Modeling and Optimization of the Adsorption of Cr (VI) in a Chitosan-Resole Aerogel Using Response Surface Methodology

Abstract

1. Introduction

2. Results and Discussion

2.1. RSM Modeling and Optimization

2.2. Characterization of CS/R Aerogel

2.2.1. Morphology of CS/R Aerogel

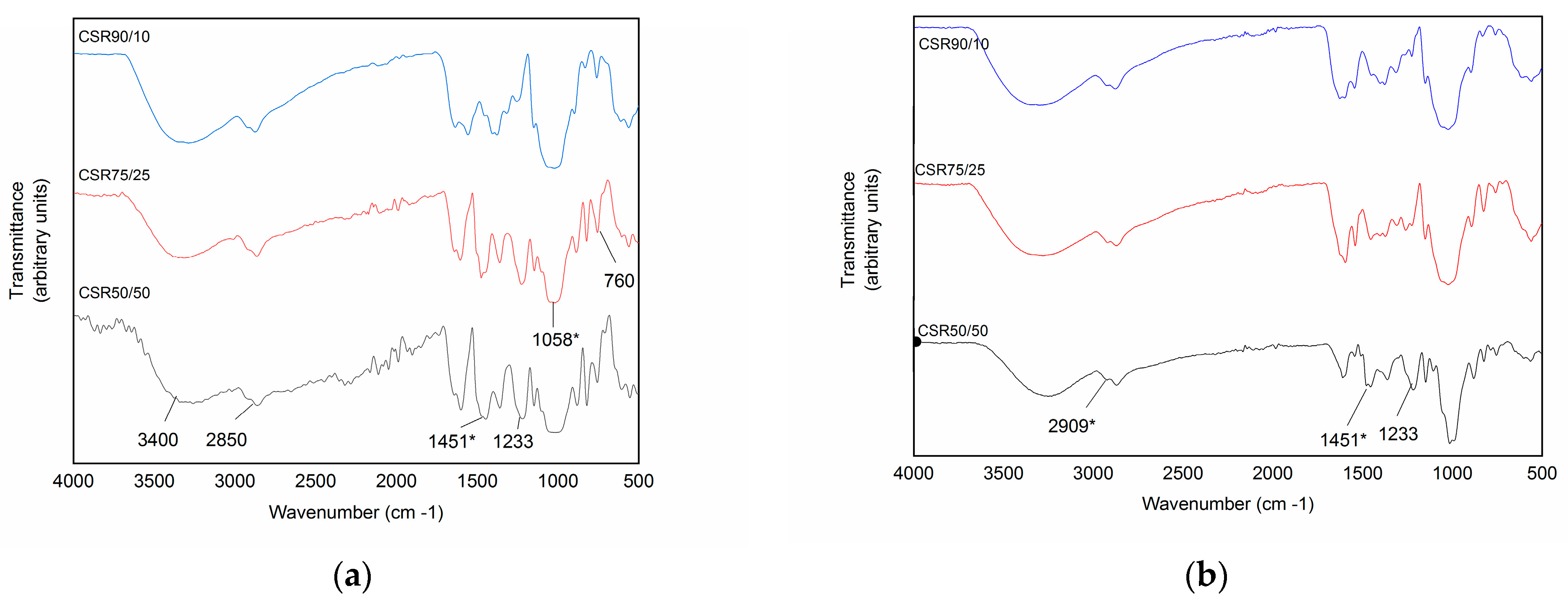

2.2.2. FTIR of CS/R Aerogel

2.3. RSM Modeling

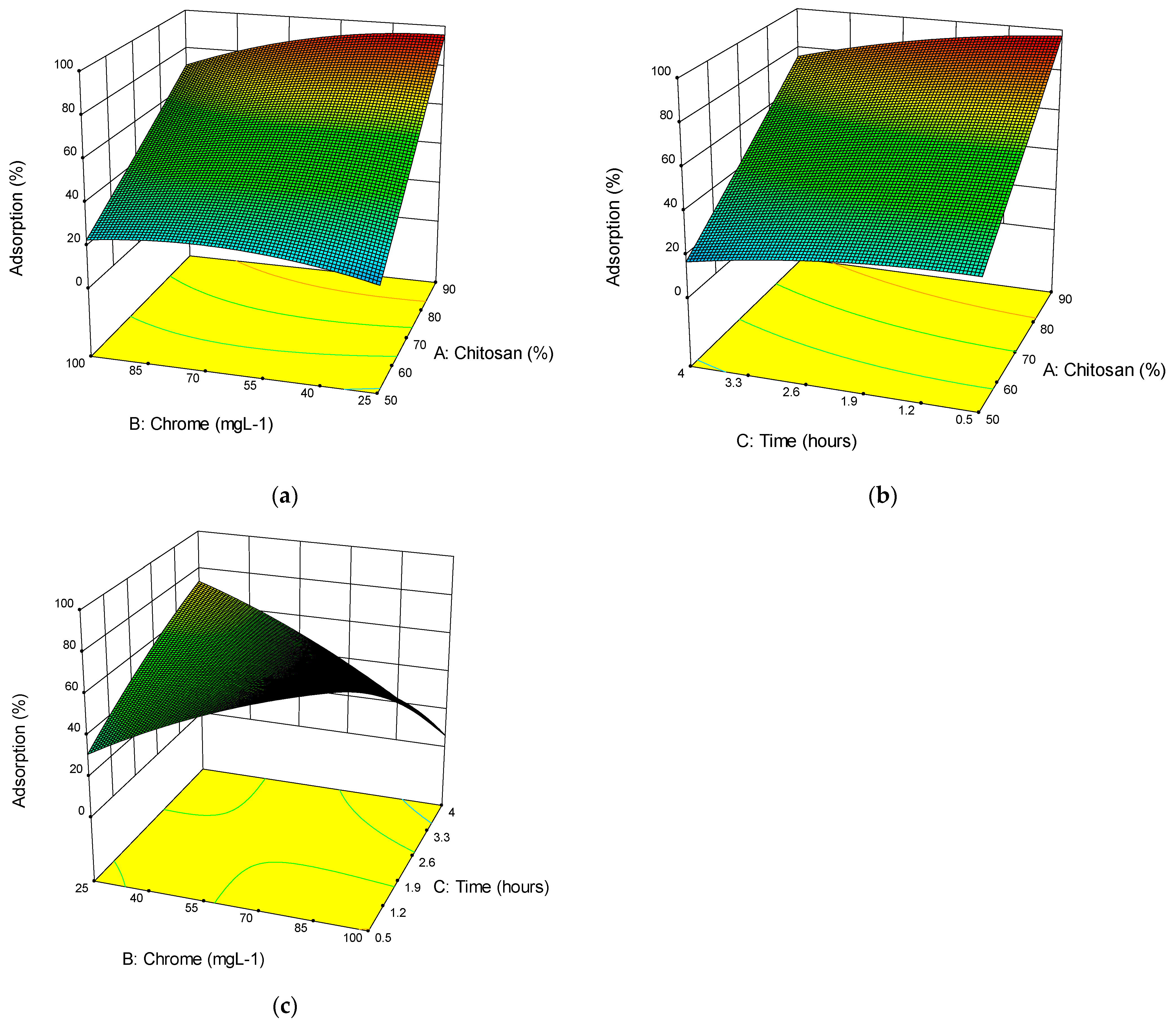

2.3.1. Effects of the Variables on Cr (VI) Adsorption

2.3.2. Effect of Chitosan/Resin Concentration

2.3.3. Effect of Initial Concentration Cr (VI)

2.3.4. Effect of Adsorption Time

2.4. Optimization Process

3. Conclusions

4. Materials and Methods

4.1. Chemicals and Reagents

4.2. Fabrication of the Aerogel Process

Formulation and Molding of the CS/R Aerogel

4.3. Characterization of the CS/R Aerogel

4.4. Adsorption Studies

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khulbe, K.C.; Matsuura, T. Removal of heavy metals and pollutants by membrane adsorption techniques. Appl. Water Sci. 2018, 8, 19. [Google Scholar] [CrossRef]

- Dorraji, M.S.S.; Mirmohseni, A.; Tasselli, F.; Criscuoli, A.; Carraro, M.; Gross, S.; Figoli, A. Preparation, characterization and application of iron (III)-loaded chitosan hollow fiber membranes as a new bio-based As (V) sorbent. J. Polym. Res. 2014, 21, 399. [Google Scholar] [CrossRef]

- Wang, B.; Zhu, Y.; Bai, Z.; Luque, R.; Xuan, J. Functionalized chitosan biosorbents with ultra-high performance, mechanical strength and tunable selectivity for heavy metals in wastewater treatment. Chem. Eng. J. 2017, 325, 350–359. [Google Scholar] [CrossRef]

- Vieira, R.S.; Beppu, M.M. Dynamic and static adsorption and desorption of Hg(II) ions on chitosan membranes and spheres. Water Res. 2006, 40, 1726–1734. [Google Scholar] [CrossRef]

- Wei, S.; Chee, Y.; Hock, C. Synthesis of chitosan aerogels as promising carriers for drug delivery: A review. Carbohydr. Polym. 2020, 231, 115744. [Google Scholar] [CrossRef]

- Chen, D.R.; Chang, X.H.; Jiao, X.L. Aerogels in the Environment Protection; Elsevier B.V.: London, UK, 2014. [Google Scholar]

- Maleki, H. Recent advances in aerogels for environmental remediation applications: A review. Chem. Eng. J. 2016, 300, 98–118. [Google Scholar] [CrossRef]

- Smirnova, I.; Gurikov, P. Aerogel production: Current status, research directions, and future opportunities. J. Supercrit. Fluids 2018, 134, 228–233. [Google Scholar] [CrossRef]

- Christy, E.J.S.; Rajeswari, A. Chitin and Chitosan-Based Aerogels; Elsevier B.V.: London, UK, 2020. [Google Scholar]

- Ma, M.; Mukerabigwi, J.F.; Huang, R.; Lei, S.; Huang, X.; Cao, Y. Eco-Friendly Superabsorbent Synthesis Based on Polysaccharides. J. Polym. Environ. 2020, 28, 2801–2809. [Google Scholar] [CrossRef]

- Wu, Z.Y.; Li, C.; Liang, H.; Chen, J.; Yu, S.H. Ultralight, flexible, and fire-resistant carbon nanofiber aerogels from bacterial cellulose. Angew. Chem.-Int. Ed. 2013, 52, 2925–2929. [Google Scholar] [CrossRef]

- Li, Y.-Q.; Samad, Y.A.; Polychronopoulou, K.; Alhassan, S.; Liao, K. Carbon Aerogel from Winter Melon for Highly Efficient and Recyclable Oils and Organic Solvents Absorption. ACS Sustain. Chem. Eng. 2014, 2, 1492–1497. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, H.-B.; Wang, M.; Qian, X.; Dasari, A.; Yu, Z.-Z. Phenolic resin-enhanced three-dimensional graphene aerogels and their epoxy nanocomposites with high mechanical and electromagnetic interference shielding performances. Compos. Sci. Technol. 2017, 152, 254–262. [Google Scholar] [CrossRef]

- Yin, R.; Cheng, H.; Hong, C.; Zhang, X. Synthesis and characterization of novel phenolic resin/silicone hybrid aerogel composites with enhanced thermal, mechanical and ablative properties. Compos. Part A Appl. Sci. Manuf. 2017, 101, 500–510. [Google Scholar] [CrossRef]

- Suenaga, S.; Osada, M. Preparation of β-chitin nanofiber aerogels by lyophilization. Int. J. Biol. Macromol. 2019, 126, 1145–1149. [Google Scholar] [CrossRef]

- Aliabadi, M. Removal of Pb(II) and Cr(VI) ions from aqueous solutions using chitosan/cobalt ferrite nanofibrous adsorbent. Fibers Polym. 2016, 17, 1162–1170. [Google Scholar] [CrossRef]

- Vieira, R.S.; Beppu, M.M. Mercury Ion Recovery Using Natural and Crosslinked Chitosan Membranes. Adsorption 2005, 11, 731–736. [Google Scholar] [CrossRef]

- Du, A.; Zhou, B.; Zhang, Z.; Shen, J. A Special Material or a New State of Matter: A Review and Reconsideration of the Aerogel. Materials 2013, 6, 941–968. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Bai, H.; Zhao, Y.; Kang, S.; Yi, H.; Zhang, T.; Song, S. Synthesis of chitosan cross-linked 3D network-structured hydrogel for methylene blue removal. Int. J. Biol. Macromol. 2019, 141, 98–107. [Google Scholar] [CrossRef]

- Shahbazi, M.-A.; Ghalkhani, M.; Maleki, H. Directional Freeze-Casting: A Bioinspired Method to Assemble Multifunctional Aligned Porous Structures for Advanced Applications. Adv. Eng. Mater. 2020, 22, 2000033. [Google Scholar] [CrossRef]

- Yu, Z.-L.; Yang, N.; Zhou, L.-C.; Ma, Z.-Y.; Zhu, Y.-B.; Lu, Y.-Y.; Qin, B.; Xing, W.-Y.; Ma, T.; Li, S.-C.; et al. Bioinspired polymeric woods. Sci. Adv. 2018, 4, eaat7223. [Google Scholar] [CrossRef] [PubMed]

- Aydin, Y.A.; Aksoy, N.D. Adsorption of chromium on chitosan: Optimization, kinetics, and thermodynamics. Chem. Eng. J. 2009, 151, 188–194. [Google Scholar] [CrossRef]

- Won, S.W.; Park, J.; Mao, J.; Yun, Y.-S. Utilization of PEI-modified Corynebacterium glutamicum biomass for the recovery of Pd(II) in hydrochloric solution. Bioresour. Technol. 2011, 102, 3888–3893. [Google Scholar] [CrossRef] [PubMed]

- Sugashini, S.; Begum, K.M.M.S. Column Adsorption Studies for the Removal of Cr(VI) Ions by Ethylamine Modified Chitosan Carbonized Rice Husk Composite Beads with Modelling and Optimization. J. Chem. 2013, 2013, 460971. [Google Scholar] [CrossRef]

- Santos-López, G.; Argüelles-Monal, W.; Carvajal-Millan, E.; López-Franco, Y.L.; Recillas-Mota, M.T.; Lizardi-Mendoza, J. Aerogels from Chitosan solutions in ionic liquids. Polymers 2017, 9, 722. [Google Scholar] [CrossRef]

- Guo, D.-M.; An, Q.-D.; Xiao, Z.-Y.; Zhai, S.-R.; Yang, D.-J. Efficient removal of Pb(II), Cr(VI) and organic dyes by polydopamine modified chitosan aerogels. Carbohydr. Polym. 2018, 202, 306–314. [Google Scholar] [CrossRef] [PubMed]

- Radwan, N.; Khan, N.; Elmanfaloty, R.A.G. Optimization of solid waste collection using RSM approach, and strategies delivering sustainable development goals (SDG’s) in Jeddah, Saudi Arabia. Sci. Rep. 2021, 11, 16612. [Google Scholar] [CrossRef]

- Wang, X.L.; Guo, D.; An, Q.D.; Xiao, Z.; Zhai, S.R. High-efficacy adsorption of Cr(VI) and anionic dyes onto β-cyclodextrin/chitosan/hexamethylenetetramine aerogel beads with task-specific, integrated components. Int. J. Biol. Macromol. 2019, 128, 268–278. [Google Scholar] [CrossRef] [PubMed]

- Grishechko, L.I.; Amaral-Labat, G.; Szczurek, A.; Fierro, V.; Kuznetsov, B.; Celzard, A. Lignin-phenol-formaldehyde aerogels and cryogels. Microporous Mesoporous Mater. 2013, 168, 19–29. [Google Scholar] [CrossRef]

- Huang, J.; Zeng, J.; Wang, H.; Etim, U.; Liang, B.; Meteku, E.B.; Li, H.; Wang, Y.; Qiu, Z.; Rood, M.J.; et al. Biomimetic fabrication of highly ordered laminae–trestle–laminae structured copper aero-sponge. Nanoscale 2020, 12, 8982–8990. [Google Scholar] [CrossRef]

- Meng, G.; Peng, H.; Wu, J.; Wang, Y.; Wang, H.; Liu, Z.; Guo, X. Fabrication of superhydrophobic cellulose/chitosan composite aerogel for oil/water separtion. Fibers Polym. 2017, 18, 706–712. [Google Scholar] [CrossRef]

- Li, L.; Li, Y.; Cao, L.; Yang, C. Enhanced chromium (VI) adsorption using nanosized chitosan fibers tailored by electrospinning. Carbohydr. Polym. 2015, 125, 206–213. [Google Scholar] [CrossRef]

- Chen, S.; Yue, Q.; Gao, B.; Li, Q.; Xu, X.; Fu, K. Adsorption of hexavalent chromium from aqueous solution by modified corn stalk: A fixed-bed column study. Bioresour. Technol. 2012, 113, 114–120. [Google Scholar] [CrossRef] [PubMed]

- Murugadoss, J.R.; Balasubramaniam, N.; Gokulan, R.; Rajesh, K.N.; Sreelal, G.P.; Sudam, P.A.; Rahman, D.R.Z.; Ali, R.N. Optimization of River Sand with Spent Garnet Sand in Concrete Using RSM and R Programming Packages. J. Nanomater. 2022, 2022, 4620687. [Google Scholar] [CrossRef]

- Amibo, T.A.; Beyan, S.; Damite, T.M. Production and Optimization of Bio-Based Silica Nanoparticle from Teff Straw (Eragrostis tef) Using RSM-Based Modeling, Characterization Aspects, and Adsorption Efficacy of Methyl Orange Dye. J. Chem. 2022, 2022, 9770520. [Google Scholar] [CrossRef]

- Naveen, N.R.; Kurakula, M.; Gowthami, B. Process optimization by response surface methodology for preparation and evaluation of methotrexate loaded chitosan nanoparticles. Mater. Today Proc. 2020, 33, 2716–2724. [Google Scholar] [CrossRef]

- Bhatt, R.; Sreedhar, B.; Padmaja, P. Adsorption of chromium from aqueous solutions using crosslinked chitosan–diethylenetriaminepentaacetic acid. Int. J. Biol. Macromol. 2015, 74, 458–466. [Google Scholar] [CrossRef]

- Ngah, W.W.; Teong, L.; Hanafiah, M. Adsorption of dyes and heavy metal ions by chitosan composites: A review. Carbohydr. Polym. 2011, 83, 1446–1456. [Google Scholar] [CrossRef]

- Herrera, G.M.D.; Ordoñez, P.P.; Anaguano, A.H. Estandarización de la difenilcarbazida como indicador y acomplejante en la identificación de cromo hexavalente—Cr (VI). Prod. Limpia 2013, 8, 9–20. [Google Scholar]

- García, H.G.; Sierra, C.A.S. Verificación analítica para las determinaciones de cromo hexavalente en aguas por espectrofotometría carlos. Ing. USBMed 2013, 4, 22–26. [Google Scholar]

| Factor | Parameter | Coded Variables | ||

|---|---|---|---|---|

| −1 | 0 | 1 | ||

| A | CS/R concentration (%vol) | 50/50 | 75/25 | 90/10 |

| B | Initial concentration Cr(VI) (mg/L) | 25 | 50 | 100 |

| C | Adsorption time (h) | 0.5 | 1.5 | 4 |

| Name | Values | ||

|---|---|---|---|

| Weight (g) | ve(cm3) | Density d/cm3 | |

| CSR90/10 | 0.1400 | 0.1267 | 0.0348 |

| CSR75/25 | 0.1892 | 0.1459 | 0.0471 |

| CSR50/50 | 0.3066 | 0.1742 | 0.0763 |

| Source | Sum of Squares | df | Mean Square | F Value | p-Value |

|---|---|---|---|---|---|

| Model | 13,405.87 | 9 | 1489.54 | 25.10 | 0.0002 |

| A: Chitosan/resole concentration at %vol | 6623.49 | 1 | 6623.49 | 111.63 | <0.0001 |

| B: Initial concentration Cr (VI) | 174.85 | 1 | 174.85 | 2.95 | 0.1297 |

| C: Adsorption time | 557.06 | 1 | 557.06 | 9.39 | 0.0182 |

| AB | 301.02 | 1 | 301.02 | 5.07 | 0.0630 |

| AC | 44.81 | 1 | 44.81 | 0.76 | 0.4136 |

| BC | 3729.75 | 1 | 3729.75 | 62.86 | <0.0001 |

| A2 | 1.83 | 1 | 1.83 | 0.031 | 0.8657 |

| B2 | 97.80 | 1 | 97.80 | 1.65 | 0.2401 |

| C2 | 17.73 | 1 | 17.73 | 0.30 | 0.6016 |

| Residual error | 415.33 | 7 | 59.33 | ||

| Lack of fit | 15.33 | 3 | 138.44 | ||

| Pure error | 0.000 | 4 | 0.000 | ||

| Cor total | 13,821.20 | 16 |

| Run | Independent Variables | ||||

|---|---|---|---|---|---|

| X1 | X2 | X3 | Experimental | Predicted RSM | |

| Chitosan/Resole Concentration (%vol) | Initial Concentration Cr (VI) (mg/L) | Adsorption Time (h) | Cr VI Removal (%) | Cr VI Removal (%) | |

| 1 | 0 | 0 | 0 | 65.87 | 57.02 |

| 2 | 0 | 0 | 0 | 65.87 | 57.02 |

| 3 | 1 | 0 | 1 | 91.41 | 75.75 |

| 4 | 1 | 0 | −1 | 81.08 | 93.09 |

| 5 | 1 | 1 | 0 | 90.68 | 68.18 |

| 6 | 0 | 0 | 0 | 65.87 | 57.02 |

| 7 | −1 | 0 | −1 | 15.97 | 31.59 |

| 8 | 0 | 1 | 1 | 5.86 | 6.64 |

| 9 | −1 | 1 | 0 | 38.78 | 23.38 |

| 10 | −1 | 0 | 1 | 30.28 | 14.25 |

| 11 | 0 | 0 | 0 | 65.87 | 57.02 |

| 12 | 1 | −1 | 0 | 85.38 | 94.74 |

| 13 | 0 | −1 | −1 | 56.41 | 33.84 |

| 14 | −1 | −1 | 0 | 0.93 | 16.54 |

| 15 | 0 | −1 | 1 | 77.47 | 73.62 |

| 16 | 0 | 1 | −1 | 86.00 | 81.1 |

| 17 | 0 | 0 | 0 | 65.87 | 57.02 |

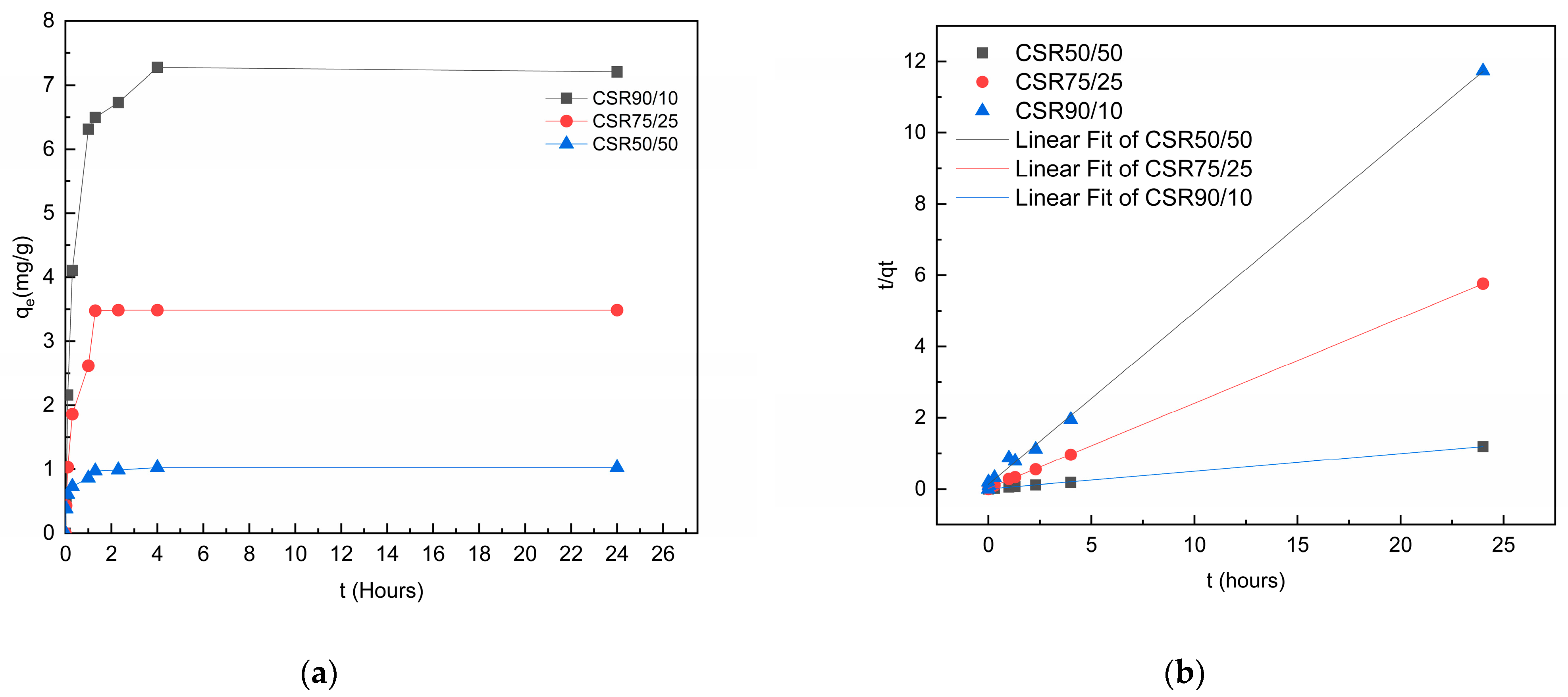

| CS/R Aerogel | Co | qe, exp | Pseudo-First-Order | Pseudo-Second-Order | ||

|---|---|---|---|---|---|---|

| (mg/L) | (mg/g) | k1 | R2 | k2 | R2 | |

| 90/10 | 25 | 7.20 | 0.0125 | 0.8926 | 0.1376 | 0.9997 |

| 50 | 8.50 | 0.0534 | 0.9011 | 0.1159 | 0.9982 | |

| 100 | 20.12 | 0.0170 | 0.8339 | 0.0669 | 0.9998 | |

| 75/25 | 25 | 3.49 | 0.0235 | 0.8334 | 0.2847 | 0.9997 |

| 50 | 6.32 | 0.0734 | 0.4513 | 0.1579 | 0.9999 | |

| 100 | 4.17 | 0.0329 | 0.8782 | 0.2393 | 0.9999 | |

| 50/50 | 25 | 1.03 | 0.0091 | 0.8378 | 0.0392 | 0.9999 |

| 50 | 1.63 | 0.0202 | 0.8288 | 0.6100 | 0.9998 | |

| 100 | 2.05 | 0.0040 | 0.3896 | 0.4833 | 0.9996 | |

| Method | Chitosan/Resole Concentration at Vol (%) | Initial Concentration Cr VI (mg/L) | Adsorption Time (h) | Predicted Value | Actual Value |

|---|---|---|---|---|---|

| RSM | 87/13 | 31.51 | 3.02 | 94.83 | 94.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Flores-Gómez, J.; Romero-Arellano, V.H.; Vazquez-Lepe, M.; Martínez-Gómez, Á.d.J.; Morales-Rivera, J. Modeling and Optimization of the Adsorption of Cr (VI) in a Chitosan-Resole Aerogel Using Response Surface Methodology. Gels 2023, 9, 197. https://doi.org/10.3390/gels9030197

Flores-Gómez J, Romero-Arellano VH, Vazquez-Lepe M, Martínez-Gómez ÁdJ, Morales-Rivera J. Modeling and Optimization of the Adsorption of Cr (VI) in a Chitosan-Resole Aerogel Using Response Surface Methodology. Gels. 2023; 9(3):197. https://doi.org/10.3390/gels9030197

Chicago/Turabian StyleFlores-Gómez, Jean, Victor Hugo Romero-Arellano, Milton Vazquez-Lepe, Álvaro de Jesús Martínez-Gómez, and Juan Morales-Rivera. 2023. "Modeling and Optimization of the Adsorption of Cr (VI) in a Chitosan-Resole Aerogel Using Response Surface Methodology" Gels 9, no. 3: 197. https://doi.org/10.3390/gels9030197

APA StyleFlores-Gómez, J., Romero-Arellano, V. H., Vazquez-Lepe, M., Martínez-Gómez, Á. d. J., & Morales-Rivera, J. (2023). Modeling and Optimization of the Adsorption of Cr (VI) in a Chitosan-Resole Aerogel Using Response Surface Methodology. Gels, 9(3), 197. https://doi.org/10.3390/gels9030197