Despite these cultivation advancements, maintaining fruit quality from harvest through consumption remains a significant challenge [10,11]. Blackberries are classified as non-climacteric fruits, meaning that they do not undergo significant ripening processes, such as a respiratory climacteric peak or a marked increase in ethylene production, after harvest [12,13]. Consequently, fruit quality at harvest largely dictates postharvest potential, and cold storage serves primarily to slow down physiological deterioration and microbial spoilage. Blackberries have delicate skin and high respiration and transpiration rates, rendering them highly perishable and vulnerable to rapid physiochemical and sensory deterioration during the postharvest storage [14]. Key postharvest defects include weight loss, leakiness, and red drupelet reversion (RDR), all of which negatively impact fruit marketability and consumer acceptance.

Effective postharvest management of non-climacteric fruits like blackberries heavily relies on precise temperature control to mitigate rapid deterioration. Cold storage at or near 0 °C is widely recognized as optimal for blackberries, as it significantly reduces respiration and transpiration rates, thereby minimizing weight loss and delaying senescence [12]. However, fruits often encounter warmer conditions further along the supply chain. Thus, a two-phase cold storage approach, incorporating both optimal 0 °C and typical retail/transit temperatures such as 5 °C, is frequently utilized to assess fruit performance under varied cold chain scenarios. This type of comprehensive evaluation provides crucial insights into cultivar resilience across diverse postharvest environments, reflecting real-world commercial challenges [12,15]. Weight loss, primarily driven by high transpiration rates, can be partially mitigated by cold storage. However, many growers lack quick access to cooling facilities, making harvest timing and time to cooling critical for quality preservation [14,16]. Similarly, fruit leakiness, characterized by juice exudation during handling, becomes significantly severe with elevated harvest temperatures, high UV exposure, and prolonged storage durations [15,17].

Red drupelet reversion (RDR), also known as reddening or color reversion, is another prevalent postharvest disorder that affects fruit appearance and marketability [18]. This disorder manifests as localized discoloration of individual drupelets during cold storage or after returning to room temperature [18,19]. While the exact mechanisms are still being elucidated, the breakdown or absence of anthocyanin pigment synthesis due to rupturing internal cell structures and altered internal pH is widely accepted as a primary cause [20,21]. Some research suggests that environmental stressors, such as high temperatures at harvest, may also contribute to its incidence [22]. Rapid cooling soon after harvest and consistent maintenance of low temperatures (0–5 °C) and high relative humidity (90–95%), coupled with a modified atmosphere (5–10% O2 and 15–20% CO2), are considered essential for mitigating RDR and other disorders, maintaining blackberry quality, and extending shelf life [23,24,25].

To address these challenges, breeding programs have targeted firmer, crisp-textured genotypes with enhanced postharvest qualities and flavor [10]. Concurrently, improved harvest and handling practices, such as early morning picking to limit accumulation of field heat and expedited transfer to cold storage, have also been adopted to enhance postharvest quality and extend shelf life [26].

Despite these efforts, our understanding of the physiological mechanisms driving postharvest disorders and their interplay with preharvest conditions and cultivar genetics remains incomplete. Thus, the goal of this study was to evaluate postharvest quality and shelf-life characteristics of three thornless blackberry cultivars—‘Prime-Ark® Freedom’, Osage’, and ‘Sweet-Ark™ Ponca’—under simulated commercial cold storage conditions, integrating physiological and biochemical assessments to provide a comprehensive understanding of cultivar-specific postharvest dynamics. Specifically, our aims were as follows:

- Assess the progression of key physiological parameters, including fresh weight loss, leakiness, and red drupelet reversion, across multiple storage durations.

- Quantify changes in fruit biochemical composition, including soluble solids content (SSC), titratable acidity (TTA), SSC/TTA ratio, and ascorbic acid content.

- Determine cultivar-specific differences in postharvest performance over a 16-day cold storage period.

The findings are expected to offer practical guidance for cultivar selection, postharvest management, and fresh-market supply chain optimization in warm-climate blackberry production systems.

2. Materials and Methods

2.1. Material and Experimental Design

This study evaluated the postharvest quality and shelf-life characteristics of three thornless blackberry (Rubus L. subgenus Rubus) cultivars: ‘Prime-Ark® Freedom’, ‘Osage’, and ‘Sweet-Ark™ Ponca’. Fruits were harvested from Gardener Farms, a commercial blackberry producer located in Mayo, Lafayette County, Florida, USA (GPS coordinates: 30.08° N, 83.28° W). Fully ripe fruits were hand-harvested at commercial maturity during the early morning hours (between 6:00 AM and 9:00 AM EDT) when ambient temperatures typically ranged from 22 °C to 28 °C to minimize field heat. Fruits were carefully selected for uniform size, color, and freedom from visible defects and picked directly into ventilated clamshells to avoid stacking or mechanical damage and ensure uniform postharvest evaluation. An absorbent pad was included at the bottom of each clamshell. A completely randomized design (CRD) was adopted. For each sampling day, three biological replicates per cultivar were prepared, for a total of nine clamshells for analysis during each sampling time point during storage (three cultivars × three replicates).

2.2. Cold Storage and Sampling Protocol

Immediately after harvest, fruit samples were placed under controlled cold storage following a two-phase temperature regime designed to simulate commercial storage practices: Phase I (0 °C for 7 days), and Phase II (5 °C for 9 additional days) with 95% humidity.

Sampling was conducted at four time points: Day 0 (baseline, immediately after harvest), Day 7 (after 0 °C storage), Day 12, and Day 16 (after 5 and 9 days at 5 °C).

In 2023, a new 6-ounce clamshell (177 g, 13 × 11 × 4 cm) was used on each evaluation to assess physiological changes. All berries within the container were examined for visible signs of physiological damage. Following the assessment, 20 representative berries were randomly selected and stored at −30 °C for subsequent biochemical analyses.

In 2024, the protocol was slightly modified based on the availability of berry clamshells. A single clamshell (12 ounces, 340 g; 16 × 16 × 5 cm) containing berries was monitored continuously from Day 0 to Day 16 to track the progression of physiological damage on the same fruit. In parallel, a separate clamshell was sampled at each time point for biochemical analyses. This modification better simulated commercial cold storage conditions, where berries typically remain in the same clamshell from harvest to retail. Following the same fruit over time allowed for direct observation of progressive physiological changes, minimized variability from repacking, and improved the continuity of visual assessments. A separate clamshell was sampled at each time point for biochemical analyses.

2.3. Visual and Physical Quality Assessments

Red drupelet reversion (RDR): Each berry was classified as exhibiting red drupelet reversion (RDR) when more than five drupelets per berry reverted to red, since minor changes in fewer drupelets are common and have limited impact on marketability. This threshold was selected based on Edgley et al. [21], who demonstrated that higher drupelet counts are strongly associated with handling-induced injury and reduced visual quality. The incidence rate was expressed as a percentage of the total number of berries in the clamshell.

Leakiness: Berries showing visible juice leakage or staining were counted, and leak incidence was calculated as a percentage of the total number of berries per clamshell.

Weight loss (WL): The initial weight of each clamshell was recorded at Day 0 (FW1). After storage, clamshells were equilibrated at room temperature for 15 min and reweighed (FW2). Weight loss (fresh weight basis) was calculated using

WL (%) = ((FW1 − FW2)/FW1) × 100

2.4. Juice Extraction and Biochemical Analyses

From each replicate, 40 g of fruit was homogenized using a chilled blender (HBB908; Brand Hamilton Beach, WA, USA). The homogenate was centrifuged at 12,000 rpm for 20 min at 4 °C (Sorvall LYNX 400; Thermo Scientific, Osterode am Harz, Germany) and filtered through four layers of cheesecloth. The resulting clear juice was used for all subsequent chemical analyses, including SSC, pH, total titratable acidity (TTA), and organic acid profiling.

Soluble Solids Content (SSC): Measured using a digital refractometer (Model r2i300, Reichert Technologies, Depew, NY, USA) and expressed as °Brix.

pH and Total Titratable Acidity (TTA): Measured using a calibrated digital pH meter. TTA was quantified via titration (905 Titrando; Metrohm Ion Analysis, Herisau, Switzerland) [27] to pH 8.2 and expressed as a percentage citric acid equivalent. The SSC/TTA ratio was calculated to evaluate fruit flavor balance.

Ascorbic acid (Vitamin C): Ascorbic acid content was determined using a modified dinitrophenylhydrazine (DNPH) colorimetric method following [28]. All steps were performed under yellow light to prevent ascorbic acid degradation.

Approximately 2 g of homogenized tissue was extracted in 20 mL of 6% metaphosphoric acid containing 2N acetic acid. The homogenate was centrifuged at 12,000 rpm for 10 min at 3 °C and the supernatant was used for analysis. For each sample, 1 mL of extract was mixed with 50 µL of 0.2% 2,6-dichloroindophenol (DCIP), vortexed, and left to react. After 1 h, 1 mL of 2% thiourea in 5% metaphosphoric acid and 0.5 mL of 2% DNPH in 9N sulfuric acid were added. After vortexing, samples were incubated at 60 °C for 3 h, cooled on ice, and treated with 2.5 mL of 90% sulfuric acid. Absorbance was read at 540 nm using a microplate spectrophotometer (PowerWave XS2; BioTek, Winooski, VT, USA). A standard curve was prepared using L-ascorbic acid solutions, and all measurements were conducted in triplicate.

2.5. Statistical Analysis

All data were analyzed using one-way Analysis of Variance (ANOVA) on the combined factor of cultivar × storage duration as the main effect to enable direct comparison of treatment combinations. When significant differences were observed (p < 0.05), means were separated using the Tukey’s Honest Significant Difference (HSD) test. Results are reported as mean ± standard error (SE). All statistical analysis was conducted using R software (version 4.4.2). Different letters in the same column indicate statistically significant differences among treatment combinations (p < 0.05).

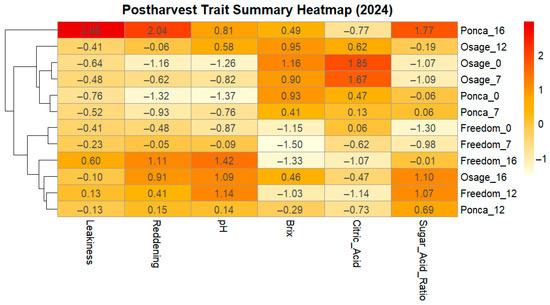

Heatmap analysis was conducted in R using standardized (z-score transformed) data for leakiness, red drupelet reversion (RDR), pH, soluble solids content (°Brix), total titratable acidity (citric acid), and the SSC/TTA ratio from the 2024 season. A yellow-to-red color gradient (low to high standardized values) was applied to visualize trait intensity. Hierarchical clustering grouped similar cultivar–storage day combinations and traits, enabling the identification of underlying patterns and relationships.

3. Results

3.1. Weight Loss During Storage

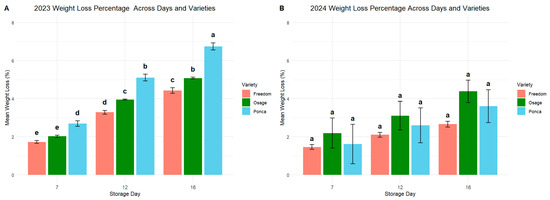

Weight loss (WL) was assessed across three cultivars (‘Prime-Ark® Freedom’, ‘Osage’, and ‘Sweet-Ark™ Ponca’) at Days 7, 12, and 16 under cold storage during the 2023 and 2024 growing seasons (Figure 1). Each data point represents the mean percent loss per clamshell (n = 3).

Figure 1.

Postharvest fresh weight loss in three blackberry cultivars over 16 days at (0 °C and 5 °C) in a two-phased cold storage in 2023 (A) and 2024 (B). The means were separated using Tukey’s HSD test. Different letters within each storage day indicate significant differences among cultivars (p < 0.05). Error bars represent ±SE.

3.1.1. 2023 Season

The significant cultivar × storage time interaction (p = 1.53 × 10−15) indicated that weight loss was strongly influenced by cultivar. All cultivars exhibited increased fresh weight loss with prolonged storage, but the magnitude differed. ‘Sweet-Ark™ Ponca’ on Day 16 had the highest weight loss (6.74%), followed by ‘Sweet-Ark™ Ponca’ on Day 12 (5.10%) and ‘Osage’ on Day 16 (5.08%). In contrast, ‘Prime-Ark® Freedom’ on Day 7 had the lowest mean loss (1.73%), indicating better postharvest weight retention under short-term storage. Overall, ‘Sweet-Ark™ Ponca’ was the most prone to moisture loss, while ‘Prime-Ark® Freedom’ exhibited greater postharvest stability.

3.1.2. 2024 Season

In 2024, the higher variability in weight loss compared with 2023 resulted in no significant differences between cultivars or storage periods (p = 0.125). Weight loss increased from Day 0 to Day 16 for all cultivars, but it did not reach statistical significance. The highest loss was recorded in ‘Osage’ on Day 16 (4.38%), followed by ‘Sweet-Ark™ Ponca’ on Day 16 (3.61%) and ‘Osage’ on Day 12 (3.10%). ‘Prime-Ark® Freedom’ on Day 7 again showed the lowest loss (1.47%). The standard error across treatments was 0.68, indicating moderate variability. These results suggest that although weight loss increased with storage duration, the effect was less pronounced in 2024 compared to the previous year, and cultivar differences were not statistically significant under the tested conditions.

3.2. Leakiness Percentage

Leak incidence was quantified as the proportion of berries showing juice leakage or staining per clamshell. Table 1 (2023) and Table 2 (2024) summarize changes across cultivars and storage durations.

Table 1.

Changes in selected postharvest quality attributes of blackberry cultivars (‘Prime-Ark® Freedom’, ‘Osage’, and ‘Sweet-Ark™ Ponca’) during 16-day cold storage in 2023.

Table 2.

Changes in selected postharvest quality attributes of blackberry cultivars (‘Prime-Ark® Freedom’, ‘Osage’, and ‘Sweet-Ark™ Ponca’) during 16-day cold storage in 2024.

In 2023, leakiness varied significantly among cultivar and storage duration combinations (p = 0.0028; Table 1). The highest leak incidence was observed in ‘Sweet-Ark™ Ponca’ at Day 0 (42.97%), which was statistically greater than most other treatments and grouped alone. This was followed by ‘Sweet-Ark™ Ponca’ at Days 12 and 7, ‘Prime-Ark® Freedom’ at Day 7, and ‘Osage’ at Day 7, all of which exhibited moderate leakage, ranging from 36.60% to 38.62%, and fell within overlapping statistical groups. The lowest leakage was recorded in ‘Prime-Ark ® Freedom’ at Day 12 (31.97%) and ‘Osage’ at Day 0 (35.36%). All cultivars exhibited some level of leakiness, even at early storage time points. ‘Sweet-Ark™ Ponca’ showed the greatest leak susceptibility across all durations.

In 2024, leak percentage again varied significantly across cultivars and storage durations (p = 1.01 × 10−7; Table 2). The highest leak incidence occurred in ‘Sweet-Ark™ Ponca’ at Day 16 (69.49%), which was significantly greater than all other treatment combinations and classified as the only member of group “a” by Tukey HSD. All other treatments—including ‘Prime-Ark® Freedom’ and ‘Osage’ at all time points, and ‘Sweet-Ark™ Ponca’ at Days 0, 7, and 12—belonged to group “b,” indicating no significant differences among them. Notably, ‘Prime-Ark® Freedom’ at Day 16 (25.54%) and Day 12 (16.68%) showed the next highest leak percentages, while the lowest was recorded in ‘Sweet-Ark™ Ponca’ at Day 0 (0%), followed by ‘Osage’ at Day 0 (2.34%) and ‘Sweet-Ark™ Ponca’ at Day 7 (4.53%). These results indicate that leakiness increased sharply in ‘Ponca’ under extended storage, while ‘Prime-Ark® Freedom’ and ‘Osage’ remained more stable across all storage durations.

3.3. Red Drupelet Reversion (RDR)

RDR was measured as the percentage of berries with five or more red drupelets per clamshell (Table 1 and Table 2).

In 2023, significant differences (p = 0.0285) were observed among the treatment combinations. Although red drupelet percentages varied visually, all treatments were classified under the same statistical group according to Tukey’s HSD. Mean values ranged from 0% in ‘Sweet-Ark™ Ponca’ at Day 0 to 16.03% in ‘Prime-Ark® Freedom’ at Day 7. Across all cultivars, a slight increase in red drupelet incidence was observed with longer storage duration, though differences were not statistically distinct. These results suggest low and stable red drupelet development during short-term cold storage under the tested conditions.

In contrast, 2024 data revealed highly significant differences (p = 7.83 × 10−12) among treatments. ‘Sweet-Ark™ Ponca’ at Day 16 exhibited the highest red drupelet percentage (89.56%), followed by ‘Prime-Ark® Freedom’ at Day 16 (65.05%) and ‘Osage’ at Day 16 (59.64%). These treatment means were categorized into distinct statistical groups, indicating a strong cultivar × storage time interaction. The lowest red drupelet percentages were observed in ‘Sweet-Ark™ Ponca’ at Day 0 (0%) and ‘Osage’ at Day 0 (4.44%). The results demonstrate a pronounced increase in red drupelet development with prolonged storage, particularly in the ‘Sweet-Ark™ Ponca’ cultivar, highlighting greater susceptibility to color reversion under extended cold storage.

3.4. Soluble Solids Content (SSC, °Brix)

Soluble solids content was measured at multiple postharvest storage durations in 2023 and 2024 (Table 1 and Table 2).

In 2023, significant differences (p = 1.72 × 10−10) were observed among cultivars and storage durations. ‘Osage’ consistently exhibited the highest Brix values across all time points, with the maximum recorded at Day 0 (11.4 °Brix), which was significantly greater than all other treatments. In contrast, all ‘Prime-Ark® Freedom’ samples—regardless of storage duration—exhibited lower Brix values, ranging from 4.80 to 6.77 °Brix. ‘Sweet-Ark™ Ponca’ generally exhibited high Brix values, ranging from 9.9 to 10.6 °Brix, consistently similar to ‘Osage’ and significantly higher than ‘Prime-Ark® Freedom’. These findings suggest that ‘Osage’ and ‘Sweet-Ark™ Ponca’ maintain superior sugar accumulation and sweetness compared to ‘Prime-Ark® Freedom’, which showed minimal variation during storage and consistently lower Brix. In 2024, cultivar and storage combinations again differed significantly in Brix content (p = 7.84 × 10−8). ‘Osage’ at Day 0 exhibited the highest Brix value (9.63 °Brix), followed closely by ‘Osage’ at Day 12 (9.20 °Brix), ‘Sweet-Ark™ Ponca’ at Day 0 (9.17 °Brix), and ‘Osage’ at Day 7 (9.10 °Brix). The lowest Brix value was observed in ‘Prime-Ark® Freedom’ at Day 16 (5.60 °Brix), suggesting a decline in sweetness under prolonged storage. Overall, the 2024 data confirmed that ‘Osage’ generally maintains higher soluble solids content across storage periods, while ‘Prime-Ark® Freedom’ consistently exhibited lower values.

3.5. SSC to TTA Ratio

The SSC/TTA ratio indicates flavor balance and perceived fruit sweetness.

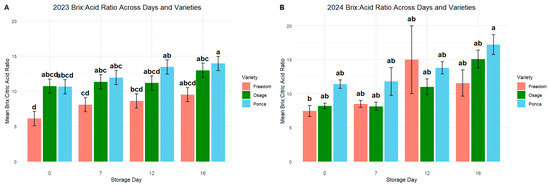

2023: Significant differences (p = 0.000318) in SSC/TTA ratio were observed among cultivar × storage duration combinations (Figure 2). The highest ratio was recorded in ‘Sweet-Ark™ Ponca’ at Day 16 (13.95), which was statistically distinct, followed by ‘Sweet-Ark™ Ponca’ at Day 12 (13.45) and ‘Osage’ at Day 16 (12.97). Moderate values were observed in ‘Sweet-Ark™ Ponca’ at Day 7 (11.94) and ‘Osage’ at Day 7 (11.34), while ‘Prime-Ark® Freedom’ at Day 0 (6.10) had the lowest SSC/TTA ratio and was grouped separately. A progressive increase in ratio was observed with prolonged storage, particularly in ‘Sweet-Ark™ Ponca’, indicating enhanced sweetness relative to acidity. In contrast, ‘Prime-Ark® Freedom’ exhibited consistently lower values, suggesting a less favorable sugar–acid balance throughout the storage period.

Figure 2.

Soluble solids content (Brix)/total titratable acid ratio in the fruit of three blackberry cultivars at Days 0, 7, 12, and 16 after cold storage in 2023 (A) and 2024 (B). All means were separated using Tukey’s HSD test. Different letters within each time point indicate significant differences among cultivars (p < 0.05). Error bars represent ±SE.

2024: Data from this season also showed significant variation (p = 0.0123) in SSC/TTA ratios across cultivar and storage combinations (Figure 2). The highest ratio was again found in ‘Sweet-Ark™ Ponca’ at Day 16 (17.23), followed by ‘Osage’ at Day 16 (15.09) and ‘Prime-Ark® Freedom’ at Day 12 (15.00). Most other treatments, including ‘Sweet-Ark™ Ponca’ at Day 12 and Day 7, ‘Prime-Ark® Freedom’ at Day 16, and ‘Osage’ at Day 12, exhibited moderate ratios (ranging from 11.00 to 13.80) and shared the same statistical grouping. The lowest ratio was observed in ‘Prime-Ark® Freedom’ at Day 0 (7.44), indicating lower sweetness perception at harvest. Overall, the data confirm that storage duration enhanced SSC/TTA ratios, particularly in ‘Sweet-Ark™ Ponca’, while early-harvested fruit, such as ‘Prime-Ark® Freedom’ at Day 0, maintains relatively poor sugar-to-acid balance.

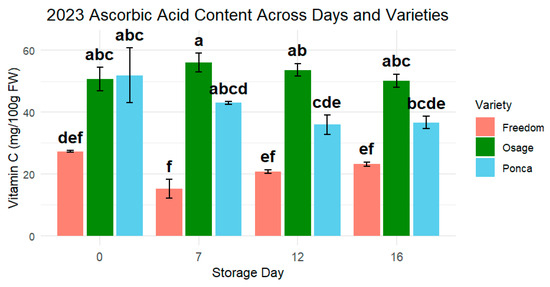

3.6. Ascorbic Acid Content

2023: Mean ascorbic acid content (mg/100 g FW) varied significantly (p = 4.48 × 10−9) among cultivar and storage duration combinations (Figure 3). At Day 0, ‘Osage’ (approx. 50 mg/100 g FW) and ‘Sweet-Ark™ Ponca’ (approx. 52 mg/100 g FW) had significantly higher ascorbic acid concentrations than ‘Prime-Ark™ Freedom’ (approx. 28 mg/100 g FW). Throughout the 16-day cold storage period, ‘Osage’ consistently maintained the highest ascorbic acid levels, peaking around Day 7 (approx. 55 mg/100 g FW) and remaining high by Day 16 (approx. 48 mg/100 g FW). In contrast, ‘Prime-Ark® Freedom’ showed the lowest initial ascorbic acid content and experienced a sharp, significant decline by Day 7 (approx. 15 mg/100 g FW), maintaining low levels thereafter. ‘Sweet-Ark™ Ponca’ started with a high ascorbic acid content but showed a progressive reduction over time, falling to approximately 37 mg/100 g FW by Day 16. Overall, ‘Osage’ demonstrated good ascorbic acid retention, while ‘Prime-Ark® Freedom’ exhibited the poorest.

Figure 3.

Ascorbic acid (Vitamin C) contents in the fruit of three blackberry cultivars at Days 0, 7, 12, and 16 after cold storage in 2023. All means were separated using Tukey’s HSD test. Different letters within each storage day indicate significant differences among cultivars (p < 0.05). Error bars represent ±SE.

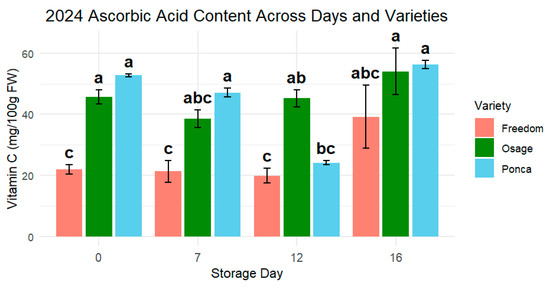

2024: Ascorbic acid content again varied significantly (p = 9.34 × 10−7) among cultivar and storage day combinations (Figure 4). At Day 0, ‘Sweet-Ark™ Ponca’ and ‘Osage’ exhibited significantly higher ascorbic acid concentrations (both approx. 48–50 mg/100 g FW) compared to ‘Prime-Ark™ Freedom’ (approx. 28 mg/100 g FW).

Figure 4.

Ascorbic acid contents in the fruit of three blackberry cultivars at Days 0, 7, 12, and 16 after cold storage in 2024. All means were separated using Tukey’s HSD test. Different letters within each storage day indicate significant differences among cultivars (p < 0.05). Error bars represent ±SE.

Unlike the sharp decline seen in 2023, ‘Prime-Ark® Freedom’ maintained a relatively stable ascorbic acid concentration throughout storage in 2024, with a noticeable increase by Day 16 (approx. 42 mg/100 g FW). ‘Osage’ and ‘Sweet-Ark™ Ponca’ also showed stable or slightly rising trends, with both cultivars peaking around Day 16 (approx. 55–58 mg/100 g FW). Notably, all cultivars maintained or increased their ascorbic acid levels by Day 16, with no significant postharvest losses observed in 2024.

These results contrast with the 2023 trend, where ascorbic acid generally declined over time. In 2024, all three cultivars showed improved ascorbic acid stability during cold storage, with ‘Sweet-Ark™ Ponca’ and ‘Osage’ maintaining superior levels and ‘Prime-Ark® Freedom’ demonstrating enhanced retention capacity compared to the previous year.

4. Discussion

This study comprehensively evaluated the postharvest quality and shelf-life characteristics of three thornless blackberry cultivars under simulated commercial cold storage conditions across two growing seasons. Our findings consistently demonstrated significant cultivar-dependent responses in both physiological and biochemical traits, which were further influenced by storage duration. The observed postharvest deterioration in blackberries is a multifaceted process that involves a combination of physiological and biochemical changes.

Weight loss is among the earliest and most visible signs of postharvest deteriorations in blackberries, largely due to the fruit’s high transpiration and respiration rates. In 2023, significant cultivar × storage duration interactions were observed, with ‘Sweet-Ark™ Ponca’ exhibiting the highest weight loss (6.74% on Day 16), while ‘Prime-Ark® Freedom’ showed the least loss (1.73% on Day 7), reflecting superior moisture retention. In contrast, weight loss patterns in 2024 were less pronounced and not statistically significant, suggesting possible intraseasonal environmental effects.

These results are consistent with previous findings by Joo and Lewandowski [14], who noted high transpiration rates in blackberries as a leading cause of rapid blackberry berry weight loss, particularly under delayed cooling. The difference in clamshell packaging size (6 ounces in 2023 vs. 12 ounces in 2024) may have influenced the observed weight loss outcomes. The smaller 2023 clamshells increased the specific surface area, potentially accelerating moisture loss and contributing to the significantly higher weight loss percentages and clearer cultivar differences observed that year. In contrast, the larger 2024 clamshells reduced specific surface area, thereby limiting moisture loss. This may explain the generally lower and less statistically significant weight loss observed in 2024, as berries likely experienced less water loss within the package [29]. Future studies should more rigorously standardize packaging volume and fruit fill weight to better isolate environmental effects. Other studies also underscore the importance of maintaining low temperatures (0–5 °C) from harvest to storage for preventing moisture loss and fruit shriveling [18]. Our data further suggest that ‘Prime-Ark® Freedom’ possesses intrinsic traits that confer better postharvest stability and are less sensitive to prolonged cold storage, potentially making it suitable for longer storage or distant markets.

The high leak incidence in ‘Sweet-Ark™ Ponca’ at Day 0 (42.97%) in 2023 and sharp increase to 69.49% by Day 16 in 2024 signifies a significant cultivar-specific vulnerability to physical degradation. This susceptibility can be influenced by multiple factors, including high temperatures and UV exposure at harvest, as well as prolonged storage duration [15,17]. This cultivar-dependent increase mirrors observations from [30], who suggested that high leakage in blackberries can result from cultivar-specific differences in skin strength and cell wall integrity. Blackberry fruit firmness is a critical trait for postharvest quality, and studies have shown that high temperatures and improper postharvest handling can negatively impact firmness and consequently increase susceptibility to leakiness [10,15]. Moreover, elevated leakiness at later stages of storage corresponds to reports that both harvest temperature and prolonged cold exposure contribute to membrane damage. ‘Sweet-Ark™ Ponca’, in particular, appears vulnerable to this disorder, highlighting the importance of handling protocols and potentially breeding for firmer skins to improve shelf life. The consistent stability of ‘Prime-Ark® Freedom’ and ‘Osage’ across storage durations in both years, particularly their low leak percentages at Day 0 in 2024, suggests better cellular integrity and firmer fruit characteristics compared to ‘Sweet-Ark™ Ponca’.

Red drupelet reversion (RDR), a common postharvest disorder causing black drupelets to turn red, is well-documented [22,31]. In 2023, RDR levels were low and consistent, suggesting relatively stable conditions for short-term cold storage that year. RDR is often observed following sudden temperature changes or physical damage during harvest and shipping [20,21,22].

In contrast, the highly significant differences in 2024, with ‘Sweet-Ark™ Ponca’ exhibiting a remarkable 89.56% RDR at Day 16, indicate a strong cultivar × time interaction. This pronounced increase in RDR with prolonged storage, particularly in ‘Sweet-Ark™ Ponca’, aligns with existing research, indicating that RDR incidence often increases with longer storage durations and is highly cultivar-dependent [16]. Furthermore, increased fruit temperatures during harvest, typically exceeding 23 °C, have been consistently associated with a higher incidence and severity of RDR [22,32,33]. This suggests that environmental conditions during harvest or subsequent handling in 2024 may have made ‘Sweet-Ark™ Ponca’ more susceptible to mechanical injury and subsequent color reversion. The underlying mechanism of RDR is associated with a decline in anthocyanin pigment concentration, often due to cellular disruption [10,33].

In both years, ‘Osage’ maintained the highest SSC content (e.g., 11.4 °Brix in 2023 Day 0), while ‘Prime-Ark® Freedom’ showed consistently lower values (4.80–6.77 °Brix). High SSC levels are desirable in fresh-market blackberries as they relate to sweetness and consumer acceptability. Our results agree with previous findings [10], who reported significant cultivar differences in SSC across postharvest stages. Notably, ‘Osage’’s high SSC indicates its superior flavor profile, whereas ‘Prime-Ark® Freedom’ may need to be marketed based on its firmness and lower physiological defect rates rather than sugar content.

The SSC/TTA ratio is a key indicator of perceived fruit sweetness and flavor balance. The significant differences observed in both years, with ‘Sweet-Ark™ Ponca’ consistently showing the highest ratios at extended storage durations (e.g., 13.95 in 2023 and 17.23 in 2024 at Day 16), indicate a progressive enhancement of sweetness relative to acidity. This is a common physiological change during fruit ripening, as blackberries naturally accumulate soluble sugars and decrease in titratable acidity over time [34]. The lowest ratios observed in ‘Prime-Ark® Freedom’ at Day 0 in both years suggest a less favorable sugar-acid balance at harvest, which remained relatively poor throughout storage compared to the other cultivars. The increased ratios in ‘Sweet-Ark™ Ponca’ with prolonged storage suggest that it develops a more desirable flavor profile over time, though this must be balanced against its high susceptibility to weight loss, leakiness, and RDR.

The ascorbic acid content of ‘Osage’, ‘Sweet-Ark™ Ponca’, and ‘Prime-Ark® Freedom’ blackberries varied significantly by cultivar and storage duration across 2023 and 2024, consistent with previous research on nutritional composition in Rubus species [35,36,37]. In 2023, ‘Osage’ (approx. 50 mg/100 g FW) and ‘Sweet-Ark™ Ponca’ (approx. 52 mg/100 g FW) began with higher ascorbic acid than ‘Prime-Ark® Freedom’ (approx. 28 mg/100 g FW). ‘Osage’ maintained the highest levels throughout 16 days of cold storage, while ‘Prime-Ark® Freedom’ had a sharp decline by Day 7. ‘Sweet-Ark™ Ponca’ also showed a progressive reduction. This general postharvest decline is typical as ascorbic acid degrades [15].

Conversely, 2024 showed improved ascorbic acid stability. All three cultivars, including ‘Prime-Ark® Freedom’, maintained or increased their ascorbic acid levels by Day 16, with no significant postharvest losses. ‘Ponca’ and ‘Osage’ remained superior (peaking around 55–58 mg/100 g FW), and ‘Prime-Ark® Freedom’ significantly improved its retention (reaching approx. 42 mg/100 g FW). This inter-seasonal difference highlights the influence of environmental factors during growth and harvest on fruit resilience and nutrient retention [38,39,40]. For example, higher light exposure can boost antioxidant synthesis [41]. The improved stability in 2024 suggests favorable conditions or cultural practices. The observed inter-annual variability in ascorbic acid retention highlights the complex interplay between preharvest environmental factors and postharvest fruit resilience, warranting further investigation into specific climatic or cultural influences. Our findings consistently demonstrated significant cultivar-dependent responses, with the integrated assessment of physiological and biochemical traits revealing the multifaceted factors that influence shelf life. Future research should investigate specific pre-harvest climatic conditions (e.g., temperature, rainfall, solar radiation) to better understand and predict postharvest ascorbic acid retention.

To further explore the complex interactions among various postharvest quality traits in 2024, a heatmap analysis was performed (Figure 5). This visualization summarizes the standardized values of leakiness, RDR, pH, Brix, citric acid, and sugar–acid ratio across different cultivar–storage day combinations, providing insights into their interrelationships and cultivar-specific patterns. The color gradient from yellow to red reflects increasing trait intensity, enabling rapid comparison of cultivar performance.

Figure 5.

Postharvest trait summary heatmap comparing selected parameters with storage periods for the three blackberry cultivars (2024).

The heatmap clearly illustrates distinct clusters of cultivar–day combinations based on their postharvest profiles. A prominent cluster shows ‘Sweet-Ark™ Ponca’ at Day 16 exhibiting exceptionally high standardized values for leakiness (2.95) and reddening (2.04), reinforcing its severe susceptibility to these disorders under extended storage, as discussed in Section 3.2 and Section 3.3. This combination also shows a notably high sugar–acid ratio (1.77), which, while indicating enhanced sweetness relative to acidity (as noted in Section 3.5), is likely a consequence of advanced deterioration rather than a desirable quality in this context, given the high disorder incidence. It also shows relatively low Brix and citric acid values, suggesting a significant deterioration in overall quality.

Conversely, early storage days for ‘Osage’ (e.g., ‘Osage_0’ and ‘Osage_7’) are characterized by lower leakiness and RDR coupled with higher Brix values (1.16 and 0.90, respectively). Their sugar–acid ratio values are also relatively high (1.85 and 1.67), consistent with ‘Osage’’s superior initial quality and high sugar content (Section 3.4) and a favorable SSC/TTA flavor balance. Similarly, ‘Freedom’ at Day 0 and Day 7 shows lower standardized values for leakiness and reddening, indicating better initial stability, though their Brix levels are also comparatively lower. Their sugar–acid ratio values are also lower (−1.30 and −0.98, respectively), reflecting the less favorable sugar–acid balance at harvest for this cultivar (Section 3.5).

The hierarchical clustering on the left side of the heatmap groups similar samples. For instance, ‘Ponca_16’ stands out as an outlier due to its extreme values for leakiness, reddening, and its distinct sugar–acid ratio. ‘Freedom_12’ and ‘Freedom_16’ cluster together, indicating similar behavior in later storage, while ‘Osage_0’ and ‘Osage_7’ form another cluster, highlighting their consistent high quality early on.

The heatmap also reveals inverse relationships between certain traits. Generally, samples with high leakiness and reddening tend to have lower Brix and citric acid, suggesting that fruit deterioration is accompanied by changes in sugar and acid metabolism. The sugar–acid ratio, while generally increasing with ripening, shows a complex relationship in deteriorated fruit like ‘Ponca_16’, where its high value might be a symptom of advanced breakdown rather than ideal flavor. This integrated view from the heatmap provides a compelling summary of the complex postharvest dynamics, underscoring the cultivar- and time-dependent vulnerabilities and strengths observed in the individual trait analyses.

5. Conclusions

In conclusion, ‘Prime-Ark® Freedom’ exhibited superior physical resilience, demonstrated by lower weight loss, reduced leakiness, and minimized red drupelet reversion (RDR), indicating its suitability for extended supply chains and distant markets. In contrast, ‘Sweet-Ark™ Ponca’ was highly susceptible to physical degradation, particularly leakiness and RDR, suggesting it is best suited for rapid market turnover. ‘Osage’ consistently maintained high soluble solids content (SSC) and ascorbic acid, highlighting its robust flavor and nutritional quality, making it ideal for fresh-market channels where optimal sensory attributes over shorter storage periods are required.

These results provide actionable insights for cultivar selection aligned with specific market needs and underscore the importance of tailored postharvest management strategies. Future research should focus on elucidating the preharvest factors driving inter-annual quality variation and on exploring advanced postharvest technologies to mitigate cultivar-specific challenges.

Author Contributions

Conceptualization, Z.D., G.L., S.S. and N.S.; methodology, S.S. and N.S.; investigation, N.S., S.S., G.L. and Z.D.; data curation, G.L. and N.S.; writing—original draft preparation, N.S.; writing—review and editing, S.S., Z.D., J.W., G.L. and N.S.; supervision, G.L.; project administration, G.L. and Z.D.; funding acquisition, Z.D. and G.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the USDA Agricultural Marketing Service (AMS) Specialty Crop Block Grant Program (SCBGP) through the Florida Department of Agriculture and Consumer Services (FDACS), Grant No.: AM21SCBPF1125. Contract #: 29247. Project #: P0278738.

Data Availability Statement

The data presented in this study are available on request from the corresponding author due to policy reasons.

Acknowledgments

The authors gratefully acknowledge financial support from the USDA Agricultural Marketing Service (AMS) and the Florida Department of Agriculture and Consumer Services (FDACS). We extend our sincere appreciation to Thomas Gardner for his contribution of blackberry fruit used in this study, and to the UF/IFAS Postharvest Laboratory team for their essential assistance in conducting the postharvest handling trials.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Andersen, P.C. The Blackberry. Publication HS807; Horticultural Sciences Department, University of Florida, Institute of Food and Agricultural Sciences, Florida Cooperative Extension Service: Gainesville, FL, USA, 2020. [Google Scholar] [CrossRef]

- Carter, K.A.; Liston, A.; Bassil, N.V.; Alice, L.A.; Bushakra, J.M.; Sutherland, B.L.; Mockler, T.C.; Bryant, D.W.; Hummer, K.E. Target capture sequencing unravels Rubus evolution. Front. Plant Sci. 2019, 10, 1615. [Google Scholar] [CrossRef] [PubMed]

- Tumbarski, Y.; Petkova, N.; Todorova, M.; Ivanov, I.; Deseva, I.; Mihaylova, D.; Ibrahim, S. Effects of pectin-based edible coatings containing a bacteriocin of Bacillus methylotro phicus BM47 on the quality and storage life of fresh blackberries. Italian J. Food Sci. 2020, 32, 420–437. [Google Scholar]

- Clark, J.R. Changing times for eastern United States blackberries. HortTechnology 2005, 15, 491. [Google Scholar] [CrossRef]

- Clark, J.R.; Finn, C.E. Blackberry cultivation in the World. Rev. Bras. Frutic. 2014, 36, 46–57. [Google Scholar] [CrossRef]

- FAOSTAT. Crop Production, Yield, Harvested Area (Global-National-Annual). 2024. Available online: https://www.fao.org/faostat/en/#data (accessed on 4 March 2022).

- Oliveira, P.B.; Oliveira, C.M.; Machado, P.V.; Lopes-da-Fonseca, L.; Monteiro, A.A. Improving off-season production of primocane-fruiting red raspberry by altering summer-pruning intensity. HortScience 1998, 3, 31–33. [Google Scholar] [CrossRef]

- Rom, C.R.; Garcia, M.E.; Johnson, D.T.; Popp, J.; Friedrich, H.; McAfee, J. High tunnel production of organic blackberries and raspberries in Arkansas. ISHS Acta Horticulturae 2010, 873, 269–276. [Google Scholar] [CrossRef]

- Rodríguez, H.G.; Popp, J.; Thomsen, M.; Friedrich, H.; Rom, C.R. Economic analysis of investing in open-field or high tunnel primocane-fruiting blackberry production in Northwestern Arkansas. HortTechnology 2012, 22, 245–251. [Google Scholar] [CrossRef]

- Salgado, A.A.; Clark, J.R. “Crispy” blackberry genotypes: A breeding innovation of the University of Arkansas blackberry breeding program. HortScience 2016, 51, 468–471. [Google Scholar] [CrossRef]

- Segantini, D.M.; Threlfall, R.; Clark, J.R.; Brownmiller, C.R.; Howard, L.R.; Lawless, L.J.R. Changes in fresh-market and sensory attributes of blackberry genotypes after postharvest storage. J. Berry Res. 2017, 7, 129–145. [Google Scholar] [CrossRef]

- Brackmann, A.; Thewes, F.R.; de Oliveira Anese, R.; de Gasperin, A.R.; Fronza, D. Interaction between maturity stages and temperature on quality of ‘Guarani’ blackberries stored under controlled atmosphere. Cienc. Rural 2017, 47, e20150987. [Google Scholar] [CrossRef]

- Sabir, F.; Sabir, A.; Ozcelik, S.; Kucukbasmaci, A. Maintenance of postharvest quality of blackberry (Rubus fructicosus L.) fruits through salicylic acid and CaCl2 immersions. Acta Sci. Pol. Hortorum Cultus 2019, 18, 121–128. [Google Scholar] [CrossRef]

- Joo, M.; Lewandowski, N.; Auras, R.; Harte, J.; Almenar, E. Comparative shelf life study of blackberry fruit in bio-based and petroleum-based containers under retail storage conditions. Food Chem. 2011, 126, 1734–1740. [Google Scholar] [CrossRef] [PubMed]

- Perkins-Veazie, P.; Collins, J.; Clark, J. Cultivar and storage temperature effects on the shelf life of blackberry fruit. Proc. Fla. State Hortic. Soc. 1999, 53, 201–208. [Google Scholar]

- Lawrence, B.; Melgar, J.C. Harvest, handling, and storage recommendations for improving postharvest quality of blackberry cultivars. HortTechnology 2018, 28, 578–583. [Google Scholar] [CrossRef]

- Liu, M. Effect of Organic Production System and Harvest Date on the Quality of Blackberry Fruit for Fresh and Processed Markets. Master’s Thesis, University of Arkansas, Fayetteville, AR, USA, 2014. [Google Scholar]

- Clark, J.R.; Stafne, E.T.; Hall, H.K.; Finn, C.E. Blackberry breeding and genetics. Plant Breed. Rev. 2007, 29, 19. [Google Scholar]

- Finn, C.E.; Clark, J.R. Blackberry. In Fruit Breeding; Springer: Boston, MA, USA, 2012; pp. 151–190. [Google Scholar]

- Pérez-Pérez, G.A.; Fabela-Gallegos, M.J.; Vázquez-Barrios, M.E.; Rivera-Pastrana, D.M.; Palma-Tirado, L.; Mercado-Silva, E.; Escalona, V. Effect of the transport vibration on the generation of the color reversion in blackberry fruit. Acta Hortic. 2016, 1194, 1329–1336. [Google Scholar] [CrossRef]

- Edgley, M. Causes and Mechanisms of Red Drupelet Reversion in Blackberries. PhD Thesis, University of Tasmania, Hobart, Australia, 2019. [Google Scholar]

- McCoy, J.; Clarke, J.; Salgado, A.; Jecmen, A. Evaluation of harvest time/temperature and storage temperature on postharvest incidence of red drupelet reversion development and firmness of blackberry (Rubus L. subgenus Rubus Watson). Discov. Stud. J. Dale Bump. Coll. Agric. Food Life Sci. 2016, 17, 59–65. [Google Scholar]

- Cia, P.; Bron, I.U.; de Toledo Valentini, S.R.; Pio, R.; Chagas, E.A. Atmosfera modificada e refrigeração para conservação pós-colheita da amora-preta. Biosci. J. 2007, 23, 73–81. [Google Scholar]

- Bolda, M.; Cahn, M.D.; Gaskell, M.; Mitcham, E.J. Fresh Market Caneberry Production Manual; UCANR Publications: Oakland, CA, USA, 2012. [Google Scholar]

- Kader, A.A. Postharvest Technology of Horticultural Crops; University of California Agriculture and Natural Resources: Oakland, CA, USA, 2002. [Google Scholar]

- Clark, J.R.; Finn, C.E. New trends in blackberry breeding. Acta Hortic. 2008, 777, 41–48. [Google Scholar] [CrossRef]

- Talasila, U.; Vechalapu, R.R.; Shaik, K.B. Clarification, preservation, and shelf life evaluation of cashew apple juice. Food Sci. Biotechnol. 2012, 21, 709–714. [Google Scholar] [CrossRef]

- Terada, M.; Watanabe, Y.; Kunitomo, M.; Hayashi, E. Differential rapid analysis of ascorbic acid and ascorbic acid 2-sulfate by dinitrophenylhydrazine method. Anal. Biochem. 1978, 84, 604–608. [Google Scholar] [CrossRef]

- Lobos, G.; Retamales, J.; Moggia, C. Modified atmosphere packaging in blueberries: Effect of harvest time and moment of bag sealing. Acta Hortic. 2014, 1017, 153–158. [Google Scholar] [CrossRef]

- Edgley, M.; Close, D.; Measham, P.; Nichols, D. Physiochemistry of blackberries (Rubus L. subgenus Rubus Watson) affected by red drupelet reversion. Postharvest Biol. Technol. 2019, 153, 183–190. [Google Scholar] [CrossRef]

- Perkins-Veazie, P.; Collins, J.; Clark, J. Cultivar and maturity affect postharvest quality of fruit from erect blackberries. HortScience 1996, 31, 258–261. [Google Scholar] [CrossRef]

- Yin, M.H. Studies in Blackberry: Development and Implementation of a Phenotyping Protocol for Blackberry Seedling Populations and Impact of Time of Day of Harvest on Red Drupelet Reversion for University of Arkansas Blackberry Genotypes; University of Arkansas: Fayetteville, AR, USA, 2017. [Google Scholar]

- Edgley, M.; Close, D.; Measham, P. Red drupelet reversion in blackberries: A complex of genetic and environmental factors. Sci. Hortic. 2020, 272, 109555. [Google Scholar] [CrossRef]

- Perkins-Veazie, P.; Clark, J.; Huber, D.; Baldwin, E. Ripening physiology in ‘Navaho’ thornless blackberries: Color, respiration, ethylene production, softening, and compositional changes. J. Amer. Soc. Hortic. Sci. 2000, 125, 245–250. [Google Scholar] [CrossRef]

- Siriwoharn, T.; Wrolstad, R.E.; Finn, C.E.; Pereira, C.B. Influence of cultivar, maturity, and sampling on blackberry (Rubus L. hybrids) anthocyanins, polyphenolics, and antioxidant properties. J. Agric. Food Chem. 2004, 52, 8021–8030. [Google Scholar] [CrossRef]

- Ali, L. Pre-Harvest Factors Affecting Quality and Shelf-Life in Raspberries and Blackberries (Rubus spp. L.). PhD Thesis, Swedish University of Agricultural Sciences, Alnarp, Sweden, 2012. [Google Scholar]

- Kaume, L.; Howard, L.R.; Devareddy, L. The blackberry fruit: A review on its composition and chemistry, metabolism and bioavailability, and health benefits. J. Agric. Food Chem. 2012, 60, 5716–5727. [Google Scholar] [CrossRef]

- Wang, S.Y.; Lin, H.-S. Antioxidant activity in fruits and leaves of blackberry, raspberry, and strawberry varies with cultivar and developmental stage. J. Agric. Food Chem. 2000, 48, 140–146. [Google Scholar] [CrossRef]

- Clark, J.R.; Demchak, K.; Finn, C.E.; Lowe, J.D.; Pomper, K.W.; Crabtree, S.B. ‘Black Magic’™ (APF-77) primocane-fruiting blackberry. HortScience 2014, 49, 1618–1620. [Google Scholar]

- Prange, R.K.; DeEll, J.R. Preharvest factors affecting postharvest quality of berry crops. HortScience 1997, 32, 824–830. [Google Scholar] [CrossRef]

- Demirsoy, L.; Demirsoy, H.; Uzun, S.; Ozturk, A. The effects of different periods of shading on growth and yield in ‘Sweet Charlie’ strawberry. Eur. J. Hortic. Sci. 2007, 72, 26–30. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).