Sustainable and Low-Input Techniques in Mediterranean Greenhouse Vegetable Production

Abstract

1. Introduction

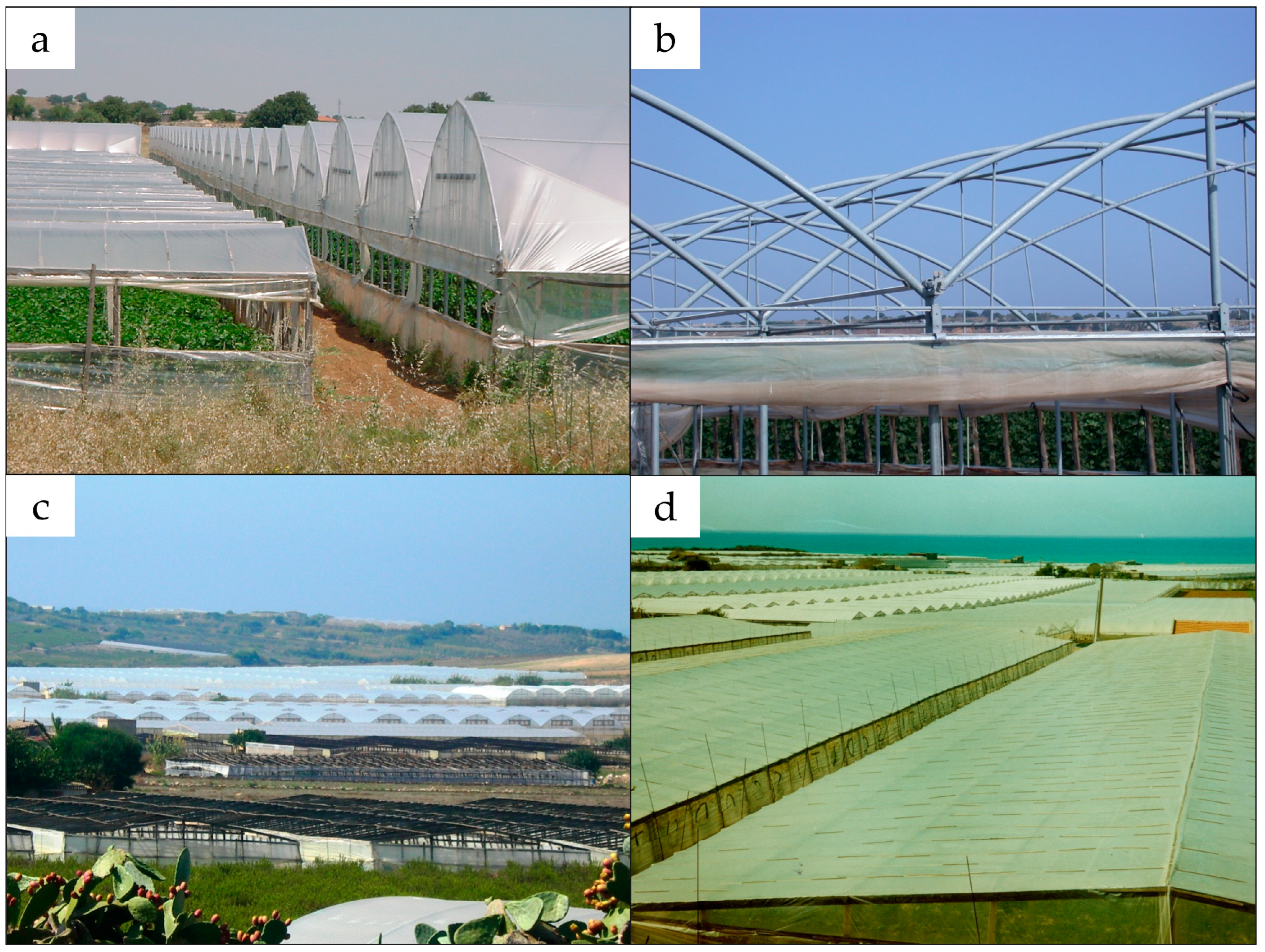

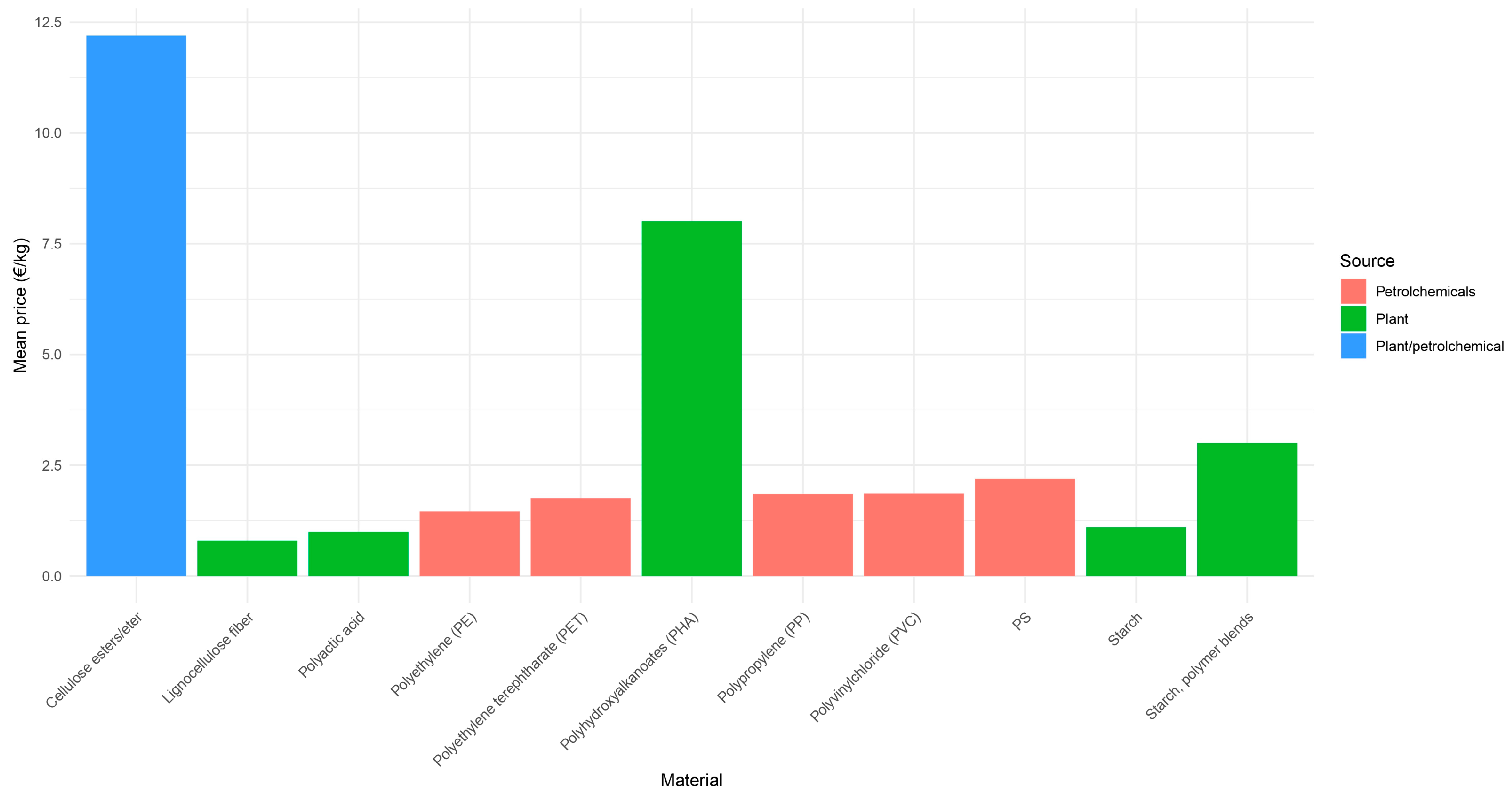

2. Different Set-Up of the Modern Greenhouses

3. Impact of “Conventional” Greenhouses in Modern Agriculture

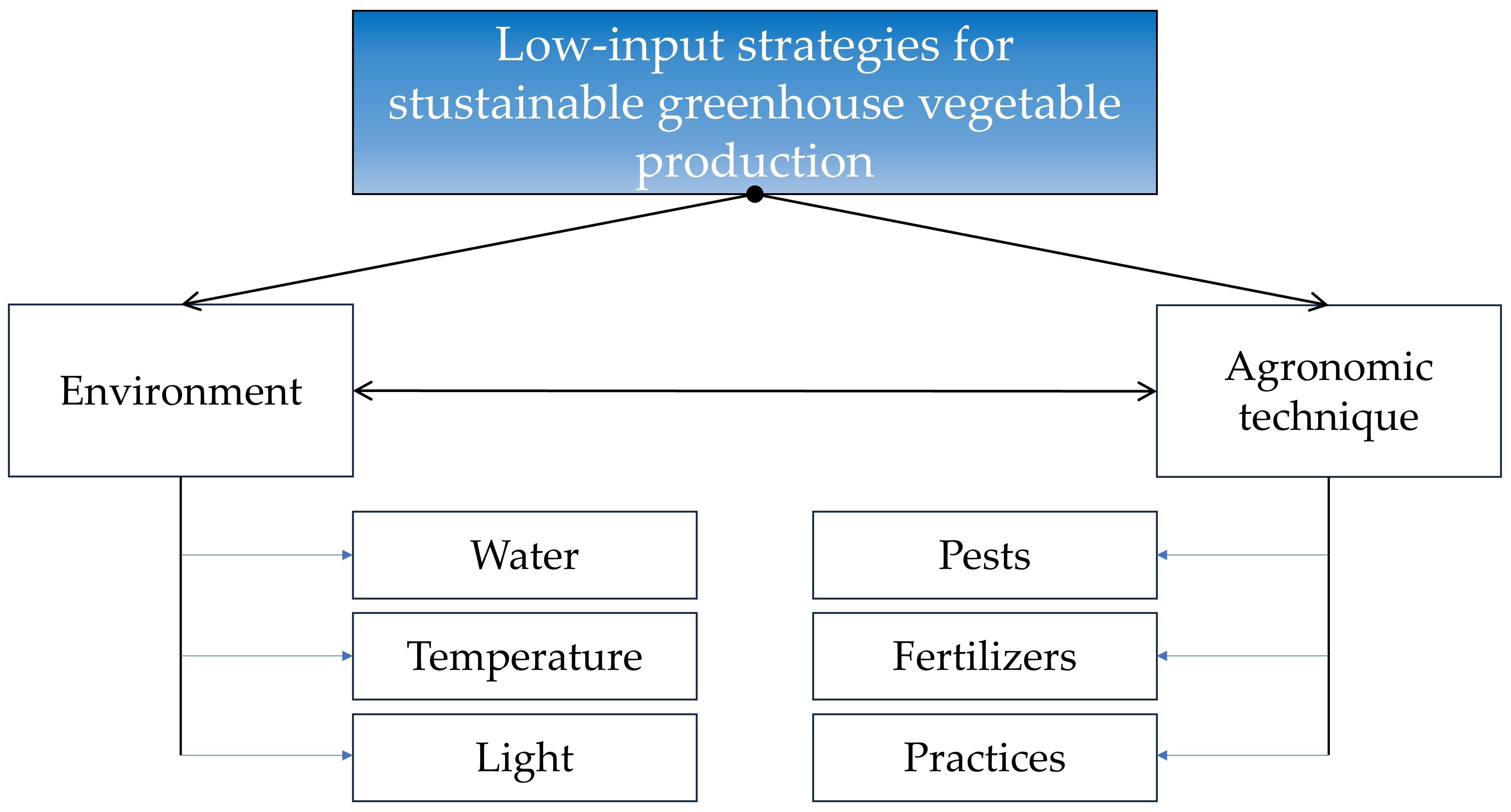

4. Optimizing the Greenhouse Environment Using Low-Input Strategies

4.1. Greenhouse Environment

4.2. Low-Input Strategies for Optimizing Water Management

4.3. Low-Input Strategies for Light Modulation

4.4. Low-Input Strategies for Controlling Temperature

5. Low-Input Agronomical Strategies

5.1. Low-Input Strategies for Controlling Pest and Diseases

5.2. Low-Input Strategies for Optimizing Fertilizations Practices

5.3. Low-Input Strategies for Optimizing Growing Technique

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cramer, W.; Guiot, J.; Fader, M.; Garrabou, J.; Gattuso, J.-P.; Iglesias, A.; Lange, M.A.; Lionello, P.; Llasat, M.C.; Paz, S.; et al. Climate Change and Interconnected Risks to Sustainable Development in the Mediterranean. Nat. Clim. Chang. 2018, 8, 972–980. [Google Scholar] [CrossRef]

- Gruda, N.; Bisbis, M.; Katsoulas, N.; Kittas, C. Smart Greenhouse Production Practices to Manage and Mitigate the Impact of Climate Change in Protected Cultivation. Acta Hortic. 2021, 1320, 189–196. [Google Scholar] [CrossRef]

- Gruda, N.; Bisbis, M.; Tanny, J. Influence of Climate Change on Protected Cultivation: Impacts and Sustainable Adaptation Strategies—A Review. J. Clean. Prod. 2019, 225, 481–495. [Google Scholar] [CrossRef]

- Deguine, J.-P.; Aubertot, J.-N.; Bellon, S.; Côte, F.; Lauri, P.-E.; Lescourret, F.; Ratnadass, A.; Scopel, E.; Andrieu, N.; Bàrberi, P.; et al. Agroecological Crop Protection for Sustainable Agriculture. Adv. Agron. 2023, 178, 1–59. [Google Scholar]

- Visvesvaran, C.; Kamalakannan, S.; Kumar, K.N.; Sundaram, K.M.; Vasan, S.M.S.S.; Jafrrin, S. Smart Greenhouse Monitoring System Using Wireless Sensor Networks. In Proceedings of the 2021 2nd International Conference on Smart Electronics and Communication (ICOSEC), 7–9 October 2021; IEEE: New York, NY, USA, 2021; pp. 96–101. [Google Scholar]

- Soheli, S.J.; Jahan, N.; Hossain, M.d.B.; Adhikary, A.; Khan, A.R.; Wahiduzzaman, M. Smart Greenhouse Monitoring System Using Internet of Things and Artificial Intelligence. Wirel. Pers. Commun. 2022, 124, 3603–3634. [Google Scholar] [CrossRef]

- Mandal, A.; Sarkar, B.; Mandal, S.; Vithanage, M.; Patra, A.K.; Manna, M.C. Impact of Agrochemicals on Soil Health. In Agrochemicals Detection, Treatment and Remediation; Elsevier: Amsterdam, The Netherlands, 2020; pp. 161–187. [Google Scholar]

- Mitra, B.; Chowdhury, A.R.; Dey, P.; Hazra, K.K.; Sinha, A.K.; Hossain, A.; Meena, R.S. Use of Agrochemicals in Agriculture: Alarming Issues and Solutions. In Input Use Efficiency for Food and Environmental Security; Springer Nature: Singapore, 2021; pp. 85–122. [Google Scholar]

- Zhang, M.; Yan, T.; Wang, W.; Jia, X.; Wang, J.; Klemeš, J.J. Energy-Saving Design and Control Strategy towards Modern Sustainable Greenhouse: A Review. Renew. Sustain. Energy Rev. 2022, 164, 112602. [Google Scholar] [CrossRef]

- Ahamed, M.S.; Guo, H.; Tanino, K. Energy Saving Techniques for Reducing the Heating Cost of Conventional Greenhouses. Biosyst. Eng. 2019, 178, 9–33. [Google Scholar] [CrossRef]

- Aznar-Sánchez, J.A.; Velasco-Muñoz, J.F.; López-Felices, B.; Román-Sánchez, I.M. An Analysis of Global Research Trends on Greenhouse Technology: Towards a Sustainable Agriculture. Int. J. Environ. Res. Public Health 2020, 17, 664. [Google Scholar] [CrossRef]

- Mizik, T. How Can Precision Farming Work on a Small Scale? A Systematic Literature Review. Precis. Agric. 2023, 24, 384–406. [Google Scholar] [CrossRef]

- Raj, R.; Kumar, S.; Lal, S.P.; Singh, H.; Pradhan, J.; Bhardwaj, Y. A Brief Overview of Technologies in Automated Agriculture: Shaping the Farms of Tomorrow. Int. J. Environ. Clim. Chang. 2024, 14, 181–209. [Google Scholar] [CrossRef]

- Evangelista, A.; Lan, Y.-C.; Chen, Z.; Tam, V.W.Y.; Datt, R. Adopting Life Cycle Assessment for Various Greenhouse Typologies in Multiple Cropping Environment in Australia. In EcoDesign and Sustainability II: Social Perspectives and Sustainability Assessment; Springer: Berlin/Heidelberg, Germany, 2021; pp. 347–360. [Google Scholar]

- Zhang, H.; Burr, J.; Zhao, F. A Comparative Life Cycle Assessment (LCA) of Lighting Technologies for Greenhouse Crop Production. J. Clean. Prod. 2017, 140, 705–713. [Google Scholar] [CrossRef]

- Kavga, A.; Souliotis, M.; Koumoulos, E.P.; Fokaides, P.A.; Charitidis, C.A. Environmental and Nanomechanical Testing of an Alternative Polymer Nanocomposite Greenhouse Covering Material. Sol. Energy 2018, 159, 1–9. [Google Scholar] [CrossRef]

- Sarkar, D.; Kar, S.K.; Chattopadhyay, A.; Shikha; Rakshit, A.; Tripathi, V.K.; Dubey, P.K.; Abhilash, P.C. Low Input Sustainable Agriculture: A Viable Climate-Smart Option for Boosting Food Production in a Warming World. Ecol. Indic. 2020, 115, 106412. [Google Scholar] [CrossRef]

- Jana, R.K.; Ghosh, I. Time-Varying Relationship between Geopolitical Uncertainty and Agricultural Investment. Financ. Res. Lett. 2023, 52, 103521. [Google Scholar] [CrossRef]

- Ponce, P.; Molina, A.; Cepeda, P.; Lugo, E.; MacCleery, B. Greenhouse Design and Control; CRC Press: Boca Raton, FL, USA, 2014; ISBN 9780429227325. [Google Scholar]

- Achour, Y.; Ouammi, A.; Zejli, D. Technological Progresses in Modern Sustainable Greenhouses Cultivation as the Path towards Precision Agriculture. Renew. Sustain. Energy Rev. 2021, 147, 111251. [Google Scholar] [CrossRef]

- Teitel, M.; Montero, J.I.; Baeza, E.J. Greenhouse Design: Concepts and Trends. Acta Hortic. 2012, 952, 605–620. [Google Scholar] [CrossRef]

- Ouazzani Chahidi, L.; Mechaqrane, A. Energy and Economic Analysis for the Selection of Optimal Greenhouse Design: A Case Study of the Six Morocco’s Climatic Zones. Energy Build. 2023, 289, 113060. [Google Scholar] [CrossRef]

- Akrami, M.; Salah, A.H.; Javadi, A.A.; Fath, H.E.S.; Hassanein, M.J.; Farmani, R.; Dibaj, M.; Negm, A. Towards a Sustainable Greenhouse: Review of Trends and Emerging Practices in Analysing Greenhouse Ventilation Requirements to Sustain Maximum Agricultural Yield. Sustainability 2020, 12, 2794. [Google Scholar] [CrossRef]

- Teitel, M.; Vitoshkin, H.; Geoola, F.; Karlsson, S.; Stahl, N. Greenhouse and Screenhouse Cover Materials: Literature Review and Industry Perspective. Acta Hortic. 2018, 1227, 31–44. [Google Scholar] [CrossRef]

- Abdel-Ghany, A.M.; Al-Helal, I.M.; Alzahrani, S.M.; Alsadon, A.A.; Ali, I.M.; Elleithy, R.M. Covering Materials Incorporating Radiation-Preventing Techniques to Meet Greenhouse Cooling Challenges in Arid Regions: A Review. Sci. World J. 2012, 2012, 906360. [Google Scholar] [CrossRef]

- Jadhav, H.; Rosentrater, K.A. Economic and Environmental Analysis of Greenhouse Crop Production with Special Reference to Low Cost Greenhouses: A Review. In Proceedings of the 2017 Spokane, Washington, DC, USA, 16–19 July 2017; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2017. [Google Scholar]

- Maraveas, C. Environmental Sustainability of Greenhouse Covering Materials. Sustainability 2019, 11, 6129. [Google Scholar] [CrossRef]

- Robles Algarín, C.; Callejas Cabarcas, J.; Polo Llanos, A. Low-Cost Fuzzy Logic Control for Greenhouse Environments with Web Monitoring. Electronics 2017, 6, 71. [Google Scholar] [CrossRef]

- Pisanu, T.; Garau, S.; Ortu, P.; Schirru, L.; Macciò, C. Prototype of a Low-Cost Electronic Platform for Real Time Greenhouse Environment Monitoring: An Agriculture 4.0 Perspective. Electronics 2020, 9, 726. [Google Scholar] [CrossRef]

- Castilla, N.; Montero, J.I. Environmental Control and Crop Production in Mediterranean Greenhouses. Acta Hortic. 2008, 797, 25–36. [Google Scholar] [CrossRef]

- Zhang, Y.; Henke, M.; Li, Y.; Xu, D.; Liu, A.; Liu, X.; Li, T. Towards the Maximization of Energy Performance of an Energy-Saving Chinese Solar Greenhouse: A Systematic Analysis of Common Greenhouse Shapes. Sol. Energy 2022, 236, 320–334. [Google Scholar] [CrossRef]

- Fernández, M.D.; González, A.M.; Carreño, J.; Pérez, C.; Bonachela, S. Analysis of On-Farm Irrigation Performance in Mediterranean Greenhouses. Agric. Water Manag. 2007, 89, 251–260. [Google Scholar] [CrossRef]

- Wang, T.; Wu, G.; Chen, J.; Cui, P.; Chen, Z.; Yan, Y.; Zhang, Y.; Li, M.; Niu, D.; Li, B.; et al. Integration of Solar Technology to Modern Greenhouse in China: Current Status, Challenges and Prospect. Renew. Sustain. Energy Rev. 2017, 70, 1178–1188. [Google Scholar] [CrossRef]

- Xu, D.; Du, S.; van Willigenburg, L.G. Optimal Control of Chinese Solar Greenhouse Cultivation. Biosyst. Eng. 2018, 171, 205–219. [Google Scholar] [CrossRef]

- Cao, K.; Xu, H.; Zhang, R.; Xu, D.; Yan, L.; Sun, Y.; Xia, L.; Zhao, J.; Zou, Z.; Bao, E. Renewable and Sustainable Strategies for Improving the Thermal Environment of Chinese Solar Greenhouses. Energy Build. 2019, 202, 109414. [Google Scholar] [CrossRef]

- Paris, B.; Vandorou, F.; Balafoutis, A.T.; Vaiopoulos, K.; Kyriakarakos, G.; Manolakos, D.; Papadakis, G. Energy Use in Greenhouses in the EU: A Review Recommending Energy Efficiency Measures and Renewable Energy Sources Adoption. Appl. Sci. 2022, 12, 5150. [Google Scholar] [CrossRef]

- Salehpour, T.; Khanali, M.; Rajabipour, A. Environmental Impact Assessment for Ornamental Plant Greenhouse: Life Cycle Assessment Approach for Primrose Production. Environ. Pollut. 2020, 266, 115258. [Google Scholar] [CrossRef] [PubMed]

- Zarei, M.J.; Kazemi, N.; Marzban, A. Life Cycle Environmental Impacts of Cucumber and Tomato Production in Open-Field and Greenhouse. J. Saudi Soc. Agric. Sci. 2019, 18, 249–255. [Google Scholar] [CrossRef]

- Ciaccia, C.; Ceglie, F.G.; Burgio, G.; Madžarić, S.; Testani, E.; Muzzi, E.; Mimiola, G.; Tittarelli, F. Impact of Agroecological Practices on Greenhouse Vegetable Production: Comparison among Organic Production Systems. Agronomy 2019, 9, 372. [Google Scholar] [CrossRef]

- Fernández, E.F.; Villar-Fernández, A.; Montes-Romero, J.; Ruiz-Torres, L.; Rodrigo, P.M.; Manzaneda, A.J.; Almonacid, F. Global Energy Assessment of the Potential of Photovoltaics for Greenhouse Farming. Appl. Energy 2022, 309, 118474. [Google Scholar] [CrossRef]

- Bersani, C.; Ouammi, A.; Sacile, R.; Zero, E. Model Predictive Control of Smart Greenhouses as the Path towards Near Zero Energy Consumption. Energies 2020, 13, 3647. [Google Scholar] [CrossRef]

- Debroy, P.; Majumder, P.; Das, A.; Seban, L. Model-Based Predictive Greenhouse Parameter Control of Aquaponic System. Environ. Sci. Pollut. Res. 2024, 31, 48423–48449. [Google Scholar] [CrossRef]

- Danner, R.I.; Mankasingh, U.; Anamthawat-Jonsson, K.; Thorarinsdottir, R.I. Designing Aquaponic Production Systems towards Integration into Greenhouse Farming. Water 2019, 11, 2123. [Google Scholar] [CrossRef]

- Grewal, H.S.; Maheshwari, B.; Parks, S.E. Water and Nutrient Use Efficiency of a Low-Cost Hydroponic Greenhouse for a Cucumber Crop: An Australian Case Study. Agric. Water Manag. 2011, 98, 841–846. [Google Scholar] [CrossRef]

- Khan, F.A. A Review on Hydroponic Greenhouse Cultivation for Sustainable Agriculture. Int. J. Agric. Environ. Food Sci. 2018, 2, 59–66. [Google Scholar] [CrossRef]

- Kalantari, F.; Tahir, O.M.; Joni, R.A.; Fatemi, E. Opportunities and Challenges in Sustainability of Vertical Farming: A Review. J. Landsc. Ecol. 2018, 11, 35–60. [Google Scholar] [CrossRef]

- Vatistas, C.; Avgoustaki, D.D.; Bartzanas, T. A Systematic Literature Review on Controlled-Environment Agriculture: How Vertical Farms and Greenhouses Can Influence the Sustainability and Footprint of Urban Microclimate with Local Food Production. Atmosphere 2022, 13, 1258. [Google Scholar] [CrossRef]

- Voutsinos, O.; Mastoraki, M.; Ntatsi, G.; Liakopoulos, G.; Savvas, D. Comparative Assessment of Hydroponic Lettuce Production Either under Artificial Lighting, or in a Mediterranean Greenhouse during Wintertime. Agriculture 2021, 11, 503. [Google Scholar] [CrossRef]

- Jin, W.; Formiga Lopez, D.; Heuvelink, E.; Marcelis, L.F.M. Light Use Efficiency of Lettuce Cultivation in Vertical Farms Compared with Greenhouse and Field. Food Energy Secur. 2023, 12, e391. [Google Scholar] [CrossRef]

- Masabni, J.; Niu, G. Aquaponics. In Plant Factory Basics, Applications and Advances; Elsevier: Amsterdam, The Netherlands, 2022; pp. 167–180. [Google Scholar]

- Lam, W.Y.; Sim, S.; Kulak, M.; van Zelm, R.; Schipper, A.M.; Huijbregts, M.A.J. Drivers of Variability in Greenhouse Gas Footprints of Crop Production. J. Clean. Prod. 2021, 315, 128121. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Rafiee, S.; Omid, M.; Mousazadeh, H.; Clark, S. Environmental Impact Assessment of Tomato and Cucumber Cultivation in Greenhouses Using Life Cycle Assessment and Adaptive Neuro-Fuzzy Inference System. J. Clean. Prod. 2014, 73, 183–192. [Google Scholar] [CrossRef]

- Liao, J.; Liang, Y.; Huang, D. Organic Farming Improves Soil Microbial Abundance and Diversity under Greenhouse Condition: A Case Study in Shanghai (Eastern China). Sustainability 2018, 10, 3825. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Zheng, C.; Cao, Z. Effects of Organic, Low Input, Conventional Management Practices on Soil Nematode Community under Greenhouse Conditions. Acta Agric. Scand. B Soil. Plant Sci. 2014, 64, 360–371. [Google Scholar] [CrossRef]

- Shamshiri, R.R.; Kalantari, F.; Ting, K.C.; Thorp, K.R.; Hameed, I.A.; Weltzien, C.; Ahmad, D.; Shad, Z.M. Advances in Greenhouse Automation and Controlled Environment Agriculture: A Transition to Plant Factories and Urban Agriculture. Int. J. Agric. Biol. Eng. 2018, 11, 1–22. [Google Scholar] [CrossRef]

- De Pascale, S.; Maggio, A. Sustainable Protected Cultivation at a Mediterranean Climate. Perspectives and Challenges. Acta Hortic. 2005, 691, 29–42. [Google Scholar] [CrossRef]

- Ouazzani Chahidi, L.; Fossa, M.; Priarone, A.; Mechaqrane, A. Energy Saving Strategies in Sustainable Greenhouse Cultivation in the Mediterranean Climate—A Case Study. Appl. Energy 2021, 282, 116156. [Google Scholar] [CrossRef]

- Panwar, N.L.; Kaushik, S.C.; Kothari, S. Solar Greenhouse an Option for Renewable and Sustainable Farming. Renew. Sustain. Energy Rev. 2011, 15, 3934–3945. [Google Scholar] [CrossRef]

- Tripanagnostopoulos, Y.; Katsoulas, N.; Kittas, C. Potential Energy Cost and Footprint Reduction in Mediterranean Greenhouses by Means of Renewable Energy Use. Acta Hortic. 2017, 1164, 461–466. [Google Scholar] [CrossRef]

- Montero, J.I.; Stanghellini, C.; Castilla, N. Greenhouse Technology For Sustainable Production in Mild Winter Climate Areas: Trends and Needs. Acta Hortic. 2009, 807, 33–44. [Google Scholar] [CrossRef]

- De Pascale, S.; Stanghellini, C. High Temperature Control in Mediterranean Greenhouse Production: The Constraints and the Options. Acta Hortic. 2011, 893, 103–116. [Google Scholar] [CrossRef]

- Al-Hamamre, Z.; Saidan, M.; Hararah, M.; Rawajfeh, K.; Alkhasawneh, H.E.; Al-Shannag, M. Wastes and Biomass Materials as Sustainable-Renewable Energy Resources for Jordan. Renew. Sustain. Energy Rev. 2017, 67, 295–314. [Google Scholar] [CrossRef]

- Taki, M.; Rohani, A.; Rahmati-Joneidabad, M. Solar Thermal Simulation and Applications in Greenhouse. Inf. Process. Agric. 2018, 5, 83–113. [Google Scholar] [CrossRef]

- Prieto, J.; Ajnannadhif, R.M.; Fernández-del Olmo, P.; Coronas, A. Integration of a Heating and Cooling System Driven by Solar Thermal Energy and Biomass for a Greenhouse in Mediterranean Climates. Appl. Therm. Eng. 2023, 221, 119928. [Google Scholar] [CrossRef]

- Lorenzo, P.; Reyes, R.; Medrano, E.; Granados, R.; Bonachela, S.; Hernández, J.; López, J.C.; Magán, J.J.; del Amor, F.M.; Sánchez-Guerrero, M.C. Hybrid Passive Cooling and Heating System for Mediterranean Greenhouses. Microclimate and Sweet Pepper Crop Response. Agric. Water Manag. 2024, 301, 108937. [Google Scholar] [CrossRef]

- Kumar, M.; Haillot, D.; Gibout, S. Survey and Evaluation of Solar Technologies for Agricultural Greenhouse Application. Sol. Energy 2022, 232, 18–34. [Google Scholar] [CrossRef]

- Lycoskoufis, I.; Lambrinos, G.; Mavrogianopoulos, G. Greenhouse Dehumidification by an Air-Air Heat Pump under Mediterranean Conditions. Acta Hortic. 2020, 1296, 193–202. [Google Scholar] [CrossRef]

- López-Martínez, A.; Molina-Aiz, F.; Moreno-Teruel, M.; Peña-Fernández, A.; Baptista, F.; Valera-Martínez, D. Low Tunnels inside Mediterranean Greenhouses: Effects on Air/Soil Temperature and Humidity. Agronomy 2021, 11, 1973. [Google Scholar] [CrossRef]

- Espinoza, K.; López, A.; Valera, D.L.; Molina-Aiz, F.D.; Torres, J.A.; Peña, A. Effects of Ventilator Configuration on the Flow Pattern of a Naturally-Ventilated Three-Span Mediterranean Greenhouse. Biosyst. Eng. 2017, 164, 13–30. [Google Scholar] [CrossRef]

- Santolini, E.; Pulvirenti, B.; Benni, S.; Barbaresi, L.; Torreggiani, D.; Tassinari, P. Numerical Study of Wind-Driven Natural Ventilation in a Greenhouse with Screens. Comput. Electron. Agric. 2018, 149, 41–53. [Google Scholar] [CrossRef]

- He, X.; Maier, C.; Chavan, S.G.; Zhao, C.-C.; Alagoz, Y.; Cazzonelli, C.; Ghannoum, O.; Tissue, D.T.; Chen, Z.-H. Light-Altering Cover Materials and Sustainable Greenhouse Production of Vegetables: A Review. Plant Growth Regul. 2021, 95, 1–17. [Google Scholar] [CrossRef]

- Baxevanou, C.; Fidaros, D.; Bartzanas, T.; Kittas, C. Yearly Numerical Evaluation of Greenhouse Cover Materials. Comput. Electron. Agric. 2018, 149, 54–70. [Google Scholar] [CrossRef]

- Tanny, J. Microclimate and Evapotranspiration of Crops Covered by Agricultural Screens: A Review. Biosyst. Eng. 2013, 114, 26–43. [Google Scholar] [CrossRef]

- Nikolaou, G.; Neocleous, D.; Kitta, E.; Katsoulas, N. Estimation of Aerodynamic and Canopy Resistances in a Mediterranean Greenhouse Based on Instantaneous Leaf Temperature Measurements. Agronomy 2020, 10, 1985. [Google Scholar] [CrossRef]

- Bárcena, A.; Graciano, C.; Luca, T.; Guiamet, J.J.; Costa, L. Shade Cloths and Polyethylene Covers Have Opposite Effects on Tipburn Development in Greenhouse Grown Lettuce. Sci. Hortic. 2019, 249, 93–99. [Google Scholar] [CrossRef]

- Knox, J.W.; Kay, M.G.; Weatherhead, E.K. Water Regulation, Crop Production, and Agricultural Water Management—Understanding Farmer Perspectives on Irrigation Efficiency. Agric. Water Manag. 2012, 108, 3–8. [Google Scholar] [CrossRef]

- García-Caparrós, P.; Llanderal, A.; El-Tarawy, A.; Maksimovic, I.; Lao, M. Crop and Irrigation Management Systems under Greenhouse Conditions. Water 2018, 10, 62. [Google Scholar] [CrossRef]

- Incrocci, L.; Thompson, R.B.; Fernandez-Fernandez, M.D.; De Pascale, S.; Pardossi, A.; Stanghellini, C.; Rouphael, Y.; Gallardo, M. Irrigation Management of European Greenhouse Vegetable Crops. Agric. Water Manag. 2020, 242, 106393. [Google Scholar] [CrossRef]

- Pathak, H.; Saharawat, Y.S.; Gathala, M.; Ladha, J.K. Impact of Resource-conserving Technologies on Productivity and Greenhouse Gas Emissions in the Rice-Wheat System. Greenh. Gases Sci. Technol. 2011, 1, 261–277. [Google Scholar] [CrossRef]

- Busari, O.; Mutamba, J. Fueling Water-Intensive Economic Growth: What Hope for Water Conservation? J. Geosci. Environ. Prot. 2015, 3, 83–90. [Google Scholar] [CrossRef]

- Fields, J.S.; Fonteno, W.C.; Jackson, B.E. Plant Available and Unavailable Water in Greenhouse Substrates: Assessment and Considerations. Acta Hortic. 2014, 1034, 341–346. [Google Scholar] [CrossRef]

- Canaj, K.; Parente, A.; D’Imperio, M.; Boari, F.; Buono, V.; Toriello, M.; Mehmeti, A.; Montesano, F.F. Can Precise Irrigation Support the Sustainability of Protected Cultivation? A Life-Cycle Assessment and Life-Cycle Cost Analysis. Water 2021, 14, 6. [Google Scholar] [CrossRef]

- Gava, O.; Antón, A.; Carmassi, G.; Pardossi, A.; Incrocci, L.; Bartolini, F. Reusing Drainage Water and Substrate to Improve the Environmental and Economic Performance of Mediterranean Greenhouse Cropping. J. Clean. Prod. 2023, 413, 137510. [Google Scholar] [CrossRef]

- Cardoso, J.; Gloria, A.; Sebastiao, P. Improve Irrigation Timing Decision for Agriculture Using Real Time Data and Machine Learning. In Proceedings of the 2020 International Conference on Data Analytics for Business and Industry: Way towards a Sustainable Economy (ICDABI), Sakheer, Bahrain, 26–27 October 2020; IEEE: New York, NY, USA, 2020; pp. 1–5. [Google Scholar]

- Payero, J.O.; Tarkalson, D.D.; Irmak, S.; Davison, D.; Petersen, J.L. Effect of Timing of a Deficit-Irrigation Allocation on Corn Evapotranspiration, Yield, Water Use Efficiency and Dry Mass. Agric. Water Manag. 2009, 96, 1387–1397. [Google Scholar] [CrossRef]

- Liu, H.; Li, H.; Ning, H.; Zhang, X.; Li, S.; Pang, J.; Wang, G.; Sun, J. Optimizing Irrigation Frequency and Amount to Balance Yield, Fruit Quality and Water Use Efficiency of Greenhouse Tomato. Agric. Water Manag. 2019, 226, 105787. [Google Scholar] [CrossRef]

- Bonachela, S.; Fernández, M.D.; Cabrera-Corral, F.J.; Granados, M.R. Salt and Irrigation Management of Soil-Grown Mediterranean Greenhouse Tomato Crops Drip-Irrigated with Moderately Saline Water. Agric. Water Manag. 2022, 262, 107433. [Google Scholar] [CrossRef]

- Fader, M.; Shi, S.; von Bloh, W.; Bondeau, A.; Cramer, W. Mediterranean Irrigation under Climate Change: More Efficient Irrigation Needed to Compensate for Increases in Irrigation Water Requirements. Hydrol. Earth Syst. Sci. 2016, 20, 953–973. [Google Scholar] [CrossRef]

- Di Nunno, F.; Granata, F. Spatio-Temporal Analysis of Drought in Southern Italy: A Combined Clustering-Forecasting Approach Based on SPEI Index and Artificial Intelligence Algorithms. Stoch. Environ. Res. Risk Assess. 2023, 37, 2349–2375. [Google Scholar] [CrossRef]

- Peres, D.J.; Bonaccorso, B.; Palazzolo, N.; Cancelliere, A.; Mendicino, G.; Senatore, A. A Dynamic Approach for Assessing Climate Change Impacts on Drought: An Analysis in Southern Italy. Hydrol. Sci. J. 2023, 68, 1213–1228. [Google Scholar] [CrossRef]

- Nikolaou, G.; Neocleous, D.; Christou, A.; Polycarpou, P.; Kitta, E.; Katsoulas, N. Energy and Water Related Parameters in Tomato and Cucumber Greenhouse Crops in Semiarid Mediterranean Regions. A Review, Part II: Irrigation and Fertigation. Horticulturae 2021, 7, 548. [Google Scholar] [CrossRef]

- Moreno-Teruel, M.d.l.Á.; Molina-Aiz, F.D.; Peña-Fernández, A.; López-Martínez, A.; Valera-Martínez, D.L. The Effect of Diffuse Film Covers on Microclimate and Growth and Production of Tomato (Solanum lycopersicum, L.) in a Mediterranean Greenhouse. Agronomy 2021, 11, 860. [Google Scholar] [CrossRef]

- Colantoni, A.; Monarca, D.; Marucci, A.; Cecchini, M.; Zambon, I.; Di Battista, F.; Maccario, D.; Saporito, M.; Beruto, M. Solar Radiation Distribution inside a Greenhouse Prototypal with Photovoltaic Mobile Plant and Effects on Flower Growth. Sustainability 2018, 10, 855. [Google Scholar] [CrossRef]

- Bonachela, S.; López, J.C.; Hernández, J.; Granados, M.R.; Magán, J.J.; Cabrera-Corral, F.J.; Bonachela-Guhmann, P.; Baille, A. How Mulching and Canopy Architecture Interact in Trapping Solar Radiation inside a Mediterranean Greenhouse. Agric. For. Meteorol. 2020, 294, 108132. [Google Scholar] [CrossRef]

- Cuce, E.; Harjunowibowo, D.; Cuce, P.M. Renewable and Sustainable Energy Saving Strategies for Greenhouse Systems: A Comprehensive Review. Renew. Sustain. Energy Rev. 2016, 64, 34–59. [Google Scholar] [CrossRef]

- Marucci, A.; Gusman, A.; Pagniello, B.; Cappuccini, A. Limits and Prospects of Photovoltaic Covers in Mediterranean Greenhouses. J. Agric. Eng. 2013, 44, e1. [Google Scholar] [CrossRef]

- Marucci, A.; Monarca, D.; Cecchini, M.; Colantoni, A.; Manzo, A.; Cappuccini, A. The Semitransparent Photovoltaic Films for Mediterranean Greenhouse: A New Sustainable Technology. Math. Probl. Eng. 2012, 2012, 451934. [Google Scholar] [CrossRef]

- Kavehrad, M. Sustainable Energy-Efficient Wireless Applications Using Light. IEEE Commun. Mag. 2010, 48, 66–73. [Google Scholar] [CrossRef]

- Graamans, L.; Baeza, E.; van den Dobbelsteen, A.; Tsafaras, I.; Stanghellini, C. Plant Factories versus Greenhouses: Comparison of Resource Use Efficiency. Agric. Syst. 2018, 160, 31–43. [Google Scholar] [CrossRef]

- Branca, F.; Treccarichi, S.; Ruberto, G.; Renda, A.; Argento, S. Comprehensive Morphometric and Biochemical Characterization of Seven Basil (Ocimum basilicum, L.) Genotypes: Focus on Light Use Efficiency. Agronomy 2024, 14, 224. [Google Scholar] [CrossRef]

- Xue, W.; Lindner, S.; Nay-Htoon, B.; Dubbert, M.; Otieno, D.; Ko, J.; Muraoka, H.; Werner, C.; Tenhunen, J.; Harley, P. Nutritional and Developmental Influences on Components of Rice Crop Light Use Efficiency. Agric. For. Meteorol. 2016, 223, 1–16. [Google Scholar] [CrossRef]

- Muneer, S.; Kim, J.H.; Park, J.G.; Shin, M.H.; Cha, G.H.; Kim, H.L.; Ban, T.; Kumarihami, H.M.P.C.; Kim, S.H.; Jeong, G.; et al. Reflective Plastic Film Mulches Enhance Light Intensity, Floral Induction, and Bioactive Compounds in ‘O’Neal’ Southern Highbush Blueberry. Sci. Hortic. 2019, 246, 448–452. [Google Scholar] [CrossRef]

- Slattery, R.A.; Ort, D.R. Perspectives on Improving Light Distribution and Light Use Efficiency in Crop Canopies. Plant Physiol. 2021, 185, 34–48. [Google Scholar] [CrossRef]

- Arena, D.; Ben Ammar, H.; Major, N.; Kovačević, T.K.; Goreta Ban, S.; Treccarichi, S.; Lo Scalzo, R.; Branca, F. Light Use Efficiency of Broccoli (Brassica oleracea var. italica Plenck) and Rocket (Eruca sativa L.) during the Initial Plant Growth Stages. Sci. Hortic. 2024, 336, 113408. [Google Scholar] [CrossRef]

- Abdel-Ghany, A.M.; Al-Helal, I.M. Solar Energy Utilization by a Greenhouse: General Relations. Renew. Energy 2011, 36, 189–196. [Google Scholar] [CrossRef]

- Timmermans, G.H.; Hemming, S.; Baeza, E.; van Thoor, E.A.J.; Schenning, A.P.H.J.; Debije, M.G. Advanced Optical Materials for Sunlight Control in Greenhouses. Adv. Opt. Mater. 2020, 8, 2000738. [Google Scholar] [CrossRef]

- Mosharafian, S.; Afzali, S.; Weaver, G.M.; van Iersel, M.; Mohammadpour Velni, J. Optimal Lighting Control in Greenhouse by Incorporating Sunlight Prediction. Comput. Electron. Agric. 2021, 188, 106300. [Google Scholar] [CrossRef]

- Lopez-Marin, J.; Rodriguez, M.; Del Amor, F.M.; Galvez, A.; Brotons-Martinez, J.M. Cost-Benefit Analysis of Tomato Crops under Different Greenhouse Covers. J. Agric. Sci. Technol. 2019, 21, 235–248. [Google Scholar]

- Palmitessa, O.D.; Paciello, P.; Santamaria, P. Supplemental LED Increases Tomato Yield in Mediterranean Semi-Closed Greenhouse. Agronomy 2020, 10, 1353. [Google Scholar] [CrossRef]

- Palmitessa, O.D.; Leoni, B.; Montesano, F.F.; Serio, F.; Signore, A.; Santamaria, P. Supplemental Lighting with LED for Efficient Year-Round Production of Soilless Tomato in a Mediterranean Greenhouse. Acta Hortic. 2021, 367–374. [Google Scholar] [CrossRef]

- Paucek, I.; Pennisi, G.; Pistillo, A.; Appolloni, E.; Crepaldi, A.; Calegari, B.; Spinelli, F.; Cellini, A.; Gabarrell, X.; Orsini, F.; et al. Supplementary LED Interlighting Improves Yield and Precocity of Greenhouse Tomatoes in the Mediterranean. Agronomy 2020, 10, 1002. [Google Scholar] [CrossRef]

- Nelson, J.A.; Bugbee, B. Economic Analysis of Greenhouse Lighting: Light Emitting Diodes vs. High Intensity Discharge Fixtures. PLoS ONE 2014, 9, e99010. [Google Scholar] [CrossRef] [PubMed]

- Ghoulem, M.; El Moueddeb, K.; Nehdi, E.; Boukhanouf, R.; Kaiser Calautit, J. Greenhouse Design and Cooling Technologies for Sustainable Food Cultivation in Hot Climates: Review of Current Practice and Future Status. Biosyst. Eng. 2019, 183, 121–150. [Google Scholar] [CrossRef]

- Ghani, S.; Bakochristou, F.; ElBialy, E.M.A.A.; Gamaledin, S.M.A.; Rashwan, M.M.; Abdelhalim, A.M.; Ismail, S.M. Design Challenges of Agricultural Greenhouses in Hot and Arid Environments—A Review. Eng. Agric. Environ. Food 2019, 12, 48–70. [Google Scholar] [CrossRef]

- Yan, S.; Fazilati, M.A.; Toghraie, D.; Khalili, M.; Karimipour, A. Energy Cost and Efficiency Analysis of Greenhouse Heating System Enhancement Using Phase Change Material: An Experimental Study. Renew. Energy 2021, 170, 133–140. [Google Scholar] [CrossRef]

- Chen, J.; Xu, F.; Tan, D.; Shen, Z.; Zhang, L.; Ai, Q. A Control Method for Agricultural Greenhouses Heating Based on Computational Fluid Dynamics and Energy Prediction Model. Appl. Energy 2015, 141, 106–118. [Google Scholar] [CrossRef]

- González-Briones, A.; Chamoso, P.; Yoe, H.; Corchado, J. GreenVMAS: Virtual Organization Based Platform for Heating Greenhouses Using Waste Energy from Power Plants. Sensors 2018, 18, 861. [Google Scholar] [CrossRef]

- Fatnassi, H.; Boulard, T.; Poncet, C.; Katsoulas, N.; Bartzanas, T.; Kacira, M.; Giday, H.; Lee, I.-B. Computational Fluid Dynamics Modelling of the Microclimate within the Boundary Layer of Leaves Leading to Improved Pest Control Management and Low-Input Greenhouse. Sustainability 2021, 13, 8310. [Google Scholar] [CrossRef]

- Mostefaoui, Z.; Amara, S. Renewable Energy Analysis in the Agriculture–Greenhouse Farms: A Case Study in the Mediterranean Region (Sidi Bel Abbes, Algeria). Environ. Prog. Sustain. Energy 2019, 38, e13029. [Google Scholar] [CrossRef]

- Cossu, M.; Cossu, A.; Deligios, P.A.; Ledda, L.; Li, Z.; Fatnassi, H.; Poncet, C.; Yano, A. Assessment and Comparison of the Solar Radiation Distribution inside the Main Commercial Photovoltaic Greenhouse Types in Europe. Renew. Sustain. Energy Rev. 2018, 94, 822–834. [Google Scholar] [CrossRef]

- García, M.L.; Medrano, E.; Sánchez-Guerrero, M.C.; Lorenzo, P. Climatic Effects of Two Cooling Systems in Greenhouses in the Mediterranean Area: External Mobile Shading and Fog System. Biosyst. Eng. 2011, 108, 133–143. [Google Scholar] [CrossRef]

- Badji, A.; Benseddik, A.; Bensaha, H.; Boukhelifa, A.; Hasrane, I. Design, Technology, and Management of Greenhouse: A Review. J. Clean. Prod. 2022, 373, 133753. [Google Scholar] [CrossRef]

- Katsoulas, N.; Kittas, C.; Bartzanas, T. Microclimate Distribution in a Greenhouse Cooled by a Fog System. Acta Hortic. 2012, 927, 773–778. [Google Scholar] [CrossRef]

- Nachidi, M.; Rodríguez, F.; Tadeo, F.; Guzman, J.L. Takagi–Sugeno Control of Nocturnal Temperature in Greenhouses Using Air Heating. ISA Trans. 2011, 50, 315–320. [Google Scholar] [CrossRef]

- Ayhan, B.; Huseyin Ozturk, H.; Kucukerdem, H.K. A Research on Greenhouse Heating with Solar Energy Using Vacuum Tubular Collectors and Nanofluid. Sci. Papers. Ser. B. Hortic. 2021, 65, 225–230. [Google Scholar]

- Kurpaska, S.; Slipek, Z. Optimization of Greenhouse Substrate Heating. J. Agric. Eng. Res. 2000, 76, 129–139. [Google Scholar] [CrossRef]

- Beyhan, B.; Paksoy, H.; Daşgan, Y. Root Zone Temperature Control with Thermal Energy Storage in Phase Change Materials for Soilless Greenhouse Applications. Energy Convers. Manag. 2013, 74, 446–453. [Google Scholar] [CrossRef]

- Argento, S.; Treccarichi, S.; Melilli, M.G.; Branca, F. Grafting Compatibility and Environmental Conditions on Soilless Eggplant (Solanum melongena) Grown in the Mediterranean Greenhouse. Horticulturae 2023, 9, 1060. [Google Scholar] [CrossRef]

- Bello, A.; López-Pérez, J.A.; García-Álvarez, A.; Sanz, R.; Lacasa, A. Biofumigation and Nematode Control in the Mediterranean Region. In Proceedings of the Fourth International Congress of Nematology, Tenerife, Spain, 8–13 June 2002; BRILL: Leiden, The Netherlands, 2004; pp. 133–149. [Google Scholar]

- Védie, H.; Mateille, T.; Tavoillot, J. Soil Solarization and Crop Rotation to Manage Root-Knot Nematodes in Organic Greenhouses. Acta Hortic. 2014, 1041, 87–94. [Google Scholar] [CrossRef]

- Giné, A.; Carrasquilla, M.; Martínez-Alonso, M.; Gaju, N.; Sorribas, F.J. Characterization of Soil Suppressiveness to Root-Knot Nematodes in Organic Horticulture in Plastic Greenhouse. Front. Plant Sci. 2016, 7, 164. [Google Scholar] [CrossRef]

- Sorribas, F.J.; Djian-Caporalino, C.; Mateille, T. Nematodes. In Integrated Pest and Disease Management in Greenhouse Crops; Springer International Publishing: Cham, Switzerland, 2020; pp. 147–174. [Google Scholar]

- Talavera-Rubia, M.; Vela-Delgado, M.D.; Verdejo-Lucas, S. A Cost-Benefit Analysis of Soil Disinfestation Methods against Root-Knot Nematodes in Mediterranean Intensive Horticulture. Plants 2022, 11, 2774. [Google Scholar] [CrossRef] [PubMed]

- Candido, V.; D’Addabbo, T.; Basile, M.; Castronuovo, D.; Miccolis, V. Greenhouse Soil Solarization: Effect on Weeds, Nematodes and Yield of Tomato and Melon. Agron. Sustain. Dev. 2008, 28, 221–230. [Google Scholar] [CrossRef]

- Shipp, L.; Johansen, N.; Vänninen, I.; Jacobson, R. Greenhouse Climate: An Important Consideration When Developing Pest Management Programs For Greenhouse Crops. Acta Hortic. 2011, 893, 133–143. [Google Scholar] [CrossRef]

- Daughtrey, M.; Buitenhuis, R. Integrated Pest and Disease Management in Greenhouse Ornamentals. In Integrated Pest and Disease Management in Greenhouse Crops; Springer International Publishing: Cham, Switzerland, 2020; pp. 625–679. [Google Scholar]

- van Lenteren, J.C.; Alomar, O.; Ravensberg, W.J.; Urbaneja, A. Biological Control Agents for Control of Pests in Greenhouses. In Integrated Pest and Disease Management in Greenhouse Crops; Springer International Publishing: Cham, Switzerland, 2020; pp. 409–439. [Google Scholar]

- Vila, E.; Cabello, T. Biosystems Engineering Applied to Greenhouse Pest Control. In Biosystems Engineering: Biofactories for Food Production in the Century XXI; Springer International Publishing: Cham, Switzerland, 2014; pp. 99–128. [Google Scholar]

- López-Felices, B.; Aznar-Sánchez, J.A.; Velasco-Muñoz, J.F.; Mesa-Vázquez, E. Installation of Hedgerows around Greenhouses to Encourage Biological Pest Control: Farmers’ Perspectives from Southeast Spain. J. Environ. Manag. 2022, 323, 116210. [Google Scholar] [CrossRef]

- Glass, R. Biological Control in the Greenhouses of Almería and Challenges for a Sustainable Intensive Production. Outlooks Pest Manag. 2012, 23, 276–279. [Google Scholar] [CrossRef]

- Deguine, J.-P.; Aubertot, J.-N.; Flor, R.J.; Lescourret, F.; Wyckhuys, K.A.G.; Ratnadass, A. Integrated Pest Management: Good Intentions, Hard Realities. A Review. Agron. Sustain. Dev. 2021, 41, 38. [Google Scholar] [CrossRef]

- Messelink, G.J.; Lambion, J.; Janssen, A.; van Rijn, P.C.J. Biodiversity in and around Greenhouses: Benefits and Potential Risks for Pest Management. Insects 2021, 12, 933. [Google Scholar] [CrossRef]

- Kumar, L.R.; Ndao, A.; Valéro, J.; Tyagi, R.D. Production of Bacillus Thuringiensis Based Biopesticide Formulation Using Starch Industry Wastewater (SIW) as Substrate: A Techno-Economic Evaluation. Bioresour. Technol. 2019, 294, 122144. [Google Scholar] [CrossRef]

- Buitenhuis, R.; Brownbridge, M.; Brommit, A.; Saito, T.; Murphy, G. How to Start with a Clean Crop: Biopesticide Dips Reduce Populations of Bemisia tabaci (Hemiptera: Aleyrodidae) on Greenhouse Poinsettia Propagative Cuttings. Insects 2016, 7, 48. [Google Scholar] [CrossRef] [PubMed]

- Parrella, M.P.; Lewis, E. Biological Control in Greenhouse and Nursery Production: Present Status and Future Directions. Am. Entomol. 2017, 63, 237–250. [Google Scholar] [CrossRef]

- Ibendahl AgManager, G.; Ibendahl, G. The Russia-Ukraine Conflict and the Effect on Fertilizer; Kansas State University: Manhattan, KS, USA, 2022. [Google Scholar]

- Shahini, E.; Skuraj, E.; Sallaku, F.; Shahini, S. The Supply Shock in Organic Fertilizers for Agriculture Caused by the Effect of Russia-Ukraine War. Sci. Horiz. 2022, 25, 97–103. [Google Scholar] [CrossRef]

- Ben Hassen, T.; El Bilali, H. Impacts of the Russia-Ukraine War on Global Food Security: Towards More Sustainable and Resilient Food Systems? Foods 2022, 11, 2301. [Google Scholar] [CrossRef] [PubMed]

- Alexander, P.; Arneth, A.; Henry, R.; Maire, J.; Rabin, S.; Rounsevell, M.D.A. High Energy and Fertilizer Prices Are More Damaging than Food Export Curtailment from Ukraine and Russia for Food Prices, Health and the Environment. Nat. Food 2022, 4, 84–95. [Google Scholar] [CrossRef]

- Russo, E.; Figueira, A.R. The Brazilian Fertilizer Diplomacy: The Case of the Russia–Ukraine Conflict and the Threat to World Food Security. Emerald Emerg. Mark. Case Stud. 2023, 13, 1–18. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, L.; Wang, Q.; Chen, D.; Liang, X. The Environmental and Socioeconomic Benefits of Optimized Fertilization for Greenhouse Vegetables. Sci. Total Environ. 2024, 908, 168252. [Google Scholar] [CrossRef]

- Treccarichi, S.; Cali, R.; Amari, M.; Mortada, A.; Felis, M.D.; Achkar, N.; Branca, F. New Tools for Organic Plant Nutrition: Microbial and Aminoacid Treatments for Organic Seed Production of Broccoli (Brassica oleracea var. italica Plenk.). Acta Hortic. 2023, 1365, 81–90. [Google Scholar] [CrossRef]

- Wei, Z.; Hoffland, E.; Zhuang, M.; Hellegers, P.; Cui, Z. Organic Inputs to Reduce Nitrogen Export via Leaching and Runoff: A Global Meta-Analysis. Environ. Pollut. 2021, 291, 118176. [Google Scholar] [CrossRef]

- Elbl, J.; Šimečková, J.; Škarpa, P.; Kintl, A.; Brtnický, M.; Vaverková, M.D. Comparison of the Agricultural Use of Products from Organic Waste Processing with Conventional Mineral Fertilizer: Potential Effects on Mineral Nitrogen Leaching and Soil Quality. Agronomy 2020, 10, 226. [Google Scholar] [CrossRef]

- Cheng, M.; Wang, H.; Fan, J.; Xiang, Y.; Tang, Z.; Pei, S.; Zeng, H.; Zhang, C.; Dai, Y.; Li, Z.; et al. Effects of Nitrogen Supply on Tomato Yield, Water Use Efficiency and Fruit Quality: A Global Meta-Analysis. Sci. Hortic. 2021, 290, 110553. [Google Scholar] [CrossRef]

- Castellanos, M.T.; Tarquis, A.M.; Ribas, F.; Cabello, M.J.; Arce, A.; Cartagena, M.C. Nitrogen Fertigation: An Integrated Agronomic and Environmental Study. Agric. Water Manag. 2013, 120, 46–55. [Google Scholar] [CrossRef]

- Li, S.; Wang, S.; Shangguan, Z. Combined Biochar and Nitrogen Fertilization at Appropriate Rates Could Balance the Leaching and Availability of Soil Inorganic Nitrogen. Agric. Ecosyst. Environ. 2019, 276, 21–30. [Google Scholar] [CrossRef]

- Muñoz, P.; Antón, A.; Paranjpe, A.; Ariño, J.; Montero, J.I. High Decrease in Nitrate Leaching by Lower N Input without Reducing Greenhouse Tomato Yield. Agron. Sustain. Dev. 2008, 28, 489–495. [Google Scholar] [CrossRef]

- Dion, P.-P.; Jeanne, T.; Thériault, M.; Hogue, R.; Pepin, S.; Dorais, M. Nitrogen Release from Five Organic Fertilizers Commonly Used in Greenhouse Organic Horticulture with Contrasting Effects on Bacterial Communities. Can. J. Soil Sci. 2020, 100, 120–135. [Google Scholar] [CrossRef]

- Holka, M.; Kowalska, J.; Jakubowska, M. Reducing Carbon Footprint of Agriculture—Can Organic Farming Help to Mitigate Climate Change? Agriculture 2022, 12, 1383. [Google Scholar] [CrossRef]

- Diacono, M.; Persiani, A.; Testani, E.; Montemurro, F.; Ciaccia, C. Recycling Agricultural Wastes and By-Products in Organic Farming: Biofertilizer Production, Yield Performance and Carbon Footprint Analysis. Sustainability 2019, 11, 3824. [Google Scholar] [CrossRef]

- Lee, M.E.; Steiman, M.W.; St. Angelo, S.K. Biogas Digestate as a Renewable Fertilizer: Effects of Digestate Application on Crop Growth and Nutrient Composition. Renew. Agric. Food Syst. 2021, 36, 173–181. [Google Scholar] [CrossRef]

- Koszel, M.; Lorencowicz, E. Agricultural Use of Biogas Digestate as a Replacement Fertilizers. Agric. Agric. Sci. Procedia 2015, 7, 119–124. [Google Scholar] [CrossRef]

- Doyeni, M.O.; Stulpinaite, U.; Baksinskaite, A.; Suproniene, S.; Tilvikiene, V. The Effectiveness of Digestate Use for Fertilization in an Agricultural Cropping System. Plants 2021, 10, 1734. [Google Scholar] [CrossRef]

- Asp, H.; Bergstrand, K.-J. Nutrient Utilization and Growth of Tomato Crops Fertilized with Solid Anaerobic Digestate. Sci. Hortic. 2024, 329, 112986. [Google Scholar] [CrossRef]

- Lv, H.; Zhou, W.; Dong, J.; He, S.; Chen, F.; Bi, M.; Wang, Q.; Li, J.; Liang, B. Irrigation Amount Dominates Soil Mineral Nitrogen Leaching in Plastic Shed Vegetable Production Systems. Agric. Ecosyst. Environ. 2021, 317, 107474. [Google Scholar] [CrossRef]

- Lv, H.; Zhao, Y.; Wang, Y.; Wan, L.; Wang, J.; Butterbach-Bahl, K.; Lin, S. Conventional Flooding Irrigation and over Fertilization Drives Soil pH Decrease Not Only in the Top- but Also in Subsoil Layers in Solar Greenhouse Vegetable Production Systems. Geoderma 2020, 363, 114156. [Google Scholar] [CrossRef]

- Fan, J.; Xiao, J.; Liu, D.; Ye, G.; Luo, J.; Houlbrooke, D.; Laurenson, S.; Yan, J.; Chen, L.; Tian, J.; et al. Effect of Application of Dairy Manure, Effluent and Inorganic Fertilizer on Nitrogen Leaching in Clayey Fluvo-Aquic Soil: A Lysimeter Study. Sci. Total Environ. 2017, 592, 206–214. [Google Scholar] [CrossRef] [PubMed]

- Sturiale, S.; Gava, O.; Gallardo, M.; Buendía Guerrero, D.; Buyuktas, D.; Aslan, G.E.; Laarif, A.; Bouslama, T.; Navarro, A.; Incrocci, L.; et al. Environmental and Economic Performance of Greenhouse Cropping in the Mediterranean Basin: Lessons Learnt from a Cross-Country Comparison. Sustainability 2024, 16, 4491. [Google Scholar] [CrossRef]

- El-Gayar, S.; Negm, A.; Abdrabbo, M. Greenhouse Operation and Management in Egypt. In Conventional Water Resources and Agriculture in Egypt; Springer: Berlin/Heidelberg, Germany, 2018; pp. 489–560. [Google Scholar]

- Colombo, N.; Galmarini, C.R. The Use of Genetic, Manual and Chemical Methods to Control Pollination in Vegetable Hybrid Seed Production: A Review. Plant Breed. 2017, 136, 287–299. [Google Scholar] [CrossRef]

- Kalia, P.; Singh, S. Innovations in Varietal Development and Seed Production Technologies for Effective Value Chain Management. Int. J. Innov. Hortic. 2019, 8, 108–114. [Google Scholar] [CrossRef]

- Mohammed, I.A.; Alabdaly, M.M.M. Production and Evaluation of F1 Hybrids of Protected Cultivation Cucumber. IOP Conf. Ser. Earth Environ. Sci. 2023, 1252, 012077. [Google Scholar] [CrossRef]

- Adegbola, Y.U.; Fisher, P.R.; Hodges, A.W. Benchmarking the Efficiency of Transplanting Plant Cuttings at Large Young Plant Greenhouse Operations. HortScience 2018, 53, 1133–1138. [Google Scholar] [CrossRef]

- Argento, S.; Treccarichi, S.; Arena, D.; Rizzo, G.F.; Branca, F. Exploitation of a Grafting Technique for Improving the Water Use Efficiency of Eggplant (Solanum melongena L.) Grown in a Cold Greenhouse in Mediterranean Climatic Conditions. Agronomy 2023, 13, 2705. [Google Scholar] [CrossRef]

- Gajc-Wolska, J.; Bujalski, D.; Chrzanowska, A. Effect of a Substrate on Yielding and Quality of Greenhouse Cucumber Frutis. J. Elem. 2008, 13, 205–210. [Google Scholar]

- Acuña, R.; Bonachela, S.; Magán, J.J. Response of a Sweet Pepper Crop Grown in New and Two-Year-Old Reused Rockwool Slabs in Greenhouse on the Mediterranean Coast of South-East Spain. Acta Hortic. 2005, 697, 189–194. [Google Scholar] [CrossRef]

- Peyvast, G.H.; Olfati, J.A.; Ramezani Kharazi, P.; Noori Roudsari, O. Effect of Substrate on Greenhouse Cucumber Production in Soilless Culture. Acta Hortic. 2010, 871, 429–436. [Google Scholar] [CrossRef]

- Oztekin, G.B.; Gul, A. Off-Seasonal Soilless Production of Green Vegetables in Reused Substrates in Mediterranean Unheated Greenhouses. Acta Hortic. 2020, 1273, 31–36. [Google Scholar] [CrossRef]

- Hemming, J. Current Developments in Greenhouse Robotics and Challenges for the Future. Acta Hortic. 2020, 1296, 975–986. [Google Scholar] [CrossRef]

- Kootstra, G.; Wang, X.; Blok, P.M.; Hemming, J.; van Henten, E. Selective Harvesting Robotics: Current Research, Trends, and Future Directions. Curr. Robot. Rep. 2021, 2, 95–104. [Google Scholar] [CrossRef]

- Bagagiolo, G.; Matranga, G.; Cavallo, E.; Pampuro, N. Greenhouse Robots: Ultimate Solutions to Improve Automation in Protected Cropping Systems—A Review. Sustainability 2022, 14, 6436. [Google Scholar] [CrossRef]

- Cañadas-Aránega, F.; Blanco-Claraco, J.L.; Moreno, J.C.; Rodriguez-Diaz, F. Multimodal Mobile Robotic Dataset for a Typical Mediterranean Greenhouse: The GREENBOT Dataset. Sensors 2024, 24, 1874. [Google Scholar] [CrossRef]

| Material | TS (MPa) | EB (%) | GTT (°C) | MT (°C) |

|---|---|---|---|---|

| Kraft paper | 68 | 3 | ||

| Cellulose acetate | 90 | 25 | 110 | 230 |

| Corn starch | 40 | 9 | 112 | |

| PLA | 59 | 2–7 | 55 | 165 |

| PHA | 15–50 | 1–800 | 12–3 | 100–175 |

| PBS | 34 | 560 | −32 | 114 |

| PBAT | 22 | 800 | −29 | 110 |

| PEF | 35–67 | 3–4 | 85 | 211 |

| PTT | 49 | 160 | 50 | 228 |

| PE | 15–30 | 1000 | −125 | 110–130 |

| PP | 36 | 400 | −13 | 176 |

| PET | 86 | 20 | 72 | 265 |

| PS | 30–60 | 1–5 | 100 | – |

| PVC | 52 | 35 | −18 | 200 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Argento, S.; Garcia, G.; Treccarichi, S. Sustainable and Low-Input Techniques in Mediterranean Greenhouse Vegetable Production. Horticulturae 2024, 10, 997. https://doi.org/10.3390/horticulturae10090997

Argento S, Garcia G, Treccarichi S. Sustainable and Low-Input Techniques in Mediterranean Greenhouse Vegetable Production. Horticulturae. 2024; 10(9):997. https://doi.org/10.3390/horticulturae10090997

Chicago/Turabian StyleArgento, Sergio, Gresheen Garcia, and Simone Treccarichi. 2024. "Sustainable and Low-Input Techniques in Mediterranean Greenhouse Vegetable Production" Horticulturae 10, no. 9: 997. https://doi.org/10.3390/horticulturae10090997

APA StyleArgento, S., Garcia, G., & Treccarichi, S. (2024). Sustainable and Low-Input Techniques in Mediterranean Greenhouse Vegetable Production. Horticulturae, 10(9), 997. https://doi.org/10.3390/horticulturae10090997