Flow Performance Analysis of Non-Return Multi-Door Reflux Valve: Experimental Case Study

Abstract

1. Introduction

2. Valve Description

Design and Operation

3. Experimental Parameters

- The valve is exposed to increasing pressure to evaluate its ability to withstand high-pressure conditions without leaking or damage.

- The primary objective is to evaluate how the multi-door reflux valve preventer influences forward flow and its ability to prevent backflow.

- The pressure drop across the valve is measured to assess the resistance the valve imposes on the fluid flow. This is crucial to determine the impact of the valve on the overall system pressure and evaluate the effectiveness of the valve in minimizing energy losses.

- Simulated backflow conditions are created to examine the effectiveness of the valve in preventing backflow. Emphasis is placed on understanding the response of the valve to abrupt changes in flow direction.

- The response time of the multi-door reflux valve is analyzed to evaluate how quickly the valve closes when the reverse flow is detected. A rapid response time is essential for effective reflux prevention.

- The multiple doors are designed to create a robust barrier against reverse fluid flow. The reliability of the sealing mechanism is evaluated through repeated opening and closing cycles. This is a simulated real-world condition in which the valve operates continuously over an extended period.

- Different materials and design variations of the multi-door configuration are tested to evaluate their impact on flow performance and sealing effectiveness. This analysis aims to identify the most appropriate materials and design parameters for optimal valve performance. The durability of the materials used in the construction of the valve is evaluated to ensure that the valve can withstand long-term use without degradation.

3.1. Multi-Door Reflux Valve Experimental Setup and Methodology

3.1.1. Test Pressure

3.1.2. Testing Equipment

3.2. Body and Doors Strength Test

3.2.1. Setup Procedure for Body and Door Strength Test

3.2.2. Commencing of Body Strength Test Procedure

3.2.3. Terminating the Body Strength Test Procedure

3.3. Valve Seal and Leak Test—Body and Doors

3.3.1. Setup Procedure and Door Seat Leak Test

3.3.2. Commencing of Body and Door Seat Leak Test

3.3.3. Terminating the Body and Door Seats Leak Test

4. Results, Analysis, and Discussions

4.1. First Test Attempt

4.1.1. Body and Door Structural Pressure Test

4.1.2. Body and Door Seat Leak Pressure Test

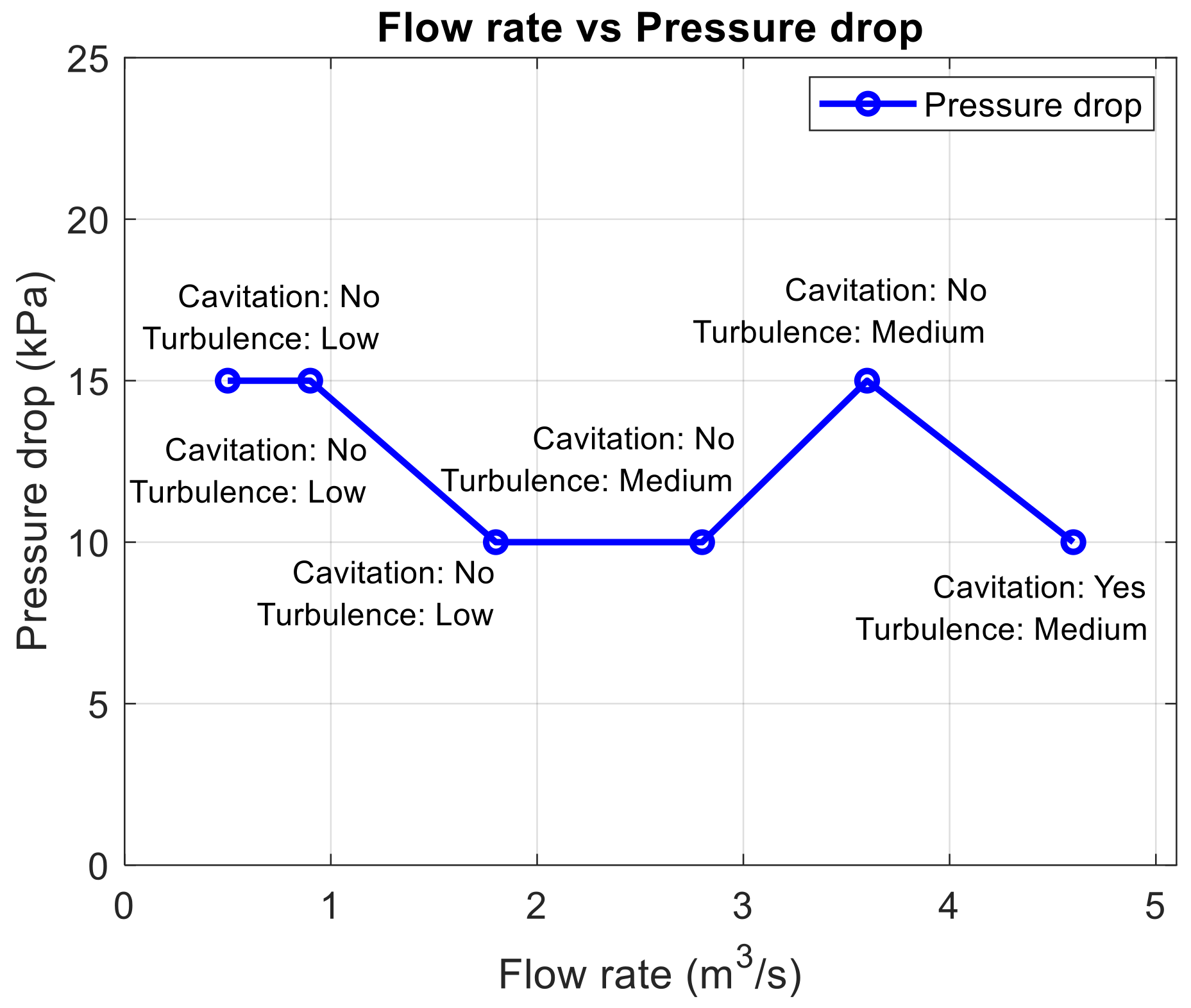

4.1.3. Flow Performance and Pressure-Drop Test

4.1.4. Flow Performance and Cavitation Test

4.1.5. Flow Performance and Response Time

4.1.6. Observed Failures

4.2. Root Cause Analysis

- Material Deficiencies

- Imperfections on the sealing surfaces occurred during manufacturing, compromising the ability of the surfaces to form a tight seal (Figure 12a).

- The repetitive motion during operation caused the sealing surfaces to gall and gouge, thus damaging the sealing surfaces, and preventing them from effectively sealing (Figure 12b).

- Leakage points were identified around the doors, suggesting inadequacies in the sealing mechanisms, potentially linked to design and manufacturing defects. Observations during operation and subsequent disassembly revealed misalignment of the shaft ring, resulting in uneven contact and wear of the sealing surfaces. This misalignment contributed to increased friction and ultimately leakage during experimental pressure tests, as shown in Figure 13.

- Inconsistent manufacturing tolerances in producing the valve components led to misalignment between the shaft bush and the sealing surfaces.

Corrective and Preventive Actions (Material Improvement)

- The manufacturing process has been enhanced to guarantee a smoother, more uniform surface finish on the stainless steel sealing surfaces, and to keep consistent tolerances and accurate alignment of the shaft ring with the sealing surfaces.

- The door sealing material has been replaced with a soft metal such as AB1 aluminum bronze, which will improve galling and corrosion resistance, thereby improving the longevity and effectiveness of the sealing surfaces compared to 316 stainless steel. In this context, 316 and AB1 refer to specific characteristics of the materials.

- A further series of pressure tests were performed on the improved valve to verify the effectiveness of the implemented recommendations and ensure that the valve meets or exceeds industry standards

4.3. Second Test Attempt and Re-Testing

4.3.1. Body and Door Structural Pressure Test

4.3.2. Body and Door Seat Leak Pressure Test

4.3.3. Flow Performance and Pressure Drop Test Results

4.3.4. Flow Performance and Cavitation Test Results

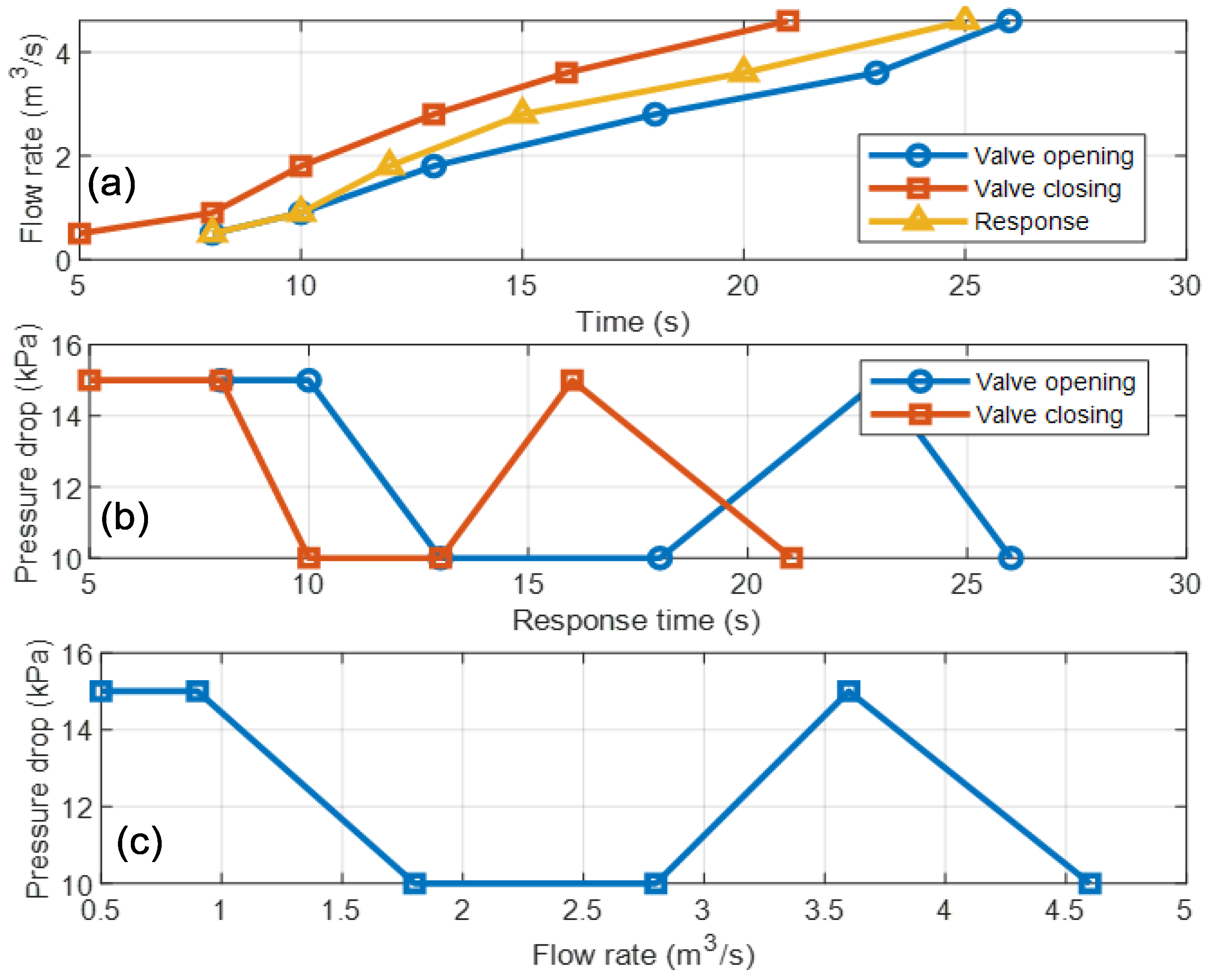

4.3.5. Flow Performance and Response Time Results

4.3.6. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, W.; Zhang, H.; Liu, W.; Cheng, Y.; Zhang, J. Flow Characteristics and Pressure Drop Analysis of Variable Opening Angle Multi-Door Reflux Valve. Chem. Eng. Res. Des. 2021, 172, 199–209. [Google Scholar]

- Cheng, X.; Wang, Y.; Li, H.; Zhao, C. Study on the flow performance of multi-door reflux valve with different door configurations. J. Mech. Eng. 2020, 56, 69–77. [Google Scholar]

- Guo, X.; Zhang, J.; Huang, W.; Liu, J. Experimental Investigation on the Flow Characteristics of a Multi-door Reflux Valve. J. Chem. Eng. Chin. Univ. 2020, 34, 542–547. [Google Scholar]

- Qian, H.; Wu, D.; Xiang, C.; Jiang, J.; Zhu, Z.; Zhou, P.; Mou, J. A Visualized Experimental Study on the Influence of Reflux Hole on the Double Blades Self-Priming Pump Performance. Energies 2022, 15, 4617. [Google Scholar] [CrossRef]

- Zhang, K.; Wu, D.; Yuan, Y.; Zhu, J.; Feng, Z.; Li, J.; Xuan, L.; Xiong, Y. Numerical Simulation and Experimental Validation of the Flow-Induced Excitation Characteristics of a Four-Way Reversing Valve. Processes 2023, 11, 2177. [Google Scholar] [CrossRef]

- Yang, Y.T.; Cheng, Y.K.; Chen, Y.C. Flow performance of multi-door reflux valves. J. Hydraul. Eng. 1994, 35, 1391–1399. [Google Scholar]

- Cheng, X.; Lu, L.; Huang, C. Flow performance of multi-door reflux valve with different door orientations. J. Mech. Eng. Sci. 2021, 35, 1391–1399. [Google Scholar]

- Xie, S.; Sun, L.; Wang, Y.; Xie, G. Effect of door shape on the performance of multi-door reflux valve. J. Mech. Eng. Sci. 2021, 35, 3333–3340. [Google Scholar]

- Dincer, K.; Kaya, S. Experimental and numerical investigation of multi-door reflux valve performance. J. Loss Prev. Process Ind. 2021, 70, 104–243. [Google Scholar]

- Chen, J.; Zhang, Y.; Zhang, J.; Zhu, J. Experimental Study on the Performance of a Multi-door Reflux Valve under Different Working Conditions. Chem. Eng. Sci. 2021, 229, 116–225. [Google Scholar]

- Tchomeni, B.X.; Alugongo, A. Experimental diagnosis of multiple faults on a rotor-stator system by fast Fourier transform and wavelet scalogram. J. Vibroeng. 2019, 21, 911–926. [Google Scholar] [CrossRef]

- Dynamic Characteristics of Check Valves. 2003. Available online: https://www.valmatic.com/Portals/0/pdfs/DynamicCharacteristicsofCheckValves_18.pdf (accessed on 9 September 2024).

- Himr, D.; Habán, V.; Hudec, M. Experimental investigation of check valve behaviour during the pump trip. J. Phys. 2017, 17, 65–88. [Google Scholar] [CrossRef]

- Ballun, J.V. A methodology for predicting check valve slam. J. AWWA 2007, 99, 60–65. [Google Scholar] [CrossRef]

- Chang, Z.; Jiang, J. Experimental Investigation of the Steady-State Flow Field with Particle Image Velocimetry on a Nozzle Check Valve and Its Dynamic Behaviour on the Pipeline System. Energies 2022, 15, 5393. [Google Scholar] [CrossRef]

- Sozinando, D.F.; Tchomeni, B.X.; Alugongo, A.A. Modal Analysis and Flow through Sectionalized Pipeline Gate Valve Using FEA and CFD Technique. J. Eng. 2023, 2023, 2215509. [Google Scholar] [CrossRef]

- Li, R.; Sun, Q.; Ding, X.; Zhang, Y.; Yuan, W.; Wu, T. Review of Flow-Matching Technology for Hydraulic Systems. Processes 2022, 10, 2482. [Google Scholar] [CrossRef]

- Li, J.; Wang, S. Study on Flow Characteristic of Multi-Door Reflux Valve. Procedia Eng. 2010, 15, 4142–4147. [Google Scholar]

- ASTM A216; Standard Specification for Steel Castings, Carbon, Suitable for Fusion Welding, for High-Temperature Service. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM A351/A351M-00; Standard Specification for Castings, Austenitic, Austenitic-Ferritic (Duplex), for Pressure-Containing Parts. ASTM International: West Conshohocken, PA, USA, 2000.

- ISO 17292:2015; Metal Ball Valves for Petroleum, Petrochemical and Allied Industries. International Organization for Standardization: Geneva, Switzerland, 2015. Available online: https://www.iso.org/standard/59736.html (accessed on 9 September 2024).

- Graciano-Uribe, J.; Pujol, T.; Puig-Bargués, J.; Duran-Ros, M.; Arbat, G.; Ramírez de Cartagena, F. Assessment of different pressure drop-flow rate equations in a pressurized porous media filter for irrigation systems. Water 2021, 13, 2179. [Google Scholar] [CrossRef]

- Filo, G.; Lisowski, E.; Rajda, J. Pressure loss reduction in an innovative directional poppet control valve. Energies 2020, 13, 3149. [Google Scholar] [CrossRef]

- Tian, Y.; Gao, J.; Chen, J.; Xie, J.; Que, Q.; Munthali, R.M.; Zhang, T. Optimization of pressure management in water distribution systems based on pressure-reducing valve control: Evaluation and case study. Sustainability 2023, 15, 11086. [Google Scholar] [CrossRef]

| Parameters Description | Value/Units |

|---|---|

| Material | Cast steel-ASTM A352-LCC |

| Nominal Diameter (DN) | DN1400 |

| Pressure Rating (PN) | PN17.5 |

| Number of Doors | 4 |

| Door Height | 600 mm |

| Door Width | 800 mm (center) |

| Door Thickness | 60 mm |

| Valve Body Diameter | 2510 mm |

| Valve Body Thickness | 50 mm |

| Max Angle of Door Opening | 65° |

| Valve Weight | 22,046 kg |

| Test Pressure (kPa) | Visual Inspection | Test Duration (min) | Results |

|---|---|---|---|

| 1800 | No deformation or crack | 15 | Acceptable |

| 2500 | No deformation or crack | 15 | Acceptable |

| 3500 | No deformation or crack | 15 | Acceptable |

| Test Pressure (kPa) | Water Leakage Rate (L/min) | Test Duration (min) | Reflux Prevention (%) | Results |

|---|---|---|---|---|

| 900 | 5 | 5 | 60 | Fail |

| 1800 | 11 | 5 | 50 | Fail |

| 2625 | 18 | 5 | 40 | Fail |

| Test Pressure (kPa) | Visual Inspection | Test Duration (min) | Results |

|---|---|---|---|

| 1800 | No deformation or crack | 15 | Acceptable |

| 2500 | No deformation or crack | 15 | Acceptable |

| 3500 | No deformation or crack | 15 | Acceptable |

| Test Pressure (kPa) | Water Leakage Rate (L/min) | Test Duration (min) | Reflux Prevention (%) | Results |

|---|---|---|---|---|

| 900 | 0 | 5 | 100 | Pass |

| 1800 | 1 | 5 | 98 | Pass |

| 2625 | 2 | 5 | 95 | Pass |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hadebe, X.P.; Tchomeni Kouejou, B.X.; Alugongo, A.A.; Sozinando, D.F. Flow Performance Analysis of Non-Return Multi-Door Reflux Valve: Experimental Case Study. Fluids 2024, 9, 213. https://doi.org/10.3390/fluids9090213

Hadebe XP, Tchomeni Kouejou BX, Alugongo AA, Sozinando DF. Flow Performance Analysis of Non-Return Multi-Door Reflux Valve: Experimental Case Study. Fluids. 2024; 9(9):213. https://doi.org/10.3390/fluids9090213

Chicago/Turabian StyleHadebe, Xolani Prince, Bernard Xavier Tchomeni Kouejou, Alfayo Anyika Alugongo, and Desejo Filipeson Sozinando. 2024. "Flow Performance Analysis of Non-Return Multi-Door Reflux Valve: Experimental Case Study" Fluids 9, no. 9: 213. https://doi.org/10.3390/fluids9090213

APA StyleHadebe, X. P., Tchomeni Kouejou, B. X., Alugongo, A. A., & Sozinando, D. F. (2024). Flow Performance Analysis of Non-Return Multi-Door Reflux Valve: Experimental Case Study. Fluids, 9(9), 213. https://doi.org/10.3390/fluids9090213