Abstract

The raw materials (coals different stages of metamorphism) and technological factors (period and temperature) of the coke-making that determine the carbon structure of blast furnace coke, and its physical and mechanical properties are analyzed. The change granulometric composition of the coke as a function of the coal batch properties is described in detail. The installation determines the possibility of influencing the carbon structure of coke, its granulometric composition in its production in order to increase the yields of the most valuable fractions, and improving its quality characteristics to achieve high-performance blast furnaces. Analysis of the results indicates that, with no changes in the coking conditions, the granulometric composition depends significantly on the ash content and packing density of the coal batch. Research has shown that the petrographic composition of the coal batch also affects the structure and size of the coke. The closest relationship is established between the magnitude of the fusinized components ΣFC and the output of the coke fractions 80–60 mm, 40–25 mm, and <25 mm. The method of mechanical treatment and stabilizing of blast furnace coke is proposed, which includes the improvement of the initial indexes of its quality M25, M10, and class >80 mm in continuous or periodically working open or closed industrial cylindrical oblique stabilizer drum.

1. Introduction

Coke performs the functions of a complex energy-technological material in the blast furnace. In the processes of its transformation, the main part of the heat necessary for melting processes is released, and the main part of the reducing gas is formed, to which an additional part of the gas from direct reduction is added horizontally above. In addition to the specified energy functions, coke performs the function of a solid deposit in the zone softening and melting of iron-containing materials, which ensures a counterflow of the charge and gases in the furnace as well as the function of gas distribution regulator over the cross-sectional area of the unit. In this regard, high demands are placed on the quality of coke.

Coke quality is key to a satisfactory furnace operation and may be assessed in terms of physical characteristics (indices of resistance to coke abrasion and crushability, granulometric composition), chemical composition, coke reactivity index, and coke strength after reaction. In terms of chemical composition, we require coke with maximum carbon content and minimum ash and sulfur content. In terms of granulometric (fractional) composition, the coke must be of a uniform size with a minimum content of the smallest (<25 mm) and largest (>80 mm) classes.

Under the conditions of improving blast furnace smelting and the use of energy-saving technologies, the requirements for the quality of coke are: crushability (M25) is not less than 90%; resistance to attrition of coke (M10) no more than 6%; class content (>80 mm) no more than 5%; class content (<25 mm) no more than 5%; humidity fluctuations no more than ±0.5%; coke reactivity index CRI = 23–26%; and coke strength after reaction CSR = 70%.

The structure of the coke substance determines its physical properties. The raw materials (coals different stages of metamorphism) and technological factors (period and temperature) of the coke-making determine the carbon structure of blast furnace coke and its physical and mechanical properties.

The presence of good clinkering properties of coals and the batch determines the high mechanical properties of the coke. The deepening of the thermochemical transformations of the coal substance also leads to an improvement in the structure of the coke. Therefore, to obtain high-strength coke with low abrasion, an appropriate component composition of the batch is required with a sufficient level of clinkering, an optimal level of grinding, and an appropriate thermal mode of its coking.

Disordered and ordered coke carbon form isotropic and anisotropic types of coke microstructures, differing in reactivity. Moreover, the formation of an anisotropic microstructure is due to the presence of carriers of the cohesive ability of coal—vitrinite and liptinite macerals. The non-sintering inertinite causes the formation of an isotropic microstructure [1,2,3].

Scientific studies have established an index of dependence of the hot strength of coke (CSR) on the degree of metamorphism of coal, which is somewhat characterized by the reflectance index of vitrinite (R0). Thus, the minimum values of CSR are typical for low-metamorphosed coal, and the maximum is reached in the area of coal in the middle stage of metamorphism (1.1 ≥ R0 ≤ 1.3), which is explained by the difference in the structure of coal depending on the degree of coalification [1,2,3].

In some works [4,5], it is shown that a higher content of inertinite in the original coal can increase the reactivity and reduce the post-reaction strength of the coke formed, and this effect is more pronounced for coal of medium stages of metamorphism than for low metamorphism.

The article [6] provides data indicating that the reactivity of coke from the coal fraction enriched with inertinite (coke from inertinite) is higher than for coke from the fraction enriched with vitrinite (coke from vitrinite). This is probably related to the surface area of micropores, which increases with the increase in the content of macerals of the inertinite group in the coal. The degree of orderliness of the carbon structure of coke depends on the maceral composition and the grade of the original coal. Thus, coke from vitrinite has a higher degree ordering of the carbon structure Lc than coke obtained from inertinite.

The authors [7,8], on the basis of experimental data, report that the lower degree order characteristic of isotropic and mosaic structure coke is clearly characterized by a decrease in the quality of the coke, which is accompanied by an increase in reactivity and a decrease in the post-reaction strength.

Thus, metallurgical coke should be considered as a composite material, the strength and reactivity of which depend on the content of isotropic carbon, the shape and size of inert anisotropic carbon units, as well as the porosity and chemical composition of the mineral component [1].

The work practice of the coke plants of Ukraine shows that in order to obtain coke with high mechanical strength, it is necessary to ensure the following quality of the coal batch: Ad ≤ 8.4%; Std ≤ 1.10%; Vdaf ≤ 27–28%; mean vitrinite reflection coefficient, R0 ≥ 1%; the clinkering, y = 16–18 mm; basicity index, Ib < 2.5 [9].

The molecular structure, strength, and porosity of the coke are determined, in addition to the properties of coals and the composition of the coked batch, by the conditions of the coking process. Increasing the coking rate lowers the hardness of the char material. The lower the speed and the higher the final temperature, the deeper the processes of condensation and ordering of the carbon layers, the higher the hardness of the coke material. As the coking rate increases, the temperature gradient increases, and hence, the shrinkage rate gradient increases. This leads to an increase in internal stresses, an increase in coke cracking, and a significant reduction in strength [9,10].

As the coal rank increases, the aromatic nuclei also increase, and the aromatic structure is altered after the heat treatment [11]. In general, as the pyrolysis temperature increases, the size of the aromatic nuclei is enhanced, as demonstrated by the crystallite size (L11), aromaticity (fa), and interlayer spacing (d002/dγ). In the study by Lu [12], after heating at 1200 °C, the L11 value of the raw coal increased from ~5.9–6.5 to ~7.8–10 Å while the fa changed from 58–72% to 75–82%. Concurrently, the d002 decreased from ~3.5–3.59 Å for the raw coal to ~3.46–3.53 Å for the heated coal while dγ reduced from ~4.72–5.01 Å to ~4.33–4.74 Å, correspondingly.

Thus, in high quality coke d002 = 0.346–0.356 nm (for graphite 0.340 nm), the amount of carbon contained in block structures (Cb) is 72–88%, Lc = 2.1–2.2 nm, La = 5–6 nm. With an increase in the final temperature, the values of d002 and Lc decrease while Cb and La increase [9].

An example of the change in properties of coke produced at the Kriviy Rih coke plant on the same day from the same batch in normal coking conditions (14 h 10 min) and after furnace deterioration was presented. In that case, the piece size of the coke increases on account of increase in the content of the 80–60 and 60–40 mm classes. Thus, the yield of the >80 mm class declines from 8.7 to 6.8%; the yield of the 80–60 and 60–40 mm classes increases, respectively, from 35 to 29.6% and from 34.7 to 41.6%; and the yield of the 40–25 mm and <25 mm classes declines, respectively, from 17.6 to 8.6% and from 4.0 to 3.4%. The strength (M40) increases from 72.2 to 82.4% while the susceptibility to wear (M10) falls from 10.0 to 5.8%. Considerable change in granulometric composition of the coke is also seen in switching from a wet to dry slaking of the coke. Dry slaking significantly increases the content of the most valuable 40–60 mm class in the gross coke and reduces the content of the >80 mm class, which consists of the weakest coke [13,14].

The study of the relationship between raw and technological factors with structural features and physical and mechanical properties of coke makes it possible to develop methods for increasing the strength, uniformity, and uniformity of its granulometric composition.

2. Materials and Methods

The study was carried out in the conditions of the coke plant of ArcelorMittal Kryvyi Rih. Sampling of coal concentrates and coal batch was carried out manually from the surface of the stopped conveyor using a device (frame). A frame was installed on the conveyor belt, which was two parallel walls vertically located at a distance that was at least two sizes of the maximum piece.

The frame was immersed in the coal raw material to the transport surface perpendicular to the flow direction. The selected sample was delivered to the coal testing room for further preparation for the test. The preparation included successive operations of grinding, reduction, and separation of the sample. Equipment and tools for sample preparation met the requirements of State standard of Ukraine 4096–2002: “Brown coal, hard coal, anthracite, combustible shale and coal briquettes. Methods of sample selection and preparation for laboratory tests” [15].

The coal batch sample was poured onto the sampling table and sifted through a sieve with cell sizes of 3 mm. Grains that did not pass through the sieve were crushed and sieved again until the entire sample passed through the sieve. Next, the sample was thoroughly mixed with the shoveling method, which consists of placing the sample on the table, then scooping it evenly around the perimeter with scoops, pouring it into one point, and taking it to the center to form a cone. The operation was repeated three times with a change in the location of the cone. Then, the sample was reduced by the quartering method in the following order:

- -

- The cone obtained after mixing was leveled so that the upper part was in the shape of a circle with a uniform thickness of the layer. The center of the circle had to coincide with the center of the cone;

- -

- The circle was divided into four parts using a cross;

- -

- Two diametrically opposite parts were discarded, and the remaining parts were combined; the reduction operation was repeated until the weight was at least 2 kg;

- -

- In order to prevent an error, two opposite parts were rejected at each subsequent operation. Next, the sample was divided into four parts with the help of a cross to determine the quality parameters of the coal raw material.

The following standardized methods were used to assess the composition and properties of coal:

- -

- State standard of Ukraine 4096–2002 “Brown coal, hard coal, anthracite, combustible shale and coal briquettes. Methods of sample selection and preparation for laboratory tests” [15];

- -

- ІSО 1171-97 “Solid mineral fuels. Methods for determination of ash” [16];

- -

- ІSО 589-81 “Hard coal—Determination of total moisture” [17];

- -

- ІSО 7404-3-84 “Methods for the petrographic analysis of bituminous coal and anthracite—Part 3: Method of determining maceral group composition” [18];

- -

- ІSО 7404-5-85 “Methods for the petrographic analysis of coals—Part 5: Method of determining microscopically the reflectance of vitrinite” [19];

- -

- State standard of Ukraine 7722:2015 “Hard coal. Method of Determining Plastometric Characteristics” [20].

We may consider the petrographic assessment of the technological value of coking batch on the basis of characteristics developed at the Ukrainian Coal-Chemistry Institute [9,21,22].

Thus, the quantity of vitrinite components corresponding to intermediate metamorphic stages, as recalculated for the coal’s organic mass, was expressed by the clinkering characteristic (Cb) of the batch [9,21,22]:

where Σ(0.90–1.39) was the content of vitrinite components with reflectance in the range 0.9–1.39%; Vt was the concentration of vitrinite-group macerals, %.

A second coking characteristic (Kb) of the batch was calculated from the formula [9,21,22]:

Here, Σ(0.90–1.39) was the content of vitrinite components with reflectance in the range 0.9–1.39%; Vt was the concentration of vitrinite-group macerals, %; L was the concentration of liptinite-group macerals, %; ΣFC was the sum of fusinized macerals (I + 2/3Sv), %; Σ(>1.70) Vt/100 was the content of vitrinite components with reflectance of 1.70% or more.

On the basis of Cb and Kb, we may obtain a general quantitative estimate of the batch’s petrographic characteristics, including the maceral composition and the results of reflectogram analysis. With increase in Cb, the strength of the coke produced will be higher. In turn, with increase in Kb, the probability of wear-resistant and relatively uncrushable coke will increase, as other conditions are equal [23].

In order to improve the preparation of coal batch for coking, we must optimize the degree of crushing (the content of the <3 mm class), taking account of the petrographic characteristics of the batch components.

On the basis of petrographic analysis and the Ukrainian Coal-Chemistry Institute method, we recommend determining the optimal size class of the batch (%) as a function of its actual rank composition [24]:

where Σ(0.5–2.6) is the content of the vitrinite components with reflectance in the range 0.5–2.6%, corresponding to different coal ranks; 75 is the recommended degree of crushing of Zh and K coal, %; 90 is the recommended degree of crushing of G, OS, and T coal, %; and ΣFC—sum of fusinized components (I + 2/3Sv), %.

In addition, determination of the plastic properties of coal according to Gieseler was used as special methods. The spacer pressure was determined on a unified laboratory furnace according to the methodology outlined in the paper [25].

The essence of Gieseler’s method is to determine the plastic properties of coal (batches) when heated in a crucible with a stirrer by measuring the speed of rotation of the stirrer in the plastic mass that is formed depending on the temperature increase. The expansion pressure is the pressure applied by the coal mass in a plastic state when free expansion is impossible. In the tests, we recorded the following temperatures (°C): the onset of softening (t1); maximum fluidity (tmax); solidification (tso); and the plastic range (Δt = t1 – tso). The most important of the measured characteristics was the maximum fluidity (Fmax, ddpm (dial divisions per minute)), which characterized the viscosity of the plastic mass [25].

The results of box coking were used to determine the yield of coke from coal concentrates and to assess its quality indicators. To carry out box coking, coal batches weighing 5–6 kg, selected in accordance with SSTU 4096–2002 [15], were loaded into metal boxes, the dimensions of which were 200 × 200 × 200 mm. The necessary bulk density of coal batches was achieved by shaking the boxes against a hard surface three times. Coal batches were covered from above with a paper pad and then with lids, which were fixed from above with rods. Samples were taken from experimental coal batches to determine their total moisture content, technical analysis, petrographic analysis, and plastometric characteristics.

Metal boxes were installed in the middle hatch of the coke oven after releasing the bunkers of the coal loading car, which are located on the coke and machine sides. After the metal boxes were installed, the middle hopper of the coal loading car was released and planning was carried out. When issuing coke from the coking chambers, the temperature along the axis of the coke cake was measured with a pyrometer.

The temperature in the control verticals and the coking period of the chamber in which the boxes were installed were recorded. After coking, the coke cake together with the experimental boxes was delivered to the extinguishing car, extinguished under the extinguishing tower, and after settling, it was delivered to the ramp. Boxes with experimental coke were removed and delivered to the laboratory, where the coke was removed from the boxes onto a baking sheet. Deco with coke was installed in a drying cabinet with a temperature of 190 °C, where the coke was dried to a constant mass. The dried coke was weighed.

The properties of coke were evaluated using the following standardized methods:

- -

- ІSО 556-80 “Coke (greater than 20 mm in size)—Determination of mechanical strength” [26];

- -

- ІSО 728-81 “Coke (nominal top size greater than 20 mm)—Size analysis” [27].

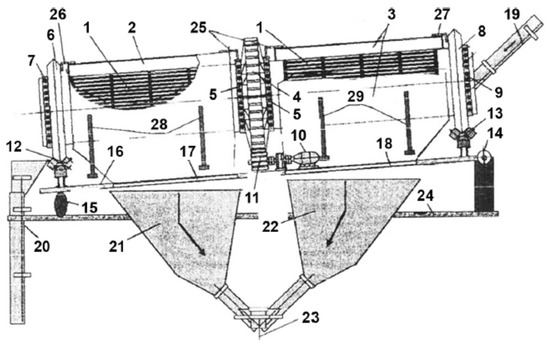

Coke processing was proposed to be carried out in the unit, which was a drum (Figure 1), the cylindrical surface of which was made in the form of profile rods with a distance between them, depending on the size of the lattice part of the coke that was given, or in the form of replaceable cards with holes of a given size and shape.

Figure 1.

Unit for obtaining the specified properties of coke: 1—classification drum; 2, 3—front and back cover; 4, 5, 25—known main drive gear, its drum attachment and retainer; 6, 8, 26, 27—front and rear support ring of the drum and their fastening; 7, 9—mounting the support rims to the drum; 10—electric drive; 11—known drive gear; 12, 13—roller supports; 14, 16—system of change of angle of inclination; 15—the location of the drum; 17, 18—front and rear openings for drum failure; 19—a coke chute that is loaded; 20—unloading chute of the drum; 21, 22, 23—gutter unloading troughs; 24—construction site for the placement of the unit for obtaining the specified properties of coke; 28, 29—support of front and back cover.

The material occurred side the rotating drum, depending on the speed of rotation, may be in cascade or waterfall or centrifugal modes. A centrifuge drum with a diameter D was created at a rotational speed equal to the critical one. Under these conditions, centrifugal force was applied to the material against the wall of the drum. The rotation of the material occured together with the drum without moving each other [28].

Managing the unit of obtaining the specified properties of coke through the method of maintaining the capacity of the coke was in the plan of stability of the bulk of the power so as to reach one of the two indicators of the given value to save a good deal for the aggregate.

3. Results and Discussion

In order to study the influence of the quality of raw materials and technology on the structure of coke and its physical and mechanical properties under the conditions of ArcelorMittal Krivyi Rih, the qualitative indicators of the coal batch (moisture content, ash content, petrographic composition (according to ΣFC), bulk density, content of class 3–0 mm in batch) [14,23,29] were used to analyze the distribution of the coke by size classes and its mechanical strength.

An analysis of the influence of raw materials and technological factors on the distribution of the coke by size classes showed the following:

- -

- Reducing the humidity of the charge leads to a decrease in the size of the coke, but the output of the coke of different classes varies unevenly;

- -

- The macerate composition of the coal batch also affects the size of the coke. The closest relationship is established between the magnitude of the fusinized components ΣFC and the output of the coke fractions 80–60 mm (correlation coefficient r = 0.8), 40–25 mm (r = 0.83), and <25 mm (r = 0.87). Thus, as the content of the fusinized components in the coal mixture increases, the coke size decreases, which is accompanied by an increase in the yield of the fractions of 40–25 mm and <25 mm;

- -

- When coal ash content is increased by 1%, there is a redistribution of the size classes, which is accompanied by an increase in the outputs of class >80 mm by an average of 3.5% and a class <25 mm by 1.5% and a corresponding decrease in the outputs of the most valuable classes of 60–40 mm and class 40–25 mm.

- -

- Increasing the uniformity and homogeneity of the granulometric composition of the coke can be obtained when optimal values of the packing density of the coal batch are achieved, which in turn is provided by the optimization of the granulometric composition of the batch, reducing humidity and ash content.

An effective tool for influencing the structure of the coke and its physical and mechanical properties can be the choice of the optimal level of grinding of the batch.

Optimization of the granulometric composition of the batch leads to fluctuations in the bulk density of the coal load and also affects the gas permeability of the plastic mass; the shrinkage of the coke and the nature of the stress during the transition of semi-coke to coke; the amount and properties of liquid, solid, and volatile products thermal destruction; and the stickiness of the batch.

The petrographic analysis is essential to the production of high-quality coke when using petrographically nonuniform coal and to expanding the enrichment of coals of different ranks. That entails the introduction of characteristics based on petrographic analysis in the theory and practice of coking-batch crushing.

To study the possibility of implementing the method in the coke production, samples of the production coal batch were taken, the quality indicators of which, according to the data of technical and plastometric analyses, are given in Table 1, the petrographic characteristics of which are given in Table 2.

Table 1.

Indicators of proximate and plastometric analysis.

Table 2.

Petrographic characteristics of coal batches.

Data for calculating the optimal grinding size for the 0–3 mm class of composite charges according to the proposed equation are taken from the reflectograms of the petrographic analysis of these batches [24,30].

According to the proposed method, the calculated value of the optimal degree of grinding for the specified batches is listed in Table 3.

Table 3.

Calculated value of the optimal degree of grinding for the batches.

Thus, the correction of the degree of coal blend crushing permits the maintenance of the coke quality consistent with blast furnace requirements (minimum strength M25 = 88–89%, M10 = 6–7%) [24].

For a better assessment of how the degree of crushing affects the strength of blast furnace coke, we determine the expansion pressure and the Gieseler plasticity of the coal blends.

Thus, with the increase in the degree of crushing batches, the fluidity of the plastic mass declines considerably (from 335 to 135 ddpm), and its viscosity increases accordingly. The spacer pressure increased from 4.2 to 7.4 kPa. The increase in the viscosity of the plastic mass leads to a decrease in its gas permeability, so the destruction products are in contact with each other for a longer time. This leads to a more complete use of the products formed during destruction as plasticizers, the formation of additional liquid products from gaseous ones inside the grain, and the improvement of their contact conditions [31].

Currently, the only direction to improve the quality of blast furnace coke at virtually all coke plants was and remains the factors provided by the properties of coal raw materials and coke production technology.

However, this process is not completely controllable. In addition, the attraction of coal concentrates with optimal caking and favorable chemical compositions of the mineral part is associated with a shortage of resources and is limited by economic feasibility.

Practically the only way to ensure the management of properties, up to obtaining the required strength and composition indicators of the coke obtained in the layer process and traditional coke ovens, is the mechanical processing (stabilization) of the coke.

The most suitable process for the classification and quality management of coke is the unit of obtaining the specified properties of the coke, which performs the function of stabilizing the coke, classifying and improving its quality with the selected indicator to the required level. It is suggested to install the specified unit (Figure 1) instead of a roller screen.

Thus, if necessary, the granulometric composition of the coke is improved, in particular by reducing the content of the fraction >80 mm from 11 to 3% and finding the number of revolutions of the test drum that is required to change the amount of the specified fraction. To do this, we solve the equation [32] with respect to:

where at = 3, = 22.5 rotate to compute:

to find:

By installing the drum stabilizer at an angle of 11.5 degrees and processing the coke, we improve its quality in terms of the particle size.

The disadvantage of this method of machining blast furnace coke, including the improvement of the output indicators of its quality M25 (M40), M10, and class >80 mm in continuous or periodically operating open or closed cylindrical oblique drum stabilizer [32], is that the improvement output cold indicators of its quality (an increase in M25 (M40) indicators and decrease in the M10 index and content of class >80 mm) do not limit the amount of blast furnace coke losses, which results in a decrease (deficiency) in the amount of coke supplied in the blast furnace, and causes the coke to be consumed in the blast furnace and increase the specific cost of pig iron production.

To improve the quality of the coke while limiting the transfer of blast furnace coke into the screenings (reducing blast furnace coke loss), it is necessary to select and set the optimum inclination angle for continuously or intermittently working open or closed industrial cylindrical oblique drum stabilizer that provides the required rotation speed.

We suggest [32] determining and installing the drum stabilizer at a certain angle of its inclination to improve the physical and mechanical properties of the coke (increase M25 to 88–90% and decrease M10 to 5–6% and class >80 mm to 3–4%). In order to improve these indicators of coke quality, it is necessary to determine and install the drum stabilizer at a certain angle of inclination to the horizon (α) and choose the required number of revolutions (n), which on the one hand, will allow for the improvement of the performance and, on the other, will prevent the transfer of pieces of the coke to the screenings, which is necessary to achieve a reduction in the output of class <25 mm and increase the number of suitable coke fractions (25–80 mm), which are loaded into the blast furnace.

The advantage and difference of the methods are that the angle of inclination of the drum stabilizer to the horizon and the number of its revolutions is chosen from the optimum number of revolutions of the test drum Mikum on the dynamics of improving the initial indicators of coke quality for every one–two revolutions of the drum, taking into account the sums of the products of the coefficients of indices each indicator and the amount of specific consumption of the coke in the blast furnace, and the number of revolutions of the drum stabilizer limits the loss of blast furnace coke not more than 3.0–3.5% of the original value.

To determine the optimal α and n for the processing pieces of the coke in a stationary drum-stabilizer, first test coke, determining changes from the original M25, M10 and class >80 mm, in the Mikum drum after 1–2 rotations.

On the basis of these tests the optimum number of revolutions (nm) is determined, for which the dynamics of improving the output indicators of coke quality for each 1–2 turns of the drum determines the sum of the outputs of indicators of quality of the coke on the coefficients of influence of each indicator on the reduction of the specific consumption of the coke (M25 + 1%—−0.6%; M10 − 1%—−2.8% and >80 mm − 1%—−0.2%) and the amount of specific consumption of the coke in a blast furnace, to which this batch of stabilized coke is fed.

The obtained amount of coke savings in the blast furnace due to its stabilization is compared with the amount of blast furnace coke losses, that is, they constantly monitor the output of the class <25 mm.

In this regard, we propose to limit the number of revolutions of the drum-stabilizer the amount of blast furnace coke, preventing the increase yield of class <25 mm more than 3.0–3.5% of the original value. Choosing the optimum number of revolutions nm determines the optimal α and n for the drum-stabilizer by the formulas:

where —angle of inclination of the drum, degrees; L—length of the drum, m; nm—optimum speed of the Mikum drum, and

where D—diameter of the drum-stabilizer.

Thus, in a blast furnace, for example, with a volume of 5000 m3, which melts 9390 tons of iron per day, at a specific consumption of coke—450 kg/t, the quality of the coke is stabilized by its stabilization in a continuously or intermittently open cylindrical roller drum which is open or closed. Possible use is to install a drum stabilizer instead of roller screen for coking in a coke shop.

The difference (Δ) of indicators M25, M10 and the amount of coke fraction >80 mm resulting from machining were multiplied by the coefficients of influence of each indicator and the amount of specific consumption of coke in the blast furnace. All results of the calculations are shown in Table 4.

Table 4.

Modification of coke properties and reduction of its specific consumption as a result of machining.

Table 4 shows that the total reduction in the specific consumption of coke first changes by 2 turns by 11.3 kg/t of iron, and then decreases. After 22 revolutions, the effect decreased to 1.2 kg in 2 revolutions. In total, if we estimate the effect of reducing the consumption of coke per ton of pig iron, which is a direct reduction in the cost of cast iron, at a processing of 14 revolutions and the conventional cost of a ton of coke (3600 $/t), the cost decrease will be 3600·0.02768 ≈ 99.6 $/t. In this case, the loss of blast furnace coke will be only 3.28%.

The drum stabilizer for coke machining can be 5–8 m long and 1.75 to 2.5 m in diameter, depending on the performance of the drum and the limits of its adjustable speed.

On a blast furnace with a volume of 5000 m3, taking into account its productivity, it is possible to use a drum stabilizer with length 8.5 m and diameter 2 m, then set the angle of inclination to the horizon equal to:

and the number of its revolutions will be equal to:

4. Conclusions

In order to improve the clinkering and coking properties of the coal and, ultimately, the quality of the coke, we must optimize the degree of crushing (the content of the <3 mm class), taking account the petrographic characteristics of the batch components.

The application of the proposed method, which involves taking into account petrographic characteristics and increasing the degree of grinding of low-clinkering components, will ensure the improvement of the coke structure.

In our opinion, in this case, the improvement in coke strength is predominantly due to an increase in the expansion pressure of the coal blend, which results not only in a greater use of the liquid destruction products as plasticizers, but also in the formation of additional liquid from the gaseous products within the grains. That is associated with better softening of the coal grains and more complete contact between the grains (in some cases, their coalescence).

In terms of the shortage of resources of coal concentrates with optimal caking the alternative economic feasibility way of obtaining high-quality coke is its stabilization.

Taking into account the high losses of blast furnace coke, the choice of rational parameters of the technology of the stabilization of coke quality indices in an industrial cylindrical oblique drum stabilizer can significantly reduce the cost of cast iron in blast furnaces.

Thus, the use of the process of machining pieces of coke can not only stabilize the properties of coke, but also significantly improve them until you get the set, desired performance particle size, strength, and resistance to friction.

Author Contributions

Conceptualization, D.M. and K.S.; methodology, D.M.; investigation, K.S.; data curation, D.M.; writing—original draft preparation, D.M., K.S., and M.K.; writing—review and editing, M.K.; visualization, K.S.; supervision, D.M.; project administration, D.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Diez, M.A.; Alvarez, R.; Barriocanal, C. Coal for metallurgical coke production: Predictions of coke quality and future requirements for cokemaking. Int. J. Coal Geol. 2002, 50, 389–412. [Google Scholar] [CrossRef]

- Gupta, S.; Shen, F.; Lee, W.J.; O’Brien, G. Improving coke strength prediction using automated coal petrography. Fuel 2012, 94, 368–373. [Google Scholar] [CrossRef]

- Xing, X.; Rogers, H.; Zulli, P.; Hockings, K.; Ostrovski, O. Effect of coal properties on the strength of coke under simulated blast furnace conditions. Fuel 2019, 237, 775–785. [Google Scholar] [CrossRef]

- Pusz, S.; Buszko, R. Reflectance parameters of cokes in relation to their reactivity index (CRI) and the strength after reaction (CSR), from coals of the Upper Silesian Coal Basin, Poland. Int. J. Coal Geol. 2012, 90, 9–43. [Google Scholar] [CrossRef]

- Dash, P.S.; Guha, M.; Chakraborty, D.; Banerjee, P.K. Prediction of coke CSR from coal blend characteristics using various techniques: A comparative evaluation. Int. J. Coal. Prep. Util. 2012, 32, 92–169. [Google Scholar] [CrossRef]

- Grigore, M.; Sakurovs, R.; French, D.; Sahajwalla, V. Properties and CO2 reactivity of the inert and reactive maceral derived components in cokes. Int. J. Coal Geol. 2012, 98, 1–9. [Google Scholar] [CrossRef]

- Pusz, S.; Krzesińska, M.; Smędowski, Ł.; Majewska, J.; Pilawa, B.; Kwiecińska, B. Changes in a coke structure due to reaction with carbon dioxide. Int. J. Coal Geol. 2010, 81, 92–287. [Google Scholar] [CrossRef]

- Pusz, S.; Buszko, R. Microscopic characteristics and technological parameters of cokes from various initial coals. In Proceedings of the 62nd Meeting of the International Committee for Coal and Organic Petrology (ICCP), Belgrade, Serbia, 26 September–2 October 2010. [Google Scholar]

- Kaftan, Y.S.; Drozdnyk, I.D.; Miroshnnichenko, D.V.; Bidolenko, N.B.; Holovko, M.B. Development of scientific foundations of the composition of coal batches from coals of different basins. J. Coal Chem. 2010, 3, 25–31. [Google Scholar]

- North, L.; Blackmore, K.; Nesbitt, K.; Mahoney, M.R. Mahoney Methods of coke quality prediction: A review. Fuel 2018, 219, 426–445. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, G.; Xue, Q.; Zuo, H.; She, X.; Wang, J. Effect of preheating on coking coal and metallurgical coke properties. Fuel Process. Technol. 2021, 22, 106942. [Google Scholar] [CrossRef]

- Lu, L.; Sahajwalla, V.; Harris, D. Characteristics of chars prepared from various pulverized coals at different temperatures using drop-tube furnace. Energy Fuels 2000, 14, 869–876. [Google Scholar] [CrossRef]

- Lyalyuk, V.P.; Kassim, D.A.; Shmeltser, E.O.; Lyakhova, I.A. Influence of the properties raw coal materials and coking technology on the granulometric composition of coke. Message 1. Analysis of changes in particle size distribution of coke on the example of the coke plant in Krivyi Rih. Pet. Coal 2020, 62, 173–177. [Google Scholar]

- Lyalyuk, V.P.; Kassim, D.A.; Shmeltser, E.O.; Lyakhova, I.A. Influence of the properties raw coal materials and coking technology on the granulometric composition of coke. Message 2. Granulometric composition of the coke as a function of the coal batch properties. Pet. Coal 2020, 62, 309–315. [Google Scholar]

- State standard of Ukraine 4096-2002; Brown Coal, Hard Coal, Anthracite, Combustible Shale and Coal Briquettes. Methods of Sample Selection and Preparation for Laboratory Tests. Technical Committee of Ukraine on standardization TK-92: Kyiv, Ukraine, 2002.

- ІSО 1171-97; Solid Mineral Fuels. Methods for Determination of Ash. International Organization for Standardization: Geneva, Switzerland, 1997.

- ІSО 589-81; Hard Coal—Determination of Total Moisture. International Organization for Standardization: Geneva, Switzerland, 1981.

- ІSО 7404-3-84; Methods for the Petrographic Analysis of Bituminous Coal and Anthracite—Part 3: Method of Determining Maceral Group Composition. International Organization for Standardization: Geneva, Switzerland, 1984.

- ІSО 7404-5-85; Methods for the Petrographic Analysis of Coals—Part 5: Method of Determining Microscopically the Reflectance of Vitrinite. International Organization for Standardization: Geneva, Switzerland, 1985.

- State standard of Ukraine 7722:2015; Hard Coal. Method of Determining Plastometric Characteristics. State enterprise “Ukrainian scientific research and training center for problems of standardization, certification and quality”: Kyiv, Ukraine, 2015.

- Mukina, N.V.; Miroshnnichenko, D.V. Coking of Stamped Coal Batch. 1. Batch with ≤40% Gas Coal. Coke Chem. 2021, 64, 237–245. [Google Scholar] [CrossRef]

- Mukina, N.V.; Miroshnnichenko, D.V. Coking of Stamped Coal Batch. 2. Batch with ≥40% Gas Coal. Coke Chem. 2021, 64, 290–298. [Google Scholar] [CrossRef]

- Shmeltser, E.O.; Lyalyuk, V.P.; Sokolova, V.P.; Miroshnichenko, D.V. The using of coal blends with an increased content of coals of the middle stage of metamorphism for the production of the blast-furnace coke. Message 1. Preparation of coal blends. Pet. Coal 2018, 60, 605–611. [Google Scholar]

- Lyalyuk, V.P.; Lyakhova, I.A.; Kassim, D.A.; Shmeltser, K.O.; Lyakhova, I.A.; Zhuravlʹov, F.M.; Svyst, N.Y. Ukrainien Patent 85803. Byull. Izobret. 2013, 22. Available online: https://base.uipv.org/searchINV/search.php?action=viewdetails&IdClaim=194518 (accessed on 6 June 2023).

- ISO 10329:2009; Coal-Determination of Plastic Properties Constant-Torque Gieseler Plastometer Method. International Organization for Standardization: Geneva, Switzerland, 2009.

- ІSО 556-80; Coke (Greater than 20 mm in Size)—Determination of Mechanical Strength. International Organization for Standardization: Geneva, Switzerland, 1980.

- ІSО 728-81; Coke (Nominal Top Size Greater than 20 mm)—SIZE Analysis. International Organization for Standardization: Geneva, Switzerland, 1981.

- Lyalyuk, V.P.; Kassim, D.A.; Shmeltser, E.O.; Lyakhova, I.A. Influence of the properties raw coal materials and coking technology on the granulometric composition of coke. Message 3. Method of Machining Blast Furnace Coke. Pet. Coal 2020, 62, 659–663. [Google Scholar]

- Lyalyuk, V.P.; Kassim, D.A.; Shmeltser, E.O.; Lyakhova, I.A. Improving the technology of preparing coal for the production of blast-furnace coke under the conditions of multi-basin raw material base. Message 3. Influence of the moisture content of coal batch on the physicomechanical characteristics of the coke. Pet. Coal 2019, 61, 433–441. [Google Scholar]

- Lyalyuk, V.P.; Kassim, D.A.; Shmeltser, E.O.; Lyakhova, I.A. Improving the technology of preparing coal for the production of blast—Furnace coke under the conditions of multi-basin raw material base. Message 2. Optimizing the degree of crushing by means of petrographic characteristics of the batch components. Pet. Coal 2019, 61, 94–99. [Google Scholar]

- Shmeltser, E.O.; Lyalyuk, V.P.; Sokolova, V.P.; Miroshnichenko, D.V. The using of coal blends with an increased content of coals of the middle stage of metamorphism for the production of the blast-furnace coke. Message 2. Assessment of coke quality. Pet. Coal 2019, 61, 52–57. [Google Scholar]

- Muchnyk, D.A.; Tovarovs’kyy, I.H.; Lyalyuk, V.P.; Shmeltser, E.O. Ukrainien Patent 127112. Byull. Izobret. 2018, 13. Available online: https://base.uipv.org/searchINV/search.php?action=viewdetails&IdClaim=249299 (accessed on 6 June 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).