Abstract

Postharvest losses amongst small-scale farmers in developing countries are high due to inadequate resources and infrastructure. Among the various affected crops, tomatoes are particularly vulnerable; however, studies on postharvest losses of most fruits and vegetables are limited. Therefore, this study aimed to assess postharvest tomato losses under different production systems within the small-scale supply chain using the indirect assessment (questionnaires and interviews) and direct quantification of losses. Farmers reported tomato losses due to insects (82.35%), cracks, bruises, and deformities (70.58%), and diseases (64.71%). Chemical sprays were the main form of pest and disease control reported by all farmers. The direct quantification sampling data revealed that 73.07% of the tomatoes were substandard at the farm level, with 47.92% and 25.15% categorized as medium-quality and poor-quality, respectively. The primary contributors to the losses were decay (39.92%), mechanical damage (31.32%), and blotchiness (27.99%). Postharvest losses were significantly higher under open-field production systems compared to closed tunnels. The fungi associated with decay were mainly Geotrichum, Fusarium spp., and Alternaria spp. These findings demonstrate the main drivers behind postharvest losses, which in turn highlight the critical need for intervention through training and support, including the use of postharvest loss reduction technologies to enhance food security.

1. Introduction

Global production and consumption of fresh produce have increased by more than 60% in the last two decades, as consumers are now conscious of the health benefits of fruits and vegetables when consumed raw [1]. The consumption of tomatoes (Solanum lycopersicum L.), specifically, has been associated with reduced susceptibility to life-threatening diseases, such as cancer, diabetes, and heart disease, among others [2]. In addition to the health benefits, tomatoes were the most produced vegetable in the world, at 186 million tonnes in 2022, representing an increase from 110 million tonnes in the last two decades. Despite these benefits, the production and consumption of tomatoes are affected by various factors at the pre- and postharvest stages, which leads to fruit losses, thus limiting food availability for consumers [3]. Food availability is further limited by the increase in tomato prices due to a combination of supply, demand, and external factors, making them inaccessible to food-insecure populations [4].

In Sub-Saharan Africa, with more than 61% moderate-to-severe food-insecure people, the impact of supply chain losses is devastating [1]. Substantial tomato losses are experienced during production and storage due to poor infrastructure, packaging, management, and financial limitations [5]. The compounded effect of several causes, namely, physical damage, physiological disorders, and biological damage, results in severe pre- and postharvest losses [6], leading to decay and mechanical damage. These challenges, compounded with other factors, affect the production and income of small-scale farmers [7].

The postharvest losses of tomatoes in the African context have previously been assessed [8,9,10], showing that these losses pose a serious threat to food security and smallholder farmer livelihoods. In household farms in Ethiopia and Rwanda, poor handling, inappropriate storage containers, rough transportation, and a lack of temperature management resulted in mechanical damage to harvested tomatoes [11]. According to Fernandez-Zamudio et al. [12], reliable information on food waste and losses in the agricultural supply chain is limited, especially when obtained through direct measurement methods. The lack of primary data obtained through direct measurements is a limiting factor in the estimation of the magnitude of food waste and its mitigation [3,12]. In South Africa, farm-level losses of tomatoes have been previously assessed using only a questionnaire-mediated study [13]. The direct quantification of tomato produce lost at a farm level and postharvest is not available for small-scale farmers, such as in the South African setting.

Therefore, this study aimed to assess and quantify postharvest tomato losses under four different small-scale production systems, to identify critical farm practices associated with postharvest losses. This information will be useful for developing “fit-for-purpose” loss mitigation strategies. Objective one focused on the assessment of farmer knowledge and practices, while objective two focused on quantifying the causes of tomato losses postharvest. To the best of our knowledge, this is the first study to quantify the postharvest losses of tomatoes experienced by small-scale farmers under different production systems.

2. Materials and Methods

2.1. Site and Participant Selection

This study was conducted in all three agricultural regions (Tshwane, Germiston, and West Rand) of the Gauteng Province of South Africa in the 2022–2023 tomato production season. Small-scale farmers who started planting in 2022 or 2023 were excluded due to a lack of historical loss data. The questionnaires and consent forms were administered through extension officers via in-person visits and emails to all 34 small-scale farmers registered with the Gauteng Department of Agriculture and Rural Development (GDARD) before visiting the farms [14]. Only 17 of the 34 farmers volunteered for this questionnaire study. Of these 17 farmers, 8 were randomly selected for the assessment of postharvest losses in storage. The selected farmers produced tomatoes in different production systems (open, netted, semi-closed, and closed tunnels) and produced and harvested tomatoes between August 2022 and March 2023.

2.2. Questionnaire Design and Administration

The final questionnaire was constructed to comprise four quantitative and qualitative semi-structured sections, with a total of 40 questions. English was used as the primary language of communication. Section A consisted of demographic information, such as the location of the farm and the produce planted by the farmer. Proportionally, there were more small-scale farmers from the West Rand (58.82%) than Tshwane (35.29%) and Germiston (5.88%) who participated in this study. The farmers operated on farms with a total size ranging from 0.5 to 20 hectares. The majority (52.94%) of the small-scale farmers cultivated their tomatoes under a covered system that included shade nets and plastic tunnels, 17.65% planted tomatoes in open fields, and 29.41% cultivated tomatoes in combination systems.

Section B focused on farm facilities to establish the impact of infrastructural and managerial challenges that can contribute to losses, section C evaluated the farmer’s preharvest practices and losses, and section D evaluated the postharvest practices and losses. Sections C and D were designed to provide insight into the potential practices that can lead to pre- and postharvest losses within the small-scale sector.

On the day of the interview, the consent form and the purpose of this study were explained to the farmers, project managers, and extension officers. The farmers were informed of the research objectives and the confidentiality of data (detailed in the ethical consideration section). The interviews were conducted with the farmer or operational manager about the day-to-day farm activities. Interview times ranged from 30 minutes to one hour, depending on the farmer’s willingness to share information on the history of the farm, practices, and losses. For the purpose of this study, questions that assessed factors contributing to losses were analysed and reported.

2.3. Sample Collection and Direct Assessment of Fruit Quality

In order to assess the causes of tomato losses, a direct assessment of tomato quality was conducted. A total of 3115 fruits from small-scale farmers were analysed in the current study. Six-kilogram boxes (commonly used packaging by small-scale farmers) of tomatoes were collected in triplicate from farms and subjected to consumer-simulated storage at room temperature [15]. The number of sampling repeats for the collection of tomatoes per farm ranged from two to four, based on the length of the harvesting season. Farm T1 was visited on four occasions, T2 was visited twice, and T3 was visited three times. Likewise, W1 was visited four times, W2 and W4 were each visited twice, and W3 and G1 were each visited three times.

Tomatoes were analysed at harvest (day 1) and postharvest (day 7 and day 14). Each fruit was individually counted and visually assessed for defects, such as blotchiness, decay, insect damage, mechanical injuries, water stress (cracked/shrivelled skin), size irregularities (undersized or oversized), and ripeness issues (green or overripe) [9]. Tomatoes were analysed for total losses by categorizing the fruits into good and substandard (medium or poor) quality. Good-quality tomatoes were free from defects, medium-quality tomatoes exhibited blotchiness and damage that mainly affected their appearance and consumer acceptance, and poor-quality tomatoes included decayed and insect-damaged fruits that rendered them inedible [8]. The poor-quality fruits were recorded and discarded. Total losses were calculated as an expression of the number of poor-quality fruits in a box. The percentage of losses per physical defect was calculated as an expression of the number of fruits with non-satisfactory quality (medium- and poor-quality).

To assess physiological quality parameters, fruit mass (g) (Mettler-Toledo AG, CH-8606 Greifensee—Zürich, Switzerland), firmness (N) (Digital fruit penetrometer, Haryana, India), pH (PH211 pH Meter, Woonsocket, RI, USA), and total soluble solids (TSSs) (%) (PR-32, Atago, TSSs 0–32%, Palette, Tokyo, Japan) were measured for five tomatoes, randomly selected from each box on days 1, 7, and 14. After these measurements, symptomatic fruits were assessed for fungal and bacterial pathogens using morphological and molecular techniques. Surface-sterilized tomato fruit tissues were plated onto malt extract agar (MEA) (Merck, Johannesburg, South Africa) supplemented with chloramphenicol and incubated at 25 °C for seven days. Subsequently, these microorganisms were identified by Sanger sequencing and BLASTn (https://blast.ncbi.nlm.nih.gov) analysis of the fungal internal transcribed spacer ITS1 and ITS4 loci amplified using the forward primer ITS1 (5′-TCCGTAGGTGAACCTGCGG-3′) and the reverse primer ITS4 (5′-TCCTCCGCTTATTGATATGC-3′) [16].

2.4. Ethical Consideration

This study received approval from the University of Pretoria’s Faculty of National and Agricultural Sciences Research Ethics Committees (ethical clearance number: NAS234/2022). For confidentiality, farm names were concealed in unique codes for each questionnaire. Farms from the Tshwane region were designated as T1 to T3, Germiston as G1, and the West Rand as W1 to W4. Production systems were categorized as closed production at T1, G1, and W4, semi-closed production at W1, W2, and W3, the netted tunnel at T3, and an open field at T2.

2.5. Data Analysis

For the questionnaire data, SPSS Statistics version 27 [8] was used, and for descriptive statistics, R package version 4.2.3 was used to assess statistical differences in loss by analysis of variance (ANOVA) across the farms, production systems, storage durations, and physical defect types [17]. Pair-wise comparison was conducted by Least Significant Difference post hoc analysis. To analyse the trends and correlations among the different causes of tomato losses, principal component analysis (PCA) was performed. In the ordination, the various causes of losses are represented by vectors. Longer vectors indicate a stronger influence. Where vectors point in the same direction and appear close together, the causes are considered to be related.

3. Results

3.1. Preharvest Practices

Tomato production of four different cultivars (Moneymaker, Renka, Rodade, and Hybrids) is performed throughout the year. The small-scale farmers interviewed reported using different cultivars depending on a high profit margin (33%) and long shelf-life potential (53%). Crops are planted from seeds and/or seedlings sourced from agricultural shops and nurseries. To achieve the expected yield, more than 50% of the farmers chose their cultivar based on the plant’s vigour and long shelf-life potential of yield, while 40% indicated that resistance to disease and pests was their main reason for choosing specific cultivars for production (Table 1). The results also show that 88.24% of farmers used borehole water that was either stored in closed plastic tanks (62.00%), open dams (12.5%), or both (25%). This water was often used for irrigation without prior treatment (Table A1).

Table 1.

A survey of preharvest activities in the production of tomatoes by small-scale farmers in Gauteng Province. N = the number of individuals.

Although farmers used resistant cultivars, the control of pests and diseases was still mainly performed through pesticides and fungicides. For better results, about 47.10% of the farmers, guided by the extension officers, followed a spray program to avoid over- or under-spraying. Meanwhile, 17.60% sprayed only when there were symptomatic plants (Table 1). Notwithstanding the spraying program, farmers still reported losses of tomatoes due to diseases (88.24%) and insects (100%). These could be attributed to inadequate disease diagnosis expertise, as was the case for more than 70% of the farmers.

In the pursuit to resolve this matter, farmers are assisted by extension officers (87.50%), chemical companies, and the Agricultural Research Council (18.75%) (25.00%) for the identification of diseases and insects (Table 1). However, these services are not readily available on-site in time to consider and apply preventative measures. Moreover, the majority of the farmers (76.47%) indicated that cracks due to excessive watering or irregular irrigation are one of the additional causes of losses in the field, followed by bruises (52.94%), scars (58.82%), and deformities (70.60%) (Table 1). The farmers (W1 and T1) who indicated having expertise obtained the information, either through training courses or from previous work experience at the Department of Agriculture, reported lower postharvest losses compared to other farmers.

3.2. Postharvest Practices and Related Losses

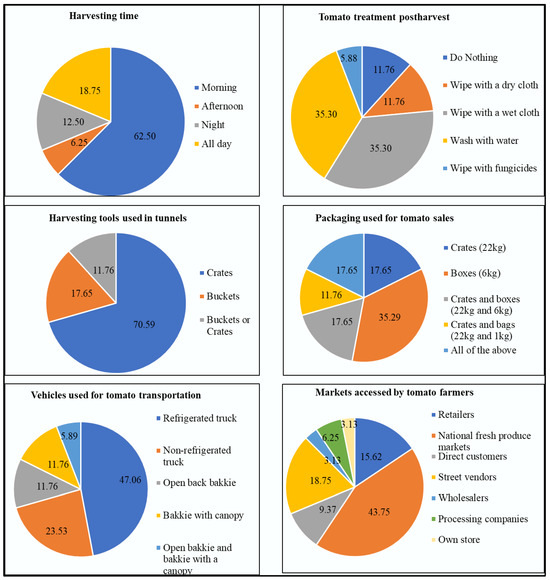

Tomatoes were harvested for three to four months after planting seedlings in the ground. Harvesting was mainly performed by hand, collected in crates and buckets, and later sorted into boxes, bags, and crates for sale. More than 60% of the farmers harvested tomatoes in the cool morning weather to reduce the field heat. The main reason for harvesting in the morning and last afternoon was that “the weather is cooler, so the fruits do not lose water”. Other farmers indicated that the harvesting time was decided based on the trading hours of the markets and the availability of direct customers (Figure 1).

Figure 1.

Different types of harvest and postharvest practices among small-scale tomato farmers represented in percentages, including harvesting time, harvesting tools, postharvest treatment, packing materials, vehicles used for transportation, and market access. The percentages indicated in each pie chart refer to farmers following the specific set of harvest and postharvest practices.

Moreover, 65% of the farms had no packhouse facility. Of the 35% (n = 6) that reported having a packhouse, only one had a cold room, water bath, and pack area facility, and the remaining farmers used any empty room, garage, or shed that was designated for the packing of fruits, often with inappropriate hygiene levels. These results indicate a lack of resources with small-scale farmers to practice suitable tomato handling postharvest. All farmers indicated that they sorted their tomatoes based on size and colour. Subsequently, fruit washing was performed to remove soil on the fruit surface—if fruits appeared clean, farmers did not enforce cleaning before sending the produce to the market. During the period of this survey, only the fruit in open-field tomato production required wiping, as it had rained the day before harvesting. Tomatoes that were cleaned before sending to the market were wiped with a wet cloth (35.29%), dry cloth (11.76%), washed with water (35.29%), and wiped with water containing fungicides (3.88%), depending on the level of dirtiness. Approximately 12% of all interviewed farmers sold tomatoes without washing or wiping.

After harvest, the tomatoes were sold into a wide range of markets, including formal and informal retailers, wholesalers, processing companies, the national fresh produce markets, and direct customers. While only 11% of the farmers use refrigerated trucks, most use open and closed pick-up trucks (called “bakkies”) and cargo trucks to transport the produce to the point of sale (Figure 1).

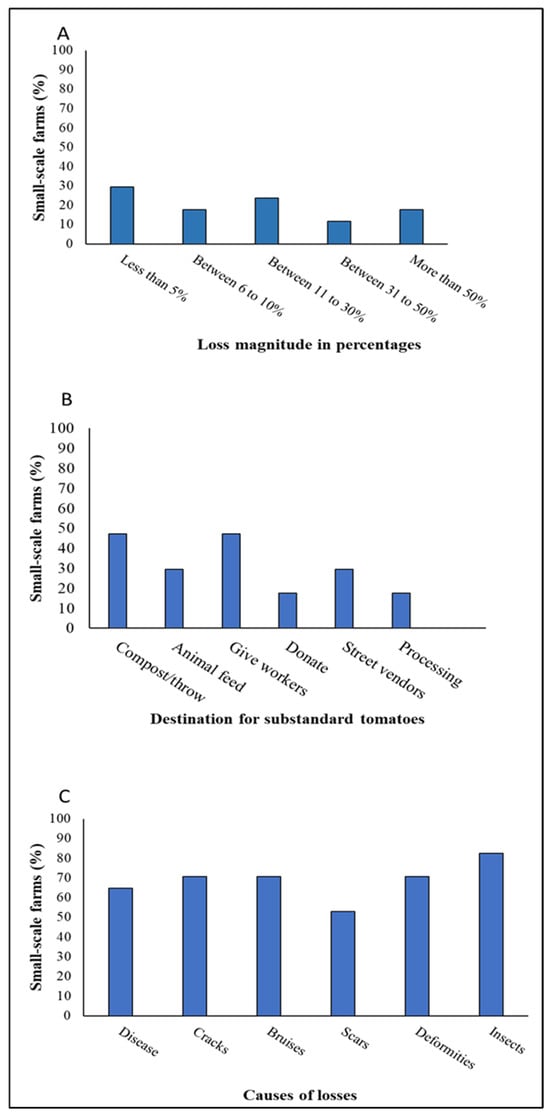

Results demonstrate that the annual tomato production in small-scale farms ranged from 2 tonnes per hector to 256 tonnes per hector. On the negative side, approximately 18% of the farmers lost more than half of their crop within a season, and about 35% indicated that they lost approximately one-third of the fruits. Losses were due to insects (82.35%), followed by cracks, bruises, and deformities (70.58%) and diseases (64.71%) (Figure 2). The results further revealed that 47% of the farmers ate or discarded low-quality fruits, followed by 30% being sold to street vendors. Less than 20% of the farmers donated or sold the fruit to processing companies.

Figure 2.

Postharvest losses of tomatoes under small-scale farming conditions, highlighting (A) percentage losses reported by small-scale farmers, (B) what farmers do with unmarketable fruits, and (C) different causes of postharvest losses.

3.3. Direct Assessment of Tomato Losses and Quality

3.3.1. Quality Attributes

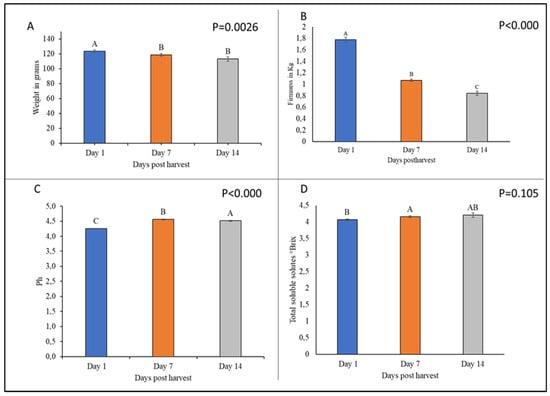

Fruit weight significantly reduced from day one to day seven (p < 0.0001); however, no significant differences were observed between day seven and day fourteen. A significant (p < 0.0001) decline was also observed in fruit firmness from day one (1.77 ± 0.04 kg) to day fourteen (0.88 ± 0.03 kg). The pH increased significantly (p < 0.0001) from the day of harvest (4.25 ± 0.01) to 14 days after storage (4.51 ± 0.01). The results also show that fruit pH and firmness significantly differed between farms (p < 0.0001). In contrast, the increase in total soluble solutes (TSSs) in storage was not significant, where it was noted as 4.07, 4.16, and 4.21 Brix for days one, seven, and fourteen, respectively (Figure A1).

3.3.2. On-Farm Losses

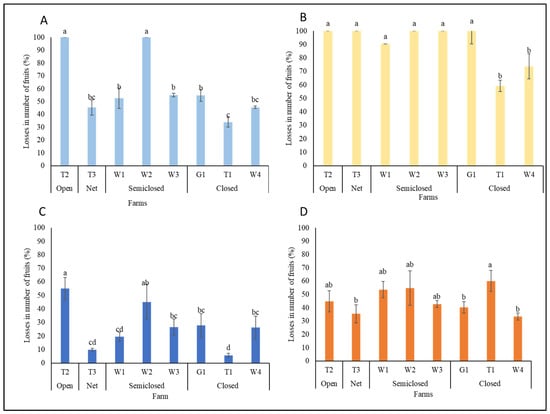

A total of 63 boxes (378 kg) of fruits were collected from the farms and analysed for postharvest losses on day 1 and day 14 of storage. Postharvest losses differed significantly between tomatoes sampled at the start and the end of the harvesting season (p < 0.0001). Figure 3A shows that losses were lower at the beginning of the season, with an average of 60.95% and a range of 28.57–100% (p < 0.0001). Meanwhile, the losses at the end (Figure 3B) of the season ranged from 46.15 to 100.00%, with an average of 90.43% (p = 0.0001). From the collected samples, the five farms that recorded 100% losses at the farm level at the beginning of the season had similar results at the end of the season. These farms had to shorten the production (T2 and W2) seasons due to severe losses. Open-field and netted tunnel losses were related to rain and hail that caused microtears on tunnels and damaged fruit. Only three farms recorded losses of less than 100% at the end of the harvesting season: two were closed tunnels, and one was semi-closed. The latter planted their tomatoes late in the season and only underwent the first harvest in early January, as compared to the November and December harvests of other farmers.

Figure 3.

Substandard tomatoes from small-scale farmers at harvest. Overall, substandard fruits monitored at the (A) beginning and (B) end of the season were categorised as (C) poor-quality and (D) medium-quality. The different letters on the bars show significant differences based on Fisher’s test (α = 0.05). The percentages in the figures indicate the number of fruits considered substandard per farm.

Overall, 73.07% of the tomatoes were substandard (Figure 4) at the farm level, with 47.92% medium-quality and 25.15% poor-quality tomatoes. Figure 3C,D show the tomato losses segregated into medium-quality and poor-quality (fruits not fit for consumption). The data further shows that farms under semi-closed production had no significant difference in the fruit categorised as medium-quality. In contrast, T1 under closed production was shown to have significantly higher numbers of medium-quality fruits than W4 (p = 0.004). This means that, even though T1 had high losses, the fruit could still be sold, albeit at a lower price, and used for human consumption. On the other hand, poor-quality (C) or quantitative losses were significantly higher in T2 (open field) compared to the other farms. Naturally, these are the two farms that showed an overall 100% qualitative losses at the end of the season. Tomatoes from farm T1 (closed production) had significantly lower poor-quality fruit losses than the other farms at the farm level. Intermediate levels of losses were observed in the remaining six farms, regardless of production system (p < 0.05).

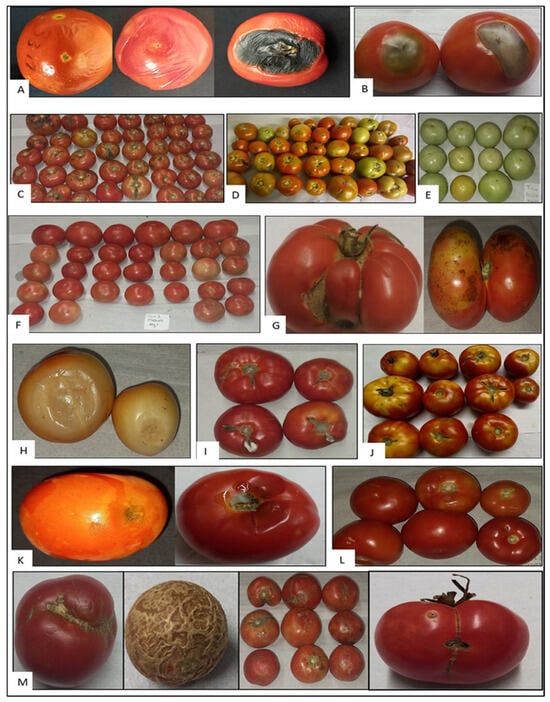

Figure 4.

Visual examples of losses of tomatoes observed at harvest and in storage caused by (A) decay, (B) blossom-end rot, (C) chilling injury, (D) insect damage, (E) green, (F) over/undersized, (G) deformities, (H) sunscald, (I) water stress cracks, (J) blotchiness, (K) leaking fruits, (L) mechanical damage, and (M) physiological losses.

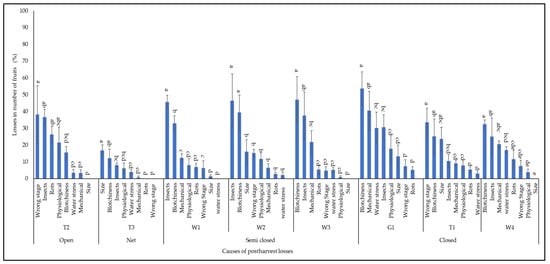

The losses observed at the farm level were caused by different factors, the most common being decay, insects, mechanical damage, physiological defects, incorrect size, and harvesting at the wrong stage. Decay was reported in all farms at harvest, with the highest prevalence observed in open fields (abundance of 19%; Figure 5). Lower decay damage was observed in six of the farms with a relative percentage lower than 10%. In poor-quality fruits, the losses were attributed to insects, decay, and mechanical damage; such damage often render the fruit unappealing and unsafe for consumption. Overall, losses caused by insects and blotchiness were significantly greater than those resulting from other types of losses. Insect damage were relatively higher in fruits harvested under semi-closed tunnels and netted and open fields and lower in the closed tunnels. A similar pattern was observed where the mechanical damage was relatively higher under closed and semi-closed production, with a loss of more than 15%, compared to the fruits harvested from netted tunnels and open fields, with a loss of less than 5%. Blotchiness was the main loss contributor to medium-quality tomatoes (43.95%). The other common causes of medium losses were harvesting of green/overripe fruit (17.57%), shrivelling and cracks (15.58%), over/undersized fruit (11.65%), and physiological damage (13.22%). There was no significant difference in the incidence of these types of losses. For one farm (G1), the losses (100%) at harvest resulted in uneven ripening, caused by chilling injury due to power outages that disrupted the cold chain.

Figure 5.

The causes of postharvest losses of tomato from small-scale farmers under different production systems, including the extent of the causes of losses, open fields, netted tunnels, semi-closed tunnels, and closed tunnels. The statistical analysis of the different causes of losses per farm are independent of analysis of another farm. The different letters on the bars show significant differences based on Fisher’s test (α = 0.05) within a specific farm.

3.3.3. Losses in Postharvest Storage

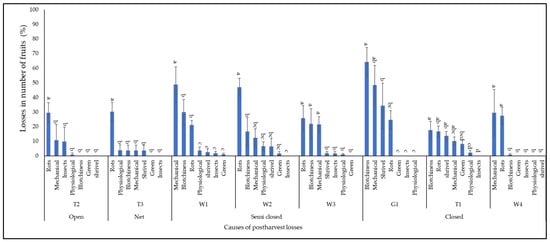

The average postharvest losses on day seven were 38.66%—these tomatoes were unfit for consumption, mainly due to insect damage and diseases, or severe mechanical damage. The lowest losses (from 4.95%) were observed in tomato fruits sourced from closed (T1) and semi-closed tunnels (W1). On the other hand, the highest losses (up to 39.18%) were from W2, which had the highest insect infestation, followed by open fields (T2) and netted tunnels (T3).

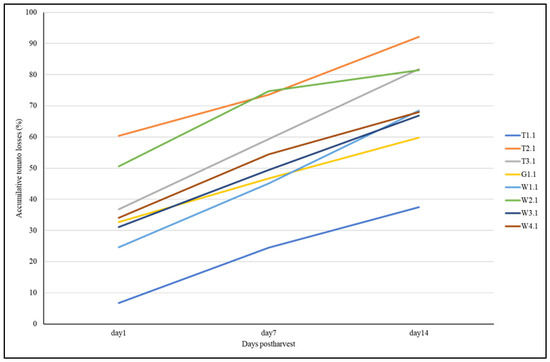

On day 14, postharvest losses were presented as cumulative losses in storage. Overall, losses in storage averaged 65.00% (Figure A2). The complete loss of produce at harvest was mainly due to the decay of wounded fruits, rain, and insect and pathogen infestation. The closed-tunnel farm, T1, had the lowest average postharvest losses recorded in this study, less than 30%, followed by W1 (45.61%). These are the only two farms that recorded less than 50% postharvest losses in storage. The other semi-closed and closed farms experienced postharvest losses between 52.60% and 62.79%, except W2. Farms T2 (open-field) and W2 (semi-closed) had the highest accumulated postharvest losses of 92.10% and 81.44%, respectively. The quality of the tomatoes collected from these farms was relatively higher than other farms on day one, and by day seven, over 70% of the fruits were discarded. Trailing behind T2 and W2 is T3, where the losses started lower on day one; however, by day seven, the losses were already above 70%, reaching 81.77% on day 14 (Figure A2). In contrast, tomatoes collected from T1 (closed) and W1 (semi-closed) had relatively higher quality produce compared to the other six farms. More than 70% of the tomatoes from T1 were still in an acceptable condition by day 14.

Overall, postharvest losses in storage were mainly caused by decay (39.92%), mechanical damage (31.32%), and blotchiness (27.99%). Figure 4 shows a visual representation of the different losses seen in this study—these types of losses are considered as defects by South African tomato quality standards. The leading causes of losses in storage differed from one farm to another. Decay was the main cause of tomato losses in 50% of the farms. In undercover production, the leading causes of losses were mechanical damage, decay, and blotchiness. In netted (Figure 6) and open fields (Figure 6), the common causes of losses were decay and mechanical damage. Within these farms, postharvest storage losses caused by decay were approximately 50%.

Figure 6.

The causes of postharvest losses of tomato in storage showing the extent of the causes of losses, open fields, netted open fields, semi-closed tunnels, and closed tunnels. The statistical analysis of the different causes of losses per farm is independent of the analysis of another farm. The different letters on the bars show significant differences based on Fisher’s test (α = 0.05) within a specific farm.

Higher losses caused by decay were also observed in W2, where more than 53% of the fruits were lost by day seven. Even though the other farms reported relatively lower incidences of decay compared to T2, T3, and W2, the losses still ranged between 24.10 and 45.85%. In addition to the physical analysis of the cause of losses, tomatoes lost due to decay were analysed for the microbiological causes of the diseases. According to molecular analysis, the dominant identified pathogenic fungal genera associated with diseased and spoiled tomatoes include Fusarium (36.49%), Alternaria spp. (24.32%), and Geotrichum spp. (14.86%) (Figure 4A,B). These three genera constituted more than 75% of the analysed fungal isolates from diseased tomatoes.

3.4. Trends in Postharvest Losses of Tomatoes

3.4.1. On Farm

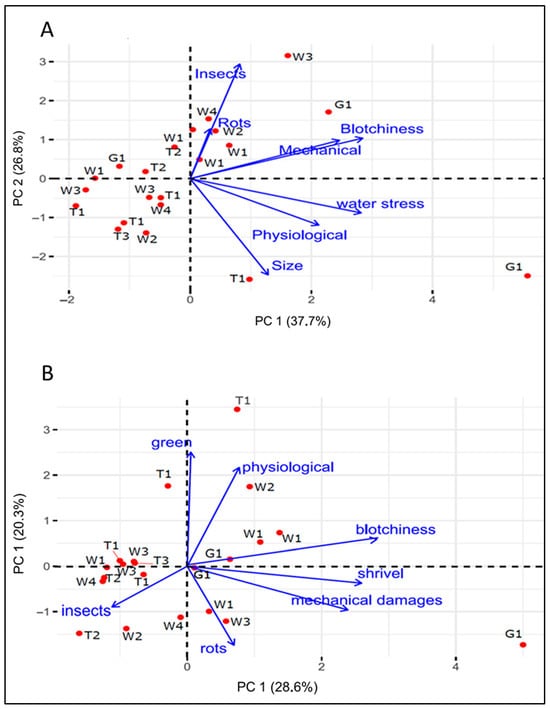

The principal component analysis (PCA) biplot (Figure 7) results show a close relationship between losses caused by fruit size (oversized/undersized), physiological damage, and water stress (in-field cracks). These losses are often linked to practices that affect plant nutrition and in-field water availability. The biplot further revealed that size-related losses were most common in farm T1; meanwhile, losses related to physiological damage and water stress were prevalent in farm G1 (Figure 7), which also experienced high damage due to chilling injury. Similar findings were observed for correlation analysis, where water stress strongly correlated with mechanical damage, physiological damage, and blotchiness (Table A2). Additionally, a strong positive correlation was observed between tomatoes with incorrect sizing and those affected by physiological damage and insect infestation. Furthermore, a close relationship was observed between the losses caused by mechanical damage and blotchiness on tomatoes from G1, consistent with their positive relationship from correlation analysis (Table A2). Meanwhile, tomatoes from farms W1, W2, W4, and T2 were more susceptible to decay and insects, with the strongest impact of insect losses seen in W3 (Figure 7). A relationship was also identified between blotchiness and insect damage (Figure 7), which was predominantly found in farms T2, G3, W1, W2, W3, and W4 (Figure 7). On the other hand, a cluster of tomatoes from various farms was not significantly influenced by the factors represented by PC1 and PC2. These findings suggest that physical and physiological losses are strong drivers of PC1 (37%) and the indicated farms and biotic or decay-related drivers (PC2 = 26.8%), thus contributing to the observed variation. Tomatoes from T2, G3, W1, W2, and W3, particularly those transported during specific trips (mainly the first trip), experienced fewer losses and were therefore less affected by the analysed factors.

Figure 7.

Principal component analysis (PCA) showing the relationship between causes of losses and tomatoes from different farms: (A) on-farm losses and (B) in-storage losses. The repeated farm ID codes signify different trips—farms visited once appear once on the biplot (T3), and farm visited repeatedly appear more in the figure (all other farms).

3.4.2. In Storage

The pattern of tomato losses in storage differed from those observed at the farm level. A. Fruits from farms G1, W1, and W3 were primarily impacted by a combination of decay and mechanical damage (Figure 7). Meanwhile, decayed tomatoes from farms T2, W2, and W4 were susceptible to both insect damage and decay. Tomatoes from farms W1, G1, and W2 (closed and semi-closed production systems) were commonly affected by blotchiness and physiological damage (Figure 7). Tomatoes collected on all trips to farm T1 were significantly affected by losses due to green fruits, supporting the loss magnitude analysis; these fruits did not ripen during storage, and they remained green or yellow. However, these tomatoes were not significantly impacted by other loss factors (e.g., decay, mechanical damage, and insects), indicating relatively better quality at T1 when compared to tomatoes from other farms.

The correlation matrix revealed that decay and insect damage did not have a strong relationship with all other factors. This suggests that losses caused by these two factors may be influenced by variables not evaluated in this study, such as the production system. Interestingly, insect damage was negatively correlated with all other defects except for decay (Table A3). These two factors showed a weak but positive correlation, which may be explained by insect-damaged fruits being more susceptible to decay. Similar to the farm-level results, mechanical damage showed a strong positive relationship with blotchiness. Additionally, water stress (shrivelling) showed a positive relation with blotchiness and mechanical damage (Table A3).

4. Discussion

Small-scale farmers in the Gauteng region of South Africa plant both tomato seeds and seedlings sourced from trusted nurseries and companies. These seeds and seedlings are mainly selected based on vigour and resistance to disease. Apart from resistant cultivars, chemicals are still used for disease and pest management. Even with the use of resistant cultivars and the application of chemicals, more than 80% of the farmers in our study still experienced losses due to diseases and pests. This is a common challenge in Africa, where farmers report that pests and diseases persist despite chemical use [18].

The impact of disease on the production of tomatoes by small-scale farmers could be attributed to insufficient disease diagnosis and management. Farmers rely on external sources for the diagnosis of pre- and postharvest diseases. In addition, according to observations made during farm visits diseased plant materials were disposed of near the production area. This poor agricultural practice can lead to a build-up of pathogen inoculum and reintroduction of the pathogen in the next planting cycle. This is especially true for annually rotated crops within the same host range, such as pepper. Further, studies show that diseases can spread by wind and splashes from contaminated tools, soils, and debris, leading to infection of healthy crops [19]. These practices indicate that small-scale farmers have limited knowledge on good agricultural practices. This is supported by Asrat et al. [20], who found that 81.6% of tomato farmers in Ethiopia demonstrated limited awareness and knowledge, particularly in areas such as trellising and other critical aspects of production and postharvest handling. Such a knowledge gap of key steps in production can result in devastating losses both pre- and postharvest. Fernandez-Zamudio et al. [12] emphasized that severe cases of food losses can be reduced or eliminated through farmer support programmes and policy interventions aimed at raising awareness and promoting effective loss mitigation strategies. A study by Abang et al. [21] recommends that the integration of training on pests and diseases is necessary to enhance farmer knowledge and improve management practices in the tropical conditions.

The observations in this study also indicate that additional poor agricultural practices can contribute to a complete production losses. Our finding indicate that one farm (W2) did not follow an appropriate schedule for spraying pesticides, leading to a complete loss of production due to insect pests. The insect pest identified in this work, T. absoluta, extended its damage up to the postharvest stage. This insect causes significant losses in over 41 countries in Africa [18]. Tuta absoluta is a significant preharvest pest in Africa, and causes extensive tomato damage by tunnelling into a fruit, creating entry points for pathogens. Despite pesticide use, this pest remains a leading cause of losses [18,22]. Although farms W1 and W2 had identical conditions (same cultivar, tunnel type, location, and water source), W2 experienced significantly fewer losses than W1, as spraying was appropriately scheduled. This agrees with Picanço et al. [23], where a proper spraying schedule led to higher yields for tomatoes (55 tonnes per hectare) as compared to the control group (13 tonnes per hectare). W1 also harvested the produce for three months, while at W2, harvesting season ceased within the first month. Collectively, this highlights the role of good management practices in small-scale tomato farms.

Different studies have reported postharvest losses of fruits and vegetables throughout the supply chain [24,25]. However, information related to the direct assessment of the postharvest losses is still limited [26,27]. The direct assessment of tomato samples revealed that harvest losses increased as the season progressed leading to the early termination of harvest, likely due to cumulative environmental stress and pathogen exposure [25]. Furthermore, the overall quality of produce is significantly poorer in open fields and semi-closed tunnels (p < 0.001). A large proportion of the losses can be attributed to management practices. In this study, 25% of the tomatoes were discarded due to poor quality, which is higher than what was previously reported by Pietrangeli and Cicatiello [27], who demonstrated that 12.6% of carrots were discarded postharvest in a study conducted in Italy. A study by Galinato and Miles [28] demonstrated that tomatoes grown in high tunnels had more returns than tomatoes in open fields, as the fruits are protected from environmental factors that can potentially reduce the marketability of the fruits. In the present study, tomatoes grown in the open field had rough, unappealing skin with physiological damage (Figure 4M), which could have created micro-wounds. These wounds likely facilitated pathogen entry, making open-field fruits more vulnerable to rot [29]. A study in Nigeria reported Alternaria and Fusarium as some of the major fungal pathogens of tomato fruits. The direct assessment of on-farm loss causes suggests that decay by pathogens such as Geotrichum candidum, Alternaria spp., and Fusarium spp. may be more prevalent in open-field farms when compared to other farming systems, highlighting potential vulnerabilities in this approach. It was further demonstrated by Thomidis et al. [30] that tomatoes cultivated under outdoor farming were susceptible to Alternaria and Fusarium preharvest.

The PCA and correlation analysis of tomatoes at harvest showed a strong relationship between insect damage and decay of tomatoes; however, these losses were not related to any of the factors analysed in this study. This may indicate that these losses were influenced by external or environmental factors. A previous study reported by Johnson et al. [25] illustrated that weather conditions and infestation caused significant losses and dictated the halting of the harvesting season regardless of the availability of fruits in the field. These losses, seen in open fields at both pre- and postharvest, can be aggravated by heavy rains, which compromise both fruit integrity and disease resistance. This exact challenge was observed during the investigation, when tomato production was halted due to unfavourable weather conditions, mainly affecting farmers planting under the open and netted production systems. In South Africa, the rainy seasons have left farmers with high losses and poor supply to the market [31]. The heavy rains cause waterlogging, as seen in T3 netted tunnels, and an increase in fungal diseases, as in T2 open field, leading to severe losses. This is further supported by Thomidis et al. [30], who indicated the duration of moisture was favourable for the germination of fungal spores and development of disease. This in turn leads to delays in tomato supply, for up four months, based on observations from the Tshwane fresh produce market [31].

At harvest, mechanical damage was predominantly reported on tomatoes from undercover production compared to the nets and open fields. This may be due to excessive handling or harvesting at an improper ripeness level in closed systems [32]. Similarly, reduced cosmetic quality due to blotchiness was observed more in closed production than in open fields. In the study by Emana et al. [8], mechanical damage and undesired colour contributed to only 16% and 24% of the qualitative losses, respectively. In a postharvest loss comparative study between Nigeria and Rwanda, mechanical damage was reported to be higher than decay. The recurring mechanical losses in Africa emphasizes the need for improved postharvest management to reduce losses [33]. Tomato losses due to decay and mishandling not only reduce the farmer’s yield and profit but also lead to increased prices, thereby limiting accessibility for the poorer segments of the community [32]. In addition, the PCA and correlation matrix revealed that losses due to mechanical damage have a strong relationship with water stress factors. These statistical analyses also revealed that the losses caused by mechanical damage and blotchiness were predominantly found in undercover production. Losses due to mechanical damage and blotchiness may stem from agricultural practices that influence fruit nutrition, water availability, and light intensity through the tunnel, thereby affecting fruit development during production [34]. For instance, high soil moisture content can cause both water stress and blotchiness and make the fruits susceptible to mechanical damage [34].

Like losses at harvest, postharvest losses in storage significantly differed from one farm to another. Farms T2 and W2 reported the highest losses due to the reduced quality of the produce at the farm level. These data concur with Arah et al. [35], where the quality of tomatoes at the postharvest stage can only be maintained and shelf-life extended but not improved. These authors also reported that the postharvest quality of tomatoes in part depends on the preharvest factors and practices. In the current study, the proportion of tomatoes discarded during the storage stage ranged from 38.66% to 64.71% from day seven to day fourteen, respectively. This was a similar pattern to that reported by Kitinoja et al. [33], where losses caused by mechanical damage and decay increased at the wholesaler and the retailer. The losses in the current study were, however, noticeably higher than 10 to 40% in Nigeria but comparable to the 50 to 60% in Rwanda reported by Kitinoja et al. [33]. Similar to observations made at harvest, tomato losses caused by mechanical damage and blotchiness were common in undercover production. The losses due to decay after storage were predominantly found in fruits sourced from open fields and netted tunnels, and were mainly caused by secondary pathogens (Geotrichum candidum) or contaminants (Rhizopus sp.). The exposure of these tomatoes to harsh weather conditions (rain and hail) in the field could have made them more susceptible to postharvest diseases in storage. For instance, tomato sampling in Tshwane was performed a day after a hailstorm. A study on grapes showed that fruits that were sheltered from rain had significantly lower disease incidence as compared to the control group [36]. On the other hand, some fruits that were harvested when green from the tunnel did not ripen during storage. These fruits were harvested before reaching sufficient maturity, translating to postharvest losses.

To better understand the losses observed, it is important to consider the physiological changes that occurred during postharvest storage. The physiological parameters, such as TSSs, pH, weight, and firmness, exhibited changes during postharvest storage. Tomato firmness was reduced significantly in room-temperature storage. The study by Kathimba et al. [37] corroborates our findings by reporting a significant decline in weight and firmness with the increase in room-temperature storage duration. Changes in weight and firmness at room temperature can be attributed to moisture loss and enzymatic changes in the cell wall [38]. Al-Dairi et al. [39] reported that the pH of tomatoes stored for 12 days increased significantly with storage time, with [40] reporting a pH range of 4.23–4.63, which concurs with the range of 4.18–4.60 found in the current study. The increase in pH was attributed to a decrease in titratable acidity in tomatoes at the postharvest [40]. When combined with improper postharvest handling, these physiological changes contribute distinctly to the overall loss of quality and value of tomatoes. In addition to the losses negatively impacting the socioeconomic status of farmers, they have an impact on the environment, which could result in the generation of greenhouse gases, therefore affecting the climate. A study by Opara et al. [41] estimated that pomegranate losses in a packhouse would generate an estimated level of 157,819 CO2 eq, necessitating the plantation of over 4 million trees to absorb the emitted CO2. In addition, tomatoes from small-scale farmers were sold to different markets, pending quality linked to farm gate prices. Retail would contractually only take Class 1 (stipulated in the agricultural product standards act, 1990, ACT No 119 OF 1990) [42] fruits at a higher secured price, while the fresh produce market agents would negotiate between Class I, II, and III fruits, and depending on the pending volume on the floor and the demand for the day, they would negotiate the price [43]. Substandard fruits are mainly sold to street vendors at very low prices. This is due to the implementation of regulated quality standards in the formal sector, while no specifications apply in the informal sector. De facto, excluding fruit of poorer quality from entering the more lucrative formal market lowers the volume of waste on the market floor. Similarly, in Ethiopia, tomatoes were sold in different markets depending on quality, where poor-quality tomatoes were sold to local retailers while good quality tomatoes were sold to wholesalers [8]. The different quality standards are often related to visual quality, such as uneven colour, shape, and size of the fruit, made to meet perceived consumer demands, based on physical and physiological quality [44]. However, these standards can have an impact on tomato losses at production and point of sale, leading to discarded non-compliant fruit due to aesthetic quality demands [45].

5. Conclusions

This study provides the first comprehensive dataset quantifying postharvest tomato losses in small-scale farming systems across different production environments in South Africa. Postharvest losses of tomato increased significantly after storage, with the highest contributions of loss in storage from decay and mechanical damage. At the farm level, losses were mainly associated with mechanical damage, insects, diseases, and uneven ripening. These losses directly reduce farmer profits and can discourage continued tomato production and compromise food security. These results highlight critical gaps in good agricultural practices in small-scale tomato farming, particularly in pest control, harvesting methods, and postharvest handling. The current study serves as a baseline report on the direct analysis of tomato losses from small-scale farmers in different regions of Gauteng Province. One of the limitations for this study was the availability and willingness of farmers to take part in this study. We therefore recommend that future study on the direct and indirect analyses of losses be conducted on a broader scale considering different climatic conditions, soil types, rainfall patterns, and postharvest infrastructure, which may affect the postharvest quality of fruits and vegetables. Nonetheless, the evidence presented paves the way for future research on targeted mitigation strategies and technologies for loss reduction for the vulnerable small-scale farming system. It is recommended that farmers be educated on the different types of postharvest losses and mitigation with good agricultural practices, including preharvest interventions. Moreover, this study underscores the need for policy and training programs aligned with the sustainable development goals (SDG 2 (Zero Hunger) and SDG 12.3 (Food Loss Reduction)) by encouraging the development of region-specific training programs, the adoption of non-chemical disease control methods, and broader food security priorities.

Author Contributions

Conceptualization, T.M., E.M.K., N.S., J.K.G. and L.K.; methodology, T.M., E.M.K., N.S., J.K.G. and L.K.; validation, T.M., E.M.K., N.S. and J.K.G.; formal analysis, T.M. and E.M.K.; investigation, T.M.; resources, L.K.; data curation, T.M.; writing—original draft preparation, T.M.; writing—review and editing, T.M., E.M.K., N.S., J.K.G. and L.K.; visualization, T.M., supervision, N.S., J.K.G. and L.K.; project administration, T.M., N.S. and L.K.; funding acquisition, L.K. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the Department of Science and Innovation (DSI)—National Research Foundation (NRF) and University of Pretoria Commonwealth Scholarship. This work is based on the research supported by the Gauteng Department of Agriculture and Rural Development (GDARD) under the research project FY 2020/21. Opinions expressed and conclusions arrived at are those of the authors and are not necessarily to be attributed to GDARD.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors would like to acknowledge D. Boikanyo, the GDARD project manager, for connecting researchers with the extension officers and farmers, and always taking the time to be part of our interviews. The authors would also like to acknowledge the support of the tomato small-scale farmers and extension in the different regions of Gauteng. The authors would like to acknowledge Z. Zulu for training and technical and laboratory assistance. Additionally, the authors note the support of M Bill, S Makau and E. Green during project conceptualization and manuscript editing, respectively, and TBJ Molelekoa and P. Kubeka for logistics and laboratory support.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Table A1.

Demographic information for small-scale farmers producing tomatoes under different production systems. N = number of individuals.

Table A1.

Demographic information for small-scale farmers producing tomatoes under different production systems. N = number of individuals.

| Questions | Responses | |

|---|---|---|

| N | % | |

| Region (n = 17) | ||

| Germiston | 1 | 5.88 |

| Tshwane | 6 | 35.29 |

| West Rand | 10 | 58.82 |

| What is the total size of your farm in hectares? (n = 17) | ||

| 0.5 to 1 ha | 3 | 17.65 |

| 2 to 5 ha | 5 | 29.41 |

| 6 to 10 ha | 4 | 23.53 |

| 11 to 20 ha | 4 | 23.53 |

| More than 20 ha | 1 | 5.88 |

| What type of production system do you use? (n = 17) | ||

| Open field | 3 | 17.65 |

| covered or netted tunnels | 9 | 52.94 |

| Dual system | 5 | 29.41 |

| What is the water source? (n = 17) | ||

| Borehole | 15 | 88.24 |

| Municipality | 1 | 5.88 |

| Borehole and municipality | 1 | 5.88 |

| Do you store water? (n = 17) | ||

| Yes | 15 | 88.24 |

| No | 2 | 11.76 |

| If yes, do you store the water in an open or closed tank? (n = 16) | ||

| Open (dam) | 2 | 12.50 |

| Closed tank | 10 | 62.50 |

| Both | 4 | 25.00 |

| Do you treat your water before using for irrigation? (n = 17) | ||

| Yes | 1 | 5.88 |

| No | 16 | 94.12 |

| Do you have a packhouse? (n = 17) | ||

| Yes | 6 | 35.29 |

| No | 11 | 64.71 |

Table A2.

Pearson correlation coefficient matrix of the causes of losses in farm-level tomatoes.

Table A2.

Pearson correlation coefficient matrix of the causes of losses in farm-level tomatoes.

| Physical Defects | Decay | Insects | Blotchiness | Mechanical | Physiological | Size | Water Stress | Wrong Stage |

|---|---|---|---|---|---|---|---|---|

| Decay | 1 | |||||||

| Insects | 0.336 | 1 | ||||||

| Blotchiness | 0.041 | 0.550 ** | 1 | |||||

| Mechanical | −0.072 | 0.289 | 0.686 ** | 1 | ||||

| Physiological | 0.212 | −0.056 | 0.361 | 0.075 | 1 | |||

| Size | −0.180 | −0.450 * | 0.222 | −0.008 | 0.433 * | 1 | ||

| Water stress | 0.038 | −0.124 | 0.521 ** | 0.612 ** | 0.599 ** | 0.357 | 1 | |

| Wrong stage | 0.088 | −0.130 | −0.049 | −0.053 | 0.158 | 0.383 * | −0.119 | 1 |

* Significance at p < 0.05, ** significance at p < 0.01. Bold values denote significance correlation.

The positive values mean that the two compared parameters are positively correlated.

Table A3.

Pearson correlation coefficient matrix between the causes of losses in tomatoes in storage.

Table A3.

Pearson correlation coefficient matrix between the causes of losses in tomatoes in storage.

| Physical Defects | Decay | Insects | Blotchiness | Mechanical | Physiological | Green | Shrivel |

|---|---|---|---|---|---|---|---|

| Decay | 1 | ||||||

| Insects | 0.039 | 1 | |||||

| Blotchiness | 0.094 | −0.269 | 1 | ||||

| Mechanical | 0.051 | −0.047 | 0.415 * | 1 | |||

| Physiological | −0.114 | −0.009 | 0.275 | 0.042 | 1 | ||

| Green | −0.157 | −0.086 | 0.060 | −0.214 | 0.232 | 1 | |

| Shrivel | 0.173 | −0.101 | 0.478 * | 0.427 * | −0.018 | 0.088 | 1 |

* Significance at p < 0.05. Bold values denote significance correlation.

The positive values mean that the two compared parameters are positively correlated.

Figure A1.

Weight (A), firmness (B), pH (C), and total soluble solutes (D) of tomato fruits from small-scale farmers stored for one, seven, and fourteen days. The different letters on the bars show significant differences based on Fisher’s test (α = 0.05).

Figure A2.

Cumulative tomato losses were recorded from day 1 to day 14 postharvest.

References

- Food and Agriculture Organization of the United Nations. Agricultural Production Statistics 2000–2022. 2023. Available online: https://openknowledge.fao.org/server/api/core/bitstreams/fba4ef43-422c-4d73-886e-3016ff47df52/content (accessed on 6 May 2025).

- Bhowmik, D.; Kumar, K.P.S.; Paswan, S.; Srivastava, S. Tomato-A Natural Medicine and Its Health Benefits. J. Pharmacogn. Phytochem. 2012, 1, 33–43. [Google Scholar]

- Sibomana, M.S.; Workneh, T.S.; Audain, K. A review of postharvest handling and losses in the fresh tomato supply chain: A focus on Sub-Saharan Africa. Food Secur. 2016, 8, 389–404. [Google Scholar] [CrossRef]

- Myeki, L.; Sotsha, K.; Rambau, K.; Nakana, E. Climate Change, Pest Attacks and Agricultural Marketing: Is There A Nexus in The Contex of South Africa’s Tomato Industry? 2022, pp. 1–4. Available online: https://www.namc.co.za/ (accessed on 17 March 2025).

- Food Agriculture Organisation (FAO); United Nations Economic Commission for Africa (ECA); African Union Commission (AUC). Regional Overview of Food Security and Nutrition Statistics and Trends; FAO: Accra, Ghana, 2023; pp. 1–73. Available online: https://www.fao.org/3/ca2127en/CA2127EN.pdf (accessed on 17 March 2025).

- Yahaya, S.M.; Mardiyya, A. Review of Post-Harvest Losses of Fruits and Vegetables. Biomed. J. Sci. Technol. Res. 2019, 13, 10192–10200. [Google Scholar]

- Nohamba, S.; Musara, J.P.; Bahta, Y.T.; Ogundeji, A.A. Drivers of Postharvest Loss among Citrus Farmers in Eastern Cape Province of South Africa: A Zero-Inflated Poisson (ZIP) Regression Model Analysis. Agriculture 2022, 12, 1651. [Google Scholar] [CrossRef]

- Emana, B.; Afari-Sefa, V.; Nenguwo, N.; Ayana, A.; Kebede, D.; Mohammed, H. Characterization of pre- and postharvest losses of tomato supply chain in Ethiopia. Agric. Food Secur. 2017, 6, 3. [Google Scholar] [CrossRef]

- Goka, M.G.; Dufrechou, M.; Picouet, P.; Soncy, K.; Ameyapoh, Y. Determinants of Postharvest Losses in Tomato Production in The Savannah Region of Togo. Eur. J. Agric. Food Sci. 2021, 3, 40–45. [Google Scholar] [CrossRef]

- Wongnaa, C.A.; Ankomah, E.D.; Ojo, T.O.; Abokyi, E.; Sienso, G.; Awunyo-Vitor, D. Valuing postharvest losses among tomato smallholder farmers: Evidence from Ghana. Cogent Food Agric. 2023, 9, 1–17. [Google Scholar] [CrossRef]

- Abera, G.; Ibrahim, A.M.; Forsido, S.F.; Kuyu, C.G. Assessment on post-harvest losses of tomato (Lycopersicon esculentem Mill.) in selected districts of East Shewa Zone of Ethiopia using a commodity system analysis methodology. Heliyon 2020, 6, e03749. [Google Scholar] [CrossRef]

- Fernandez-Zamudio, M.A.; Barco, H.; Schneider, F. Direct measurement of mass and economic harvest and post-harvest losses in spanish persimmon primary production. Agriculture 2020, 10, 581. [Google Scholar] [CrossRef]

- Garikai, M. Assessment of Vegetable Postharvest Losses Among. Master’s Thesis, University of KwaZulu-Natal, Pietermaritzburg, South Africa, 2014. [Google Scholar]

- Robert, A.; Rita, A.D.; James, O.M. Determinants of postharvest losses in tomato production in the Offinso North district of Ghana. J. Dev. Agric. Econ. 2014, 6, 338–344. [Google Scholar] [CrossRef]

- Blanckenberg, A.; Opara, U.L.; Fawole, O.A. Postharvest losses in quantity and quality of table grape (Cv. crimson seedless) along the supply chain and associated economic, environmental and resource impacts. Sustainability 2021, 13, 4450. [Google Scholar] [CrossRef]

- Bill, M.; Chidamba, L.; Gokul, J.K.; Korsten, L. Mango endophyte and epiphyte microbiome composition during fruit development and post-harvest stages. Horticulturae 2021, 7, 495. [Google Scholar] [CrossRef]

- Opara, I.K.; Fawole, O.A.; Kelly, C.; Opara, U.L. Quantification of on-farm pomegranate fruit postharvest losses and waste, and implications on sustainability indicators: South African case study. Sustainability 2021, 13, 5168. [Google Scholar] [CrossRef]

- Rwomushana, I.; Beale, T.; Chipabika, G.; Day, R.; Gonzalez-Moreno, P.; Godwin, J.L.; Makale, F.; Pratt, C.; Tambo, J. Tomato leafminer (Tuta absoluta): Impacts and coping strategies for Africa. 2019; 56p. [Google Scholar] [CrossRef]

- Islam, A.H.M.S.; Schreinemachers, P.; Kumar, S. Farmers’ knowledge, perceptions and management of chili pepper anthracnose disease in Bangladesh. Crop. Prot. 2020, 133, 105139. [Google Scholar] [CrossRef]

- Asrat, F.; Ayalew, A.; Degu, A. Postharvest Loss Assessment of Tomato (Solanum lycopersicum L.) in Fogera, Ethiopia. Turk. J. Agric.-Food Sci. Technol. 2019, 7, 1146–1155. [Google Scholar] [CrossRef]

- Abang, A.F.; Kouamé, C.M.; Abang, M.; Hanna, R.; Fotso, A.K. Assessing Vegetable Farmer Knowledge of Diseases and Insect Pests of Vegetable and Management Practices Under Tropical Conditions. Int. J. Veg. Sci. 2014, 20, 240–253. [Google Scholar] [CrossRef]

- Garzia, G.T.; Siscaro, G.; Biondi, A.; Zappalà, L. Tuta absoluta, a South American pest of tomato now in the EPPO region: Biology, distribution and damage. EPPO Bull. 2012, 42, 205–210. [Google Scholar] [CrossRef]

- Picanço, M.C.; Bacci, L.; Crespo, A.L.B.; Miranda, M.M.M.; Martins, J.C. Effect of integrated pest management practices on tomato production and conservation of natural enemies. Agric. Entomol. 2007, 9, 327–335. [Google Scholar] [CrossRef]

- Lu, S.; Cheng, G.; Li, T.; Xue, L.; Liu, X.; Huang, J.; Liu, G. Quantifying supply chain food loss in China with primary data: A large-scale, field-survey based analysis for staple food, vegetables, and fruits. Resour. Conserv. Recycl. 2022, 177, 106006. [Google Scholar] [CrossRef]

- Johnson, L.K.; Bloom, J.D.; Dunning, R.D.; Gunter, C.C.; Boyette, M.D.; Creamer, N.G. Farmer harvest decisions and vegetable loss in primary production. Agric. Syst. 2019, 176, 102672. [Google Scholar] [CrossRef]

- Redlingshöfer, B.; Coudurier, B.; Georget, M. Quantifying food loss during primary production and processing in France. J. Clean. Prod. 2017, 164, 703–714. [Google Scholar] [CrossRef]

- Pietrangeli, R.; Cicatiello, C. Lost vegetables, lost value: Assessment of carrot downgrading and losses at a large producer organisation. J. Clean. Prod. 2024, 478, 143873. [Google Scholar] [CrossRef]

- Galinato, S.P.; Miles, C.A. Economic profitability of producing tomato and lettuce in Western Washington under open-field and high-Tunnel production systems©. Acta Hortic. 2015, 1085, 353–354. [Google Scholar] [CrossRef]

- Rizwana, H.; Bokahri, N.A.; Alsahli, S.A.; Al Showiman, A.S.; Alzahrani, R.M.; Aldehaish, H.A. Postharvest disease management of Alternaria spots on tomato fruit by Annona muricata fruit extracts. Saudi J. Biol. Sci. 2021, 28, 2236–2244. [Google Scholar] [CrossRef]

- Thomidis, T.; Prodromou, I.; Paresidou, M.; Damos, P. Effects of temperature and leaf wetness duration on pathogens causing preharvest fruit rots on tomato. J. Plant Pathol. 2023, 105, 1431–1448. [Google Scholar] [CrossRef]

- Dippenaar, A. Rain Strips Vegetable Supply on Tshwane Market Over. 2025, Volume 11, pp. 1–14. Available online: https://www.freshplaza.com/north-america/article/9700449/rain-strips-vegetable-supply-on-tshwane-market/ (accessed on 6 May 2025).

- Dessalegn, Y.; Assefa, H.; Derso, T.; Haileslassie, A. Assessment of fruit postharvest handling practices and losses in Bahir Dar, Ethiopia. African Journal of Agricultural Research. Afr. J. Agric. Res. 2016, 11, 5209–5214. [Google Scholar] [CrossRef][Green Version]

- Kitinoja, L.; Motunrayo Odeyemi, O.; Dubey, N.; Musanase, S.; Gill, G.S. Commodity system assessment studies on the postharvest handling and marketing of tomatoes in Nigeria, Rwanda and Maharashtra, India. J. Hortic. Postharvest. Res. 2019, 2, 1–14. [Google Scholar] [CrossRef]

- Gleason, M.L.; Edmunds, B.A.; Tomato Diseases and Disorders. Department of Plant Pathology. Iowa State University. 2005. Available online: https://vinesgardens.org/wp-content/uploads/2014/04/13_Tomato-Diseases-and-Disorders.pdf (accessed on 2 April 2025).

- Arah, I.K.; Ahorbo, G.K.; Anku, E.K.; Kumah, E.K.; Amaglo, H. Postharvest handling practices and treatment methods for tomato handlers in developing countries: A mini review. Adv. Agric. 2016, 2016, 436945. [Google Scholar] [CrossRef]

- Du, F.; Deng, W.; Yang, M.; Wang, H.; Mao, R.; Shao, J.; Fan, J.; Chen, Y.; Fu, Y.; Li, C.; et al. Protecting grapevines from rainfall in rainy conditions reduces disease severity and enhances profitability. Crop. Prot. 2015, 67, 261–268. [Google Scholar] [CrossRef]

- Kathimba, F.K.; Kimani, P.M.; Narla, R.D.; Kiirika, L.M. Effect of storage temperature on fruit firmness and weight loss of nine tomato lines. Afr. J. Plant Sci. 2022, 16, 276–284. [Google Scholar]

- Kaur, P.; Bhatia, S. Effect of packaging films on cell wall hydrolyzing enzymes in relation to shelf-life enhancement of tomatoes stored under ambient conditions. Appl. Biol. Res. 2017, 19, 71–78. [Google Scholar] [CrossRef]

- Al-Dairi, M.; Pathare, P.B.; Al-Yahyai, R. Chemical and nutritional quality changes of tomato during postharvest transportation and storage. J. Saudi Soc. Agric. Sci. 2021, 20, 401–408. [Google Scholar] [CrossRef]

- Teka, T.A. Analysis of the effect of maturity stage on the postharvest biochemical quality characteristics of tomato (Lycopersicon esculentum Mill.) Fruit. Int. Res. J. Pharm. Appl. Sci. 2013, 3, 180–186. [Google Scholar]

- Opara, I.K.; Fawole, O.A.; Opara, U.L. Postharvest losses of pomegranate fruit at the packhouse and implications for sustainability indicators. Sustainability 2021, 13, 5187. [Google Scholar] [CrossRef]

- Department of Agriculture, Land Reform and Rural Development. Agricultural Product Standard ACT, 1990 (ACT No 119 of 1990): Regulations Relating to the Quality, Grading, Packing and Marking of Tomatoes Sale Intended for in the Republic of South Africa. 2023; pp. 62–76. Available online: https://www.gov.za/sites/default/files/gcis_document/201410/38033rg10278gon750.pdf (accessed on 12 July 2025).

- Department of Agriculture, Land Reform and Rural Development. A Profile of the South African Tomato Market Value Chain. 2020; pp. 1–43. Available online: https://www.dalrrd.gov.za/images/Branches/Economica%20Development%20Trade%20and%20Marketing/marketing/annual-publications/vegetables/tomato-market-value-chain-profile-2020.pdf (accessed on 12 July 2025).

- Oltman, A.E.; Jervis, S.M.; Drake, M.A. Consumer attitudes and preferences for fresh market tomatoes. J. Food Sci. 2014, 79, S2091–S2097. [Google Scholar] [CrossRef]

- Collart, A.J.; Interis, M.G.; Henson, C.; Maples, J. The Impacts of Food Waste Information on Consumer Preferences for Blemished Produce and Implications for Food Retailers. J. Agric. Appl. Econ. 2022, 54, 440–460. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).