Tribological Properties and Wear Mechanisms of Carbide-Bonded Graphene Coating on Silicon Substrate

Abstract

1. Introduction

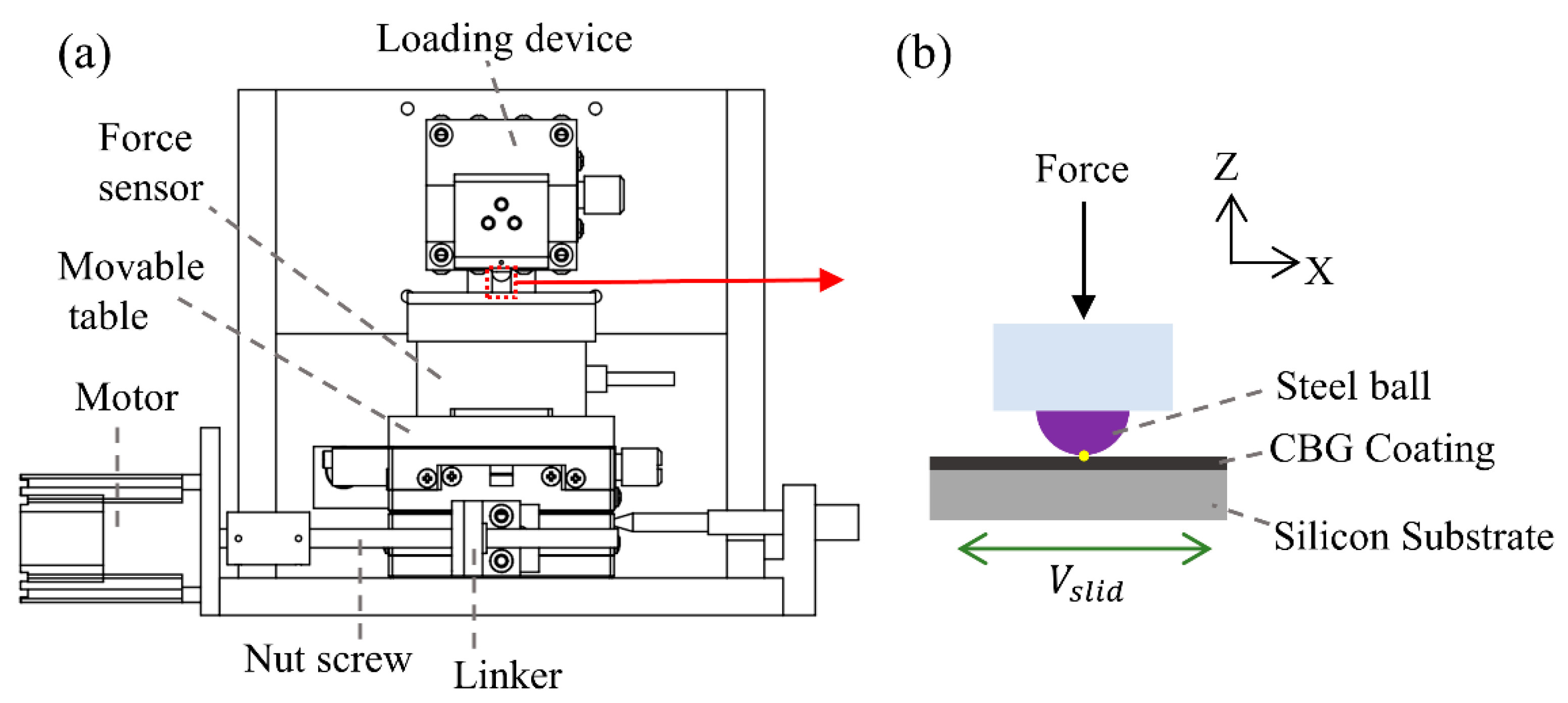

2. Materials and Methods

2.1. Preparation and Characterization of CBG Coating

2.2. Tribological Test Procedure

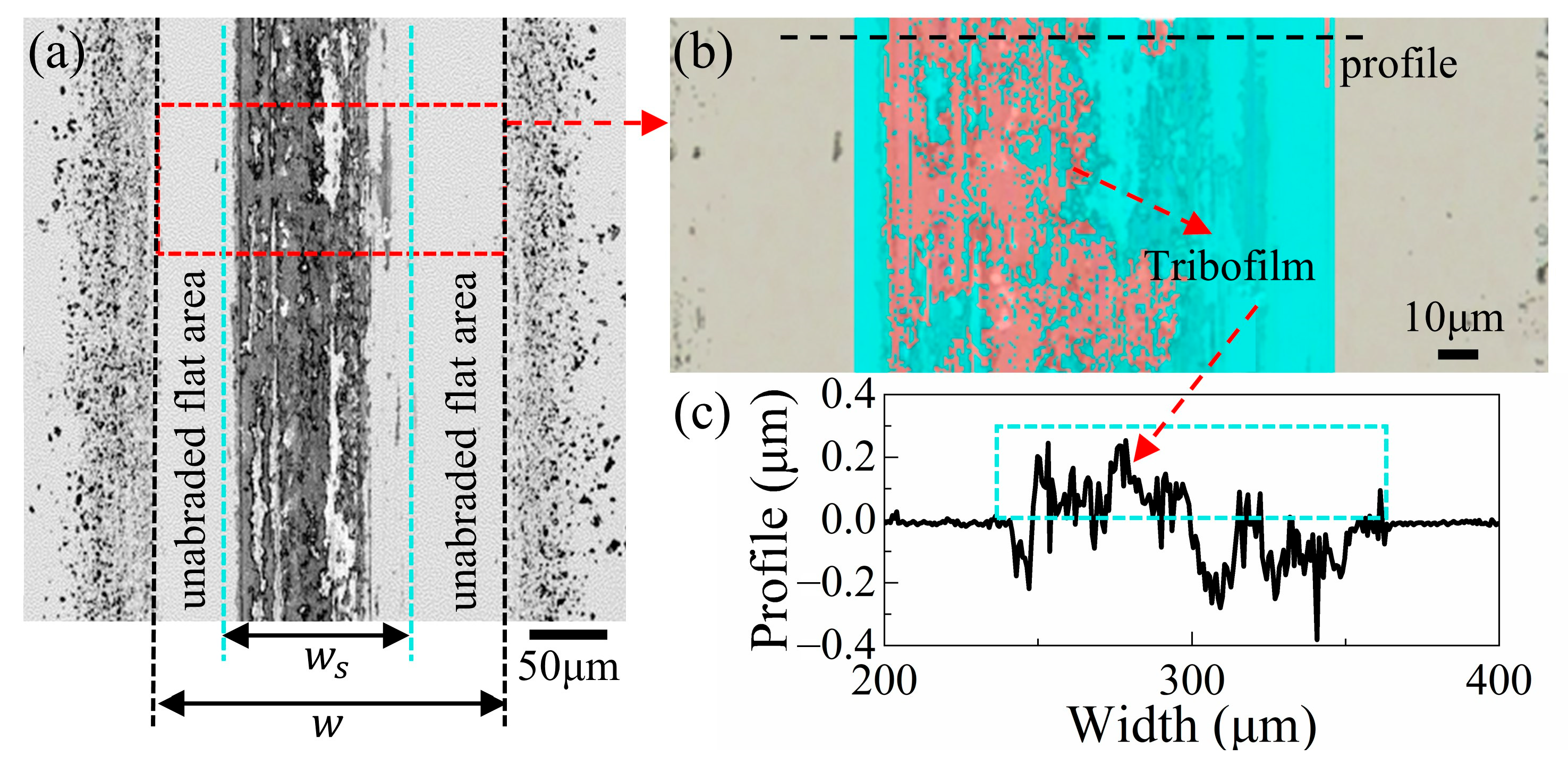

2.3. Quantitative Characterization of Worn Coating

3. Results

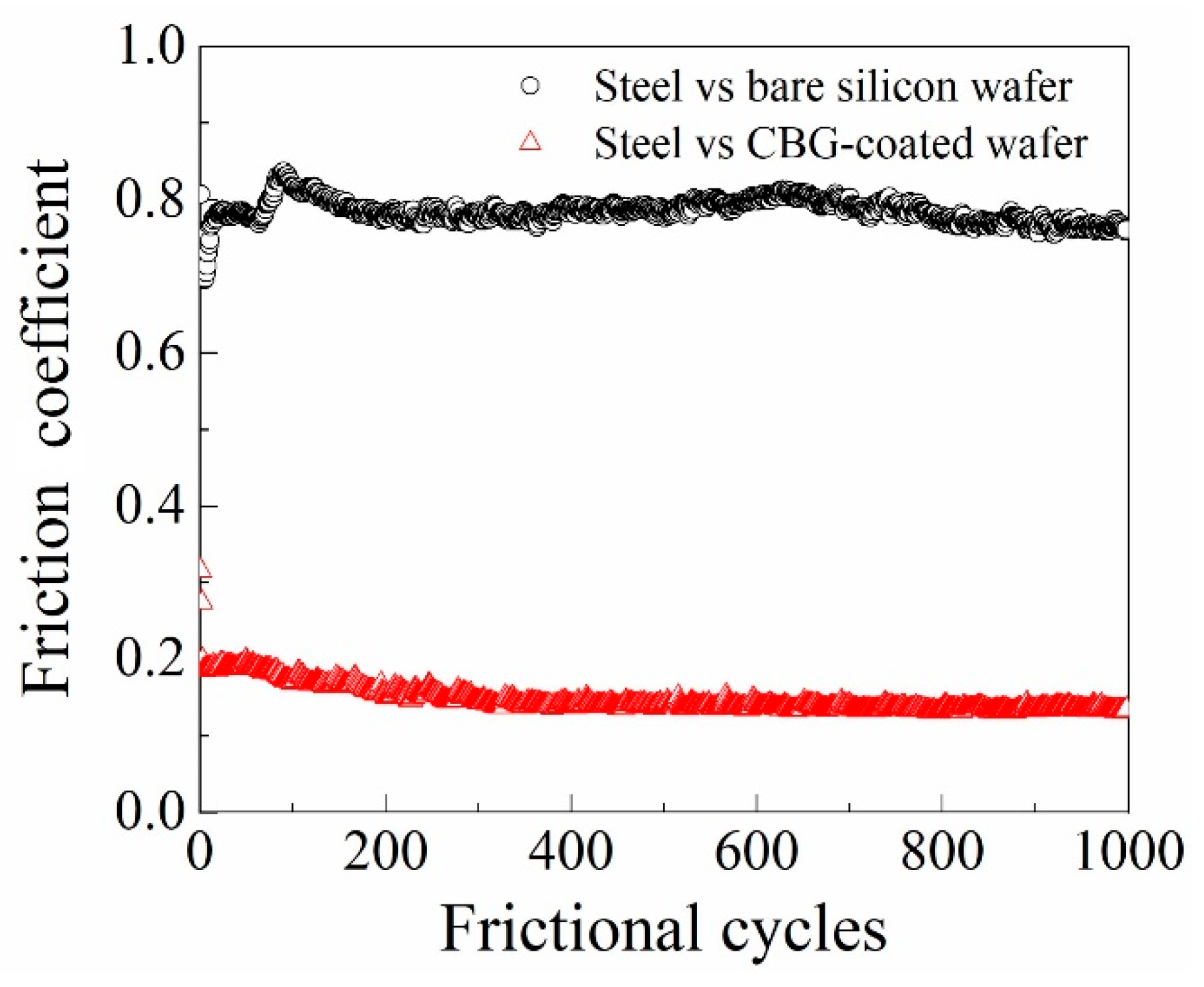

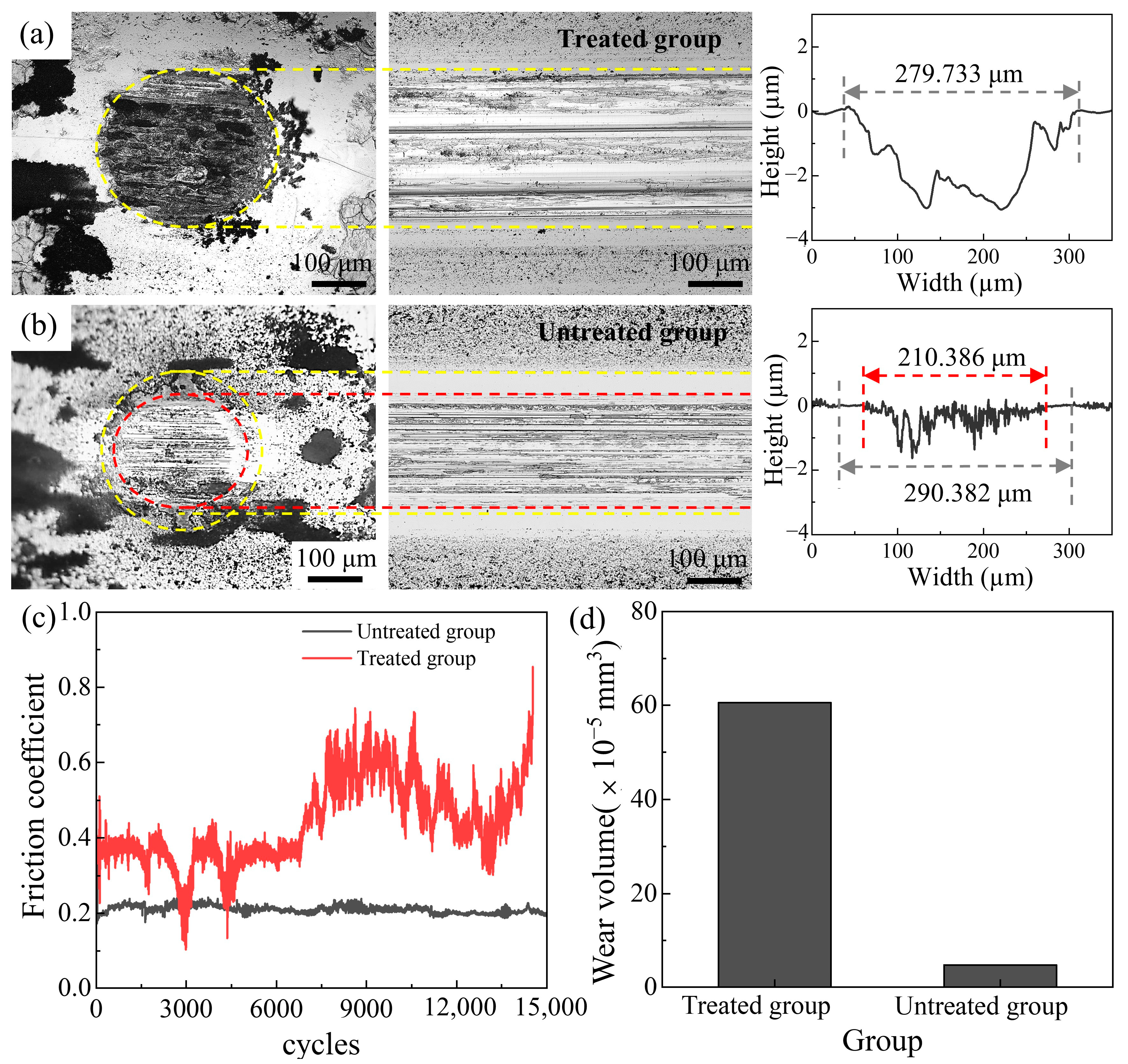

3.1. Friction-Reduction and Anti-Wear Performance of CBG Coating

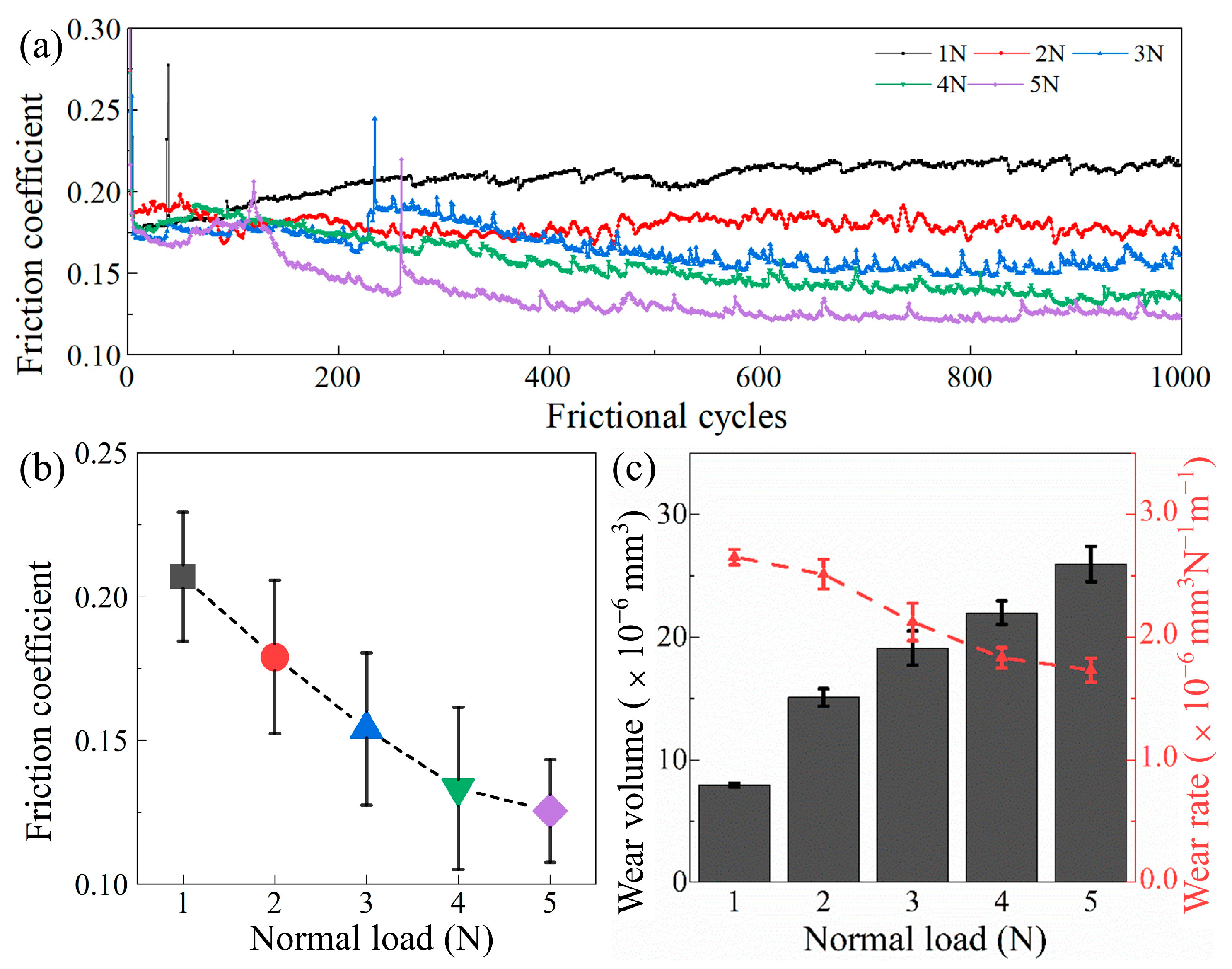

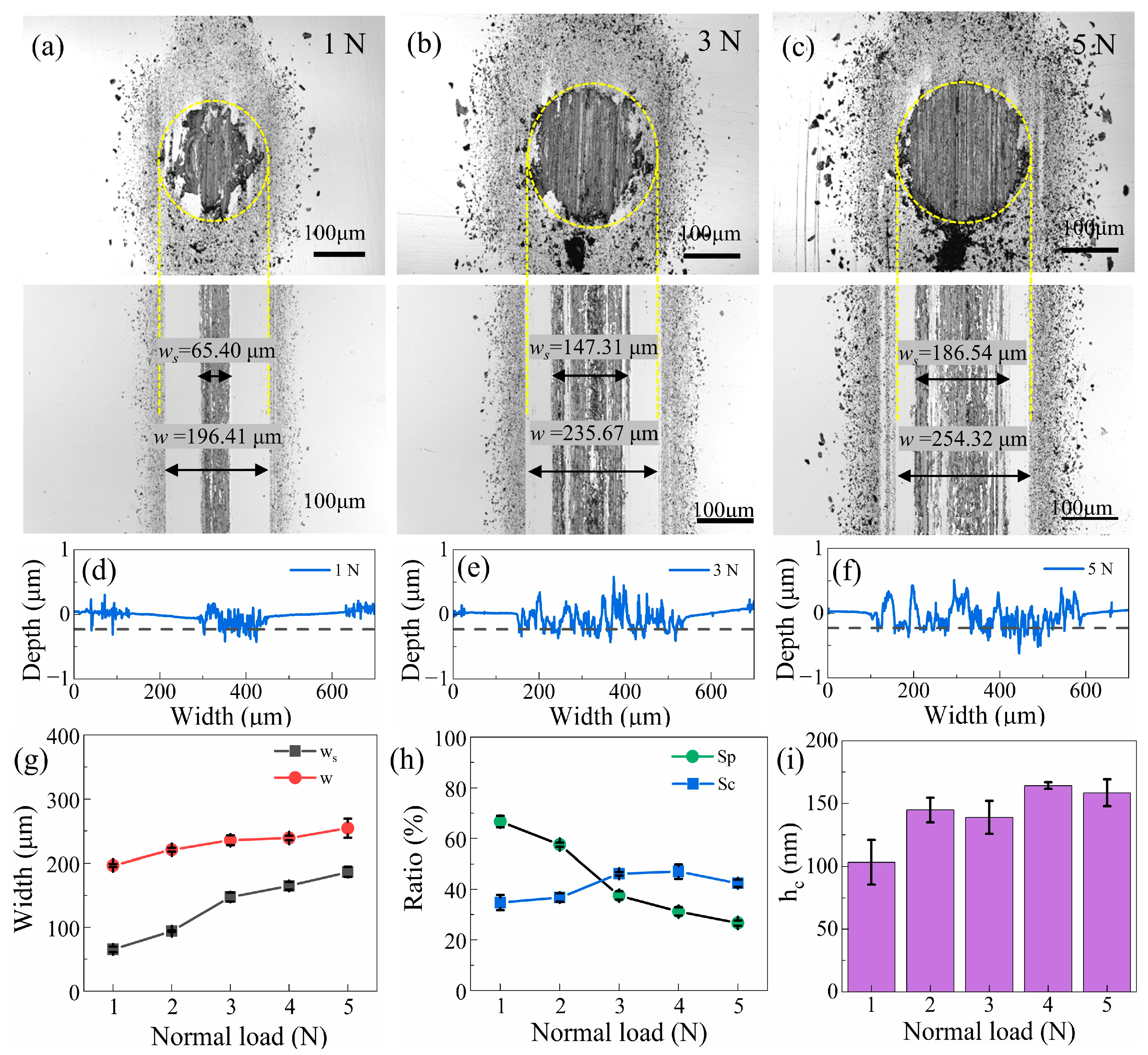

3.2. Load Dependence of Tribological Properties

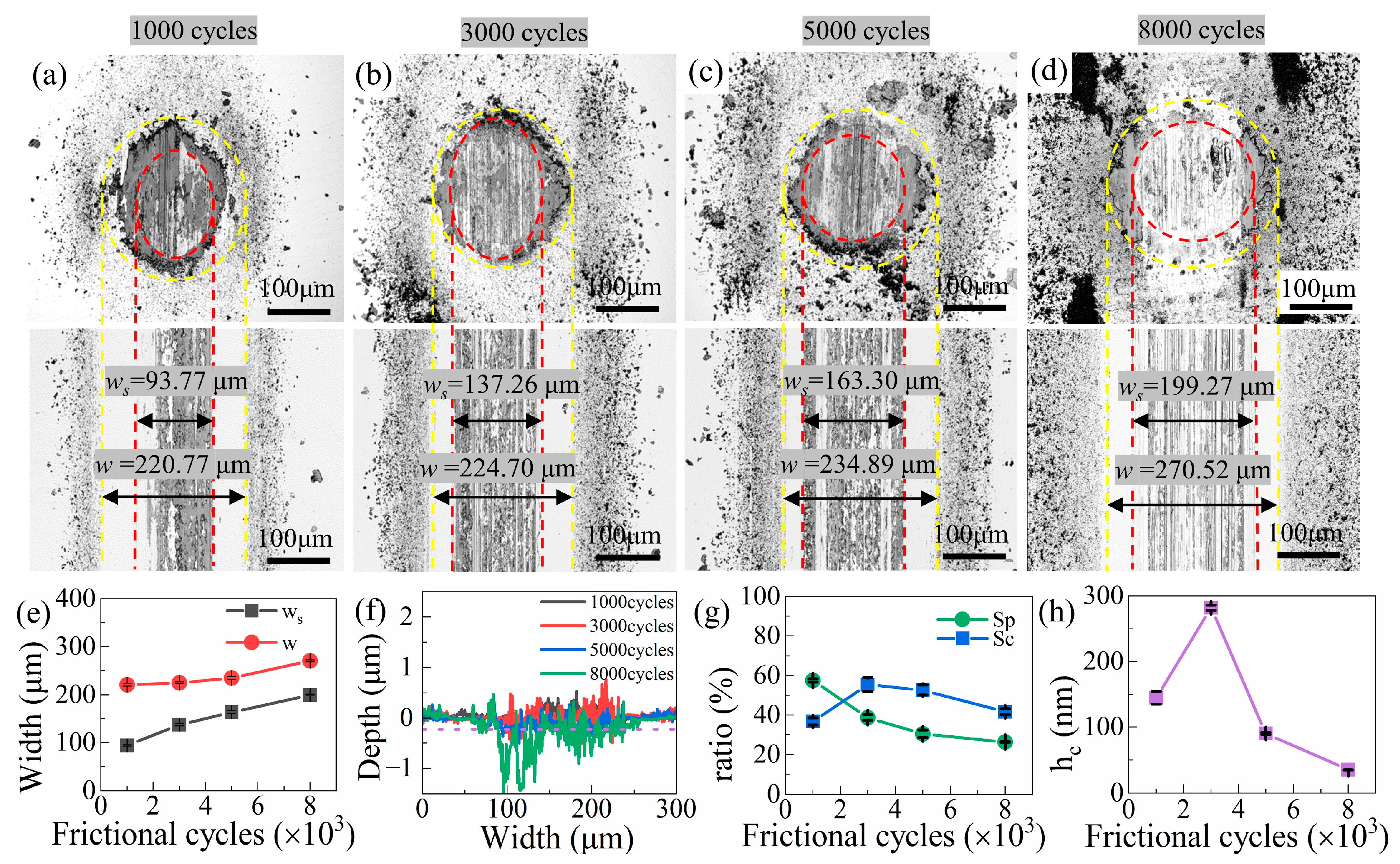

3.3. Wear Evolution and Mechanisms

4. Discussion

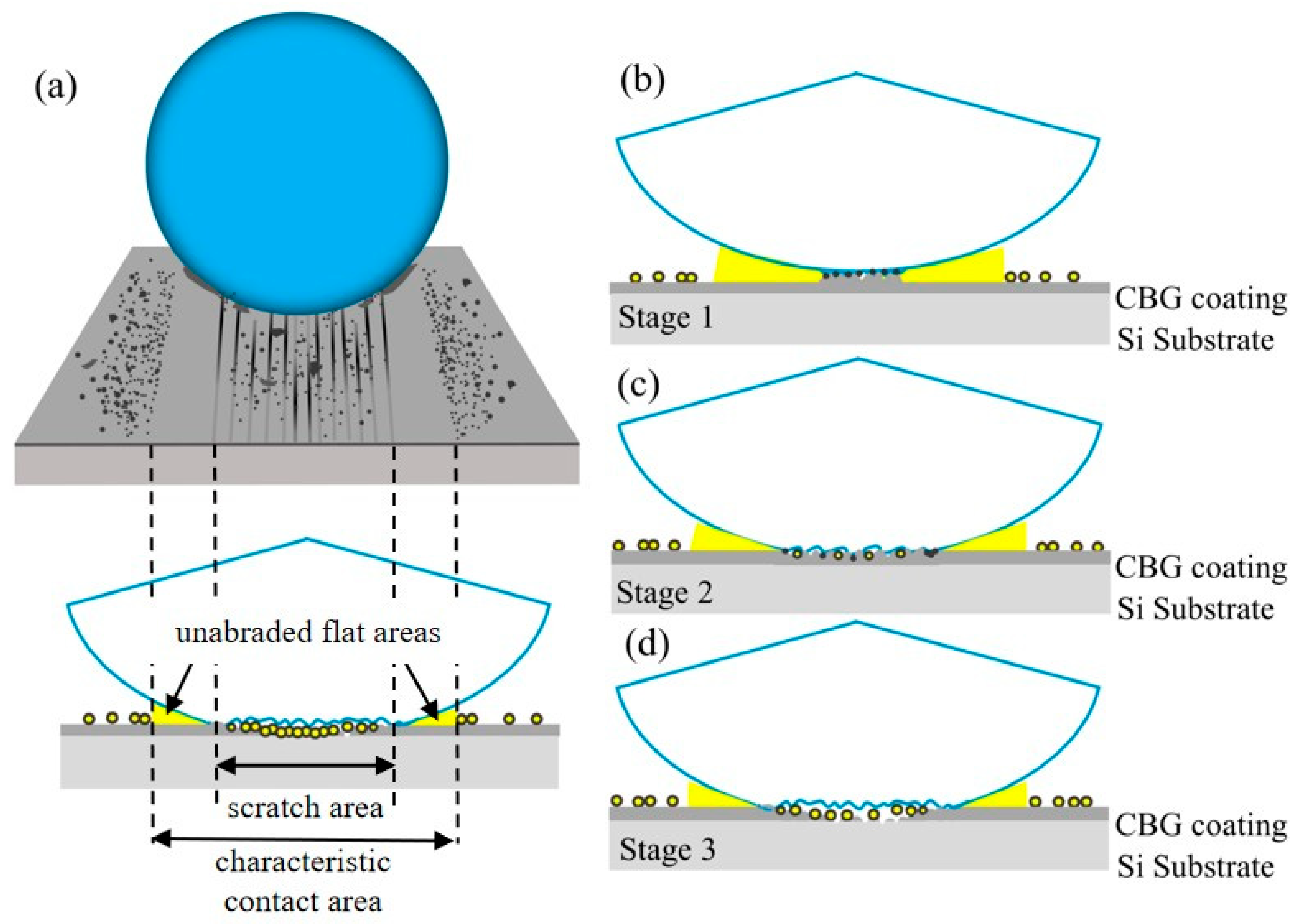

4.1. The Effect of the Unabraded Flat Areas on the Coating’s Tribological Properties

4.2. The Role of the Unabraded Flat Areas in the Wear Process

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Carvalho, A.F.; Kulyk, B.; Fernandes, A.J.S.; Fortunato, E.; Costa, F.M. A Review on the Applications of Graphene in Mechanical Transduction. Adv. Mater. 2021, 34, 2101326. [Google Scholar] [CrossRef]

- Urade, A.R.; Lahiri, I.; Suresh, K.S. Graphene Properties, Synthesis and Applications: A Review. JOM 2022, 75, 614–630. [Google Scholar] [CrossRef]

- Janavika, K.M.; Prakash Thangaraj, R. Graphene and its application: A review. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Few layer graphene to reduce wear and friction on sliding steel surfaces. Carbon 2013, 54, 454–459. [Google Scholar] [CrossRef]

- Berman, D.; Deshmukh, S.A.; Sankaranarayanan, S.K.R.S.; Erdemir, A.; Sumant, A.V. Extraordinary Macroscale Wear Resistance of One Atom Thick Graphene Layer. Adv. Funct. Mater. 2014, 24, 6640–6646. [Google Scholar] [CrossRef]

- Tamuly, J.; Bhattacharjya, D.; Saikia, B.K. Graphene/Graphene Derivatives from Coal, Biomass, and Wastes: Synthesis, Energy Applications, and Perspectives. Energy Fuels 2022, 36, 12847–12874. [Google Scholar] [CrossRef]

- Siow, L.T.; Lee, J.R.; Ooi, E.H.; Lau, E.V. Application of graphene and graphene derivatives in cooling of photovoltaic (PV) solar panels: A review. Renew. Sustain. Energy Rev. 2024, 193, 114288. [Google Scholar] [CrossRef]

- Li, C.; Zheng, C.; Cao, F.; Zhang, Y.; Xia, X. The Development Trend of Graphene Derivatives. J. Electron. Mater. 2022, 51, 4107–4114. [Google Scholar] [CrossRef]

- Huang, W.; Yu, J.; Kwak, K.J.; Gallego-Perez, D.; Liao, W.C.; Yang, H.; Ouyang, X.; Li, L.; Lu, W.; Lafyatis, G.P.; et al. Atomic Carbide Bonding Leading to Superior Graphene Networks. Adv. Mater. 2013, 25, 4668–4672. [Google Scholar] [CrossRef]

- Yang, H.; Yilmaz, G.; Han, G.; Eriten, M.; Zhang, Z.; Yu, S.; Shi, M.; Yan, H.; Yang, W.; Xie, P.; et al. A quick response and tribologically durable graphene heater for rapid heat cycle molding and its applications in injection molding. Appl. Therm. Eng. 2020, 167, 114791. [Google Scholar] [CrossRef]

- Garman, P.D.; Johnson, J.M.; Talesara, V.; Yang, H.; Du, X.; Pan, J.; Zhang, D.; Yu, J.; Cabrera, E.; Yen, Y.C.; et al. Dual Silicon Oxycarbide Accelerated Growth of Well-Ordered Graphitic Networks for Electronic and Thermal Applications. Adv. Mater. Technol. 2019, 4, 1800324. [Google Scholar] [CrossRef]

- Xie, P.; Yang, H.; Zhao, Y.; Yu, W.; Cheng, L.; Yang, W.; Yan, H.; Tan, J. Carbide-bonded graphene coating of mold insert for rapid thermal cycling in injection molding. Appl. Therm. Eng. 2017, 122, 19–26. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, L.; Zhou, W.; Zhou, T.; Yu, J.; Lee, L.J.; Yi, A.Y. Fabrication of Plano-Concave Plastic Lens by Novel Injection Molding Using Carbide-Bonded Graphene-Coated Silica Molds. J. Manuf. Sci. Eng. 2019, 141, 081011. [Google Scholar] [CrossRef]

- Li, L.; Yang, G.; Lee, W.B.; Ng, M.C.; Chan, K.L. Carbide-bonded graphene-based Joule heating for embossing fine microstructures on optical glass. Appl. Surf. Sci. 2020, 500, 144004. [Google Scholar] [CrossRef]

- Cabrera, E.D.; Zhang, P.; Liao, W.C.; Yen, Y.C.; Yu, J.; Castro, J.; Lee, L.J. Graphene coating assisted injection molding of ultra-thin thermoplastics. Phys. Eng. Sci. Med. 2015, 55, 1374–1381. [Google Scholar] [CrossRef]

- Yang, G.; Li, L.; Lee, W.B.; Ng, M.C.; Chan, C.Y. Investigation of the heating behavior of carbide-bonded graphene coated silicon wafer used for hot embossing. Appl. Surf. Sci. 2018, 435, 130–140. [Google Scholar] [CrossRef]

- Garman, P.D.; Yang, H.; Yen, Y.C.; Yu, J.; Kwak, K.J.; Malkoc, V.; Talesara, V.V.; Lee, L.J.; Lu, W. SiOC-Accelerated Graphene Grown on SiO2/Si with Tunable Electronic Properties. Phys. Status Solidi (RRL)–Rapid Res. Lett. 2019, 13, 1900017. [Google Scholar] [CrossRef]

- Zhou, J.; He, P.; Yu, J.; Lee, L.J.; Shen, L.; Yi, A.Y. Investigation on the friction coefficient between graphene-coated silicon and glass using barrel compression test. J. Vac. Sci. Technol. B 2015, 33, 031213. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Reduced wear and friction enabled by graphene layers on sliding steel surfaces in dry nitrogen. Carbon 2013, 59, 167–175. [Google Scholar] [CrossRef]

- Bhowmick, S.; Banerji, A.; Alpas, A.T. Friction reduction mechanisms in multilayer graphene sliding against hydrogenated diamond-like carbon. Carbon 2016, 109, 795–804. [Google Scholar] [CrossRef]

- Wang, D.; Li, F.; Huang, Q.; Wang, F.; Liu, B.; Zhao, Y. Effect of normal load on the tribological behavior of graphene coating under current-carrying state. J. Mech. Sci. Technol. 2024, 38, 6193–6203. [Google Scholar] [CrossRef]

- Toosinezhad, A.; Alinezhadfar, M.; Mahdavi, S. Tribological behavior of cobalt/graphene composite coatings. Ceram. Int. 2020, 46, 16886–16894. [Google Scholar] [CrossRef]

- Johnson, K.L. Adhesion and friction between a smooth elastic spherical asperity and a plane surface. Proc. R. Soc. Lond. Ser. A 1997, 453, 163–179. [Google Scholar] [CrossRef]

- Yang, X.; Li, C.; Ye, Z.; Zhang, X.; Zheng, M.; Gu, J.; Jiang, J. Effects of tribo-film on wear resistance of additive manufactured cobalt-based alloys during the sliding process. Surf. Coat. Technol. 2021, 427, 127784. [Google Scholar] [CrossRef]

- Liang, S.; Shen, Z.; Yi, M.; Liu, L.; Zhang, X.; Ma, S. In-situ exfoliated graphene for high-performance water-based lubricants. Carbon 2016, 96, 1181–1190. [Google Scholar] [CrossRef]

- Wu, P.; Li, X.; Zhang, C.; Chen, X.; Lin, S.; Sun, H.; Lin, C.-T.; Zhu, H.; Luo, J. Self-Assembled Graphene Film as Low Friction Solid Lubricant in Macroscale Contact. ACS Appl. Mater. Interfaces 2017, 9, 21554–21562. [Google Scholar] [CrossRef]

- Hu, Z.; Fan, X.; Diao, D. Facilitation of sp2 nanocrystallites on the formation of transfer films for stable low friction with in-situ TEM nanofriction study. Tribol. Int. 2022, 174, 107713. [Google Scholar] [CrossRef]

- Wahl, K.J.; Chromik, R.R.; Lee, G.Y. Quantitative in situ measurement of transfer film thickness by a Newton’s rings method. Wear 2008, 264, 731–736. [Google Scholar] [CrossRef]

- Li, L.; Zhou, J. Evaluation of Warpage and Residual Stress of Precision Glass Micro-Optics Heated by Carbide-Bonded Graphene Coating in Hot Embossing Process. Nanomaterials 2021, 11, 363. [Google Scholar] [CrossRef]

- Xu, J.; Kawaguchi, M.; Kato, T. Evolution of transfer layers on steel balls sliding against hydrogenated amorphous carbon coatings in ambient air. Tribol. Int. 2014, 70, 42–51. [Google Scholar] [CrossRef]

- Zhu, G.; Zhu, W.; Lou, Y.; Ma, J.; Yao, W.; Zong, R.; Zhu, Y. Encapsulate α-MnO2 nanofiber within graphene layer to tune surface electronic structure for efficient ozone decomposition. Nat. Commun. 2021, 12, 4152. [Google Scholar] [CrossRef]

- Lee, A.Y.; Yang, K.; Anh, N.D.; Park, C.; Lee, S.M.; Lee, T.G.; Jeong, M.S. Raman study of D* band in graphene oxide and its correlation with reduction. Appl. Surf. Sci. 2021, 536, 147990. [Google Scholar] [CrossRef]

- Silva, D.L.; Campos, J.L.E.; Fernandes, T.F.D.; Rocha, J.N.; Machado, L.R.P.; Soares, E.M.; Miquita, D.R.; Miranda, H.; Rabelo, C.; Vilela Neto, O.P.; et al. Raman spectroscopy analysis of number of layers in mass-produced graphene flakes. Carbon 2020, 161, 181–189. [Google Scholar] [CrossRef]

- Alaferdov, A.V.; Savu, R.; Fantini, C.; Cançado, L.G.; Moshkalev, S.A. Raman spectra of multilayer graphene under high temperatures. J. Phys. Condens. Matter 2020, 32, 385704. [Google Scholar] [CrossRef]

- Ji, Z.; Lin, Q.; Huang, Z.; Chen, S.; Gong, P.; Sun, Z.; Shen, B. Enhanced lubricity of CVD diamond films by in-situ synthetization of top-layered graphene sheets. Carbon 2021, 184, 680–688. [Google Scholar] [CrossRef]

- Yu, G.; Qian, Q.; Li, D.; Zhang, Z.; Ren, K.; Gong, Z.; Zhang, J. The pivotal role of oxygen in establishing superlow friction by inducing the in situ formation of a robust MoS2 transfer film. J. Colloid Interface Sci. 2021, 594, 824–835. [Google Scholar] [CrossRef]

- Qi, S.; Wei, X.; Chen, L.; Geng, Z.; Luo, J.; Lu, Z.; Zhang, G. 3D graphene/hexagonal boron nitride composite nanomaterials synergistically reduce the friction and wear of Steel-DLC contacts. Nano Sel. 2021, 2, 791–801. [Google Scholar] [CrossRef]

- Bai, M.; Yang, L.; Li, J.; Luo, L.; Sun, S.; Inkson, B. Mechanical and tribological properties of Si and W doped diamond like carbon (DLC) under dry reciprocating sliding conditions. Wear 2021, 484–485, 204046. [Google Scholar] [CrossRef]

- Lofaj, F.; Tanaka, H.; Bureš, R.; Kabátová, M.; Sawae, Y. Tribochemistry of Transfer Layer Evolution during Friction in HiPIMS W-C and W-C:H Coatings in Humid Oxidizing and Dry Inert Atmospheres. Coatings 2022, 12, 493. [Google Scholar] [CrossRef]

- Lofaj, F.; Kabátová, M.; Bureš, R. Transfer layer evolution during friction in HIPIMS W–C coatings. Wear 2021, 486–487, 204123. [Google Scholar] [CrossRef]

- Shi, X.; Liskiewicz, T.W.; Beake, B.D.; Chen, J.; Wang, C. Tribological performance of graphite-like carbon films with varied thickness. Tribol. Int. 2020, 149, 105586. [Google Scholar] [CrossRef]

- Chen, S.; Shen, B.; Sun, F. The influence of normal load on the tribological performance of electrophoretic deposition prepared graphene coating on micro-crystalline diamond surface. Diam. Relat. Mater. 2017, 76, 50–57. [Google Scholar] [CrossRef]

- Şenel, M.C.; Üstün, M. Dry Sliding Wear and Friction Behavior of Graphene/ZrO2 Binary Nanoparticles Reinforced Aluminum Hybrid Composites. Arab. J. Sci. Eng. 2022, 47, 9253–9269. [Google Scholar] [CrossRef]

- Zhang, H.; Qu, J.; Guo, Z.; Huang, L.; Xie, Q. Negative area-dependent nanoscale friction of annular graphene sheets. AIP Adv. 2022, 12, 115312. [Google Scholar] [CrossRef]

- Cai, S.; Guo, P.; Zuo, X.; Zhang, D.; Zhi, L.; Ke, P.; Wang, A. Effect of Load on Tribological Behavior of MoS2/C Composite Films. Tribology 2018, 38, 51–58. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K.; Singh, G.; Kuntoğlu, M.; Patange, A.; Demirsoz, R.; Ross, N.S.; Prasad, B. Machine learning models for online detection of wear and friction behaviour of biomedical graded stainless steel 316L under lubricating conditions. Int. J. Adv. Manuf. Technol. 2023, 128, 2671–2688. [Google Scholar] [CrossRef]

- Kim, M.-G.; Lee, K.-R.; Eun, K.Y. Tribological behavior of silicon-incorporated diamond-like carbon films. Surf. Coat. Technol. 1999, 112, 204–209. [Google Scholar] [CrossRef]

- Gong, M.; Li, H.; Wu, M.; Lv, P. Investigation of the Microstructure and Properties of Cage-Shaped Hollow Cathode Bias Voltage Modulated Si-Doped DLC Thick Film. Coatings 2025, 15, 930. [Google Scholar] [CrossRef]

- Polymer Engineering and ScienceEstrada-Martínez, J.; Reyes-Gasga, J.; García-García, R.; Vargas-Becerril, N.; Zapata-Torres, M.G.; Gallardo-Rivas, N.V.; Mendoza-Martínez, A.M.; Paramo-García, U. Wettability modification of the AISI 304 and 316 stainless steel and glass surfaces by titanium oxide and titanium nitride coating. Surf. Coat. Technol. 2017, 330, 61–70. [Google Scholar] [CrossRef]

- Frérot, L.; Pastewka, L. Elastic Shakedown and Roughness Evolution in Repeated Elastic–Plastic Contact. Tribol. Lett. 2024, 72, 23. [Google Scholar] [CrossRef]

- Bouillanne, O.; Mollon, G.; Saulot, A.; Descartes, S.; Serres, N.; Chassaing, G.; Demmou, K. Wear in Progress: How Third Body Flow Controls Surface Damage. Tribol. Lett. 2024, 72, 84. [Google Scholar] [CrossRef]

- Zhao, J.; Sheng, W.; Li, Z.; Zhang, H.; Zhu, R. Modeling and analysis of sliding wear based on fractal surface reconstruction in line contact mixed lubrication. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 135065012210777. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Xiao, C. The synergistic mechanism between transfer layer and surface passivation of diamond-like carbon film under different gas pressure environments. Appl. Surf. Sci. 2022, 587, 152874. [Google Scholar] [CrossRef]

- Xu, R.; Liu, Y.; Cheng, Q.; Wang, Z.; Ma, K.; Ke, P.; Deng, Y. The synergistic mechanism of transition layer and transfer layer on dry sliding wear of multi-layered diamond-like carbon (DLC) coating at wide temperature. Diam. Relat. Mater. 2024, 141, 110589. [Google Scholar] [CrossRef]

- Amaral, I.R.; Forestier, A.; Piednoir, A.; Galafassi, R.; Bousige, C.; Machon, D.; Pierre-Louis, O.; Alencar, R.S.; Souza Filho, A.G.; San-Miguel, A. Delamination of multilayer graphene stacks from its substrate through wrinkle formation under high pressures. Carbon 2021, 185, 242–251. [Google Scholar] [CrossRef]

- Fuadi, Z.; Adachi, K. Properties of tribofilm formed on self-mated stainless steel lubricated by palm methyl ester mixed petroleum diesel fuel. Lubr. Sci. 2021, 33, 347–357. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, X.; Liu, X.; Li, L.; Liu, K.; Zhou, J. Tribological Properties and Wear Mechanisms of Carbide-Bonded Graphene Coating on Silicon Substrate. C 2025, 11, 72. https://doi.org/10.3390/c11030072

Zhu X, Liu X, Li L, Liu K, Zhou J. Tribological Properties and Wear Mechanisms of Carbide-Bonded Graphene Coating on Silicon Substrate. C. 2025; 11(3):72. https://doi.org/10.3390/c11030072

Chicago/Turabian StyleZhu, Xiaomeng, Xiaojun Liu, Lihua Li, Kun Liu, and Jian Zhou. 2025. "Tribological Properties and Wear Mechanisms of Carbide-Bonded Graphene Coating on Silicon Substrate" C 11, no. 3: 72. https://doi.org/10.3390/c11030072

APA StyleZhu, X., Liu, X., Li, L., Liu, K., & Zhou, J. (2025). Tribological Properties and Wear Mechanisms of Carbide-Bonded Graphene Coating on Silicon Substrate. C, 11(3), 72. https://doi.org/10.3390/c11030072