Productivity, Fermentation Parameters, and Chemical Composition of Silages from Biomass Sorghum Hybrids in Ratoon Crop

Abstract

1. Introduction

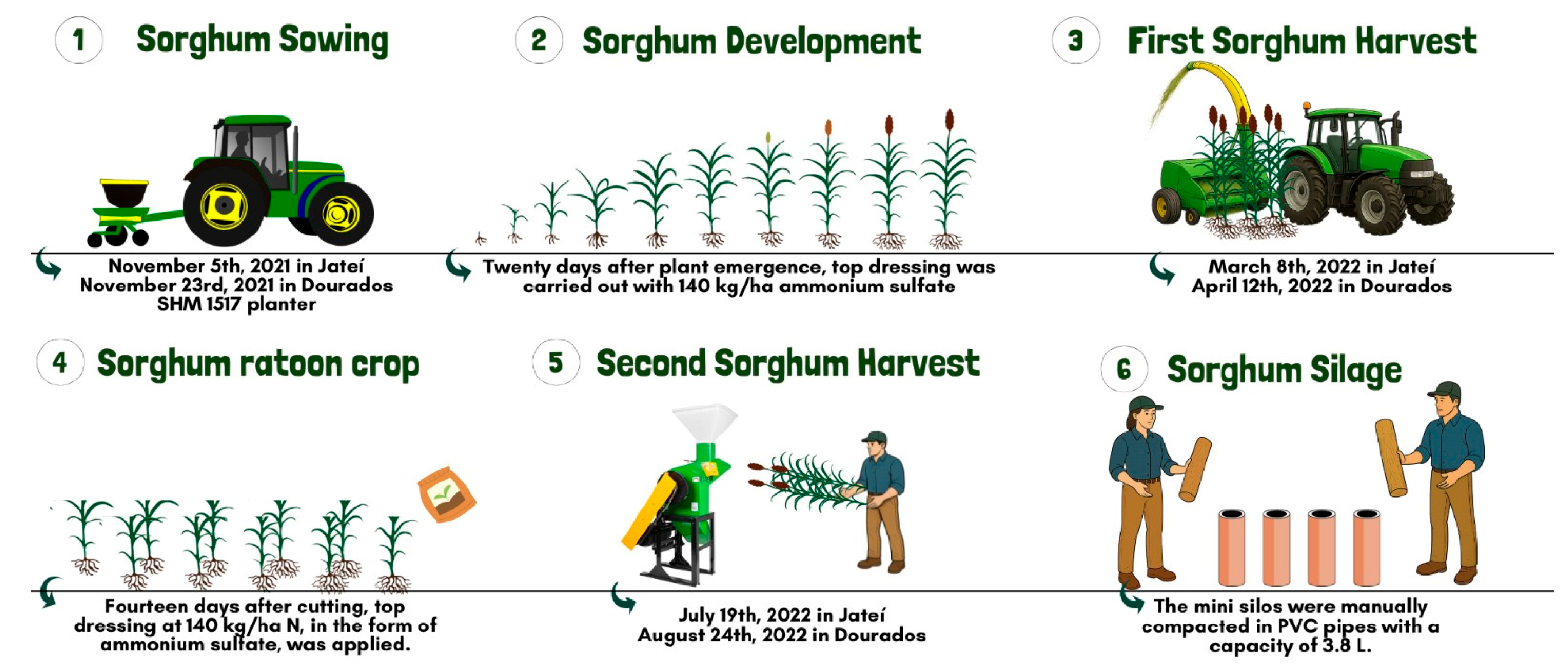

2. Materials and Methods

3. Results

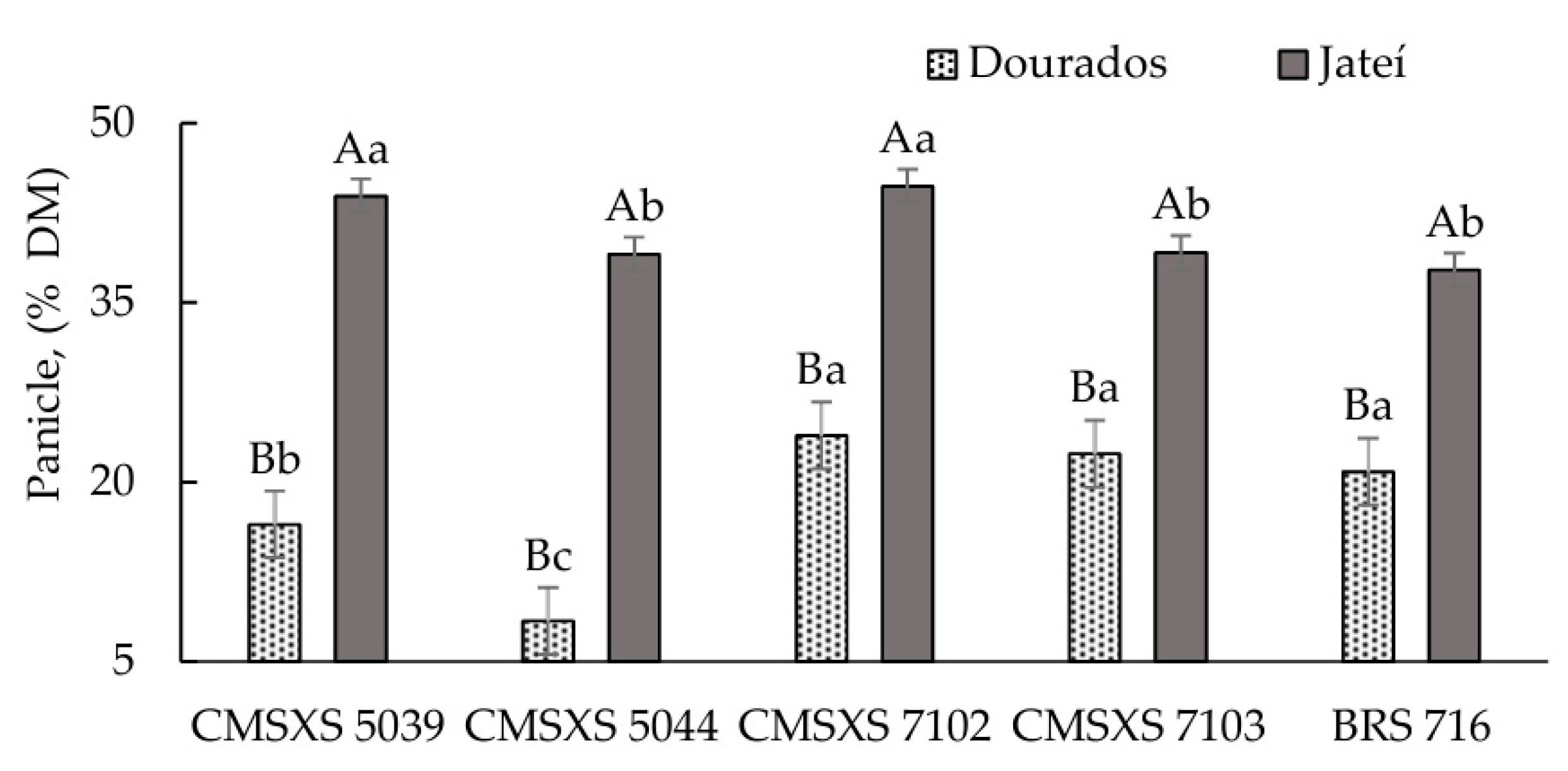

3.1. Productivity and Morphological Characteristics of the Biomass Sorghum Hybrids

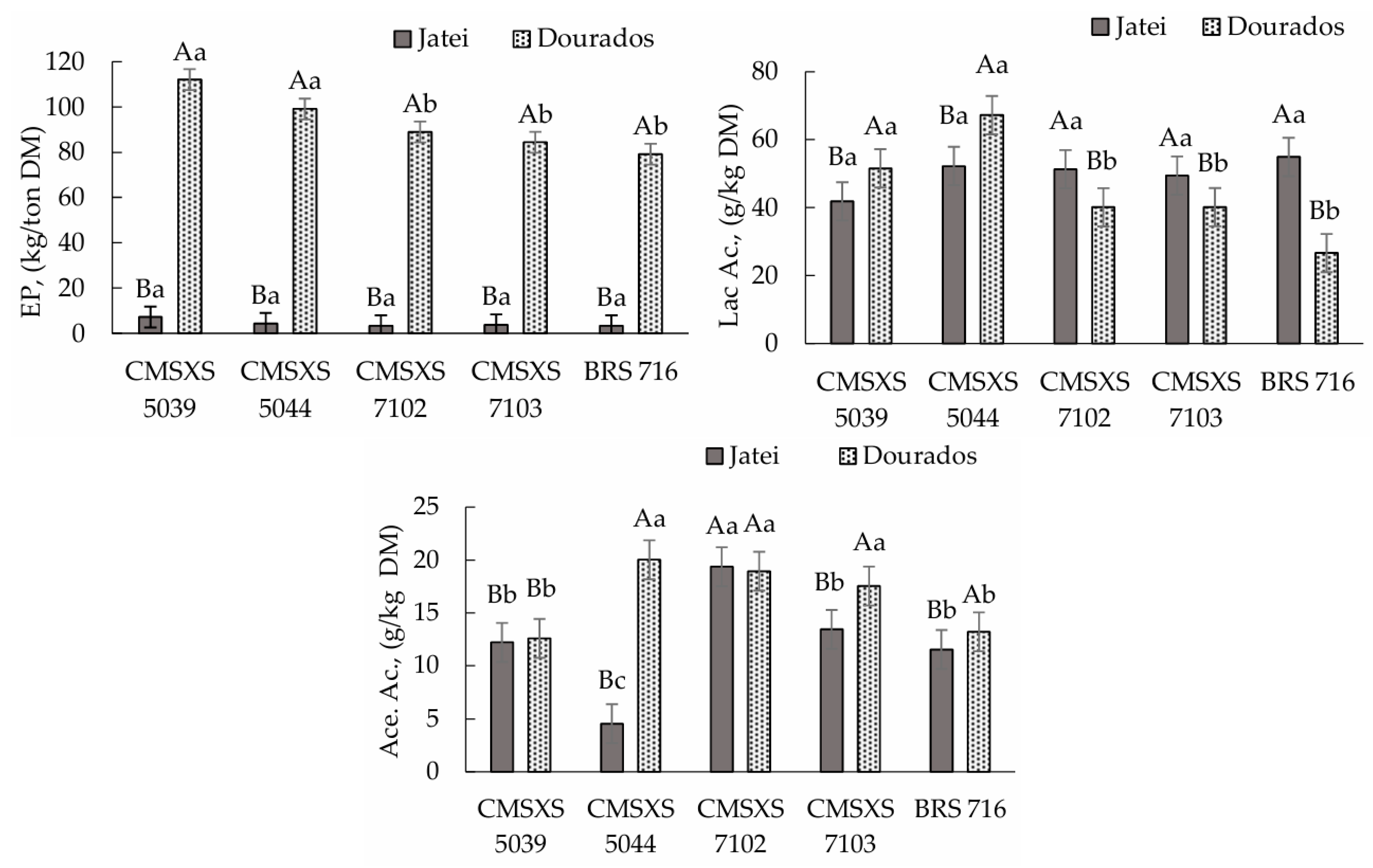

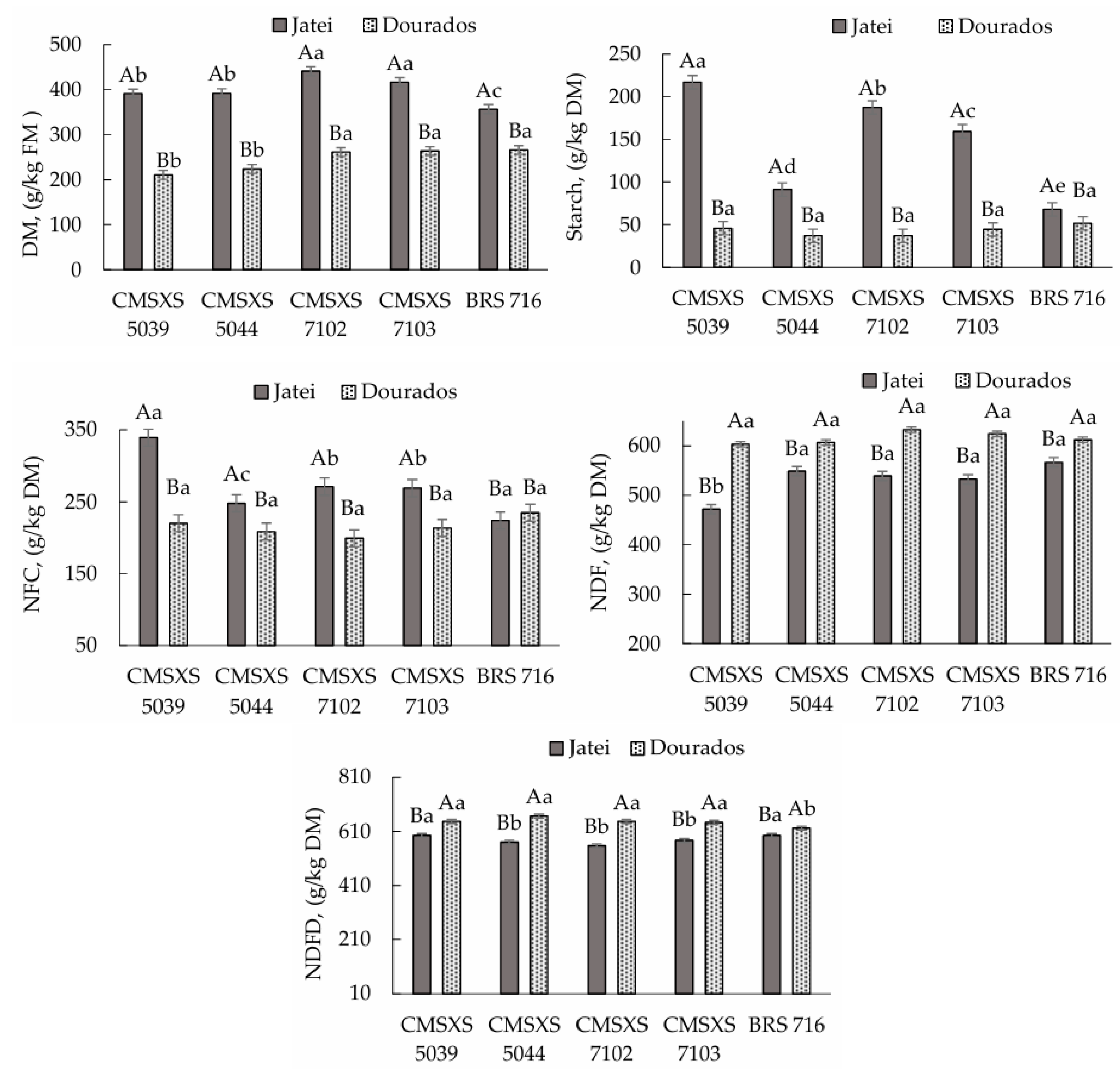

3.2. Fermentation Parameters and Chemical Composition of Silages from Different Biomass Sorghum Hybrids

4. Discussion

4.1. Productivity and Morphological Characteristics of the Biomass Sorghum Hybrids

4.2. Fermentation and Nutritional Parameters of Silages from Biomass Sorghum Hybrids

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Orrico Junior, M.A.P.; Retore, M.; Manarelli, D.M.; De Souza, F.B.; Ledesma, L.L.M.; Orrico, A.C.A. Forage Potential and Silage Quality of Four Varieties of Saccharine Sorghum. Pesqui. Agropecu. Bras. 2015, 50, 1201–1207. [Google Scholar] [CrossRef]

- Castro, M.; Bruzi, A.T.; Nunes, J.A.R.; Parrella, R.A.C.; Lombardi, G.M.R.; Albuquerque, C.J.; Lopes, M. Agronomic and Energetic Potential of Biomass Sorghum Genotypes. Am. J. Plant Sci. 2015, 6, 1862–1873. [Google Scholar] [CrossRef]

- De Queiroz, F.E.; Rocha, V.R.; Monção, F.P.; Rigueira, J.P.S.; Parrella, R.A.d.C.; Rufino, L.D.d.A.; Santos, A.S.d.; Cordeiro, M.W.S. Effect of Row Spacing and Maturity at Harvest on the Fermentative Profile, Aerobic Stability, and Nutritional Characteristics of Biomass Sorghum (BRS 716) Silage in the Semiarid Region of Brazil. Rev. Bras. Zootec. 2021, 50, e20200254. [Google Scholar] [CrossRef]

- Manarelli, D.M.; Orrico, M.A.P.; Retore, M.; de Vargas, F.M.; da Silva, M.S.J.; Orrico, A.C.A.; Borquis, R.R.A.; Crone, C.; de Oliveira Neves, F. Productive Performance and Quantitative Carcass Traits of Lambs Fed Saccharine Sorghum Silage. Pesqui. Agropecu. Bras. 2019, 54, e00577. [Google Scholar] [CrossRef]

- Ra, K.; Shiotsu, F.; Abe, J.; Morita, S. Biomass Yield and Nitrogen Use Efficiency of Cellulosic Energy Crops for Ethanol Production. Biomass Bioenergy 2012, 37, 330–334. [Google Scholar] [CrossRef]

- Souza, Í.D.A.d.S.; Rocha Júnior, V.R.; Monção, F.P.; Parrella, R.A.d.C.; Cordeiro, M.W.S.; Carvalho, C.d.C.S.; Rigueira, J.P.S.; Aspiazú, I.; Silva, F.V.; Delvaux Júnior, N.d.A. Yield and Nutritional Value of Biomass Sorghum (BRS 716) Managed in Different Row Spacing and Maturity at Harvest in the Semiarid Region of Brazil. Semin. Agrar. 2021, 42, 3463–3484. [Google Scholar] [CrossRef]

- Peerzada, A.M.; Ali, H.H.; Chauhan, B.S. Weed Management in Sorghum [Sorghum bicolor (L.) Moench] Using Crop Competition: A Review. Crop Prot. 2017, 95, 74–80. [Google Scholar] [CrossRef]

- Lestari, E.; Dewi, I.S.; Yunita, R.; Nur, A. Evaluation of Ratooning Ability in Several Sweet Sorghum (Sorghum bicolor [L.] Moench) Mutant Lines. AIP Conf. Proc. 2022, 2462, 050003. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, J.; Li, Z.; Wu, Y.; Zhang, J.; Zhang, Y. Yield and Quality in Main and Ratoon Crops of Grain Sorghum under Different Nitrogen Rates and Planting Densities. Front. Plant Sci. 2022, 12, 778663. [Google Scholar] [CrossRef]

- Kung, L., Jr.; Shaver, R.D.; Grant, R.J.; Schmidt, R.J. Silage Review: Interpretation of Chemical, Microbial, and Organoleptic Components of Silages. J. Dairy Sci. 2018, 101, 4020–4033. [Google Scholar] [CrossRef] [PubMed]

- Rosa, M.A.B.; Tardin, F.D.; Souza, J.M.d.S.; Santos, J.A.P.; Macedo, T.d.F.; Santos, J.; de Freitas, M.H.; Todescatto, F.; Parrella, R.A.d.C.; Figueiredo, J.E.F.; et al. Characterization of Forage, Sweet and Biomass Sorghum for Agronomic Performance and Ensilability. Rev. Bras. Milho e Sorgo 2022, 21, 1–22. [Google Scholar] [CrossRef]

- Santos, H.G.; Jacomine, P.K.; Anjos, L.H.C.; Oliveira, V.A.; Lumbreras, J.F.; Coelho, M.R.; Almeida, J.A.; Araújo Filho, J.C.; Oliveira, J.B.; Cunha, T.J.F. Sistema Brasileiro de Classificação de Solos, 5th ed.; Embrapa: Brasilia, Brazil, 2018; p. 356. [Google Scholar]

- Soil Survey. Keys to Soil Taxonomy, 12th ed.; USDA—Natural Resources Conservation Service: Washington, DC, USA, 2014.

- Fietz, C.R.; Fisch, G.F. O Clima Da Região de Dourados, MS. Embrapa Agropecuária Oeste 2008, 92, 32. [Google Scholar]

- Silva, F.C. Manual de Análises Químicas de Solos, Plantas e Fertilizantes, 2nd ed.; Silva, F.C., Ed.; Embrapa Informação Tecnológica: Brasilia, Brazil, 2009; ISBN 978-85-7383-430-7. [Google Scholar]

- Borém, A.; Pimentel, L.; Parrella, R. Sorgo: Do Plantio a Colheita, 1st ed.; UFV: Vicosa, Brazil, 2014. [Google Scholar]

- Jobim, C.C.; Nussio, L.G.; Reis, R.A.; Schmidt, P. Avanços Metodológicos Na Avaliação Da Qualidade Da Forragem Conservada Methodological Advances in Evaluation. Rev. Bras. Zootec. 2007, 36, 101–119. [Google Scholar] [CrossRef]

- Playne, M.J.; Mc Donald, P.T. The Buffering Constituents of Herbage and of Silage. J. Sci. Food Agric. 1966, 17, 264–268. [Google Scholar] [CrossRef]

- Pryce, J.D. A Modification of Barker-Summerson Method for the Determination of Lactic Acid. Analyst 1969, 94, 1151–1152. [Google Scholar] [CrossRef] [PubMed]

- Von Pinho, R.G.V.; Vasconcelos, R.C. Cultura Do Sorgo, 1st ed.; UFLA: Lavras, Brazil, 2002. [Google Scholar]

- Ferraz-Almeida, R.; Albuquerque, C.J.B.; Camargo, R.; Lemes, E.M.; Soares de Faria, R.; Quintão Lana, R.M. Sorghum–Grass Intercropping Systems under Varying Planting Densities in a Semi-Arid Region: Focusing on Soil Carbon and Grain Yield in the Conservation Systems. Agriculture 2022, 12, 1762. [Google Scholar] [CrossRef]

- Oliveira, I.C.M.; Guilhen, J.H.S.; Ribeiro, P.C.d.O.; Gezan, S.A.; Schaffert, R.E.; Simeone, M.L.F.; Damasceno, C.M.B.; Carneiro, J.E.d.S.; Carneiro, P.C.S.; Parrella, R.A.d.C.; et al. Genotype-by-Environment Interaction and Yield Stability Analysis of Biomass Sorghum Hybrids Using Factor Analytic Models and Environmental Covariates. Field Crops Res. 2020, 257, 107929. [Google Scholar] [CrossRef]

- Li, Y.; Li, C.; Cheng, Q.; Duan, F.; Zhai, W.; Li, Z.; Mao, B.; Ding, F.; Kuang, X.; Chen, Z. Estimating Maize Crop Height and Aboveground Biomass Using Multi-Source Unmanned Aerial Vehicle Remote Sensing and Optuna-Optimized Ensemble Learning Algorithms. Remote Sens. 2024, 16, 3176. [Google Scholar] [CrossRef]

- Shah, A.N.; Tanveer, M.; Abbas, A.; Yildirim, M.; Shah, A.A.; Ahmad, M.I.; Wang, Z.; Sun, W.; Song, Y. Combating Dual Challenges in Maize Under High Planting Density: Stem Lodging and Kernel Abortion. Front. Plant Sci. 2021, 12, 1–19. [Google Scholar] [CrossRef]

- Bibi, A.; Sadaqat, H.A.; Tahir, M.H.N.; Fatima Usman, B.; Ali, M. Genetic Analysis of Forage Quality Traits in Sorghum-Sudangrass Hybrids under Water Stress. J. Anim. Plant Sci. 2012, 22, 1092–1100. [Google Scholar]

- Gebrehanna, M.M.; Gordon, R.J.; Madani, A.; VanderZaag, A.C.; Wood, J.D. Silage Effluent Management: A Review. J. Environ. Manag. 2014, 143, 113–122. [Google Scholar] [CrossRef] [PubMed]

- Borreani, G.; Tabacco, E.; Schmidt, R.J.; Holmes, B.J.; Muck, R.E. Silage Review: Factors Affecting Dry Matter and Quality Losses in Silages. J. Dairy Sci. 2018, 101, 3952–3979. [Google Scholar] [CrossRef]

- Kung, L.; Williams, P.; Schmidt, R.J.; Hu, W. A Blend of Essential Plant Oils Used as an Additive to Alter Silage Fermentation or Used as a Feed Additive for Lactating Dairy Cows. J. Dairy Sci. 2008, 91, 4793–4800. [Google Scholar] [CrossRef] [PubMed]

- Silva, Y.A.; Orrico Junior, M.A.P.; Retore, M.; Ceccon, G.; Fernandes, T.; Orrico, A.C.A. Chemical Composition, Fermentation Parameters and Losses of Silages from Different Hybrids of Biomass Sorghum. Grass Forage Sci. 2025, 80, e12706. [Google Scholar] [CrossRef]

- Alves, J.P.; Galeano Jara, E.S.; Orrico Junior, M.A.P.; Fernandes, T.; Retore, M.; Silva, M.S.J.; Orrico, A.C.A.; Lopes, L.S. The Influence of Plant Age and Microbes-Enzymatic Additives on Fermentation of Total Mixed Ration Silages of Capiaçu Grass (Pennisetum Purpureum, Schum). Trop. Anim. Sci. J. 2022, 45, 56–63. [Google Scholar] [CrossRef]

- Muck, R.E. Silage Microbiology and Its Control through Additives. Rev. Bras. Zootec. 2010, 39, 183–191. [Google Scholar] [CrossRef]

- Orrico Junior, M.A.P.; Vendramini, J.M.B.; Erickson, J.; Moriel, P.; Silveira, M.L.A.; Aguiar, A.D.; Sanchez, J.M.D.; Silva, W.L.; Silva, H.M. Nutritive Value and Fermentation Characteristics of Silages Produced from Different Sweet Sorghum Plant Components with or without Microbial Inoculation. Appl. Anim. Sci. 2020, 36, 777–783. [Google Scholar] [CrossRef]

- Mccormick, M.E.; Morris, D.R.; Ackerson, B.A.; Blouin, D.C. Ratoon Cropping Forage Sorghum for Silage: Yield, Fermentation, and Nutrition. Agron. J. 1995, 87, 952–957. [Google Scholar] [CrossRef]

- Wilkinson, J.M.; Rinne, M. Highlights of Progress in Silage Conservation and Future Perspectives. Grass Forage Sci. 2018, 73, 40–52. [Google Scholar] [CrossRef]

- NRC. Nutrient Requirements of Dairy Cattle, 8th ed.; National Academy Press: Washington, DC, USA, 2021.

| Parameters | (H) | (S) | SEM | p-Value | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| H5039 | H5044 | H7102 | H7103 | H716 | Jateí | Dourados | H | S | H × S | ||

| Agronomic characteristics | |||||||||||

| DMP, t/ha | 7.49 | 8.04 | 7.74 | 7.26 | 8.38 | 12.55 | 3.00 | 0.20 | 0.85 | <0.01 | 0.708 |

| HS, m | 1.80 a | 1.46 b | 1.92 a | 1.87 a | 1.81 a | 2.44 | 1.10 | 0.08 | <0.01 | <0.01 | 0.069 |

| SD, mm | 12.41 a | 11.03 b | 9.77 c | 9.56 c | 10.71 b | 12.39 | 9.00 | 0.51 | <0.01 | <0.01 | 0.449 |

| Stem, % | 47.06 | 47.49 | 45.71 | 47.30 | 47.16 | 43.02 | 50.87 | 0.32 | 0.81 | <0.01 | 0.181 |

| Leaf, % | 22.74 b | 28.80 a | 19.97 b | 21.93 b | 23.55 b | 16.06 | 30.73 | 1.47 | 0.02 | <0.01 | 0.227 |

| Panicle, % | 30.20 | 23.71 | 34.32 | 30.77 | 29.29 | 40.92 | 18.40 | 4.03 | <0.01 | <0.01 | <0.01 |

| Chemical composition | |||||||||||

| DM (g/kg FM) | 320.04 b | 314.23 b | 356.18 a | 370.44 a | 324.52 b | 397.26 | 264.11 | 10.21 | <0.01 | <0.01 | 0.054 |

| CP (g/kg DM) | 112.25 b | 120.01 a | 95.00 c | 105.5 b | 118.25 a | 121.90 | 94.10 | 1.99 | <0.01 | <0.01 | 0.078 |

| SC (g/kg DM) | 68.25 b | 73.50 b | 45.75 c | 62.00 b | 92.00 a | 75.10 | 57.50 | 9.75 | 0.04 | 0.07 | 0.128 |

| ST (g/kg DM) | 125.25 a | 52.25 c | 97 b | 101.25 b | 70.5 c | 125.90 | 52.60 | 7.36 | <0.01 | <0.01 | 0.547 |

| EE (g/kg DM) | 23.750 | 27.50 | 21.50 | 22.75 | 27.25 | 30.90 | 18.20 | 1.93 | 0.18 | <0.01 | 0.216 |

| NFC (g/kg DM) | 242.75 | 193.50 | 181.00 | 199.50 | 204.75 | 246.40 | 162.20 | 13.36 | 0.07 | <0.01 | 0.402 |

| NDF (g/kg DM) | 594.25 b | 642.02 a | 669.75 a | 648.25 a | 622.75 b | 577.00 | 693.80 | 12.03 | 0.01 | <0.01 | 0.677 |

| Parameters | (H) | (S) | SEM | p-Value | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| H5039 | H5044 | H7102 | H7103 | H716 | Jateí | Dourados | H | S | H × S | ||

| EP (kg/t DM) | 59.66 | 51.75 | 46.13 | 44.06 | 41.23 | 4.39 | 92.74 | 4.62 | <0.01 | <0.01 | 0.022 |

| DMR (g/kg DM) | 858.74 a | 871.33 a | 840.28 b | 860.96 a | 860.73 a | 859.64 | 857.18 | 4.31 | 0.04 | 0.688 | 0.136 |

| GL (g/kg DM) | 25.57 | 38.23 | 24.53 | 23.35 | 30.78 | 26.07 | 30.92 | 0.55 | 0.06 | 0.173 | 0.073 |

| pH | 3.84 b | 3.82 b | 3.91 a | 3.80 c | 3.77 c | 3.91 | 3.74 | 0.07 | <0.01 | <0.01 | 0.065 |

| Lac. Ac. (g/kg DM) | 46.71 | 59.73 | 45.7 | 44.78 | 40.77 | 49.95 | 45.13 | 0.56 | 0.02 | 0.181 | <0.01 |

| Ace. Ac. (g/kg DM) | 12.39 | 12.28 | 19.14 | 15.48 | 12.37 | 12.21 | 16.46 | 0.18 | <0.01 | 0.01 | <0.01 |

| But. Ac. (g/kg DM) | 1.40 a | 0.43 c | 1.29 b | 1.44 a | 0.88 b | 1.04 | 1.14 | 0.02 | <0.01 | 0.433 | 0.21 |

| NH3-N (g/kg TN) | 9.48 a | 5.01 c | 9.47 a | 7.92 a | 6.71 b | 9.12 | 6.47 | 0.08 | <0.01 | <0.01 | 0.31 |

| AS (h) | 25.55 | 31.98 | 28.29 | 28.9 | 27.75 | 20.78 | 36.71 | 3.61 | 0.51 | <0.01 | 0.341 |

| DM (g/kg FM) | 301.00 | 307.92 | 351.08 | 340.34 | 311.42 | 399.6 | 245.1 | 9.79 | <0.01 | <0.01 | <0.01 |

| CP (g/kg DM) | 113.50 b | 118.33 a | 109.75 c | 110.58 c | 115.17 a | 128.57 | 98.37 | 2.98 | 0.04 | <0.01 | 0.074 |

| EE (g/kg DM) | 38.25 b | 46.5 a | 38.17 b | 37.25 b | 36.58 b | 44.76 | 32.2 | 1.86 | 0.05 | <0.01 | 0.516 |

| Starch (g/kg DM) | 131.5 | 64.00 | 112.17 | 102 | 59.67 | 144.67 | 43.07 | 7.84 | <0.01 | <0.01 | <0.01 |

| NFC (g/kg DM) | 279.83 | 228.5 | 235.33 | 241.5 | 229.58 | 270.43 | 215.47 | 1.85 | <0.01 | <0.01 | <0.01 |

| NDF (g/kg DM) | 537.83 | 577.92 | 585.83 | 578.33 | 589.58 | 531.93 | 615.87 | 9.27 | <0.01 | <0.01 | <0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, Y.A.d.; Orrico Junior, M.A.P.; Retore, M.; Ceccon, G.; Amaral, I.P.d.O.; Orrico, A.C.A.; Muglia, G.R.P.; Fernandes, T. Productivity, Fermentation Parameters, and Chemical Composition of Silages from Biomass Sorghum Hybrids in Ratoon Crop. Fermentation 2025, 11, 540. https://doi.org/10.3390/fermentation11090540

Silva YAd, Orrico Junior MAP, Retore M, Ceccon G, Amaral IPdO, Orrico ACA, Muglia GRP, Fernandes T. Productivity, Fermentation Parameters, and Chemical Composition of Silages from Biomass Sorghum Hybrids in Ratoon Crop. Fermentation. 2025; 11(9):540. https://doi.org/10.3390/fermentation11090540

Chicago/Turabian StyleSilva, Yara América da, Marco Antonio Previdelli Orrico Junior, Marciana Retore, Gessí Ceccon, Isabele Paola de Oliveira Amaral, Ana Carolina Amorim Orrico, Giuliano Reis Pereira Muglia, and Tatiane Fernandes. 2025. "Productivity, Fermentation Parameters, and Chemical Composition of Silages from Biomass Sorghum Hybrids in Ratoon Crop" Fermentation 11, no. 9: 540. https://doi.org/10.3390/fermentation11090540

APA StyleSilva, Y. A. d., Orrico Junior, M. A. P., Retore, M., Ceccon, G., Amaral, I. P. d. O., Orrico, A. C. A., Muglia, G. R. P., & Fernandes, T. (2025). Productivity, Fermentation Parameters, and Chemical Composition of Silages from Biomass Sorghum Hybrids in Ratoon Crop. Fermentation, 11(9), 540. https://doi.org/10.3390/fermentation11090540