A Vaporization Model for Continuous Surface Force Approaches and Subcooled Configurations

Abstract

:1. Introduction

2. Phase Change Modeling

2.1. Mathematical Framework—Level Set Method

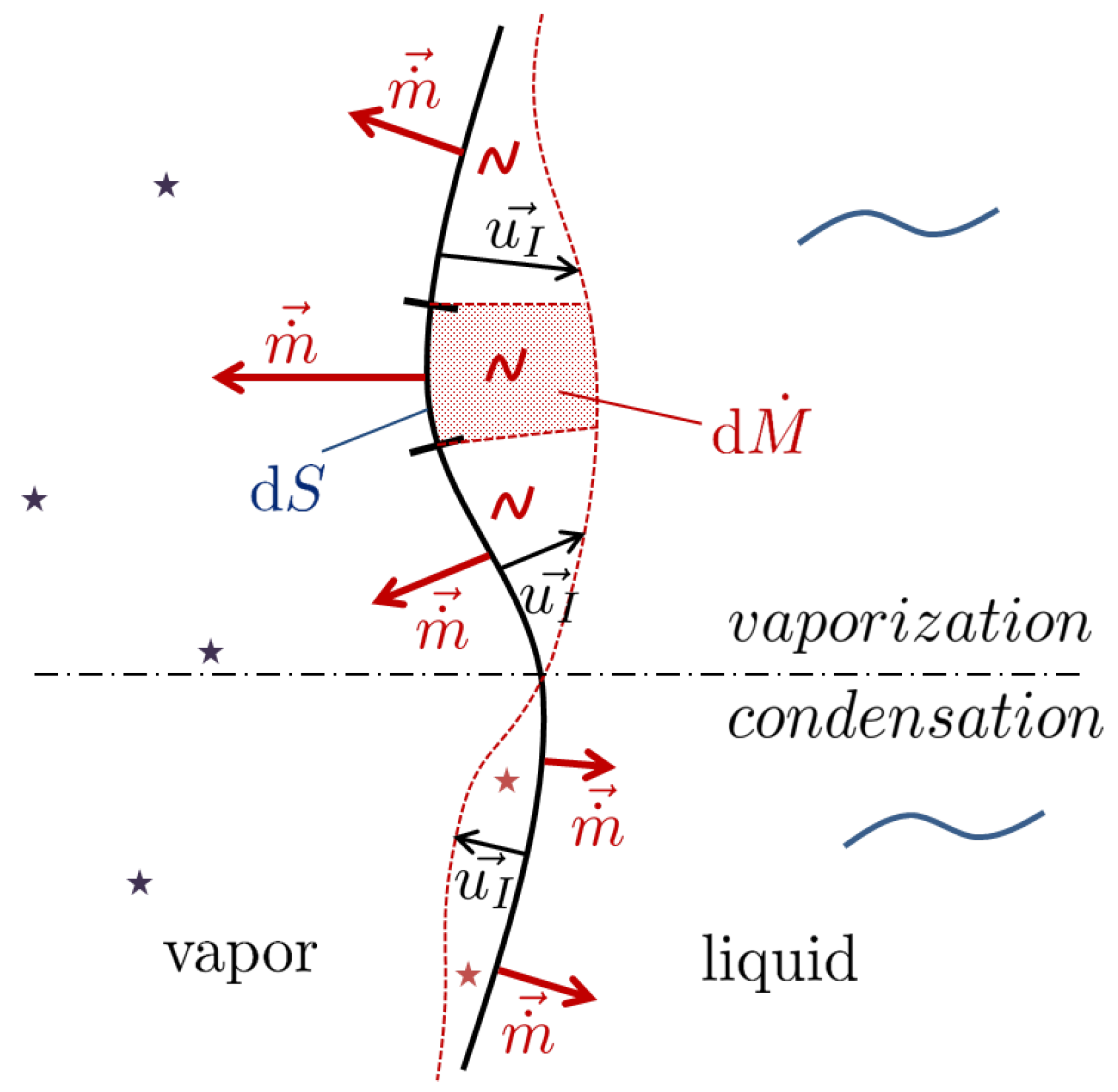

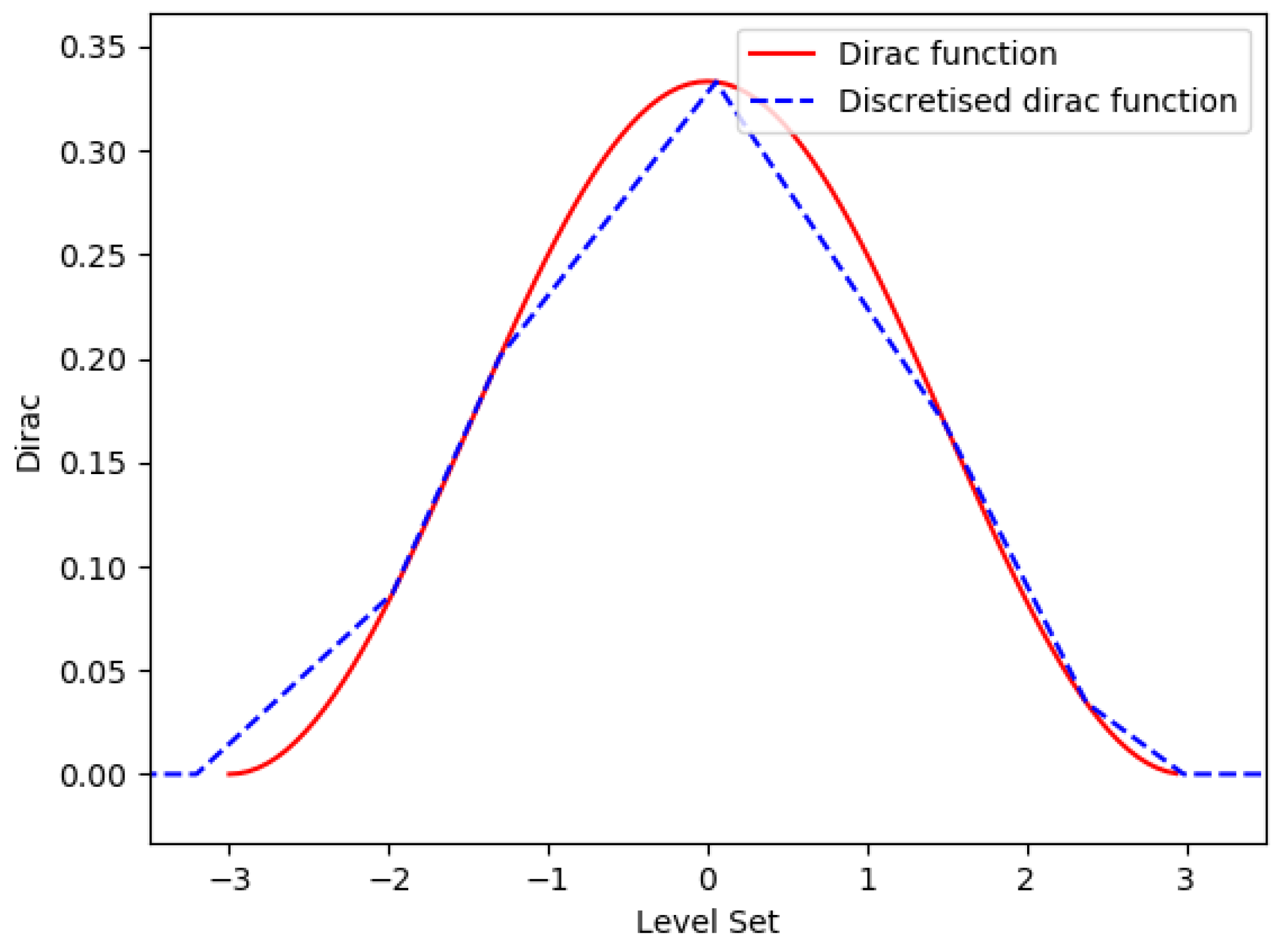

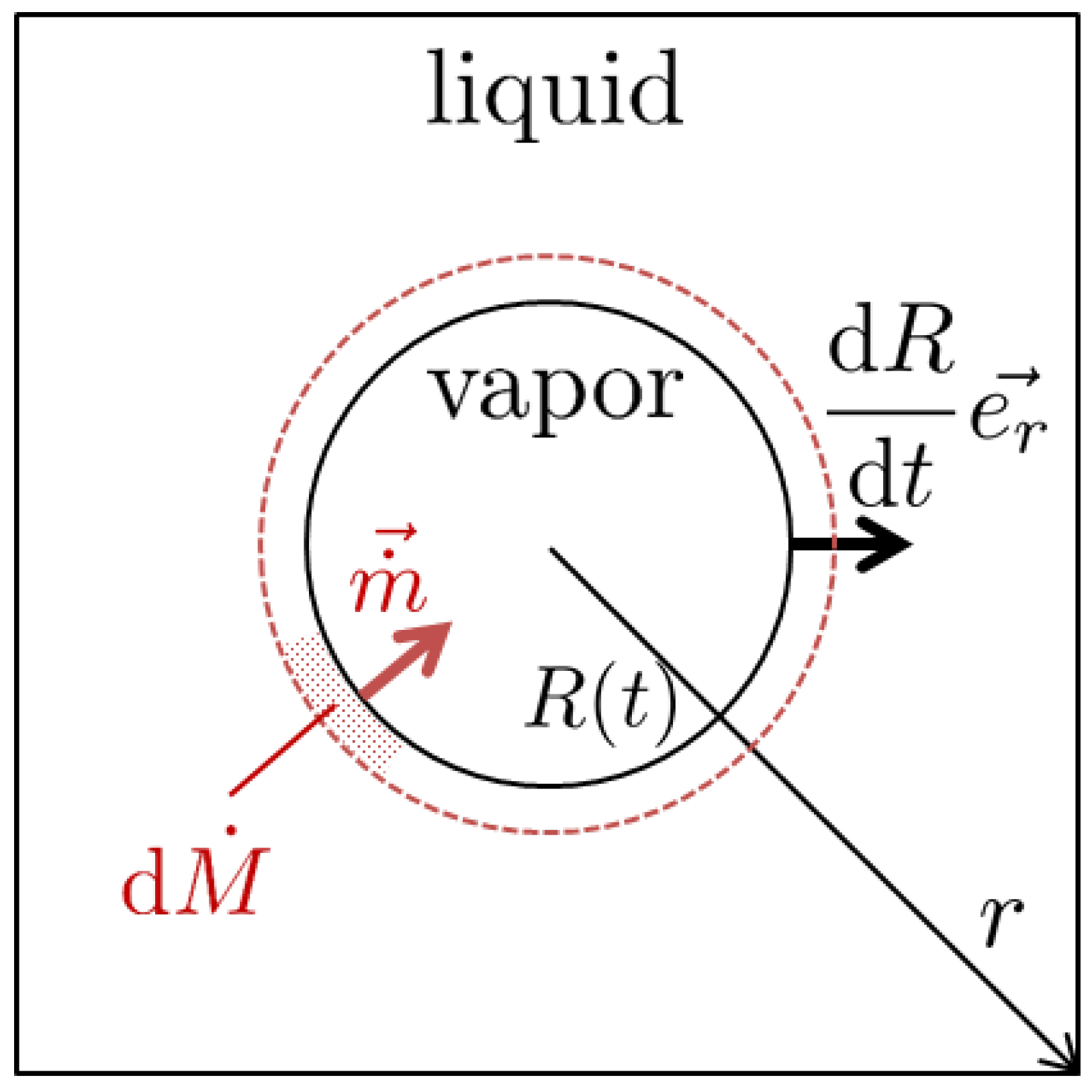

2.2. Continuous Description of Phase Change

3. Heat Flux Jump Computation

3.1. Description of the Extension Method

3.2. The Disc Case

3.3. Determination of Heat Flux Jumps over a Smooth Interface

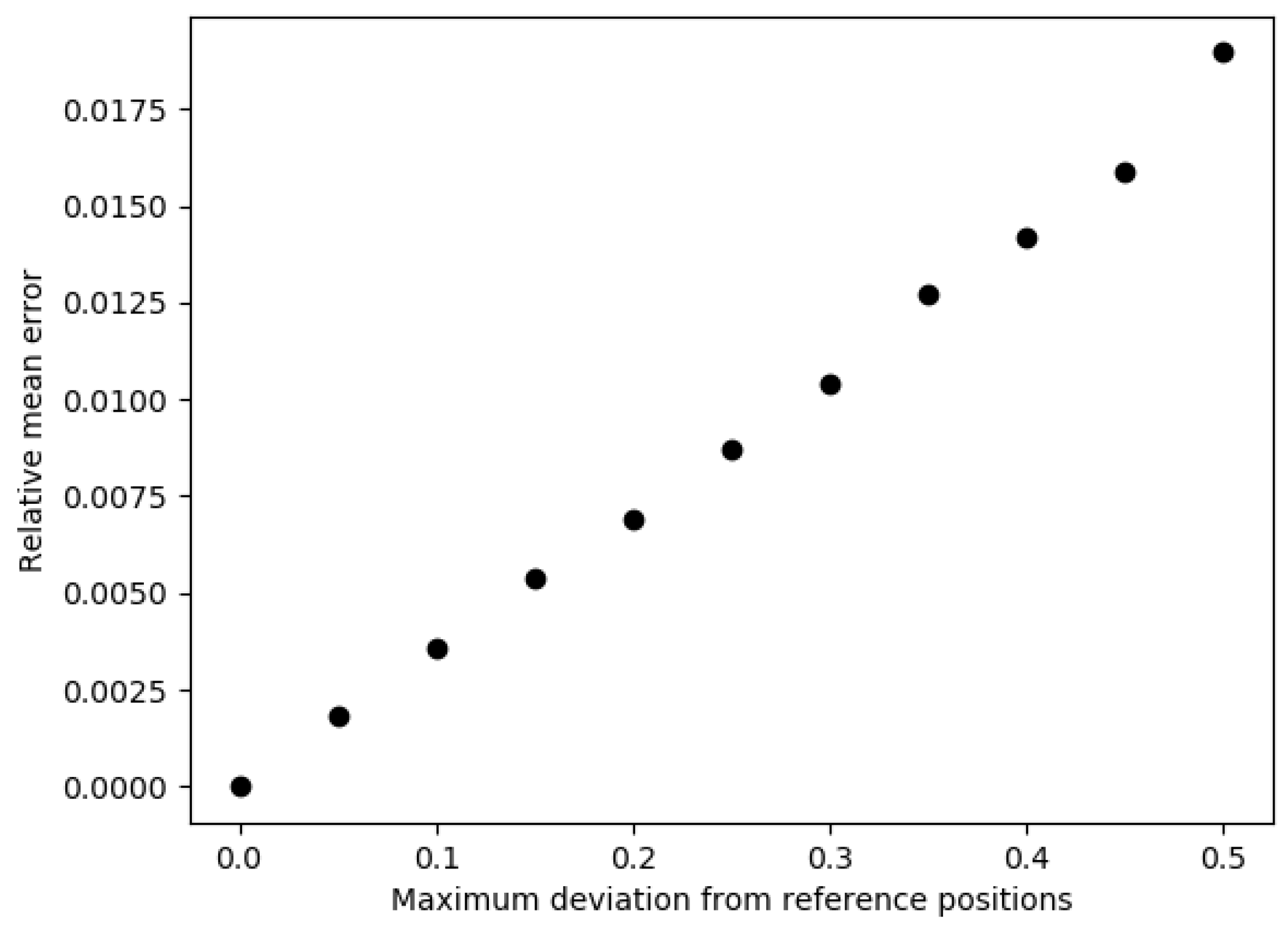

3.4. Precision of the Method

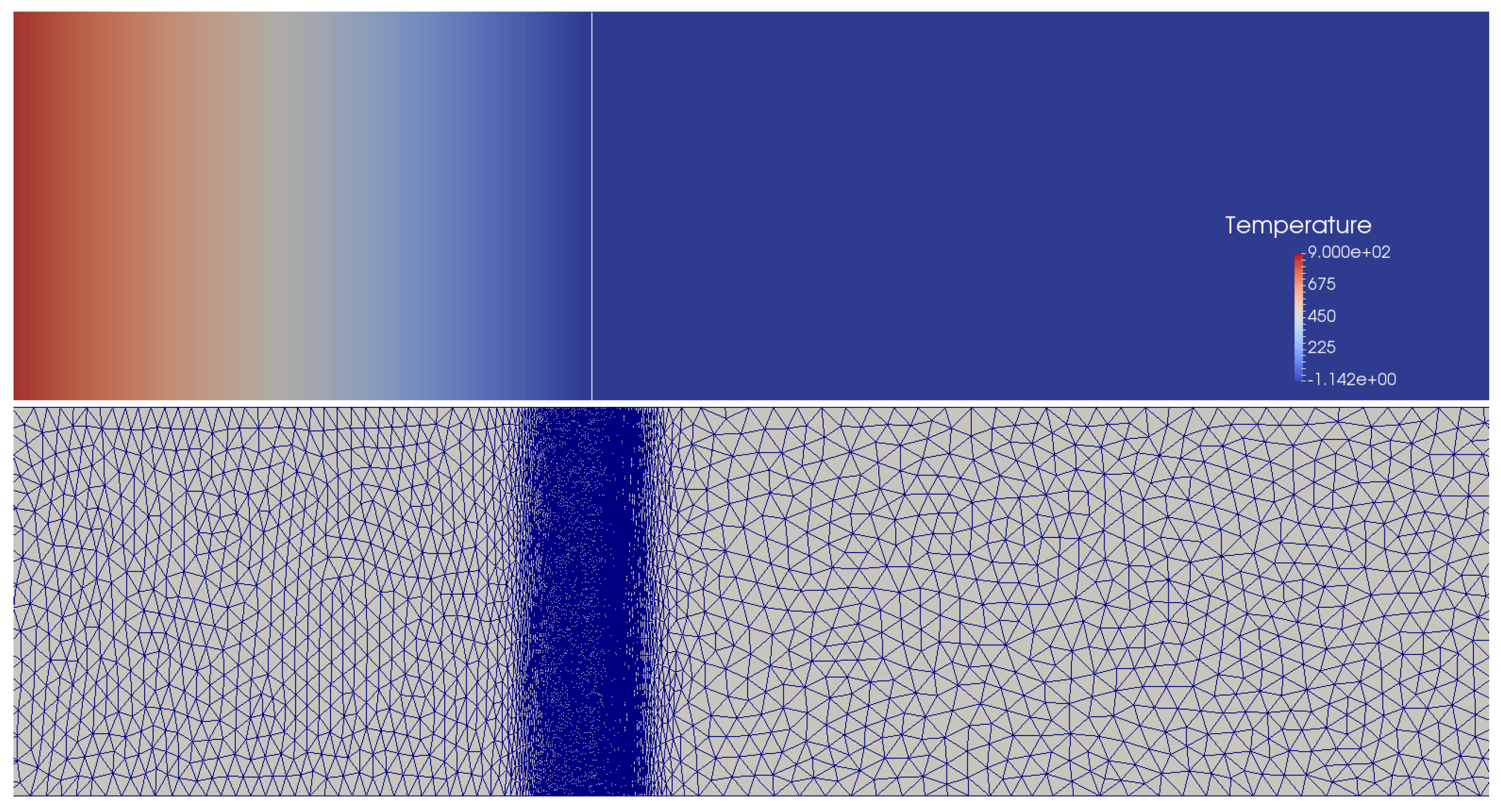

4. Two-Phase Thermal Solver

4.1. Thermal Equations

4.2. Stabilization

4.3. Numerical Method and Mesh

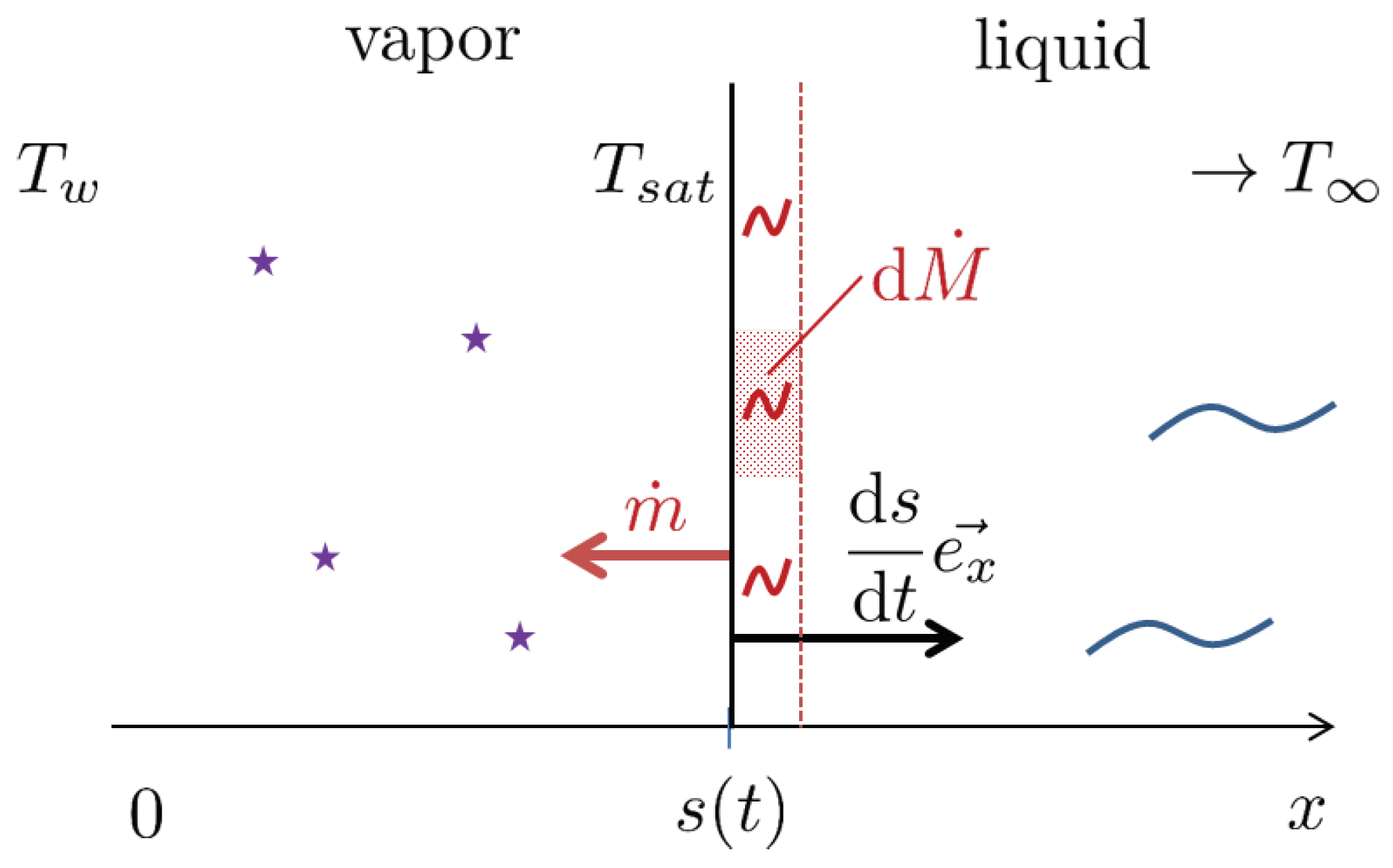

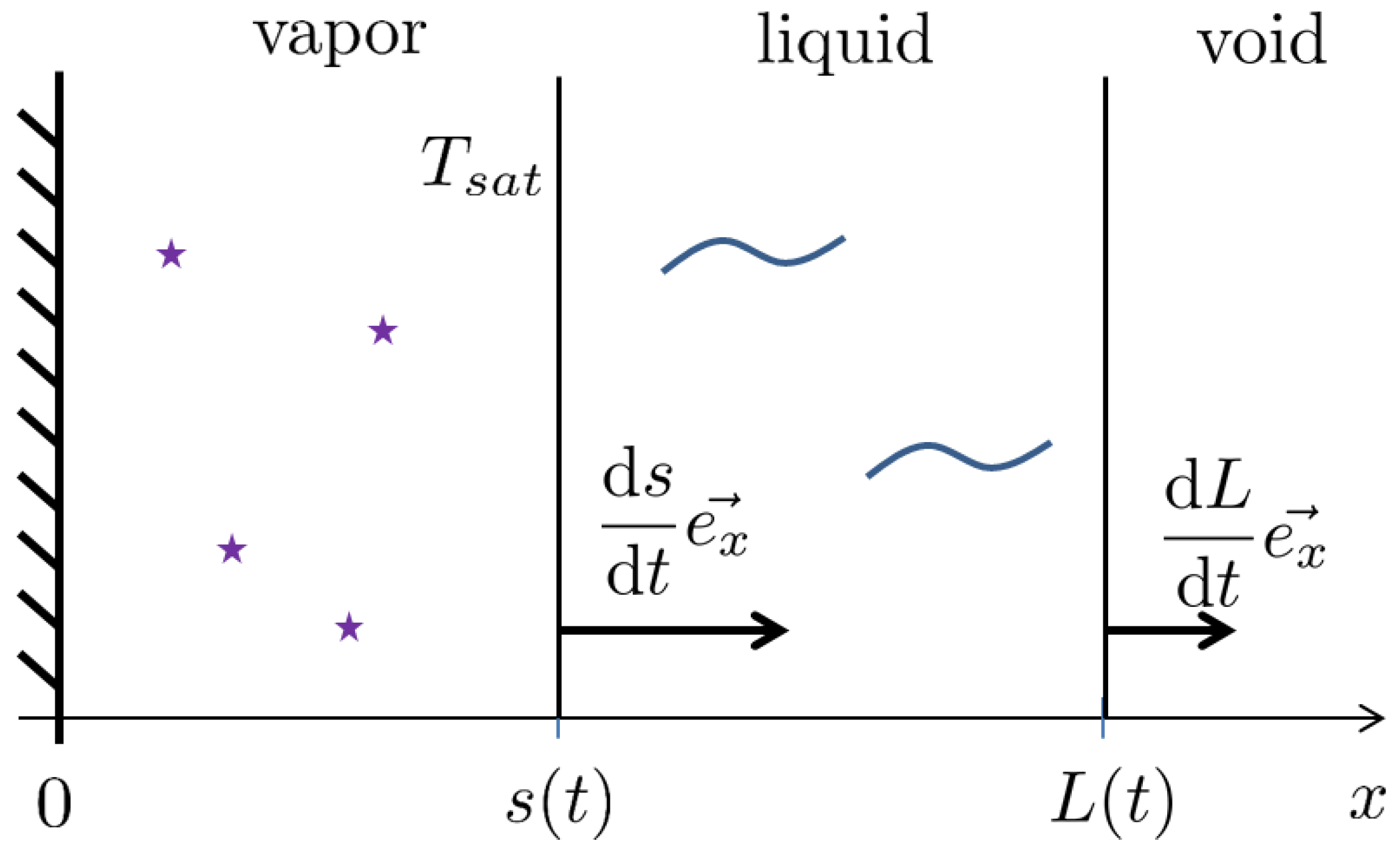

5. The Isochoric Stefan Problem

5.1. Reminders of the Problem

5.2. Studied Cases

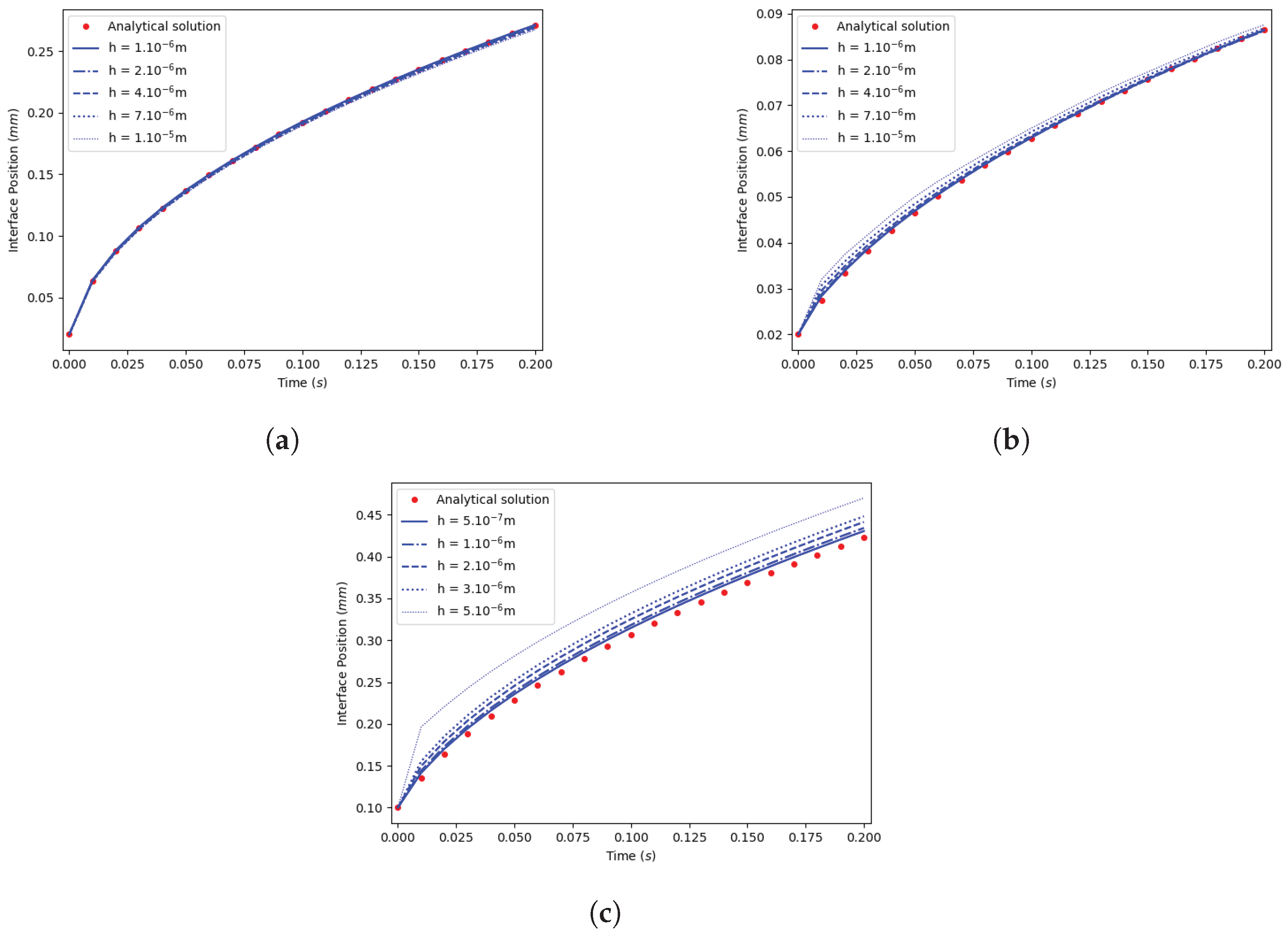

5.2.1. Case 1: Without Subcooling

5.2.2. Case 2: With a Small Subcooling

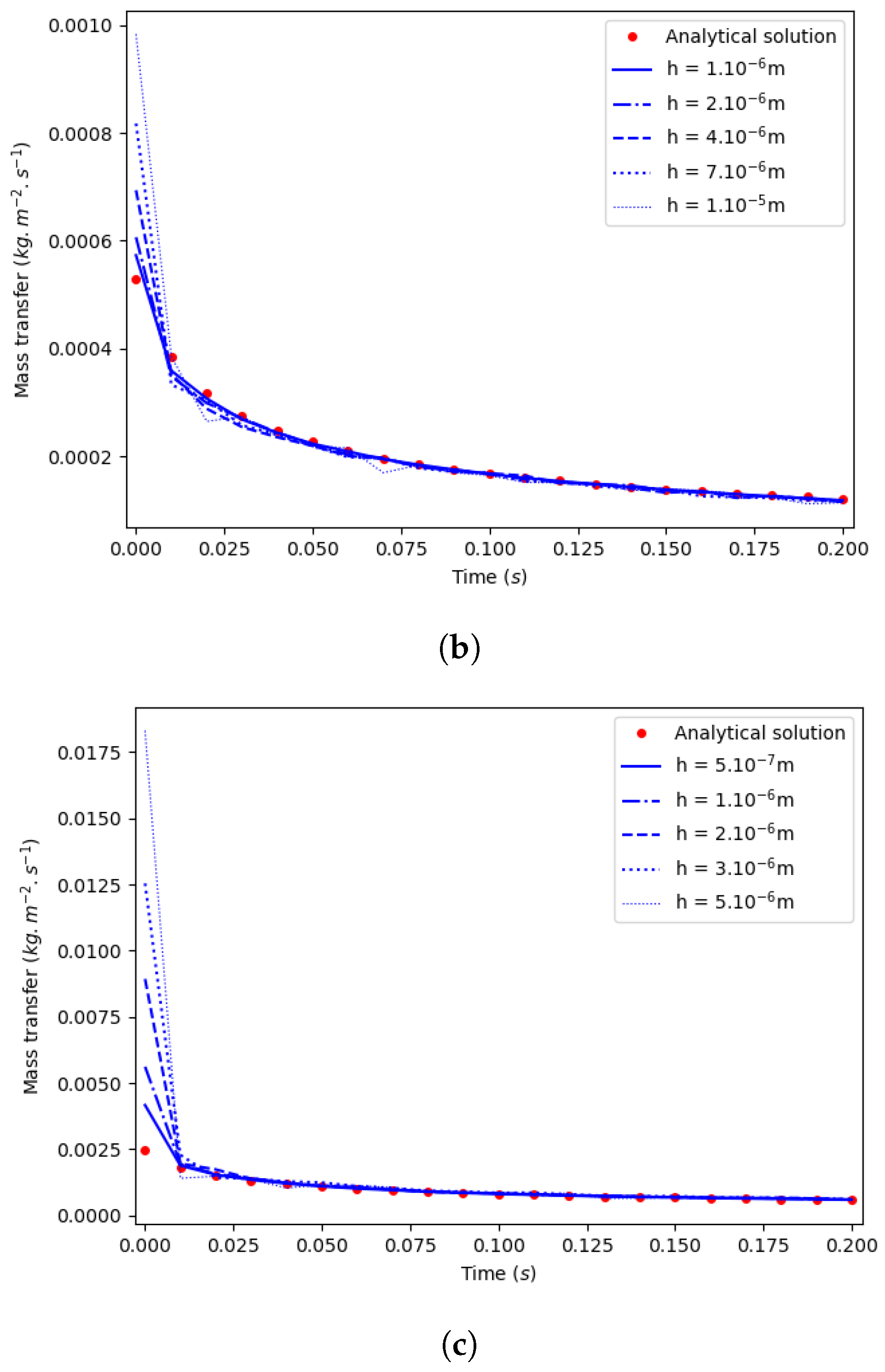

5.2.3. Case 3: With a High Subcooling

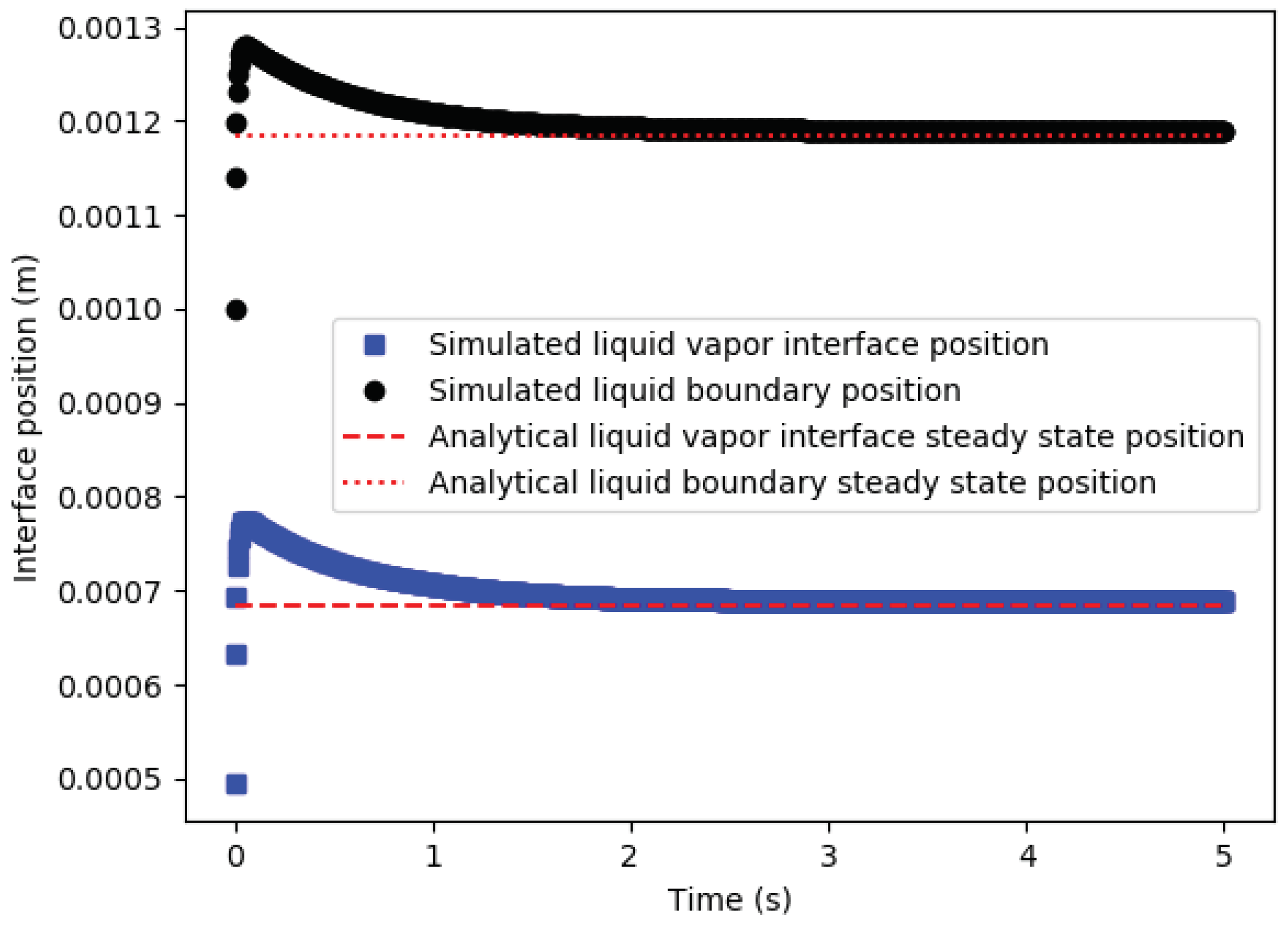

5.3. Results

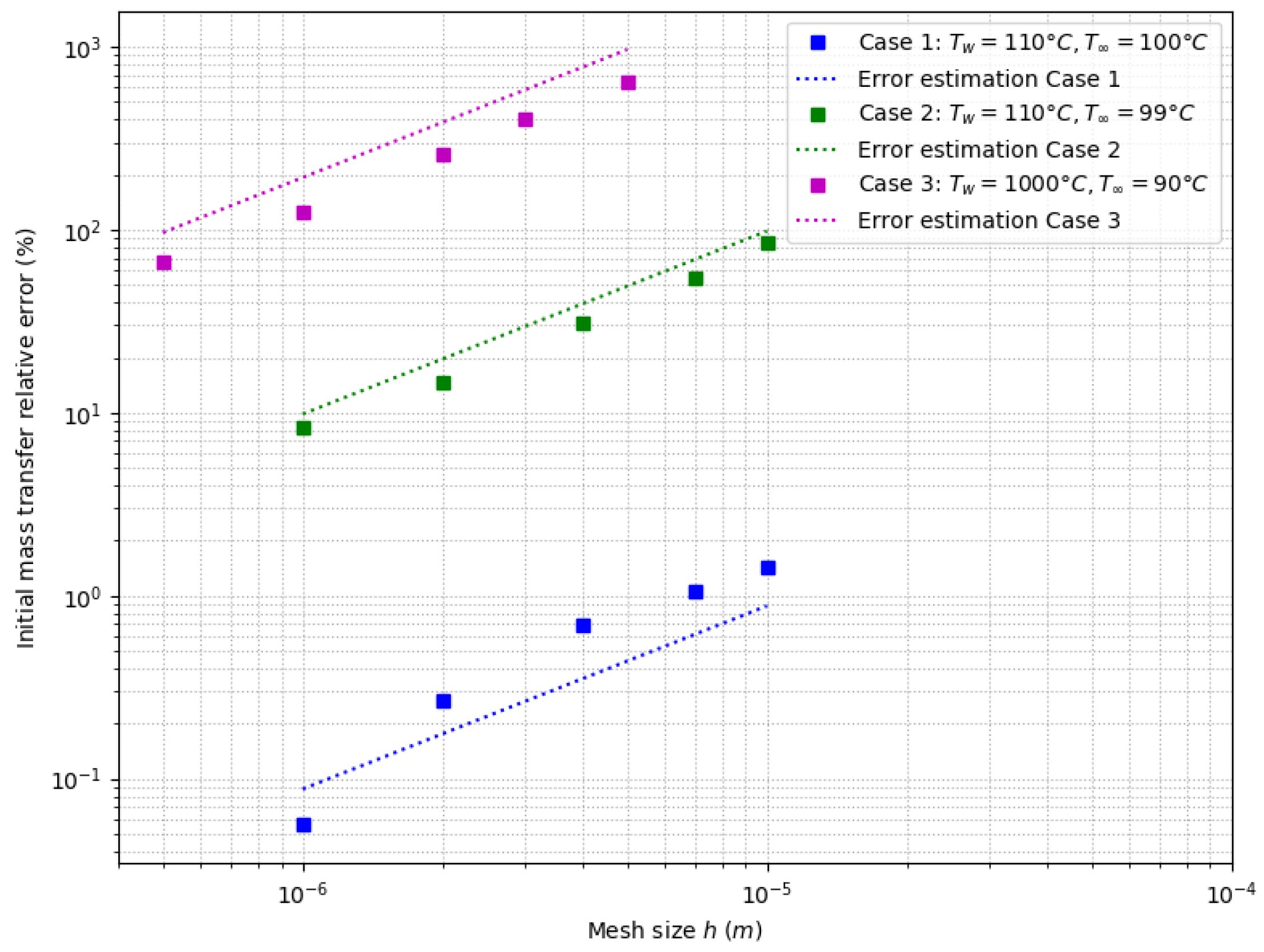

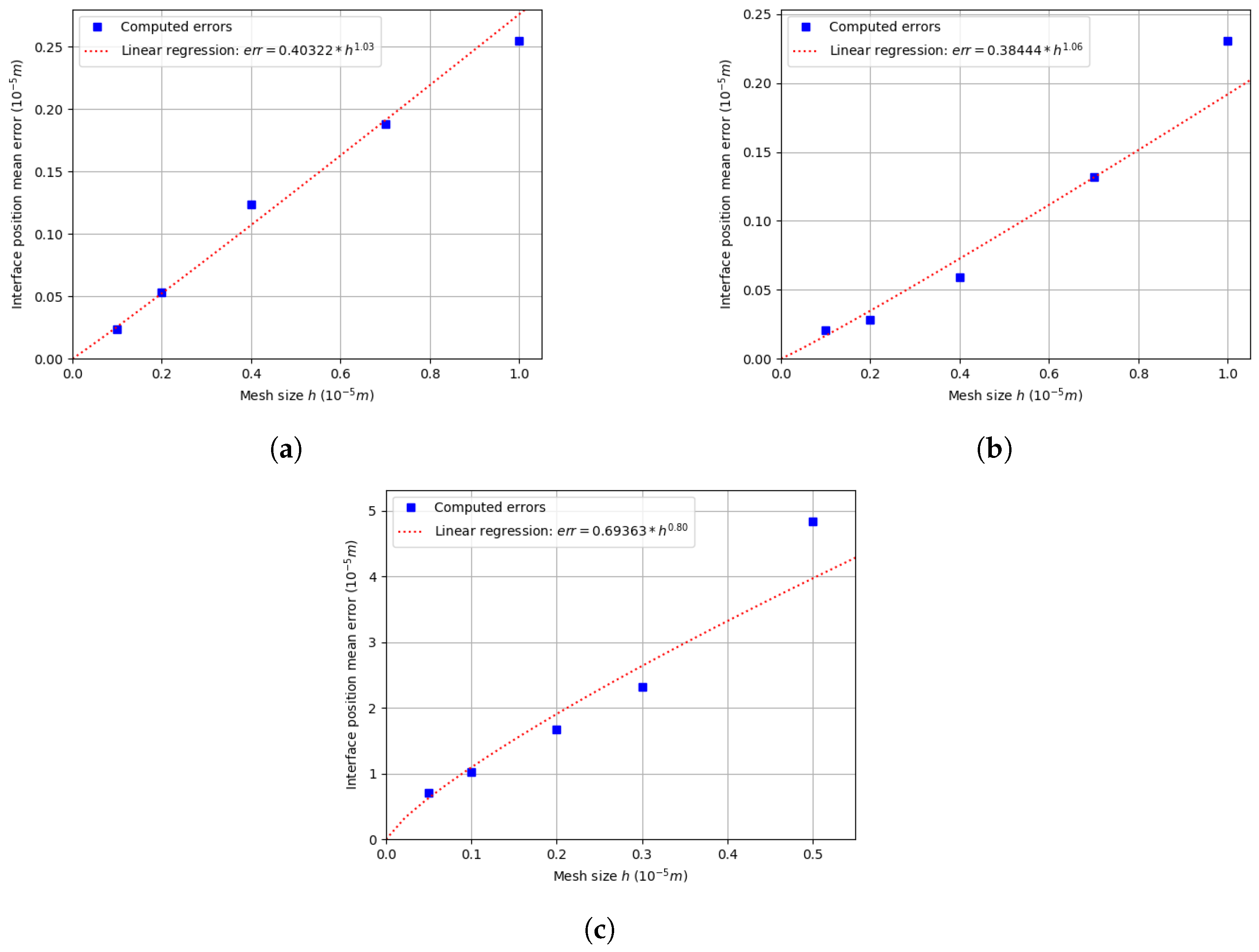

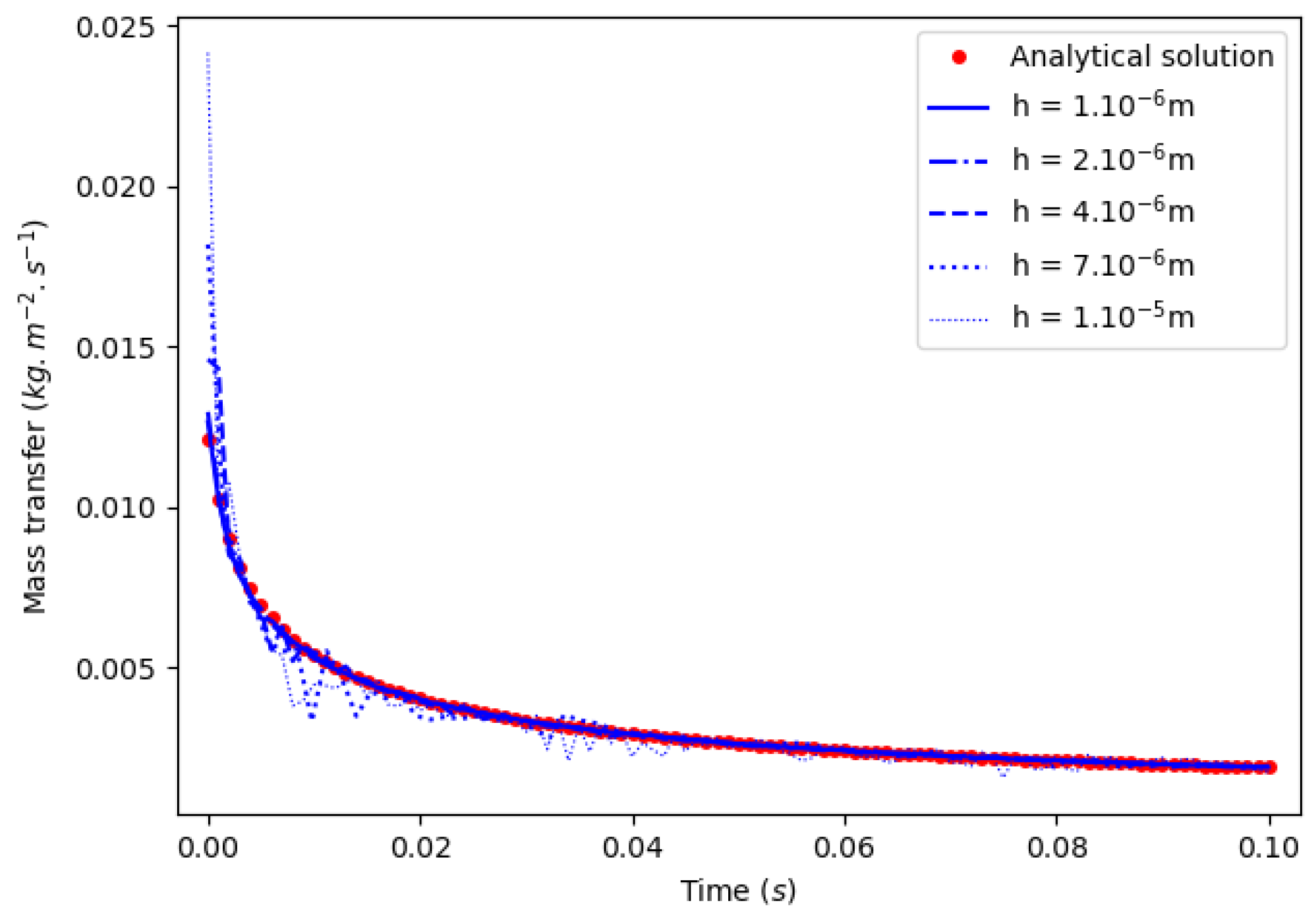

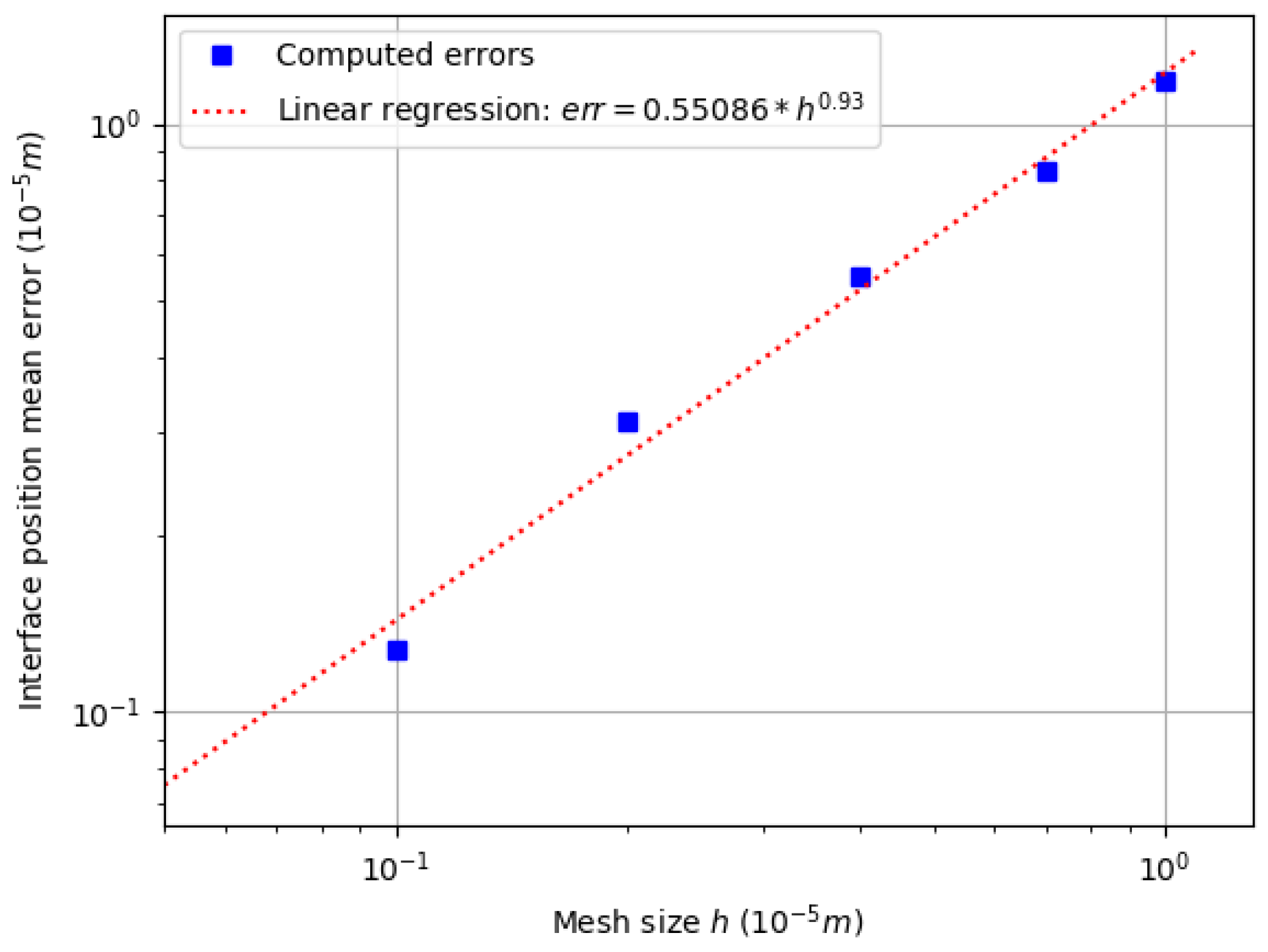

5.4. Precision and Accuracy Order

6. Multiphase Pseudo-Compressible Framework

6.1. Pseudo-Compressible Navier–Stokes Solver

6.2. Numerical Method

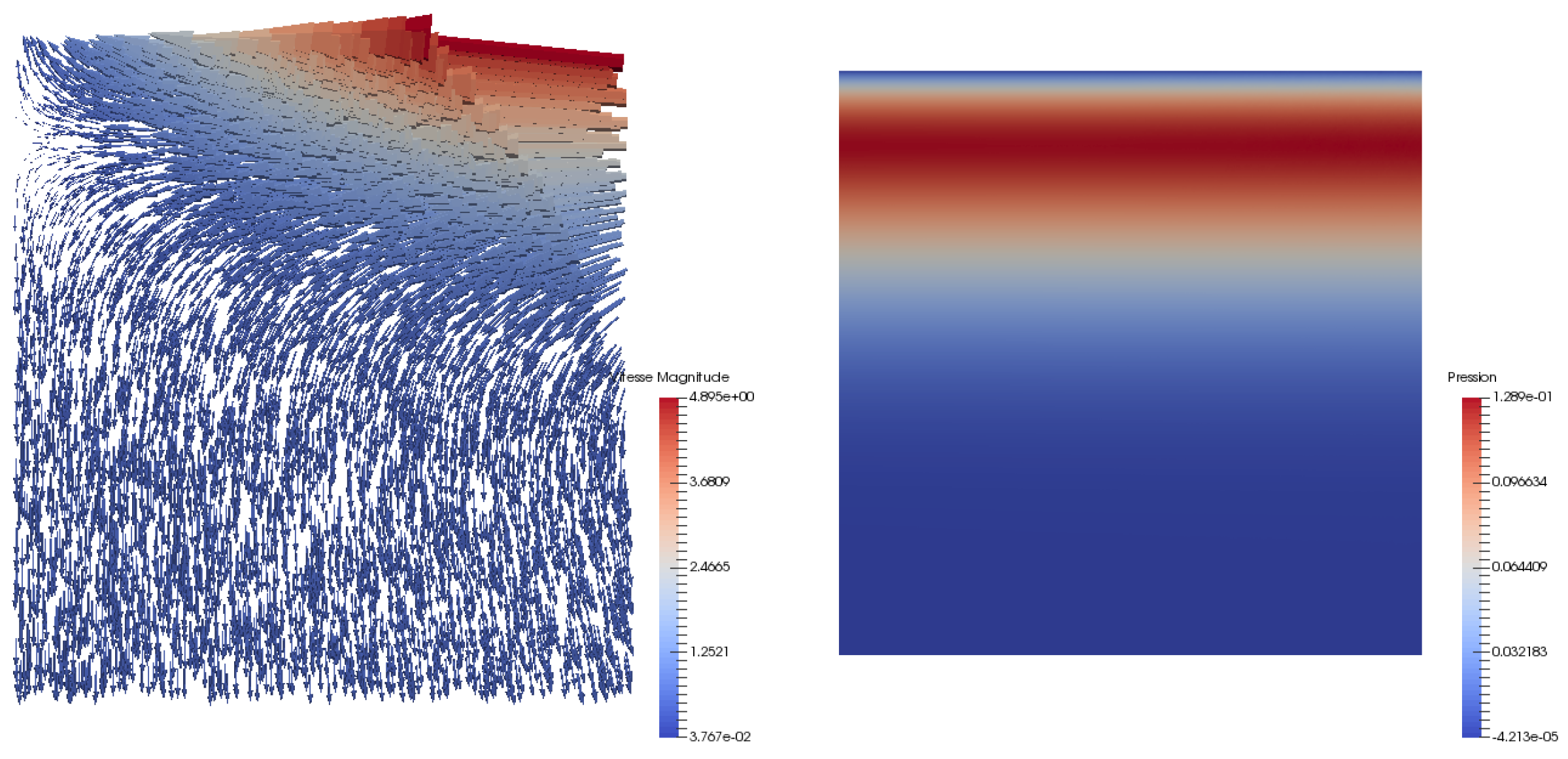

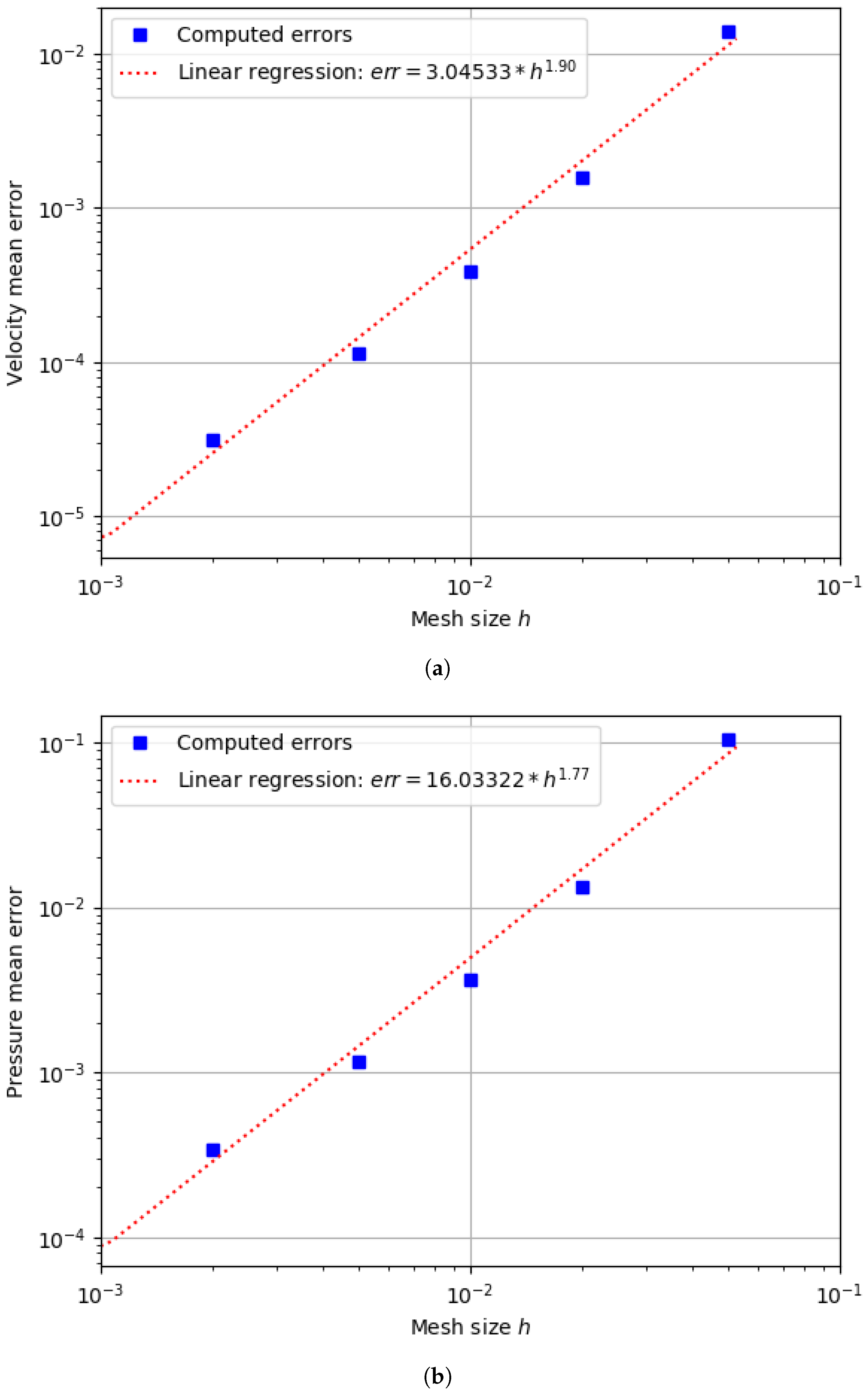

6.3. A 2D Benchmark—The Pseudo-Compressible Square

6.4. Combination with the Level Set Method

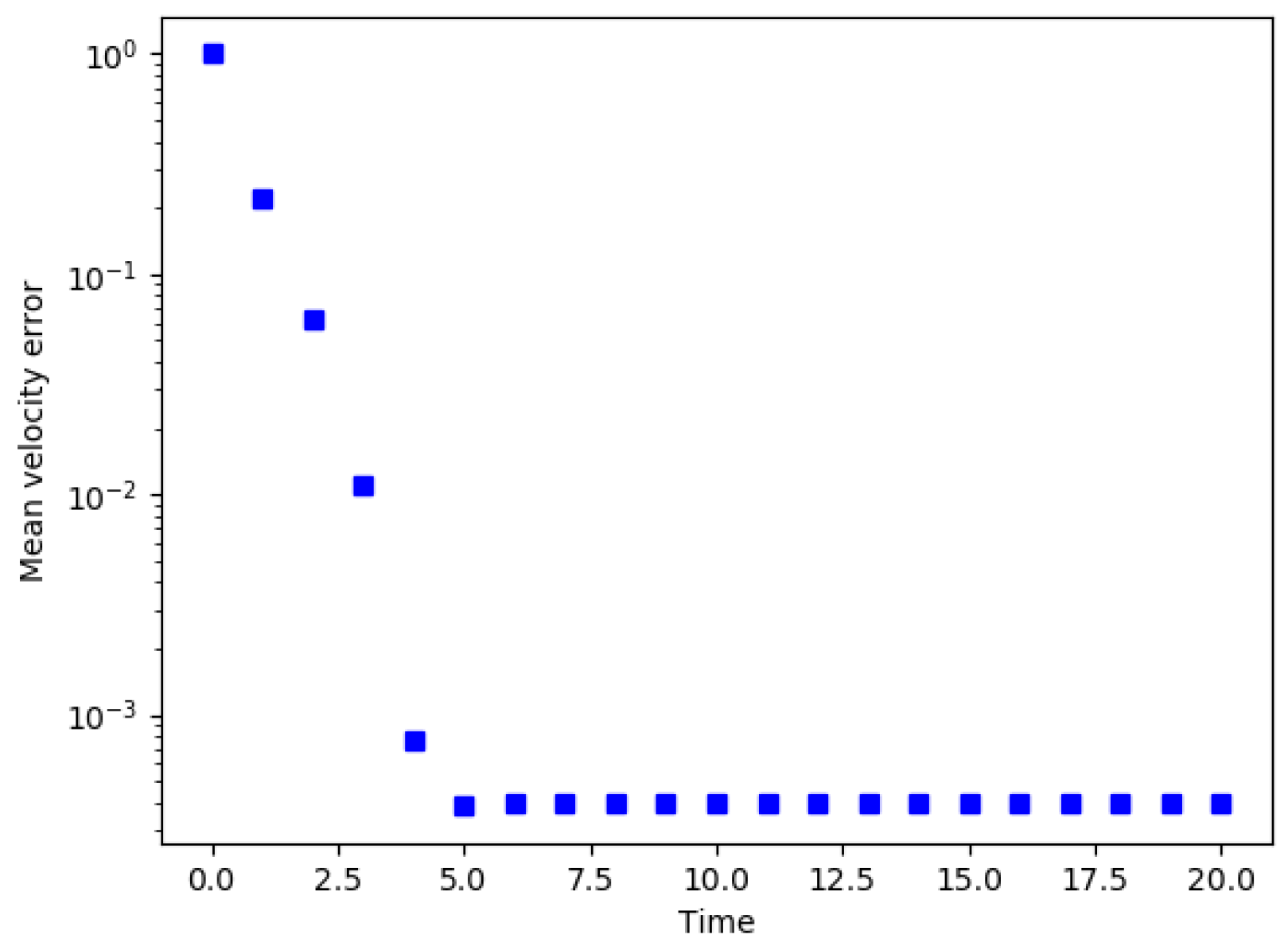

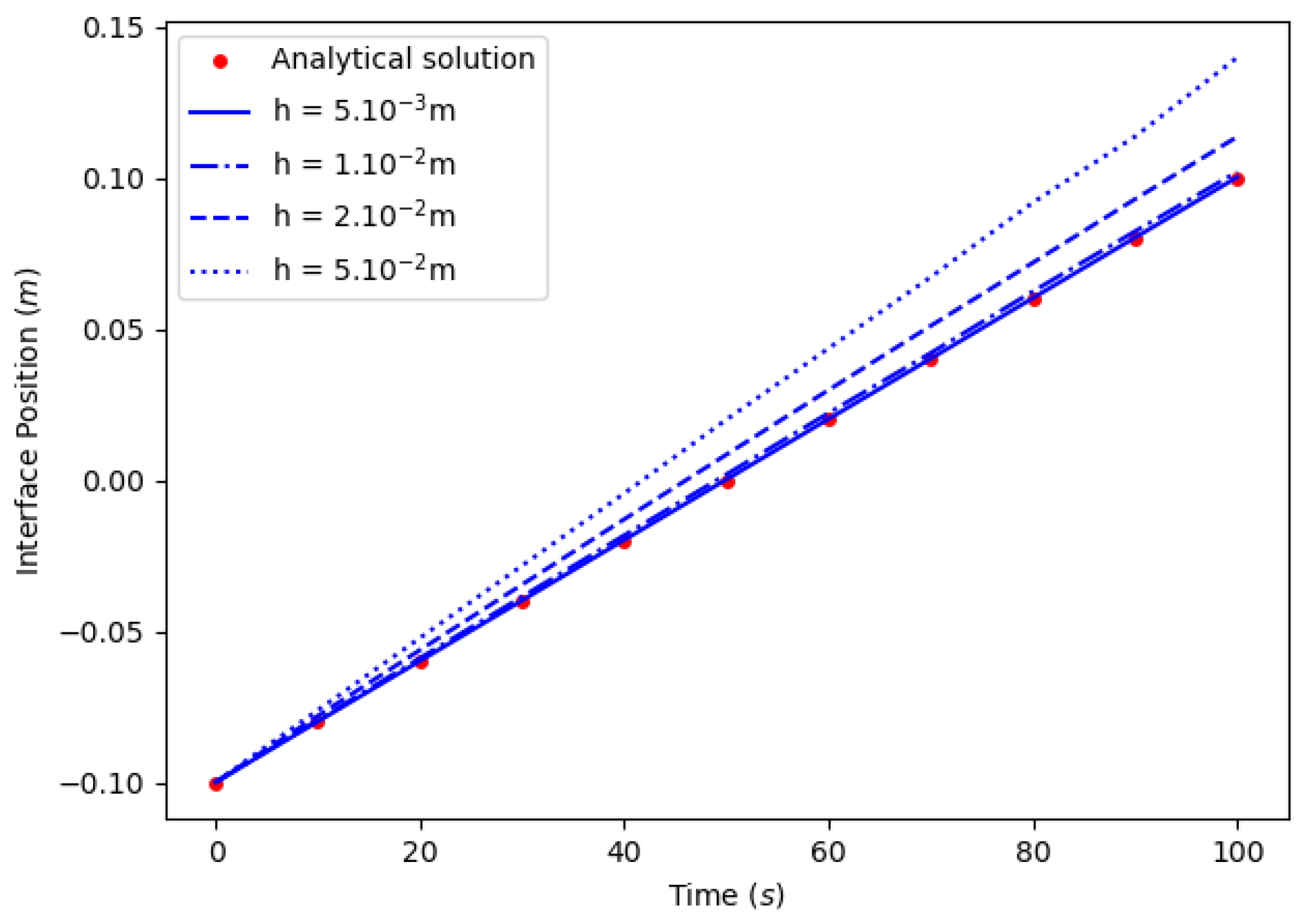

6.5. A 1D Benchmark—Moving Interface

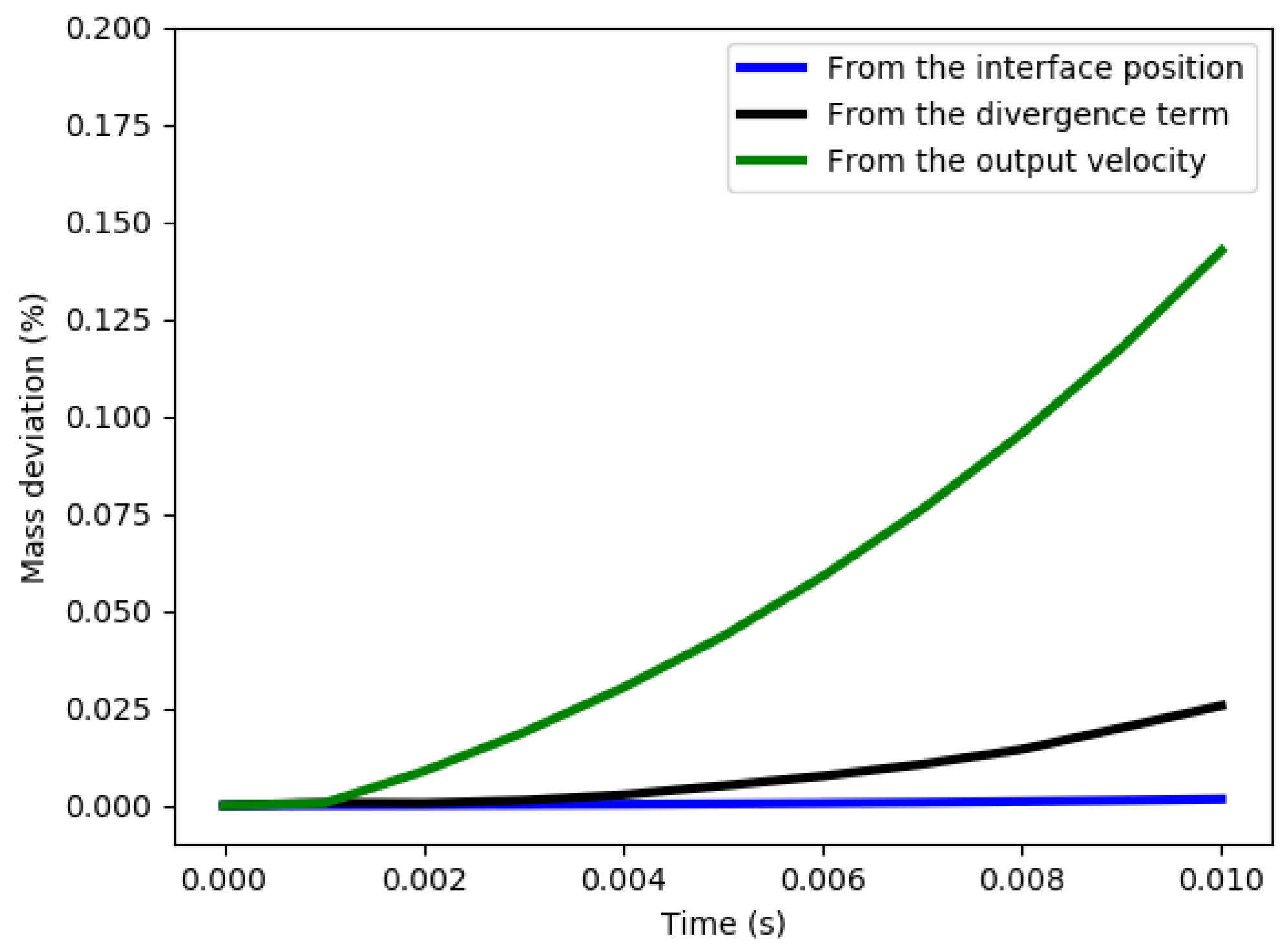

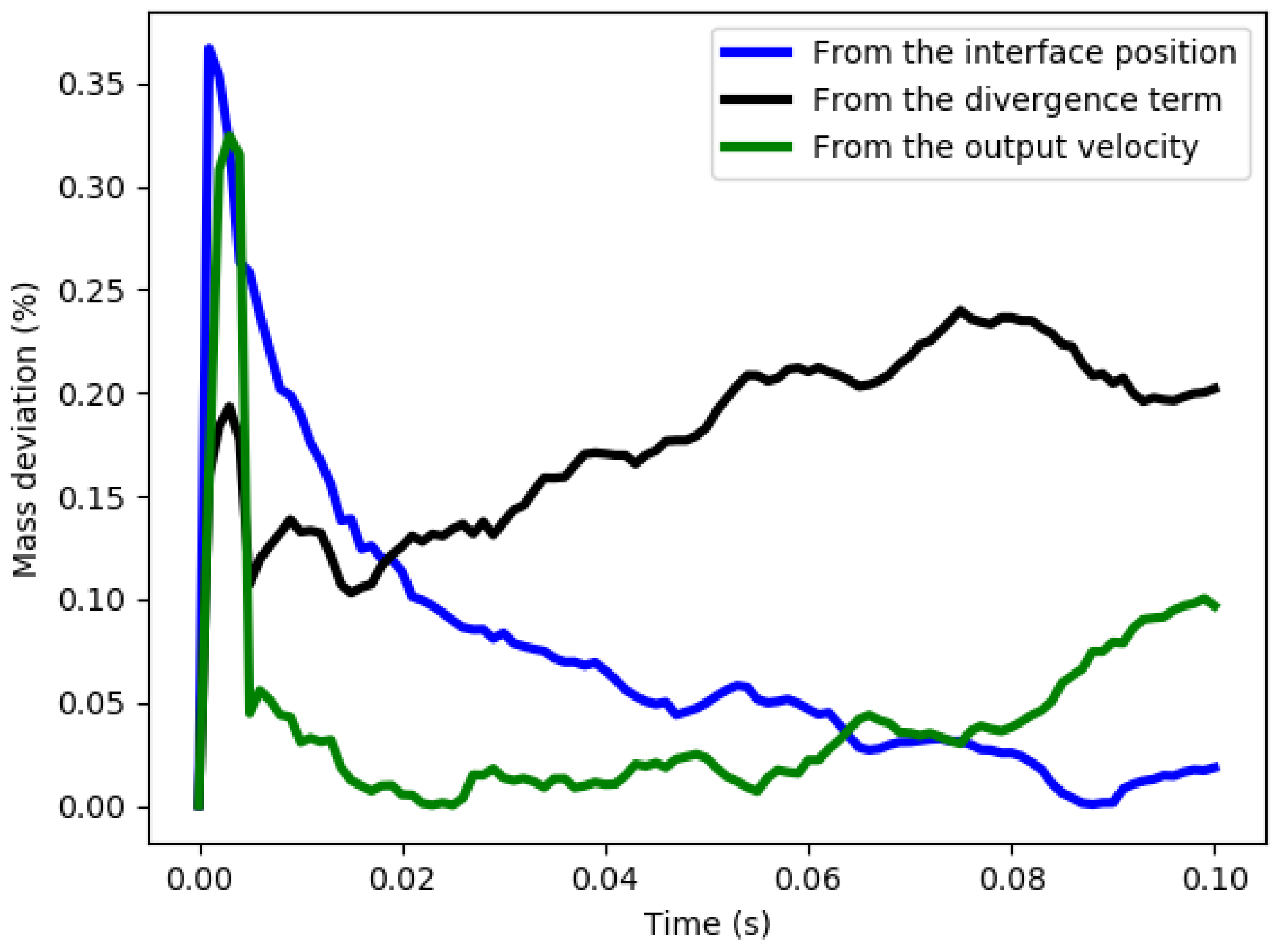

6.5.1. Constant

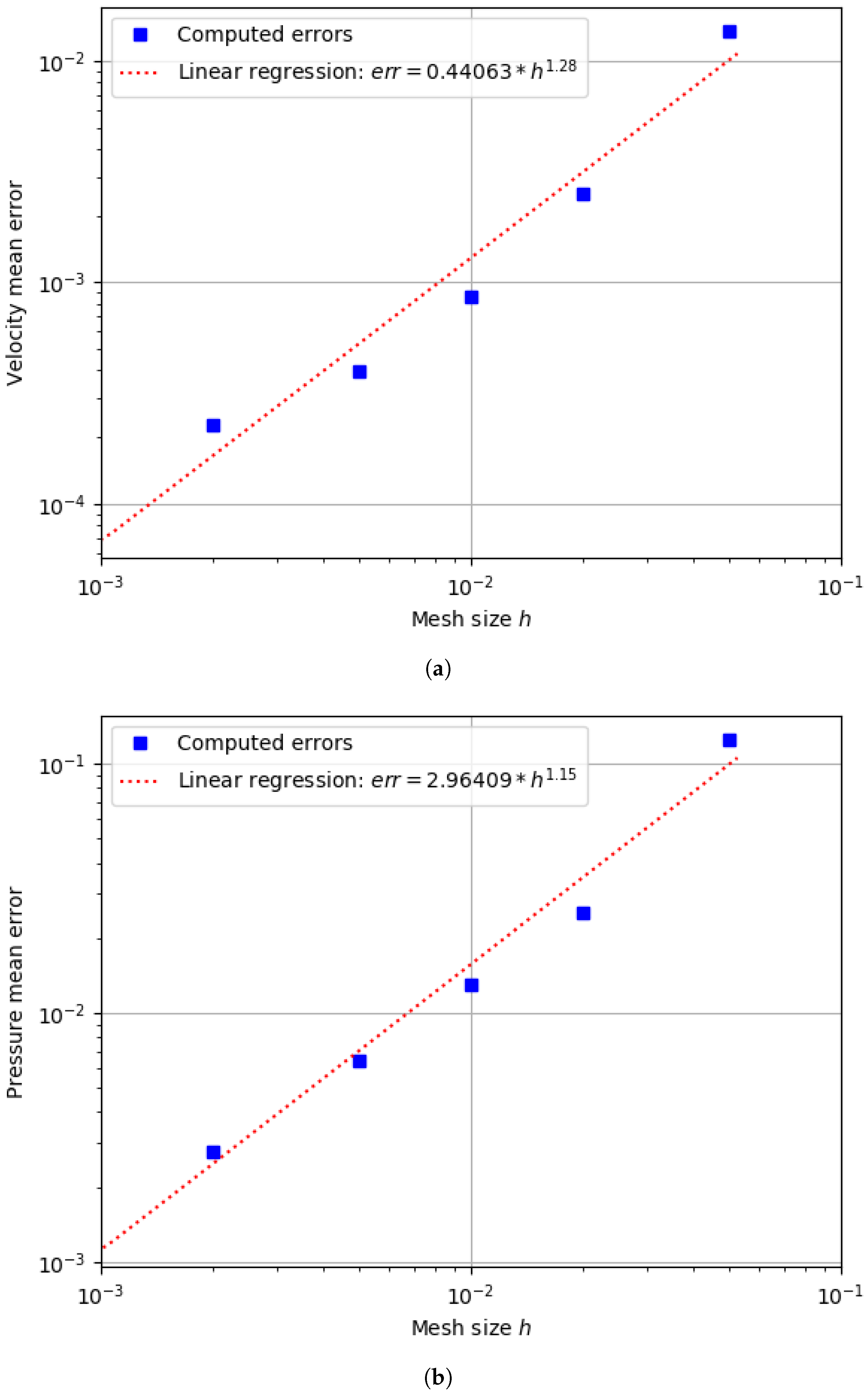

6.5.2. Varying

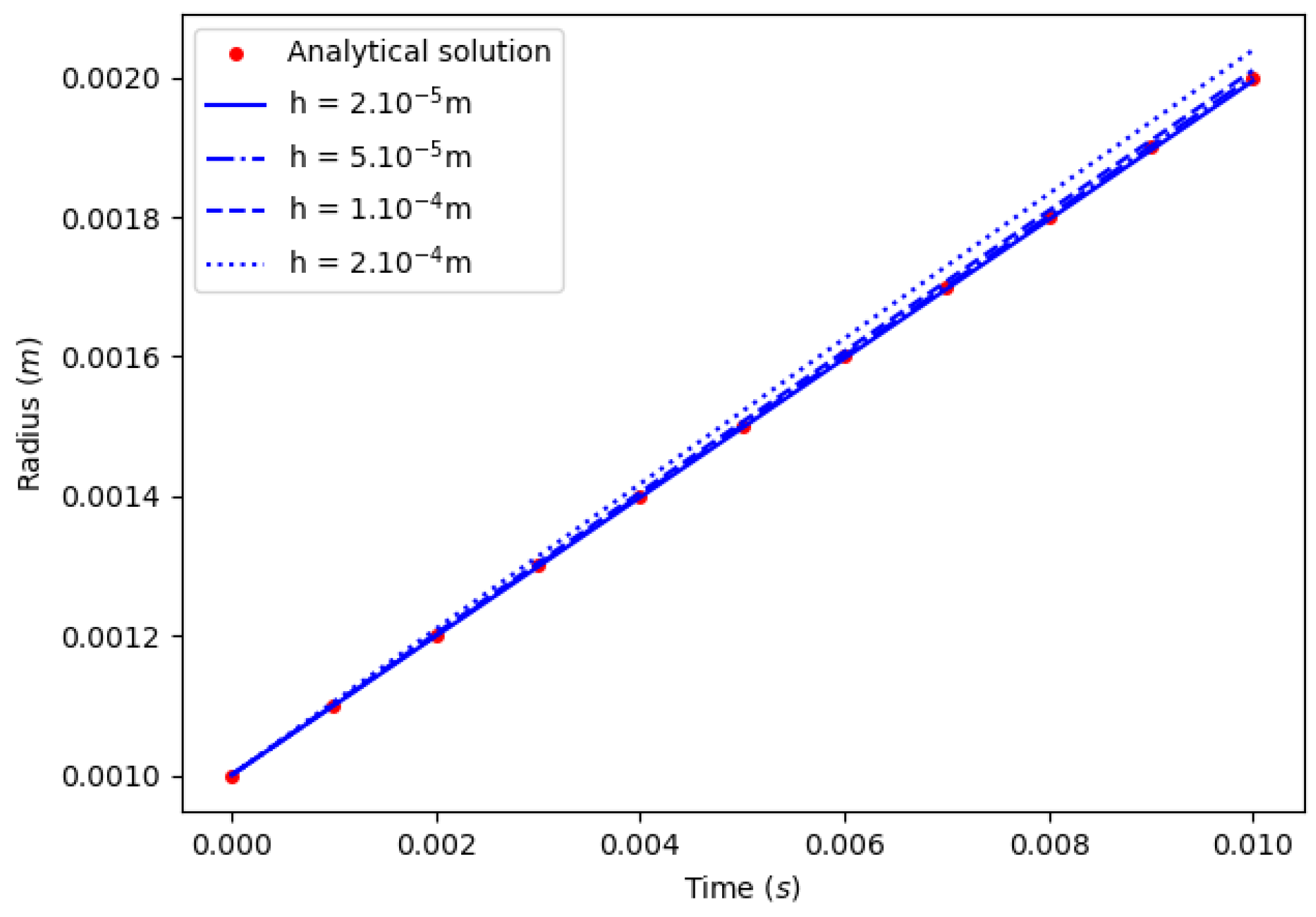

6.6. A 2D Benchmark—Growing Bubble

7. The Complete Phase Change Solver

7.1. A 1D Benchmark—Compressible Stefan Test Case

7.2. A 1D Benchmark—Adiabatic Problem

8. Conclusions and Perspectives

- This methods has been tested and validated on several analytic tests and isochoric Stefan Problem without and with subcooling.

- Then a remeshing algorithm has been added and good results are showed for the combination of these two methods on a stiffer Stefan problem.

- A Navier–Stokes solver embedding a source term in the mass conservation equation has been developed and coupled with a new formulation of the Level Set convection equation to account for a density change during phase change. This framework has been tested and validated on simple 1D and 2D benchmarks. The discretization of the interface has been shown to be a critical feature to control for a proper behavior of the method.

- Finally, these two frameworks have been merged to create a complete phase change solver. It has been tested on a compressible Stefan problem. The conclusion is that this solver is valid for stable configurations where no phase is overheated or undercooled.

- The model is based on several simplifications: the fluids are considered incompressible, only thermal energy variations are prevailing, the interface is in thermal equilibrium, and the viscous dissipation is negligible. This framework is then applicable only in those conditions. Thus, violent thermal shock waves are not modeled, which can be troublesome when dealing with boiling modeling. Furthermore, second order effects due to the compressibility of vapor are not taken into account, and the simulation can under-estimate hydrodynamical effects.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

- The following abbreviations are used in this manuscript:

| LS | Level Set |

| CSF | Continuous Surface Force |

| t | Time (s) |

| Velocity (m·s−1) | |

| P | Pressure (Pa) |

| T | Temperature (K) |

| Heat flux (W·m−2) | |

| Surface mass transfer rate vector (kg·s−1·m−2) | |

| s | Interface position (m) |

| R | Radius (m) |

| M | Mass (kg) |

| Local mass transfer rate (kg·s−1) | |

| Interface velocity (m·s−1) | |

| Infinitesimal surface (m2) | |

| Infinitesimal volume (m3) | |

| Density (kg·m−3) | |

| Dynamic viscosity (Pa·s) | |

| Specific heat capacity at constant pressure (J·K−1·kg−1) | |

| k | Thermal conductivity (W·m−1·K−1) |

| Saturation temperature of the fluid at atmospheric pressure (K) | |

| Specific enthalpy of vaporization at saturation temperature (J·kg−1) | |

| D | Thermal diffusivity (m2·s−1) |

| Surface tension coefficient (J·m−2) | |

| Gravity (m·s−2) | |

| Strain rate tensor (s−1) | |

| Stefan constant (⌀) | |

| L | Liquid |

| V | Vapor |

| Wall | |

| ∞ | Far from the interface |

| Normal vector of the liquid-vapor interface | |

| d | Distance function |

| Level Set function | |

| Heaviside function | |

| Dirac function | |

| Characteristic length of the smoothed interface | |

| Gradient operator | |

| Divergence operator | |

| Diffusivity of the extension solver |

References

- Nukiyama, S. The maximum and minimum values of the heat Q from metal to boilng water under atmospheir pressure. J. Jpn. Soc. Mech. Eng. 1934, 37, 367–374. [Google Scholar]

- Zuber, N. Hydrodynamic Aspects of Boiling Heat Transfer (Thesis); Technical Report; University of California: Los Angeles, CA, USA, 1959. [Google Scholar] [CrossRef]

- Berenson, P.J. Transition Boiling Heat Transfer from a Horizontal Surface; Technical Report 17; The National Science Foundation: Cambridge, MA, USA, 1960. [Google Scholar]

- Chen, J.C. Correlation for Boiling Heat Transfer to Saturated Fluids in Convective Flow. Industrial & Engineering Chemistry Process Design and Development 1966, 5, 322–329. [Google Scholar] [CrossRef]

- Judd, R.L.; Hwang, K.S. A Comprehensive Model for Nucleate Pool Boiling Heat Transfer Including Microlayer Evaporation. J. Heat Transfer 1976, 98, 623–629. [Google Scholar] [CrossRef]

- Cooper, M. Saturation Nucleate Pool Boiling—A Simple Correlation. In First U.K. National Conference on Heat Transfer; Elsevier: Amsterdam, The Netherlands, 1984; pp. 785–793. [Google Scholar] [CrossRef]

- Ramilison, J.M.; Lienhard, J.H. Transition Boiling Heat Transfer and the Film Transition Regime. J. Heat Transfer 1987, 109, 746–752. [Google Scholar] [CrossRef]

- Steiner, H.; Kobor, A.; Gebhard, L. A wall heat transfer model for subcooled boiling flow. Int. J. Heat Mass Transfer 2005, 48, 4161–4173. [Google Scholar] [CrossRef]

- Meduri, P.K.; Warrier, G.R.; Dhir, V.K. Wall heat flux partitioning during subcooled forced flow film boiling of water on a vertical surface. Int. J. Heat Mass Transfer 2009, 52, 3534–3546. [Google Scholar] [CrossRef]

- Brennen, C.E. Fundamentals of Multiphase Flow, reprint ed.; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Lee, W.H. A Pressure Iteration Scheme for Two-Phase Flow Modeling. In Computational Methods for Two-Phase Flow and Particle Transport; World Scientific: Singapore, 1980; pp. 61–82. [Google Scholar] [CrossRef]

- Rattner, A.S.; Garimella, S. Simple Mechanistically Consistent Formulation for Volume-of-Fluid Based Computations of Condensing Flows. J. Heat Transfer 2014, 136, 071501. [Google Scholar] [CrossRef]

- Giustini, G.; Issa, R.I. A method for simulating interfacial mass transfer on arbitrary meshes. Phys. Fluids 2021, 33, 087102. [Google Scholar] [CrossRef]

- Son, G.; Dhir, V.K. Numerical Simulation of Film Boiling Near Critical Pressures With a Level Set Method. J. Heat Transfer 1998, 120, 183–192. [Google Scholar] [CrossRef]

- Juric, D. Computations of Boiling Flows. Int. J. Multiph. Flow 1998, 24, 387–410. [Google Scholar] [CrossRef]

- Welch, S.W.; Wilson, J. A Volume of Fluid Based Method for Fluid Flows with Phase Change. J. Comput. Phys. 2000, 160, 662–682. [Google Scholar] [CrossRef]

- Kang, M.; Fedkiw, R.P.; Liu, X.D. A Boundary Condition Capturing Method for Multiphase Incompressible Flow. J. Sci. Comput. 2000, 15, 323–360. [Google Scholar] [CrossRef]

- Tanguy, S.; Ménard, T.; Berlemont, A. A Level Set Method for vaporizing two-phase flows. J. Comput. Phys. 2007, 221, 837–853. [Google Scholar] [CrossRef]

- Gibou, F.; Chen, L.; Nguyen, D.; Banerjee, S. A level set based sharp interface method for the multiphase incompressible Navier–Stokes equations with phase change. J. Comput. Phys. 2007, 222, 536–555. [Google Scholar] [CrossRef]

- Esmaeeli, A.; Tryggvason, G. Computations of film boiling. Part I: Numerical method. Int. J. Heat Mass Transf. 2004, 47, 5451–5461. [Google Scholar] [CrossRef]

- Sato, Y.; Ničeno, B. A sharp-interface phase change model for a mass-conservative interface tracking method. J. Comput. Phys. 2013, 249, 127–161. [Google Scholar] [CrossRef]

- Khalloufi, M.; Valette, R.; Hachem, E. Adaptive Eulerian framework for boiling and evaporation. J. Comput. Phys. 2020, 401, 109030. [Google Scholar] [CrossRef]

- Kumar Singh, N.; Premachandran, B. A coupled level set and volume of fluid method on unstructured grids for the direct numerical simulations of two-phase flows including phase change. Int. J. Heat Mass Transfer 2018, 122, 182–203. [Google Scholar] [CrossRef]

- Hachem, E.; Rivaux, B.; Kloczko, T.; Digonnet, H.; Coupez, T. Stabilized finite element method for incompressible flows with high Reynolds number. J. Comput. Phys. 2010, 229, 8643–8665. [Google Scholar] [CrossRef]

- Unverdi, S.O.; Tryggvason, G. A Front-Tracking Method for Viscous, Incompressible, Multi-fluid Flows. J. Comput. Phys. 1992, 100, 25–37. [Google Scholar] [CrossRef]

- Sussman, M.; Smereka, P.; Osher, S. A Level Set Approach for Computing Solutions to Incompressible Two-Phase Flows. J. Comput. Phys. 1994, 114, 146–159. [Google Scholar] [CrossRef]

- Osher, S.; Fedkiw, R. Level Set Methods and Dynamic Implicit Surfaces; Applied Mathematical Sciences; Springer: Berlin/Heidelberg, Germany, 2004; Volume 153. [Google Scholar]

- Feng, Q.; Johannsen, K. Experimental results of maximum transition boiling temperature during upflow in a circular tube at medium pressure. Exp. Therm. Fluid Sci. 1991, 4, 90–102. [Google Scholar] [CrossRef]

- Ebrahim, S.A.; Chang, S.; Cheung, F.B.; Bajorek, S.M. Parametric investigation of film boiling heat transfer on the quenching of vertical rods in water pool. Appl. Therm. Eng. 2018, 140, 139–146. [Google Scholar] [CrossRef]

- Liscic, B.; Tensi, H.M.; Luty, W. Theory and Technology of Quenching; Springer: Berlin/Heidelberg, Germany, 1992. [Google Scholar]

- Kim, J.; Benton, J.F.; Wisniewski, D. Pool boiling heat transfer on small heaters: Effect of gravity and subcooling. Int. J. Heat Mass Transfer 2002, 45, 3919–3932. [Google Scholar] [CrossRef]

- Ikkene, R.; Koudil, Z.; Mouzali, M. Pouvoir de refroidissement des solutions de trempe à base de polymères hydrosolubles. Comptes Rendus Chim. 2008, 11, 297–306. [Google Scholar] [CrossRef]

- Kopun, R.; Škerget, L.; Hriberšek, M.; Zhang, D.; Stauder, B.; Greif, D. Numerical simulation of immersion quenching process for cast aluminium part at different pool temperatures. Appl. Therm. Eng. 2014, 65, 74–84. [Google Scholar] [CrossRef]

- Hachem, E.; Feghali, S.; Codina, R.; Coupez, T. Immersed stress method for fluid–structure interaction using anisotropic mesh adaptation: A monolithic approach to fluid–structure interaction. Int. J. Numer. Meth. Engng 2013, 94, 805–825. [Google Scholar] [CrossRef]

- Aslam, T.D. A partial differential equation approach to multidimensional extrapolation. J. Comput. Phys. 2004, 193, 349–355. [Google Scholar] [CrossRef]

- Patankar, S.V. Numerical Heat Transfer and Fluid Flow; Series in Computational Methods in Mechanics and Thermal Sciences; Hemisphere Publ. Co.: New York, NY, USA, 1980. [Google Scholar]

- Hachem, E. Stabilized Finite Element Method for Heat Transfer and Turbulent Flows Inside Industrial Furnaces. Ph.D. Thesis, Ecole Nationale Supérieure des Mines de Paris, Paris, France, 2009. [Google Scholar]

- Hachem, E.; Kloczko, T.; Digonnet, H.; Coupez, T. Stabilized finite element solution to handle complex heat and fluid flows in industrial furnaces using the immersed volume method. Int. J. Numer. Meth. Fluids 2012, 68, 99–121. [Google Scholar] [CrossRef]

- Santiago, R.D.; Hernández, E.M.; Otero, J.A. Constant mass model for the liquid–solid phase transition on a one-dimensional Stefan problem: Transient and steady state regimes. Int. J. Therm. Sci. 2017, 118, 40–52. [Google Scholar] [CrossRef]

- Chaurasiya, V.; Singh, J. An analytical study of coupled convective heat and mass transfer with volumetric heating describing sublimation of a porous body under most sensitive temperature inputs: Application of freeze-drying. Int. J. Heat Mass Transf. 2023, 214, 124294. [Google Scholar] [CrossRef]

- Chaurasiya, V.; Singh, J. Numerical investigation of a non-linear moving boundary problem describing solidification of a phase change material with temperature dependent thermal conductivity and convection. J. Therm. Stress. 2023, 46, 799–822. [Google Scholar] [CrossRef]

- Chaurasiya, V.; Jain, A.; Singh, J. Numerical Study of a Non-Linear Porous Sublimation Problem With Temperature-Dependent Thermal Conductivity and Concentration-Dependent Mass Diffusivity. ASME J. Heat Mass Transf. 2023, 145, 072701. [Google Scholar] [CrossRef]

- Chaurasiya, V.; Upadhyay, S.; Rai, K.; Singh, J. A temperature-dependent numerical study of a moving boundary problem with variable thermal conductivity and convection. Waves Random Complex Media 2023, 1–25. [Google Scholar] [CrossRef]

- Kim, D.G.; Jeon, C.H.; Park, I.S. Comparison of numerical phase-change models through Stefan vaporizing problem. Int. Commun. Heat Mass 2017, 87, 228–236. [Google Scholar] [CrossRef]

- Denis, R. Modélisation et Simulation de l’effet Leidenfrost dans les Micro-Gouttes. Ph.D. Thesis, Université de Grenoble, Grenoble, France, 2014. [Google Scholar]

- Ramezanzadeh, H.; Ramiar, A.; Yousefifard, M. Numerical investigation into coolant liquid velocity effect on forced convection quenching process. Appl. Therm. Eng. 2017, 122, 253–267. [Google Scholar] [CrossRef]

- Khalloufi, M.; Mesri, Y.; Valette, R.; Massoni, E.; Hachem, E. High fidelity anisotropic adaptive variational multiscale method for multiphase flows with surface tension. Comput. Methods Appl. Mech. Eng. 2016, 307, 44–67. [Google Scholar] [CrossRef]

- Shakoor, M.; Scholtes, B.; Bouchard, P.O.; Bernacki, M. An efficient and parallel level set reinitialization method—Application to micromechanics and microstructural evolutions. Appl. Math. Model. 2014, 39, 7291–7302. [Google Scholar] [CrossRef]

- Denner, F.; van Wachem, B.G. Numerical time-step restrictions as a result of capillary waves. J. Comput. Phys. 2015, 285, 24–40. [Google Scholar] [CrossRef]

| Density | Volume Heat Capacity | Thermal Conductivity k | Latent Heat | |

|---|---|---|---|---|

| kg m−3 | J m−3 K−1 | W m−1 K−1 | J kg−1 | |

| Vapor | 5.97 × 10−1 | 1.12 × 103 | 2.48 × 10−2 | 2.26 × 106 |

| Liquid | 4.40 × 106 | 6.79 × 10−1 |

| Density | Viscosity | Surface Tension | |

|---|---|---|---|

| (kg m−3) | (Pa s) | (J m−2) | |

| Vapor | 5 × 10−1/5/5 × 101/5 × 102 | 1.2 × 10−5 | 6 × 10−2 |

| Liquid | 103 | 2.8 × 10−4 |

| Density | Viscosity | Surface Tension | |

|---|---|---|---|

| (kg m−3) | (Pa s) | (J m−2) | |

| Vapor | 1 | 1.78 × 10−5 | 7 × 10−2 |

| Liquid | 103 | 10−3 |

| Density | Specific Heat Capacity | Thermal Conductivity k | Viscosity | Latent Heat | |

|---|---|---|---|---|---|

| (kg m−3) | (J kg−1 K−1) | (W m−1 K−1) | (Pa s) | (J kg−1) | |

| Vapor | 5.97 × 10−1 | 2.030 × 103 | 2.48 × 10−2 | 1.20 × 10−5 | 2.26 × 106 |

| Liquid | 9.584 × 102 | 4.216 × 103 | 6.76 × 10−1 | 2.8 × 10−4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brissot, C.; Cailly-Brandstäter, L.; Hachem, E.; Valette, R. A Vaporization Model for Continuous Surface Force Approaches and Subcooled Configurations. Fluids 2023, 8, 233. https://doi.org/10.3390/fluids8080233

Brissot C, Cailly-Brandstäter L, Hachem E, Valette R. A Vaporization Model for Continuous Surface Force Approaches and Subcooled Configurations. Fluids. 2023; 8(8):233. https://doi.org/10.3390/fluids8080233

Chicago/Turabian StyleBrissot, Charles, Léa Cailly-Brandstäter, Elie Hachem, and Rudy Valette. 2023. "A Vaporization Model for Continuous Surface Force Approaches and Subcooled Configurations" Fluids 8, no. 8: 233. https://doi.org/10.3390/fluids8080233

APA StyleBrissot, C., Cailly-Brandstäter, L., Hachem, E., & Valette, R. (2023). A Vaporization Model for Continuous Surface Force Approaches and Subcooled Configurations. Fluids, 8(8), 233. https://doi.org/10.3390/fluids8080233