The Quality and Flavor Changes of Different Soymilk and Milk Mixtures Fermented Products during Storage

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Preparation of Soymilk and Milk

2.2.2. Preparation of Fermented Soymilk and Milk Mixtures

2.2.3. Physicochemical Analysis

2.2.4. Microbiological Analysis

2.2.5. Volatile Aromatic Compound Analyses

2.2.6. Sensory Analysis

2.2.7. Textural Properties

2.2.8. Rheological Properties

2.3. Statistical Analyses

3. Results and Discussion

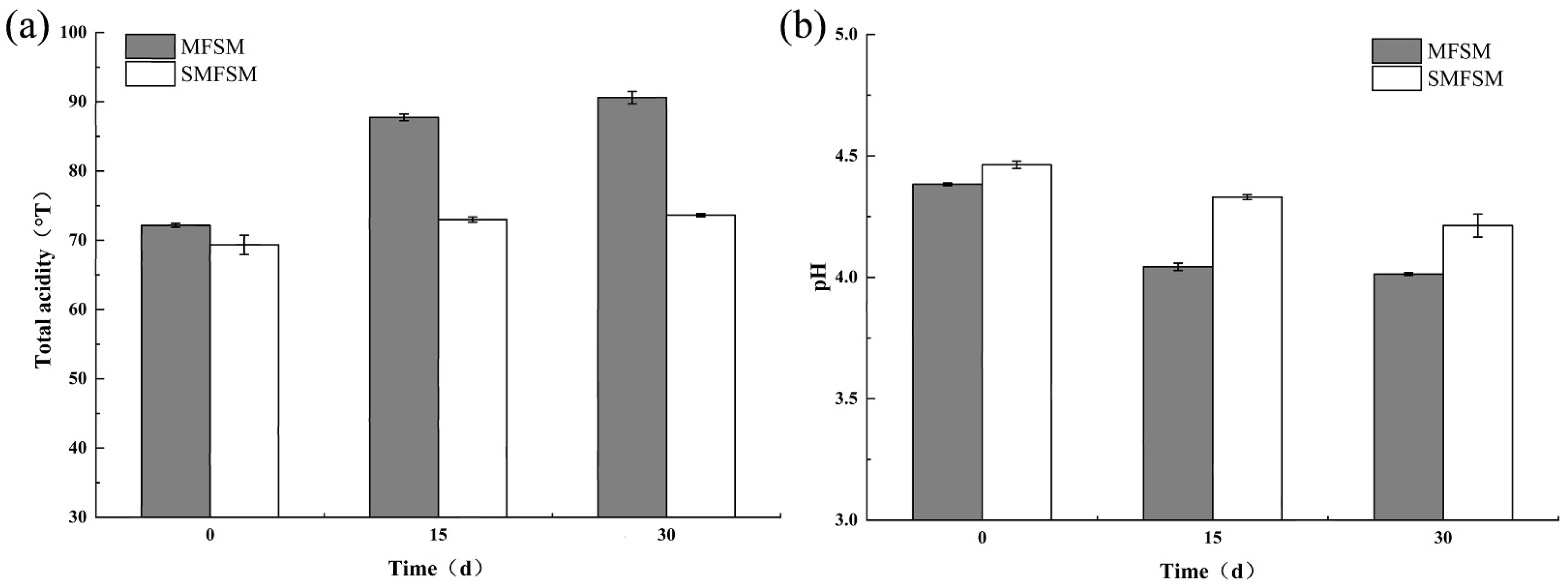

3.1. Acidity and pH of Fermented Soymilk during Storage

3.2. Microbiology of Fermented Soymilk during Storage

3.3. Viscosity and Water-Holding Capacity of Fermented Soymilk during Storage

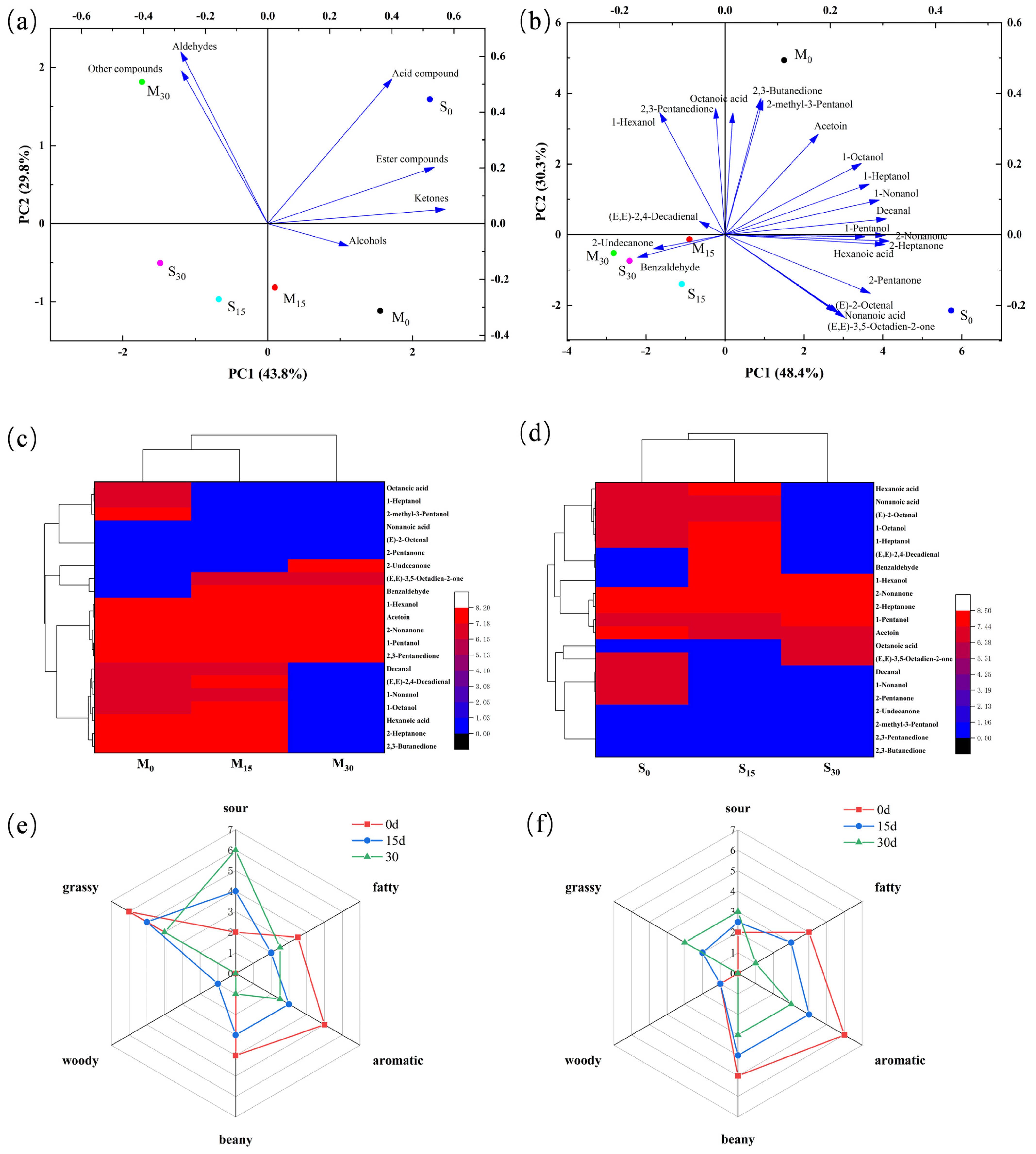

3.4. Changes of Volatile Components during Storage

3.5. Principal Component Analysis, Cluster Analysis and Sensory Analysis

3.6. Textural Properties

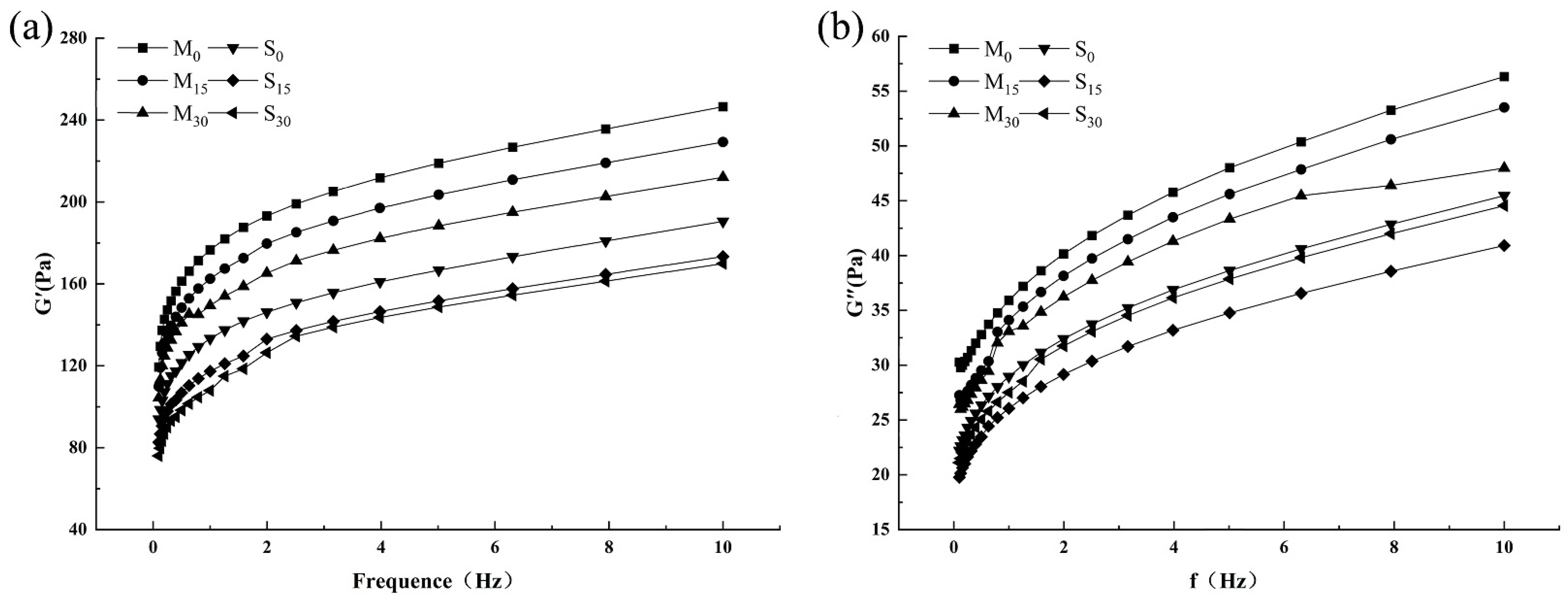

3.7. Rheological Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kumari, M.; Kokkiligadda, A.; Dasriya, V.; Naithani, H. Functional relevance and health benefits of soymilk fermented by lactic acid bacteria. J. Appl. Microbiol. 2022, 133, 104–119. [Google Scholar] [CrossRef]

- Kumari, M.; Patel, H.K.; Kokkiligadda, A.; Bhushan, B.; Tomar, S.K. Characterization of probiotic lactobacilli and development of fermented soymilk with improved technological properties. LWT 2022, 154, 112827. [Google Scholar] [CrossRef]

- Wan, J.; Ningtyas, D.W.; Bhandari, B.; Liu, C.; Prakash, S. Oral perception of the textural and flavor characteristics of soy-cow blended emulsions. J. Texture Stud. 2022, 53, 108–121. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Guo, H.; Wu, A.; Ju, C.; Jiang, J.; Chen, J. Multiple-strain Lactobacillus-fermented soymilk with antioxidant capacity and delicate flavour. Int. J. Food Sci. Technol. 2021, 56, 6052–6061. [Google Scholar] [CrossRef]

- Zheng, Y.; Fei, Y.; Yang, Y.; Jin, Z.; Yu, B.; Li, L. A potential flavor culture: Lactobacillus harbinensis M1 improves the organoleptic quality of fermented soymilk by high production of 2,3-butanedione and acetoin. Food Microbiol. 2020, 91, 103540. [Google Scholar] [CrossRef]

- Almghawesh, E.; Slik, S.; Okkou, H. Processing of Functional Yoghurt-Like Product from Soymilk Supplemented by Probiotics. Int. J. Food Sci. 2022, 2022, 5898537. [Google Scholar] [CrossRef] [PubMed]

- Ahsan, S.; Khaliq, A.; Chughtai, M.F.J.; Nadeem, M.; Tahir, A.B.; Din, A.A.; Ntsefong, G.N.; Shariati, M.A.; Rebezov, M.; Yessimbekov, Z.; et al. Technofunctional quality assessment of soymilk fermented with Lactobacillus acidophilus and Lactobacillus casei. Biotechnol. Appl. Biochem. 2022, 69, 172–182. [Google Scholar] [CrossRef] [PubMed]

- Yilmaz-Ersan, L.; Topcuoglu, E. Evaluation of instrumental and sensory measurements using multivariate analysis in probiotic yogurt enriched with almond milk. J. Food Sci. Technol. 2022, 59, 133–143. [Google Scholar] [CrossRef]

- Li, S.; Tang, S.; He, Q.; Gong, J.; Hu, J. Physicochemical, textural and volatile characteristics of fermented milk co-cultured with Streptococcus thermophilus, Bifidobacterium animalis or Lactobacillus plantarum. Int. J. Food Sci. Technol. 2019, 55, 461–474. [Google Scholar] [CrossRef]

- Sertovic, E.; Saric, Z.; Barac, M.; Barukcic, I.; Kostic, A.; Bozanic, R. Physical, Chemical, Microbiological and Sensory Characteristics of a Probiotic Beverage Produced from Different Mixtures of Cow’s Milk and Soy Beverage by Lactobacillus acidophilus La5 and Yoghurt Culture. Food Technol. Biotechnol. 2019, 57, 461–471. [Google Scholar] [CrossRef]

- Fatima, S.M.; Hekmat, S. Microbial and Sensory Analysis of Soy and Cow Milk-Based Yogurt as a Probiotic Matrix for Lactobacillus rhamnosus GR-1. Fermentation 2020, 6, 74. [Google Scholar] [CrossRef]

- Huang, M.L.; Huang, J.Y.; Kao, C.Y.; Fang, T.J. Fermented soymilk and soy and cow milk mixture, supplemented with orange peel fiber or Tremella flava fermented powder as prebiotics for high exopolysaccharide-producing Lactobacillus pentosus SLC 13. J. Sci. Food Agric. 2019, 99, 4373–4382. [Google Scholar] [CrossRef] [PubMed]

- Mishra, S.; Mishra, H. Comparative study of the synbiotic effect of inulin and fructooligosaccharide with probiotics with regard to the various properties of fermented soy milk. Food Sci. Technol. Int. 2018, 24, 564–575. [Google Scholar] [CrossRef] [PubMed]

- Cui, L.; Chang, S.K.C.; Nannapaneni, R. Comparative studies on the effect of probiotic additions on the physicochemical and microbiological properties of yoghurt made from soymilk and cow’s milk during refrigeration storage (R2). Food Control 2021, 119, 107474. [Google Scholar] [CrossRef]

- Dan, T.; Ren, W.; Liu, Y.; Tian, J.; Chen, H.; Li, T.; Liu, W. Volatile Flavor Compounds Profile and Fermentation Characteristics of Milk Fermented by Lactobacillus delbrueckii subsp. bulgaricus. Front. Microbiol. 2019, 10, 2183. [Google Scholar] [CrossRef]

- Yi, C.; Li, Y.; Zhu, H.; Liu, Y.; Quan, K. Effect of Lactobacillus plantarum fermentation on the volatile flavors of mung beans. LWT 2021, 146, 111434. [Google Scholar] [CrossRef]

- Cao, J.; Yu, L.; Zhao, J.; Zhang, H.; Chen, W.; Zhai, Q. Genomic analysis of B. coagulans ATCC 7050T reveals its adaption to fermented milk as an adjunct starter culture for yogurt. LWT 2022, 154, 112721. [Google Scholar] [CrossRef]

- Ayyash, M.; Abdalla, A.; Abu-Jdayil, B.; Huppertz, T.; Bhaskaracharya, R.; Al-Mardeai, S.; Mairpady, A.; Ranasinghe, A.; Al-Nabulsi, A. Rheological properties of fermented milk from heated and high pressure-treated camel milk and bovine milk. LWT 2022, 156, 113029. [Google Scholar] [CrossRef]

- Cao, J.; Yu, Z.; Zhang, Q.; Yu, L.; Zhao, J.; Zhang, H.; Chen, W.; Zhai, Q. Effects of Bacillus coagulans GBI-30, 6086 as an adjunct starter culture on the production of yogurt. Food Res. Int. 2022, 160, 111398. [Google Scholar] [CrossRef]

- Sieuwerts, S.; de Bok, F.A.; Hugenholtz, J.; van Hylckama Vlieg, J.E. Unraveling microbial interactions in food fermentations: From classical to genomics approaches. Appl. Environ. Microbiol. 2008, 74, 4997–5007. [Google Scholar] [CrossRef]

- Hou, B.; Wang, H.; Yan, T.; Shan, Y.; Zhou, W.; Zhang, L.; Man, C.; Deng, Y.; Jiang, Y. Production for High-vitality Starter Culture of Lactobacillus plantarum NDC 75017 by High Cell-density Cultivation and Low-temperature Vacuum Drying. Food Sci. Technol. Res. 2016, 22, 519–527. [Google Scholar] [CrossRef][Green Version]

- Bulut, M.; Adal, E.; Aktar, T. Plant protein enrichment effect on the physical, chemical, microbiological, and sensory characteristics of yogurt. J. Food Process. Preserv. 2022, 46, e16865. [Google Scholar] [CrossRef]

- Temiz, H.; Çakmak, E. The effect of microbial transglutaminase on probiotic fermented milk produced using a mixture of bovine milk and soy drink. Int. J. Dairy Technol. 2018, 71, 906–920. [Google Scholar] [CrossRef]

- Yue, Y.; Wang, S.; Lv, X.; Wang, C.; Xu, B.; Ping, L.; Guo, J.; Li, X.; Evivie, S.E.; Liu, F.; et al. Analysis of the complete genome sequence of Lactobacillus delbrueckii ssp. bulgaricus with post-acidification capacity and its influence on yogurt in storage. J. Dairy Sci. 2022, 105, 1058–1071. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Singh, M.; Bhargava, K.; Ramanathan, R. Yogurt Fortification with Chickpea (Cicer arietinum) Flour: Physicochemical and Sensory Effects. J. Am. Oil Chem. Soc. 2018, 95, 1041–1048. [Google Scholar] [CrossRef]

- Arena, M.P.; Caggianiello, G.; Russo, P.; Albenzio, M.; Massa, S.; Fiocco, D.; Capozzi, V.; Spano, G. Functional Starters for Functional Yogurt. Foods 2015, 4, 15–33. [Google Scholar] [CrossRef]

- Brodziak, A.; Krol, J.; Barlowska, J.; Teter, A.; Florek, M. Changes in the Physicochemical Parameters of Yoghurts with Added Whey Protein in Relation to the Starter Bacteria Strains and Storage Time. Animals 2020, 10, 1350. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, K.; Jin, J.; Safian Murad, M.; Mu, G.; Wu, X. Comparison on properties between normal and A2 bovine milk fermented using commercial bacteria mixed with/without two probiotics from human milk. Int. J. Biol. Macromol. 2022, 216, 105–113. [Google Scholar] [CrossRef]

- Grygorczyk, A.; Duizer, L.; Lesschaeve, I.; Corredig, M. Gelation of recombined soymilk and cow’s milk gels: Effect of homogenization order and mode of gelation on microstructure and texture of the final matrix. Food Hydrocoll. 2014, 35, 69–77. [Google Scholar] [CrossRef]

- Barakat, H.; Mohamed, A.; Gemiel, D.G.; Atallah, A.A. Microstructural, Volatile Compounds, Microbiological and Organoleptical Characteristics of Low-Fat Buffalo Milk Yogurt Enriched with Whey Protein Concentrate and Ca-Caseinate during Cold Storage. Fermentation 2021, 7, 250. [Google Scholar] [CrossRef]

- Zhang, C.; Hua, Y.; Li, X.; Kong, X.; Chen, Y. Key volatile off-flavor compounds in peas (Pisum sativum L.) and their relations with the endogenous precursors and enzymes using soybean (Glycine max) as a reference. Food Chem. 2020, 333, 127469. [Google Scholar] [CrossRef] [PubMed]

- Du, H.; Yang, H.; Wang, X.; Zhu, F.; Tang, D.; Cheng, J.; Liu, X. Effects of mulberry pomace on physicochemical and textural properties of stirred-type flavored yogurt. J. Dairy Sci. 2021, 104, 12403–12414. [Google Scholar] [CrossRef] [PubMed]

- Xia, J.; Zu, Q.; Yang, A.; Wu, Z.; Li, X.; Tong, P.; Yuan, J.; Wu, Y.; Fan, Q.; Chen, H. Allergenicity reduction and rheology property of Lactobacillus-fermented soymilk. J. Sci. Food Agric. 2019, 99, 6841–6849. [Google Scholar] [CrossRef] [PubMed]

- Mishra, S.; Mishra, H.N. Effect of Synbiotic Interaction of Fructooligosaccharide and Probiotics on the Acidification Profile, Textural and Rheological Characteristics of Fermented Soy Milk. Food Bioprocess Technol. 2012, 6, 3166–3176. [Google Scholar] [CrossRef]

- Charchoghlyan, H.; Bae, J.-E.; Kwon, H.; Kim, M. Rheological properties and volatile composition of fermented milk prepared by exopolysaccharide-producing Lactobacillus acidophilus n.v. Er2 317/402 strain Narine. Biotechnol. Bioprocess Eng. 2017, 22, 327–338. [Google Scholar] [CrossRef]

| Time | English Name | Molecular Formula | MFSM | SMFSM | |||||

|---|---|---|---|---|---|---|---|---|---|

| M0 | M15 | M30 | S0 | S15 | S30 | ||||

| 1 | 2.47 | 2,3-Butanedione | C4H6O2 | 11.75 | 1.28 | - | - | - | - |

| 2 | 2.50 | Deoxyspergualin | C17H37N7O3 | - | - | 1.21 | - | - | - |

| 3 | 2.55 | Cystine | C6H12N2O4S2 | - | - | - | 1.5 | - | - |

| 4 | 3.69 | 2-Pentanone | C5H10O | - | - | - | 1.05 | - | - |

| 5 | 3.89 | Acetaldehyde | C2H4O | - | - | - | - | - | 0.68 |

| 6 | 4.19 | Acetic acid | C2H4O2 | - | - | - | 2.83 | 0.75 | 1.41 |

| 7 | 4.22 | 2,3-Pentanedione | C5H8O2 | 2.22 | 0.98 | 1.16 | - | - | - |

| 8 | 4.43 | Acetoin | C4H8O2 | 11.81 | 4.21 | 5.4 | 7.12 | 3.28 | 0.53 |

| 9 | 6.62 | 1-Pentanol | C5H12O | 1.57 | 1.14 | 1.25 | 2.96 | 0.16 | 0.74 |

| 10 | 7.06 | 9-Octadecen-12-ynoic acid, methyl ester | C19H32O2 | 0.24 | - | - | - | - | - |

| 11 | 7.71 | 2-methyl-3-Pentanol | C6H14O | 4.79 | - | - | - | - | - |

| 12 | 7.76 | (R)-2-Methyl-2,4-pentanediol | C6H14O2 | - | 2.73 | 4.49 | - | - | - |

| 13 | 8.19 | 2-Hydroxy-3-pentanone | C5H10O2 | - | 0.93 | - | - | - | - |

| 14 | 9.05 | 1,2-bis[(4-amino-3-furazanyl)oxy]- Ethane | C6H8N6O4 | - | - | - | 2.05 | - | - |

| 15 | 10.67 | 1-Hexanol | C6H14O | 8.11 | 5.81 | 4.76 | - | 2.38 | 3.57 |

| 16 | 11.26 | 2-Heptanone | C7H14O | 7.77 | 2.78 | - | 16.35 | 4.1 | 0.87 |

| 17 | 13.87 | (Z)-2-Heptenal | C7H12O | - | 0.45 | - | 0.72 | 0.39 | - |

| 18 | 14.03 | Benzaldehyde | C7H6O | - | 1.18 | 3.68 | - | 0.62 | - |

| 19 | 14.46 | 1-Heptanol | C7H16O | 1.25 | - | - | 1.26 | 0.48 | - |

| 20 | 14.55 | Formic acid, heptyl ester | C8H16O2 | - | 0.48 | - | - | - | - |

| 21 | 15.00 | 2-pentyl-Furan | C9H14O | 1.01 | - | - | - | 0.21 | - |

| 22 | 15.53 | Hexanoic acid | C6H12O2 | 1.74 | 1.61 | - | 3.83 | 1 | - |

| 23 | 15.84 | (E,E)-2,4-Heptadienal | C7H10O | - | - | - | 1.19 | - | - |

| 24 | 16.72 | cis-11-Eicosenoic acid | C20H38O2 | - | - | - | 0.37 | - | - |

| 25 | 17.21 | 3-ethyl-5-(2-ethylbutyl)- Octadecane | C26H54 | 0.24 | - | - | - | - | - |

| 26 | 17.24 | 2,6,10-trimethyl-Tetradecane | C17H36 | - | 0.19 | - | - | - | - |

| 27 | 17.42 | (E)-2-Octenal | C8H14O | - | 0.29 | - | 0.47 | 0.24 | - |

| 28 | 17.79 | (Z)-3-Nonen-2-ol | C9H18O | - | - | - | 0.89 | - | - |

| 29 | 17.87 | (Z)-2-Octen-1-ol | C8H16O | - | 0.19 | - | - | 0.12 | - |

| 30 | 17.91 | 1-Octanol | C8H18O | 1.34 | 0.65 | - | 1.12 | 0.36 | - |

| 31 | 18.45 | 2-Nonanone | C9H18O | 4.40 | 1.53 | 1.74 | 7.38 | 2.78 | 1.36 |

| 32 | 18.58 | (E,E)-3,5-Octadien-2-one | C8H12O | 1.16 | 0.39 | 0.56 | 1.86 | 0.24 | 0.34 |

| 33 | 18.64 | Isopentyl 3-hydroxy-2-methylenebutanoate | C10H18O3 | - | 0.25 | - | - | - | - |

| 34 | 18.72 | 3-ethyl-5-(2-ethylbutyl)- Octadecane | C26H54 | 0.17 | 0.13 | - | - | 0.19 | - |

| 35 | 18.73 | 6-methyl-Octadecane | C19H40 | - | 0.29 | - | 0.7 | - | - |

| 36 | 20.61 | 2,6,10-trimethyl- Dodecane | C15H32 | 0.62 | 0.21 | - | 1.32 | 0.16 | - |

| 37 | 21.08 | 1-Nonanol | C9H20O | 0.74 | 0.43 | - | 1.03 | - | - |

| 38 | 21.45 | Octanoic acid | C8H16O2 | 1.02 | - | - | - | - | 0.5 |

| 39 | 21.84 | Dodecane | C12H26 | 0.40 | - | - | 0.55 | - | - |

| 40 | 22.06 | Decanal | C10H20O | 0.38 | 0.16 | - | 0.68 | - | - |

| 41 | 22.41 | (2-phenyl-1,3-dioxolan-4-yl) methyl ester, cis-9-Octadecenoic acid | C28H44O4 | - | - | 1.78 | - | - | - |

| 42 | 22.51 | Ethyl maltol | C7H8O3 | - | - | 4.8 | - | - | - |

| 43 | 22.61 | 3-ethyl-5-(2-ethylbutyl)-Octadecane | C26H54 | - | - | 0.65 | 0.31 | - | - |

| 44 | 22.84 | 3-(octadecyloxy) propyl ester Oleic acid | C39H76O3 | - | - | 0.3 | - | - | - |

| 45 | 23.20 | 2,4-dimethyl-Benzaldehyde | C9H10O | - | - | 1.72 | - | - | 1.39 |

| 46 | 24.20 | Nonanoic acid | C9H18O2 | - | - | - | 0.4 | 0.3 | - |

| 47 | 24.58 | 2-Undecanone | C11H22O | - | - | 0.58 | - | - | - |

| 48 | 25.32 | (E,E)-2,4-Decadienal | C10H16O | 0.39 | 0.56 | - | - | 0.98 | - |

| 49 | 27.63 | 3-ethyl-5-(2-ethylbutyl)- Octadecane | C26H54 | 0.24 | - | - | - | 0.12 | - |

| 50 | 30.28 | Dodecalactone | C12H22O2 | 0.24 | - | - | - | - | - |

| 51 | 30.34 | 2-Tridecanone | C13H26O | - | 0.22 | - | - | - | - |

| 52 | 30.54 | Butylated Hydroxytoluene | C15H24O | - | - | 8.43 | - | - | 6.83 |

| 53 | 33.94 | 3-ethyl-5-(2-ethylbutyl)-Octadecane | C26H54 | - | - | - | - | 0.17 | - |

| 54 | 35.58 | Isopropyl myristate | C17H34O2 | - | - | - | - | 0.23 | - |

| 55 | 36.04 | 1,2-Benzenedicarboxylic acid, bis(2-methylpropyl) ester | C16H22O4 | - | - | - | 1.49 | - | - |

| Time (d) | Hardness (N) | Adhesiveness (mJ) | Cohesiveness (Ratio) | Stickiness (N) | Chewiness (mJ) | |

|---|---|---|---|---|---|---|

| MFSM | 0 | 0.19 ± 0.00 b | 0.14 ± 0.00 d | 0.72 ± 0.02 b | 0.13 ± 0.01 a | 3.04 ± 0.10 b |

| 15 | 0.21 ± 0.01 a | 0.17 ± 0.01 d | 0.58 ± 0.01 c | 0.11 ± 0.01 a | 4.19 ± 0.02 a | |

| 30 | 0.20 ± 0.00 ab | 0.26 ± 0.03 c | 0.57 ± 0.03 c | 0.11 ± 0.01 a | 4.08 ± 0.10 a | |

| SMFSM | 0 | 0.07 ± 0.00 c | 0.39 ± 0.03 a | 0.86 ± 0.07 a | 0.06 ± 0.01 b | 1.77 ± 0.05 c |

| 15 | 0.05 ± 0.00 d | 0.33 ± 0.03 b | 0.84 ± 0.06 a | 0.04 ± 0.00 c | 1.38 ± 0.09 d | |

| 30 | 0.06 ± 0.00 c | 0.26 ± 0.03 c | 0.90 ± 0.07 a | 0.06 ± 0.01 b | 1.85 ± 0.10 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zong, L.; Lu, M.; Wang, W.; Wa, Y.; Qu, H.; Chen, D.; Liu, Y.; Qian, Y.; Ji, Q.; Gu, R. The Quality and Flavor Changes of Different Soymilk and Milk Mixtures Fermented Products during Storage. Fermentation 2022, 8, 668. https://doi.org/10.3390/fermentation8120668

Zong L, Lu M, Wang W, Wa Y, Qu H, Chen D, Liu Y, Qian Y, Ji Q, Gu R. The Quality and Flavor Changes of Different Soymilk and Milk Mixtures Fermented Products during Storage. Fermentation. 2022; 8(12):668. https://doi.org/10.3390/fermentation8120668

Chicago/Turabian StyleZong, Lina, Maolin Lu, Wenqiong Wang, Yunchao Wa, Hengxian Qu, Dawei Chen, Yang Liu, Yi Qian, Qingyang Ji, and Ruixia Gu. 2022. "The Quality and Flavor Changes of Different Soymilk and Milk Mixtures Fermented Products during Storage" Fermentation 8, no. 12: 668. https://doi.org/10.3390/fermentation8120668

APA StyleZong, L., Lu, M., Wang, W., Wa, Y., Qu, H., Chen, D., Liu, Y., Qian, Y., Ji, Q., & Gu, R. (2022). The Quality and Flavor Changes of Different Soymilk and Milk Mixtures Fermented Products during Storage. Fermentation, 8(12), 668. https://doi.org/10.3390/fermentation8120668