Artisanal Cream Cheese Fermented with Kefir Grains

Abstract

1. Introduction

2. Materials and Methods

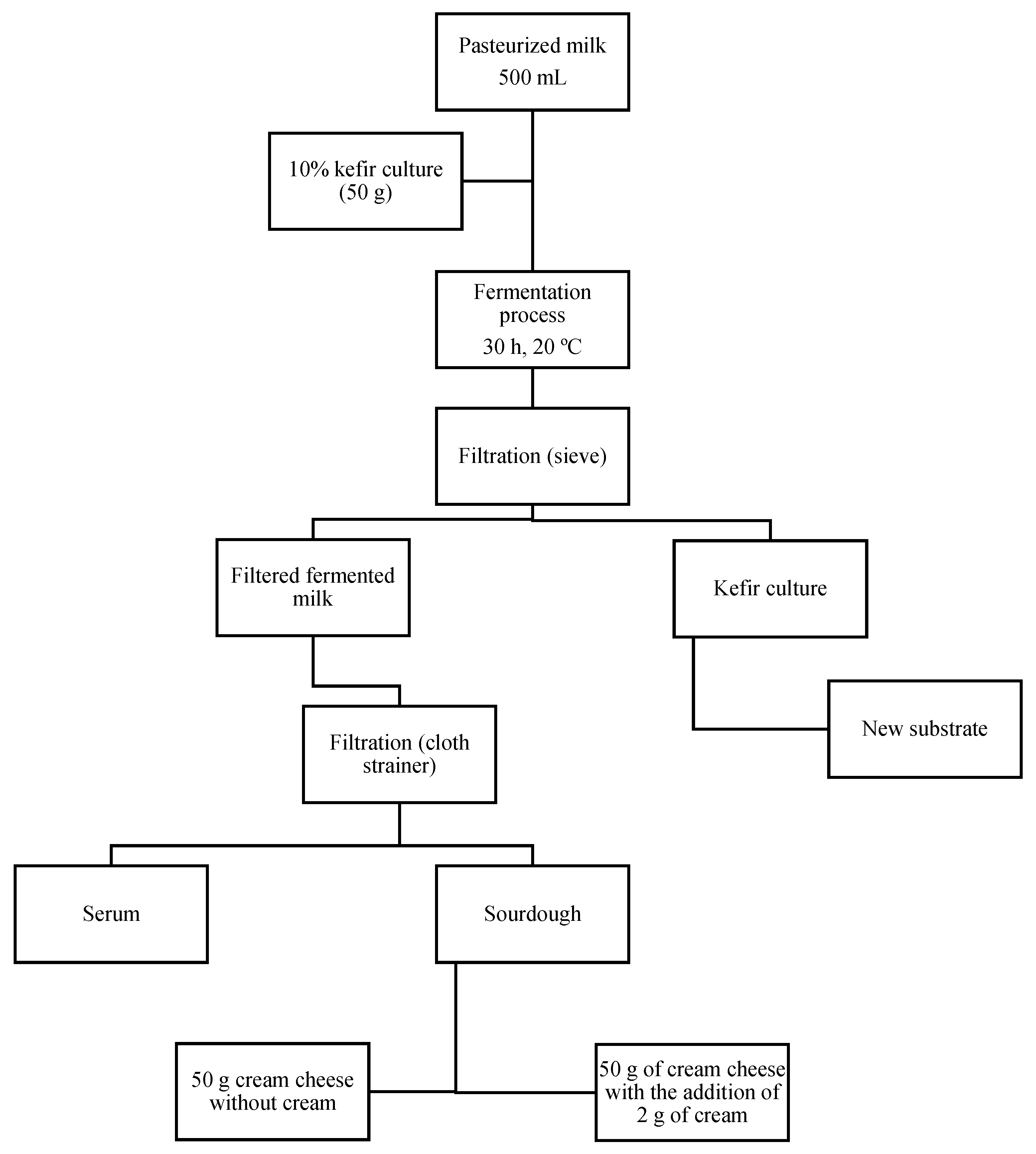

2.1. Artisanal Cheese Cream Fermented with Kefir Grains

2.2. Lactic Acid Bacteria Count

2.3. Soluble Solids, pH, Acidity Measurement, and Centesimal Composition

2.4. Glucose-Reducing and Non-Sucrose-Reducing Carbohydrates

| Lactose: the GRC value × 1.39 (hexose to lactose conversion factor); Total carbohydrates in glucose (TCG); Sucrose: TCG − GRC × 0.95 (hexose to sucrose conversion factor); Total carbohydrates: sucrose + GRC. |

2.5. Fatty Acid Profile

2.6. Sensory Analysis

2.7. Statistical Analysis

3. Results and Discussion

3.1. Lactic Acid Bacteria Count

3.2. Soluble Solids, pH, Acidity Measurement and Determination of Carbohydrate Reduction in Lactose

3.3. Centesimal Composition

3.4. Fatty Acid Profile

3.5. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Braccini, V.P.; Arbello, D.D.R.; Erhardt, M.M.; Jiménez, M.S.E.; Pedroso, M.A.P.; Richards, N.S. Leite fermentado: Kefir. Braz. J. Dev. 2021, 7, 21121–21135. [Google Scholar] [CrossRef]

- Bengoa, A.A.; Iraporda, C.; Garrote, G.L.; Abraham, A.G. Kefir micro-organisms: Their role in grain assembly and health properties of fermented milk. J. Appl. Microbiol. 2019, 126, 686–700. [Google Scholar] [CrossRef] [PubMed]

- Brasil. Presidência da República. Decreto Nº 9.918, de 18 de Julho de 2019. Regulamenta o art. 10-A da Lei Nº 1.283, de 18 de Dezembro de 1950, que Dispõe Sobre o Processo de Fiscalização de Produtos Alimentícios de Origem Animal Produzidos de Forma Artesanal. Diário Oficial da União, Brasília, 19 Jul 2019. Seção 1. 2024; p. 4. Available online: https://www.in.gov.br/web/dou/-/decreto-n-9918-de-18-de-julho-de-2019-198615217 (accessed on 21 July 2024).

- Kamimura, B.A.; Magnani, M.; Luciano, W.A.; Campagnollo, F.B.; Pimentel, T.C.; Alvarenga, V.O.; Pelegrino, B.O.; Cruz, A.G.; Sant’Ana, A.S. Brazilian Artisanal Cheeses: An Overview of their Characteristics, Main Types and Regulatory Aspects. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1636–1657. [Google Scholar] [CrossRef] [PubMed]

- Maldonado, R.R.; Aguiar-Oliveira, E.; Kamimura, E.S.; Mazalli, M.R. Kefir and Kombucha Beverages: New Substrates and Nutritional Characteristics. In Fermented Food Products; CRC Press: Boca Raton, FL, USA, 2020; pp. 295–312. [Google Scholar]

- de Souza, H.F.; Monteiro, G.F.; Bogáz, L.T.; Freire, E.N.S.; Pereira, K.N.; de Carvalho, M.V.; Kamimura, E.S. Bibliometric analysis of water kefir and milk kefir in probiotic foods from 2013 to 2022: A critical review of recent applications and prospects. Food Res. Int. 2023, 175, 113716. [Google Scholar] [CrossRef] [PubMed]

- Bessa, M.K.; Bessa, G.R.; Bonamigo, R.R. Kefir as a therapeutic agent in clinical research: A scoping review. Nutr. Res. Rev. 2023, 37, 79–95. [Google Scholar] [CrossRef] [PubMed]

- Azizi, N.F.; Kumar, M.R.; Yeap, S.K.; Abdullah, J.O.; Khalid, M.; Omar, A.R.; Alitheen, N.B. Kefir and its biological activities. Foods 2021, 10, 1210. [Google Scholar] [CrossRef] [PubMed]

- Bell, V.; Ferrão, J.; Pimentel, L.; Pintado, M.; Fernandes, T. One health, fermented foods, and gut microbiota. Foods 2018, 7, 195. [Google Scholar] [CrossRef] [PubMed]

- Peluzio, M.D.C.G.; Dias, M.M.E.; Martinez, J.A.; Milagro, F.I. Kefir and intestinal microbiota modulation: Implications in human health. Front. Nutr. 2021, 22, 638740. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Wang, J.; Du, L.; Chen, J.; Zheng, Q.; Li, P.; Liao, Z. Kefir microbiota and metabolites stimulate intestinal mucosal immunity and its early development. Crit. Rev. Food Sci. Nutr. 2024, 64, 1371–1384. [Google Scholar] [CrossRef] [PubMed]

- Mirzaei, R.; Bouzari, B.; Hosseini-Fard, S.R.; Mazaheri, M.; Ahmadyousefi, Y.; Abdi, M.; Karampoor, S. Role of microbiota-derived short-chain fatty acids in nervous system disorders. Biomed. Pharmacother. 2021, 139, 111661. [Google Scholar] [CrossRef] [PubMed]

- Mollica, M.P.; Mattace Raso, G.; Cavaliere, G.; Trinchese, G.; De Filippo, C.; Aceto, S.; Meli, R. Butyrate regulates liver mitochondrial function, efficiency, and dynamics in insulin-resistant obese mice. Diabetes 2017, 66, 1405–1418. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez, A.; Krieg, R.; Massey, H.D.; Carl, D.; Ghosh, S.; Gehr, T.W.; Ghosh, S.S. Sodium butyrate ameliorates insulin resistance and renal failure in CKD rats by modulating intestinal permeability and mucin expression. Nephrol. Dial. Transplant. 2019, 34, 783–794. [Google Scholar] [CrossRef] [PubMed]

- Tanca, A.; Palomba, A.; Fraumene, C.; Manghina, V.; Silverman, M.; Uzzau, S. Clostridial butyrate biosynthesis enzymes are significantly depleted in the gut microbiota of nonobese diabetic mice. Msphere 2018, 3, 10–1128. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Ley, S.H.; Hu, F.B. Global aetiology and epidemiology of type 2 diabetes mellitus and its complications. Nat. Rev. Endocrinol. 2018, 14, 88–98. [Google Scholar] [CrossRef] [PubMed]

- Sun, M.; Wu, W.; Liu, Z.; Cong, Y. Microbiota metabolite short chain fatty acids, GPCR, and inflammatory bowel diseases. J. Gastroenterol. 2017, 52, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Lin, S.; Zheng, B.; Cheung, P.C.K. Short-chain fatty acids in control of energy metabolism. Crit. Rev. Food Sci. Nutr. 2018, 58, 1243–1249. [Google Scholar] [CrossRef] [PubMed]

- Nagpal, R.; Wang, S.; Ahmadi, S.; Hayes, J.; Gagliano, J.; Subashchandrabose, S.; Kitzman, D.W.; Becton, T.; Read, R.; Yadav, H. Human-origin probiotic cocktail increases short-chain fatty acid production via modulation of mice and human gut microbiome. Sci. Rep. 2018, 8, 12649. [Google Scholar] [CrossRef] [PubMed]

- Markowiak-Kopeć, P.; Śliżewska, K. The effect of probiotics on the production of short-chain fatty acids by human intestinal microbiome. Nutrients 2020, 12, 1107. [Google Scholar] [CrossRef] [PubMed]

- Singh, V.; Lee, G.; Son, H.; Koh, H.; Kim, E.S.; Unno, T.; Shin, J.H. Butyrate producers, “The Sentinel of Gut”: Their intestinal significance with and beyond butyrate, and prospective use as microbial therapeutics. Front. Microbiol. 2023, 13, 1103836. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Li, X.; Zhang, G.; Sadiq, F.A.; Simal-Gandara, J.; Xiao, J.; Sang, Y. Probiotics in the dairy industry-Advances and opportunities. Compr. Rev. Food Sci. Food Saf. 2021, 20, 3937–3982. [Google Scholar] [CrossRef]

- Furse, S.; Torres, A.G.; Koulman, A. Fermentation of milk into yoghurt and cheese leads to contrasting lipid and glyceride profiles. Nutrients 2019, 11, 2178. [Google Scholar] [CrossRef] [PubMed]

- Silva, N. Manual de Métodos de Análise Microbiológica de Alimentos, 3rd ed.; Livraria Varela: São Paulo, Brazil, 2007. [Google Scholar]

- Zenebon, O.; Pascuet, N.S. Métodos Físico-Químicos Para Análise de Alimentos, 4th ed.; Instituto Adolfo Lutz: São Paulo, Brasil, 2008; pp. 83–158. Available online: http://www.ial.sp.gov.br/ial/publicacoes/livros/metodos-fisico-quimicos-para-analise-de-alimentos. (accessed on 28 July 2024).

- Khan, T.H. Titrimetric determination of reducing sugars with copper (II) sulphate. Analyst 1979, 104, 261–265. [Google Scholar] [CrossRef]

- Mazalli, M.R.; Saldanha, T.; Bragagnolo, N. Determinação de colesterol em ovos: Comparação entre um método enzimático e um método por cromatografia líquida de alta eficiência. Rev. Inst. Adolfo Lutz 2003, 62, 49–54. [Google Scholar] [CrossRef]

- Ortiz, C.M.L.; Moya, M.S.P.; Navarro, V.B. A rapid chromatogr aphic method for simultaneous determination of β-sitosterol and tocopherol homologues in vegetable oils. J. Food Compos. Anal. 2006, 19, 141–149. [Google Scholar] [CrossRef]

- Kramer, J.K.; Fellner, V.; Dugan, M.E.; Sauer, F.D.; Mossoba, M.M.; Yurawecz, M.P. Evaluating acid and base catalysts in the methylation of milk and rumen fatty acids with special emphasis on conjugated dienes and total trans fatty acids. Lipids 1997, 32, 1219–1228. [Google Scholar] [CrossRef] [PubMed]

- Metz, P.A.M.; Menezes, L.F.G.D.; Santos, A.P.D.; Brondani, I.L.; Restle, J.; Lanna, D.P.D. Perfil de ácidos graxos na carne de novilhos de diferentes idades e grupos genéticos terminados em confinamento. Rev. Bras. Zootec. 2009, 38, 523–531. [Google Scholar] [CrossRef][Green Version]

- Brasil. Ministério da Agricultura Pecuária e Abastecimento. Instrução Normativa Nº 46, de 23 de Outubro de 2007. Regulamento Técnico de Identidade e Qualidade de Leites Fermentados. Diário Oficial da República Federativa do Brasil, Brasília, DF 2007. Available online: https://www.cidasc.sc.gov.br/inspecao/files/2019/09/INSTRUÇÃO-NORMATIVA-N-46-de-23-de-outubro-de-2007-Leites-Fermentados.pdf (accessed on 10 May 2024).

- Bengoa, A.A.; Iraporda, C.; Acurcio, L.B.; de Cicco Sandes, S.H.; Costa, K.; Guimarães, G.M.; Abraham, A.G. Physicochemical, immunomodulatory and safety aspects of milks fermented with Lactobacillus paracasei isolated from kefir. Food Res. Int. 2019, 123, 48–55. [Google Scholar] [CrossRef] [PubMed]

- Bousmaha-Marroki, L.; Boutillier, D.; Marroki, A.; Grangette, C. In vitro anti-staphylococcal and anti-inflammatory abilities of lacticaseibacillus rhamnosus from infant gut microbiota as potential probiotic against infectious women mastitis. Probiotics Antimicrob. Proteins 2021, 13, 970–981. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Zhong, X.; Liu, X.; Wang, X.; Gao, X. Therapeutic and improving function of Lactobacilli in the prevention and treatment of cardiovascular-related diseases: A novel perspective from gut microbiota. Front. Nutr. 2021, 8, 693412. [Google Scholar] [CrossRef] [PubMed]

- Karaçali, R.; ÖzdemIR, N.; Çon, A.H. Aromatic and functional aspects of kefir produced using soya milk and Bifidobacterium species. Int. J. Dairy Technol. 2018, 71, 921–933. [Google Scholar] [CrossRef]

- Sharma, H.; Ozogul, F.; Bartkiene, E.; Rocha, J.M. Impact of lactic acid bacteria and their metabolites on the techno-functional properties and health benefits of fermented dairy products. Crit. Rev. Food Sci. Nutr. 2023, 63, 4819–4841. [Google Scholar] [CrossRef] [PubMed]

- Araujo, T.F.; Sant’ Anna, M.D.E.S.L.; Rodrigues, V.C.; Costa, E.C.; Paula, H.A.D.A.; Teixeira, T.F.S. Avaliação do perfil de conformidade de diferentes leites fermentados com a legislação brasileira de alimentos. Rev. Inst. Laticínios Cândido Tostes 2011, 66, 40–45. Available online: https://revistadoilct.com.br/rilct/article/view/167 (accessed on 28 July 2024).

- de Medeiros, E.J.; Lima, A.R.C.D.E.; Moura, M.D.; Moreira, R.T. Leite fermentado de marcas comerciais: Estudo da aceitação e correlação com ph e acidez. Rev. Inst. Laticínios Cândido Tostes 2011, 66, 46–51. Available online: https://rilct.emnuvens.com.br/rilct/article/view/175 (accessed on 28 July 2024).

- Setyawardani, T.; Rahardjo, A. Physiochemical and Organoleptic Features of Goat Milk Kefir Made of Different Kefir Grain Concentration on Controlled Fermentation. Anim. Prod. J. 2014, 16, 48–54. Available online: http://animalproduction.net/index.php/JAP/article/view/444 (accessed on 26 July 2024).

- Brasil. Ministério da Agricultura Pecuária e Abastecimento. Instrução Normativa Nº 71, de 24 de julho de 2020. Secretaria de Defesa Agropecuária. 2020. Available online: https://wikisda.agricultura.gov.br/dipoa_baselegal/in_71-2020_rt_cream_chesse.pdf (accessed on 10 May 2024).

- Triwibowo, B.; Wicaksono, R.; Antika, Y.; Ermi, S.; Jarmiati, A.; Setiadi, A.A.; Syahriar, R. The effect of kefir grain concentration and fermentation duration on characteristics of cow milk-based kefir. J. Phys. Conf. Ser. 2020, 1444, 012001. [Google Scholar] [CrossRef]

- Czyżak-Runowska, G.; Wójtowski, J.A.; Łęska, B.; Bielińska-Nowak, S.; Pytlewski, J.; Antkowiak, I.; Stanisławski, D. Lactose content and selected quality parameters of sheep milk fermented beverages during storage. Animals 2022, 12, 3105. [Google Scholar] [CrossRef] [PubMed]

- USDA. Nutrient Database for Standard Reference. Food Data Central. 2023. Available online: https://fdc.nal.usda.gov/data-documentation.html (accessed on 10 May 2024).

- Batista, M.C.M.; De Jesus, K.A.; Freitas, F.M.N.d.O. Evaluation of the effects of kefir on the intestinal microbiota. Braz. J. Dev. 2021, 7, 93727–93744. [Google Scholar] [CrossRef]

- Bhupathi, V.; Mazariegos, M.; Cruz Rodriguez, J.B.; Deoker, A. Dairy intake and risk of cardiovascular disease. Curr. Cardiol. Rep. 2020, 22, 11. [Google Scholar] [CrossRef] [PubMed]

- Zock, P.L.; De Vries, J.H.; Katan, M.B. Impact of myristic acid versus palmitic acid on serum lipid and lipoprotein levels in healthy women and men. Arter. Thromb. 1994, 14, 567–575. [Google Scholar] [CrossRef] [PubMed]

- Hunter, J.E.; Zhang, J.; Kris-Etherton, P.M. Cardiovascular disease risk of dietary stearic acid compared with trans, other saturated, and unsaturated fatty acids: A systematic review. Am. J. Clin. Nutr. 2010, 91, 46–63. [Google Scholar] [CrossRef] [PubMed]

- Gonçalinho, G.H.F.; Sampaio, G.R.; Soares-Freitas, R.A.M.; Damasceno, N.R.T. Stearic Acid, but not Palmitic Acid, is Associated with Inflammatory and Endothelial Dysfunction Biomarkers in Individuals at Cardiovascular Risk. Arq. Bras. Cardiol. 2023, 120, e20220598. [Google Scholar] [CrossRef] [PubMed]

- Farag, M.A.; Gad, M.Z. Omega-9 fatty acids: Potential roles in inflammation and cancer management. J. Genet. Eng. Biotechnol. 2022, 20, 48. [Google Scholar] [CrossRef] [PubMed]

- Carrillo, C.; del M. Cavia, M.; Alonso-Torre, S. Role of oleic acid in immune system; mechanism of action; a review. Nutr. Hosp. 2012, 27, 978–990. [Google Scholar] [CrossRef] [PubMed]

- Gillingham, L.G.; Harris-Janz, S.; Jones, P.J. Dietary monounsaturated fatty acids are protective against metabolic syndrome and cardiovascular disease risk factors. Lipids 2011, 46, 209–228. [Google Scholar] [CrossRef] [PubMed]

- Arsic, A.; Stojanovic, A.; Mikic, M. Oleic acid-health benefits and status in plasma phospholipids in the Serbian population. Exp. Appl. Biomed. Res. 2019, 20, 3–8. [Google Scholar] [CrossRef]

- Izar, M.C.D.O.; Lottenberg, A.M.; Giraldez, V.Z.R.; Santos Filho, R.D.D.; Machado, R.M.; Bertolami, A.; Machado, V.A. Position statement on fat consumption and cardiovascular health. Arq. Bras. Cardiol. 2021, 116, 160–212. [Google Scholar] [CrossRef] [PubMed]

- Barnes, S.; Chowdhury, S.; Gatto, N.M.; Fraser, G.E.; Lee, G.J. Omega-3 fatty acids are associated with blood–brain barrier integrity in a healthy aging population. Brain Behav. 2021, 11, e2273. [Google Scholar] [CrossRef] [PubMed]

- Mehdi, S.; Manohar, K.; Shariff, A.; Kinattingal, N.; Wani, S.U.D.; Alshehri, S.; Krishna, K.L. Omega-3 fatty acids supplementation in the treatment of depression: An observational study. J. Pers. Med. 2023, 13, 224. [Google Scholar] [CrossRef] [PubMed]

- Sedighiyan, M.; Abdollahi, H.; Karimi, E.; Badeli, M.; Erfanian, R.; Raeesi, S.; Abdolahi, M. Omega-3 polyunsaturated fatty acids supplementation improve clinical symptoms in patients with Covid-19: A randomised clinical trial. Int. J. Clin. Pract. 2021, 75, e14854. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Q.; Xie, F.; Huang, W.; Hu, M.; Yan, Q.; Chen, Z.; Liu, L. The review of alpha-linolenic acid: Sources, metabolism, and pharmacology. Phytother. Res. 2022, 36, 164–188. [Google Scholar] [CrossRef] [PubMed]

| Whole Milk before Fermentation | Whole Milk Fermented with Kefir 30 h after Fermentation |

|---|---|

| pH | |

| 6.7 a | 3.9 b |

| 6.7 a | 3.9 b |

| 6.7 a | 3.9 b |

| 6.7 ± 0.03 a | 3.9 ± 0.01 b |

| % lactic acid | |

| 0.3 b | 0.5 a |

| 0.3 b | 0.6 a |

| 0.3 b | 0.8 a |

| 0.3 ± 0.01 b | 0.6 ± 0.08 a |

| (%) | Pasteurized Whole Milk | Fermented Cream Cheese with Cream | Fermented Cream Cheese without Cream |

|---|---|---|---|

| Total carbohydrates | 3.7 a | 2.5 b | 2.0 c |

| Glucose-reducing carbohydrates | 3.7 a | 2.5 b | 2.1 c |

| Total carbohydrates in Glucose | 3.7 a | 2.5 b | 2.0 |

| Lactose | 5.2 a | 3.4 b | 2.9 c |

| Sucrose | 0 | 0 | 0 |

| (%) | Fermented Cream Cheese without Cream | Fermented Cream Cheese with Cream |

|---|---|---|

| Humidity | 80.4 a | 80.1 a |

| Carbohydrates | 8.9 a | 8.9 a |

| Protein | 5.7 a | 5.7 a |

| Lipids | 4.3 a | 4.6 a |

| Ash | 0.7 a | 0.7 a |

| Fatty Acid Common Names (g/100 g) | Commercial Cream Cheese | Fermented Cream Cheese without Cream | Fermented Cream Cheese with Cream |

|---|---|---|---|

| C4:0 (butyric) | 0.01 b ± 0.01 | 0.004 c ± 0.00 | 0.08 a ± 0.00 |

| C6:0 (caproic) | 0.02 b ± 0.02 | 0.004 c ± 0.00 | 0.08 a ± 0.05 |

| C8:0 (caprylic) | 0.01 b ± 0.01 | 0.002 c ± 0.00 | 0.06 a ± 0.03 |

| C10:0 (capric) | 0.04 b ± 0.02 | 0.014 c ± 0.00 | 0.15 a ± 0.05 |

| C12:0 (lauric) | 0.08 b ± 0.03 | 0.039 c ± 0.00 | 0.22 a ± 0.06 |

| C14:0 (myristic) | 0.37 a ± 0.08 | 0.209 c ± 0.01 | 0.95 a ± 0.28 |

| C14:1 (myristoleic) | 0.03 b ± 0.01 | 0.014 c ± 0.00 | 0.08 a ± 0.02 |

| C15:0 (pentadecanoic) | 0.04 b ± 0.01 | 0.031 c ± 0.00 | 0.11 a ± 0.03 |

| C16:0 (palmitic) | 1.62 c ± 0.01 | 0.973 b ± 0.08 | 1.84 a ± 0.20 |

| C16:1 (trans-palmitoleic) | 0.05 b ± 0.01 | 0.031 c ± 0.00 | 0.13 a ± 0.03 |

| C17:0 (heptadecanoic) | 0.03 b ± 0.00 | 0.028 b ± 0.00 | 0.08 a ± 0.03 |

| C18:0 (stearic) | 0.79 c ± 0.00 | 0.929 b ± 0.10 | 1.51 a ± 0.66 |

| C18:1 n9 (oleic) | 1.24 c ± 0.06 | 1.401 b ± 0.14 | 3.26 a ± 0.17 |

| C18:3 n3 (alfa-linolenic) | - | 0.01 b ± 0.00 | 0.02 a ± 0.00 |

| C18:2 n6 (linoleic) | 0.08 b ± 0.01 | 0.071 c ± 0.00 | 0.13 a ± 0.04 |

| C20:0 (arachidic) | 0.10 c ± 0.01 | 0.175 b ± 0.02 | 0.26 a ± 0.05 |

| C22:0 (beenic) | - | 0.008 a ± 0.00 | 0.01 a ± 0.00 |

| C20:4 (arachidonic) | 0.00 a ± 0.00 | 0.01 a ± 0.00 | 0.08 a ± 0.00 |

| Total fatty acids | |||

| Saturated | 3.13 b | 2.43 c | 5.35 a |

| Unsaturated | 1.60 b | 1.35 c | 7.62 a |

| Trans fatty acid | 0 | 0 | 0 |

| Monounsaturated | 1.31 c | 1.45 b | 3.47 a |

| Polyunsaturated | 0.09 b | 0.09 b | 0.15 a |

| Omega 3 | 0 c | 0.01 b | 0.02 a |

| Omega 6 | 0.08 b | 0.08 b | 0.45 a |

| Omega 9 | 1.24 c | 1.40 b | 3.30 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Freitas, D.R.; Kamimura, E.S.; Mazalli, M.R. Artisanal Cream Cheese Fermented with Kefir Grains. Fermentation 2024, 10, 420. https://doi.org/10.3390/fermentation10080420

Freitas DR, Kamimura ES, Mazalli MR. Artisanal Cream Cheese Fermented with Kefir Grains. Fermentation. 2024; 10(8):420. https://doi.org/10.3390/fermentation10080420

Chicago/Turabian StyleFreitas, Denise Rossi, Eliana Setsuko Kamimura, and Mônica Roberta Mazalli. 2024. "Artisanal Cream Cheese Fermented with Kefir Grains" Fermentation 10, no. 8: 420. https://doi.org/10.3390/fermentation10080420

APA StyleFreitas, D. R., Kamimura, E. S., & Mazalli, M. R. (2024). Artisanal Cream Cheese Fermented with Kefir Grains. Fermentation, 10(8), 420. https://doi.org/10.3390/fermentation10080420