Abstract

The recent global trend aims to limit the use of chemicals in all aspects of our lives, necessitating research into the use of plant extracts and ultraviolet light as eco-friendly treatments to improve mango fruit storage. The literature did not introduce studies on plant extracts as coating materials for mango fruit storage. Although ginger, lemon, and green tea were utilized individually as edible coatings for some fruits, their combination in a single solution is not evaluated on mango fruits. To preserve the quality of Keitt mango fruit against decay during storage, fruits were treated with plant extracts (a mixture of ginger, lemon, and green tea), 50 g L−1 for each of them, and ultraviolet (UV) light, 250 nm for 5 min, either alone or in combination then stored at 22 °C or 13 °C. Data showed that the mixture of plant extracts treatment followed by the combination of plant extracts and UV treatment then UV treatments resulted in a decrease in weight loss and soluble solid contents (SSCs) compared to the control while reducing the decrease in firmness, acidity, vitamin C (Vit C), and phenols compared to the control. Mangoes stored at 22 °C reached 4 weeks with good quality while achieving 8 weeks at 13 °C.

1. Introduction

In Egypt, as well as many other countries, the mango is the most favorable fruit. Mango exports have increased in recent years from numerous Egyptian agro-companies. To produce clean, nutritious mango fruits, several orchards have begun to employ organic farming methods, which involve using natural fertilizers and minimizing the use of chemicals to treat the plants. Additionally, they try to treat fruits in orchards naturally after harvesting them until they are consumed.

These days, the importance of fresh fruits cannot be overstated because they are a great source of essential vitamins, minerals, and other plant components. To reduce postharvest losses and extend the shelf life of fresh fruits, there is a growing push for safer and more environmentally friendly alternatives. Natural plant extracts, effective substitutes for synthetic insecticides and preservatives, show great promise because of their high level of effectiveness. Given that plant-based extracts are non-chemical byproducts of the fruit sector, they can be combined with economic methods and be safe for human health [1,2].

According to several studies, postharvest losses in fruit crops can be significantly reduced by using edible coatings enhanced with plant extracts. Plant extracts that are non-toxic and environmentally friendly are added to edible coatings to boost customer acceptance. By reducing weight loss and adding extra antioxidants that support the fruit’s enzymatic activity regulation, these formulations preserve the fruit’s quality and increase the shelf life of harvested fruits [3].

Ginger may be used as a natural fungicide to prevent crop infections in place of traditional synthetic fungicides due to its inhibitory effects both in vitro and in vivo during storage circumstances [4,5,6]. Moreover, ginger extract coating demonstrated an antifungal impact on yam tubers, tomatoes, citrus, dragon fruits, guava fruits, and walnuts [7,8,9,10,11,12,13]. During the storage period, ginger extract considerably preserved the acidity, total sugar, and sugar/acid ratio and also reduced orange fruit weight loss and fruit degradation [14].

The lemon extract contains antioxidant compounds that could protect the treated fruits from the microbial growth of yeasts and molds, resulting in their extended shelf life and maintained quality during storage. The lemon extract could be suggested for long-term storage and maintenance of postharvest qualities of banana cv. Sabri at ambient conditions [15]. This protective effect of lemon was displayed in strawberry fruits and rambutan fruit [16,17,18].

Furthermore, green tea (GT) extracts have been shown to enhance the antioxidant qualities of postharvest fruits and increase their shelf life, including strawberries, fruit-based salads, and apples [19,20,21,22]. Similarly, green tea extracts have been found by Shiekh et al. (2021) to be rich in phenolic compounds, which may serve as a substitute for chemically manufactured wax coatings. Moreover, plant extracts lessen microbiological and physiological deterioration by preventing moisture loss, flesh softening, ripening, and decay brought on by mold, rot, and pathogenic bacterial strains [23]. The impact of green tea polyphenols (GTP) on passion fruit preservation quality was investigated by Feng et al. (2023) [24]. Effectively, it postponed the rise in respiratory intensity, weight loss rate, and shrinkage index. Furthermore, the GTP coating may delay the aging and browning of passion fruit while blocking the rise in polyphenol oxidase and peroxidase activity. Bobo et al. (2022) found that fresh-cut potatoes (cv. Monalisa) maintained for 14 days at 4 °C did not brown when treated with GT extract [25].

Many of the ultraviolet (UV) induced acclimation modifications trigger a variety of beneficial effects in plant physiology by stimulating natural defenses and secondary antioxidant metabolites. To benefit from its advantageous responses, it is therefore worthy of application in harvested commodities [26]. Ultraviolet-C (UV-C) radiation works well because it may strengthen plant defenses in addition to its disinfecting properties [27]. Tomatoes exposed to UV light have shown resistance to microbial development and deterioration. While UV irradiation lessens vitamin C loss during storage, vitamin E loss is still an issue. Higher levels of flavonoids, phenolic content, and antioxidant capacity are the results of UV treatments [28].

Postharvest UV radiation influences oxidative metabolism and raises antioxidant activity in plant products, which may assist in postponing vegetable senescence and yellowing, activate defense mechanisms, and lessen decay and illness in fruits such as peaches, tomatoes, dragon fruit, sweet cherry, and gourd fruit. The softening and senescence of peach fruit were caused by the UV-C treatment, which also downregulated the expression of genes linked to ethylene production, membrane lipid peroxidation, cell wall breakdown, and oxidative stress while instead upregulating a few genes related to antioxidant and defense responses [29,30,31,32,33,34,35]. According to Hu et al. (2019), the outcomes demonstrated that UV irradiation not only hastened orange ripening but also significantly altered the fruit’s soluble sugar, organic acid, and carotenoid content [36]. According to Abdipour et al. (2020), the UV and chitosan coating (CS) treatments considerably slowed down the sweet cherry fruit’s increasing rate of weight loss and total soluble solids, as well as its decline in firmness and total acidity content [37].

Although the beneficial characteristics of natural plant extracts and UV are proven, there are still unsolved research questions about their effect on mango fruits. So, the goal was to improve the postharvest conditions and maintain the high quality of Keitt mango fruits throughout storage without using chemicals by using eco-friendly treatments such as natural plant extracts, including ginger, lemon, and green tea, as well as UV treatments.

2. Materials and Methods

2.1. Sample Preparation and Treatments

The current study was carried out during two successive growing seasons, 2022 and 2023, on mango Keitt fruits of 15-year-old trees grown in a privet orchard in the Ismailia governorate (30.642796, 32.262920) in the northeastern part of Egypt. Mangoes of 500 kg were harvested in the physiological maturity stage (December of each season), transferred directly to the postharvest laboratory, washed, and dried. The fruit was chosen as uniformly as possible for the experiment in size, color, and maturity stage. The experiment was divided into two groups of temperature storage (22 ± 2 °C and 13 °C) with 4 treatments in every group, and each treatment was replicated five times in a completely randomized design.

The experiment included 4 treatments as follows:

- Control: mangoes were dipped in clean tap water (5 min).

- Ex: mangoes were dipped in plant extracts (5 min).

- UV: mangoes were exposed to ultraviolet radiation (5 min).

- ExUV: mango fruits were dipped in plant extracts (5 min) and then exposed to ultraviolet radiation (5 min).

Plant extracts consist of dried ginger, fresh lemon, and dried green tea. Each of them was prepared one day before treating the fruit by boiling a concentration of 250 g from each of them in 5 L of water (50 g L−1) for 10 min; then the juice was filtered and stored in a Frigidaire until fruit treatment by dipping the fruits in the plant extracts for 5 min. Ultraviolet (UV) treatment was performed using a UV lamp at 250 nm on the fruits for 5 min.

2.2. Measurements

Fruit color was recorded using a Minolta colorimeter (model CR-400, Tokyo, Japan) of two points for every fruit as per CIE Lab, then transferred to H° Hue using the converter in the https://colorizer.org (accessed on 11 June 2024) website. Fruit weight loss (g) was determined on separated treated fruits using digital balance by recording the weight of the fruit every week and calculating the weight loss percentage of fruit every week. Fruit firmness was recorded from two opposite points on the fruit flesh using a Magness–Taylor pressure tester (Shahe GY-3 Fruit Hardness Tester, China) (N). Fruit juice soluble solid contents (SSCs%) measured using digital refractometer (Infitek model RFT-PD35F, Infitek Co., Ltd., Shenzhen, China), fruit juice acidity (%), fruit juice vitamin C content (mg g−1), fruit juice phenol as Gallic acid (mg g−1), fruit juice total sugars (%), fruit juice reduced sugar (%), fruit juice non-reduced sugar (%), fruit juice volume (cm3), fruit flesh weight (g), fruit dry weight (g), and fruit peel weight (g) were measured according to [38].

2.3. Statistical Analysis

Statistical analysis of variance (one-way ANOVA) was implemented using the CoStat computer software program (ver. 6.451). Means comparison was performed using Duncan’s Multiple Range Test among treatment means at a 5% level of probability.

3. Results

The CIE Lab color was transformed to Hsl Hue color as H°, which gives an accurate indication of the change in the fruit color. In the current investigation, the fruit color changed normally during the storage period from green to the direction of yellow. That is the reason for the decrease in H° of the Hue color values during storage periods on both temperature conditions (22 °C and 13 °C). The data in Table 1 generally do not show a clear significant difference between treatments except treatments that contain UV, which showed high significant values in Hue during the 2nd week of shelf life in the two seasons and in the 6th week of the 1st season and the 7th week of the 2nd season.

Table 1.

Effect of plant extracts (Ex), ultraviolet (UV), and combination of them (ExUV) pre storing mango Keitt at 22 °C and 13 °C during seasons 2022 and 2023 on fruit Hue color (H°).

During storage, mango fruits lost some weight. Controlled fruits recorded a significant weight loss percentage compared to all other treatments during the two seasons at both storage temperatures. Treatment with natural plant extracts (Ex) showed the lowest significant values of fruit weight loss percentage at different temperature storage during the two seasons of the study, as shown in Table 2.

Table 2.

Effect of plant extracts (Ex), ultraviolet (UV), and combination of them (ExUV) pre storing mango Keitt at 22 °C and 13 °C during seasons 2022 and 2023 on fruit weight loss (%).

Firmness showed the opposite significant direction in the treatment order of weight loss percentage. Plant extract treatments recorded the highest significant values in firmness compared to other treatments, while the control recorded the lowest significant values in firmness during the two seasons of mango storage on shelf life or cold storage, as shown in Table 3.

Table 3.

Effect of plant extracts (Ex), ultraviolet (UV), and combination of them (ExUV) pre storing mango Keitt at 22 °C and 13 °C during seasons 2022 and 2023 on fruit firmness (N).

Soluble solid contents (SSCs) recorded the lowest significant values with plant extract treatments compared to other treatments, while the control recorded the highest significant values during the two seasons of mango storage on shelf life or cold storage, as shown in Table 4.

Table 4.

Effect of plant extracts (Ex), ultraviolet (UV), and combination of them (ExUV) pre storing mango Keitt at 22 °C and 13 °C during seasons 2022 and 2023 on fruit juice soluble solid content (SSC%).

Acidity was normally decreased periodically during mango storage periods. Plant extract treatments observed weekly showed the significantly highest acidity values compared to other treatments. At the same time, the control recorded the significantly lowest values compared to other treatments in all periods of both storage conditions (shelf life and cold storage) in the two seasons of the investigation, as viewed in Table 5.

Table 5.

Effect of plant extracts (Ex), ultraviolet (UV), and combination of them (ExUV) pre storing mango Keitt at 22 °C and 13 °C during seasons 2022 and 2023 on acidity of fruit juice (%).

Plant extract treatments (Ex) resulted in the highest values of vitamin C (Vit C) compared to other treatments, and the control that recorded the significantly lowest values in most record dates of both temperatures of storage in both two investigation seasons, as recorded in Table 6.

Table 6.

Effect of plant extracts (Ex), ultraviolet (UV), and combination of them (ExUV) pre storing mango Keitt at 22 °C and 13 °C during seasons 2022 and 2023 on vitamin C (Vit C) in fruit juice (mg g−1).

Phenols contents recorded in Table 7 showed significantly higher values when treating mango fruits with plant extracts than other treatments, and the control group recorded the lowest values when storing mangoes on shelf life or in cold storage temperatures.

Table 7.

Effect of plant extracts (Ex), ultraviolet (UV), and combination of them (ExUV) pre storing mango Keitt at 22 °C and 13 °C during seasons 2022 and 2023 on fruit juice phenol contents as Gallic acid (mg g−1).

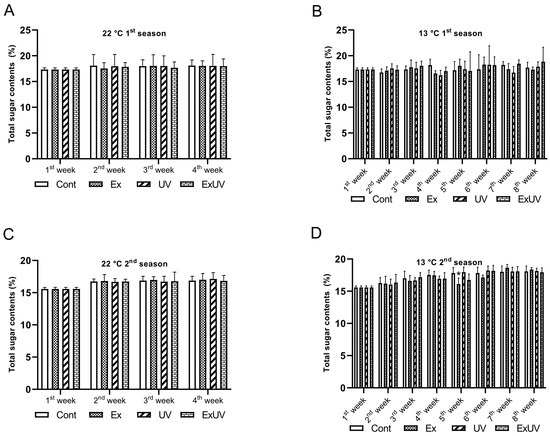

According to sugar content (total, reduced, and non-reduced sugar), the data generally did not show a clear significant direction of effect by the treatments. Figure 1 shows the effect of treatments on total sugar contents in fruit juice without any significant differences between all treatments.

Figure 1.

Effect of plant extracts (Ex), ultraviolet (UV), and combination of them (ExUV) pre storing mango Keitt at (A) 22 °C season 2022; (B) 13 °C season 2022; (C) 22 °C season 2023; (D) 13 °C season 2023 on total sugar contents in fruit juice (%). The results are expressed as the mean ± standard deviation. * p < 0.05 versus the control group according to ANOVA with Duncan’s test.

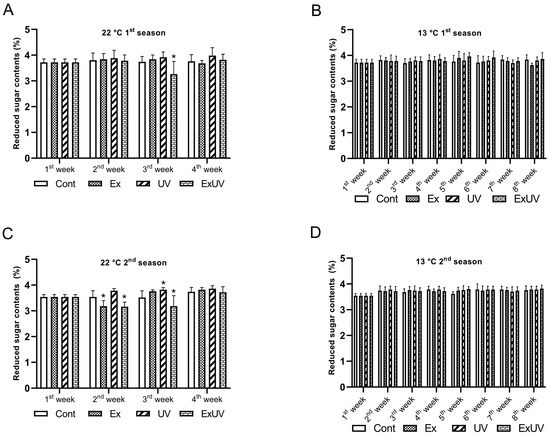

Figure 2 shows the effect of treatments on reduced sugar content in mango fruit. The data show that there was no significant difference between treatments except the lowest significant values of the effect of ExUV at 22 °C in the 3rd week of season 2022 versus the control (Figure 2A). Meanwhile, in the next season, Ex and ExUV treatments showed the lowest significant difference at 22 °C in the 2nd week of season 2023 versus the control, and ExUV treatment stabilized in the same direction in the 3rd week, but UV treatment showed the highest significant values at 22 °C in the 3rd week of season 2023 versus the control (Figure 2C).

Figure 2.

Effect of plant extracts (Ex), ultraviolet (UV), and combination of them (ExUV) pre storing mango Keitt at (A) 22 °C season 2022; (B) 13 °C season 2022; (C) 22 °C season 2023; (D) 13 °C season 2023 on reduced sugar in fruit juice (%). The results are expressed as the mean ± standard deviation. * p < 0.05 versus the control group according to ANOVA with Duncan’s test.

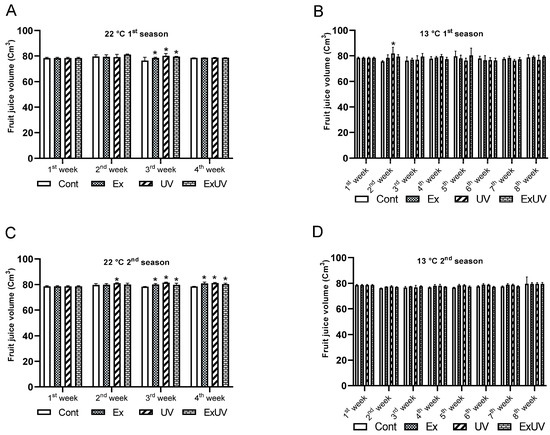

Figure 3 shows the effect of treatments on fruit juice volume (cm3). The data show a highly significant difference in all treatments compared to the control only in the 3rd week of the shelf life storage in the first season (Figure 3A) and in the 3rd and 4th weeks in the 2nd season (Figure 3C). Meanwhile, there were no significant differences between treatments and the control at 13 °C during the two seasons of the investigation except for the highest significant values with UV treatment in the 2nd week of the 1st season on cold storage (Figure 3B).

Figure 3.

Effect of plant extracts (Ex), ultraviolet (UV), and combination of them (ExUV) pre storing mango Keitt at (A) 22 °C season 2022; (B) 13 °C season 2022; (C) 22 °C season 2023; (D) 13 °C season 2023 on fruit juice volume (cm3). The results are expressed as the mean ± standard deviation. * p < 0.05 versus the control group according to ANOVA with Duncan’s test.

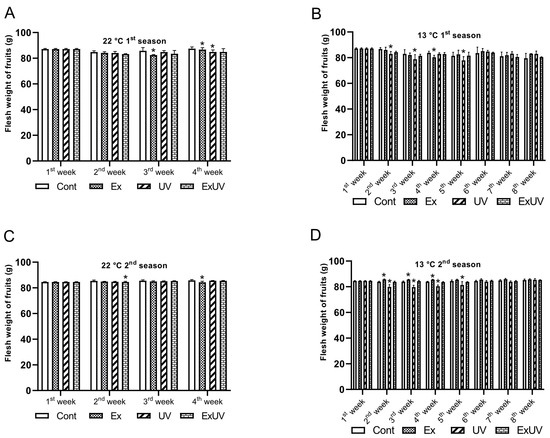

Figure 4 demonstrates the effect of plant extracts (Ex), ultraviolet (UV), and a combination of them (ExUV) on the flesh weight of fruits. On the shelf life, Ex treatment resulted in the lowest significant values on flesh weight of fruits versus the control during the two seasons of the experiment (Figure 4A,C), while radiating the fruits with UV resulted in the lowest significant values of flesh weight versus the control while storing the mangoes at the cold temperature (13 °C) in the two seasons of the current investigation (Figure 4B,D).

Figure 4.

Effect of plant extracts (Ex), ultraviolet (UV), and combination of them (ExUV) pre storing mango Keitt at (A) 22 °C season 2022; (B) 13 °C season 2022; (C) 22 °C season 2023; (D) 13 °C season 2023 on flesh weight of fruits (g). The results are expressed as the mean ± standard deviation. * p < 0.05 versus the control group according to ANOVA with Duncan’s test.

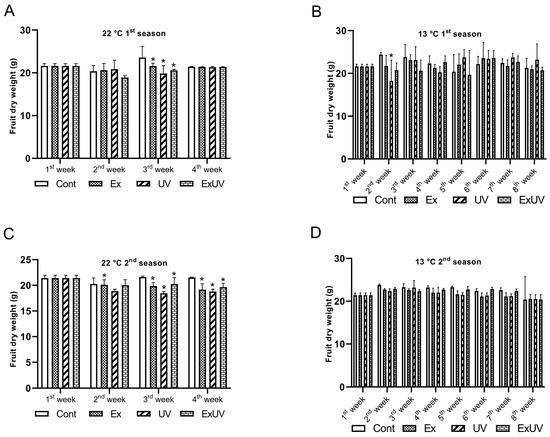

Fruit dry weight was not affected using plant extract or UV when storing mangoes at 13 °C during the current experiment (Figure 5B,D), while the effect of these treatments appeared when storing mangoes at 22 °C by significantly reducing the fruit dry weight versus the control. The effect of the treatment appeared in the 3rd week of the first season and in the 3rd and 4th weeks of the 2nd season (Figure 5A,C).

Figure 5.

Effect of plant extracts (Ex), ultraviolet (UV), and combination of them (ExUV) pre storing mango Keitt at (A) 22 °C season 2022; (B) 13 °C season 2022; (C) 22 °C season 2023; (D) 13 °C season 2023 on fruit dry weight (g). The results are expressed as the mean ± standard deviation. * p < 0.05 versus the control group according to ANOVA with Duncan’s test.

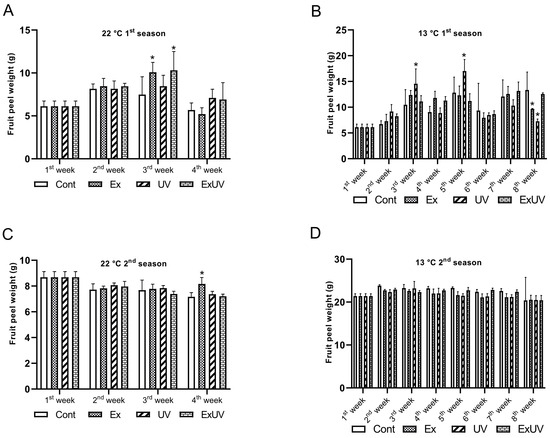

Treatments varied in their effects on fruit peel weight between the two seasons of the experiment and the conditions of storage temperature, as shown in Figure 6.

Figure 6.

Effect of plant extracts (Ex), ultraviolet (UV), and combination of them (ExUV) pre storing mango Keitt at (A) 22 °C season 2022; (B) 13 °C season 2022; (C) 22 °C season 2023; (D) 13 °C season 2023 on fruit peel weight (g). The results are expressed as the mean ± standard deviation. * p < 0.05 versus the control group according to ANOVA with Duncan’s test.

The data generally showed that during mango storage at 22 °C or 13 °C, the fruits could be affected by plant extract and UV treatments. The data showed that plant extract treatment followed by the combination of plant extracts and UV treatment then UV treatments resulted in a decrease in weight loss percentage and SSCs compared to the control while treatments delayed the decrease of firmness, acidity, Vit C, and phenols. Treatment did not affect the parameters of fruit juice content, the weight of flesh, dry weight, and peel weight. The data concluded that plant extract treatments affected the parameters of mango fruits and delayed the ripening of fruits during storage, followed by the combination of Ex and UV treatment and UV treatment compared to the control untreated fruits.

4. Discussion

According to Siddiq et al. (2017), more than 80 countries produce mangoes, which can be picked when physiologically ready but not quite ripe and then allowed to ripen further [39]. The rates at which fresh fruit deteriorates after harvest are influenced by many biological variables, such as transpiration, ethylene production, and respiration. Furthermore, some physiological conditions also lower the quality of postharvest fruit. If suitable preharvest and postharvest procedures are followed, many of these issues could be mitigated or under control [40]. In the current investigation, Keitt mangoes were harvested in the physiological maturity stage before becoming ripe in the 1st week of December in each season and then treated with plant extracts or UV before storing. Both the quick deterioration of the produce and its ability to retain quality are directly impacted by several environmental factors surrounding it. In India, mango availability is poor despite India being the world leader in mango production and area due to significant postharvest losses that happen at several points along the value chain from consumption to production [41]. In the current work, there was a need to choose the best conditions for storing mangos both near markets and for export.

Yahia and Carrillo-López (2019) concluded that, during fruit development, the process of ripening involves a range of changes to the fruit’s color, texture, aroma, and other qualities that make it both nutrient-dense enough for human interest [42]. Moreover, the fruit alters physiologically, changing color, acquiring scents, and softening due to the activation of numerous additional enzymes by the fruit’s ethylene synthesis. While phenol content, total soluble solid, total sugar, and non-reducing sugar contents gradually increase along with respiration rate, ethylene synthesis, and distinctive aromas, acidity, vitamin C, starch content, and reducing sugars are higher at the unripe state and gradually decrease during the ripening and maturing process [39,43]. Therefore, there was a need to measure changes in fruit color, weight loss, firmness, soluble solid contents, etc., under the current investigation conditions. A commodity’s shelf life can be increased by using chemical preservatives or irradiation therapy, as well as by keeping it at the ideal temperature and optimum conditions [44]. Also, Ahmad and Siddiqui (2015) reported that, up to a certain time, storage cannot increase quality, but it can preserve it or slow down the rate at which it deteriorates [45,46].

In the current research, mangoes were stored to maintain shelf life at 22 °C for near markets and at 13 °C for export and far markets. Data showed that mangoes were able to withstand shelf storage for four weeks with good quality parameters using plant extract and UV treatments at 22 °C and up to 8 weeks at 13 °C. These findings were in agreement with Siddiq et al. (2017), who reported that for most mango cultivars, two to four weeks can be maintained by harvesting at optimal maturity, rapid cooling, optimal temperature utilization, and optimal storage conditions. Mature mangoes have reportedly been harmed by storage temperatures above freezing but below roughly 10–13 °C [39].

Plant extracts in the current work contain extracts of ginger, lemon, and green tea that are individually known from the review literature for their antioxidant effects. Plant extract treatments improved the properties of stored mangoes on shelf life or cold storage (13 °C). The data exhibited a decrease in weight loss and SSCs with a delay in the decrease of firmness, acidity, Vit C, and phenols using plant extract treatments compared to control. When fruits are treated with edible coatings, the internal atmosphere is altered by a decrease in oxygen content and an increase in carbon dioxide. Investigating the impact of edible coatings on internal gas composition and their interactions with quality metrics of fresh fruit that has been coated is, therefore, crucial. Most edible coatings have a lower O2 permeability than traditional plastic films. Furthermore, a thick coating can lower internal O2 concentration below an acceptable level and raise CO2 concentration above a crucial tolerable level, which can harm fruit quality [46]. The creation of novel edible packaging materials to extend the shelf life of products has drawn more attention in recent years. These coatings are made by combining extracts from several herbs. These plant extracts have medicinal, antibacterial, antioxidant, and nutritional qualities [47]. The given data were in the same opinion of Fallik and Ilic (2018), who reported that when coating materials are applied to fresh food, they provide luster and minimize shrinkage and water loss [48]. In addition, Siddiqui (2016) concluded that many fruits have edible coatings and films applied to them to regulate gas exchange, manage moisture transfer, or stop oxidation processes [49].

In the current research, the treatment with plant extracts or UV did not affect all parameters (weight of flesh, dry weight, and peel weight) of stored mangoes. Postharvest irradiation of fruits is mostly used as a fungicide or pesticide to lessen or delay damage caused by diseases or insects, so it can be applied as a preservation technique to prolong the shelf life of some products. In the current investigation, the data showed good results for using UV to preserve mangoes’ quality during storage on shelf life or in cold temperature conditions. This was in agreement with Siddiq et al. (2017), who concluded that by postponing the ripening of fresh fruit, radiation processing has been demonstrated to be a potential technique for extending the shelf life of mangoes. Radiation has reportedly been shown to alter the activity of the enzymes [39]. UV-C treatment is beneficial in lowering pathogen microbial loads on the surface of fresh produce, averting illnesses, and improving the quality and shelf life of the produce [49]. An alternative and potentially useful technology in food processing is UV treatment, which lowers the number of microorganisms in food while maintaining product quality [50,51]. Moreover, Florkowski et al. (2022) demonstrated that UV-C can significantly reduce the growth of microorganisms by forming pyrimidine dimer photoproducts in DNA [44].

According to Ahmad and Siddiqui (2015), the most crucial factor in determining the quality of fruits, both fresh and processed, is color. Fresh fruit’s color is frequently correlated with its level of ripeness, making it an indirect measure of its texture, flavor, nutritional value, and overall wholesomeness [45]. With maturation, skin tone may shift from a dark green to an olive green or a lighter hue. This has to do with the peel’s declining chlorophyll content [39]. In the current investigation, the color of mangoes was not affected by treatments of plant extracts or UV. Siddiqui (2018) gave the reason for that when he reported that the fruit’s skin color varies as it ages or ripens. However, noticeable color changes could not happen in some fruits as they mature. On some cultivars, color changes might happen, but not on others, which means that it is difficult to use skin color as a gauge of maturity in some fruits [49].

The treatments used did not affect the acidity of the mango juice; the acidity was decreased during the storage period with the agreement of Siddiqui (2018), who reported that as many fruit varieties grew and ripened, their acidity gradually decreased [49].

Plant extract and UV treatments significantly decreased the weight loss percentages while increasing firmness compared to the control. Fruits may undergo textural changes as they mature, particularly during ripening, when they may soften quickly. Additionally, crops’ textures may be impacted by excessive moisture loss [49]. Any fruit’s firmness or texture varies as it ripens and matures. This becomes more noticeable when it ripens and loses texture more quickly. The texture of the fruits may also be impacted by excessive moisture loss. The cellulose fibrils in the cell wall, which are embedded in a matrix of proteins, hemicelluloses, pectic compounds, and lignin, help to further preserve the distinctive textural characteristics. Aside from the turgor pressure reduction that occurs when fruits are stored, the enzymatic conversion of insoluble protopectin into soluble pectin contributes to the softening of fruit [45]. The edible films and coatings may help fresh food last longer on the shelf. The numerous natural compounds and essential oils could function as antioxidants, preventing the growth of pathogenic or spoilage bacteria and prolonging the shelf life of perishables. Enzyme inhibition by the oxidized compounds is one of the mechanisms hypothesized to be responsible for the phenolic toxicity to microorganisms [50].

The given data exhibited that the treatments used decreased weight loss and reduced the detrition of acidity, vitamin C, and phenols compared to the control. Meanwhile, plant extract and UV treatments improved the preservation of fruit quality.

5. Conclusions

The recent global trend aims to reduce the use of chemicals in all areas of our lives, and this necessitates studying the use of plant extracts and ultraviolet rays to improve the storage conditions of mango fruits. The literature did not indicate any research on plant extracts as coating materials during the storage of mango fruits. Although ginger, lemon, and green tea were used individually as edible coatings for some fruits, their combination in a single plant extract was not used, and they were not tested on mango fruits. Therefore, to preserve the quality of the Keitt mango fruit from decay during the storage period, fruits were treated with plant extracts (mixture of ginger, lemon, and green tea) and UV alone or combined. The results of the current investigation showed that plant extract treatment is the most beneficial treatment for storing Keitt mangoes, followed by the combination of plant extracts and UV treatment then UV treatments as all treatments resulted in a decrease in weight loss, and SSCs compared to the control while reducing the decrease of firmness, acidity, Vit C, and phenols compared to the control untreated fruits, suggesting a potential eco-friendly alternative for suitable conditions for storage of mango fruits. Also, the data showed that mango Keiit could be stored with a shelf life (22 °C) of up to 4 weeks with good quality for sale to near markets while it could be stored for up to 8 weeks for far markets and export at 13 °C. The data exhibited that plant extracts and ultraviolet radiation could be used as eco-friendly treatments to preserve the quality of mangoes during the storage period. More research on the postharvest of fruits is recommended in the future using other eco-friendly treatments that do not harm the environment.

Author Contributions

M.I.S.: Conceptualization, Methodology, Data curation, Validation, Formal analysis, Investigation, Resources, Funding acquisition, Writing—Original Draft, Writing—Review and Editing, Visualization. S.I.: Formal analysis, Resources, Funding acquisition, Writing—Review and Editing. M.S.M.A.: Conceptualization, Methodology, Data curation, Validation, Formal analysis, Investigation, Resource, Funding acquisition, Writing—Review and Editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Shahbaz, M.U.; Arshad, M.; Mukhtar, K.; Nabi, B.G.; Goksen, G.; Starowicz, M.; Nawaz, A.; Ahmad, I.; Walayat, N.; Manzoor, M.F.; et al. Natural Plant Extracts: An Update about Novel Spraying as an Alternative of Chemical Pesticides to Extend the Postharvest Shelf Life of Fruits and Vegetables. Molecules 2022, 27, 5152. [Google Scholar] [CrossRef]

- Matrose, N.A.; Obikeze, K.; Belay, Z.A.; Caleb, O.J. Plant Extracts and Other Natural Compounds as Alternatives for Post-Harvest Management of Fruit Fungal Pathogens: A Review. Food Biosci. 2021, 41, 100840. [Google Scholar] [CrossRef]

- Bajaj, K.; Adhikary, T.; Gill, P.P.S.; Kumar, A. Edible Coatings Enriched with Plant-Based Extracts Preserve Postharvest Quality of Fruits: A Review. Prog. Org. Coat. 2023, 182, 107669. [Google Scholar] [CrossRef]

- Al-Samarrai, G.F.; Singh, H.; Syarhabil, M. Extracts Some Plants on Controlling Green Mold of Orange and on Postharvest Quality Parameters. World Appl. Sci. J. 2013, 22, 564–570. [Google Scholar] [CrossRef]

- Bordoh, P.K.; Ali, A.; Dickinson, M.; Siddiqui, Y.; Ansah, F.A. Bioefficacy of Composite Medicinal Plant Extracts and Gum Arabic on Improving Postharvest Quality in Dragon Fruit. Int. J. Food Sci. 2022, 2022, 3889563. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, N.F.; Rostam, N.F.S.; Azman, N.A.I.N.; Razak, S.B.A. Effects of kaffir lime peel extract and ginger extract on the postharvest quality of tomato. MABJ 2020, 49, 247–251. [Google Scholar] [CrossRef]

- Anjum, M.A.; Akram, H.; Zaidi, M.; Ali, S. Effect of Gum Arabic and Aloe Vera Gel Based Edible Coatings in Combination with Plant Extracts on Postharvest Quality and Storability of ‘Gola’ Guava Fruits. Sci. Hortic. 2020, 271, 109506. [Google Scholar] [CrossRef]

- Baleba, C.C.; Bedine, M.A.B.; Kouam, I.D.; Aghofack, K.K.; Béyégué, H.; Yaouba, A. Efficacy of Ginger (Zingiber officinale) in Controlling Fungi Causing Postharvest Deterioration in Yam Tuber. Trends Hortic. 2024, 7, 3605. [Google Scholar] [CrossRef]

- Bordoh, P.K.; Ali, A.; Dickinson, M.; Siddiqui, Y. Antimicrobial Effect of Rhizome and Medicinal Herb Extract in Controlling Postharvest Anthracnose of Dragon Fruit and Their Possible Phytotoxicity. Sci. Hortic. 2020, 265, 109249. [Google Scholar] [CrossRef]

- Gong, M.; Guan, Q.; Xu, S. Inhibitory Effects of Crude Extracts from Several Plants on Postharvest Pathogens of Citrus; AIP Conference Proceedings (Vol. 1956, No. 1); AIP Publishing: Offenburg, Germany, 2018; p. 020043. [Google Scholar]

- Nor Azman, N.A.I.; Rostam, N.F.S.; Ibrahim, N.F.; Lob, S. Potential of aqueous ginger extract as fruit coating on tomato. UMT JUR 2020, 2, 23–30. [Google Scholar] [CrossRef]

- Shaukat, M.N.; Palmeri, R.; Restuccia, C.; Parafati, L.; Fallico, B. Glycerol Ginger Extract Addition to Edible Coating Formulation for Preventing Oxidation and Fungal Spoilage of Stored Walnuts. Food Biosci. 2023, 52, 102420. [Google Scholar] [CrossRef]

- Xi, K.-Y.; Xiong, S.-J.; Li, G.; Guo, C.-Q.; Zhou, J.; Ma, J.-W.; Yin, J.-L.; Liu, Y.-Q.; Zhu, Y.-X. Antifungal Activity of Ginger Rhizome Extract against Fusarium Solani. Horticulturae 2022, 8, 983. [Google Scholar] [CrossRef]

- Al-Hajani, R.M.A.; Haded, N.N.F.; Bamarny, S.F.A.A. Influence of citric acid, ginger extract and storage period on fruit quality of local orange (Citrus sinensis L. Osbeck). Iraqi J. Agric. Sci. 2022, 53, 850–856. [Google Scholar] [CrossRef]

- Tabassum, P.; Khan, S.A.K.U.; Siddiqua, M.; Sultana, S. Effect of guava leaf and lemon extracts on postharvest quality and shelf life of banana cv. Sabri (Musa sapientum L.). J. Bangladesh Agric. Univ. 2018, 16, 337–342. [Google Scholar] [CrossRef]

- Dhital, R.; Mora, N.B.; Watson, D.G.; Kohli, P.; Choudhary, R. Efficacy of Limonene Nano Coatings on Post-Harvest Shelf Life of Strawberries. LWT 2018, 97, 124–134. [Google Scholar] [CrossRef]

- Perdones, Á.; Escriche, I.; Chiralt, A.; Vargas, M. Effect of Chitosan–Lemon Essential Oil Coatings on Volatile Profile of Strawberries during Storage. Food Chem. 2016, 197, 979–986. [Google Scholar] [CrossRef]

- Ummarat, N.; Seraypheap, K. Application of Essential Oils for Maintaining Postharvest Quality of ‘Rongrien’ Rambutan Fruit. Agriculture 2021, 11, 1204. [Google Scholar] [CrossRef]

- Amiri, S.; Akhavan, H.; Zare, N.; Radi, M. Effect of gelatin-based edible coatings incorporated with aloe vera and green tea extracts on the shelf-life of fresh-cut apple. Ital. J. Food Sci. 2017, 30, 61–74. [Google Scholar] [CrossRef]

- Chiu, P.-E.; Lai, L.-S. Antimicrobial Activities of Tapioca Starch/Decolorized Hsian-Tsao Leaf Gum Coatings Containing Green Tea Extracts in Fruit-Based Salads, Romaine Hearts and Pork Slices. Int. J. Food Microbiol. 2010, 139, 23–30. [Google Scholar] [CrossRef]

- Jayamali, N.A.I.; Wijesinghe, J.; Silva, P.A.P.M.D. Green Tea Incorporated Edible Coating Extends the Postharvest Life of Strawberry Fruits (Fragaria ananassa). Adv. Technol. 2022, 2, 382–393. [Google Scholar] [CrossRef]

- Yang, C.; Lu, J.-H.; Xu, M.-T.; Shi, X.-C.; Song, Z.-W.; Chen, T.-M.; Herrera-Balandrano, D.D.; Zhang, Y.-J.; Laborda, P.; Shahriar, M.; et al. Evaluation of Chitosan Coatings Enriched with Turmeric and Green Tea Extracts on Postharvest Preservation of Strawberries. LWT 2022, 163, 113551. [Google Scholar] [CrossRef]

- Shiekh, K.A.; Ngiwngam, K.; Tongdeesoontorn, W. Polysaccharide-Based Active Coatings Incorporated with Bioactive Compounds for Reducing Postharvest Losses of Fresh Fruits. Coatings 2021, 12, 8. [Google Scholar] [CrossRef]

- Feng, S.; Pan, H.; Li, G.; Li, X.; Luo, L.; Yang, T.; Lv, Z. Effect of Composite Coating of Konjac Glucomannan with Green Tea Polyphenols on Antioxidant Activity and Shelf-Life of Post-Harvest Passion Fruit. 2023. Available online: https://www.researchsquare.com/article/rs-2428876/v1 (accessed on 11 June 2024).

- Bobo, G.; Arroqui, C.; Virseda, P. Natural Plant Extracts as Inhibitors of Potato Polyphenol Oxidase: The Green Tea Case Study. LWT 2022, 153, 112467. [Google Scholar] [CrossRef]

- Darré, M.; Vicente, A.R.; Cisneros-Zevallos, L.; Artés-Hernández, F. Postharvest Ultraviolet Radiation in Fruit and Vegetables: Applications and Factors Modulating Its Efficacy on Bioactive Compounds and Microbial Growth. Foods 2022, 11, 653. [Google Scholar] [CrossRef] [PubMed]

- Forges, M.; Bardin, M.; Urban, L.; Aarrouf, J.; Charles, F. Impact of UV-C Radiation Applied during Plant Growth on Pre- and Postharvest Disease Sensitivity and Fruit Quality of Strawberry. Plant Dis. 2020, 104, 3239–3247. [Google Scholar] [CrossRef]

- Mditshwa, A.; Magwaza, L.S.; Tesfay, S.Z.; Mbili, N.C. Effect of Ultraviolet Irradiation on Postharvest Quality and Composition of Tomatoes: A Review. J. Food Sci. Technol. 2017, 54, 3025–3035. [Google Scholar] [CrossRef]

- Abdipour, M.; Hosseinifarahi, M.; Naseri, N. Combination Method of UV-B and UV-C Prevents Post-Harvest Decay and Improves Organoleptic Quality of Peach Fruit. Sci. Hortic. 2019, 256, 108564. [Google Scholar] [CrossRef]

- Dyshlyuk, L.; Babich, O.; Prosekov, A.; Ivanova, S.; Pavsky, V.; Chaplygina, T. The Effect of Postharvest Ultraviolet Irradiation on the Content of Antioxidant Compounds and the Activity of Antioxidant Enzymes in Tomato. Heliyon 2020, 6, e03288. [Google Scholar] [CrossRef] [PubMed]

- Kan, J.; Hui, Y.; Lin, X.; Liu, Y.; Jin, C. Postharvest ultraviolet-C Treatment of Peach Fruit: Changes in Transcriptome Profile Focusing on Genes Involved in Softening and Senescence. J. Food Process. Preserv. 2021, 45, e15813. [Google Scholar] [CrossRef]

- Lin, M.G.; Lasekan, O.; Saari, N.; Khairunniza-Bejo, S. The Effect of the Application of Edible Coatings on or before Ultraviolet Treatment on Postharvested Longan Fruits. J. Food Qual. 2017, 2017, 5454263. [Google Scholar] [CrossRef]

- Ng, L.C.; Tan, J.S.; Fauziah, T.A. Efficacy of ultraviolet-c irradiation to suppress fruit decay and retain the postharvest quality of dragon fruit (Hylocereus polyrhizus). MABJ 2022, 51, 119–128. [Google Scholar] [CrossRef]

- Prajapati, U.; Asrey, R.; Varghese, E.; Singh, A.K.; Pal Singh, M. Effects of Postharvest Ultraviolet-C Treatment on Shelf-Life and Quality of Bitter Gourd Fruit during Storage. Food Packag. Shelf Life 2021, 28, 100665. [Google Scholar] [CrossRef]

- Sonntag, F.; Liu, H.; Neugart, S. Nutritional and Physiological Effects of Postharvest UV Radiation on Vegetables: A Review. J. Agric. Food Chem. 2023, 71, 9951–9972. [Google Scholar] [CrossRef] [PubMed]

- Hu, L.; Yang, C.; Zhang, L.; Feng, J.; Xi, W. Effect of Light-Emitting Diodes and Ultraviolet Irradiation on the Soluble Sugar, Organic Acid, and Carotenoid Content of Postharvest Sweet Oranges (Citrus Sinensis (L.) Osbeck). Molecules 2019, 24, 3440. [Google Scholar] [CrossRef]

- Abdipour, M.; Sadat Malekhossini, P.; Hosseinifarahi, M.; Radi, M. Integration of UV Irradiation and Chitosan Coating: A Powerful Treatment for Maintaining the Postharvest Quality of Sweet Cherry Fruit. Sci. Hortic. 2020, 264, 109197. [Google Scholar] [CrossRef]

- Álvaro Fuentes, J.; Lóczy, D.; Thiele-Bruhn, S.; Zornoza Belmonte, R. Handbook of Plant and Soil Analysis for Agricultural Systems; Universidad Politécnica de Cartagena: Cartagena, Spain, 2019; ISBN 978-84-16325-86-3. [Google Scholar]

- Siddiq, M.; Brecht, J.K.; Sidhu, J.S. Handbook of Mango Fruit: Production, Postharvest Science, Processing Technology and Nutrition; Wiley: Chichester, UK, 2017; ISBN 978-1-119-01438-6. [Google Scholar]

- Mir, S.A.; Shah, M.A.; Mir, M.M. (Eds.) Postharvest Biology and Technology of Temperate Fruits; Springer International Publishing: Cham, Switzerland, 2018; ISBN 978-3-319-76842-7. [Google Scholar]

- Paliyath, G.; Subramanian, J.; Lim, L.; Subramanian, K.S.; Handa, A.K.; Mattoo, A.K. (Eds.) Postharvest Biology and Nanotechnology, 1st ed.; Wiley: Chichester, UK, 2018; ISBN 978-1-119-28944-9. [Google Scholar]

- Yahia, E.M.; Carrillo-López, A. Postharvest Physiology and Biochemistry of Fruits and Vegetables; Woodhead Publ: Duxford, UK, 2019; ISBN 978-0-12-813279-1. [Google Scholar]

- Saif, M. Reducing Fruit Quality Losses in Peach Fruits and Increasing Profitability during Postharvest Storage Using Salicylic Acid and Aspirin. Egypt. J. Hortic. 2022, 49, 35–57. [Google Scholar] [CrossRef]

- Florkowski, W.J.; Banks, N.H.; Shewfelt, R.L.; Prussia, S.E. (Eds.) Postharvest Handling: A Systems Approach, 4th ed.; Academic Press: London, UK; San Diego, CA, USA; Cambridge, MA, USA; Kidlington, UK; Oxford, UK, 2022; ISBN 978-0-12-822845-6. [Google Scholar]

- Ahmad, M.S.; Siddiqui, M.W. Postharvest Quality Assurance of Fruits: Practical Approaches for Developing Countries; Springer International Publishing: Cham, Switzerland, 2015; ISBN 978-3-319-21196-1. [Google Scholar]

- Siddiqui, M.W. (Ed.) Eco-Friendly Technology for Postharvest Produce Quality; Academic Press: London, UK; San Diego, CA, USA, 2016; ISBN 978-0-12-804313-4. [Google Scholar]

- Barman, K.; Sharma, S.; Siddiqui, M.W. (Eds.) Emerging Postharvest Treatment of Fruits and Vegetables; Postharvest Biology and Technology Book Series; Apple Academic Press: Oakville, ON, USA; Waretown, NJ, USA, 2019; ISBN 978-1-351-04631-2. [Google Scholar]

- Fallik, E.; Ilic, Z. Pre- and Postharvest Treatments Affecting Flavor Quality of Fruits and Vegetables. In Preharvest Modulation of Postharvest Fruit and Vegetable Quality; Elsevier: Amsterdam, The Netherlands, 2018; pp. 139–168. ISBN 978-0-12-809807-3. [Google Scholar]

- Siddiqui, M.W. (Ed.) Preharvest Modulation of Postharvest Fruit and Vegetable Quality; Elsevier: London, UK; Academic Press: London, UK, 2018; ISBN 978-0-12-809807-3. [Google Scholar]

- Wills, R.B.H.; Golding, J. Advances in Postharvest Fruit and Vegetable Technology; CRC Press: Boca Raton, FL, USA, 2016; ISBN 978-1-4822-1697-4. [Google Scholar]

- Pareek, S. (Ed.) Novel Postharvest Treatments of Fresh Produce; Innovations in Postharvest Technology Series; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: Boca Raton, FL, USA, 2018; ISBN 978-1-4987-2991-8. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).