Dynamic Sweep Experiments on a Heterogeneous Phase Composite System Based on Branched-Preformed Particle Gel in High Water-Cut Reservoirs after Polymer Flooding

Abstract

1. Introduction

2. Results and Discussion

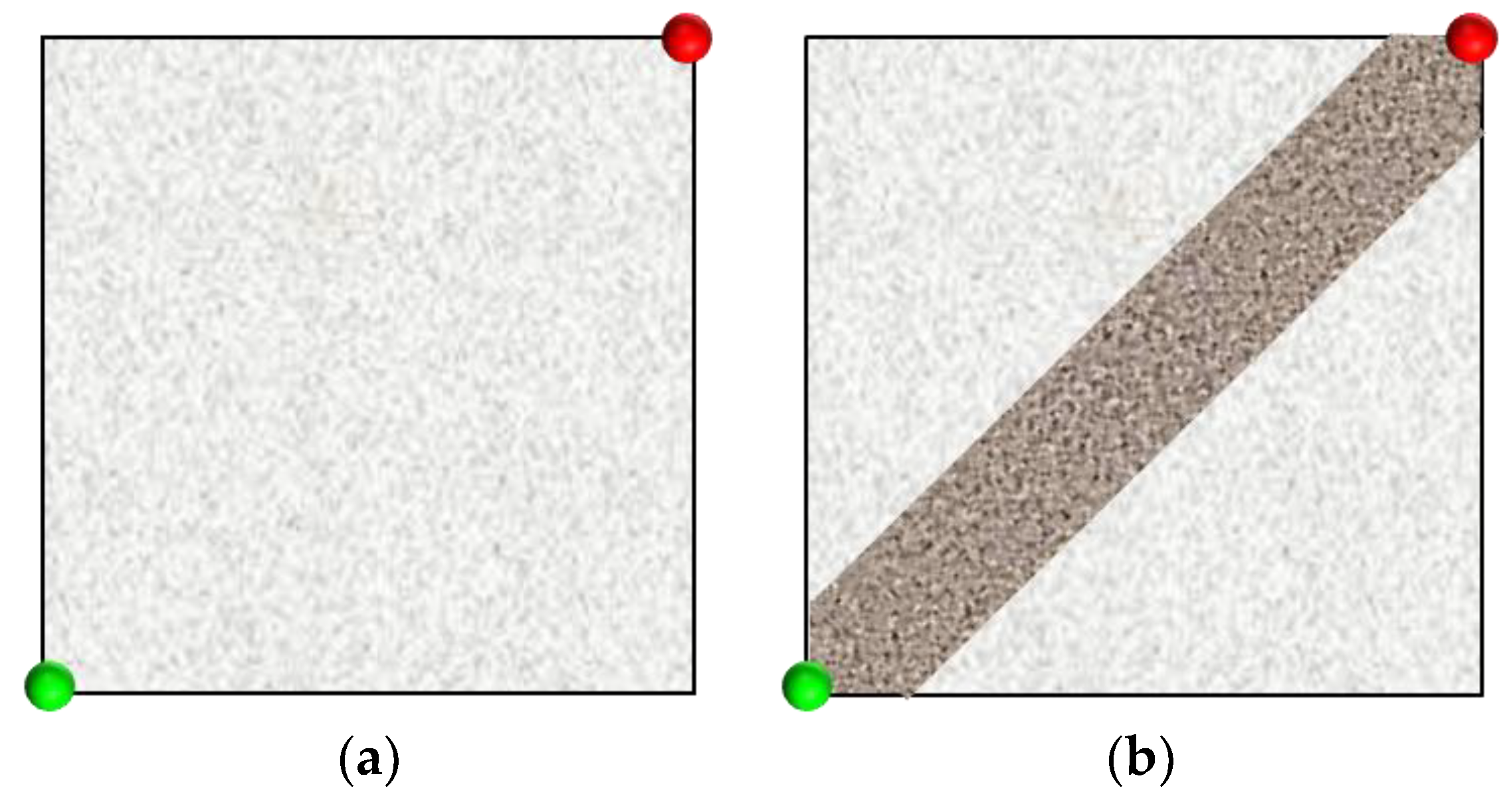

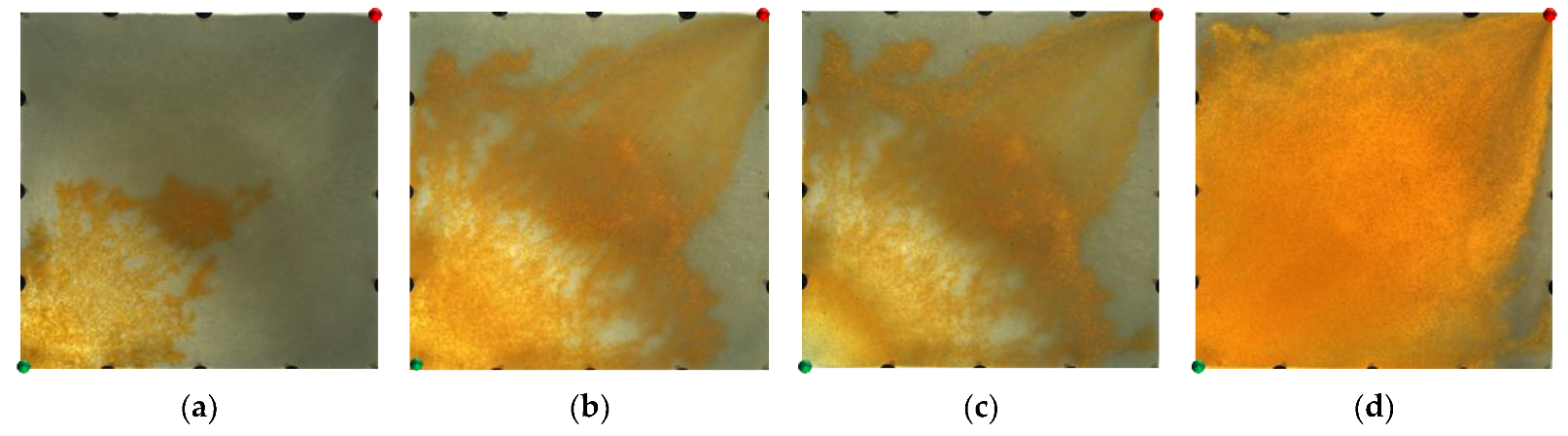

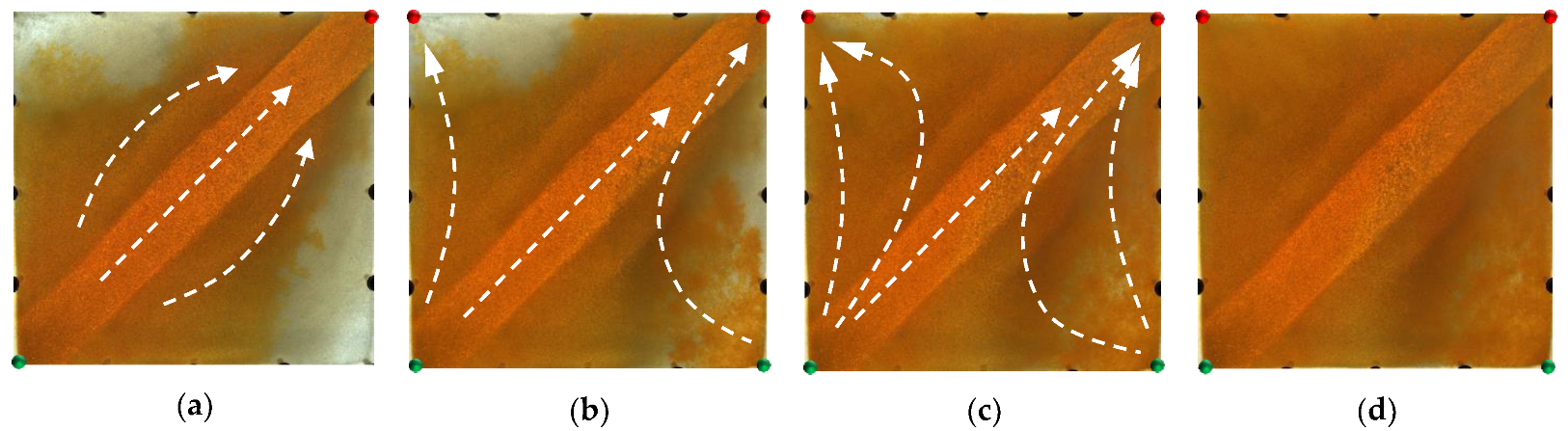

2.1. Dynamic Sweep Evaluation in HPCF Experiments

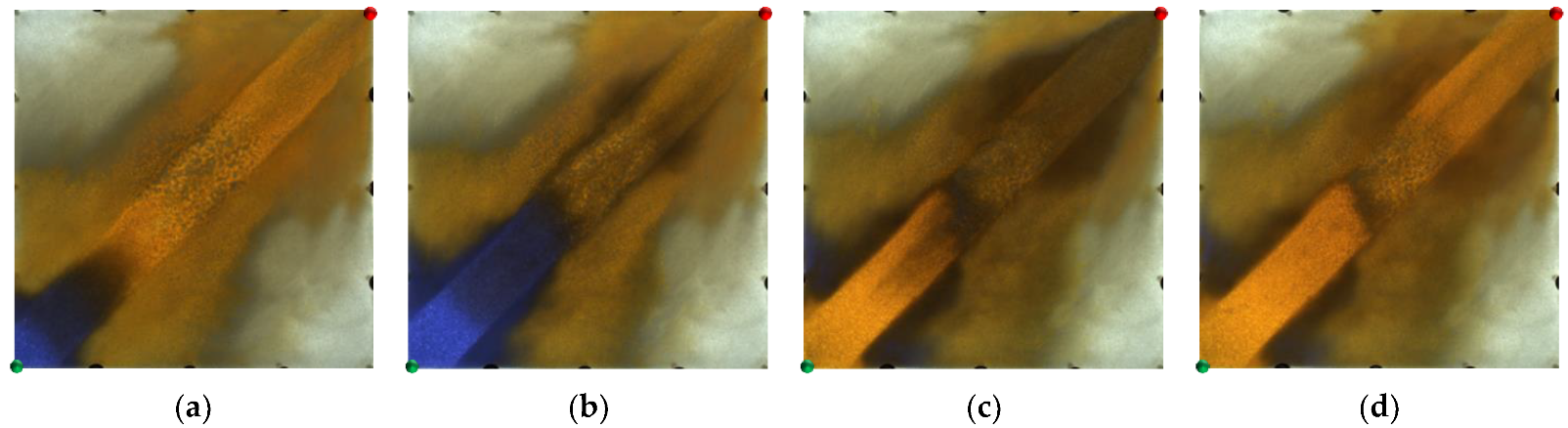

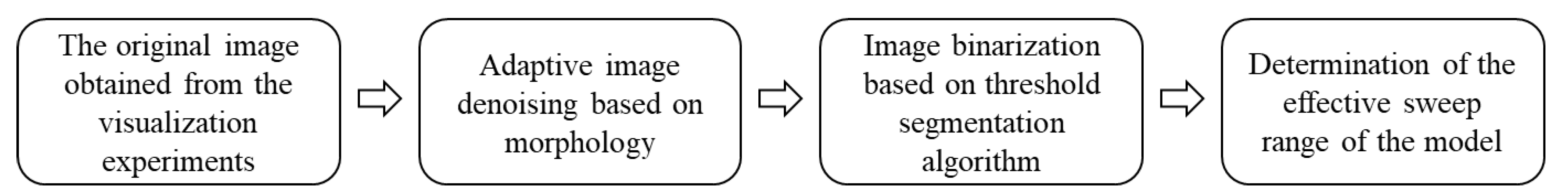

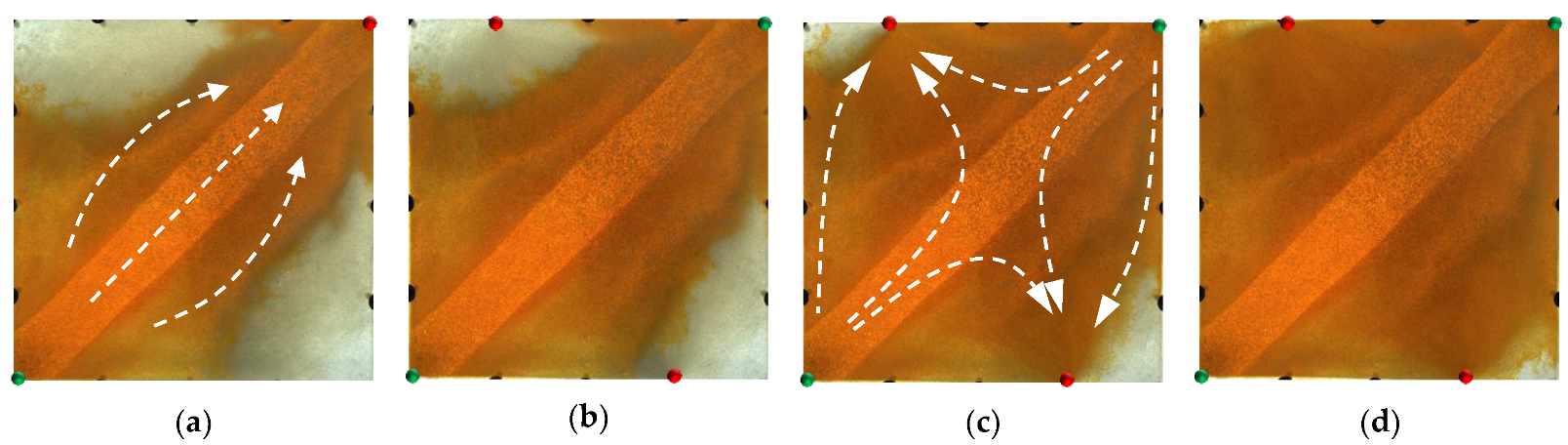

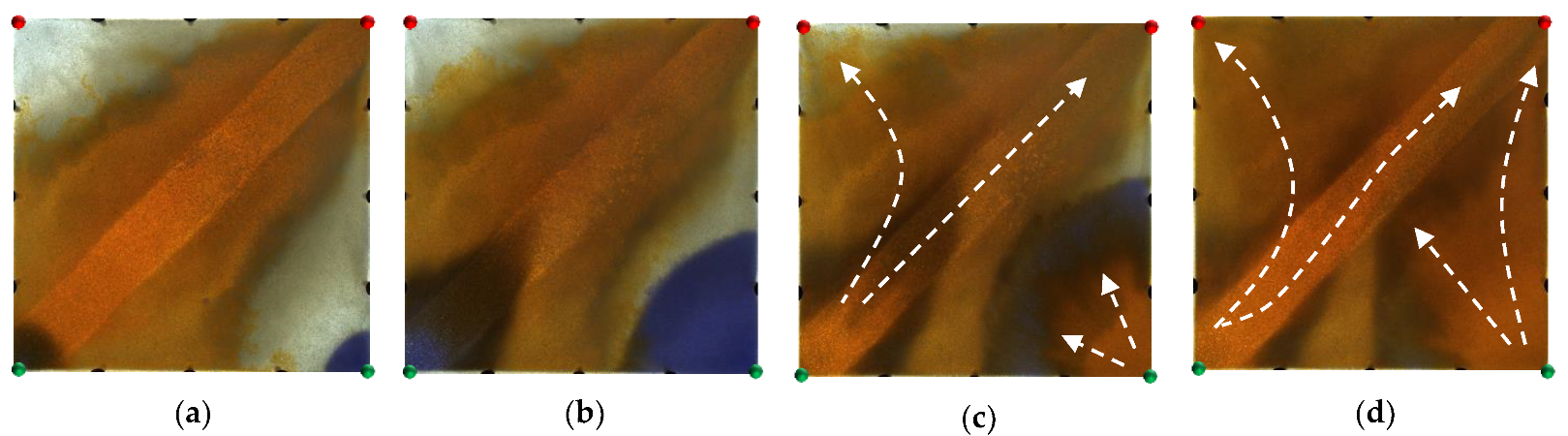

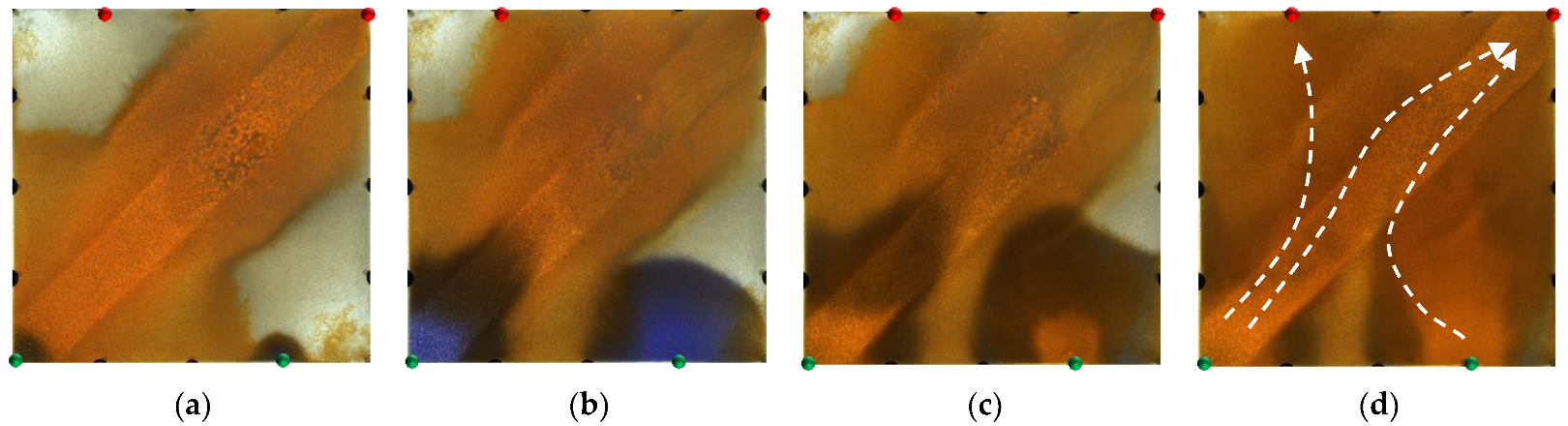

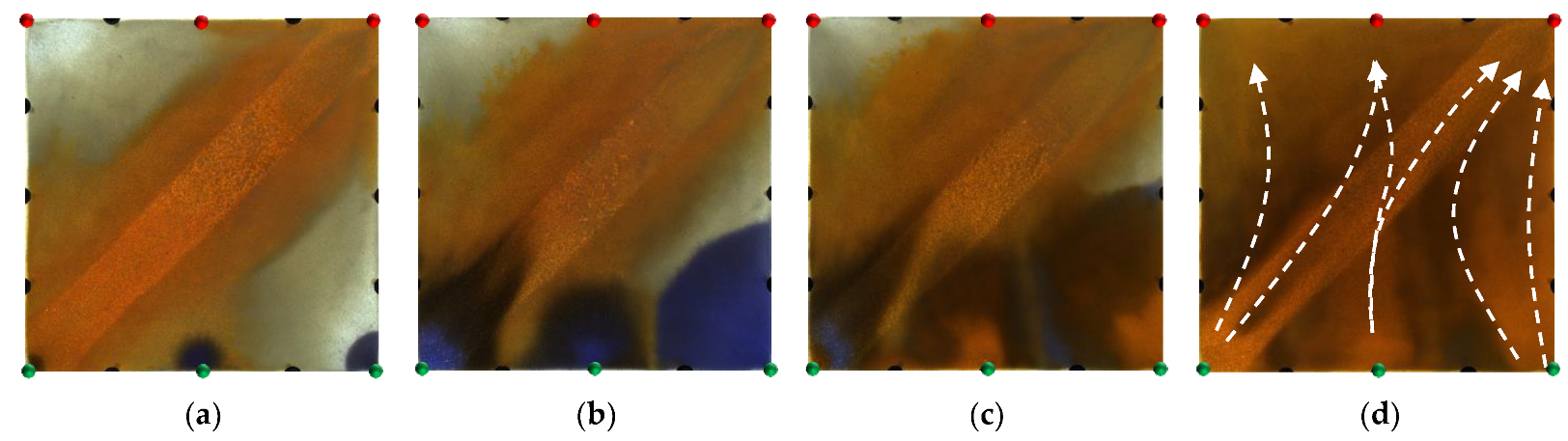

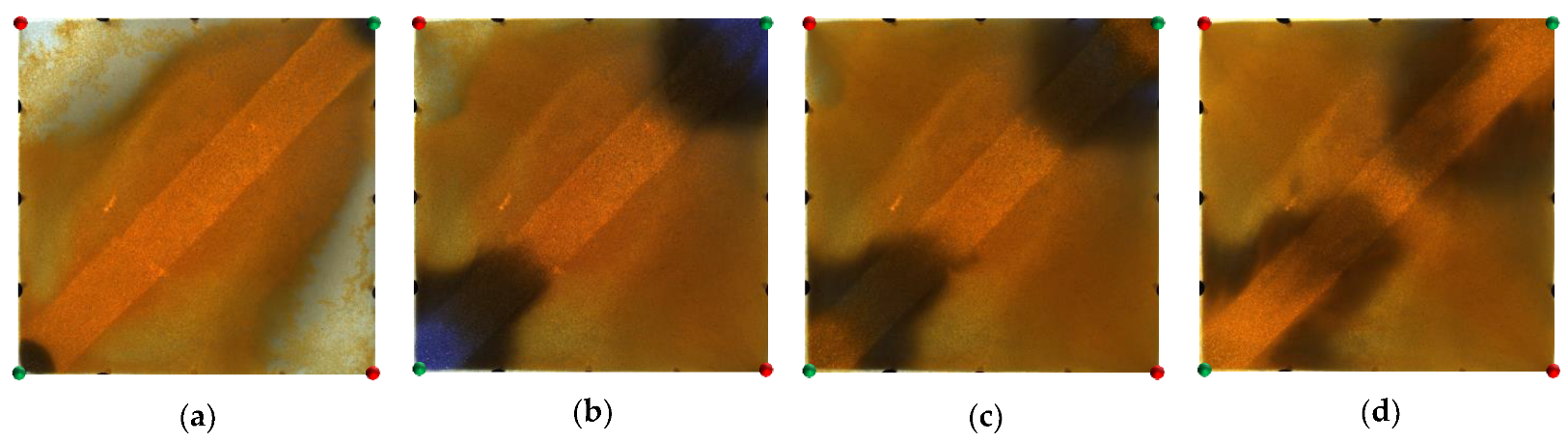

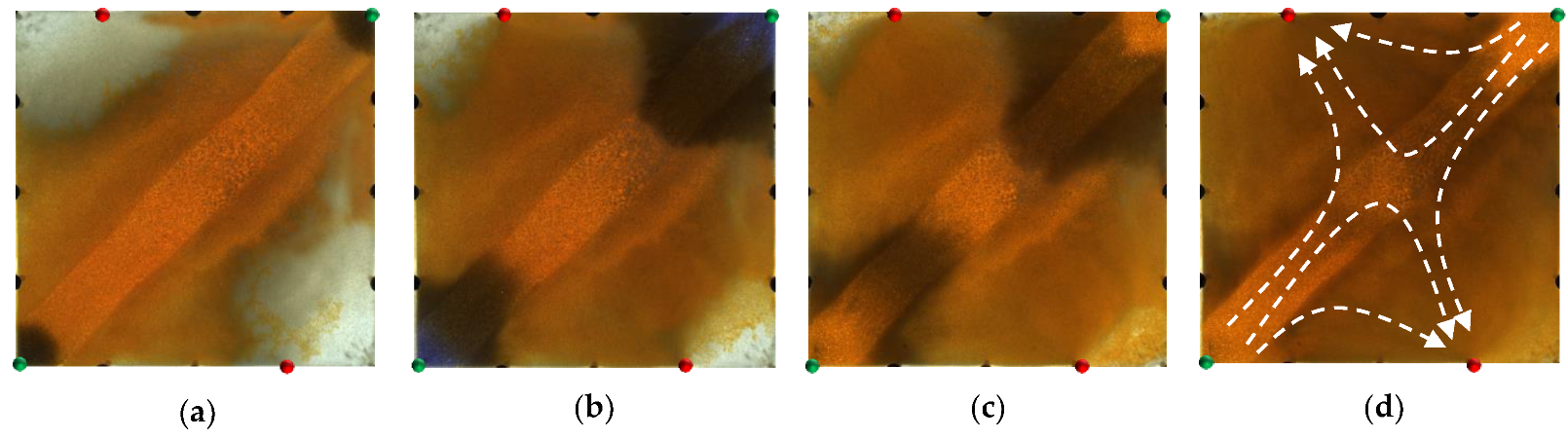

2.1.1. Visual Experimental Results

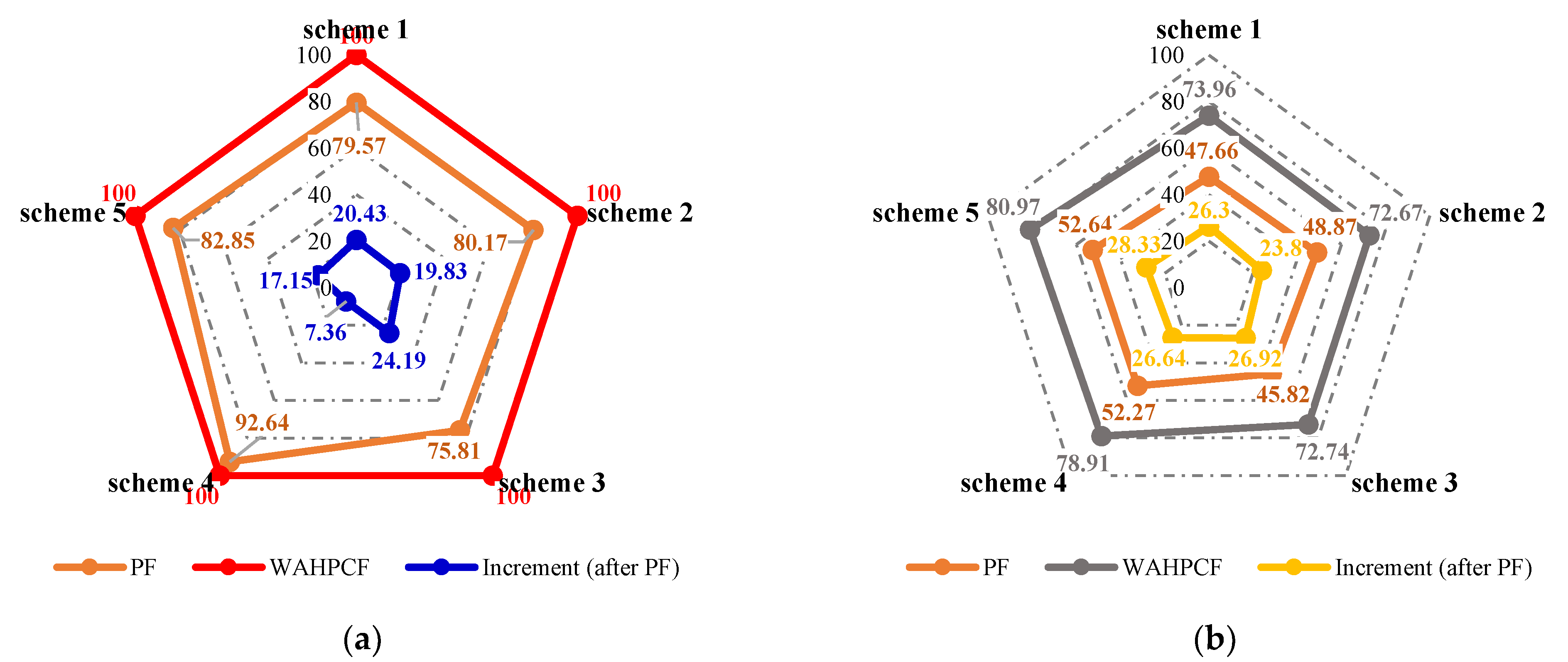

2.1.2. Evaluation of Sweep Efficiency

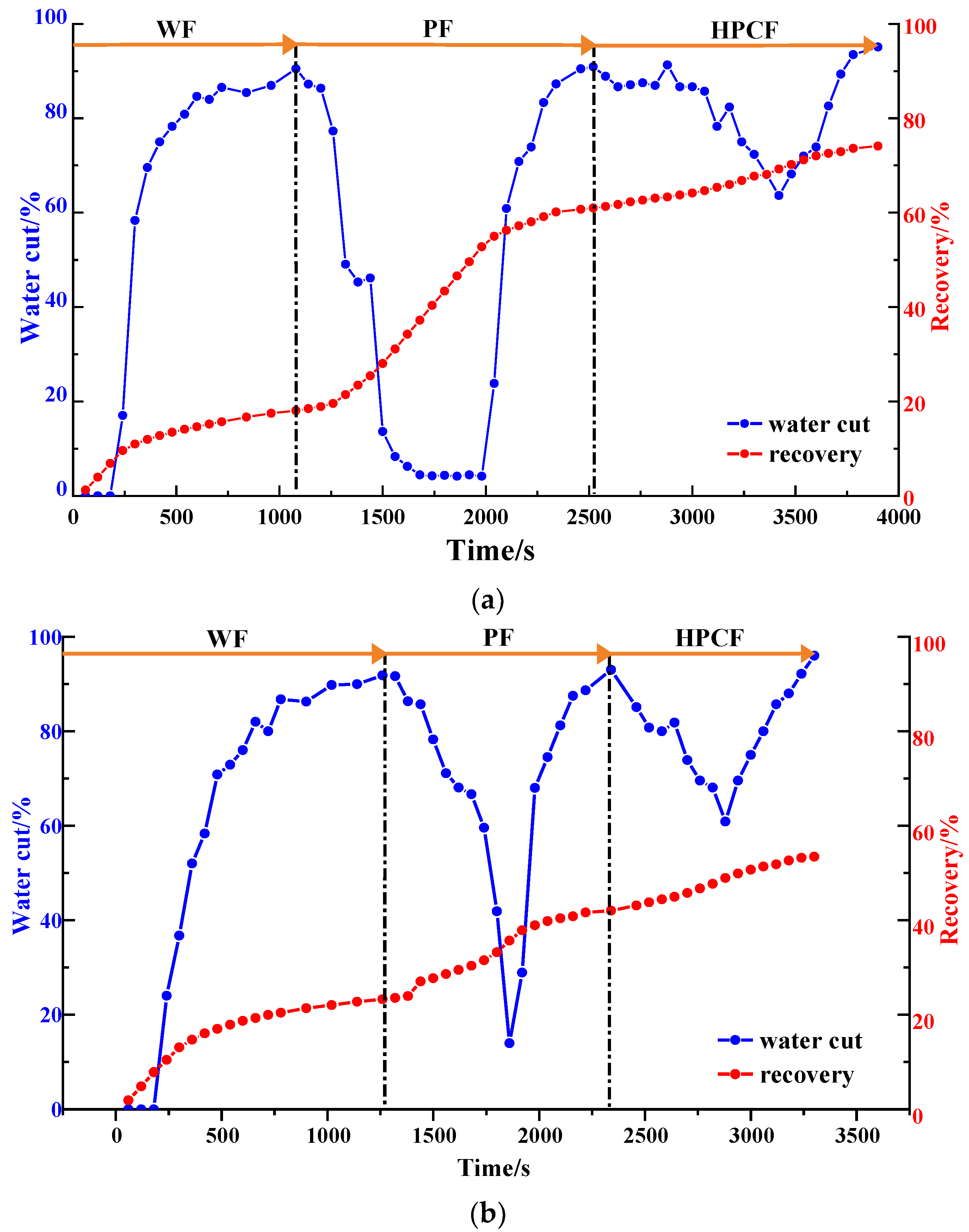

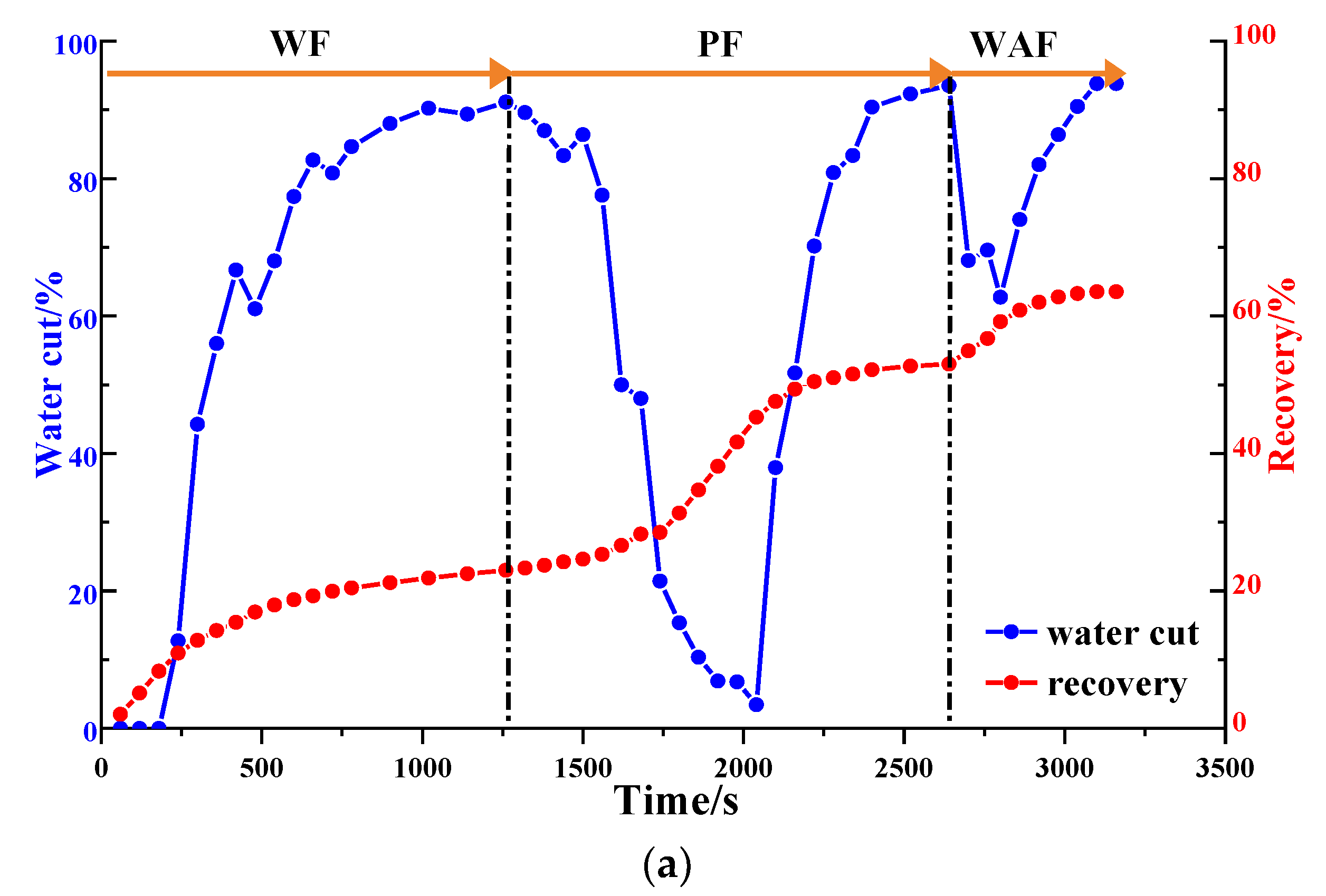

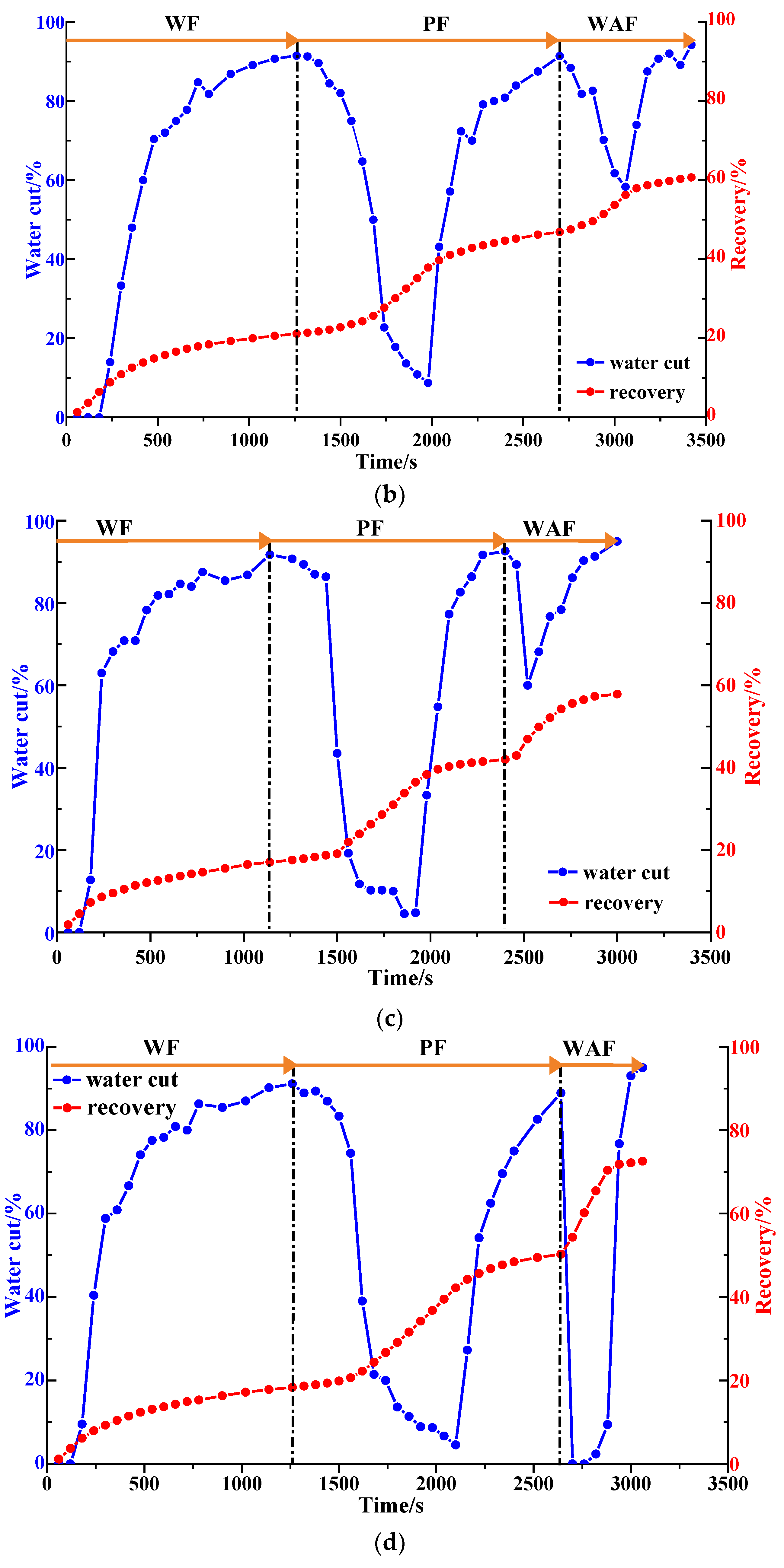

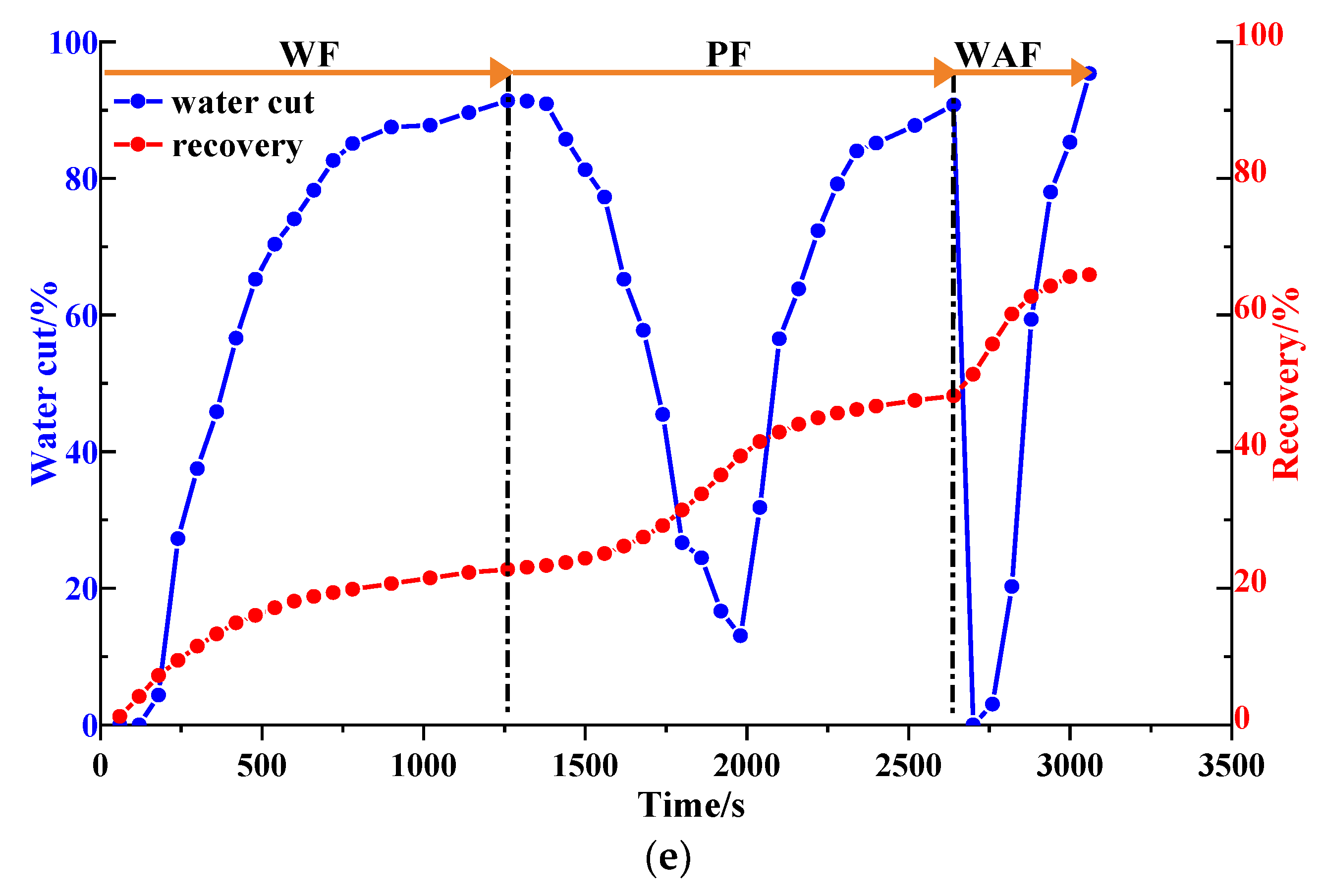

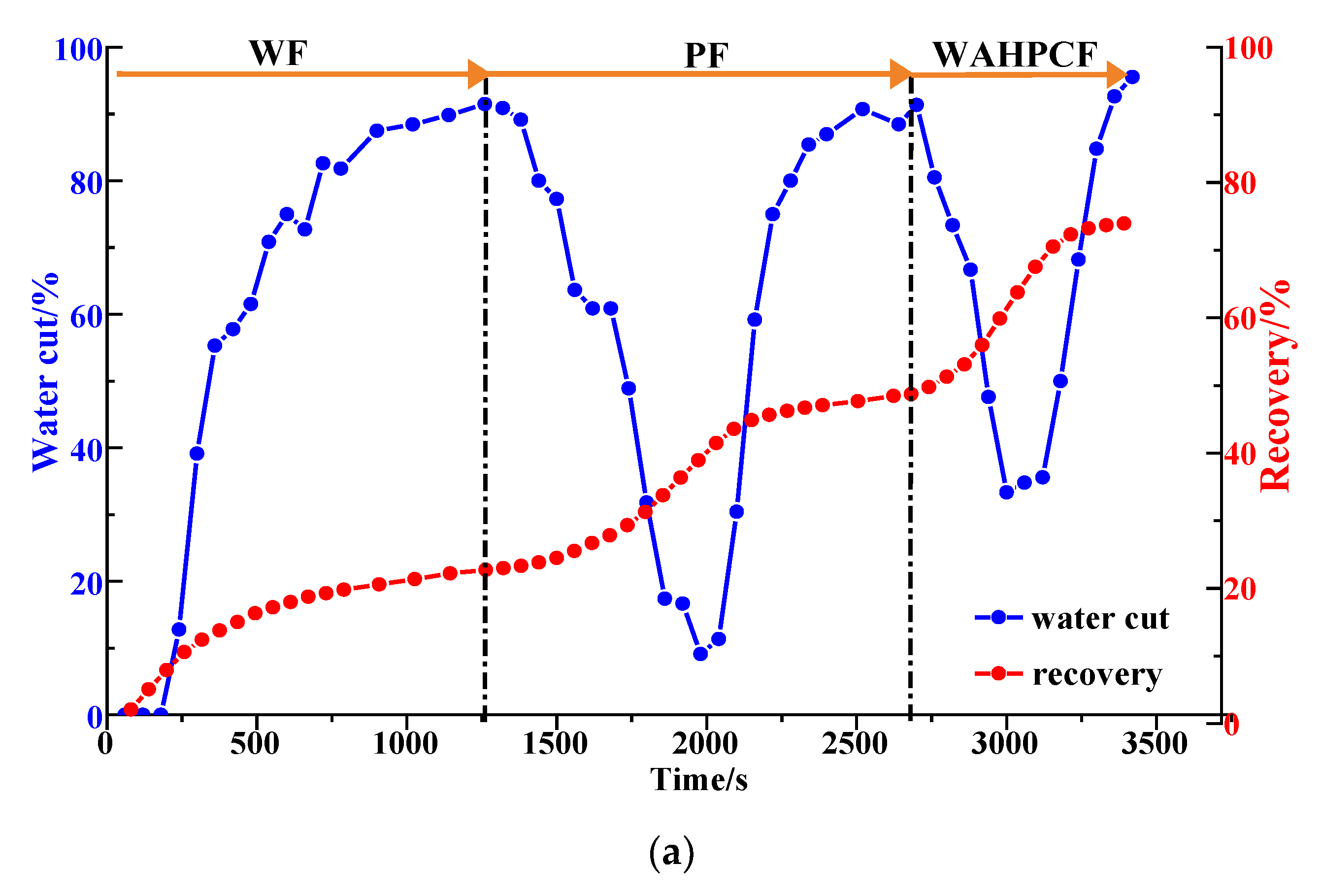

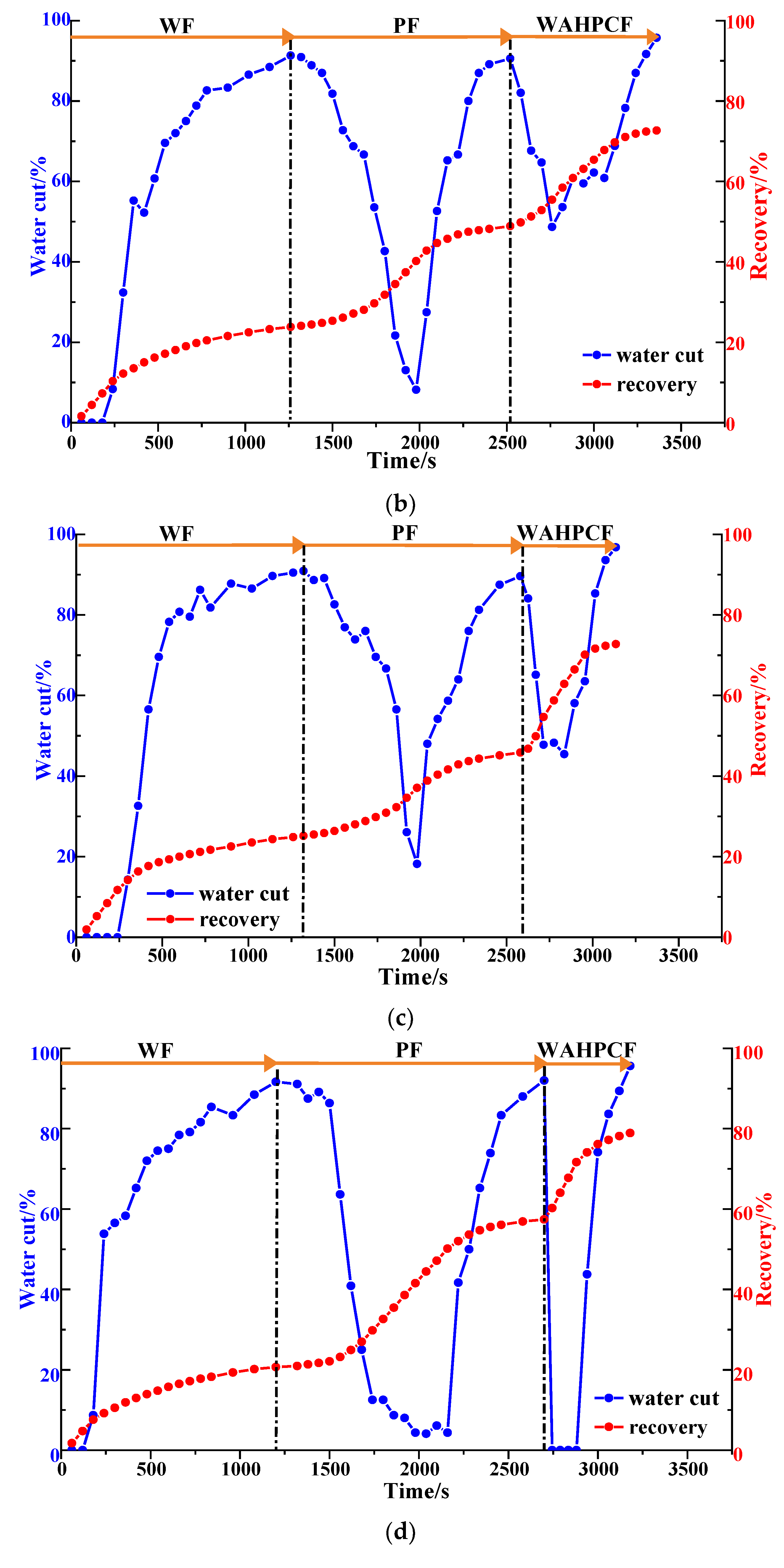

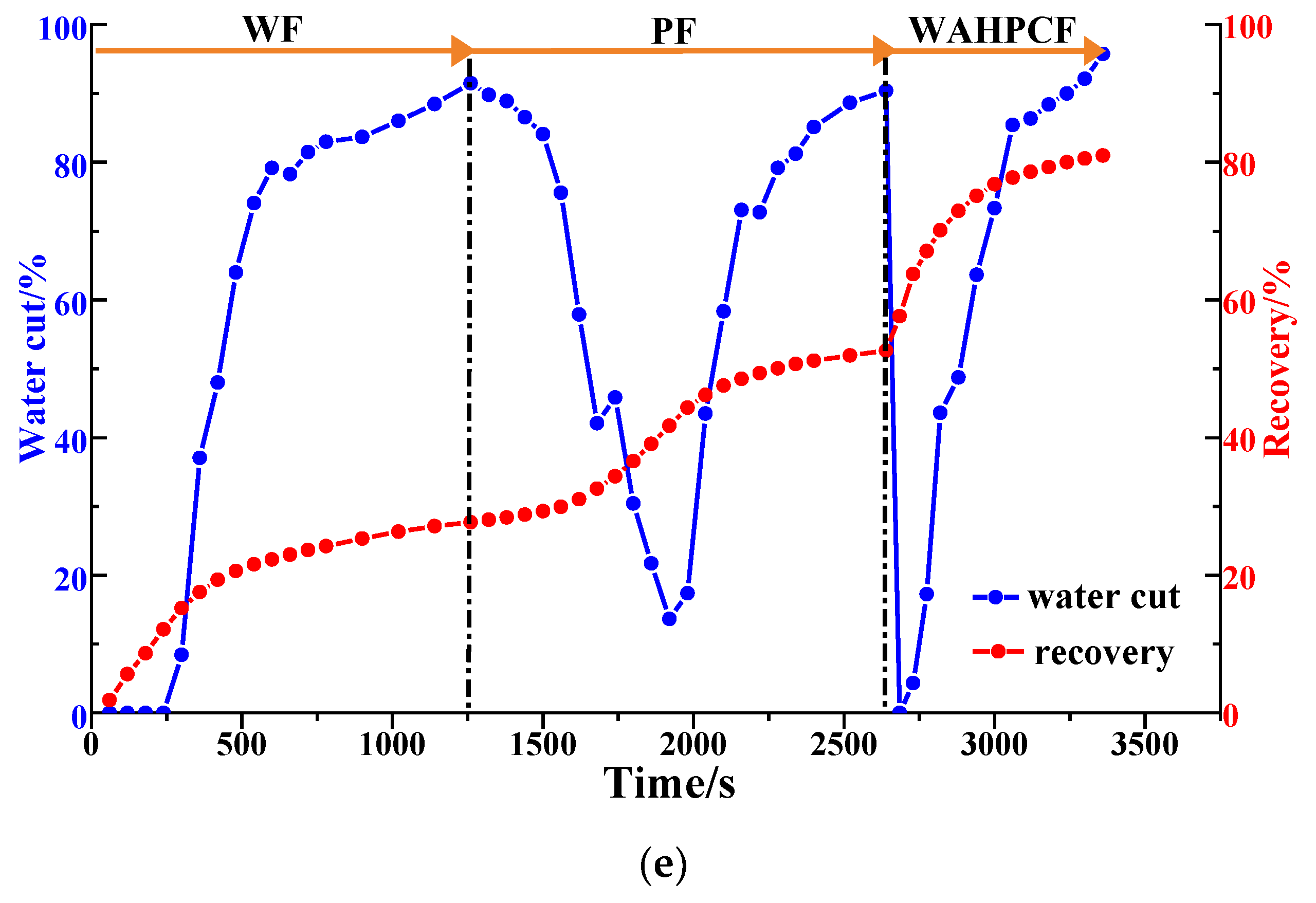

2.1.3. Water Cut and Recovery

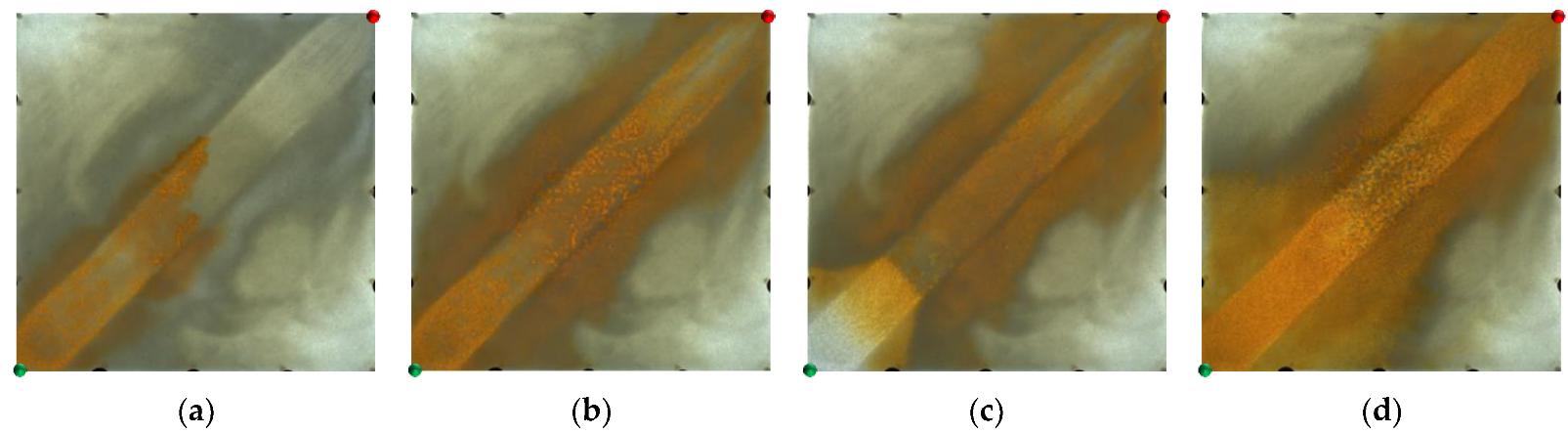

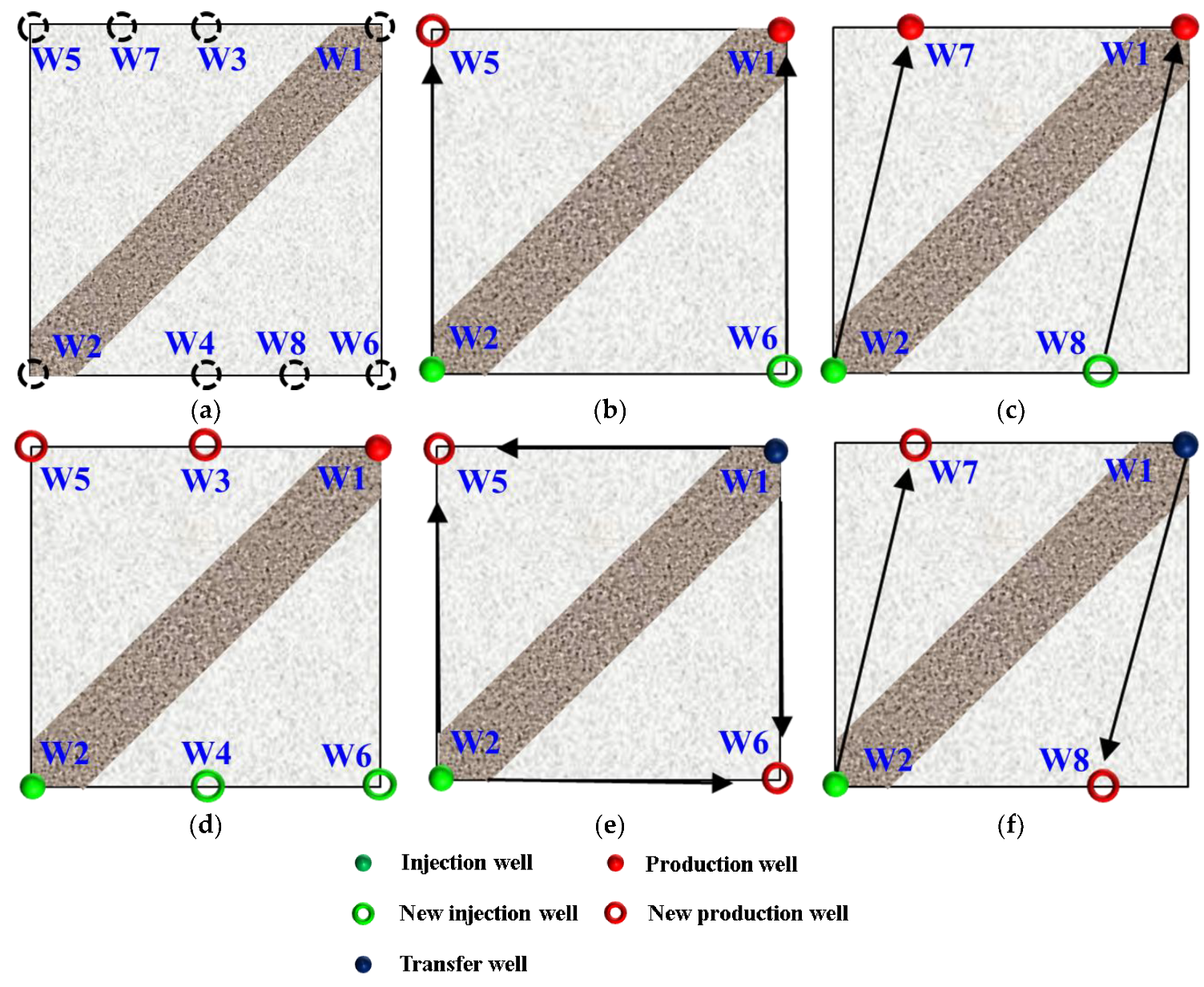

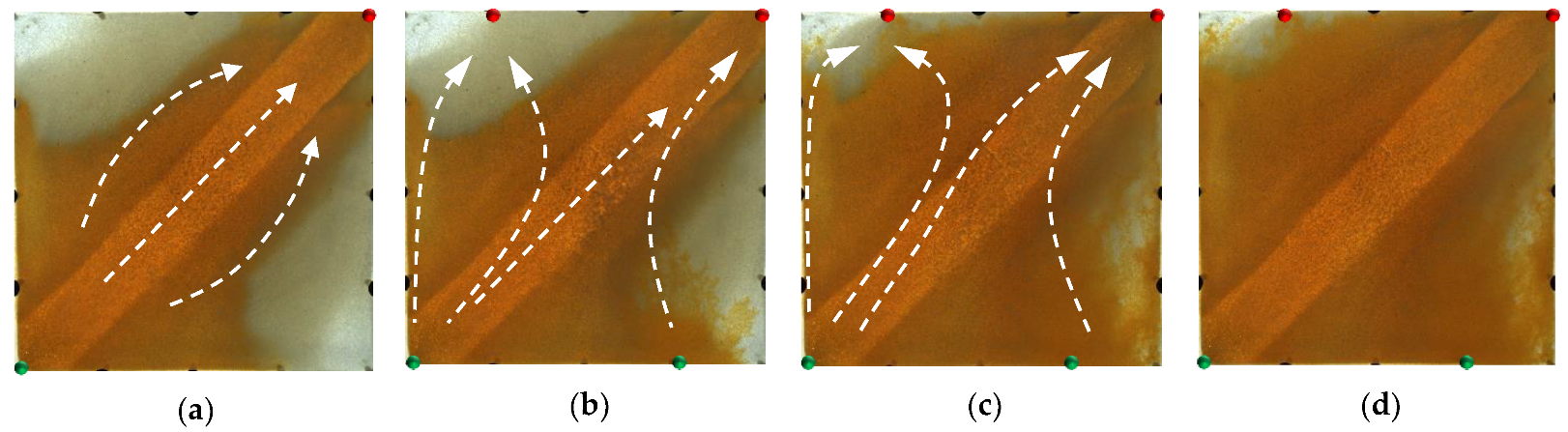

2.2. Dynamic Sweep Evaluation in WAF Experiments

2.2.1. Visual Experimental Results

2.2.2. Quantitative Results Analysis

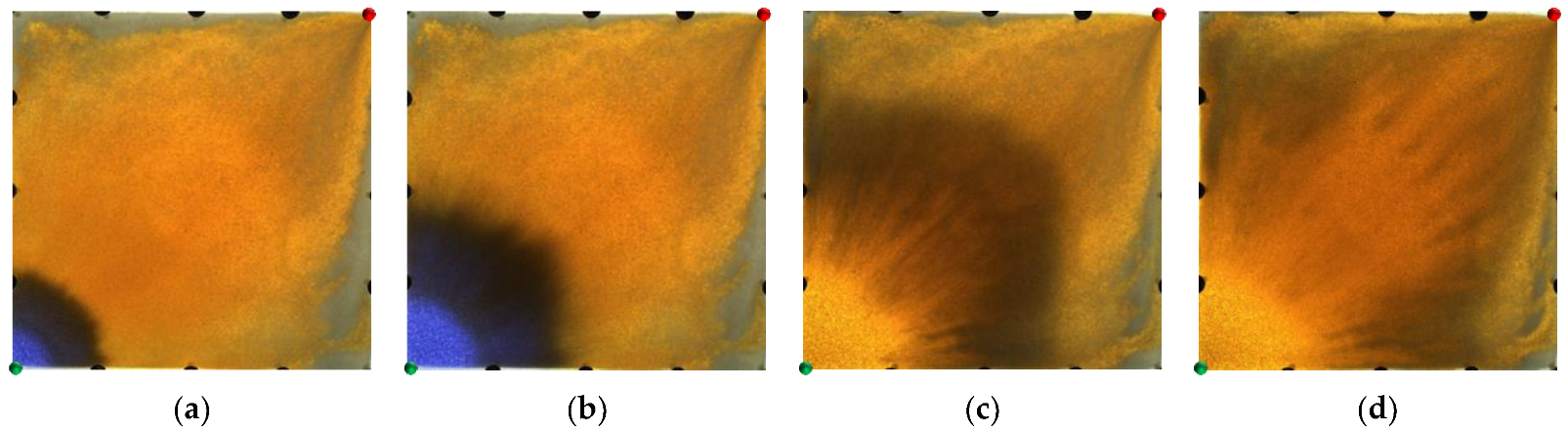

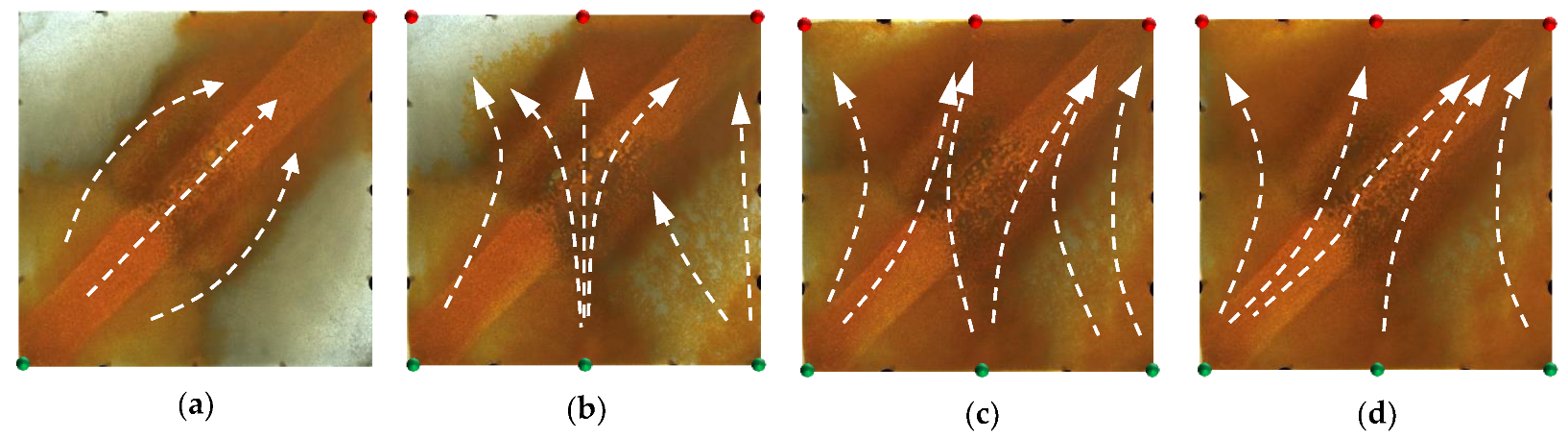

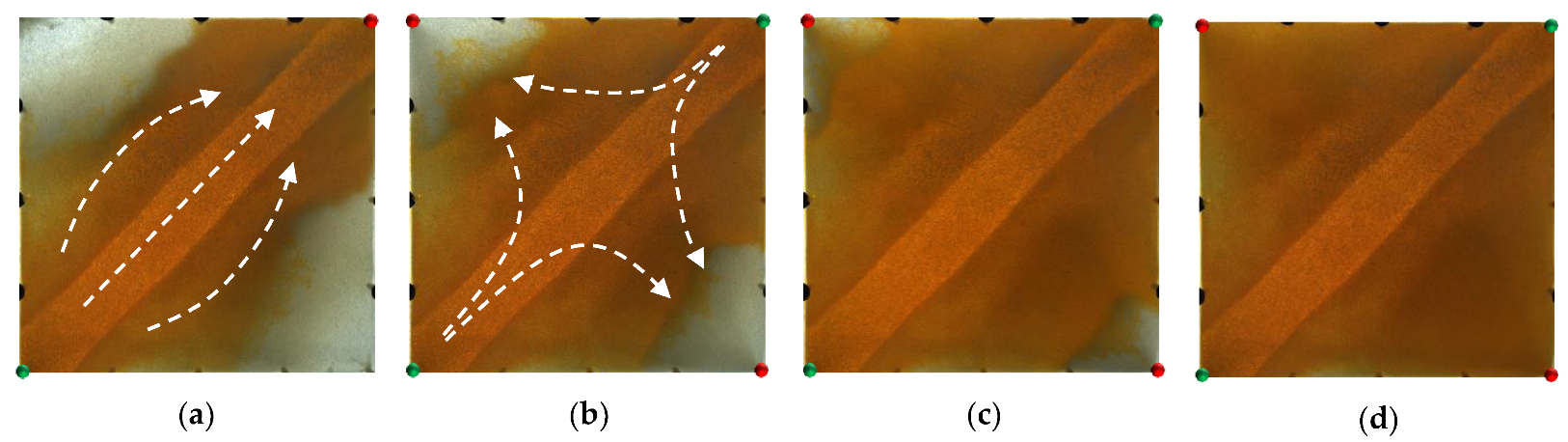

2.3. Dynamic Sweep Evaluation in WAHPCF Experiments

2.3.1. Visual Experimental Results

2.3.2. Quantitative Results Analysis

3. Conclusions

- For the reservoirs after polymer flooding, HPC flooding can block the mainstream channel, and significantly increase oil production; however, the injected HPC system mainly advanced along the high-permeability channel between the injection and production wells, and there was still a large area of unswept remaining oil at the edge of the model, with a limited sweep expansion;

- Well pattern densification and adjustment have a positive effect on HPC flooding, which can divert the original mainstream direction after polymer flooding, and effectively expand the sweeping range. After well pattern densification and adjustment, under the synergetic effect of residual polymers and multiple chemical agents in the HPC system, the water cut reduction significantly increased after polymer flooding;

- Conversion schemes were better than non-conversion schemes in terms of expanding the sweep efficiency and enhancing oil recovery. After converting the original production well to an injection well and infilling new production wells, the mainstream direction of the original flow field was broken. The injected water was displaced along the high-permeability channel and diverted to the unswept area, effectively expanding the sweeping range of injected water.

4. Materials and Methods

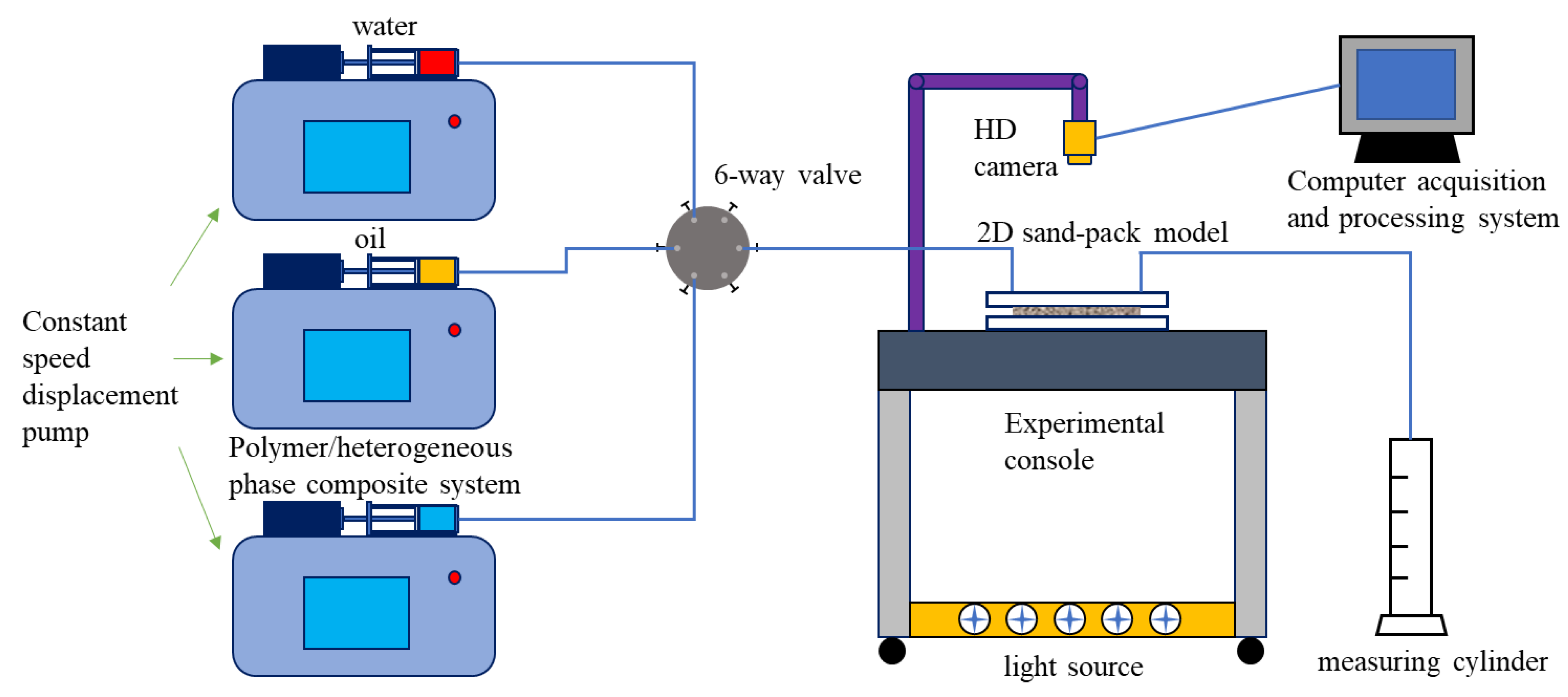

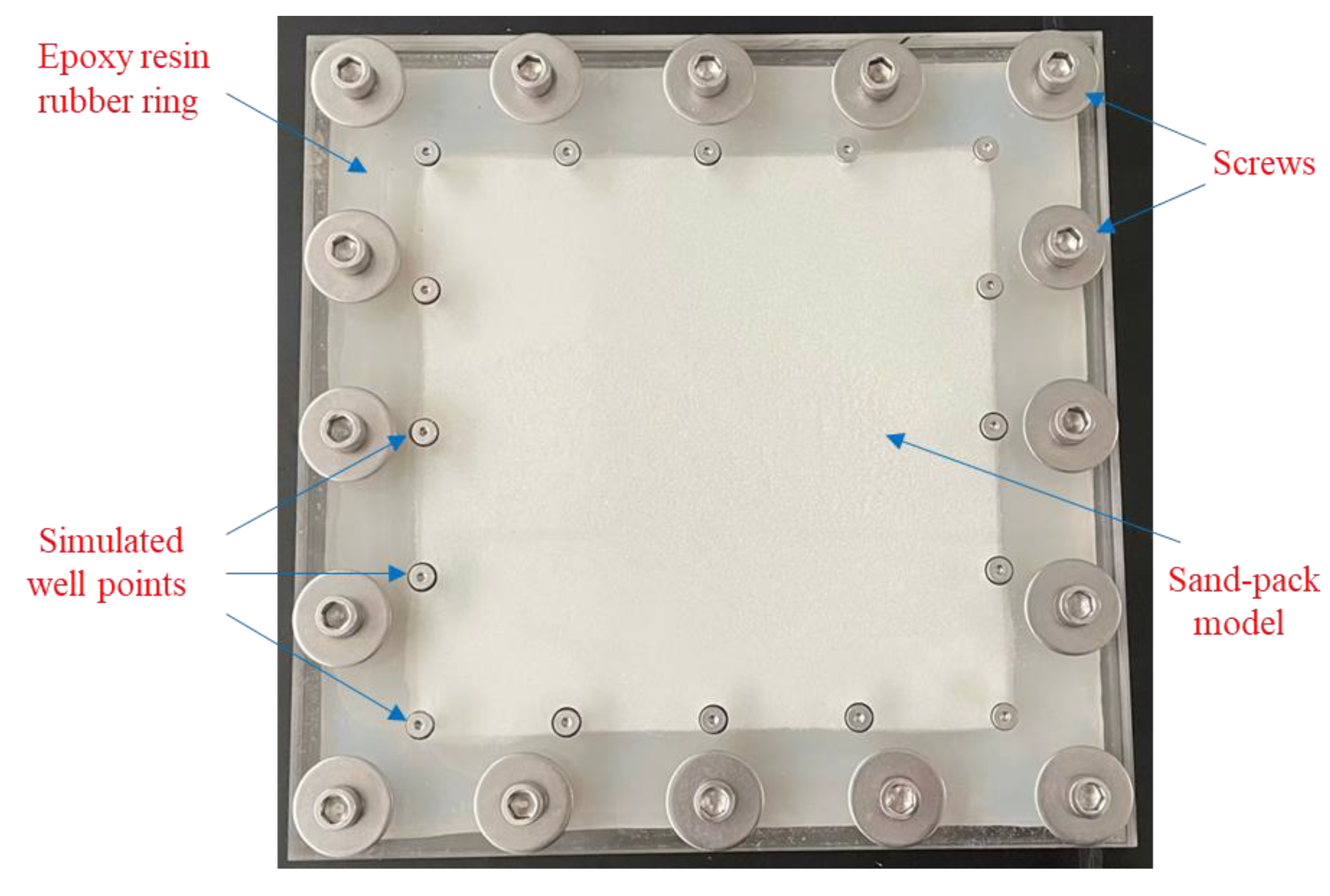

4.1. Experimental Apparatus

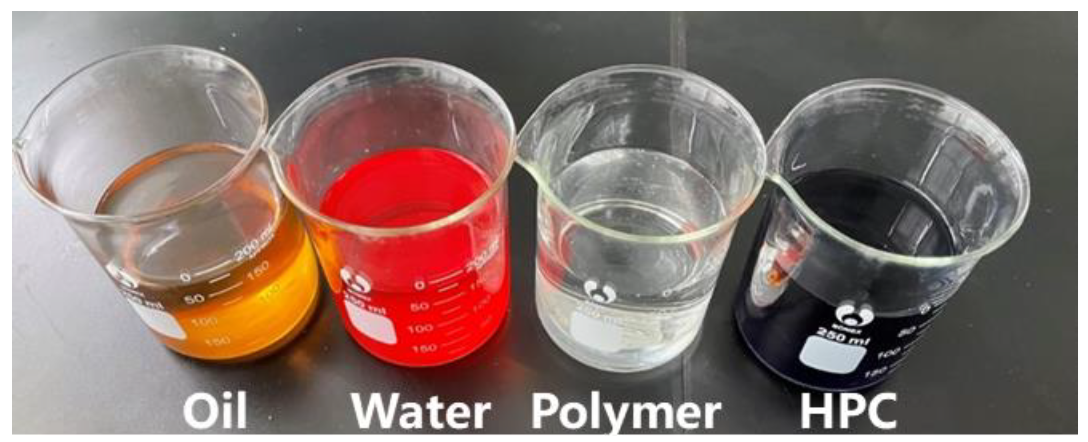

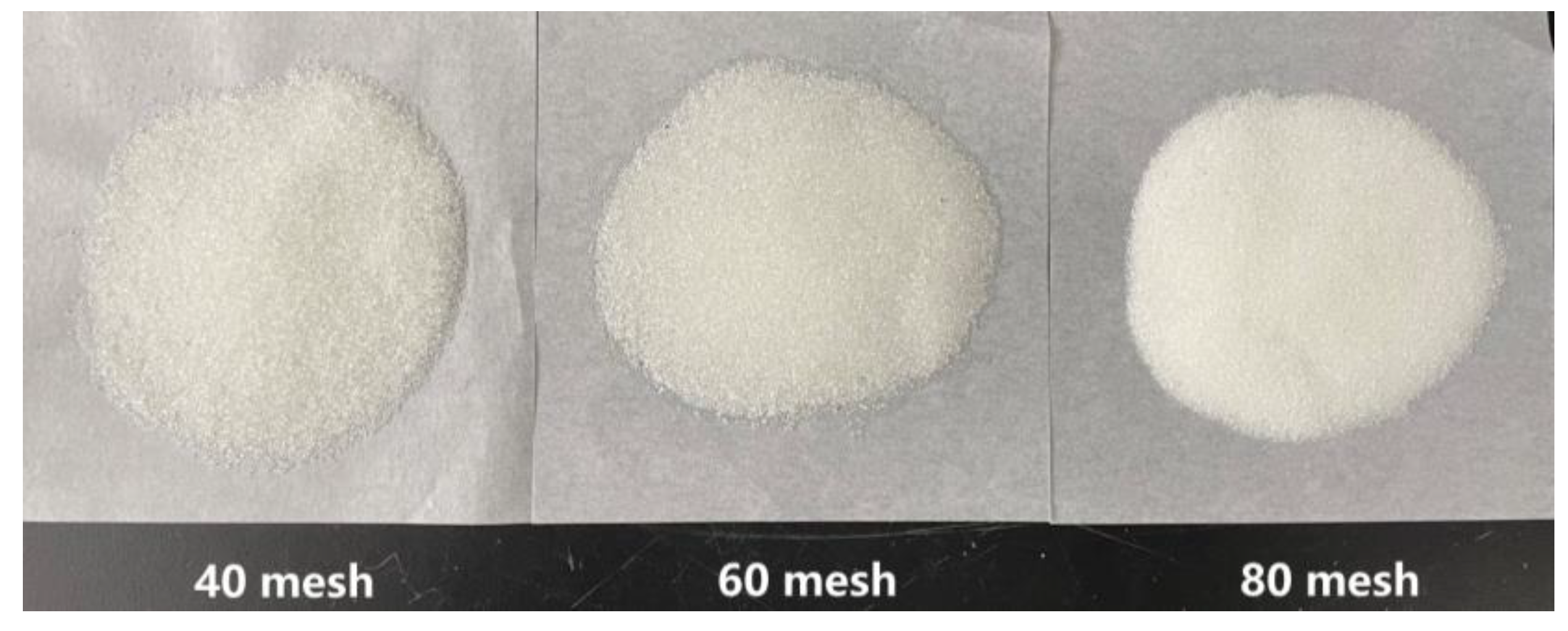

4.2. Experimental Materials

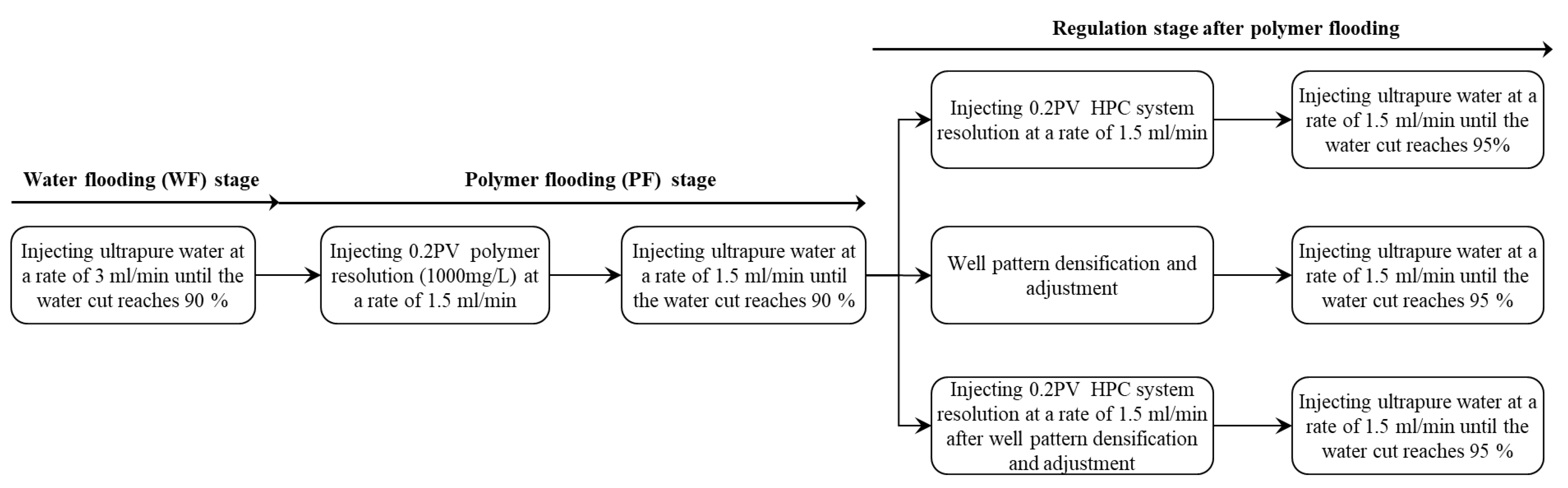

4.3. Experimental Methods

- Pour the dried glass microspheres into the model, and separate and fill the high- and low-permeability zones using a partition. Smooth and compact, and then compress and seal the model with screws;

- Using the positive displacement pump, inject the ultrapure water into the model at a rate of 3 mL/min, and leave it for 3 h after saturation;

- Using the positive displacement pump, inject the simulated oil into the model at a rate of 2 mL/min until the outlet oil content reaches 100%, and record the total injected volume of the ultrapure water and simulated oil;

- Allow the ultrapure water and simulated oil to stabilize in the model.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| WF | Water flooding |

| PF | Polymer flooding |

| HPC | Heterogeneous phase composite system |

| HPCF | Heterogeneous phase composite flooding |

| WA | Well pattern densification and adjustment |

| WAF | Well pattern densification and adjustment combined with water flooding |

| WAHPCF | Well pattern densification and adjustment combined with HPC flooding |

References

- Liu, F. Development and application of the water control and profile modification technology in China oil fields. In Proceedings of the SPE International Meeting on Petroleum Engineering, Beijing, China, 14–17 November 1995. [Google Scholar]

- Dong, L.; Li, W.; Fang, X. Genetic classification and distribution characteristics of continental petroleum systems in China. Pet. Explor. Dev. 1996, 23, 92–98. [Google Scholar]

- He, H.; Fu, J.; Zhao, H. Synergistic mechanism of hydrolyzed polyacrylamide enhanced branched-preformed particle gel for enhanced oil recovery in mature oilfields. Energy Fuels 2018, 32, 11093–11104. [Google Scholar] [CrossRef]

- Wang, X.; Yin, H.; Zhao, X. Microscopic remaining oil distribution and quantitative analysis of polymer flooding based on CT scanning. Adv. Geo-Energy Res. 2019, 3, 448–456. [Google Scholar] [CrossRef]

- Chang, H.L.; Zhang, Z.Q.; Wang, Q.M. Advances in polymer flooding and alkaline/surfactant/polymer processes as developed and applied in the People’s Republic of China. J. Pet. Technol. 2006, 58, 84–89. [Google Scholar] [CrossRef]

- Pi, Y.F.; Liu, J.X.; Cao, R.B.; Liu, L.; Ma, Y.X. Visualized Study on a New Preformed Particle Gels (PPG) + Polymer System to Enhance Oil Recovery by Oil Saturation Monitoring Online Flooding Experiment. Gels 2023, 9, 81. [Google Scholar] [CrossRef]

- Maghzi, A.; Kharrat, R.; Mohebbi, A.; Ghazanfari, M. The impact of silica nanoparticles on the performance of polymer solution in presence of salts in polymer flooding for heavy oil recovery. Fuel 2014, 123, 123–132. [Google Scholar] [CrossRef]

- Bondor, P.L. Applications of carbon dioxide in enhanced oil recovery. Energy Convers. Manag. 1992, 33, 579–586. [Google Scholar] [CrossRef]

- Gao, J.C.; Lu, X.G.; He, X.; Liu, J.X.; Zheng, K.Q. Effect Evaluation and Action Mechanism Analysis of “Profile Control + Plugging Removal” after Chemical Flooding. Gels 2022, 8, 396. [Google Scholar] [CrossRef]

- Ye, Y.Z.; Liu, Y.; Guan, B.S.; Yang, Z.; He, L.P. Study on Micro-Displacement Mechanism and Reservoir Compatibility of Soft Dispersed Microgel. Gels 2023, 9, 177. [Google Scholar] [CrossRef]

- Sui, J.; Wang, F.L.; Wang, Z.Y. Study on the pilot test with microbial profile modification after polymer flooding in Daqing oilfield. In Proceedings of the SPE Saudi Arabia Section Technical Symposium, Dhahran, Saudi Arabia, 7 May 2007. [Google Scholar]

- Zhang, L. Progress and research direction of EOR technology in eastern mature oilfields of Sinopec. Oil Gas Geol. 2022, 43, 717–723. [Google Scholar]

- Romero-Zeron, L.B.; Kantzas, A. The effect of wettability and pore geometry on foamed-gel-blockage performance. SPE Res. Eval. Eng. 2007, 10, 150–163. [Google Scholar] [CrossRef]

- Wang, L.L.; Wang, T.F.; Wang, J.X.; Tian, H.T.; Chen, Y.; Song, W. Enhanced Oil Recovery Mechanism and Technical Boundary of Gel Foam Profile Control System for Heterogeneous Reservoirs in Changqing. Gels 2022, 8, 371. [Google Scholar] [CrossRef] [PubMed]

- Vargo, J.; Turner, J.; Vergnani, B. Alkaline-surfactant-polymer flooding of the Cambridge Minnelusa field. SPE Res. Eval. Eng. 2000, 3, 552–558. [Google Scholar] [CrossRef]

- Al-Muntasheri, G.; Zitha, P.L. Gel under dynamic stress in porous media: New insights using computed tomography. In Proceedings of the SPE Saudi Arabia Section Technical Symposium, AlKhobar, Saudi Arabia, 9–11 May 2009. [Google Scholar]

- Khormali, A.; Koochi, M.; Ahmadi, S. Experimental study of the low salinity water injection process in the presence of scale inhibitor and various nanoparticles. J. Pet. Explor. Prod. Technol. 2023, 13, 903–916. [Google Scholar] [CrossRef]

- Sun, H.Q. Application of pilot test for well pattern adjusting heterogeneous combination flooding after polymer flooding-case of Zhongyiqu Ng3 block, Gudao oilfield. Pet. Geol. Recov. Effic. 2014, 21, 1–4. [Google Scholar]

- Coste, J.P.; Liu, Y.; Bai, B. In-depth fluid diversion by pre-gelled particles. laboratory study and pilot testing. In Proceedings of the SPE/DOE Improved Oil Recovery Symposium, Tulsa, Oklahoma, 3–5 April 2000. [Google Scholar]

- Han, J.L.; Sun, J.H.; Lv, K.H.; Yang, J.B.; Li, Y.H. Polymer Gels Used in Oil-Gas Drilling and Production Engineering. Gels 2022, 8, 637. [Google Scholar] [CrossRef]

- Li, J.B.; Jiang, Z.M.; Wang, Y.; Zheng, J.; Huang, G.S. Stability, seepage and displacement characteristics of heterogeneous branched-preformed particle gels for enhanced oil recovery. RSC Adv. 2018, 8, 4881–4889. [Google Scholar] [CrossRef]

- Muhammed, F.A.; Bai, B.J.; Al Brahim, A. A Simple Technique to Determine the Strength of Millimeter-Sized Particle Gel. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 12–16 April 2014. [Google Scholar]

- Mehrabianfar, P.; Malmir, P.; Soulgani, B.S.; Hashemi, A. Study on the optimization of the performance of preformed particle gel (PPG) on the isolation of high permeable zone. J. Pet. Sci. Eng. 2020, 195, 107530. [Google Scholar] [CrossRef]

- Saghafi, H.R.; Emadi, M.A.; Farasat, A.; Arabloo, M.; Naderifar, A. Performance evaluation of optimized preformed particle gel (PPG) in porous media. Chem. Eng. Res. Des. 2016, 112, 175–189. [Google Scholar] [CrossRef]

- Bai, B.; Liu, Y.; Coste, J.P. Preformed particle gel for conformance control: Transport mechanism through porous media. SPE Res. Eval. Eng. 2007, 10, 176–184. [Google Scholar] [CrossRef]

- Tongwa, P.; Bai, B.J. Degradable nanocomposite preformed particle gel for chemical enhanced oil recovery applications. J. Pet. Sci. Eng. 2014, 124, 35–45. [Google Scholar] [CrossRef]

- Zhou, K.; Wu, D.J.; An, Z.B.; Liu, S. Selective Penetration and Profile Control Performance of Preformed Particle Gels for Heterogeneous Oil Reservoirs. Gels 2022, 8, 601. [Google Scholar] [CrossRef] [PubMed]

- Cui, X. A study on the heterogeneous combination flooding system. Acta Pet. Sin. 2011, 32, 122–126. [Google Scholar]

- Cao, X. Design and performance evaluation on the heterogeneous combination flooding system. Acta Pet. Sin. 2013, 29, 115–121. [Google Scholar]

- Al-Hashim, H.S. Performance of horizontal injection-horizontal production wells in a five spot pattern: Experimental approach. Pet. Sci. Technol. 2009, 27, 933–942. [Google Scholar] [CrossRef]

- Grinestaff, G.H. Waterflood pattern allocations: Quantifying the injector to producer relationship with streamline simulation. In Proceedings of the SPE Western Regional Meeting, Anchorage, Alaska, 26–27 May 1999. [Google Scholar]

- Jadhawar, P.S.; Sarma, H.K. Effect of well pattern and injection well type on the CO2-assisted gravity drainage enhanced oil recovery. J. Pet. Sci. Eng. 2012, 98–99, 83–94. [Google Scholar] [CrossRef]

- Zhao, X.; Zuo, S.; Wu, J. Study and application of strata & well pattern reconstruction technique at extra high water cut stage in Daqing oilfield. Pet. Geol. Recovery Effic. 2019, 26, 82–87. [Google Scholar]

- Zhang, D.; Wei, J.; Fang, X. Study on the variation of rock pore structure after polymer gel flooding. e-Polymers 2020, 20, 32–38. [Google Scholar] [CrossRef]

- Gao, Q.; Zhong, C.; Han, P. Synergistic effect of alkali-surfactant–polymer and preformed particle gel on profile control after polymer flooding in heterogeneous reservoirs. Energy Fuels 2020, 34, 15957–15968. [Google Scholar] [CrossRef]

- Gong, H.J.; Zhang, H.; Xu, L. The synergistic effect of branched preformed particle gel and hydrolyzed polyacrylamide on further enhanced oil recovery after polymer flooding. Energy Fuels 2017, 31, 7904–7910. [Google Scholar] [CrossRef]

- Li, Z.; Song, X.; Wang, Q. Enhanced foam flooding pilot test in Chengdong of Shengli Oilfield: Laboratory experiment and field performance. In Proceedings of the International Petroleum Technology Conference, Doha, Qatar, 7–9 December 2009. [Google Scholar]

- Sun, C.; Hou, J.; Pan, G. Optimized polymer enhanced foam flooding for ordinary heavy oil reservoir after cross-linked polymer flooding. J. Pet. Explor. Prod. Technol. 2016, 6, 777–785. [Google Scholar] [CrossRef] [PubMed]

- Du, Q.; Pan, G.; Hou, J. Study of the mechanisms of streamline-adjustment-assisted heterogeneous combination flooding for enhanced oil recovery for post-polymer-flooded reservoirs. Petrol. Sci. 2019, 16, 606–618. [Google Scholar] [CrossRef]

- Wu, D.; Zhou, K.; Hou, J. Experimental study on combining heterogeneous phase composite flooding and streamline adjustment to improve oil recovery in heterogeneous reservoirs. J. Pet. Sci. Eng. 2020, 194, 107478. [Google Scholar] [CrossRef]

- Vicente, M.; Crosta, D.; Eliseche, L.; Scolari, J.; Castelo, R. Determination of volumetric sweep efficiency in barrancas unit, barrancas field. In Proceedings of the SPE Western Regional Meeting, Bakersfield, CA, USA, 26–30 March 2001. [Google Scholar]

- Sun, X.Y.; Ge, J.J. Analysis of visualized displacement experiment with image analysis technology of Matlab graphics. In Proceedings of the International Petroleum and Petrochemical Technology Conference, Shanghai, China, 26–28 August 2020. [Google Scholar]

- Spacek, L.A. Edge detection and motion detection. Image Vis. Comput. 1986, 4, 43–56. [Google Scholar] [CrossRef]

- Fan, D.; Lin, Z.; Zhang, Z.; Zhu, M.; Cheng, M. Rethinking RGB-D salient object detection: Models, data sets, and large-scale benchmarks. IEEE Trans. Neural Netw. Learn. Syst. 2020, 32, 2075–2089. [Google Scholar] [CrossRef]

- Houssein, E.; Helmy, B.; Oliva, D.; Elngar, A.; Shaban, H. A novel Black Widow Optimization algorithm for multilevel thresholding image segmentation. Expert Syst. Appl. 2021, 167, 114159. [Google Scholar] [CrossRef]

- Leung, C.; Marussi, S.; Atwood, R.; Towrie, M.; Withers, P.; Lee, P. In situ X-ray imaging of defect and molten pool dynamics in laser additive manufacturing. Nat. Commun. 2018, 9, 1355. [Google Scholar] [CrossRef]

- Mason, G.; Morrow, N. Developments in spontaneous imbibition and possibilities for future work. J. Pet. Sci. Eng. 2013, 110, 268–293. [Google Scholar] [CrossRef]

| Process | Weakly Heterogeneous Model | Strongly Heterogeneous Model | ||

|---|---|---|---|---|

| Oil Recovery (%) | Sweep Efficiency (%) | Oil Recovery (%) | Sweep Efficiency (%) | |

| Water flooding (WF) | 17.50 | 80.35 | 22.70 | 60.31 |

| Polymer flooding (PF) | 60.13 | 92.52 | 42.02 | 70.88 |

| HPC Flooding (HPCF) | 74.10 | 98.45 | 53.45 | 79.87 |

| Increment (after PF) | 13.97 | 5.93 | 11.43 | 8.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Zhang, Y.; Liu, H.; Li, S.; Liu, L. Dynamic Sweep Experiments on a Heterogeneous Phase Composite System Based on Branched-Preformed Particle Gel in High Water-Cut Reservoirs after Polymer Flooding. Gels 2023, 9, 364. https://doi.org/10.3390/gels9050364

Zhang X, Zhang Y, Liu H, Li S, Liu L. Dynamic Sweep Experiments on a Heterogeneous Phase Composite System Based on Branched-Preformed Particle Gel in High Water-Cut Reservoirs after Polymer Flooding. Gels. 2023; 9(5):364. https://doi.org/10.3390/gels9050364

Chicago/Turabian StyleZhang, Xianmin, Yiming Zhang, Haicheng Liu, Shanshan Li, and Lijie Liu. 2023. "Dynamic Sweep Experiments on a Heterogeneous Phase Composite System Based on Branched-Preformed Particle Gel in High Water-Cut Reservoirs after Polymer Flooding" Gels 9, no. 5: 364. https://doi.org/10.3390/gels9050364

APA StyleZhang, X., Zhang, Y., Liu, H., Li, S., & Liu, L. (2023). Dynamic Sweep Experiments on a Heterogeneous Phase Composite System Based on Branched-Preformed Particle Gel in High Water-Cut Reservoirs after Polymer Flooding. Gels, 9(5), 364. https://doi.org/10.3390/gels9050364