Influence of the Nozzle-to-Surface Distance on Spray Cooling Efficiency

Abstract

:1. Introduction

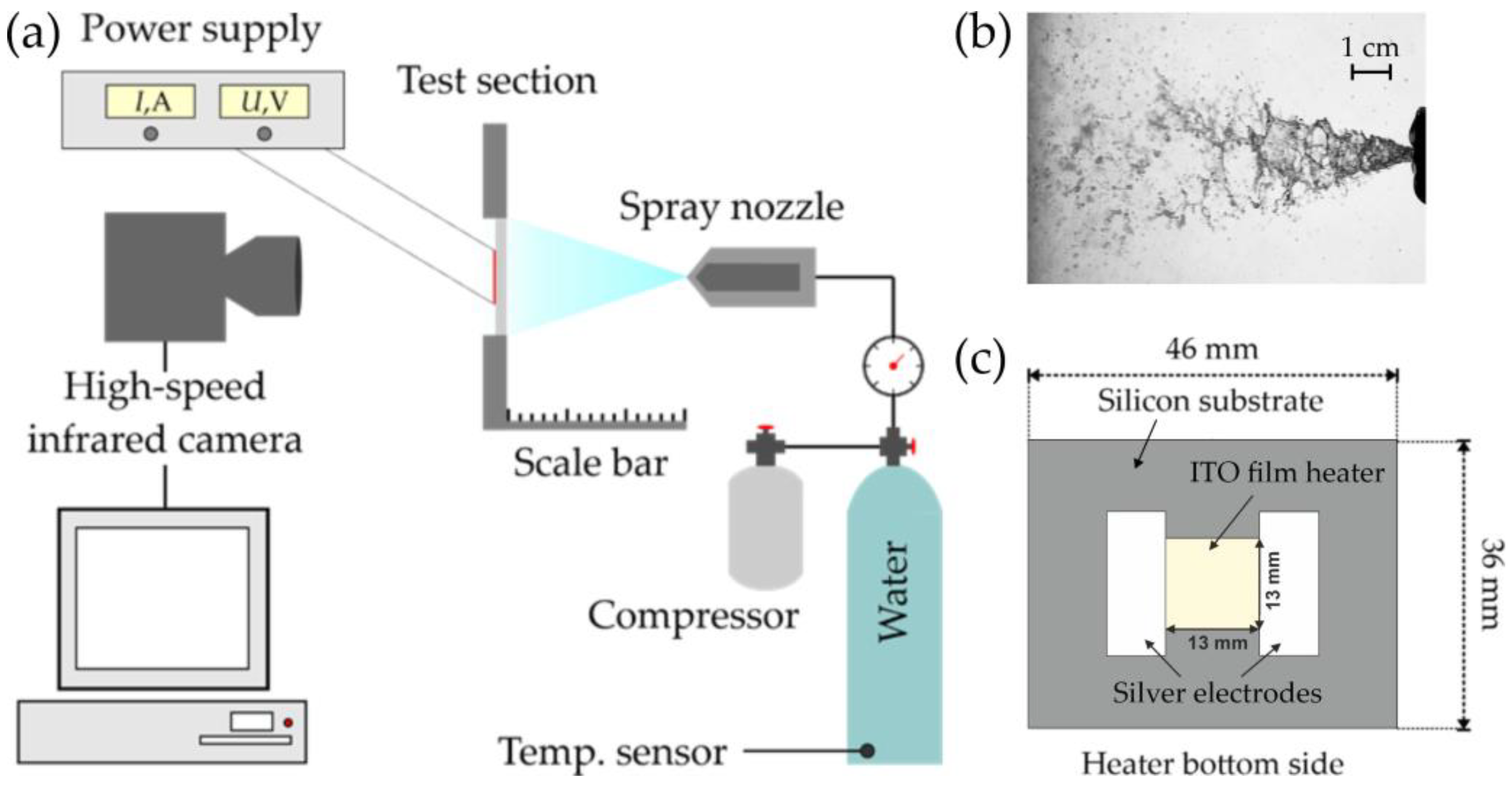

2. Materials and Methods

2.1. Experimental Setup and Heater Design

2.2. IR thermography

2.3. Experimental Procedure

2.4. Uncertainty Analysis

3. Results

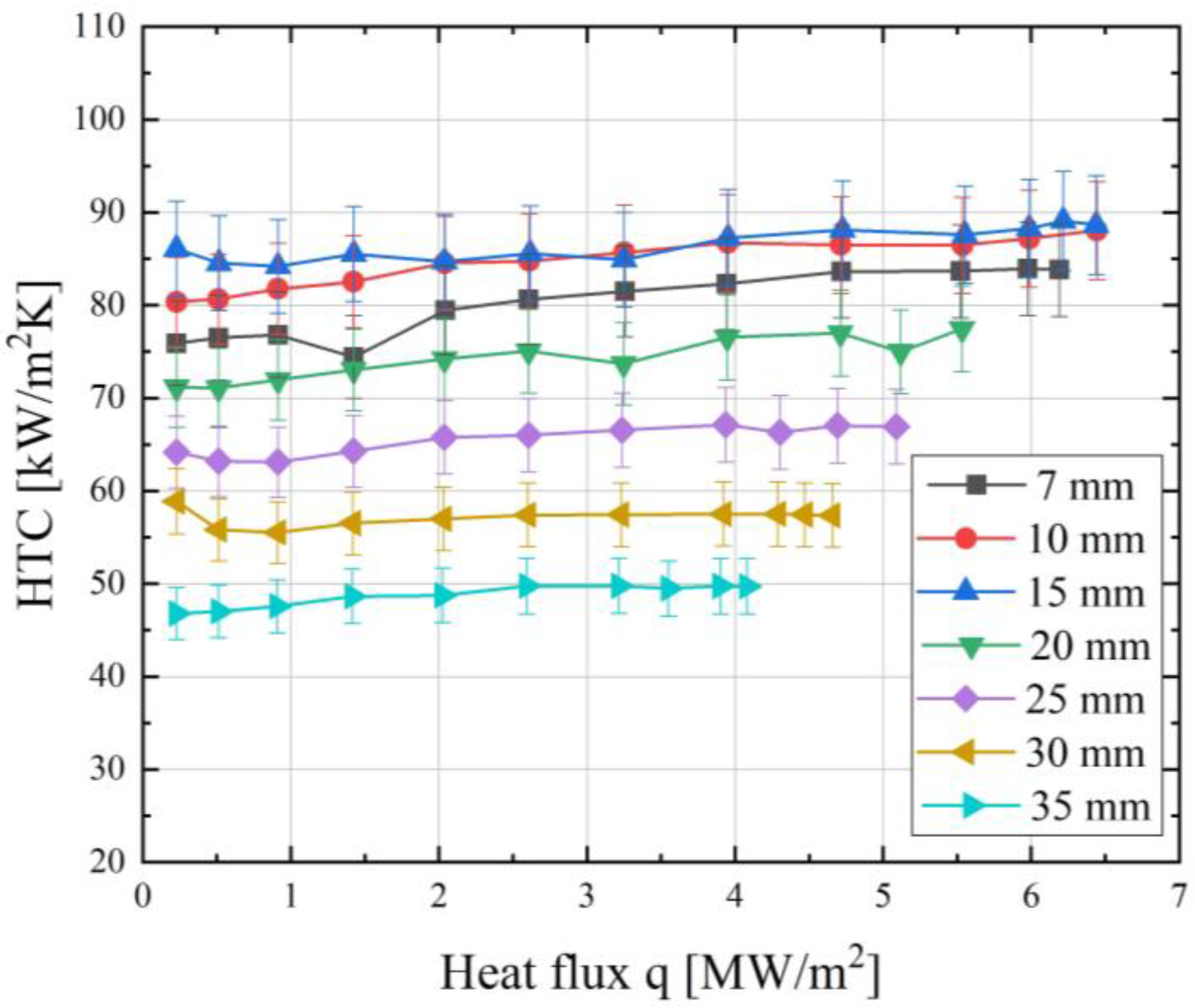

3.1. Effect of Liquid Flow Rate

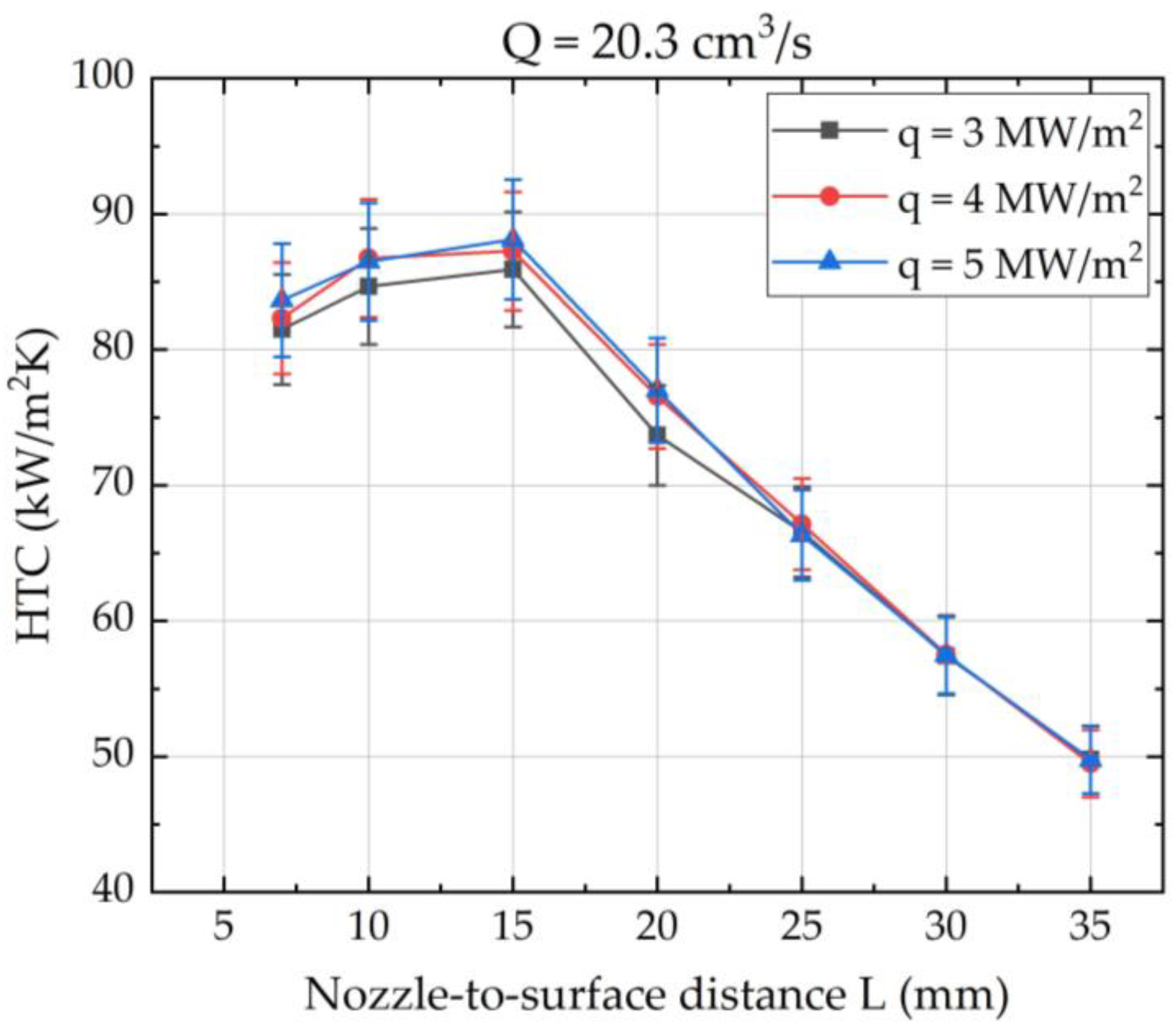

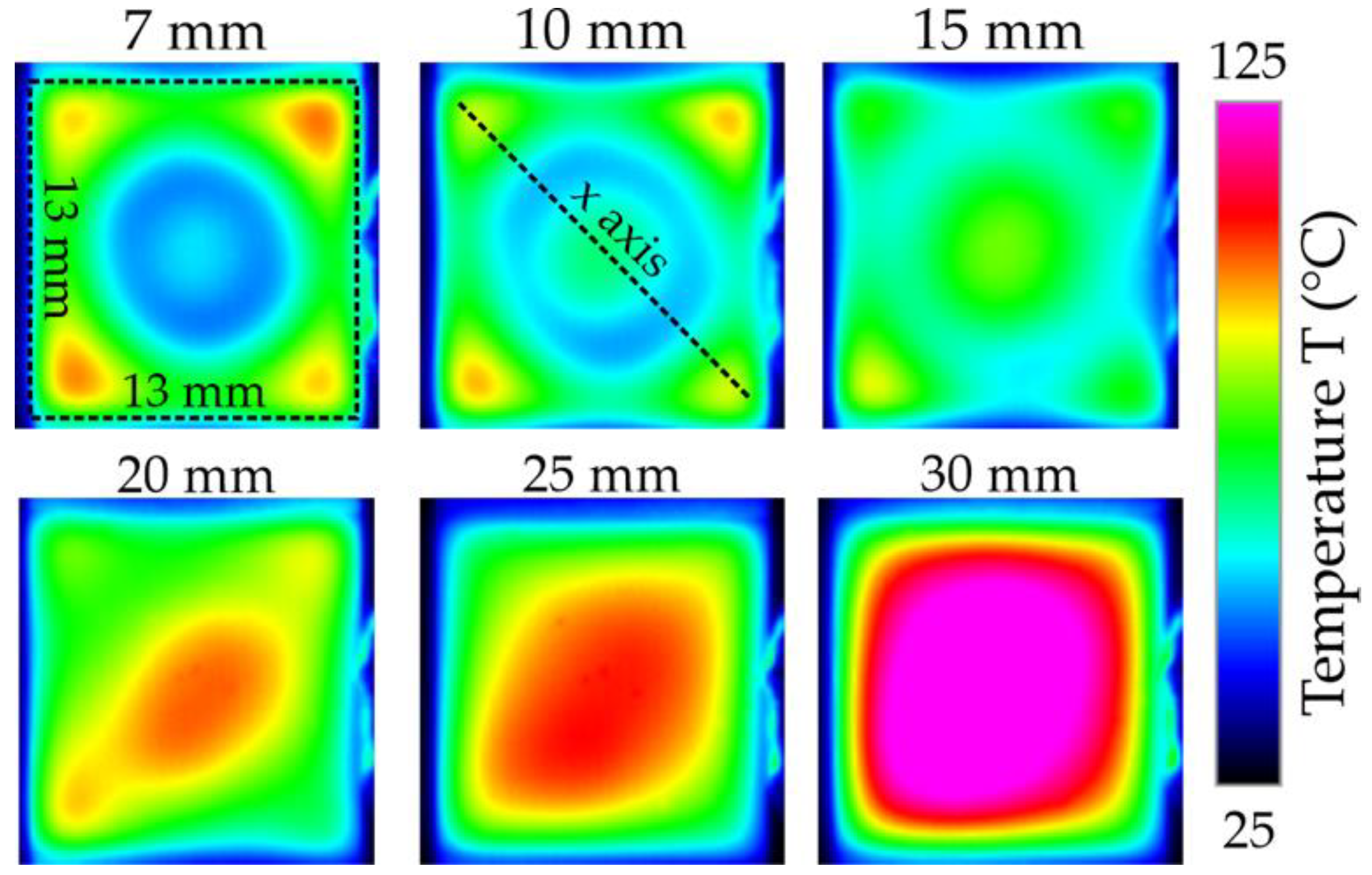

3.2. Effect of Nozzle-to-Surface Distance

4. Conclusions

- The increase in the liquid flow rate in the studied range led to a slight increase in cooling performance in the non-boiling mode. Thus, increasing the flow rate by 60% only increased the heat transfer coefficient by 14%.

- The experimental results demonstrate that the heat transfer coefficient exhibited a weak dependence on the heat flux in non-boiling mode but tended to increase as the heat flux increased within the measurement error.

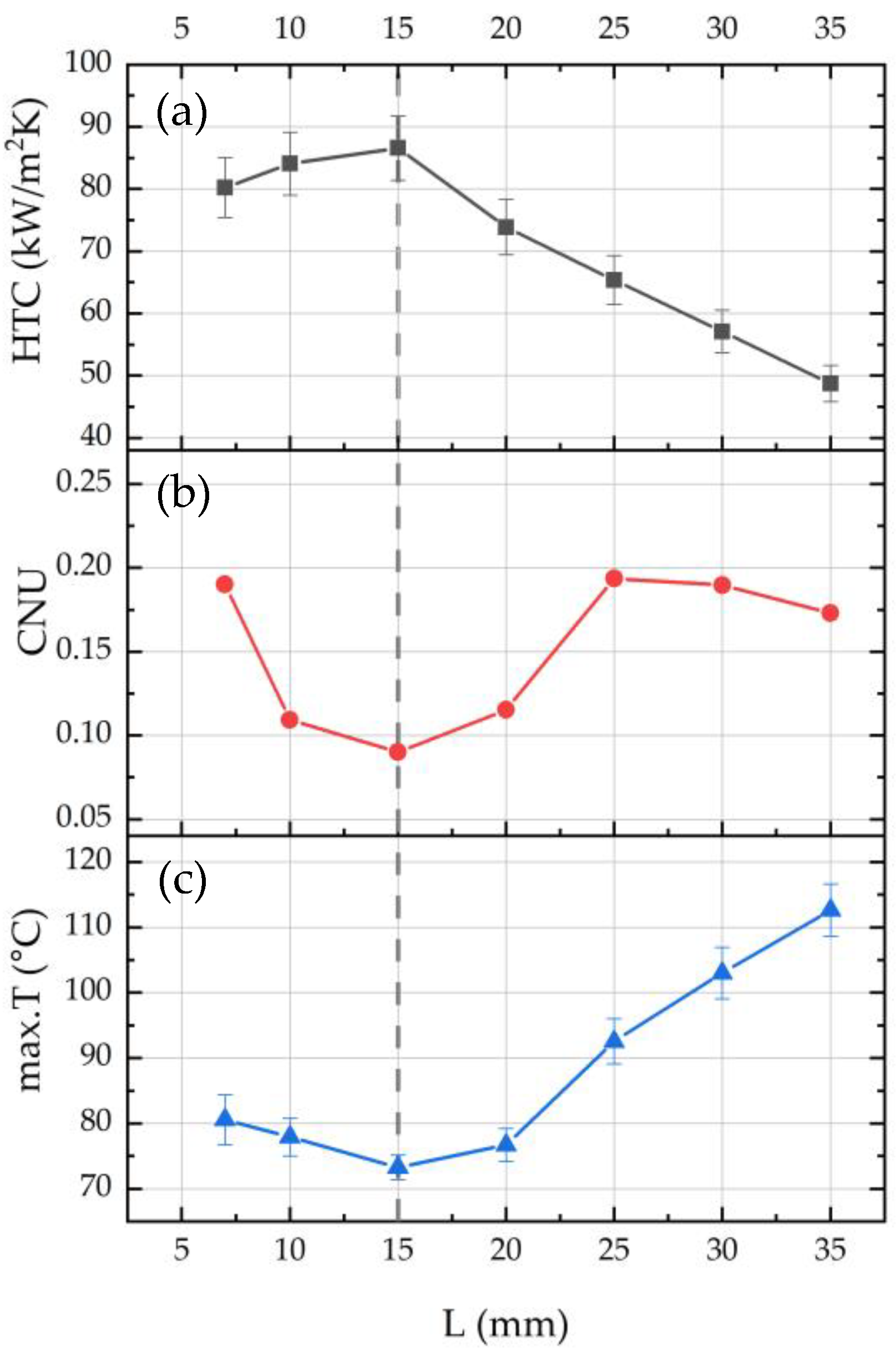

- Spray cooling performance strongly depends on the distance from the nozzle to the surface in non-boiling mode. It was shown that there was an optimal distance at which the maximum heat transfer rate is achieved during spray cooling. Moreover, the heat transfer rate could change by more than 44% for the investigated nozzle when changing from 0.3 to 1.5, where is the spray cone base diameter, and is the side length of the heater.

- For the studied parameters, including the heater size, the optimal distance providing the best heat transfer performance was determined and equalled 15 mm for the investigated nozzle, which is less than the distance at which the spray cone completely covers the heater. It is suggested to use Equation (5) with the correction factor K = 0.6 for determining the optimal nozzle-to-surface distance for a heat exchange surface of similar sizes.

- The nozzle-to-surface distance significantly affects the local temperature distribution. The degree of temperature non-uniformity was evaluated using the cooling non-uniformity (CNU) parameter, which reached its minimum value at 15 mm. As an alternative method for determining the optimal position, it is proposed to analyse the measurements of the maximum temperature of the surface. The distance at which the minimum value of the maximum local temperature is observed is optimal for achieving maximum heat transfer.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liang, G.; Mudawar, I. Review of Spray Cooling—Part 1: Single-Phase and Nucleate Boiling Regimes, and Critical Heat Flux. Int. J. Heat Mass Transf. 2017, 115, 1174–1205. [Google Scholar] [CrossRef]

- Gao, X.; Li, R. Spray Impingement Cooling: The State of the Art. In Advanced Cooling Technologies and Applications; Murshed, S.M.S., Ed.; IntechOpen: Rijeka, Croatia, 2019. [Google Scholar]

- Khandekar, S.; Sahu, G.; Muralidhar, K.; Gatapova, E.Y.; Kabov, O.A.; Hu, R.; Luo, X.; Zhao, L. Cooling of High-Power LEDs by Liquid Sprays: Challenges and Prospects. Appl. Therm. Eng. 2021, 184, 115640. [Google Scholar] [CrossRef]

- Yoshida, K.; Abe, Y.; Oka, T.; Mori, Y.H.; Nagashima, A. Spray Cooling under Reduced Gravity Condition. J. Heat Transfer. 2001, 123, 309–318. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, H.; Zhang, B.; Yang, Z.; Ma, X. Experimental Investigation of the Mechanism of Isolated Liquid Film Flow in Spray Cooling. Int. J. Heat Mass Transf. 2022, 192, 122904. [Google Scholar] [CrossRef]

- Rini, D.P.; Chen, R.H.; Chow, L.C. Bubble Behavior and Nucleate Boiling Heat Transfer in Saturated FC-72 Spray Cooling. J. Heat Transfer. 2002, 124, 63–72. [Google Scholar] [CrossRef]

- Griffin, A.R.; Vijayakumar, A.; Chen, R.-H.; Sundaram, K.B.; Chow, L.C. Development of a Transparent Heater to Measure Surface Temperature Fluctuations under Spray Cooling Conditions. J. Heat Transfer. 2008, 130, 114501. [Google Scholar] [CrossRef]

- Serdyukov, V.; Miskiv, N.; Surtaev, A. The Simultaneous Analysis of Droplets’ Impacts and Heat Transfer during Water Spray Cooling Using a Transparent Heater. Water 2021, 13, 2730. [Google Scholar] [CrossRef]

- Mudawar, I.; Valentine, W.S. Determination of the Local Quench Curve for Spray-Cooled Metallic Surfaces. J. Heat Treat. 1989, 7, 107–121. [Google Scholar] [CrossRef]

- Rybicki, J.R.; Mudawar, I. Single-Phase and Two-Phase Cooling Characteristics of Upward-Facing and Downward-Facing Sprays. Int. J. Heat Mass Transf. 2006, 49, 5–16. [Google Scholar] [CrossRef]

- Gao, X.; Kong, L.; Li, R.; Han, J. Heat Transfer of Single Drop Impact on a Film Flow Cooling a Hot Surface. Int. J. Heat Mass Transf. 2017, 108, 1068–1077. [Google Scholar] [CrossRef]

- Hou, Y.; Jie, P.; Wang, H. Heat Transfer Mechanisms of Single Droplet Impacting onto Flowing Film. Int. J. Heat Mass Transf. 2019, 132, 952–960. [Google Scholar] [CrossRef]

- Park, C.; Seol, J.; Aldalbahi, A.; Rahaman, M.; Yarin, A.L.; Yoon, S.S. Drop Impact Phenomena and Spray Cooling on Hot Nanotextured Surfaces of Various Architectures and Dynamic Wettability. Phys. Fluids 2023, 35, 027126. [Google Scholar] [CrossRef]

- Soriano, G.E.; Zhang, T.; Alvarado, J.L. Study of the Effects of Single and Multiple Periodic Droplet Impingements on Liquid Film Heat Transfer. Int. J. Heat Mass Transf. 2014, 77, 449–463. [Google Scholar] [CrossRef]

- Qiu, L.; Dubey, S.; Choo, F.H.; Duan, F. Splashing of High Speed Droplet Train Impinging on a Hot Surface. Appl. Phys. Lett. 2015, 107, 164102. [Google Scholar] [CrossRef]

- Qiu, L.; Dubey, S.; Hoong Choo, F.; Duan, F. The Statistical Analysis of Droplet Train Splashing after Impinging on a Superheated Surface. J. Heat Transfer. 2017, 139, 052201. [Google Scholar] [CrossRef]

- Zhang, T.; Alvarado, J.L.; Muthusamy, J.P.; Kanjirakat, A.; Sadr, R. Heat Transfer Characteristics of Double, Triple and Hexagonally-Arranged Droplet Train Impingement Arrays. Int. J. Heat Mass Transf. 2017, 110, 562–575. [Google Scholar] [CrossRef]

- Liang, G.; Mudawar, I. Review of Mass and Momentum Interactions during Drop Impact on a Liquid Film. Int. J. Heat Mass Transf. 2016, 101, 577–599. [Google Scholar] [CrossRef]

- Gao, X.; Li, R. Local Heat Transfer of Spray Cooling on a Thin Film Heater. In Proceedings of the 8th International Symposium on Multiphase Flow, Heat & Mass Transfer and Energy Conversion, Chengdu, China, 17–19 December 2016. [Google Scholar]

- Xiang, L.; Yu, X.; Hong, T.; Yang, X.; Xie, B.; Hu, R.; Luo, X. Performance of Spray Cooling with Vertical Surface Orientation: An Experimental Investigation. Appl. Therm. Eng. 2023, 219, 119434. [Google Scholar] [CrossRef]

- Mudawar, I.; Estes, K.A. Optimizing and Predicting CHF in Spray Cooling of a Square Surface. J. Heat Transfer. 1996, 118, 672–679. [Google Scholar] [CrossRef]

- Gao, X.; Li, R. Effects of Nozzle Positioning on Single-Phase Spray Cooling. Int. J. Heat Mass Transf. 2017, 115, 1247–1257. [Google Scholar] [CrossRef]

- Wang, J.-X.; Li, Y.-Z.; Zhang, H.-S.; Wang, S.-N.; Mao, Y.-F.; Zhang, Y.-N.; Liang, Y.-H. Investigation of a Spray Cooling System with Two Nozzles for Space Application. Appl. Therm. Eng. 2015, 89, 115–124. [Google Scholar] [CrossRef]

- Xia, Y.; Gao, X.; Li, R. Management of Surface Cooling Non-Uniformity in Spray Cooling. Appl. Therm. Eng. 2020, 180, 115819. [Google Scholar] [CrossRef]

- Schäfer, W.; Tropea, C. Time-Shift Technique for Simultaneous Measurement of Size, Velocity, and Relative Refractive Index of Transparent Droplets or Particles in a Flow. Appl. Opt. 2014, 53, 588. [Google Scholar] [CrossRef] [PubMed]

- Serdyukov, V.; Starinskiy, S.; Malakhov, I.; Safonov, A.; Surtaev, A. Laser Texturing of Silicon Surface to Enhance Nucleate Pool Boiling Heat Transfer. Appl. Therm. Eng. 2021, 194, 117102. [Google Scholar] [CrossRef]

- Serdyukov, V.; Vladyko, I.; Starinskiy, S.; Rodionov, A.; Shukhov, Y.; Malakhov, I.; Safonov, A.; Surtaev, A. Pool Boiling Performance on the Textured Hemi-Wicking Surfaces Fabricated by Nanosecond Laser Ablation. Appl. Therm. Eng. 2023, 228, 120472. [Google Scholar] [CrossRef]

- Zhifu, Z.; Weitao, W.; Bin, C.; Guoxiang, W.; Liejin, G. An Experimental Study on the Spray and Thermal Characteristics of R134a Two-Phase Flashing Spray. Int. J. Heat Mass Transf. 2012, 55, 4460–4468. [Google Scholar] [CrossRef]

| Overpressure P (Bar) | Liquid Flow Rate Q (cm3/s) | Sauter Mean Diameter d32 (µm) | Mean Velocity vm (m/s) | Spray Angle α (°) |

|---|---|---|---|---|

| 1.5 | 15.1 | 201 | 6.4 | 27.7 |

| 2.5 | 20.3 | 153 | 8.7 | 28.4 |

| 3.5 | 24.2 | 146 | 10.6 | 30.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vladyko, I.; Miskiv, N.; Serdyukov, V.; Nazarov, A.; Surtaev, A. Influence of the Nozzle-to-Surface Distance on Spray Cooling Efficiency. Fluids 2023, 8, 191. https://doi.org/10.3390/fluids8070191

Vladyko I, Miskiv N, Serdyukov V, Nazarov A, Surtaev A. Influence of the Nozzle-to-Surface Distance on Spray Cooling Efficiency. Fluids. 2023; 8(7):191. https://doi.org/10.3390/fluids8070191

Chicago/Turabian StyleVladyko, Ilya, Nikolay Miskiv, Vladimir Serdyukov, Aleksandr Nazarov, and Anton Surtaev. 2023. "Influence of the Nozzle-to-Surface Distance on Spray Cooling Efficiency" Fluids 8, no. 7: 191. https://doi.org/10.3390/fluids8070191

APA StyleVladyko, I., Miskiv, N., Serdyukov, V., Nazarov, A., & Surtaev, A. (2023). Influence of the Nozzle-to-Surface Distance on Spray Cooling Efficiency. Fluids, 8(7), 191. https://doi.org/10.3390/fluids8070191