Variable Temperature Synthesis of Tunable Flame-Generated Carbon Nanoparticles

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bond, T.C.; Doherty, S.J.; Fahey, D.W.; Forster, P.M.; Berntsen, T.; Deangelo, B.J.; Flanner, M.G.; Ghan, S.; Kärcher, B.; Koch, D.; et al. Bounding the role of black carbon in the climate system: A scientific assessment. J. Geophys. Res. Atmos. 2013, 118, 5380–5552. [Google Scholar]

- Ramanathan, V.; Carmichael, G. Global and regional climate changes due to black carbon. Nat. Geosci. 2008, 1, 221–227. [Google Scholar] [CrossRef]

- Kennedy, I.M. The health effects of combustion-generated aerosols. Proc. Combust. Inst. 2007, 31, 2757–2770. [Google Scholar] [CrossRef]

- Pedata, P.; Stoeger, T.; Zimmermann, R.; Peters, A.; Oberdörster, G.; D’Anna, A. Are we forgetting the smallest, sub 10 nm combustion generated particles? Part. Fibre Toxicol. 2015, 12, 1–4. [Google Scholar] [CrossRef] [PubMed]

- De Falco, G.; Terlizzi, M.; Sirignano, M.; Commodo, M.; D’Anna, A.; Aquino, R.P.; Pinto, A.; Sorrentino, R. Human peripheral blood mononuclear cells (PBMCs) from smokers release higher levels of IL-1-like cytokines after exposure to combustion-generated ultrafine particles. Sci. Rep. 2017, 7, 43016. [Google Scholar] [CrossRef] [PubMed]

- Khodabakhshi, S.; Fulvio, P.F.; Andreoli, E. Carbon black reborn: Structure and chemistry for renewable energy harnessing. Carbon 2020, 162, 604–649. [Google Scholar] [CrossRef]

- Liu, H.; Ye, T.; Mao, C. Fluorescent carbon nanoparticles derived from candle soot. Angew. Chem. Int. Ed. 2007, 46, 6473–6475. [Google Scholar] [CrossRef]

- Wei, Z.; Yan, K.; Chen, H.; Yi, Y.; Zhang, T.; Long, X.; Li, J.; Zhang, L.; Wang, J.; Yang, S. Cost-efficient clamping solar cells using candle soot for hole extraction from ambipolar perovskites. Energy Environ. Sci. 2014, 7, 3326–3333. [Google Scholar] [CrossRef]

- Bruno, A.; Commodo, M.; Haque, S.A.; Minutolo, P. Spectroscopic investigation of flame synthesized carbon nanoparticle/P3HT blends. Carbon 2015, 94, 955–961. [Google Scholar] [CrossRef]

- Kakunuri, M.; Sharma, C.S. Candle soot derived fractal-like carbon nanoparticles network as high-rate lithium ion battery anode material. Electrochim. Acta 2015, 180, 353–359. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, D.; Yu, B.; Zhou, F.; Liu, W. Candle soot as a supercapacitor electrode material. RSC Adv. 2014, 4, 2586–2589. [Google Scholar] [CrossRef]

- Li, R.; Mao, H.; Zhu, M.; Yang, Y.; Xiong, J.; Wang, W. Facile preparation of broadband absorbers based on patternable candle soot for applications of optical sensors. Sens. Actuators A 2019, 285, 111–117. [Google Scholar] [CrossRef]

- Pankaj, A.; Tewari, K.; Singh, S.; Singh, S.P. Waste candle soot derived nitrogen doped carbon dots based fluorescent sensor probe: An efficient and inexpensive route to determine Hg(II) and Fe(III) from water. J. Environ. Chem. Eng. 2018, 6, 5561–5569. [Google Scholar] [CrossRef]

- Liang, C.-J.; Liao, J.-D.; Li, A.-J.; Chen, C.; Lin, H.-Y.; Wang, X.-J.; Xu, Y.-H. Relationship between wettabilities and chemical compositions of candle soots. Fuel 2014, 128, 422–427. [Google Scholar] [CrossRef]

- Campbell, D.J.; Andrews, M.J.; Stevenson, K.J. New nanotech from an ancient material: Chemistry demonstrations involving carbon-based soot. J. Chem. Educ. 2012, 89, 1280–1287. [Google Scholar] [CrossRef]

- Commodo, M.; De Falco, G.; Larciprete, R.; D’Anna, A.; Minutolo, P. On the hydrophilic/hydrophobic character of carbonaceous nanoparticles formed in laminar premixed flames. Exp. Therm. Fluid Sci. 2016, 73, 56–63. [Google Scholar] [CrossRef]

- Cao, H.; Fu, J.; Liu, Y.; Chen, S. Facile design of superhydrophobic and superoleophilic copper mesh assisted by candle soot for oil water separation. Colloids Surf. A Physicochem. Eng. Asp. 2018, 537, 294–302. [Google Scholar] [CrossRef]

- Zulfiqar, U.; Hussain, S.Z.; Subhani, T.; Hussain, I.; Rehman, H.-U. Mechanically robust superhydrophobic coating from sawdust particles and carbon soot for oil/water separation. Colloids Surf. A Physicochem. Eng. Asp. 2018, 539, 391–398. [Google Scholar] [CrossRef]

- Esmeryan, K.D.; Fedchenko, Y.I.; Yankov, G.P.; Temelkov, K.A. Laser irradiation of super-nonwettable carbon soot coatings–physicochemical implications. Coatings 2021, 11, 58. [Google Scholar] [CrossRef]

- Mulay, M.R.; Chauhan, A.; Patel, S.; Balakrishnan, V.; Halder, A.; Vaish, R. Candle soot: Journey from a pollutant to a functional material. Carbon 2019, 144, 684–712. [Google Scholar] [CrossRef]

- Li, S.; Ren, Y.; Biswas, P.; Tse, S.D. Flame aerosol synthesis of nanostructured materials and functional devices: Processing, modeling, and diagnostics. Prog. Energy Combust. Sci. 2016, 55, 1–59. [Google Scholar] [CrossRef]

- Kumal, R.R.; Gharpure, A.; Viswanathan, V.; Mantri, A.; Skoptsov, G.; Wal, R.V. Microwave plasma formation of nanographene and graphitic carbon black. C. J. Carbon Res. 2020, 6, 70. [Google Scholar] [CrossRef]

- D’Anna, A. Combustion-formed nanoparticles. Proc. Combust. Inst. 2009, 32, 593–613. [Google Scholar] [CrossRef]

- Wang, H. Formation of nascent soot and other condensed-phase materials in flames. Proc. Combust. Inst. 2011, 33, 41–67. [Google Scholar] [CrossRef]

- Michelsen, H.A. Probing soot formation, chemical and physical evolution, and oxidation: A review of in situ diagnostic techniques and needs. Proc. Combust. Inst. 2017, 36, 717–735. [Google Scholar] [CrossRef]

- Karataş, A.E.; Gülder, O.L. Soot formation in high pressure laminar diffusion flames. Prog. Energy Combust. Sci. 2012, 38, 818–845. [Google Scholar] [CrossRef]

- Zhao, B.; Yang, Z.; Wang, J.; Johnston, M.V.; Wang, H. Analysis of soot nanoparticles in a laminar premixed ethylene flame by scanning mobility particle sizer. Aerosol Sci. Technol. 2003, 37, 611–620. [Google Scholar] [CrossRef]

- Maricq, M.M. Size and charge of soot particles in rich premixed ethylene flames. Combust. Flame 2004, 137, 340–350. [Google Scholar] [CrossRef]

- Abid, A.D.; Camacho, J.; Sheen, D.A.; Wang, H. Quantitative measurement of soot particle size distribution in premixed flames—The burner-stabilized stagnation flame approach. Combust. Flame 2009, 156, 1862–1870. [Google Scholar] [CrossRef]

- Commodo, M.; De Falco, G.; Bruno, A.; Borriello, C.; Minutolo, P.; D’Anna, A. Physicochemical evolution of nascent soot particles in a laminar premixed flame: From nucleation to early growth. Combust. Flame 2015, 162, 3854–3863. [Google Scholar] [CrossRef]

- Carbone, F.; Attoui, M.; Gomez, A. Challenges of measuring nascent soot in flames as evidenced by high-resolution differential mobility analysis. Aerosol Sci. Technol. 2016, 50, 740–757. [Google Scholar] [CrossRef]

- Betrancourt, C.; Liu, F.; Desgroux, P.; Mercier, X.; Faccinetto, A.; Salamanca, M.; Ruwe, L.; Kohse-Höinghaus, K.; Emmrich, D.; Beyer, A.; et al. Investigation of the size of the incandescent incipient soot particles in premixed sooting and nucleation flames of n-butane using LII, HIM, and 1 nm-SMPS. Aerosol Sci. Technol. 2017, 51, 916–935. [Google Scholar] [CrossRef]

- De Falco, G.; Commodo, M.; Bonavolontà, C.; Pepe, G.P.; Minutolo, P.; D’Anna, A. Optical and electrical characterization of carbon nanoparticles produced in laminar premixed flames. Combust. Flame 2014, 161, 3201–3210. [Google Scholar] [CrossRef]

- De Falco, G.; Commodo, M.; Barra, M.; Chiarella, F.; D’Anna, A.; Aloisio, A.; Cassinese, A.; Minutolo, P. Electrical characterization of flame-soot nanoparticle thin films. Synth. Met. 2017, 229, 89–99. [Google Scholar] [CrossRef]

- Commodo, M.; De Falco, G.; Minutolo, P.; D’Anna, A. Structure and size of soot nanoparticles in laminar premixed flames at different equivalence ratios. Fuel 2018, 216, 456–462. [Google Scholar] [CrossRef]

- Liu, Y.; Song, C.; Lv, G.; Fan, C.; Zhang, X.; Qiao, Y. Relationships between the electrical properties and nanostructure of soot particles in a laminar inverse diffusion flame. Proc. Combust. Inst. 2019, 37, 1185–1192. [Google Scholar] [CrossRef]

- De Falco, G.; Mattiello, G.; Commodo, M.; Minutolo, P.; Shi, X.; D’Anna, A.; Wang, H. Electronic band gap of flame-formed carbon nanoparticles by scanning tunneling spectroscopy. Proc. Combust. Inst. 2021, 38, 1805–1812. [Google Scholar] [CrossRef]

- Liu, Y.; Song, C.; Lv, G.; Zhang, W.; Chen, H. Evaluation of the oxidative reactivity and electrical properties of soot particles. Carbon 2021, 178, 37–47. [Google Scholar] [CrossRef]

- Öktem, B.; Tolocka, M.P.; Zhao, B.; Wang, H.; Johnston, M.V. Chemical species associated with the early stage of soot growth in a laminar premixed ethylene–oxygen–argon flame. Combust. Flame 2005, 142, 364–373. [Google Scholar] [CrossRef]

- Cain, J.P.; Camacho, J.; Phares, D.J.; Wang, H.; Laskin, A. Evidence of aliphatics in nascent soot particles in premixed ethylene flames. Proc. Combust. Inst. 2011, 33, 533–540. [Google Scholar] [CrossRef]

- Miller, J.H.; Herdman, J.D.; Green, C.D.O.; Webster, E.M. Experimental and computational determinations of optical band gaps for PAH and soot in a N2-diluted, ethylene/air non-premixed flame. Proc. Combust. Inst. 2013, 34, 3669–3675. [Google Scholar] [CrossRef]

- Schulz, F.; Commodo, M.; Kaiser, K.; De Falco, G.; Minutolo, P.; Meyer, G.; D’Anna, A.; Gross, L. Insights into incipient soot formation by atomic force microscopy. Proc. Combust. Inst. 2019, 37, 885–892. [Google Scholar] [CrossRef]

- Commodo, M.; Kaiser, K.; De Falco, G.; Minutolo, P.; Schulz, F.; D’Anna, A.; Gross, L. On the early stages of soot formation: Molecular structure elucidation by high-resolution atomic force microscopy. Combust. Flame 2019, 205, 154–164. [Google Scholar] [CrossRef]

- Jacobson, R.S.; Korte, A.R.; Vertes, A.; Miller, J.H. The molecular composition of soot. Angew. Chem. Int. Ed. 2020, 59, 4484–4490. [Google Scholar] [CrossRef] [PubMed]

- Dasappa, S.; Camacho, J. Evolution in size and structural order for incipient soot formed at flame temperatures greater than 2100 K. Fuel 2021, 291, 120196. [Google Scholar] [CrossRef]

- Bonpua, J.; Yagües, Y.; Aleshin, A.; Dasappa, S.; Camacho, J. Flame temperature effect on sp2 bonds on nascent carbon nanoparticles formed in premixed flames (Tf, max & gt; 2100 K): A Raman spectroscopy and particle mobility sizing study. Proc. Combust. Inst. 2019, 37, 943–951. [Google Scholar]

- De Falco, G.; Moggia, G.; Sirignano, M.; Commodo, M.; Minutolo, P.; D’Anna, A. Exploring soot particle concentration and emissivity by transient thermocouples measurements in laminar partially premixed coflow flames. Energies 2017, 10, 232. [Google Scholar] [CrossRef]

- Abid, A.D.; Heinz, N.; Tolmachoff, E.D.; Phares, D.J.; Campbell, C.S.; Wang, H. On evolution of particle size distribution functions of incipient soot in premixed ethylene–oxygen–argon flames. Combust. Flame 2008, 154, 775–788. [Google Scholar] [CrossRef]

- Gu, C.; Lin, H.; Camacho, J.; Lin, B.; Shao, C.; Li, R.; Gu, H.; Guan, B.; Huang, Z.; Wang, H. Particle size distribution of nascent soot in lightly and heavily sooting premixed ethylene flames. Combust. Flame 2016, 165, 177–187. [Google Scholar] [CrossRef]

- Ferreira, E.H.M.; Moutinho, M.V.O.; Stavale, F.; Lucchese, M.M.; Capaz, R.B.; Achete, C.A.; Jorio, A. Evolution of the Raman spectra from single-, few-, and many-layer graphene with increasing disorder. Phys. Rev. B Condens. 2010, 82, 125429. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Basko, D.M. Raman spectroscopy as a versatile tool for studying the properties of graphene. Nat. Nanotechnol. 2013, 8, 235–246. [Google Scholar] [CrossRef] [PubMed]

- Merlen, A.; Buijnsters, J.G.; Pardanaud, C. A guide to and review of the use of multiwavelength raman spectroscopy for characterizing defective aromatic carbon solids: From graphene to amorphous carbons. Coatings 2017, 7, 153. [Google Scholar] [CrossRef]

- Sadezky, A.; Muckenhuber, H.; Grothe, H.; Niessner, R.; Pöschl, U. Raman microspectroscopy of soot and related carbonaceous materials: Spectral analysis and structural information. Carbon 2005, 43, 1731–1742. [Google Scholar] [CrossRef]

- Lapuerta, M.; Oliva, F.; Agudelo, J.R.; Stitt, J.P. Optimization of Raman spectroscopy parameters for characterizing soot from different diesel fuels. Combust. Sci. Technol. 2011, 183, 1203–1220. [Google Scholar] [CrossRef]

- Herdman, J.D.; Connelly, B.C.; Smooke, M.D.; Long, M.B.; Miller, J.H. A comparison of Raman signatures and laser-induced incandescence with direct numerical simulation of soot growth in non-premixed ethylene/air flames. Carbon 2011, 49, 5298–5311. [Google Scholar] [CrossRef]

- Seong, H.J.; Boehman, A.L. Evaluation of Raman parameters using visible Raman microscopy for soot oxidative reactivity. Energy Fuels 2013, 27, 1613–1624. [Google Scholar] [CrossRef]

- Minutolo, P.; Commodo, M.; Santamaria, A.; De Falco, G.; D’Anna, A. Characterization of flame-generated 2-D carbon nano-disks. Carbon 2014, 68, 138–148. [Google Scholar] [CrossRef]

- Le, K.C.; Lefumeux, C.; Bengtsson, P.-E.; Pino, T. Direct observation of aliphatic structures in soot particles produced in low-pressure premixed ethylene flames via online Raman spectroscopy. Proc. Combust. Inst. 2019, 37, 869–876. [Google Scholar] [CrossRef]

- Ess, M.N.; Ferry, D.; Kireeva, E.D.; Niessner, R.; Ouf, F.-X.; Ivleva, N.P. In situ Raman microspectroscopic analysis of soot samples with different organic carbon content: Structural changes during heating. Carbon 2016, 105, 572–585. [Google Scholar] [CrossRef]

- Casiraghi, C.; Piazza, F.; Ferrari, A.C.; Grambole, D.; Robertson, J. Bonding in hydrogenated diamond-like carbon by Raman spectroscopy. Diam. Relat. Mater. 2005, 14, 1098–1102. [Google Scholar] [CrossRef]

- Buijnsters, J.G.; Gago, R.; Jiḿnez, I.; Camero, M.; Agulló-Rueda, F.; Gómez-Aleixandre, C. Hydrogen quantification in hydrogenated amorphous carbon films by infrared, Raman, and x-ray absorption near edge spectroscopies. J. Appl. Phys. 2009, 105, 093510. [Google Scholar] [CrossRef]

- Schuepfer, D.B.; Badaczewski, F.; Guerra-Castro, J.M.; Hofmann, D.M.; Heiliger, C.; Smarsly, B.; Klar, P.J. Assessing the structural properties of graphitic and non-graphitic carbons by Raman spectroscopy. Carbon 2020, 161, 359–372. [Google Scholar] [CrossRef]

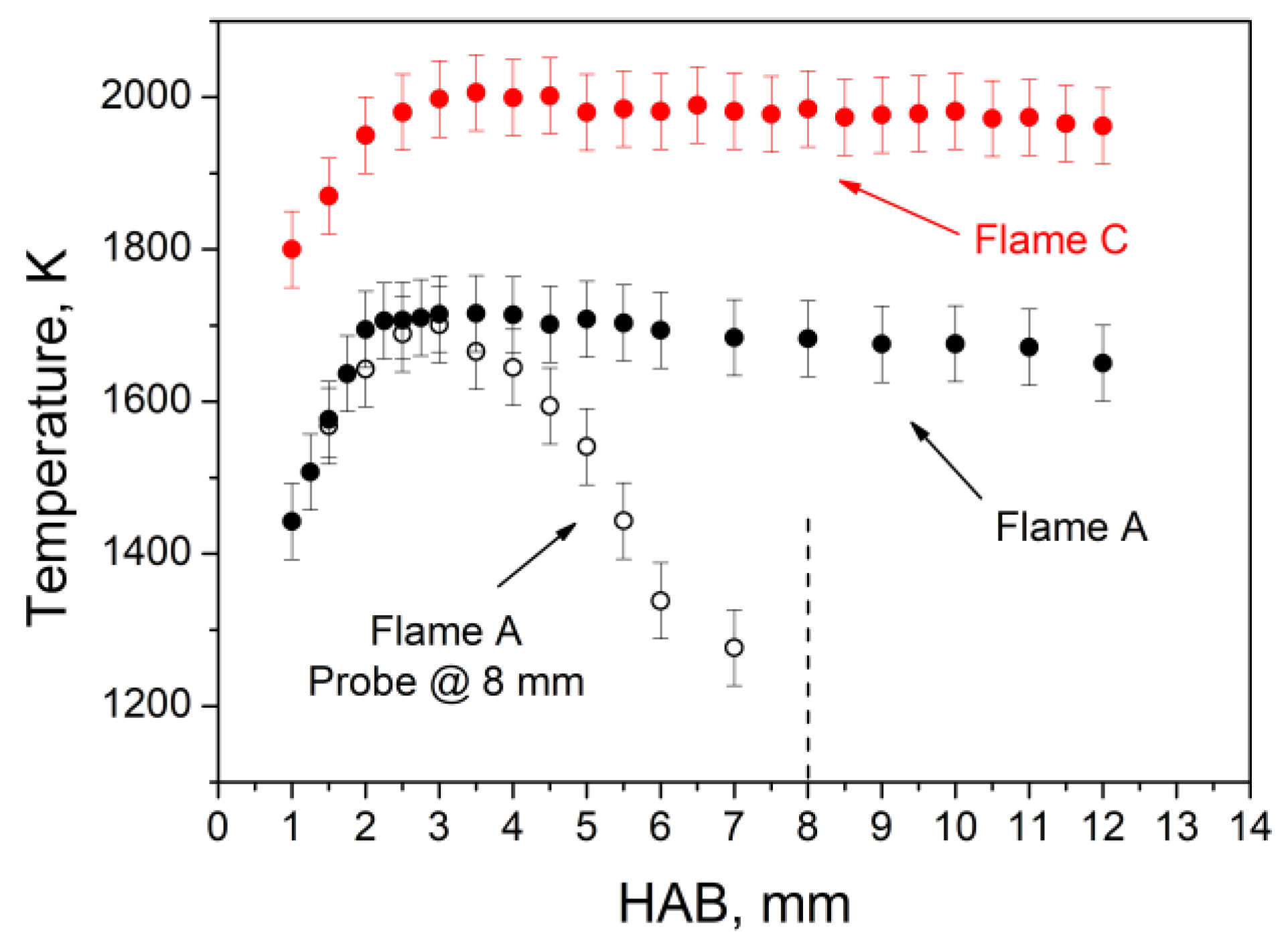

| Flame | Feed Gas | C/O | Gas Velocity, cm/s | Max Temperature, K |

|---|---|---|---|---|

| A | Ethylene/air | 0.67 | 9.8 cm/s | 1715 |

| B | Ethylene/air | 0.67 | 9.8 cm/s | 1820 |

| C | Ethylene/air | 0.69 | 20 cm/s | 2006 |

| D | Ethylene/air | 0.71 | 20 cm/s | 1984 |

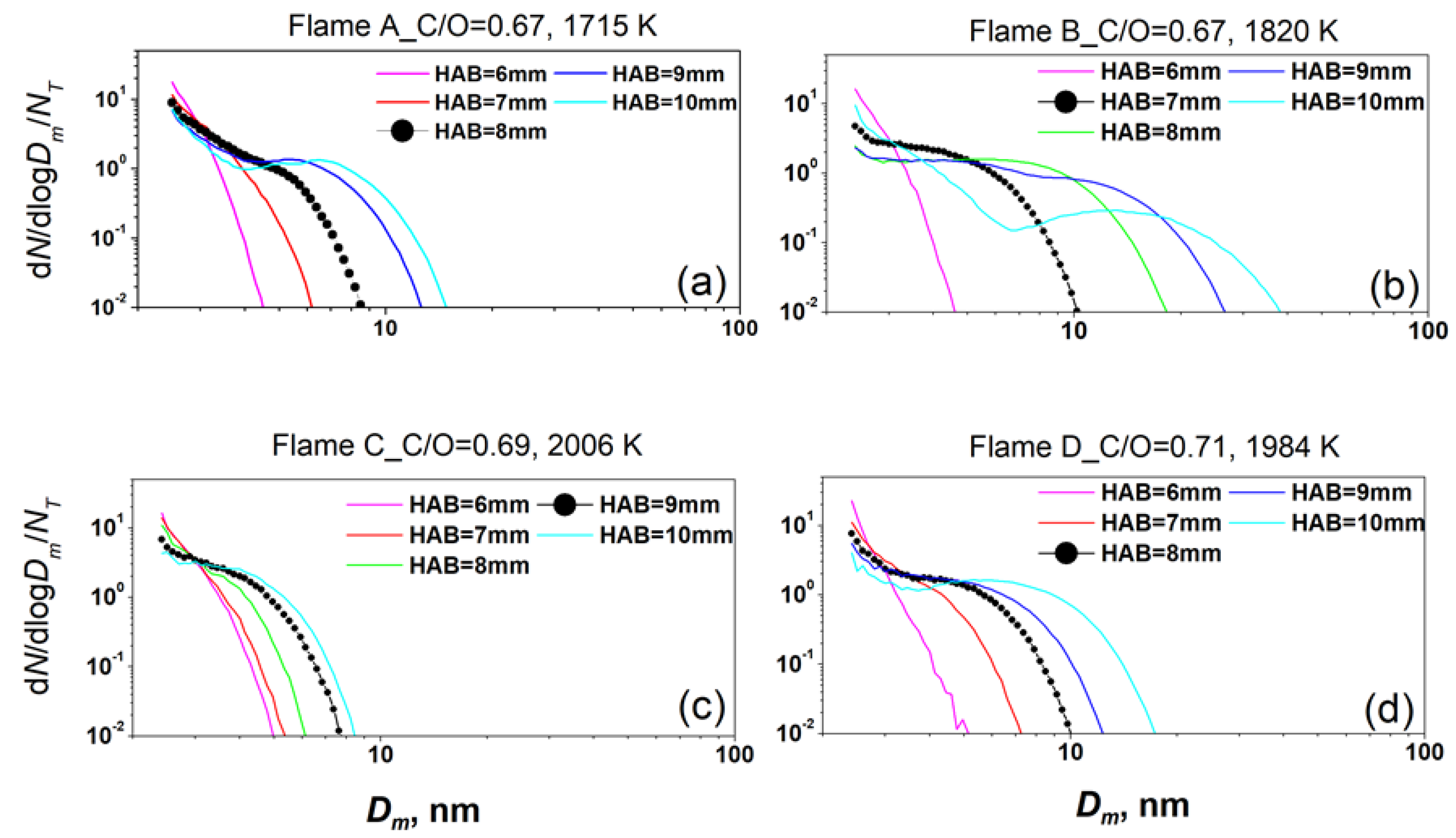

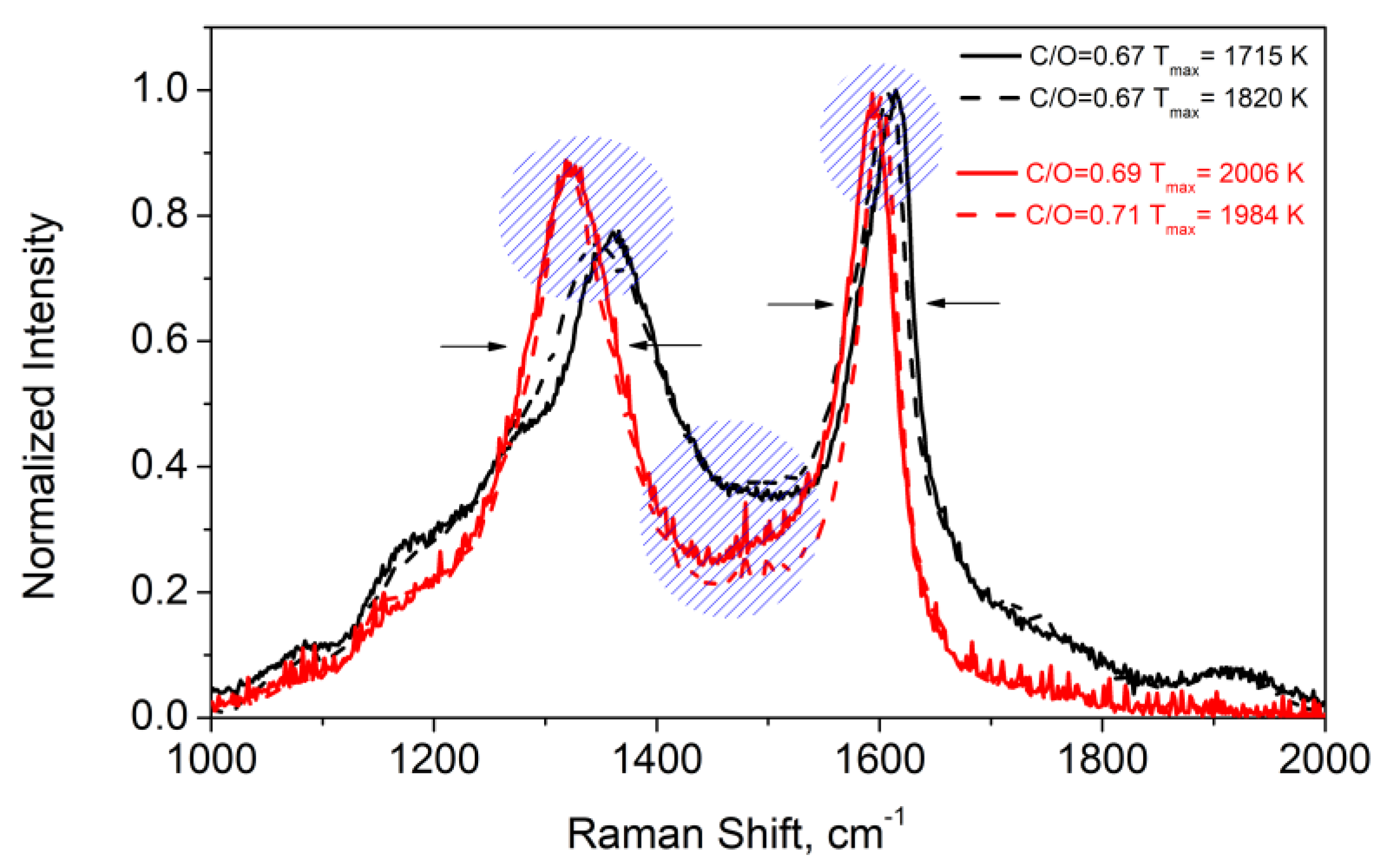

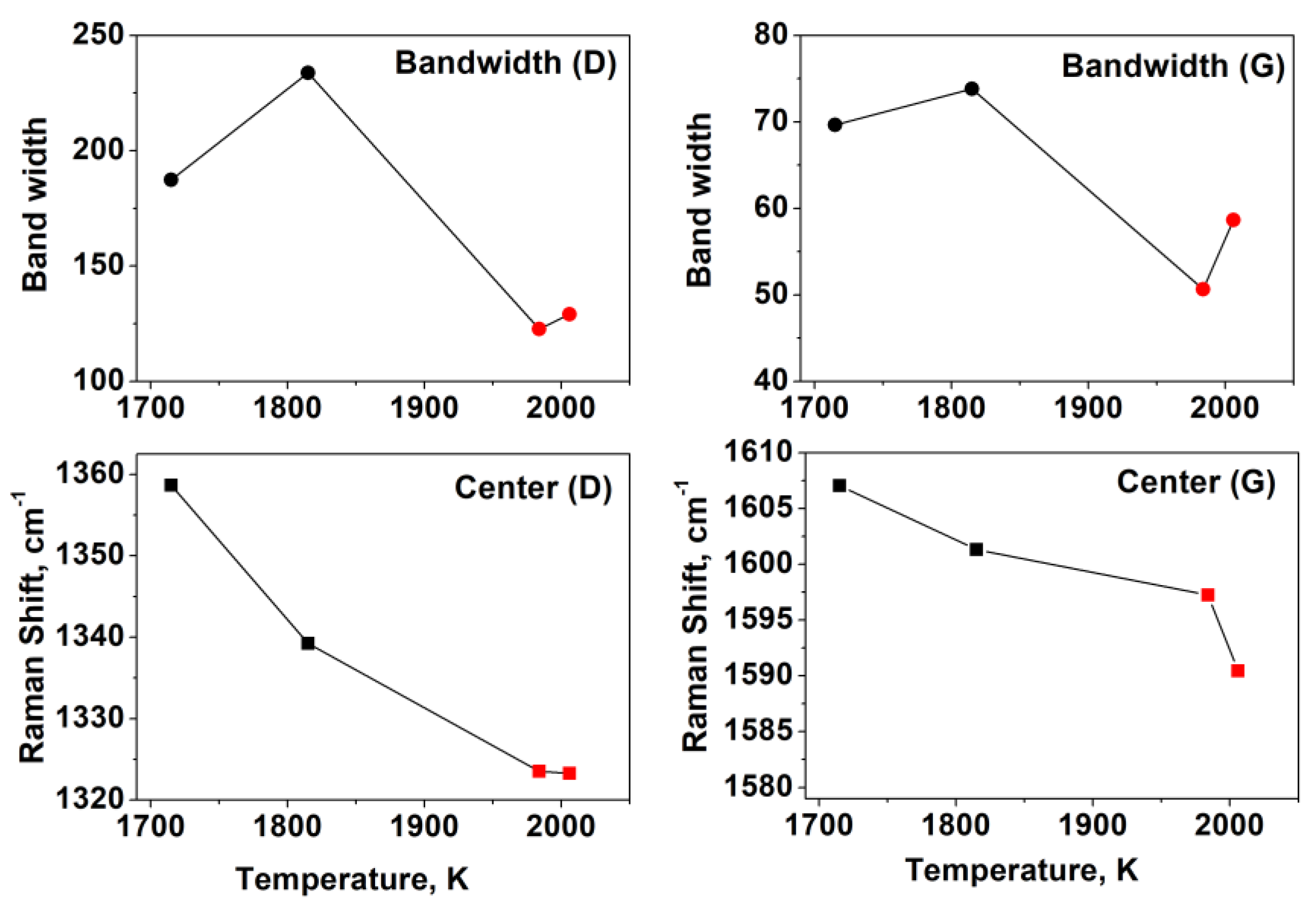

| Flame | C/O Tmax HAB | <Dp> | I(D)/I(G) | La (nm) | m/I(G) | H [%] |

|---|---|---|---|---|---|---|

| A | C/O = 0.67 1715 K 8 mm | 3.34 nm | 0.76 | 1.10 | 3.2 | 30.0 |

| B | C/O = 0.67 1820 K 7 mm | 3.80 nm | 0.75 | 1.09 | 6.6 | 35.3 |

| C | C/O = 0.69 2006 K 9 mm | 3.30 nm | 0.88 | 1.18 | 0.3 | 13.5 |

| D | C/O = 0.71 1984 K 8 mm | 4.06 nm | 0.89 | 1.19 | 0.5 | 17.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Picca, F.; Pietro, A.D.; Commodo, M.; Minutolo, P.; D’Anna, A. Variable Temperature Synthesis of Tunable Flame-Generated Carbon Nanoparticles. C 2021, 7, 44. https://doi.org/10.3390/c7020044

Picca F, Pietro AD, Commodo M, Minutolo P, D’Anna A. Variable Temperature Synthesis of Tunable Flame-Generated Carbon Nanoparticles. C. 2021; 7(2):44. https://doi.org/10.3390/c7020044

Chicago/Turabian StylePicca, Francesca, Angela Di Pietro, Mario Commodo, Patrizia Minutolo, and Andrea D’Anna. 2021. "Variable Temperature Synthesis of Tunable Flame-Generated Carbon Nanoparticles" C 7, no. 2: 44. https://doi.org/10.3390/c7020044

APA StylePicca, F., Pietro, A. D., Commodo, M., Minutolo, P., & D’Anna, A. (2021). Variable Temperature Synthesis of Tunable Flame-Generated Carbon Nanoparticles. C, 7(2), 44. https://doi.org/10.3390/c7020044