Abstract

Bacillus pumilus plays a very important role in the biological control of plant diseases. In this study, we conducted indoor biocontrol experiments using the LYMC-3 strain of B. pumilus to assess its efficacy against poplar canker and tea gray blight. Simultaneously, we explored the optimal fermentation conditions for the production of inhibitory substances against Phomopsis macrospora and Pestalotiopsis vesicolor. Subsequently, the inhibitory substances were extracted crudely and subjected to a preliminary investigation of their properties. The results of the indoor biocontrol experiments showed that the LYMC-3 strain exhibited disease prevention rates of 44.12% and 48.59% against poplar canker and tea gray blight, respectively. The fermentation optimization experiment showed that a culture medium containing 10 g/L of glucose, 15 g/L of tryptone, and 5 g/L of sodium chloride favored the production of inhibitory substances via the LYMC-3 strain. Among the crude extracts obtained, the non-protein extracts demonstrated the most obvious inhibitory effects. Furthermore, the inhibitory substances exhibited high polarity, excellent thermal stability, and high sensitivity to strong acids and bases. This study establishes a theoretical foundation for the purification and identification of inhibitory substances using the LYMC-3 strain. Additionally, it contributes to elucidating biological control mechanisms and facilitates the application of the LYMC-3 strain in production.

1. Introduction

Due to the adverse impacts of chemical control, such as environmental pollution and the disruption of the ecological balance, many developed countries and regions worldwide have restricted the use of some toxic chemical reagents in plant disease control [1]. With the global focus on ecological environmental protection, biological control has emerged as the preferred alternative to chemical agents in plant disease control because of its environmentally friendly, sustainable, and long-lasting effects [2]. Numerous studies have demonstrated that Bacillus pumilus is a widely used microorganism in the biological control of plant diseases [3,4], such as chickpea root rot [5], rice blast [6], pine shoot blight [7], pine seedling damping-off disease [8], black rot in strawberries [9], and cucumber wilt [10], etc.

In the realm of microbial preparation research and production, cost reduction is often achieved by employing inexpensive raw materials and enhancing the effectiveness of the fermentation liquid. The improvement of a fermentation broth’s effectiveness necessitates fermentation process technology, which requires a lot of human and material resources to be invested in exploration. Laboratory-based fermentation process optimization typically utilizes one-way tests combined with orthogonal tests to swiftly identify the optimal fermentation medium ratio. Through fermentation optimization, Pan [11] increased the antifungal rate of B. pumilus LYMC-3 against the pathogen of pine shoot blight by 15.84% compared to before optimization. Dai [12] optimized the fermentation conditions of Bacillus pumilus HR10 to achieve an 87.04% inhibition of Sphaeropsis sapinea. Yao [13] optimized the fermentation conditions of Bacillus licheniformis to achieve a final fibrinolytic enzyme activity (FEA) of 2434.45 ± 28.49 IU/mL. Shi [14] significantly enhanced the number of Bacillus velezensis YH-18 fermentation broth spores and enhanced the antifungal ability of the fermentation broth’s de-bacterialized filtrate through optimized design. After optimizing the design, Yu [15] increased the antifungal activity and antagonistic substance production of a Bacillus pumilus BSH-4 fermentation broth by more than three times. In order to enhance the antifungal activity of the Bacillus pumilus LYMC-3 strain against P. macrospora and P. vesicolor and expand its production application, the optimization of its fermentation conditions is very significant.

As an important class of microbial resources, Bacillus has garnered considerable attention. However, scholars from various countries hold different opinions regarding the inhibition mechanism of Bacillus. The physicochemical properties of the LYMC-3 strain are useful for a further understanding of the mechanisms of action and the composition of inhibitory substances. Therefore, this study conducted preliminary research on the physicochemical properties of the LYMC-3 strain.

Preliminary experiments have revealed that the B. pumilus LYMC-3, a strain with a potent antagonistic effect, was isolated from Pinus massoniana stems. It exhibited a broad spectrum of antifungal inhibition and a strong inhibitory effect on the poplar canker pathogen (P. macrospora) and the pine shoot blight pathogen (S. sapinea) [11,16]. It also has strong nematicidal activity against Bursaphelenchus xylophilu, which is the causal agent of pine wilt disease. In order to elucidate the effect of a fermentation broth of B. pumilus LYMC-3 on the control of poplar canker and tea gray blight, this study conducted an indoor biocontrol test of the LYMC-3 stain. The aim was to provide realistic and feasible methods and a theoretical basis for developing the application technology of this strain for the control of P. macrospora and P. vesicolor. Moreover, the study explored the optimal fermentation conditions for producing P. macrospora and P. vesicolor inhibitory substances using a one-way experimental design combined with an orthogonal design to search for a more efficient and cost-effective fermentation condition. This would provide a theoretical basis for the research and development of biofungicides. Subsequently, the physicochemical properties, such as polarity, thermal stability, and acid-base stability, of the inhibitory substances of the B. pumilus LYMC-3 strain were initially explored. This exploration paved the way for the purification and identification of the inhibitory substances at a later stage.

2. Materials and Methods

2.1. Test Strains

A poplar canker pathogen (Phomopsis macrospora) and tea gray blight pathogen (Pestalotiopsis vesicolor) were provided by the Pathology Laboratory of the College of Forestry and Grassland of Nanjing Forestry University.

The Bacillus pumilus LYMC-3 strain was isolated from the stems of P. massoniana at Sui Tang Botanical Gardens in Luoyang, China.

2.2. Culture Media

- Bacterial culture medium (NA): Beef paste, 5 g; peptone, 10 g; sodium chloride, 5 g; agar, 15–20 g; pH 7.2; distilled water, 1 L;

- Bacterial fermentation medium (NB): Beef paste, 5 g; peptone, 10 g; glucose, 10 g; sodium chloride, 5 g; pH 8; distilled water, 1 L;

- Phytopathogenic fungus medium (PDA): Potato, 200 g; glucose, 20 g; agar, 20 g; distilled water, 1 L;

- Seed medium: Peptone, 10 g; glucose, 10 g; NaCl, 10 g; deionized water, 1000 mL; pH 7.0; autoclaved at 121 °C for 20 min.

2.3. Cultivation Method for the Test Strains

2.3.1. LYMC-3 Strain Culture

- (1)

- Seed solution culture

The B. pumilus LYMC-3 strain was inoculated on the NA plate using the plate scribing method [17], and a single colony was selected for purification. The purified single colony was placed into 50 mL of seed medium in 100 mL conical flasks and cultured for 16–24 h with shaking on a constant-temperature shaking incubator at 28 °C and 200 r/min.

- (2)

- Shake flask fermentation culture

A 100 mL conical flask containing 50 mL of the NB medium with 2% inoculum was incubated on a constant-temperature shaking incubator at 28 °C and 200 r/min with shaking for 48 h. Each single-factor and orthogonal test was conducted separately to optimize the fermentation conditions.

- (3)

- Fermentation broth acquisition

The LYMC-3 strain was activated via streaking on an NA plate, and single colonies were selected to be transferred to the NB culture medium. The shake flasks were incubated on a shaker at a constant temperature for 24 h until the logarithmic growth stage was reached to obtain the seed solution (28 °C, 200 r/min). The seed solution was transferred to the bacterial fermentation medium (NB) with an inoculum of 2% by volume and incubated in a shaker for 48 h (28 °C, 200 r/min) for an indoor control effect test.

2.3.2. Culture of Pathogenic Fungi and Preparation of Spore Solution

P. macrospora and P. vesicolor were inoculated in the center of PDA plates. When P. macrospora and P. vesicolor had grown all over the plates, they were placed under a UV light (100 µw/cm2) in the dark to promote spore production The pathogen spores were collected after 7 d. The spores were prepared into a spore solution containing a concentration of approximately 1 × 106 cfu with sterile water.

2.4. Indoor Control Effect Test of Fermentation Broth on Poplar Canker and Tea Gray Blight Disease

2.4.1. Inoculation of Pathogenic Fungi

- (1)

- Inoculation of P. macrospora

Poplar branches and trunks were inoculated using the puncture method [18]. A sterilized inoculation needle was used to create perforations at equal points on the seedling trunks, reaching deep into the xylem. Subsequently, spore liquid was injected into the wounds, and sterile, water-soaked cotton wool was placed to keep the wounds moisturized. Finally, the wounds were wrapped using a sealing film (BKMANLAB).

- (2)

- Inoculation of P. vesicolor

Tea tree seedlings were inoculated using the spore suspension needling method [19]. The tea tree leaves’ surfaces were sterilized with 75% alcohol. Subsequently, the leaves were gently touched with a red-hot inoculation needle to create punctate scalded spots, and the diameter of the initial wound was measured. After the scald treatment, the spore solution was sprayed onto the leaf surface, and the inoculated area was moisturized and treated for 24 h post-inoculation.

2.4.2. Indoor Control Effect Test of Fermentation Broth on Poplar Canker Disease

- (1)

- Experiment on the prevention of poplar canker disease

The fermentation broth was incubated for 48 h and then diluted 2 times for subsequent use. The specific treatments were conducted as follows:

- Irrigation treatment: One week prior to inoculation with the pathogenic fungus, each poplar seedling was irrigated with 100 mL of diluted fermentation broth;

- Coating treatment: One week before the inoculation with the pathogenic fungus, each poplar seedling was coated with 100 mL of diluted fermentation broth. After drying, the coating was repeated three times;

- Root irrigation and coating treatment: One week before the inoculation with the pathogenic fungus, each poplar sapling was inoculated with 50 mL of diluted fermentation broth via root irrigation and was then coated with 50 mL of diluted fermentation broth. After drying, the coating was repeated 3 times.

Each treatment was placed in a greenhouse and inoculated with sterile water as a control with 10 replicates for both the treatment and control groups. The size of the greenhouse is 125 × 85 × 150 cm, and it is covered with polyvinyl chloride. A constant temperature of 28 °C and approximately 60% humidity were maintained within the greenhouse.

- (2)

- Experiment on the treatment of poplar canker disease

After a 2-month period of inoculation with the pathogenic fungus, the fermentation broth incubated for 48 h was utilized and diluted 2 times for subsequent use. The specific treatments remained consistent with those described in Section 2.4.2 (1). Each treatment was then placed within the greenhouse and subjected to inoculation with sterile water as the control. There were 10 replicates for each treatment and control group.

2.4.3. Indoor Control Effect Test of Fermentation Broth on Tea Gray Blight Disease

- (1)

- Preventive test of tea gray blight disease

The fermentation broth, cultured for 48 h and diluted 2 times, was used for the preventive test. The specific treatments were as follows:

- Rooting treatment: The same as that described in Section 2.4.2 (1);

- Spray treatment: Ten tea leaves were selected from each tea sapling one week before inoculation. These tea leaves were sprayed with 50 mL of diluted fermentation broth until they started dripping. After drying, the spraying process was repeated three times;

- Root irrigation and spraying treatment: One week before inoculation, each tea sapling was subjected to root irrigation with 50 mL of diluted fermentation broth. Additionally, ten tea leaves were selected for a spraying treatment, which was repeated three times after drying.

Each treatment was performed in the greenhouse. Sterile water was used as a negative control, and pathogenic fungus alone was used as a positive control. Five replicates were performed for each treatment and control.

- (2)

- Treatment test of tea gray blight disease

One week after inoculation with the pathogenic fungus, the tea tree seedlings were uniformly treated with the fermentation broth cultured for 48 h. Each tea tree seedling was sprayed and left to dry, with the spraying process repeated three times. Inoculation with sterile water was used as the negative control, and only the pathogen was used as the positive control. Five replications were conducted for each treatment and control. Each treatment was performed in the greenhouse. Leaf spot expansion was observed every 3 days, and the size of the spots’ diameter was recorded using a vernier caliper (Guilin Guanglu Measuring Instrument Co., Ltd., Guilin, China).

2.4.4. Investigation of Disease Development

The morbidity following pathogen inoculation was investigated, and the disease index and control effect were calculated. The disease grading standards of poplar canker and tea gray blight disease can be found in Table 1 and Table 2, respectively. The formulas for disease index and control effect were as follows:

Table 1.

Disease grading for poplar inoculated with P. macrospora.

Table 2.

The disease grade of the tea tree inoculated with P. vesicolor.

- Disease index formula: Disease index = 100 × ∑ (number of diseased plants (leaves) at each grade × representative value of each grade)/(total number of plants (leaves) surveyed × representative value of the highest grade);

- Control effect formula: Control effect (%) = 100 × (disease index of control − disease index after treatment)/disease index of control).

2.5. Determination of the Bacterial Biomass and Antifungal Activity of the LYMC-3 Strain

2.5.1. Measurement of Bacterial Biomass

A specific volume of LYMC-3 fermentation broth was measured, and the optical density (OD) value was determined at a wavelength of 600 nm using a spectrophotometer, with an NB medium serving as the control. The biomass of the LYMC-3 strain was quantified using the OD value, for which a high OD value indicated a large amount of bacterial biomass, and vice versa.

2.5.2. Antifungal Activity Assay

- Toxic plate method [20]: PDA medium and bacterial metabolism liquid from decontaminated organisms were thoroughly mixed in a ratio of 4:1 to create a poisoned plate. After the plate solidified and dried, a pathogenic fungus cake (d = 5 mm) was placed at the center of the plate, and the diameter of the pathogenic fungus colony was measured after 4–5 d.

- Inhibition rate (%) [11] = (diameter of control colony − diameter of treated colony) × 100/(diameter of control colony − 5).

2.6. Optimization of the Composition of the Fermentation Medium for Inhibitory Substances

2.6.1. Effects of Different Carbon Sources on the Inhibitory Activity of Antifungal Substances

The carbon sources in the basal medium (NB) were replaced with 5 g/L of maltose, glucose, sucrose, lactose, and mannitol, respectively, to formulate five kinds of media. The medium without a carbon source was used as the control. A 2% seed solution by total volume was added to each of the six media, and after incubation at 28 °C and 200 rpm for 48 h, the metabolite containing antifungal substances was filtered through a 0.22 µm bacterial filter, following centrifugation at 4 °C and 10,000 rpm for 10 min using a refrigerated high-speed centrifuge. The activity of the inhibitory substances in the different carbon source media was detected using the toxic plate method, with the medium without a metabolic solution serving as the control. Three replications were performed.

2.6.2. Effects of Different Nitrogen Sources on the Inhibitory Activity of Antifungal Substances

The nitrogen sources in the basal medium were replaced with tryptone, peptone, potassium nitrate, monarkite, ammonium sulfate, and urea, respectively, to formulate six different nitrogen sources, and the medium without nitrogen sources was used as the control. A 2% seed solution by total volume was added to each of the seven media, and the inhibition rates of strain LYMC-3 against the two pathogenic fungi were determined according to the method described in Section 2.6.1.

2.6.3. Effects of Different Inorganic Salts on the Inhibitory Activity of Antifungal Substances

The inorganic salts in the basal medium were replaced with manganese sulfate, zinc sulfate, potassium dihydrogen phosphate, potassium chloride, sodium chloride, and magnesium chloride, respectively, to formulate six kinds of media containing different inorganic salts, and the medium without inorganic salts was used as the control. A 2% seed solution by total volume was added to each of the seven media, and the inhibition rates of strain LYMC-3 against the two pathogenic fungi were determined according to the method described in Section 2.6.1.

2.6.4. Orthogonal Tests with Different Components of the Culture Medium

Based on the optimal screening results obtained via the aforementioned three experiments and the optimal dosage ranges of each nutrient ingredient derived from the tests, nine sets of orthogonal tests were designed based on Table 3. These tests comprised varying concentrations of the screened optimal ingredients to identify the optimal medium ingredients and their ratios [21].

Table 3.

Orthogonal test table showing three components of the medium.

2.7. Optimization of Culture Conditions for the Fermentation of the Inhibitory Substances

2.7.1. Effects of Different Fermentation Times on the Inhibitory Activity of Antifungal Substances

A 2% LYMC-3 strain seed solution was introduced into 50 mL of the modified medium and incubated under constant conditions at 28 °C and 200 rpm with shaking. The biomass of the bacteria was measured at regular intervals after 12, 24, 36, 48, 60, 72, 84, and 96 h of fermentation incubation. The inhibition rates on P. macrospora and P. vesicolor were determined following the method described in Section 2.6.1.

2.7.2. Effects of Different Temperatures on the Inhibitory Activity of Antifungal Substances

A 2% LYMC-3 strain seed solution was introduced into 50 mL of the modified medium while the other conditions were kept constant. Five temperature gradients (20 °C, 25 °C, 30 °C, 35 °C, and 40 °C) were set using a horizontal shaker operating at a constant speed of 200 rpm. After 48 h of incubation, the OD600 was determined for each temperature gradient. The inhibition rates were assessed following the method described in Section 2.6.1.

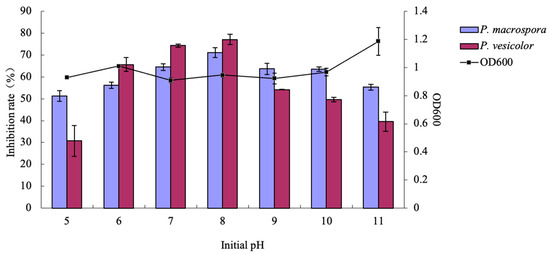

2.7.3. Effects of Different Initial pH Levels on the Inhibitory Activity of Antifungal Substances

A 2% LYMC-3 strain seed solution was introduced into 50 mL of the modified medium, and the pH was adjusted to 5.0, 6.0, 7.0, 8.0, 9.0, 10.0, and 11.0 using sodium hydroxide and hydrochloric acid solutions. The mixture was then incubated for 48 h at 28 °C and 200 rpm, after which OD600 was measured. The inhibition rates were calculated following the method described in Section 2.6.1.

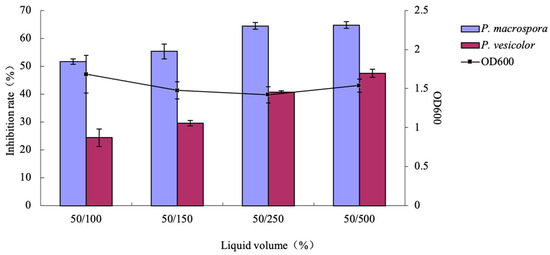

2.7.4. Effects of Different Liquid Volumes on the Inhibitory Activity of Antifungal Substances

Four conical flasks of varying sizes (100 mL, 150 mL, 250 mL, and 500 mL) were utilized to hold 50 mL of the modified medium. A 2% LYMC-3 strain seed liquid was added to each flask, followed by incubation at 28 °C and 200 rpm for 48 h. The OD600 was subsequently measured, and the inhibition rates were calculated following the method described in Section 2.6.1.

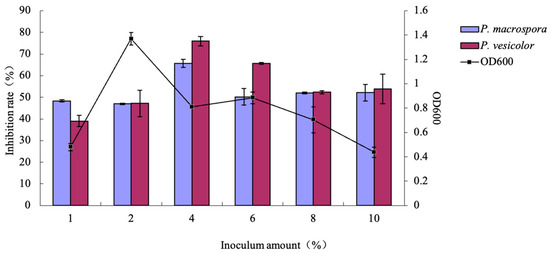

2.7.5. Effects of Different Inoculum Amounts on the Inhibitory Activity of Antifungal Substances

Different concentrations of the seed solution (1%, 2%, 4%, 6%, 8%, and 10%) were introduced to 50 mL of the modified medium. The mixture was incubated in a constant-temperature horizontal shaker at 28 °C and 200 rpm for 48 h. Subsequently, the OD600 was measured using a spectrophotometer. The inhibition rates were calculated following the method described in Section 2.6.1.

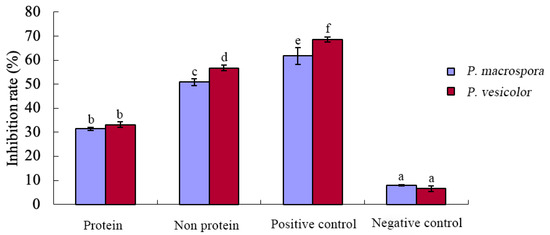

2.8. Determination of Protein and Non-Protein Inhibitory Activities in the Fermentation Filtrate

The anhydrous ethanol precipitation method [22] was employed to separate proteins from non-proteins in the fermentation filtrate. Specifically, 2–3 times the volume of anhydrous ethanol was added to a certain volume of sterilized fermentation filtrate (performed in an ice bath) and stirred slowly for a period of time to allow for the complete precipitation of macromolecular proteins, polysaccharides, and nucleic acids. The mixture was then frozen and centrifuged for 15 min at 2 °C and 5000 r/ min to collect the protein fraction and the non-protein fraction, respectively. The protein fraction was dissolved in deionized water and restored to the original volume. The non-protein fraction was rotary-evaporated at 40 °C for 120 r/min until the ethanol was completely removed, and then deionized water was added, and the original volume was restored. The activity of the inhibitory substances of each fraction was detected using the toxic plate method, with the fermentation filtrate serving as the positive control and the culture medium serving as a negative control. Three replications were performed.

2.9. Preparation of Antifungal Crude Extracts

A certain volume of fermentation filtrate was measured and rotary-evaporated at 50 °C to dryness, and then the evaporated liquid was collected. The dry material was then mixed thoroughly with an appropriate amount of methanol through three slow oscillations. The mixture was centrifuged, and the supernatant fluid was retained. The supernatant fluid was rotary-evaporated to dryness at 40 °C and dissolved in distilled water to the original volume to obtain the antifungal crude extract (methanol extract). The residue after centrifugation (mainly proteins, nucleic acids, polysaccharides, and other macromolecules) was redissolved in distilled water to its original volume. The inhibitory activity of the crude extract (methanol extract), the residue after centrifugation (methanol residue), and the evaporated liquid was determined using the toxic plate method. The fermentation filtrate was used as the positive control, and the NB medium was used as the negative control. Three replications were performed.

2.10. Determination of Antifungal Crude Extract Activity at Different Temperatures

The antifungal crude extracts were subjected to treatments at various temperatures (−20 °C, 0 °C, 20 °C, 40 °C, 60 °C, 80 °C, 100 °C, and 120 °C) for a duration of 1 h. Bacteria present in the filtrate were eliminated using a 0.22 µm bacterial filter. The inhibitory activity of the antifungal crude extracts treated at different temperatures was evaluated using the toxic plate method. The experiment was repeated three times.

2.11. Determination of Antifungal Crude Extract Activity at Different pH Values

The pH value of the inhibition crude extract was adjusted to 4.0, 5.0, 6.0, 7.0, 8.0, 9.0, 10.0, and 11.0 using 1 mol/ L HCl and NaOH solutions, respectively. The inhibitory activity was assessed by treating the inhibition crude extract with P. macrospora and P. vesicolor as the target strains. The experiment was repeated three times with untreated inhibitory substances serving as the positive control and the NB medium as the negative control.

2.12. Solubility of Antifungal Substances in Organic Solvents of Different Polarities

A volume of 20 mL of fermentation filtrate was measured and combined with 40 mL of organic solvents with varying polarities, including ethyl acetate, chloroform, dichloromethane, benzene, n-butanol, and carbon tetrachloride, for extraction. The mixture was vigorously shaken and allowed to stand in a refrigerator at 2 °C for 24 h. Subsequently, the organic and aqueous phases were separated in a separating funnel under a fume hood. The organic solvent was then removed from the organic phase using a rotary evaporator, and the original volume of distilled water was added to obtain an aqueous solution of the organic phase extract. Antifungal activity tests were conducted on the aqueous solutions extracted from the various organic phases with the fermentation filtrate serving as the positive control and the NB culture medium as the negative control. The experiment was repeated three times.

3. Results

3.1. Biological Control of the Fermentation Broth for Poplar Canker Disease in a Greenhouse

3.1.1. Symptoms of the Poplar Seedlings after Inoculation with P. macrospora

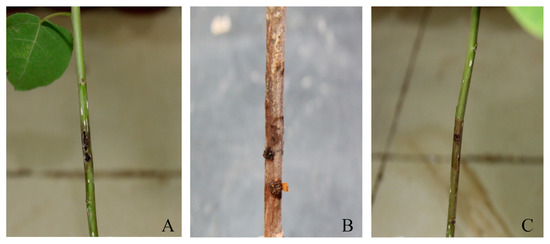

Experiments were conducted in a greenhouse to investigate the control effect of poplar canker disease. After inoculation with P. macrospora, the initial wound of the poplar seedlings became water-stained, followed by the production of small fruit bodies. After a period of time, the bark cracked, and ultimately, the entire plant died (Figure 1).

Figure 1.

Symptoms of poplar seedlings after inoculation with P. macrospora in the greenhouse: (A) the early symptoms; (B) the symptoms at the time of death; (C) the control.

3.1.2. The Preventive Effect of the Fermentation Broth on Poplar Canker Disease in a Greenhouse

Poplar seedlings were treated with the B. pumilus LYMC-3 strain and then inoculated with P. macrospora to investigate the disease’s development after 30 days of inoculation. The fermentation broth was found to have a certain effect on controlling the inoculated P. macrospora, but there were differences in the control effects of different bacterial application methods. As shown in Table 4, the disease index was lower for the 48-h fermentation broth infused into the roots before inoculation than that of the other two treatments, and the prevention effect reached 44.12%.

Table 4.

The preventive effect of the LYMC-3 strain on poplar canker caused by P. macrospora.

3.1.3. The Therapeutic Effect of the Fermentation Broth on Poplar Canker Disease in a Greenhouse

After a 2-month inoculation period for P. macrospora on poplar trees, the fermentation broth incubated for 48 h was employed to assess its efficacy in treating poplar canker disease caused by P. macrospora. As shown in Table 5, the fermentation broth exhibited a certain therapeutic effect on poplar canker disease, with the disease indexes of the treatment groups being lower compared to those of the control group. Among the three treatments, the root irrigation treatment demonstrated the most effective therapeutic effect against canker disease, achieving a therapeutic efficacy of 28.83% for poplar canker disease.

Table 5.

The therapeutic effect of the LYMC-3 strain on poplar canker caused by P. macrospora.

Comprehensively, while an indoor therapeutic effect test could reduce the disease index of poplar seedlings to some extent, their therapeutic effect was lower than that of the indoor preventive effect test. These results indicated that, for the control of poplar canker disease, emphasis should be placed on prevention, with treatment serving as an auxiliary measure. Only in this way can we fully utilize the biological control effect of the LYMC-3 strain on poplar canker disease.

3.2. Biological Control of the Fermentation Broth for Tea Gray Blight Disease in a Greenhouse

3.2.1. Symptoms of the Tea Trees’ Inoculation with P. vesicolor

One week after inoculation with the pathogen, symptoms started to appear on the tea trees. As depicted in Figure 2, during the initial phase of tea gray blight disease, small yellowish-green spots emerged on the tips of the leaves. These spots were subsequently enlarged into irregular brown patches and eventually developed a grayish-white color at the center during a later stage. Gradually, the affected area expanded across the entire leaf, resulting in the shedding of numerous leaves and eventual plant death.

Figure 2.

The symptoms of tea gray blight in the greenhouse: (A) the early symptoms; (B) the late symptoms; (C) the control.

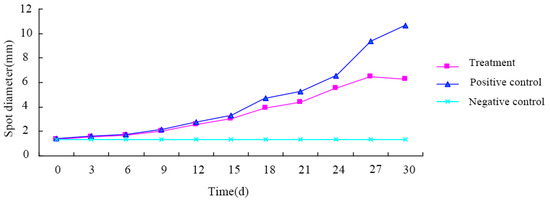

3.2.2. Effect of the Fermentation Broth on the Control of Tea Gray Blight in a Greenhouse

The study’s findings revealed variations in the preventive effects of the three treatments employed for tea gray blight prevention testing. Notably, the treatment involving pre-inoculation spraying of the LYMC-3 strain exhibited a lower disease index compared to that of the other two treatments, demonstrating the most effective preventive outcome at 48.59% (Table 6).

Table 6.

The preventive effect of the fermentation broth on P. vesicolor in a greenhouse.

Following the inoculation of P. vesicolor in tea trees, the fermentation broth incubated for 48 h was utilized for the treatment test against tea gray blight disease caused by the pathogen. As illustrated in Figure 3, the spray treatment with the fermentation broth hindered the expansion of tea gray blight spots after 9 days, and this inhibition effect became more pronounced by day 18. After 30 days, the leaf spots in the treatment group no longer demonstrated any growth when compared to the control group. These observations indicate that the fermentation broth exerts a certain therapeutic effect on tea gray blight spots, making it a potential biocontrol agent for managing such spots.

Figure 3.

Changes in the spot diameter of tea leaf spots after treatment with the fermentation broth.

3.3. Optimization of the Composition of the Fermentation Medium for Inhibitory Substances

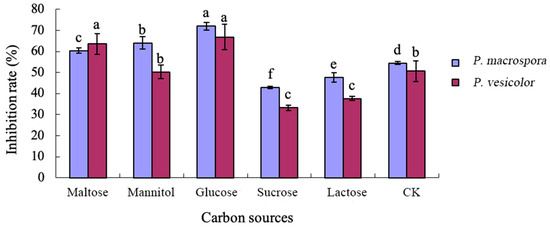

3.3.1. Effect of Different Carbon Sources on the Inhibitory Activity of the Fermentation Broth

The investigation into the influence of carbon sources on the inhibitory activity of the LYMC-3 fermentation broth revealed that the fermentation broth containing five different carbon sources, as well as a carbon-source-free medium, exhibited certain inhibitory activity against both P. macrospora and P. versicolor. Among these, the glucose medium demonstrated the highest inhibitory activity, while the sucrose medium displayed the lowest inhibitory activity. The impact of the carbon source type on the inhibitory activity of the fermentation broth against the two fungi followed a similar pattern. For P. macrospora, the inhibitory activity of the fermentation broth, ranked from high to low, was as follows: glucose, mannitol, maltose, lactose, and sucrose. Similarly, for P. vesicolor, the order of inhibitory activity was as follows: glucose, maltose, mannitol, lactose, and sucrose (Figure 4). The LYMC-3 strain exhibited the highest metabolite inhibitory activity in the glucose-containing medium, with inhibition rates of 72.04% and 66.89% against P. macrospora and P. vesicolor, respectively. In contrast, the inhibitory activity of the sucrose and lactose mediums was even lower than that of the carbon-source-free medium, with inhibition rates below 50% for both. These findings suggest that glucose can be effectively utilized as a carbon source for the modified medium.

Figure 4.

Effects of different carbon source media on the inhibitory activity of the fermentation broth. Means with different letters had significant differences (p < 0.05; Duncan test).

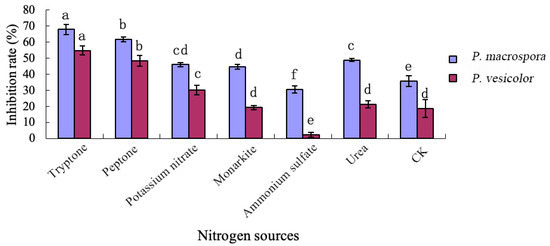

3.3.2. Effect of Different Nitrogen Source Media on the Inhibitory Activity of the Fermentation Broth

The impact of nitrogen sources on the antifungal activity of the fermentation broth is shown in Figure 5. The figure reveals an overall enhancement in inhibitory activity with the utilization of nitrogen sources. Notably, organic nitrogen demonstrated a more substantial effect compared to inorganic nitrogen. Specifically, tryptone exhibited the most potent inhibitory effect among the organic nitrogen sources. P. macrospora and P. vesicolor displayed inhibitory rates of 67.89% and 54.78%, respectively, when exposed to tryptone. Peptone and urea followed, albeit with lesser inhibitory effects. Among the inorganic nitrogen sources, nitrate nitrogen (potassium nitrate and monarkite) proved to be more effective than ammonium nitrogen (ammonium sulfate). Ammonium sulfate exhibited the weakest inhibitory activity among all treatments, with inhibition rates of 30.45% and 2.45% for P. macrospora and P. vesicolor, respectively, which were lower than those observed in the nitrogen-free medium. Consequently, it can be inferred that tryptone may serve as a suitable nitrogen source for the modified medium.

Figure 5.

Effects of different nitrogen source media on the inhibitory activity of the fermentation broth. Means with different letters have significant differences (p < 0.05; Duncan test).

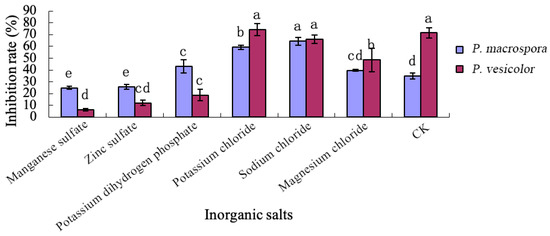

3.3.3. Effects of Different Inorganic Salts on the Inhibitory Activity of the Fermentation Broth

The experimental findings (Figure 6) revealed that the sodium chloride medium exhibited a significant improvement in the inhibition effect of the fermentation broth against P. macrospora, with an impressive inhibition rate of 64.41%. Potassium chloride followed closely as the second most effective medium, displaying an inhibition rate of 59.23%. In contrast, the manganese sulfate and zinc sulfate media demonstrated comparatively weaker effects, with inhibition rates of 24.86% and 25.78% respectively, which were both lower than the inhibition observed in the inorganic salt-free medium.

Figure 6.

Effects of different inorganic salt source media on the inhibitory activity of the fermentation broth. Means with different letters have significant differences (p < 0.05; Duncan test).

Regarding P. vesicolor, the impact of the sodium chloride and potassium chloride media on the antifungal inhibition of the fermentation broth mirrored that of the medium without inorganic salt, showing inhibition rates of 66.16%, 74.34%, and 71.45%, respectively. On the other hand, manganese sulfate exhibited the poorest inhibitory activity among all the treatments, with a mere 6.25% inhibitory rate, which was significantly lower than that of the medium without inorganic salt. These results were notably inferior to those obtained using the medium without inorganic salts. Considering future applications in production, it is recommended to select sodium chloride as the preferred inorganic salt for the modified medium for both pathogenic fungi.

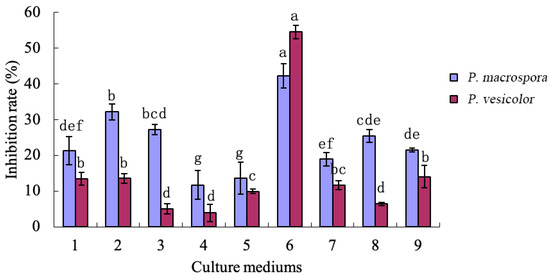

3.3.4. Orthogonal Tests of Medium Composition

Based on the results of the aforementioned experiments, the three factors that influenced the inhibitory activity of the fermentation broth were glucose (A), tryptone (B), and sodium chloride (C). Further optimization was conducted using a 3 × 3 orthogonal table (Table 3), and the results were analyzed using Minitab software (Version 1.5.0, Minitab, State College, PA, USA). The results are presented in Table 7 and Table 8 and Figure 7. For P. macrospora, the factors that had the most significant impact on inhibitory activity were tryptone > sodium chloride > glucose. The optimized combination medium consisted of 5 g/L of glucose, 15 g/L of tryptone, and 5 g/L of sodium chloride. For P. vesicolor, the factors that had the most significant impact on inhibitory activity were sodium chloride > tryptone > glucose. The optimized combination medium consisted of 10 g/L of glucose, 15 g/L of tryptone, and 5 g/L of sodium chloride.

Table 7.

Mean Response Table 1.

Table 8.

Mean Response Table 2.

Figure 7.

Orthogonal test results. Means with different letters have significant differences (p < 0.05; Duncan test). The numbers in the horizontal axis represent 9 treatments shown in Table 3.

3.4. Optimization of Fermentation Medium Conditions for Inhibitory Substances

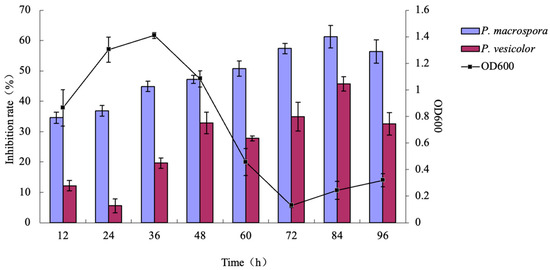

3.4.1. Effect of Fermentation Time on the Inhibitory Activity of the Fermentation Broth

The growth curve of the B. pumilus LYMC-3 strain revealed that, when cultured up to 12 h, the bacterial count began to increase, and it tended to plateau after 24 h, indicating that the strain had entered the growth stabilization period. When cultured for 48 h, the bacterial growth showed a decreasing trend, indicating that the strain began to enter the decay period at 48 h (Figure 8). As shown in Figure 8, the inhibitory activity demonstrated a general trend of increasing and then decreasing, with the maximum inhibitory effect on both pathogens achieved at 84 h of culture time. The inhibitory rates were 61.24% and 45.76%, respectively.

Figure 8.

Effects of different fermentation times on inhibitory activity and growth.

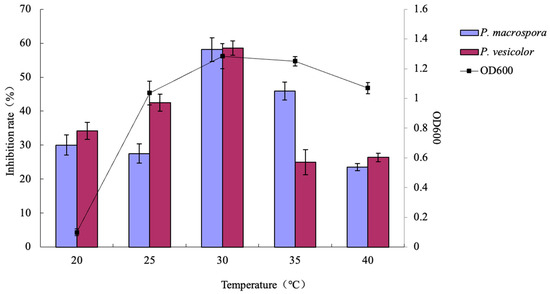

3.4.2. Effect of Fermentation Temperature on the Inhibitory Activity of the Fermentation Broth

The test results indicated that the LYMC-3 strain exhibited favorable growth within the temperature range of 25–40 °C, while it was not suitable for survival in a low-temperature environment (Figure 9). As depicted in Figure 9, within the temperature range of 20–40 °C, the overall trend of the inhibitory activity of the fermentation broth displayed an initial increase, followed by a decrease. The maximum inhibitory effects on both P. macrospora and P. vesicolor were observed at 30 °C, with inhibition rates of 58.16% and 58.52%, respectively.

Figure 9.

Effect of different fermentation temperatures on inhibitory activity and growth.

3.4.3. Effects of Initial pH Values on the Inhibitory Activity of the Fermentation Broth

The test results indicated that the growth of the LYMC-3 strain exhibited a general pattern of initially increasing, reaching a plateau, and then declining when the initial pH ranged from 5 to 11. However, within the initial pH range of 7–9, the growth of this strain remained stable. In highly acidic and alkaline environments, the biomass of the LYMC-3 strain was found to be minimal (Figure 10). Figure 10 demonstrates that the impact of the initial pH value on the inhibitory activity of the fermentation broth showed an increasing trend and then a decreasing trend. Specifically, at an initial pH value of 8, the fermentation broth of this strain exhibited the most potent inhibitory effect against P. macrospora and P. vesicolor, with inhibition rates as high as 71.04% and 77.04%, respectively. Conversely, at an initial pH of 5, the fermentation broth of this strain displayed the weakest inhibitory effect against the two pathogenic fungi, with inhibition rates of 51.33% and 30.73%, respectively.

Figure 10.

Effects of different fermentation initial pH levels on inhibitory activity and growth.

3.4.4. Effect of Inoculum Amount on the Inhibitory Activity of the Fermentation Broth

The test results indicated a trend of increasing and then decreasing biomass for the LYMC-3 strain as the inoculum amount increased. The maximum bacterial biomass and OD600 value of this strain were observed at an inoculum amount of 2% (Figure 11). As depicted in Figure 11, when the inoculum amount was 4%, the fermentation broth exhibited its highest inhibitory effect on both P. macrospora and P. vesicolor, with inhibition rates of 65.68% and 75.97%, respectively. It was found that the optimal growth of the bacteria occurred at an inoculum amount of 2%, suggesting that this amount was suitable for the strain’s growth but not conducive to the production of inhibitory substances.

Figure 11.

Effects of different fermentation inoculum amounts on inhibitory activity and growth.

3.4.5. Effect of Liquid Volume on the Inhibitory Activity of the Fermentation Broth

The test results revealed an increasing trend in the inhibitory effect of the fermentation broth on the two pathogenic fungi as the liquid volume increased, indicating the influence of liquid volume on the production of inhibitory substances using this strain (Figure 12). Concerning the antifungal effect of P. macrospora, no significant difference was observed between the volumes of 100 mL and 150 mL, but significant differences were observed for 250 mL and 500 mL. In terms of the antifungal effect of P. vesicolor, significant differences were observed among the different liquid volumes, with the highest inhibitory activity recorded in the treatment group that had a volume of 500 mL, resulting in an antifungal inhibition rate of 47.46%. This finding further supports the notion that increasing the liquid volume has a certain impact on the production of inhibitory substances. As depicted in Figure 12, the OD600 value of the LYMC-3 strain exhibited minimal changes with the increase in liquid volume, indicating a negligible effect of increasing the liquid volume on the bacteria growth.

Figure 12.

Effects of different fermentation liquid volumes on the inhibitory activity and growth of the fermentation broth.

3.5. Comparison of Protein Fraction Activity with Non-Protein Fraction in the Fermentation Filtrates

The test results (Figure 13) demonstrated that both protein and non-protein extracts exhibited inhibitory activity for both pathogens. However, larger molecules, such as proteins, exhibited lower inhibitory activity compared to the small-molecule non-protein extracts dissolved in ethanol for both P. macrospora and P. vesicolor. In comparison to the positive control’s inhibitory activity, the inhibitory activity of the non-protein extracts was slightly lower, while the inhibitory activity of the protein extracts was less than half. The non-protein extracts displayed inhibitory activity of 50.86% and 56.76% against P. macrospora and P. vesicolor, respectively, whereas the protein extracts exhibited inhibitory activity of 31.44% and 33.15%, respectively. Therefore, among the inhibitory substances present in the fermentation filtrate, the non-protein extracts played a major role in inhibiting the pathogenic fungi.

Figure 13.

Inhibition rates of protein and non-protein extracts from the fermentation filtrates against pathogenic fungi. Means with different letters have significant differences (p < 0.05; Duncan test).

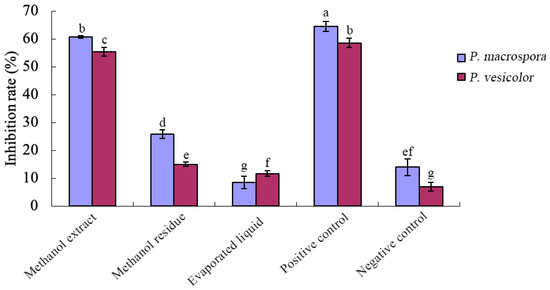

3.6. Inhibitory Activity of Different Extract Fractions from the Fermentation Filtrates

The fermentation filtrate was subjected to methanol crude extraction, resulting in three distinct fractions: methanol extract, methanol residue, and evaporated liquid. The inhibition rates of the three fractions were evaluated, as depicted in Figure 14. The results indicated that the evaporated liquid and methanol residue of the fermentation filtrate exhibited a weak inhibitory effect on the two pathogens. In contrast, only the methanol extract displayed significant inhibitory activity, with inhibition rates of 60.71% and 55.43% against the two pathogens, respectively. The inhibitory effect of the methanol extract from the fermentation filtrate on both P. macrospora and P. vesicolor was comparable to that of the positive control. Notably, the methanol residue solubilizer demonstrated some inhibitory activity against P. macrospora, possibly due to a short resting time and insufficient methanol extraction during the experiment.

Figure 14.

Inhibition rates of different extracts from the fermentation filtrates against pathogenic fungi. Means with different letters have significant differences (p < 0.05; Duncan test).

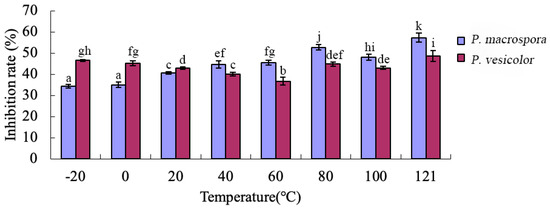

3.7. Effect of Temperature on the Biological Activity of the Inhibitory Substances

The impact of different temperatures on inhibitory substances’ biological activity was investigated (Figure 15). The results revealed that, under various temperature treatments, the inhibitory substances exhibited different effects on the two pathogens, with distinct trends observed as the temperature increased. In the case of P. macrospora, the inhibitory activity displayed a weak upward trend with an increasing temperature, although this increase was not prominent. The highest inhibitory activity of the antifungal substance was observed at a treatment temperature of 121 °C, reaching 57.31%. Conversely, for P. vesicolor, temperature variations did not significantly impact inhibitory activity. The inhibition rate fluctuated within a narrow range, indicating that the inhibitory substances targeting P. vesicolor in the fermentation broth were not sensitive to temperature and exhibited better thermal stability.

Figure 15.

Effect of temperature on the inhibitory activity of antifungal substances. Means with different letters have significant differences (p < 0.05; Duncan test).

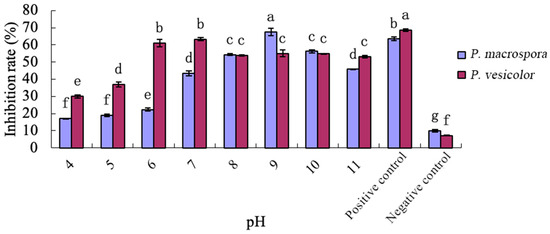

3.8. Effect of pH Value on the Biological Activity of the Inhibitory Substances

The inhibitory effects of the inhibitory substances on the two pathogenic fungi exhibited distinct trends under different pH treatments (Figure 16). Within the pH range of 4–9, the antifungal substances demonstrated an increasing inhibitory activity against P. macrospora as the pH increased. The highest inhibitory activity was observed at pH 9, resulting in an inhibitory rate of 67.42%. Subsequently, the inhibitory activity declined with a further increase in pH. These findings suggest that the inhibitory substances targeting P. macrospora are sensitive to pH and lack resistance against strong acids and bases. In the case of P. vesicolor, the strongest inhibitory activity of the antifungal substances was observed at pH 6–7, followed by a slight decrease at pH 8–11, and the lowest activity was recorded at pH 4–5. This indicates that the inhibitory substances possess a broad adaptability to both acidic and alkaline conditions.

Figure 16.

Effect of pH value on the inhibitory activity of the antifungal substances. Means with different letters have significant differences (p < 0.05; Duncan test).

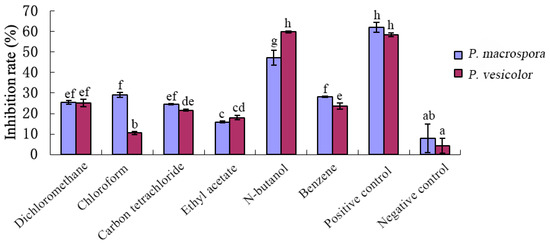

3.9. Solubility of the Inhibitory Substances in Different Organic Solvents

The toxic plate test was employed to assess the antifungal activity of the crude extracts obtained via dichloromethane, chloroform, carbon tetrachloride, ethyl acetate, n-butanol, and benzene. The results indicated the antifungal activity of the crude extracts extracted using the six organic solvents (Figure 17). For P. macrospora, the inhibitory activity was ranked as follows: n-butanol > chloroform = benzene > dichloromethane = carbon tetrachloride > ethyl acetate. The highest amount of inhibitory substances was extracted with n-butanol, with an inhibition rate of 47.33%. In the case of P. vesicolor, the inhibitory activity was ranked as follows: n-butanol > dichloromethane = benzene > carbon tetrachloride > ethyl acetate > chloroform. The most active antifungal crude extract extracted with n-butanol exhibited an inhibition rate of 59.86%. In summary, the antifungal active substances demonstrated strong polarity, indicating that the separation and purification of inhibitory substances in later stages could be achieved using organic solvents of strong polarity.

Figure 17.

Distribution of the inhibitory substances in the different organic solvents. Means with different letters have significant differences (p < 0.05; Duncan test).

4. Discussion

In recent years, biological control has gained increasing popularity due to its environmentally friendly nature. Among the various biocontrol microorganisms that have been researched and developed, biocontrol bacteria to control plant diseases has become a focal point for scholars in the field of biocontrol. In this study, we found that the endophytic bacterium B. pumilus LYMC-3 has certain preventive and therapeutic effects on poplar canker and tea gray blight disease through indoor control effect experiments. For poplar canker, the highest indoor preventive effect reached 44.12%, while the therapeutic effect reached only 28.83%. For tea gray blight, the highest indoor preventive effect was 48.59%, which was slightly higher than the therapeutic effect. These findings suggest that the indoor preventive effect of the B. pumilus strain LYMC-3 is superior to its therapeutic effect, highlighting the importance of emphasizing prevention when applying this strain for the control of poplar canker and tea gray blight. However, it is important to note that this trial had a limited scope, and further improvements in application methods are necessary. Additionally, the potential of this biocontrol bacteria against these two diseases requires further exploration.

The optimization of the fermentation process plays a crucial role in the industrialization of microbial fermentation products, as it ensures their effectiveness as biopesticides. Various experimental techniques and design methods have been employed for fermentation process optimization [23]. The single-factor method is the most traditional approach to optimization. However, due to the complexity of medium composition and fermentation conditions in most fermentation processes, relying solely on the single-factor method may not achieve the desired results. It can increase the workload, prolong the experimental period, and potentially lead to unreliable or incorrect conclusions due to variations in experimental conditions and batches [24]. Moreover, conclusions cannot be drawn about the presence of interactions between factors based solely on the result of a single-factor test. Hence, it is commonly incorporated into an orthogonal test [25]. Therefore, single-factor tests are frequently utilized in conjunction with orthogonal tests or response surface methodology.

The approach of arranging multifactorial experiments with orthogonal tables is referred to as the orthogonal experimental design method. Orthogonal tests have found extensive application in fermentation process optimization. Chen [26] employed the orthogonal test method to optimize the fermentation medium of Streptomyces aureus, resulting in a 16% increase in the demeclocycline yield. Madjirebaye [27] determined that a combination of one-way and orthogonal tests optimized the conditions for fermented soybean milk, leading to an improved flavor and enhanced storage stability. Wu [28] developed a low-cost medium and significantly enhanced the production capacity of fibrinolytic enzymes in Bacillus subtilis WR350 through the utilization of one-way and orthogonal tests, with optimized fibrinolytic activity reaching 5865 U/mL. While the results of the orthogonal test may have aligned with those obtained using the single-factor method, the orthogonal test offers advantages, such as rationality in factor and level section, uniform distribution, the estimation of errors without the need for replicated experiments, and high accuracy [29]. In our study, the fermentation conditions of the LYMC-3 strain were initially investigated via a combination of the single-factor and orthogonal tests. The bacterium was found to be adaptable to a broad temperature range (25–40 °C) but unable to thrive under strong acidic or alkaline environments, with its optimal pH range being 7–10. The optimal fermentation conditions for antifungal substances’ production can be summarized as follows: a culture medium consisting of 10 g/L of glucose, 15 g/L of tryptone, and 5 g/L of sodium chloride; an initial pH of 8; a 10% liquid volume; a 4% inoculum amount; and a shaking culture at 30 °C for 84 h.

Through the crude isolation of inhibitory substances in the fermentation broth and the preliminary study of their properties, it was determined that these substances belonged to a class of small, strongly polar non-protein molecules. They exhibited good thermal stability but were sensitive to acid and alkali, with their inhibitory activity significantly reduced under strong acidic and alkaline conditions. Various organic solvents were employed for the extraction of these non-protein antifungal substances. Methanol extraction yielded crude antifungal substances that displayed a notable inhibitory effect on P. macrospora, while n-butanol extraction resulted in crude substances with a strong inhibitory effect on t P. vesicolor. Lin [30] discovered that the anti-Listeria substance produced via Bacillus amyloliquefaciens maintains stable activity across a wide pH and temperature range. Lei [31] compared the inhibition substance of Lactobacillus plantarum zrx03′s inhibition substance extracted using different organic solvents (such as n-butanol, n-hexane, dichloromethane, and trichloromethane) and ultimately determined that ethyl acetate was the optimal solution for crude extraction.

Pan [32] extracted and purified the inhibition substance from Bacillus megaterium L2 and identified it as a non-protein phenylacetic acid (PAA) that antagonized Agrobacterium tumefaciens. Furthermore, PAA exerted its antifungal activity by disrupting cell membrane integrity and cell ultrastructure. Tian [33] demonstrated that Talaromyces purpurogenus Q2 effectively reduced the relative tolerance of Fusarium oxysporum by secreting cell wall degrading enzymes, thereby achieving excellent biological control effects on Fusarium wilt. It has been hypothesized that the main disease prevention mechanism of LYMC-3 involves the following: (1) the production of antagonistic substances (non-protein antimicrobial substances), which may play a significant role in disease prevention; (2) the competition for space and nutrition with pathogenic fungus. The LYMC-3 strain exhibits a vigorous growth ability in comparison to other microorganisms that inhabit the same environment. This characteristic enables the strain to rapidly acquire the resources needed for growth and reproduction, consequently impeding the proliferation of pathogenic fungi. However, it is important to note that disease prevention may be influenced by various factors, such as induced host resistance. In conclusion, the control mechanism employed by the LYMC-3 strain to combat poplar canker and tea gray blight encompasses multiple factors, necessitating further investigations into its intricate nature. Additionally, the specific substances inhibiting fungal growth also warrant further exploration.

5. Conclusions

In this study, we conducted an indoor biocontrol test on the B. pumilus LYMC-3 strain and found that its fermentation broth exhibited the highest indoor preventive efficacy of 44.12% against poplar canker and 48.59% against tea gray blight. Subsequently, we optimized the growth conditions of the LYMC-3 strain and the fermentation conditions of inhibitory substances using a single-way test combined with an orthogonal design. Our results indicated that a medium consisting of 10 g/L of glucose, 15 g/L of tryptone, and 5 g/L of sodium chloride was conducive to the production of inhibitory substances via strain LYMC-3. Moreover, a culture medium with a shaking cultivation temperature of 30 °C, a cultivation time of 84 h, an initial pH of 8.0, a 10% liquid volume, and a 4% inoculum amount was found to be suitable for the production of inhibitory substances using strain LYMC-3. Finally, we crudely extracted the inhibitory substances from the fermentation broth and preliminarily investigated their properties. Our findings indicate that the non-protein extracts exhibited a notable inhibitory effect on P. macrospora and P. vesicolor. Additionally, the inhibitory substances displayed strong polarity and good thermal stability, and they were more sensitive to strong acidic or strong alkaline environments.

Author Contributions

Conceptualization, M.P. and M.Z.; methodology, J.T.; software, M.Z.; validation, M.P., M.Z. and H.J.; formal analysis, M.P.; investigation, M.P. and M.Z.; resources, H.J. and X.Z.; data curation, M.P. and M.Z.; writing—original draft preparation, M.P. and M.Z.; writing—review and editing, M.P.; visualization, M.Z.; supervision, J.T.; project administration, J.T.; funding acquisition, J.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Key Research and Development Program of China (2021YFD1400300).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Fernando, W.G.D.; Nakkeeran, S.; Zhang, Y.; Savchuk, S. Biological control of Sclerotinia sclerotiorum (Lib.) de Bary by Pseudomonas and Bacillus species on canola petals. Crop Prot. 2007, 26, 100–107. [Google Scholar] [CrossRef]

- Alabouvette, C.; Olivain, C.; Migheli, Q.; Steinberg, C. Microbiological control of soil-borne phytopathogenic fungi with special emphasis on wilt-inducing Fusarium oxysporum. New Phytol. 2009, 184, 529–544. [Google Scholar] [CrossRef] [PubMed]

- Jakub, D.; Zuzanna, J.; Iryna, K.; Paweł, K.; Karol, K. Biocontrol of fungal phytopathogens by Bacillus pumilus. Front. Microbiol. 2023, 14, 1194606. [Google Scholar] [CrossRef]

- Agarwal, M.; Dheeman, S.; Dubey, R.C.; Kumar, P.; Maheshwari, D.K.; Bajpai, V.K. Differential antagonistic responses of Bacillus pumilus MSUA3 against Rhizoctonia solani and Fusarium oxysporum causing fungal diseases in Fagopyrum esculentum Moench. Microbiol. Res. 2017, 205, 40–47. [Google Scholar] [CrossRef]

- Akhtar, M.S.; Siddiqui, Z.A. Glomus intraradices, Pseudomonas alcaligenes, and Bacillus pumilus: Effective agents for the control of root-rot disease complex of chickpea (Cicer arietinum L.). J. Gen. Plant Pathol. 2007, 74, 53–60. [Google Scholar] [CrossRef]

- Sha, Y.X.; Zeng, Q.C.; Sui, S.T. Screening and application of Bacillus strains isolated from nonrhizospheric rice soil for the biocontrol of rice blast. Plant Pathol. J. 2020, 36, 231–243. [Google Scholar] [CrossRef]

- Dai, Y.; Wu, X.Q.; Wang, Y.H.; Zhu, M.L. Biocontrol potential of Bacillus pumilus HR10 against Sphaeropsis shoot blight disease of pine. Biol. Control 2021, 152, 104458. [Google Scholar] [CrossRef]

- Zhu, M.L.; Wu, X.Q.; Wang, Y.H.; Dai, Y. Role of biofilm formation by Bacillus pumilus HR10 in biocontrol against pine seedling damping-off disease caused by Rhizoctonia solani. Forests 2020, 11, 652. [Google Scholar] [CrossRef]

- Abd-El-Kareem, F.; Elshahawy, I.E.; Abd-Elgawad, M.M.M. Application of Bacillus pumilus isolates for management of black rot disease in strawberry. Egypt. J. Biol. Pest Control 2021, 31, 25. [Google Scholar] [CrossRef]

- Huang, X.Q.; Zhang, N.; Yong, X.Y.; Yang, X.M.; Shen, Q.R. Biocontrol of Rhizoctonia solani damping-off disease in cucumber with Bacillus pumilus SQR-N43. Microbiol. Res. 2011, 167, 135–143. [Google Scholar] [CrossRef]

- Pan, M.; Wang, Y.R.; Tan, J.J.; Liu, F.; Hu, J.F. Optimization of fermentation conditions for Bacillus pumilus LYMC-3 to antagonize Sphaeropsis sapinea. Fermentation 2023, 9, 482. [Google Scholar] [CrossRef]

- Dai, Y.; Wang, Y.H.; Li, M.; Zhu, M.L.; Wen, T.Y.; Wu, X.Q. Medium optimization to analyze the protein composition of Bacillus pumilus HR10 antagonizing Sphaeropsis sapinea. AMB Express 2022, 12, 61. [Google Scholar] [CrossRef] [PubMed]

- Jing, Y.M.; Min, M.C.; Xin, B.; Yang, Y.; Yue, X.; Yan, W.Q.; Yu, X.X.; Lu, L.L.; Na, Z.; Jun, T.Y. Isolation and optimal fermentation conditions of Bacillus licheniformis SFD-Y5 for new douchi fibrinolytic enzyme producer. Fermentation 2023, 9, 668. [Google Scholar]

- Shi, H.M.; Ye, J.R.; Wang, Y.; Lu, L.X.; Shi, J.W. Optimizing spore-producing medium and culture conditions of Bacillus velezensis strain YH-18 by response surface methodology. J. Nanjing For. Univ. (Nat. Sci. Ed.) 2023, 47, 209–218. [Google Scholar] [CrossRef]

- Yu, T. Partial Characterization and Isolation of Antifungal Protein from Bacillas pumilus BSH-4 Strain. Master’s Thesis, Shandong Agricultural University, Taian, China, 2009. Available online: https://kns.cnki.net/reader/review?invoice=u%2BRyDoNXgts%2BBUzQ7oHgqa08K2diVHclBowVUv%2BeG6jiCWp5Eoj1p1eHj83PVpQCRBmjUeGpwiZhrAPcv9NBcUFYa64LnyxiWa2TVRwenQxDvDxemEFcOwes%2FeKPVYZWDVq4V1ROntTob5rkM85eRuHiISSKEmHckncuI3%2F4prA%3D&platform=NZKPT&product=CMFD&filename=2009234268.nh&tablename=cmfd2010&type=DISSERTATION&scope=trial&cflag=overlay&dflag=&pages=&language=chs&trial=&nonce=4883144F67A445DD8253EED64E19B3C6 (accessed on 11 September 2023).

- Pan, M.; Zhu, M.L.; Tan, J.J.; Li, L.L.; Hao, D.J. The antagonism of Bacillus pumilus LYMC-3 strain on Phomopsis macrospora. J. Nanjing For. Univ. (Nat. Sci. Ed.) 2022, 46, 151–156. [Google Scholar] [CrossRef]

- Amann, R.I.; Ludwig, W.; Schleifer, K.H. Phylogenetic identification and in situ detection of individual microbial cells without cultivation. Microbiol. Rev. 1995, 59, 143–169. [Google Scholar] [CrossRef]

- Li, L.-m.; Zheng, T.; Chen, Y.; Sui, Y.; Ding, R.; Hou, L.; Zheng, F.; Zhu, C. The antagonistic mechanisms of Streptomyces sioyaensis on the growth and metabolism of poplar canker pathogen Valsa sordida. Biol. Control 2020, 151, 104392. [Google Scholar] [CrossRef]

- Saleh Ahmed, S.; Abdul Omar, N.-S.; Masratul Hawa, M. Neopestalotiopsis clavispora and Pseudopestalotiopsis camelliae-sinensis causing grey blight disease of tea (Camellia sinensis) in Malaysia. Eur. J. Plant Pathol. 2021, 162, 709–724. [Google Scholar] [CrossRef]

- Liu, J.; Li, X.; Yang, Y.; Wei, H.; Xue, L.; Min, Z.; Jinxiu, C. Optimization of combined microwave and hot air drying technology for purple cabbage by Response Surface Methodology (RSM). Food Sci. Nutr. 2021, 87, 2980–2998. [Google Scholar] [CrossRef]

- Xu, G.; Gong, X.; Yu, Y.; Chen, X. A rapid method for the determination of SBS content based on the principle of orthogonal testing. Appl. Sci. 2021, 11, 10911. [Google Scholar] [CrossRef]

- Lawton, J.W. Isolation of zein using 100% ethanol. Cereal Chem. 2006, 83, 455–575. [Google Scholar] [CrossRef]

- Ahuja, S.K.; Ferreira, G.M.; Moreira, A.R. Application of Plackett-Burman design and response surface methodology to achieve exponential growth for aggregated shipworm bacterium. Biotechnol. Bioeng. 2004, 85, 666–675. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.Z.; Xiong, Y.H.; Weng, L.P.; Ji, L.N. Bioprocess opimization. J. Sun Yat-sen Univ. (Nat. Sci. Ed.) 2002, 41, 132–136. [Google Scholar]

- Sigal, I.A.; Whyne, C.M. Mesh morphing and response surface analysis: Quantifying sensitivity of vertebral mechanical behavior. Ann. Biomed. Eng. 2009, 38, 41–56. [Google Scholar] [CrossRef]

- Chen, L.J. Breeding of Demethylchlortetracycline producting mutant and studying udder fermentation conditions. Strait Pharm. J. 2010, 22, 203–304. Available online: https://kns.cnki.net/KXReader/Detail?invoice=kZmDyWd4f7A1SibyyU98Y2v10ka1oSK%2BPUIBJvcoZeoOolPA%2BRhcIPieLtYqKxb5fwg6lz6B1MH6edqO3%2Fl7ZiIJ%2FBK77R%2F7%2FVY6C8BzFQWn%2BeDMIz1csUvjtTbQ87vxP7JD7UUbnHDuOwNpIYbIznkvGNyIDjbkMzc3Cm09HH4%3D&DBCODE=CJFD&FileName=HAIX201009115&TABLEName=cjfd2010&nonce=50D0276401604C20A76E8F91A580863F&TIMESTAMP=1694836592327&uid= (accessed on 13 September 2023).

- Madjirebaye, P.; Peng, F.; Huang, T.; Zhang Gen, L.; Mueed, A.; Pahane, M.M.; Guan, Q.Q.; Xiao, M.; Du, T.H.; Wei, B.L.; et al. Effects of fermentation conditions on bioactive substances in lactic acid bacteria-fermented soymilk and its storage stability assessment. Food Biosci. 2022, 50, 102207. [Google Scholar] [CrossRef]

- Wu, R.; Chen, G.G.; Pan, S.H.; Zeng, J.J.; Liang, Z.Q. Cost-effective fibrinolytic enzyme production by Bacillus subtilis WR350 using medium supplemented with corn steep powder and sucrose. Sci. Rep. 2019, 9, 6824. [Google Scholar] [CrossRef]

- Saudagar, P.S.; Singhal, R.S. Optimization of nutritional requirements and feeding strategies for clavulanic acid production by Streptomyces clavuligerus. Bioresour. Technol. 2006, 98, 2010–2017. [Google Scholar] [CrossRef]

- Lin, L.-Z.; Zheng, Q.-W.; Wei, T.; Zhang, Z.-Q.; Zhao, C.-F.; Zhong, H.; Xu, Q.-Y.; Lin, J.-F.; Guo, L.-Q. Isolation and characterization of fengycins produced by Bacillus amyloliquefaciens JFL21 and its broad-spectrum antimicrobial potential against multidrug-resistant foodborne pathogens. Front. Microbiol. 2020, 11, 579621. [Google Scholar] [CrossRef]

- Lei, S.; Zhao, R.; Sun, J.; Ran, J.; Ruan, X.; Zhu, Y. Partial purification and characterization of a broad-spectrum bacteriocin produced by a Lactobacillus plantarum zrx03 isolated from infant’s feces. Food Sci. Nutr. 2020, 8, 2214–2222. [Google Scholar] [CrossRef]

- Pan, H.; Xiao, Y.; Xie, A.; Li, Z.; Ding, H.; Yuan, X.; Sun, R.; Peng, Q. The antibacterial mechanism of phenylacetic acid isolated from Bacillus megaterium L2 against Agrobacterium tumefaciens. PeerJ 2022, 10, e14304. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Zhao, Y.; Fu, X.; Yu, C.; Gao, K.; Liu, H. Isolation and identification of Talaromyces sp. strain Q2 and its biocontrol mechanisms involved in the control of Fusarium Wilt. Front. Microbiol. 2021, 12, 724842. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).