1. Introduction

1.1. Discussion Scope

This perspective paper (i.e., not a review) examines the research and development challenges faced by plant factories (vertical farms or closed plant production systems relying exclusively on artificial light) that contribute to resolving each of the four aspects of the four-way deadlock problem simultaneously.

The main products from plant factories as of 2025 are leafy lettuce, spinach, basil, microgreens. Since 2020, some plant factories have started producing tomatoes [

1] and strawberries [

2]. In subsequent years, more types of fruit and vegetables, such as eggplants and cucumbers, medicinal plants/herbs, and edible flowers, as well as seedlings of food plants, such as rice, corn, and wheat, and vegetatively propagated transplants of trees for afforestation, will be produced in plant factories. These transplants are mostly transplanted in open farmland (fields), forest land, or semi-enclosed plant production facilities (i.e., greenhouses) that allow sunlight to penetrate. In this case, the transplants are acclimatized in the plant factory, so that they can grow smoothly in open farmland. Simultaneously, appropriate amounts of water, organic and inorganic fertilizer, and beneficial microbes are applied to the soil of farmland.

Plant factories are well-suited for the rapid breeding of functional (horticultural, medicinal, ornamental, and cosmetic) plants, food plants, and trees for afforestation [

3,

4], but they are not considered in this paper. In the future, plant factories will also be used to produce vaccines to prevent infectious diseases in humans and livestock [

5], allergen-free food [

6,

7], and medicines derived from cannabis [

8,

9], using safe, genome (one entire set of DNAs)-edited plants. However, these topics are also not addressed in this paper.

1.2. The Four-Way Deadlock Problem

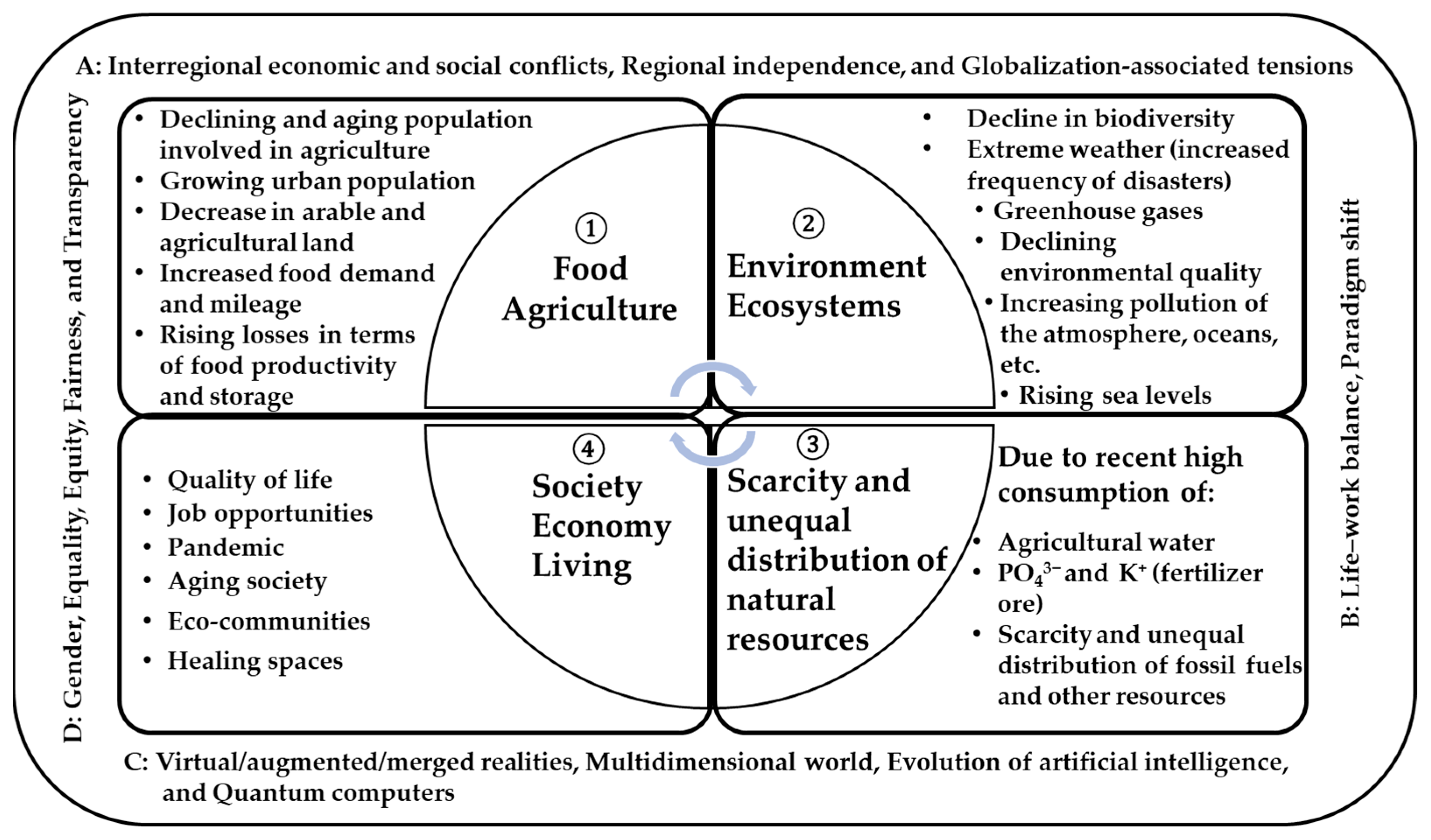

The current global and local or regional challenges can be broadly categorized into (1) food and agriculture; (2) environment and ecosystems; (3) depletion, uneven distribution, and the overuse of nonbiological (or abiotic) resources, such as fossil fuel, agricultural and industrial water, potash ore, phosphate ore, and rare metals; and (4) society, economy, and quality of life (including culture, civilization, clothing, and housing) (

Figure 1).

The four-way deadlock problem arises when focusing on solving only one of these issues, which exacerbates one or two of the remaining three. To address this challenge, all four issues must be resolved concurrently. Each issue consists of several sub-tasks (

Figure 2). These issues and sub-tasks must be resolved within the context of the A–D framework, which is shown in the outer frame of

Figure 2.

2. Plant Factories

2.1. Engineering Features of the Cultivation Room

A plant factory comprises a cultivation room (CR hereafter), a workroom, a precooling room, an inventory control room, a rest area, and a shipping area, etc. [

10]. In this paper, only the main component, namely the CR, will be examined. CRs are enclosed by light-opaque, highly insulated, and sealed walls, ceilings, and floors, and equipped with hydroponic cultivation units. Thus, the physical, chemical, and biological environments within CRs are not influenced by the weather and soil, but are instead almost entirely controlled by the parameters set for each environmental factor, which are determined by the CR supervisor; however, the room supervisor may not necessarily know the best combination of environmental factors [

11].

The main components of CRs include cultivation racks, air conditioning equipment, nutrient solution tanks, and piping. Large CRs are equipped with forced ventilation units for emergencies, such as fires, that cause extreme room environments. In this study, we assume that each cultivation rack consists of multiple shelves, with each shelf equipped with lighting units, and cultivation beds, each covered with a cultivation panel, and other components. Each cultivation bed receives a supply of nutrient solution through a piping system, and the seeds or seedlings are either sown or transplanted onto supporting material or artificial media on the cultivation panel. The supporting material/artificial medium is fixed in holes in the cultivation panel to prevent algal growth and to ensure that light does not reach the nutrient solution. The nutrient solution is usually circulated through pipes that run between the cultivation beds and nutrient solution tanks. One of the objectives of this paper is to present basic ideas on the simplification of the structure and operation of the CR in regard to the establishment of sustainable plant factories.

2.2. Overview of the Current Status of Annual Yields

As of 2025, the annual yield (annual production per unit of land area) for leafy vegetables in a plant factory consisting of cultivation racks, each with 15-tier cultivation shelves, is approximately 100 times higher than that of open-field cultivation. The reasons behind this enhancement are: (1) the cultivation area per unit of land area is 15 times larger owing to the presence of a 15-tier cultivation shelf; (2) the number of cultivation days per year exceeds 350, which is about three times greater than that of open-field cultivation; (3) the growth rate is approximately 1.5 times higher due to the near absence of disease and damage caused due to pests, and (4) the environment remains favorable all year round, free from extreme weather conditions, such as strong winds, heavy rain, droughts, and temperature fluctuations, contributing to an additional growth rate increase of approximately 1.5 times (15 × 3 × 1.5 × 1.5 = 101.25).

In other words, the land area required for a given production unit is about one-hundredth of that required for open-field cultivation. In addition, plant factories can be built on wasteland and in shaded areas, and a vacant room can be included in the building for residence, business, and industry-related purposes, making them highly adaptable to cities. Annual yields from 15-tier shelf cultivation of strawberries, dwarf tomatoes, etc., with a height of 50 cm or less, are approaching 100 times higher than those of open-field cultivation, and with much better quality.

2.3. General Benefits of Starting Plant Factories in Cities

When a plant factory is established in a densely populated area, the distance between production and consumption locations is often reduced to less than one-tenth. This effect reduces the energy, time, labor, packaging costs, and the deterioration in produce freshness, and the damage to the produce caused by long-distance transportation.

The net irrigation water required per kg of product is about one-tenth that of conventional greenhouse horticulture, due to the use of transpired water vapor from plants condensed by the cooling panels of the air conditioners (heat pumps) for cooling and which is returned to the nutrient solution tank [

12].

By increasing the CO2 concentration in the CR to approximately 1500 ppm (compared to approximately 400 ppm outdoors), the dry matter of plants is significantly increased due to plant photosynthesis. CO2 released from industrial areas in the city can be captured and used after proper processing (compressing, purification, etc.) for CO2 enrichment to enhance the plant dry weight increase.

Since the production volume and working environment of plant factories are not affected by the weather or seasons, and the work is safe, easy, and proceeds almost according to plan, opportunities for short-time work near the residences of diverse citizens, including families raising children, the mentally and physically disabled, and elderly people, will increase. This increase in job opportunities will also help eliminate the gender pay gap.

3. Perspectives That Need Consideration: Culture and Civilization, and Participatory Science

In order for plant factories to contribute to the simultaneous resolution of the four-way deadlock problem, the aforementioned general benefits, along with a significant reduction in the power required and greenhouse gas emissions per unit of production, must also sustainably contribute to areas such as stakeholder satisfaction, increased marketable plant production, reduced production costs, and environmental improvements around plant factories. A discussion on the methodologies that contribute to solving the four-way deadlock problem is presented below from the following two perspectives: (1) civilization and culture, and (2) participatory science.

3.1. Civilization and Culture

There is considerable debate regarding the differences between civilization and culture [

13]. This paper defines civilization as being formed by universal STEM (science, technology, engineering, and mathematics) disciplines that are independent of local factors, such as soil, climate, history, and landscape. The laws of celestial navigation, basic protocols of the internet, and genome analysis technologies are considered global STEM fields, as they are largely unaffected by local factors and are, therefore, classified as aspects of civilization. However, certain civilization-related STEM fields have only spread locally owing to factors like the long amount of time required for their dissemination.

Culture is an STEM field that is formed through the interaction of people with the soil, climate, history, and landscape in a specific region. STEM fields related to agriculture and forestry are robustly associated with the local soil, climate, history, and landscape.

The word “culture” has been used in the English-speaking world since the 19th century to refer to the culture of a group of people, stemming from the metaphor “cultivation of the mind” (Oxford Dictionary). In other words, culture is etymologically and semantically closely related to cultivation. In fact, many rituals, performing arts, and traditions about scenic beauty have been passed down through agriculture and the local soil, climate, history, and landscape.

The association of STEM in regard to plant factories is classified as a civilizational STEM because it is largely unaffected by the local soil, climate, history, and landscape. The aforementioned reduction in greenhouse gas emissions per unit of electricity generated is an example of such an STEM-related goal. However, in many cases, the products are considered to be cultural because plant factory managers, supervisors, and workers, who possess local knowledge, produce and sell plants that meet the expectations of local markets.

3.2. Philosophy and Art

Philosophy can be broadly categorized into Western and Eastern or Oriental philosophy [

12]. Civilization is often considered a term associated with Western philosophy, science, and technology. The reason for this is the fact that, while Oriental philosophy is highly developed and Oriental technologies, such as acupuncture and traditional Chinese medicine, are of high quality, they are not necessarily universal as an Oriental science. Oriental science based on Oriental philosophy is expected to be developed in the near future, based on the latest nonbiological technology, such as artificial intelligence (AI) and genome analysis. Some complex technological problems are expected to be solved efficiently by Oriental science in the near future.

While art is an inherently vital component of both culture and civilization, distinguishing between civilizational and cultural art is challenging. Consequently, this distinction is not discussed in this paper. Up until the modern era, there were clear differences between Western and Oriental art, but subsequent interactions have gradually brought the two closer together.

3.3. Participatory Science

Participatory science is frequently paired with expert science. While expert science is constructed from an external perspective, participatory science is developed from an internal perspective. For example, medicine is developed by experts, while patient science is developed through the active participation of patients as stakeholders. Most studies aimed at resolving the four-way deadlock problem concern participatory sciences, created through the involvement of citizens, policymakers, businesses, and educational research organizations, etc. The study of urban planning, wherein citizens participate as stakeholders, is also referred to as citizen science [

14]. Care science is a field of participatory or citizen science covering the nursing care of children, pregnant women, the elderly, sick, and disabled people by nursing attendants. Interactions between caring personnel and those being cared for are an essential part of care science. The science of natural therapy, including horticultural practice and forest/horticultural therapy, is also a field of citizen science [

15].

3.4. Plant Factories in Cities and Local Regions and Their Relationship in Regard to the Four-Way Deadlock Problem, Civilization, Culture, and Participatory Science

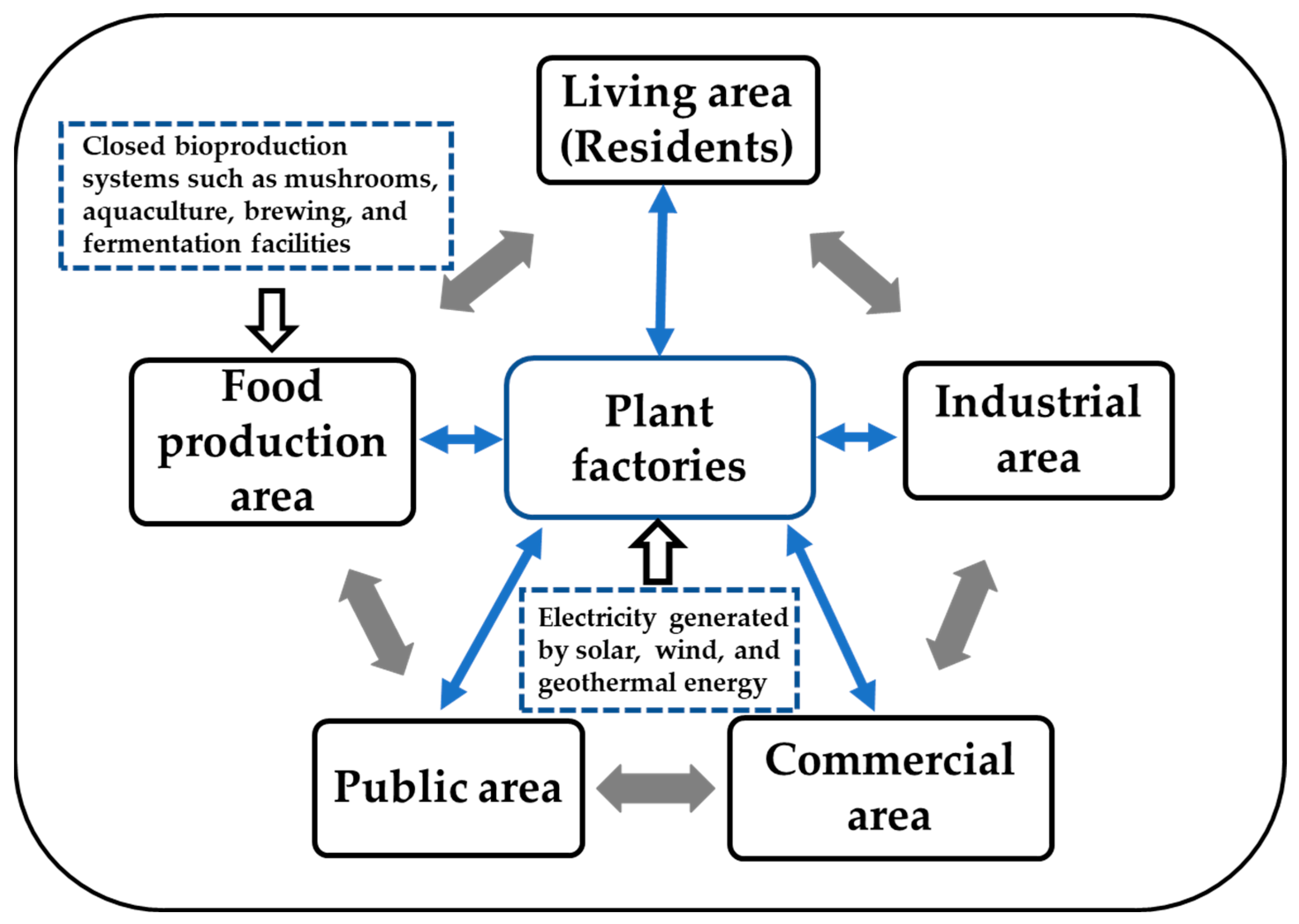

Plant production in plant factories can be called “civilized technology” because it is not affected by the soil, weather, landscape, and history of the locality. This technology can significantly contribute to solving major urban challenges simultaneously. This is because (1) their yield is approximately 100 times higher than that of farmland, making it easy to improve food self-sufficiency within urban areas, (2) they facilitate a resource recycling economy between residential, industrial, commercial, and public sectors, and (3) the recycling of resources makes it easier to reduce the total amount of waste generated within a city (

Figure 3).

Plant factories can enhance the land availability in cities, and can increase the self-sufficiency of food production. Consequently, public spaces, such as green spaces and parks, can be enlarged to enhance the sustainability of the city. If closed biological production facilities, such as aquaculture, mushroom culture, and brewing/fermentation in closed facilities, are integrated with plant factories, the resource recycling economy will be further promoted (

Figure 3). To support this circular economy, it is essential to develop a science of participatory involvement.

In general, the simultaneous resolution of the four-way deadlock problem in cities and local regions requires: (1) the autonomy of energy, material, and communication networks essential for the provision of food, clothing, and housing; (2) connectivity among the resource circulation units within the local region; (3) flexibility or resilience in the organization and operation of various organizations; (4) an appropriate scale; and (5) the diversity and inclusiveness of the constituent units [

16].

4. Integration of Latest Nonbiological Technology and Biological Technology

Various technologies, whether classified as participatory or expert science, can be broadly divided into nonbiological and biological technologies. The future introduction of the latest nonbiological technologies into biological systems will remarkably reduce electricity consumption and greenhouse gas emissions per kilogram of product. This can be achieved, for example, by greatly improving the efficiency of electricity usage and the physiological effectiveness of photon absorption by leaves in the CR.

4.1. Latest Nonbiological Technology

The latest nonbiological technologies include civilizational technologies, such as semiconductor circuits (arithmetic and image processing, storage, and input/output devices), communication circuits, and AI-based computer software, all of which have become smaller, faster, and cheaper in recent years. Recently developed nonbiological products, such as smartphones, large-scale databases, 3D printers, renewable energy generation and utilization devices, and quantum computers, are becoming integral components of civilization technology. In particular, Generative AI (GPT: generative pretrained transformer), based on Large Language Models (LLMs), has made remarkable technological advancements and has become widely used.

Furthermore, there has been marked progress in genome analysis/sequencing technology, utilizing next-generation sequencers that integrate hardware and software. Although genome analysis is a nonbiological civilization technology, it can be easily linked to biological technologies. As a result, genome analysis is transforming many areas of traditional selective breeding into civilizational breeding. It should be noted that all of the technologies mentioned above were at the primitive stages at the beginning of the 2000s, and they are still advancing annually.

The initial development costs of nonbiological civilization technologies are substantial, but the marginal cost of its diffusion is minimal; hence, once their practicality is confirmed, the rate of diffusion is high [

17]. Conversely, it is necessary to take measures to prevent their excessive use or misuse that may result from low marginal costs.

4.2. Biotechnology

Individual living organisms are hierarchically composed of cells, tissues, and organs. Cells, in turn, are made up of water, nucleic acids, proteins, fats, carbohydrates, and inorganic compounds, whose structure and functions change over time. Biological communities composed of populations, each consisting of many individuals, from multiple species, interact with their environment to form ecosystems. The structure and function of populations and ecosystems change over time and space.

It is almost impossible to represent, simulate, and predict the dynamics of biosocial and ecological systems on agricultural land by applying mathematical models, based on the cellular level, due to their complexity. Even creating mathematical models, simulations, and predictions of biological societies and ecosystems at the individual level is, in general, extremely challenging. These mathematical models include deterministic, probabilistic, statistical, and logical equation models. Currently, the only dynamics that can be modeled with certainty are the interactions of photosynthesis, dark respiration, and transpiration in individual leaves, or a canopy, with its environment.

Although leaf and flower bud formation, flowering, fruiting, and the translocation of assimilated products can be modeled deterministically at the individual level, they are typically represented by stochastic or statistical models. This is because the growth of a particular leaf or flower bud is influenced by its surrounding environment and by interactions with neighboring organs, such as buds. The same applies to the translocation of photoassimilates. In the future, when the modeling of biological societies using LLMs is possible, agricultural production technology is likely to change significantly. The simplest example of this is the implementation of an LLM model in plant factories, wherein the growth environment is unaffected by the weather, soil, and pests outside the plant factory.

4.3. Conventional Agriculture

In general, the physical, chemical, and biological environment of an agroecosystem is heavily influenced by the local soil and climate, which makes agroecosystem management culturally specific. In regard to conventional agriculture, stakeholders manage the ecosystems on farmland or within facilities, working within the remit of specific production targets and constraints, such as demand and input limits. Management approaches can vary widely, from an almost laissez faire approach to relatively strict control. The target ecosystems range from single species at a particular growth stage to multispecies at various growth stages.

Although simplifying or automating the measurement and control of plant phenotypic traits (Pp), the environment (ER), and management (M) in agricultural fields is relatively challenging, it is possible, to a certain extent, with the use of the latest nonbiological technologies, such as image processing, small biosensors, robots, and AI. The extent of the automation to be achieved would depend on the values, attitudes, social conditions, and development-associated funding provided by the stakeholders involved. In this context, the fundamental components of the technology are related to the civilization, but the technology appears to be like a culture superficially because it is tailored to the local climate, soil, history, and landscape.

5. Characteristics of Production Technology Used in Plant Factories

5.1. Ecological Simplification and Production Technology Configuration

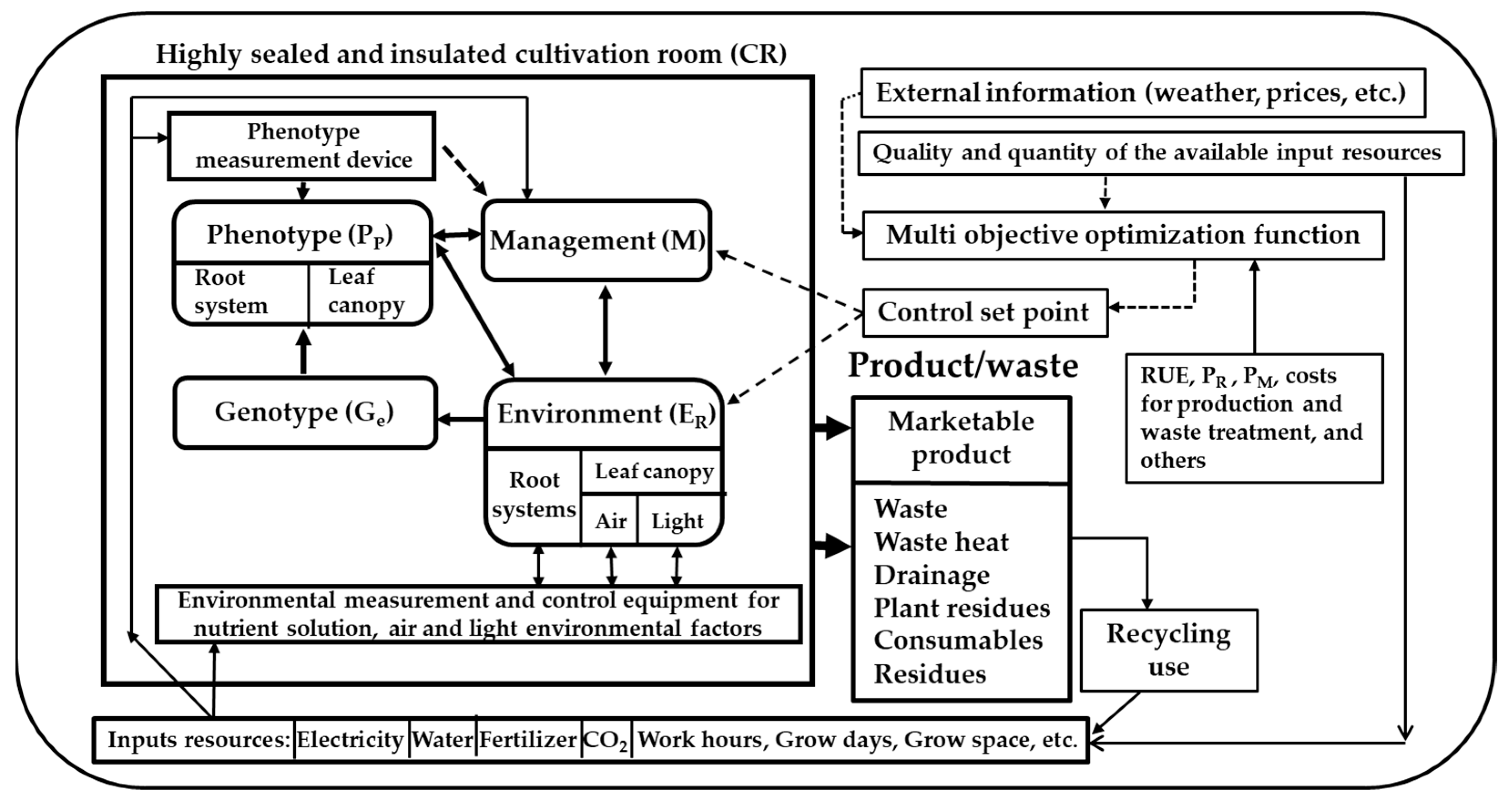

In a plant factory, plant communities (root systems and leaf canopies consisting of leaves, stems, and branches, hereafter referred to as “communities”) are cultivated in an airtight, well-insulated CR. This setup eliminates the effects of weather, soil, and pests on plant growth, simplifying the ecosystem (the community, its environment, and their interactions) within the CR.

Figure 4 shows the interactions between the plant phenotype (P

p), environment (E

R), management (M), and genotype (G

e) in the CR (the genome does not change; however, some genotypes, G

e, interact with the E

R and M, and become active or inactive). P

p refers to the observable characteristics of the plant, E

R refers to environmental factors, and M refers to human or instrumental intervention. Examples of the variable names for E

R, M, P

p, and G

e are given in

Table 1.

The grower/manager seeks to maximize the value of the multiobjective functions (a dimensionless weighted combination of multiple objective functions), considering the constraints and interrelationships between Pp, ER, M, and Ge. The objective functions include: (1) the economic or social value of the phenotype (quality, quantity, and timing of production); (2) cost of production, recycling use, and waste disposal; (3) the contribution of greenhouse gas emissions to global warming; and (4) stakeholder satisfaction.

5.2. Greenhouse Gas Emissions per Unit of Electricity Generated

The “current status of annual yields” and the “general advantages of plant factories” outlined in “

Section 2” are insufficient to claim that plant factories will contribute to the simultaneous resolution of the four-way deadlock problem. Technological advancements in terms of plant factories, by around 2035, will likely double the annual yield and its social value, but, even then, this will not be enough to contribute to the simultaneous resolution of the four-way deadlock problem.

In order for plant factories to contribute to the simultaneous resolution of the four-way deadlock problem, it is necessary to: (1) generate the majority of the input electricity from renewable energy sources, such as solar radiation, wind power, hydropower, geothermal energy, and biomass energy, etc.; (2) improve the power generation efficiency (the ratio of electricity generated to the available renewable energy) by approximately 1.5 times; and (3) increase the electricity storage capacity per volume of battery by approximately two times compared to the levels achieved in 2025. Measures (1) and (2) will significantly reduce the greenhouse gas emissions (CO

2, CH

4, N

2O, etc.) per unit of electricity consumed. According to the internationally recognized Life Cycle Assessment (LCA) method [

18,

19,

20], the amount of greenhouse gas emissions per unit of electricity generated by solar energy is approximately one-tenth that of heavy oil [

21].

5.3. Reductions in the Maximum Power Requirements for Lighting and Cooling, the Winter Heating Load, and the Air Conditioning Capacity

If the lighting units in a CR are divided into three groups, with each group’s lighting start time (16 h of light) staggered by 8 h, cooling is required throughout the day to remove the heat generated by the lamps into the outdoors [

11]. In other words, heating is no longer necessary, even during winter nights in colder regions. By using this three-group staggered lighting method, the maximum power requirement is reduced to two-thirds of the amount compared with the method involving all the lighting units being turned on and off simultaneously. The three-group alternating lighting method will also reduce the overall cooling capacity need, thereby reducing the initial investment in terms of the air conditioner by about two-thirds; however, the total electricity consumption per day cannot be reduced significantly. In addition, the hot air, ranging from 40 to 45 °C, discharged from the outdoor unit of the air conditioner during cooling can be used, for example, (1) drying the wet plant residue produced in plant factories, (2) heating adjacent greenhouses in winter, and (3) other purposes in spaces adjacent to the CR.

When two-thirds of the lamps are turned on for 24 h daily, it is easier to maintain the room’s vapor pressure deficit (VPD) at approximately 0.5–1.0 kPa without the use of dehumidifiers because of the dehumidifying effect of cooling. Conversely, when the lamps are completely turned off, the VPD in the room approaches 0 kPa (100% relative humidity), which can easily cause physiological disorders in plants, as well as promote excessive plant and fungal growth. In either case, transpiration from the culture media needs to be minimized and the surface of the culture media needs to be kept dry.

In addition, the reuse of wastewater from plant factories after purification and proper sterilization treatment, along with the conversion of plant residues into fertilizers through microbial decomposition, can enhance local self-sufficiency regarding water and fertilizer use. In addition to the methods mentioned above, there are many other ways to save electricity, including dynamically adjusting the setpoints of different environmental factors [

22].

5.4. Improvement of Local Self-Sufficiency in Terms of Input Resources and the Benefits

Solar panels for electricity generation can be installed on the roof of the plant factory and adjacent land, making it easier to establish electricity-autonomous plant factories in each location. In addition to meeting electricity requirements, improving local self-sufficiency in terms of the use of water, fertilizers, and other input resources will help mitigate disruptions in regard to the import/transfer of these resources, due to factors such as extreme weather events, geopolitical conflicts, large-scale earthquakes, and volcanic eruptions, etc. If the abovementioned local self-sufficiency can be achieved, plant factories can contribute to the simultaneous resolution of the four-way deadlock problem occurring at the location. More detailed quantitative studies will be needed in the future.

6. Measurement and Control of Mean Values, 3D Distribution, and Interactions in a Cultivation Room

The P

p and E

R factors, shown in

Figure 4, vary over time and in 3D space. In general, as the spatial density (kg/m

3) of a plant community increases, the difference between the mean values of the E

R within and outside the community increases, along with the variation in the 3D distribution of P

p and E

R within the community [

23,

24,

25]. In a hydroponic cultivation bed, there is significant variation in the environmental factors, such as the flow rate of the nutrient solution and the dissolved oxygen concentration inside and outside the root system.

The average value of photosynthetically active radiation (PAR) or PPFD and its spectral (wavelength) flux density within the leaf canopy declines exponentially with an increase in the leaf area index (LAI; ratio of the leaf area to the cultivated area). The spatial variation in the airflow speed within the leaf canopy increases with an increasing LAI [

26]. Consequently, fluctuations in the air diffusion coefficient, temperature, VPD, and CO

2 concentration in the leaf canopy are often markedly greater than those above the leaf canopy, especially during the photoperiod [

27].

The difference in the environment between the inside and the outside of the root systems is also significantly affected by the root system density, which is the mass of roots per unit of weight of the nutrient solution (kg/kg) [

28]. Thus, to maximize the multiobjective function, the environmental factors above the leaf canopy and in regard to the inlet/outlet of the nutrient solution in the cultivation bed need to be controlled considering the canopy density and root system density, respectively. In addition, 3D distributions of the P

p and E

R affect the value of the multiobjective function considerably. The methodology of the 3D measurement and control of the E

R and P

p in the community is expected to be developed in the near future.

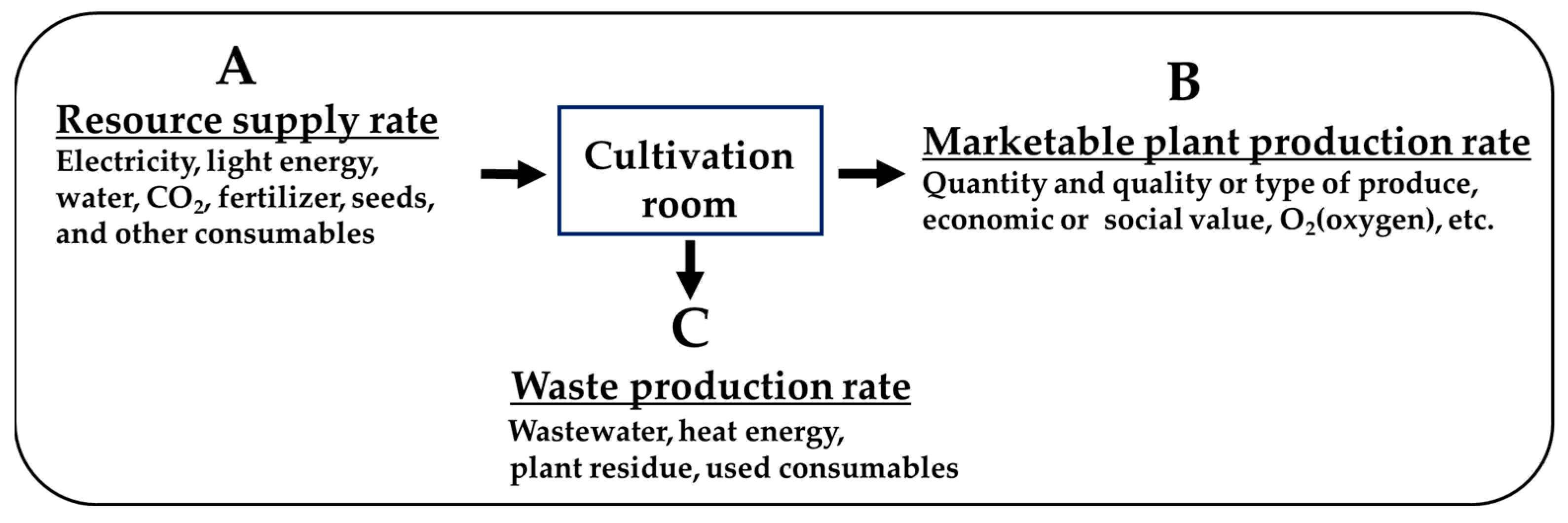

6.1. Mean Value Measurement and Control in an Airtight and Thermally Insulated Cultivation Room

The continuous measurement of various resource inputs, such as electricity for lighting and air conditioning and CO

2 for promoting photosynthesis, in the CR can also be accurately monitored. Additionally, the daily production rates of marketable products and waste can be accurately monitored. Based on the above measurements, the resource use efficiency (RUE) (

Figure 5) and resource productivity (P

R = RUE × S/R

min) can be calculated with relative accuracy, wherein S is the amount of produce and R

min is the minimum amount of resources required to produce S [

29].

Similarly, the ER of the nutrient solution at the inlet and outlet of each cultivation bed can be measured continuously, with relative accuracy. Then, the water uptake rate and exchange rates of chemical substances between the nutrient solution and root systems can be estimated continuously. Then, the RUE and PR can be estimated theoretically in terms of the water used and each ion in the fertilizer applied, considering the ion uptake by the plants and ion reactions in the nutrient solution.

From the abovementioned measurements and the energy–water–CO2 balance equation, the rates of the net photosynthesis, dark respiration, water absorption, and transpiration of the plant community can be calculated with relative accuracy and continuity. While it is a challenge to perform continuous measurements, daily values, such as the fresh weight, dry matter weight, and plant height, components of the plant community’s Pp, can be measured with reasonable accuracy. The calculated averages of the abovementioned ER and Pp, RUE, PR, and the net photosynthetic rate are useful to calculate an appropriate M. However, all of these measurements and calculations represent averages or totals in regard to the CR, and their 3D spatial distribution remains unknown.

6.2. The Measurement of the 3D Spatial Distribution and Cohort Measurement Control

Nondestructive and noninvasive measurement technology for the time-series dataset on the 3D spatial distribution of the Pp and ER will be developed in the near future. Such technology is expected to control the 3D distribution of the ER surrounding the leaves and individual plants considering their interaction with the 3D distribution of Pp.

If the mean values of the E

R and P

p derived from their 3D distribution differ from the previously mentioned community mean values of E

R and P

p, the parameters employed to calculate the 3D distribution of P

p need to be adjusted to align with the direct measurements of the mean value. This adjustment would allow for the control of P

p and its environment at a specific location in terms of an individual leaf or plant. This approach would facilitate further research and development in regard to controlling P

p and its surrounding environment in the specific location of a specific individual based on cohort research [

30], where “cohort” means a group of plants with a common characteristic.

To promote the research mentioned above, it is essential to accurately collect the 3D time-series dataset of various variables, as shown in

Figure 5. From a 3D time-series dataset, the 3D distribution of the interaction between the P

p and E

R could be calculated. Ultimately, the 3D distribution of the E

R will be controlled to achieve the 3D distribution of P

p that maximizes the multiobjective function.

Although the research and development of the relevant 3D measurement and control is still in its early stages, recent growing interest from researchers in various fields, such as engineering, science, information technology, and economics, has led to remarkable advancements in plant factory research [

31,

32,

33,

34,

35,

36,

37,

38,

39,

40,

41,

42]. As a result, future progress in this area of research and development is highly anticipated.

Figure 6 shows the interactions among P

P, E

R, M, and G

e in a highly sealed and insulated cultivation room (CR) in a plant factory. The diagram also includes the equipment for environmental measurement and control, and major resource inputs and product outputs, including waste. The objective of environmental control is to maximize the multiobjective function under given constraints. Dashed lines in the figure represent the signal flow only. RUE, P

R, and P

M denote resource use efficiency, resource productivity, and monetary productivity, respectively.

6.3. Uniformity of Spatial Distribution of ER and Pp

While the multiobjective function may not necessarily be maximized when the ER within a leaf canopy and root system are spatially uniform, measuring the 3D distribution of Pp when ER and Pp are, respectively, spatially uniform would be the first research step. To achieve the spatial uniformity of light-related ER within a leaf canopy, for example, LED point sources with variable spectral distribution and radiant flux (unit: W) must be distributed within the leaf canopy. Alternatively, projection mapping, using a spectral laser beam with a controlled light flux to illuminate fluctuating and growing leaves only, will maximize the net photosynthetic rate of the plants as per the electricity consumption in regard to lighting, in cases where other environmental factors are optimally controlled.

To ensure the spatial uniformity of the air current speed, temperature, VPD, and CO2 concentration, etc., within a leaf canopy, small tubes that deliver air with a controlled ER must be distributed within the canopy. To achieve the spatial uniformity of the ER in terms of the root system, for example, small tubes delivering the nutrient solution with a controlled flow rate, dissolved oxygen concentration, nutrient solution composition, pH, and temperature need to be distributed within the root systems. While controlling these environmental factors in response to the time-varying dimensions and geometry of the leaf canopy and roots will generally be difficult, breakthroughs are expected to occur in the near future.

It should be noted again that the uneven spatial distribution of the E

R often brings about the uneven spatial distribution of the P

p and vice versa, where P

p includes the concentrations of secondary metabolites and minerals, etc., in plants. In fact, the concentrations of bioactive secondary metabolites and minerals in hydroponic leafy plants are affected by the light quality [

43,

44,

45,

46] and root zone temperature [

47].

6.4. Airborne Particulates and VOCs

The air in the CR contains various airborne particulates, including blooms (harmless powder exuded from the surface of plant organs), volatile organic compounds (VOCs), algae, and more, all suspended in three dimensions. It is nearly impossible and unnecessary to eliminate all of them. Nevertheless, it is vital to be mindful of allelopathic substances, namely VOCs produced by plants that can have sensory effects. VOCs are also emitted from the walls, structural materials, paint on electronic equipment, and workers in the CR. Some of these VOCs can cause physiological abnormalities in plants and discomfort for workers.

Cannabis sativa L. emits significant amounts of VOCs, which may cause health issues for workers [

48].

Ethylene has positive and negative effects on plants, promoting or inhibiting growth processes depending on its concentration, the time of application, and the type of plant [

49,

50]. An increase in the concentration of ethylene in the air may stimulate further ethylene production by plants. There are still many uncertainties regarding the interaction between airborne particulates in the CR and the P

p.

Malfunctions in environmental control equipment or fires caused by electrical leakage may lead to abnormal increases in CO2 and CO concentrations, as well as an abnormally high air temperature in the CR. The increase in CO2 in the CR higher than 5000 ppm may affect human health and the closure of leaf stomata. The combustion of plastics caused by fire emits CO2, and its incomplete combustion emits CO (carbon monoxide), which can cause deadly carbon monoxide poisoning in humans. In the case of abnormally high air temperatures, the first step is to turn off the lighting units. Since natural ventilation cannot provide the necessary ventilation rate to reduce the high air temperature and concentration of various gases, a forced ventilation system is required in all but the smallest CRs.

7. Ecosystems in Cultivation Beds and Their Simplification

7.1. Ecosystems in Cultivation Beds

The nutrient solution, plant root systems, supporting materials, and microorganisms in the cultivation bed form a rhizosphere ecosystem. The nutrient solution often contains organic acids, including allelopathic substances exuded by the root system, in addition to inorganic nutrient ions. The fine roots and other parts of the root system are easily damaged, triggering microbial decomposition. Microorganisms are classified into pathogenic, beneficial, and neutral. It is anticipated that, in the future, a majority of the microorganisms in the ecosystem will be beneficial or neutral.

Algae proliferate and grow anywhere (e.g., the wet surfaces of supporting materials, floors, walls, and structural elements in the CR), as long as light, water, and nutrients exist. For example, algae proliferate and grow in the nutrient solution in instances when the light penetrates it. Since some dead roots and algae accumulate in cultivation beds, it is impossible to completely eliminate microorganisms from cultivation beds. Therefore, further progress in the research on the 3D measurement and control of microbial ecosystems and the ER within cultivation beds is expected.

7.2. Function of Roots and Supports

The function of roots is to: (1) uptake water, nutrients, and dissolved oxygen; (2) produce cytokinin (one of the phytohormones), which travel to the shoots; and (3) physically support the aerial parts of a plant. The function of supports (or supporting material) is to physically support the aerial parts of a plant. Typical supports include a mixture of peat, vermiculite, perlite, and peat, formed rockwool fiber cubes, and foamed polyurethane cubes. The mixture of formed rockwool fiber cubes and peat emit significant amounts of global warming gases during digging, manufacturing, and transportation. In addition to this, they are not chemically inert. Foamed polyurethane cubes are made of fossil fuel. Thus, a hydroponic cultivation bed with cultivation panels that support plants without the use of a medium/supporting material would be a future innovation in regard to hydroponic cultivation units.

7.3. Plant Biostimulants

A plant biostimulant is any substance or microorganism applied to plants with the aim to enhance its nutritional use efficiency, abiotic stress tolerance, and/or crop quality traits, regardless of its nutrient content. The above definition is partially overlapped with that of fertilizer. Then, the term biofertilizer is proposed as a subcategory of biostimulants [

51]. It has been reported that biostimulants could enhance plant photosynthesis by opening the stomata and increasing gas exchange [

52]. The effects of biostimulants on plant growth and development can be analyzed and controlled more easily in plant factories than on farmland as the first step in terms of their wider application to farmland.

7.4. One-Way Nutrient Solution Flow Unit for Simplifying the Structure and Control of Cultivation

One of the methods to simplify the ecosystem in a cultivation bed is to install a one-way nutrient solution flow unit. The structure of a cultivation bed can be simplified by using a non-circulating or one-way nutrient solution flow unit, which eliminates the need for return piping from the nutrient solution outlet to the nutrient tank. This simplification significantly reduces the amount of nutrient solution required per plant, shortens the time required for temporal changes to the nutrient solution composition, and the concentration, temperature, and other related variables, improving the controllability of these variables.

In instances when the ratio of the water uptake rate to the ion uptake rate of plants does not change over time, the ion concentration of the nutrient solution in the cultivation bed remains the same. However, if the supply rate of the ion concentration into the cultivation bed exceeds the absorption rate of the plants in the cultivation bed, ions accumulate in the cultivation bed and, thus, the ion concentration increases. Conversely, if the supply rate of the ion concentration is lower than the absorption rate of the plants, the concentration of the ions in the cultivation bed decreases.

This phenomenon can be utilized to actively control the absorption rate of each ion. To enable this form of control, it is necessary to control the water supply rate and the concentration of each ion in the cultivation bed considering the valency (combining power) of each ion. Through the use of this unit, the amount of water and the nutrient supply into the cultivation bed need to be minimized to minimize the excess water and nutrients discharged from the cultivation bed. Therefore, the development of an affordable and simple measurement and control unit for this purpose is awaited.

8. The Use of Plant Residues as Organic Fertilizer

The plant residues produced in plant factories can be used as organic fertilizers in regard to two methods: (1) the microbial decomposition of plant residues within the cultivation bed to convert organic fertilizer into inorganic fertilizer, and (2) the microbial decomposition of plant residues outside the CR to produce inorganic fertilizer, and return it to the cultivation bed. The former requires maintaining the temperature and moisture levels of the plant residues within a range that is also suitable for plant growth, because they influence the microbial decomposition process significantly. Conversely, the latter allows for more flexible control over the temperature and moisture levels of the plant residues. In either case, research and development are necessary to ensure that microbial degradation proceeds effectively, along with the consideration of the valency of each ion and the effects of environmental variables [

53].

Pathogenic microorganisms need to be eliminated, and only beneficial or neutral microbes must remain in cultivation beds. The use of beneficial and neutral microbes is crucial to maintain a high fertilizer use efficiency by recycling and reusing plant residues. Thus, further research in this area is highly anticipated on the efficient use of organic fertilizer in simplified ecosystems (plant factories), as the fertilizers used in plant factories will serve as the foundation for the cultivation of organic fertilizers and the application of microorganisms in agricultural land.

9. The Reason for Aiming to Achieve Microbe-Free Ecosystems in Plant Factories

It is actually impossible to maintain microbe-free ecosystems, even in CRs. However, in this paper, methods for realizing microbe-free ecosystems in CRs are discussed to clarify the advantages of pseudo-microbe-free and/or pathogen-free ecosystems. The advantages of pathogen-free ecosystems include the simplified structure and environmental control of the CR to lower the cost of their construction and operation, and to understand, measure, and control the fundamental relationships among plants, environments, and their interactions in the CR. Then, the complexity of the ecosystem can be increased, one step at a time. For example, the population of a certain kind of microbe can be increased to an extent where it is possible to measure and control their fundamental relationships among plants, environments, and their interactions. However, this approach is effective only in airtight and thermally insulated CRs.

Another aim of plant factory research on pseudo-microbe-free ecosystems is to take an interdisciplinary approach that includes groups of biologists, engineers, and researchers from other fields. The interdisciplinary approach can be conducted alongside the simultaneous resolution of the four-way deadlock problem. This approach is similar to interdisciplinary research on the universe or cosmos by a group of particle theory researchers and cosmologists. The STEM disciplines in terms of microbe-free ecosystems and farmland agricultural ecosystems correspond to the STEM disciplines of the particle theory world and cosmic world, respectively.

10. Conclusions

The concurrent solution of the four-way deadlock problem is discussed from the perspective of civilization and culture, participatory science, and the integration of nonbiological technologies into biological technologies. While addressing the simultaneous resolution of the four-way deadlock problem, measures are also required to address the forthcoming large-scale droughts, floods, storms, heavy snowfall, extremely high/low temperatures, and pest and disease damage that will occur in future, partially due to global warming, because it will take more than 10 years to resolve most of the aspects of the four-way deadlock problem.

Although it may seem like a passive disaster countermeasure, “Noah’s Ark”-type electrically autonomous plant factories with electricity generation units, using solar energy, wind power, and hydropower that can float on water during floods, withstand storms, pests, and other extreme environments, it is a feasible solution. In “Noah’s Ark”, a variety of plants can be cultivated, and seeds and seedlings can be stored to produce food and processed products. In emergencies, it can serve as a supply base for seeds, plants, and other resources in regard to disaster-stricken areas.

The basic functions of “Noah’s Ark” are almost identical to those required for space or lunar farms. Since both rely on the integration of the latest nonbiological STEM disciplines into biological STEM disciplines, they can be considered nearly equivalent to plant factories on Earth when constructed based on participatory science [

54]; however, space farms will benefit from only 1/6 of Earth’s gravity, will require shielding from cosmic radiation, and will require air pressure sufficient for plants and humans.

Author Contributions

Conceptualization, T.K., E.H. and N.L.; methodology, D.T.P.N. and H.N.; software, H.N.; validation, H.N., D.T.P.N. and N.L.; formal analysis, H.N. and N.L.; investigation, D.T.P.N.; resources, H.N.; data curation, H.N.; writing, original draft preparation, T.K. and E.H.; writing, review and editing, D.T.P.N., H.N. and T.K.; visualization, D.T.P.N., H.N. and N.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by JST SICORP, Grant Number JPMJSC24C6, Japan.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare that there are no conflicts of interest.

References

- Kreuger, M.; Meeuws, L.; Meeuws, G. Applications for Breeding and High-Wire Tomato Production in Plant Factory. In Smart Plant Factory: The Next Generation Indoor Vertical Farms; Kozai, T., Ed.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 289–299. [Google Scholar]

- Koga, H.; Uchigasaki, K. Oishii Farm: Gaining the Leading Edge in the Plan Factory Business and Looking Forward. In Advances in Plant Factories—New Technologies in Indoor Vertical Farming; Kozai, T., Hayashi, E., Eds.; Burleigh Dodds Science Publishing: Cambridgeshire, UK, 2023; pp. 435–452. [Google Scholar]

- Watson, A.; Ghosh, S.; Williams, J.M.; Cuddy, S.W.; Simmonds, J.; Rey, M.-D.; Hatta, M.A.M.; Hinchliffe, A.; Steed, A.; Reynolds, D.; et al. Speed Breeding Is a Powerful Tool to Accelerate Crop Research and Breeding. Nat. Plants 2018, 4, 23–29. [Google Scholar] [CrossRef]

- SharathKumar, M.; Heuvelink, E.; Marcelis, L.F.M. Vertical Farming: Moving from Genetic to Environmental Modification. Trends Plant Sci. 2020, 8, 724–727. [Google Scholar] [CrossRef]

- Goto, E. Production of Pharmaceutical Materials Using Genetically Modified Plants Grown under Artificial Lighting. Acta Hortic. 2011, 907, 45–52. [Google Scholar] [CrossRef]

- Stander, J.; Mbewana, S.; Meyers, A.E. Plant-Derived Human Vaccines: Recent Developments. BioDrugs 2022, 36, 573–589. [Google Scholar] [CrossRef]

- Yuki, Y.; Kurokawa, S.; Sugiura, K.; Kashima, K.; Maruyama, S.; Yamanoue, T.; Honma, A.; Mejima, M.; Takeyama, N.; Kuroda, M.; et al. MucoRice-CTB Line 19A, a New Marker-Free Transgenic Rice-Based Cholera Vaccine Produced in an LED-Based Hydroponic System. Front. Plant. Sci. 2024, 15, 1342662. [Google Scholar] [CrossRef]

- Mitchell, C.A. History of Controlled Environment Horticulture: Indoor Farming and Its Key Technologies. HortScience 2022, 57, 247–256. [Google Scholar] [CrossRef]

- Nakaoka, H.; Hayashi, E. Perspectives and revision of the law regarding the cultivation of Cannabis sativa L. Agric. Hortic. 2025, 100, 299–303. (In Japanese) [Google Scholar]

- Kozai, T.; Niu, G.; Takagaki, M. Plant Factory: An Indoor Vertical Farm for Efficient Quality Food Production, 2nd ed.; Kozai, T., Niu, G., Takagaki, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Kozai, T.; Niu, G.; Masabni, J. Plant Factory: Basics, Applications, and Advances; Kozai, T., Niu, G., Masabni, J., Eds.; Academic Press: Cambridge, MA, USA, 2021. [Google Scholar]

- Kozai, T. Resource Use Efficiency of Closed Plant Production System with Artificial Light: Concept, Estimation and Application to Plant Factory. Proc. Jpn. Acad. Ser. B Phys. Biol. Sci. 2013, 89, 447–461. [Google Scholar] [CrossRef]

- Winter, H.J.J. Eastern Science; an Outline of Its Scope and Contribution; J. Murray Collection: London, UK, 1952. [Google Scholar]

- Kozai, T. Involved−person−constructed science and civic science—Their relationships with forthcoming nursing and integrative science. Jpn. Acad. Gerontol. Nurs. 2012, 17, 12–17. (In Japanese) [Google Scholar] [CrossRef]

- Ikei, H. Human-Centered Perspective on Urban Agriculture. In Plant Factory Basics, Applications and Advances; Elsevier: Amsterdam, The Netherlands, 2022; pp. 401–416. ISBN 9780323851527. [Google Scholar]

- Goodman, P.; Goodman, P. Communitas-Means of Livelihood and Ways of Life; Vintage Books: New York, NY, USA, 1960. [Google Scholar]

- Rifkin, J. The Zero Marginal Cost Society; Griffin Pub.: Brentford, UK, 2015. [Google Scholar]

- Hikosaka, S.; Hayashi, E.; Nakano, A.; Kasai, M.; Yamaguchi, T.; Kozai, T. Development of LCA-Multidimensional Map (LAMP): A Platform to Support Information Sharing and Formulate CO2-Level-Reduction Plans toward Zero Emissions. Sustainability 2023, 15, 6066. [Google Scholar] [CrossRef]

- Martin, M.; Orsini, F. Life Cycle Assessment of Indoor Vertical Farms; Burleigh Dodds Scientific Publishing: Cambridgeshire, UK, 2023. [Google Scholar]

- Martin, M.; Elnour, M.; Siñol, A.C. Environmental life cycle assessment of a large-scale commercial vertical farm. Sustain. Prod. Consum. 2023, 40, 182–193. [Google Scholar] [CrossRef]

- Imamura, E.; Iuchi, M.; Bando, S. Comprehensive Assessment of Life Cycle CO2 Emissions from Power Generation Technologies in Japan; Central Research Institute of Electric Power Industry: Tokyo, Japan, 2016. [Google Scholar]

- Kaiser, E.; Kusuma, P.; Vialet-Chabrand, S.; Folta, K.; Liu, Y.; Poorter, H.; Woning, N.; Shrestha, S.; Ciarreta, A.; van Brenk, J.; et al. Vertical farming goes dynamic: Optimizing resource use efficiency, product quality, and energy costs. Front. Sci. 2024, 2, 1411259. [Google Scholar] [CrossRef]

- Oikawa, T. Light Regime in Relation to Plant Population Geometry III. Ecological Implications of a Square-Planted Population from the Viewpoint of Utilization Efficiency of Solar Energy. Bot. Mag. Tokyo 1977, 90, 301–311. [Google Scholar] [CrossRef]

- Oikawa, T. Light Regime in Relation to Plant Population Geometry II. Light Penetration in a Square-Planted Population. Bot. Mag. Tokyo 1977, 90, 11–22. [Google Scholar] [CrossRef]

- Oikawa, T.; Saeki, T. Light Regime in Relation to Plant Population Geometry I. A Monte Carlo Simulation of Light Microclimates within a Random Distribution Foliage. Bot. Mag. Tokyo 1977, 90, 1–10. [Google Scholar] [CrossRef]

- Yabuki, K. Photosynthesis Rate and Dynamic Environment, 1st ed.; Springer: Dordrecht, The Netherlands, 2004. [Google Scholar]

- Kitaya, Y. Plant Production for Sustainable Society as a Semi-Closed Ecosystem; Springer: Singapore, 2024. [Google Scholar]

- Liu, A.; Qu, Z.; Nachshon, U. On the Potential Impact of Root System Size and Density on Salt Distribution in the Root Zone. Agric. Water Manag. 2020, 234, 106118. [Google Scholar] [CrossRef]

- Kozai, T.; Hayashi, E. Requirements and Features of Cultivation System Modules in Advanced Plant Factories with Artificial Lighting. In Advances in Plant Factories: New Technologies in Indoor Vertical Farming; Kozai, T., Hayashi, E., Eds.; Burleigh Dodds Science Publishing: Cambridgeshire, UK, 2023. [Google Scholar]

- Hayashi, E.; Amagai, Y.; Kozai, T.; Maruo, T.; Tsukagoshi, S.; Nakano, A.; Johkan, M. Variations in the Growth of Cotyledons and Initial True Leaves as Affected by Photosynthetic Photon Flux Density at Individual Seedlings and Nutrients. Agronomy 2022, 12, 194. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, J.W.; Ahn, T.I.; Shin, J.H.; Park, K.S.; Son, J.E. Sweet Pepper (Capsicum annuum L.) Canopy Photosynthesis Modeling Using 3D Plant Architecture and Light Ray-Tracing. Front. Plant Sci. 2016, 7, 1321. [Google Scholar] [CrossRef]

- Ohashi, Y.; Ishigami, Y.; Gotoa, E. Estimation of the Light Environment inside a Tomato Canopy in a Greenhouse by Using the Ray Tracing Method. Acta Hortic. 2020, 1296, 93–100. [Google Scholar] [CrossRef]

- Ohashi, Y.; Torii, T.; Ishigami, Y.; Goto, E. Estimation of the Light Interception of a Cultivated Tomato Crop Canopy under Different Furrow Distances in a Greenhouse Using the Ray Tracing. J. Agric. Meteorol. 2020, 76, 188–193. [Google Scholar] [CrossRef]

- Saito, K.; Yoshida, H.; Hikosaka, S.; Goto, E. Validation of the Estimated Photosynthetic Rate of Komatsuna (Brassica rapa L. Var. Perviridis) Plants in a Plant Factory with Artificial Light Using an Optical Simulation. Acta Hortic. 2025, 1423, 9–16. [Google Scholar] [CrossRef]

- Saito, K.; Goto, E. Evaluation of the Enhancement of Photosynthetic Rate in a Komatsuna (Brassica rapa L. Var. Perviridis) Canopy with Upward Lighting Using an Optical Simulation in a Plant Factory with Artificial Light. Front. Plant Sci. 2023, 14, 1111338. [Google Scholar] [CrossRef]

- Saito, K.; Ishigami, Y.; Goto, E. Evaluation of the Light Environment of a Plant Factory with Artificial Light by Using an Optical Simulation. Agronomy 2020, 10, 663. [Google Scholar] [CrossRef]

- Nagano, S.; Moriyuki, S.; Wakamori, K.; Mineno, H.; Fukuda, H. Leaf-Movement-Based Growth Prediction Model Using Optical Flow Analysis and Machine Learning in Plant Factory. Front. Plant Sci. 2019, 10, 227. [Google Scholar] [CrossRef]

- Ueno, T.; Nagano, S.; Moriyuki, S.; Hayashi, T.; Fukuda, H. Optimized Excess-Green Image Binarization for Accurate Estimation of Lettuce Seedling Leaf-Area in a Plant Factory. Environ. Control Biol. 2022, 60, 153–159. [Google Scholar] [CrossRef]

- Rizkiana, A.; Nugroho, A.P.; Salma, N.M.; Afif, S.; Masithoh, R.E.; Sutiarso, L.; Okayasu, T. Plant Growth Prediction Model for Lettuce (Lactuca sativa.) in Plant Factories Using Artificial Neural Network. Proc. IOP Conf. Ser. Earth Environ. Sci. 2021, 733, 012027. [Google Scholar] [CrossRef]

- Shimamura, S.; Uehara, K.; Koakutsu, S. Automatic Identification of Plant Physiological Disorders in Plant Factory Crops. IEEJ Trans. Electron. Inf. Syst. 2019, 139, 818–819. [Google Scholar] [CrossRef]

- Hwang, Y.; Lee, S.; Kim, T.; Baik, K.; Choi, Y. Crop Growth Monitoring System in Vertical Farms Based on Region-of-Interest Prediction. Agriculture 2022, 12, 656. [Google Scholar] [CrossRef]

- Abedi, M.; Tan, X.; Stallknecht, E.J.; Runkle, E.S.; Klausner, J.F.; Murillo, M.S.; Bénard, A. Incorporating the effect of the photon spectrum on biomass accumulation of lettuce using a dynamic growth model. Front. Plant Sci. 2023, 14, 1106576. [Google Scholar] [CrossRef]

- Dou, H.; Niu, G.; Gu, M.; Masabni, J.G. Effects of light quality on growth and phytonutrient accumulation of herbs under controlled environments. Horticulturae 2017, 3, 36. [Google Scholar] [CrossRef]

- Zhang, X.; He, D.; Niu, G.; Yan, Z.; Song, J. Effects of environment lighting on the growth, photosynthesis, and quality of hydroponic lettuce in a plant factory. Int. J. Agric. Biol. Eng. 2018, 11, 33–40. [Google Scholar] [CrossRef]

- Kelly, N.; Runkle, E.S. End-of-production ultraviolet A and blue light similarly increase lettuce coloration and phytochemical concentrations. HortScience 2023, 58, 525–531. [Google Scholar] [CrossRef]

- Kelly, N.; Runkle, E.S. Dependence of far-red light on red and green light at increasing growth of lettuce. PLoS ONE 2024, 19, e0313084. [Google Scholar] [CrossRef]

- Wittayathanarattana, T.; Wanichananan, P.; Supaibulwatana, K.; Goto, E. A short-term cooling of root-zone temperature increases bioactive compounds in baby leaf Amaranthus tricolor L. Front. Plant Sci. 2022, 13, 944716. [Google Scholar]

- de Ferreyro Monticelli, D.; Bhandari, S.; Eykelbosh, A.; Henderson, S.B.; Giang, A.; Zimmerman, N. Cannabis Cultivation Facilities: A Review of Their Air Quality Impacts from the Occupational to Community Scale. Environ. Sci. Technol. 2022, 56, 2880–2896. [Google Scholar] [CrossRef]

- Mohorović, P.; Geldhof, B.; Holsteens, K.; Rinia, M.; Daems, S.; Reijnders, T.; Ceusters, J.; Van den Ende, W.; Van de Poel, B. Ethylene Inhibits Photosynthesis via Temporally Distinct Responses in Tomato Plants. Plant Physiol. 2024, 195, 762–784. [Google Scholar] [CrossRef]

- Iqbal, N.; Khan, N.A.; Ferrante, A.; Trivellini, A.; Francini, A.; Khan, M.I.R. Ethylene Role in Plant Growth, Development and Senescence: Interaction with Other Phytohormones. Front. Plant Sci. 2017, 8, 475. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, J.; Jeong, S.J.; Masabni, J.; Niu, G. Biostimulants Applied in Seedling Stage Can Improve Onion Early Bulb Growth: Cultivar- and Fertilizer-Type-Specific Positive Effects. Horticulturae 2025, 11, 402. [Google Scholar] [CrossRef]

- Inagaki, Y.; Ishino, N.; Isoyama, Y.; Takayama, K. Effects of Foliar Application of Fatty Acid Solution Containing 13 Oxo ODA as an Active Substance on Photosynthesis, Transpiration, Stomatal Conductance in Tomato. Eco-Engineering 2015, 1, 1–5. [Google Scholar] [CrossRef]

- Meeboon, J.; Nishida, R.; Iwai, T.; Fujiwara, K.; Takano, M.; Shinohara, M. Development of Soil-Less Substrates Capable of Degrading Organic Nitrogen into Nitrate as in Natural Soils. Sci. Rep. 2022, 12, 785. [Google Scholar] [CrossRef]

- Wheeler, R.M. NASA’s Contributions to Vertical Farming. In Proceedings of the XXXI International Horticultural Congress (IHC2022): International Symposium on Advances in Vertical Farming, Angers, France, 14–20 August 2022; pp. 1–13. [Google Scholar]

Figure 1.

A schematic diagram illustrating the four-way deadlock problem that needs a resolution.

Figure 1.

A schematic diagram illustrating the four-way deadlock problem that needs a resolution.

Figure 2.

Global/regional issues and background of the four-way deadlock problem, all of the aspects of which must be solved concurrently. To improve the yield of crops grown in conventional ways, more land area, chemical fertilizer, irrigation water, labor, and machine inputs are required. To conserve the natural environment and ecosystems, the agricultural land area and application of agricultural chemicals need to be reduced. To conserve natural resources, such as fossil fuels, and ores, such as rock phosphate, potash ore, iron ore, and rare metals, the application of agricultural fertilizer and metals need to be reduced. To improve the sustainability of our society, the consumption of fossil fuels for air conditioning and the emission of gases that contribute to global warming in cities need to be reduced. The above characteristics will help reduce the disparities in terms of gender, age, and mental and physical disability.

Figure 2.

Global/regional issues and background of the four-way deadlock problem, all of the aspects of which must be solved concurrently. To improve the yield of crops grown in conventional ways, more land area, chemical fertilizer, irrigation water, labor, and machine inputs are required. To conserve the natural environment and ecosystems, the agricultural land area and application of agricultural chemicals need to be reduced. To conserve natural resources, such as fossil fuels, and ores, such as rock phosphate, potash ore, iron ore, and rare metals, the application of agricultural fertilizer and metals need to be reduced. To improve the sustainability of our society, the consumption of fossil fuels for air conditioning and the emission of gases that contribute to global warming in cities need to be reduced. The above characteristics will help reduce the disparities in terms of gender, age, and mental and physical disability.

Figure 3.

A flowchart showing the role of plant factories in cities, which includes the use of electricity generated by natural energy to improve the sustainability of cities by enhancing the resource recycling economy. ‘Two-directional solid line arrows in blue’ denote the flows of produce and waste between the two aspects. ‘Two-directional bold solid line arrows in grey color’ denote the flows of products other than produce between the two aspects. One-way solid white arrows denote the one-way flows of electric energy or products (aquatic, mushroom, and brewery).

Figure 3.

A flowchart showing the role of plant factories in cities, which includes the use of electricity generated by natural energy to improve the sustainability of cities by enhancing the resource recycling economy. ‘Two-directional solid line arrows in blue’ denote the flows of produce and waste between the two aspects. ‘Two-directional bold solid line arrows in grey color’ denote the flows of products other than produce between the two aspects. One-way solid white arrows denote the one-way flows of electric energy or products (aquatic, mushroom, and brewery).

Figure 4.

A flowchart showing the interactions among the environment (E

R), phenotype (P

P), management (M), and genotype (G

e) in the CR. Examples of the variable names for E

R, P

P, M, and G

e are given in

Table 1.

Figure 4.

A flowchart showing the interactions among the environment (E

R), phenotype (P

P), management (M), and genotype (G

e) in the CR. Examples of the variable names for E

R, P

P, M, and G

e are given in

Table 1.

Figure 5.

Resource use efficiency (RUE) of the CR containing a plant community is defined as B/A or (A–C)/A, ranging between 0 and 1. Namely, the ratio of the marketable plant production rate to the resource supply rate. The RUE is calculated for each resource input.

Figure 5.

Resource use efficiency (RUE) of the CR containing a plant community is defined as B/A or (A–C)/A, ranging between 0 and 1. Namely, the ratio of the marketable plant production rate to the resource supply rate. The RUE is calculated for each resource input.

Figure 6.

A diagram showing the interactions among PP, ER, M, and Ge in a highly sealed and insulated cultivation room (CR) in a plant factory.

Figure 6.

A diagram showing the interactions among PP, ER, M, and Ge in a highly sealed and insulated cultivation room (CR) in a plant factory.

Table 1.

Examples of variable names for environment (ER), management (M), plant phenotype (Pp), and genotype (Ge) in the CR.

Table 1.

Examples of variable names for environment (ER), management (M), plant phenotype (Pp), and genotype (Ge) in the CR.

| Symbol | Group Name | Example of Variable Name |

|---|

| ER | Environment within and around the community | Light: photosynthetically active photon flux density (PPFD), spectral distribution, irradiation direction. Air: water vapor pressure deficit (VPD), air velocity, CO2 concentration, temperature. Rhizosphere: pH, ion concentration, dissolved oxygen concentration, temperature. Microbes and algae: species and density |

| M | Management | Pre-seeding seed treatment (e.g., dormancy breaking), sowing, thinning, transplanting (or spacing), planting, pruning, and harvesting, whether performed manually or automated |

| Pp | Plant phenotype | Leaf canopy: leaf area, shape, angle of inclination, color, chemical composition and concentration, number and position, internode length, plant height, number and position of leaf buds, flower buds, and branches. Root systems: fresh root weight, dry weight percentage |

| Ge | Genotype | Genotype refers to a single gene or set of genes, such as the genotype for leaf color, which are either activated or inactivated |

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).