1. Introduction

Anaerobic digestion (AD) is an established process for the production of biogas from various types of biomass such as municipal waste (organic waste, sewage sludge), industrial and commercial residues, agricultural biomass (e.g., maize, sugar beet, straw, manure, etc.) or residues from landscape management. In Germany, there are currently around 8700 biogas production plants in operation [

1]. Some of them upgrade biogas by separating biomethane (CH

4) from carbon dioxide (CO

2) and other minor components. In addition, most biogas plants produce and transmit electricity and thermal energy through combined heat and power (CHP) modules in energy grids. In the past, government support (Renewable Energy Sources Act) guaranteed fixed prices for electricity fed into the grid over a 20-year period. Due to the newly started revaluation of CO

2 in terms of global warming potential (GWP

100) and monetary reimbursement for CO

2 saved or avoided, some biogas plants are now restructuring and changing to liquefy biomethane and CO

2 to sell to the market and stopping power generation, the funding for which is ceasing in the near future.

The agricultural sector in Germany “produces” about 209 million metric tonnes of manure per year [

2], of which about one-quarter to a third is already used for biogas. Potentially, another third could also be used economically. This would be achieved with existing plant capacity. In practice, large plants with an electrical capacity of more than 1000 kW often consume more than 30,000 t/a of biomass. Depending on substrate availability, process inhibition, economic aspects and legal framework, the manure concentration has to be optimised. In these large plants, the average manure concentration is less than 30%. Increasing manure concentration leads to an increase in protein and its degradation products, ammonia (NH

3) and ammonium (NH

4+), that inhibit the microbial community in AD [

3].

It has long been known from the literature that the use of BC is suitable for increasing biogas yield in AD [

4] although with increased levels of inhibitors such as NH

3 and NH

4+ [

5].

In a critical review, Kumar et al. [

6] list six properties of BC (porosity, specific surface area, cation exchange capacity, electrical conductivity, surface functional groups, redox properties) that are thought to influence AD. Tang S. et al. [

7] add particle size, elements and pH value to this list. Of course, particle size and porosity are elemental structures of BC in contact with microorganisms in AD. It has been reported that microorganisms can live within the BC particles [

8,

9]. Unfortunately, the article by Heitkamp et al. [

8] only characterises BC as “Carboferm”, a wood-based capillary BC, without any further details, e.g., type of wood, particle size, or other physical or chemical analytical data. Lü et al. [

9] characterise their BC as obtained by the pyrolysis of fruit wood (without further specification). In many publications concerning the use of BC in AD [

4,

8,

9], the origin of the pyrolysis feedstock, e.g., bamboo or eucalyptus, instead of botanical names is insufficiently described. The same applies to the production methods, e.g., process equipment, temperature/time regime and/or product characteristics.

The type of BC feedstock such as bamboo, straw, husks, wood, etc., plays an important structural role. For example, a typical European conifer, such as Scots pine (

Pinus sylvestris) studied in this paper, consists of about 93% (area per cent of a specimen for light microscopy) of tracheids, cells of approximately 3100 µm length and approximately 45 µm width (including the cell walls). The tracheids are axially oriented and connected tangentially in radial walls by elliptical pits of several micrometres high that can be closed by tori [

10,

11]. The maintenance or structural change in tori and pits in BC depends on the severity of the pyrolysis.

Common beech (

Fagus sylvatica), a typical European hardwood consisting of several cell types, including relatively short (300–700 µm) vessel elements in the longitudinal direction, which are joined into tubes and have a diameter of 30–100 µm, accounting for about 29%, and fibres with a length of about 1200 µm and a lumen diameter of about 5 µm, accounting for about 40% in the tissue [

10]. The wood structure is largely retained during pyrolysis, but in a reduced form due to shrinkage. The BC structure can be used to identify the wood species the BC was made from. Haag et al. [

12] have shown that sometimes the wood species of commercial charcoal does not match the information on the packaging.

Our aim is to increase the manure content in AD to more than 50% and to stabilise the process by adding charcoal. The effect on fermentation and viscosity will be published as “Charcoal in anaerobic digestion: Part 2—Influence of charcoal on anaerobic digestion” elsewhere.

This paper deals with the production and characterisation of BC cubes of approximately 6 × 6 × 6 mm

3 and rods made from Scots pine (

P. sylvestris) and common beech (

F. sylvatica) produced simultaneously in a 90-litre batch retort [

13] and will be compared with commercial charcoal powder (CCP). By comparing the structural characteristics of the BC types with the characteristics of the AD microorganisms, we clarify what might be living in the charcoal and have a look into the opened cubes to see if microorganisms are colonising them. BC is characterised chemically by its wood resources and processing conditions, according to the European Biochar Certificate (EBC) [

14]; structurally by microscopy; and physically by surface area, specific surface area, pore size and pore volume distribution.

2. Materials and Methods

The uncharred beech and pine wood samples were analysed by classic light microscopy. Transverse and radial sections (approximately 25 μm thick) were sequentially cut from solid heartwood samples using a sliding microtome and stained with a solution of safranin and astra blue to study microstructural details. The study was carried out using a digitised image analysis system (analySIS

®, Olympus, Tokyo, Japan) mounted on an Olympus AX 70 microscope. To characterise the charred samples, a 3D-reflected light microscopy technique (digital microscope VHX-5000, Keyence, Neu-Isenburg, Germany) was used to visualise the characteristic structural features [

15]. Transverse and tangential section measurements were performed on three samples of pine and beech. Quantitative characteristics were measured on the average of at least 50 measurements of each parameter studied [

16]. The average tangential tracheid diameter in pine was only measured in the first third of the earlywood tracheids, which can be clearly distinguished from the narrow latewood. The average pit diameter (vertical) was measured to characterise the volume change in the axial direction.

Softwood, Scots pine (

P. sylvestris) and hardwood, common beech (

F. sylvatica) were pyrolysed as cubes with starting dimensions of 8 × 8 × 7 mm

3 or rods of 8 × 8 × 500 mm

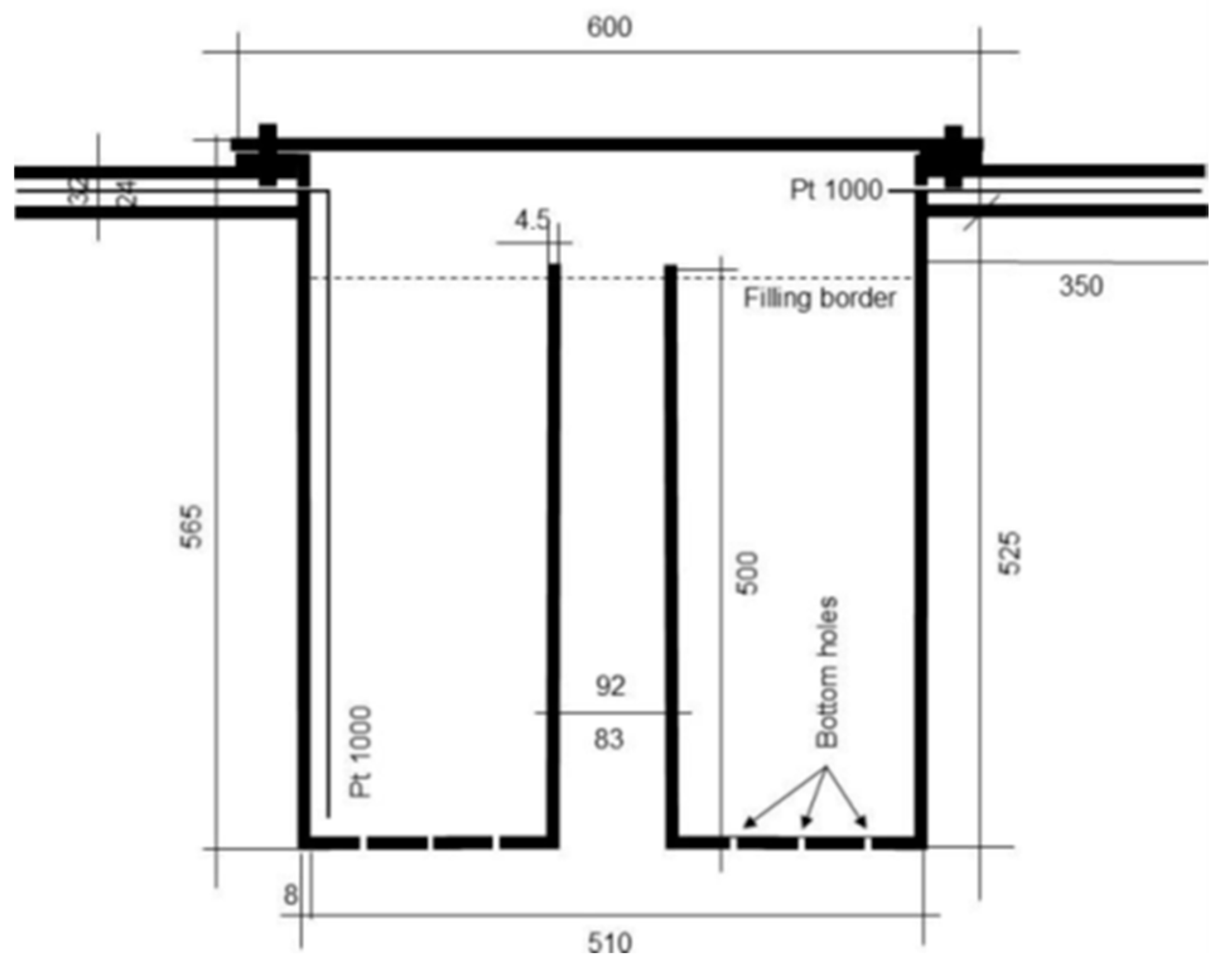

3 in a 90 L retort, a closed cylindrical vessel with a lid and a central degassing tube with an opening at the bottom (

Figure 1). Cubes were used as they are and rods were ground to powder for use in AD and chemical characterisation. The temperature was recorded close to the bottom and close to the lid near the inner wall of the retort. The retort was heated with a 10.5 kW gas stove using a 5.5 kg (netto) propane gas container. Once a sufficient temperature was reached in the retort, heating was assisted by combustible outgassing wood gases. The retort contained 4 baskets, placed approximately 2.5 cm above the bottom of the retort to pyrolyse cubes and rods of two types of wood simultaneously in this project. The bottom of the retort contained 12 × 3 holes of 4 mm in diameter in the radial direction which were closed with screws resulting in a reducing atmosphere in the retort (Pyr

red). To increase the functional groups at the surface of the charcoal, the holes in the bottom were open for pyrolysis. The hot retort was then removed from the oven and placed on a tray filled with sand. Water was then applied to the sand and the steam generated by the hot retort was channelled through the bottom holes in the retort, partially oxidising the charcoal (Pyr

ox), and was discharged through the central tube.

Temperature was measured with Pt 1000 elements and data were recorded with a Voltkraft data logger DL-240K (Conrad Electronic, Wernberg-Köblitz, Germany). Dimensions of wood and BC cubes were measured with callipers. BC rods were ground using a Retsch cutting mill SM 2000 and a Retsch ZM 1000 centrifugal mill. Chemical analysis according to EBC [

14] was performed externally (Wessling GmbH, Hannover, Germany), as well as pore size according to ISO 15901-1 [

17], density according to DIN 66137 [

18] and specific surface area analysis according to DIN ISO 9277 [

19] (3P Instruments GmbH, Odelzhausen, Germany). CCP was purchased as Nerolit 10 µm from PHK Polymertechnik GmbH, Wismar, Germany, a charcoal powder with particle size d90 of less than 10 µm, a fineness that we cannot produce on our laboratory equipment.

Microorganisms in biochar cubes were observed by using the LIVE/DEAD BacLight Bacterial Viability Kit (Catalogue number L7012, Invitrogen, Waltham, MA, USA) under a fluorescence microscope (Olympus BX51, Olympus, Tokyo, Japan) to monitor the viability of bacteria and archaea by examining the integrity of the cell membrane. Cells with damaged membranes which are considered dead or dying, are stained red, while cells with intact membranes are stained green. BC cubes were collected from the anaerobic digesters and frozen. BC samples were cleaned at the surface with a scalpel, cut and scraped from the centre on glass slides under sterile conditions. Samples were stained with the dye mixture and incubated for 15 min in the dark at room temperature prior to analysis. The following excitation/emission maxima were used to detect the fluorescence of the dyes: 480/500 nm for SYTO9 and 490/635 nm for propidium iodide (PI). All images were analysed using the computer program analySIS (Soft Imaging System, Münster, Germany).

The functional groups of BC were analysed using the universal attenuated total reflectance–Fourier transform infrared spectroscopy (UATR−FTIR) accessory, used with a Spectrum Two FTIR spectrometer (Perkin Elmer Inc., Waltham, MA, USA). Samples were prepared by crushing biochar cubes in a mortar and pestle. Powdered samples were directly placed on the top of the diamond-covered platform and pellets were manually pressed until the “force gauge” was at 100. Spectra were recorded in 4000–600 cm−1 wave number range using the Spectrum IR computer program.

3. Results and Discussion

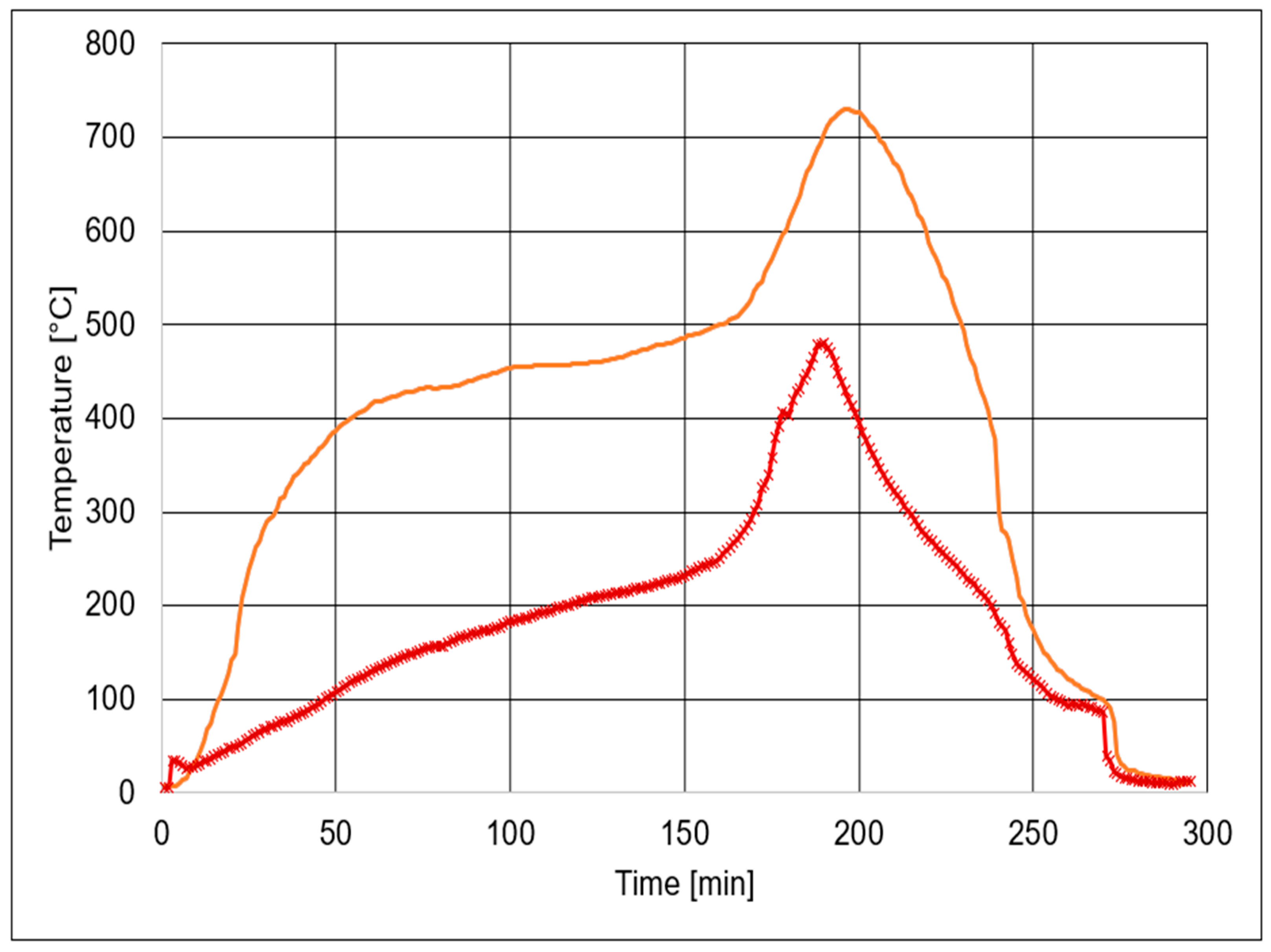

One hundred cubes of pine and beech were callipered, weighed, placed in a wire basket and placed among the other cubes of the same type in the retort baskets. After closing the retort and the furnace, the fire was started by igniting the propane gas stove. The pyrolysis process was completed after approximately 1200 min (20 h) when the gas filling of the vessel was complete. A typical temperature versus time curve is shown in

Figure 2. The maximum temperature of 541 °C measured near the lid near the cylinder wall was reached after 200 min, corresponding to a heating rate of 2.7 °C min

−1. After 125 min, 275 °C was reached, the temperature at which the autogenous exothermic charring reaction starts [

20]. The combustible wood supports the gas cooker as it leaves the retort through the central tube. Pyrolysis is complete after about 340 min, when the temperature reaches about 250 °C; the temperature that can be reached in the specific furnace with the propane stove alone.

After opening the retort, the pyrolysed pine and beech cubes were removed from the wire baskets, callipered and reweighed. The average dimensions and weights of 100 wood and charcoal cubes are given in

Table 1.

The (envelope) density decreased from 0.72 g cm

−3 to 0.45 g cm

−3 (loss of 36.6%) for beech and from 0.52 g cm

−3 to 0.35 g cm

−3 for pine (loss of 32.7%). The volume shrank to 44% for beech and 43% for pine, corresponding to an average linear shrinkage in one dimension of about 75%. Charcoal yield by weight was 27% for beech and 29% for pine, figures known from the literature [

20] corresponding to the carbonisation factors (1/yield) of 3.7 for beech and 3.4 for pine.

An impression of the wood and BC cubes is given in

Figure 3. It can be seen that the structure remains in place but at a reduced size. There are no visible cracks in the BC cubes. Wide and narrow annual rings are easily visible in pine wood and BC (white arrows in

Figure 3).

We compare two different types of pyrolysis. One with closed holes in the bottom of the retort, resulting in an overall reduced atmosphere (Pyr

red) (

Figure 2), and a second with open holes for a partially oxidising atmosphere and final steam treatment (Pyr

ox).

Pyr

ox differed from Pyr

red in that way, that a second thermometer was placed near the cylinder wall close to the bottom between two baskets. The temperature versus time curves are shown in

Figure 4. The two temperature curves are very different in height.

Near the bottom, the temperature rose to over 400 °C within 60 min, but only reached 130 °C near the lid. For both Pt 1000 elements, it is important to note that their tips measure the surrounding gaseous atmosphere (at room temperature both Pt elements showed the same temperature comparable to other thermometers). We therefore have no information about the temperatures inside the wood/coal itself. Both temperature curves show that the exothermic reaction started after about 160 min, reaching about 740 °C near the bottom and about 480 °C near the lid after about 190 min. This experimental set-up shows that temperature data given in the literature must be treated with caution unless the experimental set-up is not described and the location of the temperature sensor is indicated.

The furnace was opened after 180 min but still was burning. The retort was removed after 220 min and placed on a tray filled with sand. Water was immediately added to the sand and steam passed through the retort, exiting through the central tube and a central tube in the tray. Three minutes later the cylinder was further cooled by spraying the retort with a watering can. After 270 min, the lid was unscrewed, the retort opened and the baskets removed. BC cubes and rods were also basted to avoid burning.

Pine and beech BC rods were ground to powder for chemical analysis. The results are given in

Table 2. Fixed carbon was very high with 93.3% ± 0.6% for all four samples. EBC defines BC with organic carbon between 35% and 95% [

14]. Total volatile carbons, therefore, are low. The molar ratios of hydrogen to carbon are between 0.20 and about 0.25 for the self-made charcoal and 0.10 for the CCP. They therefore meet the EBCs highest quality requirement of less than 0.40. No EBC values are given for the molar ratio of oxygen to carbon. Pine BC from Pyr

red has a ratio of 0.0248 and 0.0282 for Pyr

ox, which is an increase of about 14% due to the steam treatment. For CCP, the ratio is 0.0354. The O/C ratio gives an indication of the amount of oxygen-containing side groups. The levels of chlorine, bromine, fluorine and sulphur are also very low.

With the exception of chromium and nickel, all the elements analysed in

Table 3 are at low levels and below the EBC limits. We do not have a clear indication of the source of the high levels of chromium and nickel, but we assume that they are from the steel material of the retort.

Polychlorinated biphenyls (PCBs) as given in

Table 4 are below the detection limit in all four samples. The situation is different for polycyclic aromatic hydrocarbons (PAH) from toluene extraction in

Table 4. Self-generated BC are below the detection limit for all PAHs, but CCP, except for acenaphthylene, show detectable concentrations of a total of 916 mg kg

−1. This is high, compared to EBC which sets the level at 6 + 2.4 mg kg

−1.

This low level in the EBC is a precautionary measure.

“In absence of investigations how PAHs in biochar may pose risks to the environment and health, it was easier and faster to use the lowest known limit values for any type of soil amendment and apply it for biochar” [

14].

EBC does not give figures for concentrations of benzene, toluene, ethylbenzene and xylene (BTEX) or volatile halogenated hydrocarbons (VHH). VHH were below or close to detection limits for all four BC samples (

Table 5). BTEX concentrations were low for self-made BC but high for CCP. The highest concentration of 2400 mg kg

−1 was found for benzene and 410 mg kg

−1 for toluene. In total, BTEX amounted to 2810 mg kg

−1. Obviously, these figures are critical for feed applications, but will be tested for poisoning in AD.

In summary, the results of the analysis show that there is little chemical difference between self-made charcoal, regardless of the type of wood, the duration of pyrolysis and/or reducing or oxidising atmosphere.

The charcoal powder was also analysed by UATR−FTIR spectroscopy for functional group characterisation/identification (

Figure 5).

In

Figure 5, the graph shows the IR spectra of both types of wood treated with the two pyrolysis methods. Particularly the functional groups are marked as described in the literature. The detected peak found in the region of wave number 2650–2745 cm

−1 for the C-H stretching vibration indicates the presence of aldehyde, together with another possible peak appearing in the region of wave number 1680–1700 cm

−1, indicating C=O stretching in the ketone and aldehyde [

21]. The peak in the region of 1610–1510 cm

−1 wave number belongs to C=C stretching [

22,

23,

24]. The broad peak appeared in the region of 1155–1200 cm

−1 for the C-O stretching bond in cellulose and hemicellulose [

22]. The peak region of 1000–600 cm

−1 is the fingerprint region; peaks appearing in this region are for the aromatic ring, formed due to the C=C bond stretching in the alkene at the higher temperature biochar [

25].

The IR spectra obtained shows how the functional groups present in the biochar showed similarity with respect to different wood species. The spectra do not allow quantification of functional groups. There was no obvious difference between the Pyrox and Pyrred spectra of beech BC. For the pine BC, the only difference was found at C=C stretching at 1660–1740 cm−1 but this bonding does not belong to an oxidising step.

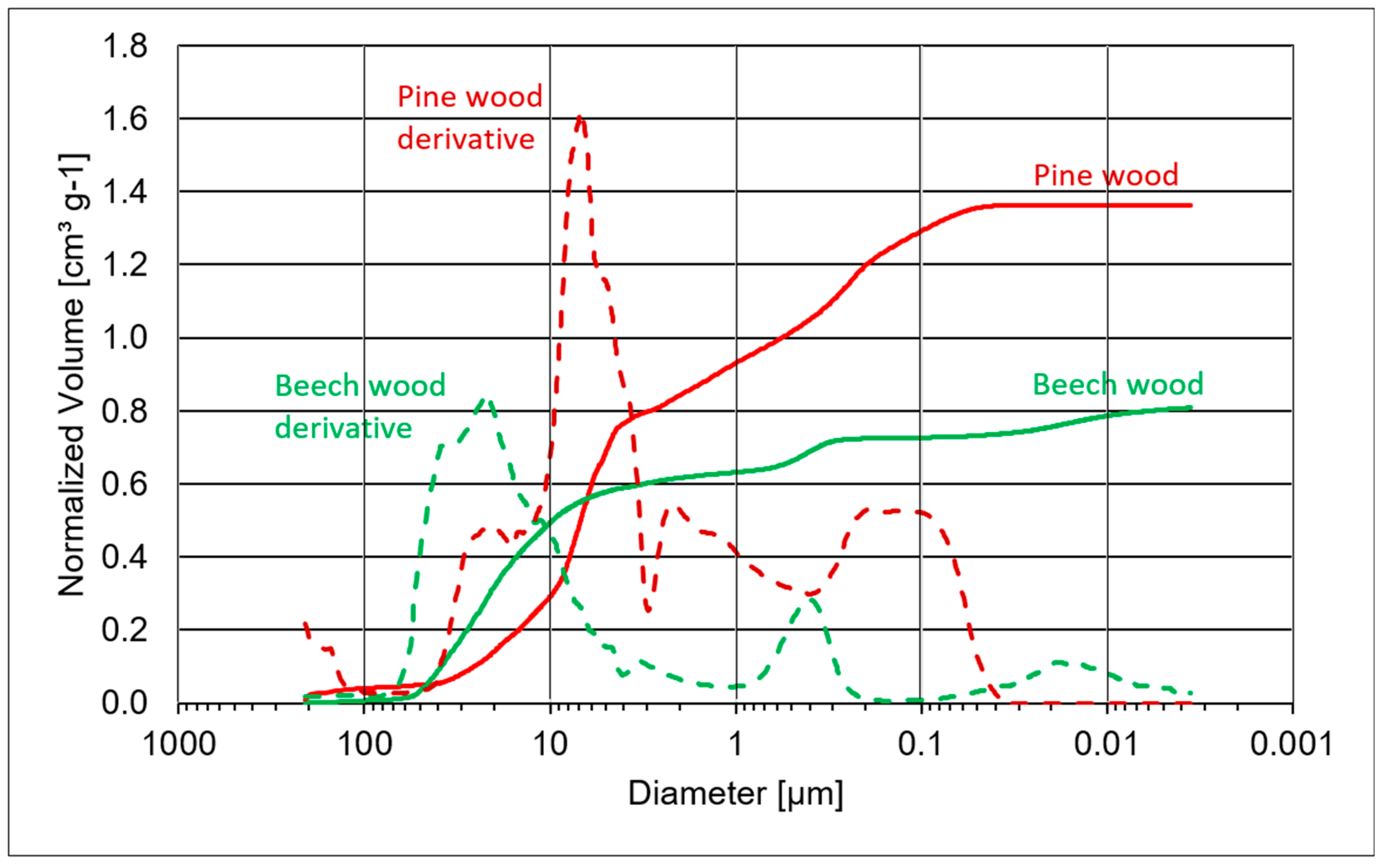

To study the pore structure of the BC samples, we used mercury (Hg) intrusion porosimetry. In Hg intrusion porosimetry, the sample pores are intruded by mercury with increasing pressure, filling first the large pores and then the smaller ones. The curves in

Figure 6 and

Figure 7 show the pore size distribution of wood and BC on a logarithmic scale, starting on the left-hand side with large pores. For better interpretation of the pore size distribution, derivation curves are shown in dotted lines as well.

The filling of beech wood pores starts at about 70 µm and ends at about 4 nm (

Figure 6). There are two peaks in the derivative curve of beech for large pores at about 40 µm and about 23 µm and one for small pores at about 4 µm. The results for large pores differ to the values given in the literature and our own findings (see

Figure 8A,B and

Table 6). Wagenführ [

10] reported tangential vessel diameters of 30

… 100 µm and a frequency of 80

... 130

... 160 vessels mm

2. Therefore, we conclude that Hg intrusion porosimetry seems to underestimate large vessels. The small pores of about 4 µm correspond to pore diameters of fibres (see

Figure 8A).

For pine wood, the filling of large pores starts at about 40 µm and ends at about 0.18 µm. The pore volume of pine wood is about 70% higher than that of beech wood. The pore diameters of large pores show a peak in the derivation curve at about 25 µm which is in good accordance with our own findings (see

Figure 8E and

Table 6) and the literature [

10] with tangential tracheid diameters of about 40 µm of early wood tracheids. Late wood tracheids have much thicker cell walls resulting in smaller pore diameters. Therefore, the “average” diameter of 25 µm is a good result. The peak of the small pores with a derivation curve peak at about 8 µm corresponds to pit apertures in tracheids.

“Downward peaks” at about 3–4 µm are artefacts due to the change in the pressure regime.

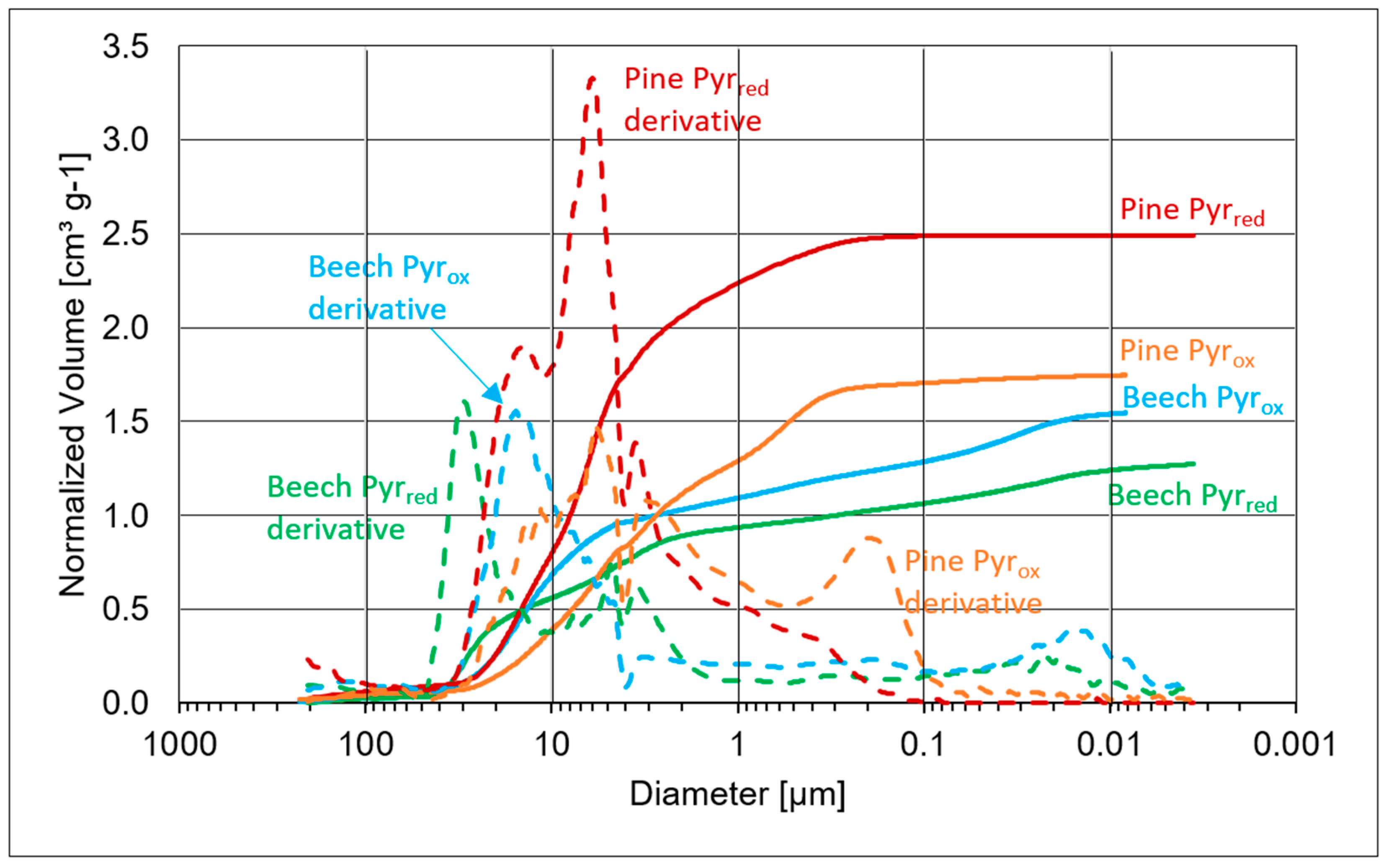

The pore-size distribution curves of beech and pine BC of Pyr

red and Pyr

ox are shown in

Figure 7. Compared to the pore size distribution of wood (

Figure 6), pine BC shows higher amounts of pores than beech BC, but there are also large differences between Pyr

red and Pyr

ox.

The pore sizes and distribution in beech BC differs between Pyrred and Pyrox. In Pyrred, large pores start at around 45 µm and end at around 10 µm with a peak at around 30 µm followed by a second pore cluster with a peak at about 5 µm and a third long stretched small cluster from about 1 µm to 6 nm. Beech BC from Pyrox shows large pores from about 40 µm to about 5 µm with a peak at about 15 µm and small pores from about 100 nm to 10 nm. Pine BC Pyrred and Pyrox also differ. Large pores of Pyrred start at about 35 µm and show a shoulder peak at about 15 µm followed by a second major peak at about 6 µm. The smallest pores end at about 0.1 µm. Large pores of pine BC from Pyrox start at about 33 µm, with a shoulder peak at about 15 µm followed by a higher peak also at about 6 µm. There is also a second cluster of pores from about 1 µm to about 0.2 µm. Steam treatment in Pyrox resulted in the appearance of or increase in small pores in pine BC and very small pores in beech BC.

An overview of skeletal density (density without pores), specific surface area (SSA), specific pore volume (SPV), modal value of pore size distribution (PS Mod), median value of pore size distribution (PS Med) and porosity, which is the ratio of pore volume to total volume of wood before and after pyrolysis treatment is given in

Table 7.

The skeletal density is determined with helium (He) pycnometry. Beech wood cubes, at 1285 g cm

−3, are slightly denser than pine wood cubes, at 1.269 g cm

−3. Both values are lower than in the literature where the skeletal density of wood is given as 1.45 g cm

−3 to 1.5 g cm

−3 [

20]. After pyrolysis, the skeletal density only increases a little by 0.1 g cm

−3 for beech BC and about 0.2 g cm

−3 for pine BC. CCP has a skeletal density of 1.635 g cm

−3.

According to Brewer [

26], the skeletal density correlates with the pyrolysis temperature. Densities of close to 1.5 g cm

−3 are achieved with mesquite biochar at about 480 °C. In our pyrolysis experiments, we certainly reached higher temperatures of more than 700 °C (

Figure 4), but corresponding high skeletal densities were not found.

In contrast to the skeletal densities, there were very large differences in the SSA of wood and BC. Both woods are below 0.3 m2 g−1, with pine wood (0.26 m2 g−1) being slightly higher than beech wood (0.21 m2 g−1). Pyrolysis increased the SSA to more than 200 m2 g−1. In Pyrred, beech BC shows a higher SSA with 267 m2 g−1 compared to pine with 237 m2 g−1. In Pyrox, it is the other way round with 201 m2 g−1 for beech and 279 m2 g−1 for pine BC. CCP has an SSA of 418 m2 g−1.

Specific pore volume (SPV) is the number used to quantify the pore volume in cubic centimetres per gram (cm

3 g

−1) of sample. Pine wood cubes with an SPV of 1.32 cm

3 g

−1 showed more than 80% more pore volume than beech wood cubes with an SPV of 0.72 cm

3 g

−1. Beech BC cubes from Pyr

red showed an increase of 72% compared to wood and pine BC cubes of 81%. The SPV of beech Pyr

ox was more than double that of wood and 22% higher than that of Pyr

red. For pine BC cubes, the results were vice versa. The Pyr

red of pine was about 40% higher in SPV than Pyr

ox. Although the pore diameters decreased (

Figure 6 and

Figure 7), the SPV increased. The reason is the decrease in density (

Table 1). It is evident that SSA does not correlate with SPV.

The modal value of the pore size distribution corresponds to the maximum of the pore size distribution curves, which can be found as peaks in the derivative curves of

Figure 6 and

Figure 7. It corresponds to the visual impression that the largest pores of beech wood and BC are larger than those of pine wood and BC. Due to shrinkage (

Table 1), the pores of BC are smaller than wood pores, except for beech BC Pyr

red, which has pore diameters of 29.6 µm compared to 21.8 µm for beech wood.

The median value of the pore size distribution corresponds to the median d50 value of the particle size distribution, with 50% of the pores being smaller and 50% larger than the median value. Beech wood cubes with a median of 17.1 µm show that there are fewer smaller pores compared to pine wood and all BC which look very similar at a level of 3.3 to 7.1 µm.

The total volume of wood or BC samples is made up of the volume of the solid components and the pore volume. The pore volume of pine wood at 62.6% is 25% higher than that of beech wood at 49.9%. Porosity increased by pyrolysis from 49.9% for beech wood to 64.9% and 68.2% for beech BC Pyrred and Pyrox. Pine BC also showed an increased porosity of 77.0% and 71.8% for Pyrred and Pyrox compared to pine wood at 62.6%.

Wood and BC cubes were also analysed by classical optical microscopy and 3D-reflected light microscopy.

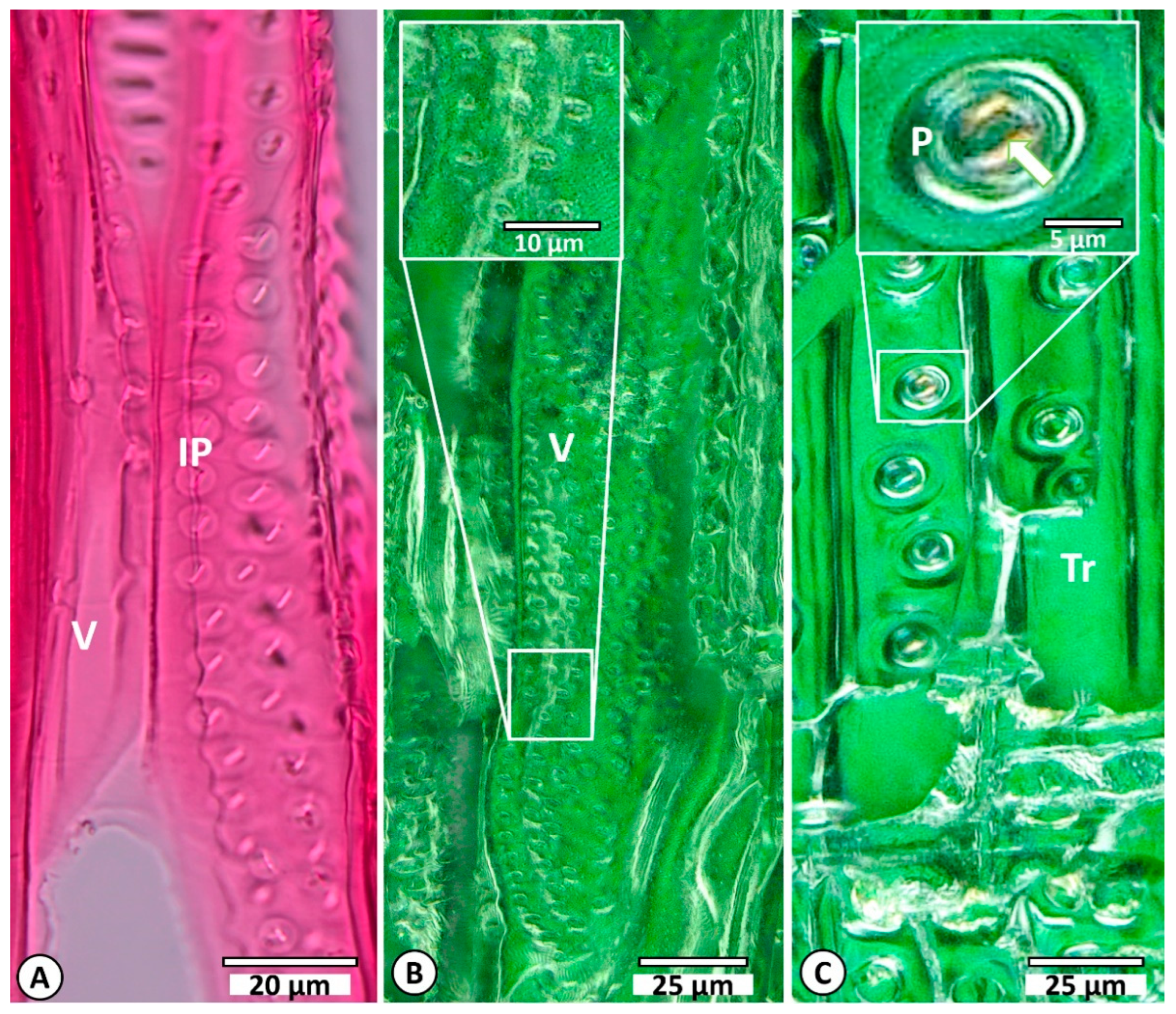

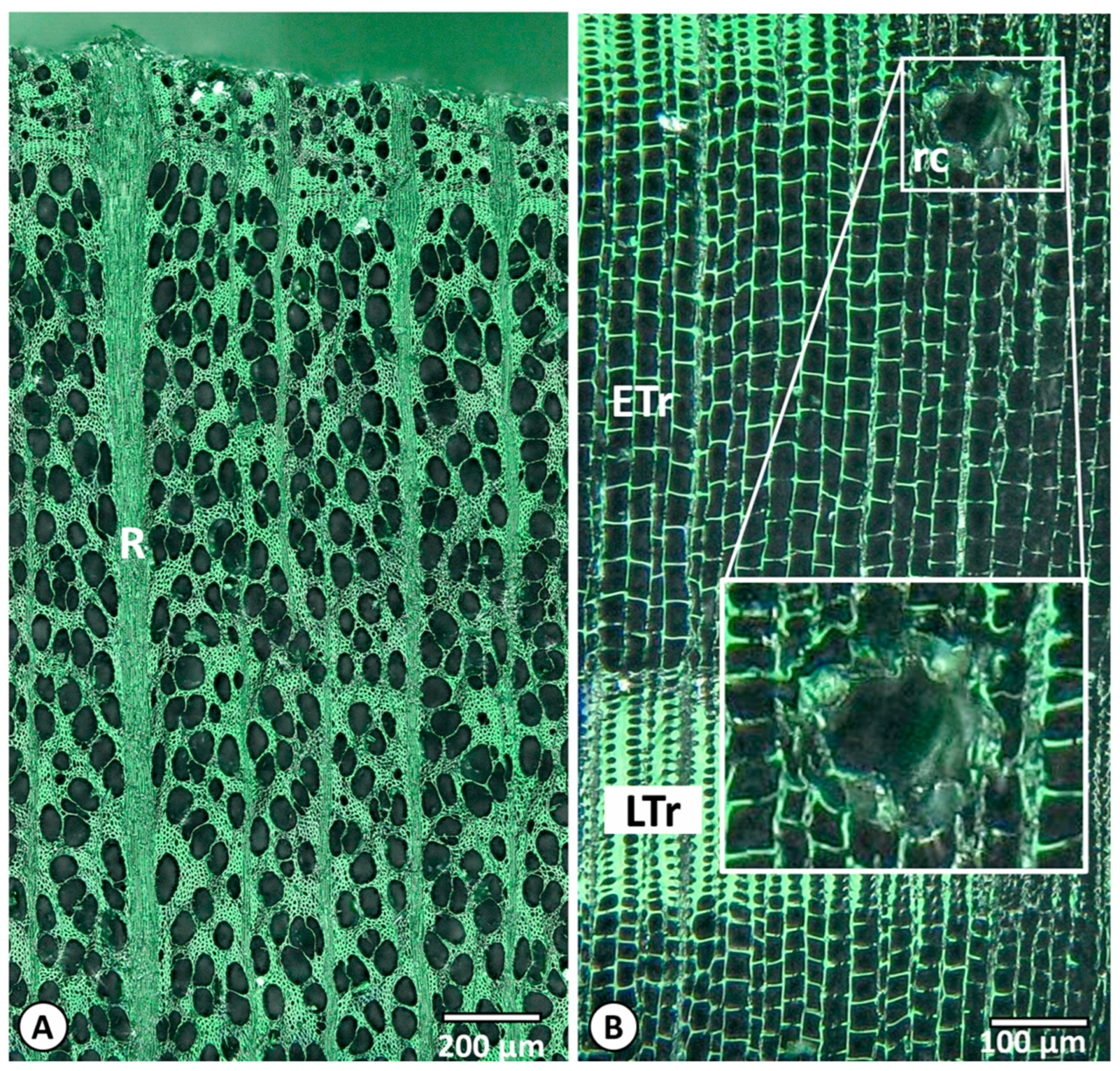

Figure 8 shows cross sections of beech wood (A and B) and pine (C). The radial section is shown in

Figure 8D, with details of the pits shown in E. Beech showed large vessels surrounded by small fibres and parenchyma cells. In contrast, pine showed relatively homogeneous tracheid cells that differed mainly in wall thickness and radial extent in early wood (ETr) and late wood (LTr). Pit size and pit aperture size can be clearly distinguished (D). In contrast to the microscopic determination of solid wood samples, charcoal cannot be prepared as flat (planar) slices because the wood tissue is strongly decomposed by pyrolysis and becomes very brittle. In 3D-reflected light microscopy, the uneven surfaces are digitally scanned. The first step is to create three-dimensional images, which then are converted into two-dimensional images. The terminology for and description of the wood structure is based on the IAWA lists of microscopic characteristics for hardwood identification [

27] and also for softwood identification [

28]. To minimise the variation in the results, vessel diameters were only measured in the first third of a growth ring (

Figure 8B). In order to estimate axial shrinkage, pine pit aperture sizes were measured (

Figure 8E and

Figure 9C).

As can be seen from

Figure 9B, there was no opportunity to determine pit size in charred beech as is possible in virgin beech (

Figure 9A). Pits and the adjacent tissues have fused together and become deformed during the charring process. The phenomenon of fused tissue is well known in the literature [

12,

15,

29,

30].

The same problem was recognised when determining the pit aperture sizes of the pine pits. Again, the individual tissue structures within the pits were no longer to be clearly distinguishable from one another (

Figure 9C). As the change in pit aperture height ultimately corresponds to the same axis as the vertical pit height, the measurement of the pit aperture height was also discarded for this reason but pit height was analysed.

As can be seen in

Figure 10A,B, the macroscopic structures of the wood are completely preserved. The vessels and rays in beech and the tracheids in pine show no damage or deformation. For example, the axial resin ducts in pine are still clearly visible. The deformation of the individual epithelial cells of the intercellular canals is only visible at high resolution. However, this may have occurred during processing, as the surfaces must first be broken for the 3D reflective light microscopy scans. The structural change therefore can be interpreted as a uniform volume change (shrinkage) in the sense of extreme drying. Major structural changes only occurred in pits that fused with adjacent tissue. Structural elements such as vessel and tracheid extensions were measured in a tangential direction, those of pit openings in an axial direction. The results are given in

Table 6.

The mean value of three beech wood vessels was 76.3 ± 10.5 µm. The charred samples shrank by about 35% to 49.8 ± 9.7 µm in the tangential direction. Pine wood tracheids showed mean values of 34.7 ± 7.5 µm and pine BC of 22.4 ± 4.4 µm, corresponding to a shrinkage of about 35.5%. Both types of wood behaved almost identically, with shrinkage in the tangential direction. In the axial direction, the pit diameter shrank by about 23% from 22.3 ± 2.2 µm in wood to 17.2 ± 1.7 µm in BC.

It is known from solid wood that shrinkage is not isotropic. From the swollen state, when saturated with water, beech/pine wood shrinks on average about 11.8/7.7% in the tangential direction, about 5.8/4.0% in the radial direction and about 0.3/0.4% in the axial direction when bone dry [

20]. These figures must be taken into account when comparing cell dimensions. Wood samples were analysed at room temperature and ambient relative humidity, corresponding to wood moisture of approximately 12%. The samples in

Figure 8 represent a swollen state of wood due to sample preparation for microscopy.

Identical cubes of beech (BC1) and pine (PC1) from Pyr

red were analysed first by microscopy and then by mercury porosimetry to compare the pore results of the two methods. In contrast to porosimetry, which covers all types of pores, the IAWA microscopic evaluation only looks at some specific cell structures in a specific way (see

Section 2). Diameters from microscopy and porosimetry slightly differ. The mean diameter of larger pine BC pores is below 20 µm by porosimetry and about 25 µm by microscopy. Larger beech BC pores are about 30 µm in porosimetry and 53 µm in microscopy.

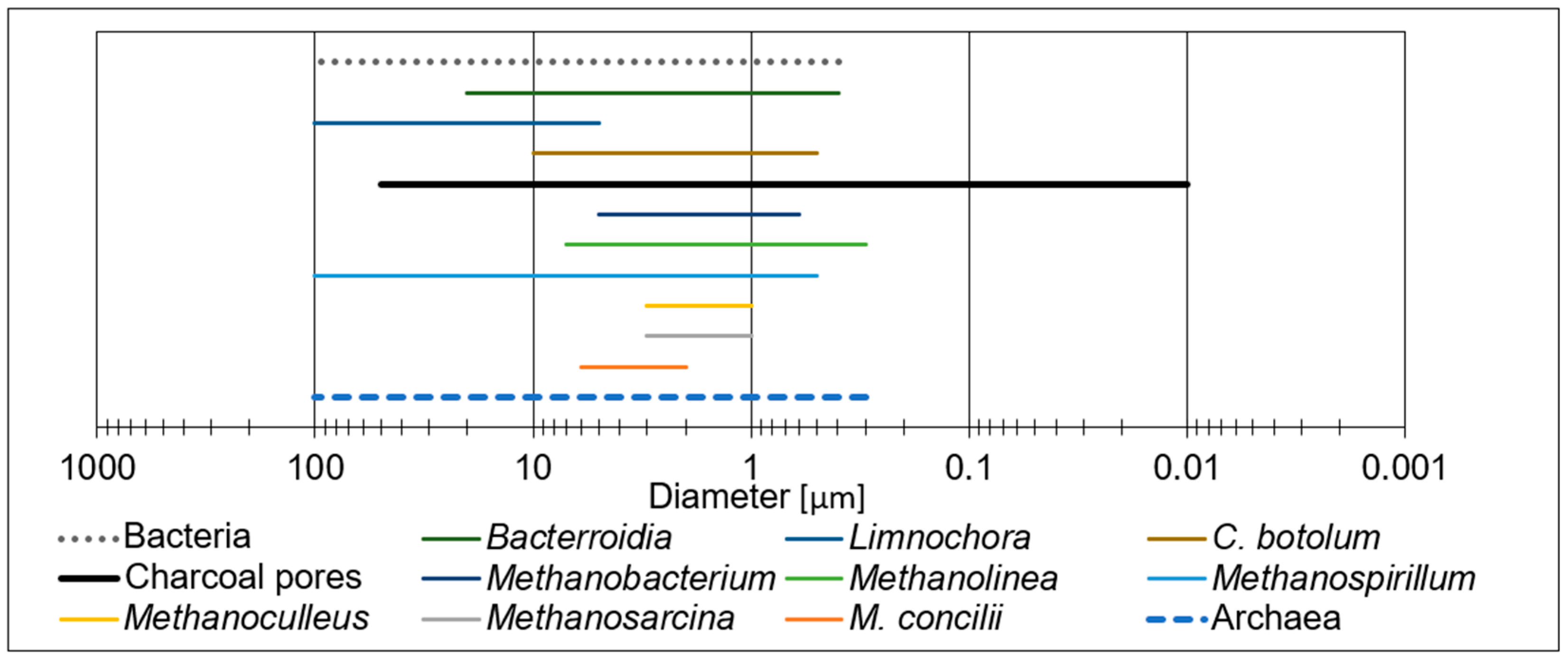

Regarding wood structure and the structure of BC with its fine pores, especially the pores of pine BC with tangential tracheid diameters of about 22 µm and inter tracheid connections with pit diameters of about 17 µm and pit aperture diameters two to three times smaller than the pit diameters, the question arises whether microorganisms such as archaea and bacteria are able to penetrate the charcoal pores in AD.

Figure 11 shows typical sizes of archaea and bacteria [

31] compared to charcoal pores (

Figure 7). Most microrganisms have an elongated shape and some are three-dimensional. The lower values in

Figure 11 correspond to the “diameters” of individual cells and the upper values to their longitudinal extent.

According to

Figure 11, by size, individual microorganisms have a chance of penetrating the charcoal pores. However, microorganisms often live together in communities bound together by biofilm. To check whether microorganisms had penetrated the BC cubes during AD incubation, we opened the cubes, extracted material and analysed it using fluorescence microscopy.

Staining of the biochar cubes with red-fluorescing nucleic acid stain PI coupled to the green-fluorescing nucleic acid stain SYTO9 showed the presence of microorganisms inside the biochar cubes. As is typical for LIVE/DEAD staining, viable microorganisms showed strong green fluorescence and weak ones red fluorescence. The ratio of fluorescent dyes used for LIVE/DEAD staining was 1:1. As can be seen in

Figure 12, the microorganisms agglomerated within the biochar material, indicating that biochar provides a habitat for microbial consortia.

Anticipating the individual results of AD with BC (details will be published elsewhere), we found that the addition of BC can increase the gas yield in inhibited systems, whereby we can demonstrate differences between BC from beech and BC from pine and the influence of particle size.