Eco-Friendly Method for Wood Aerogel Preparation with Efficient Catalytic Reduction of 4-Nitrophenol

Abstract

:1. Introduction

2. Results and Discussion

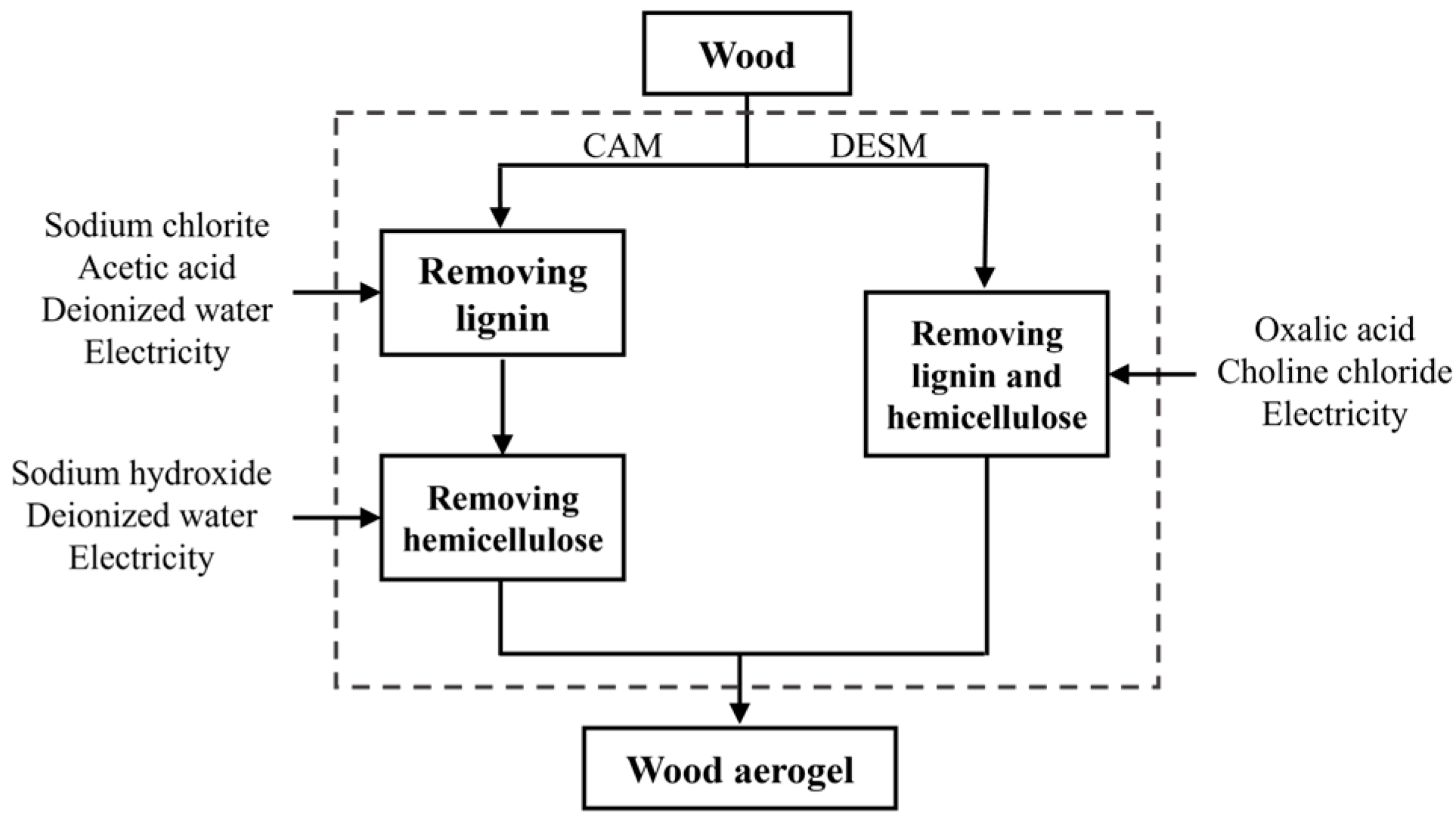

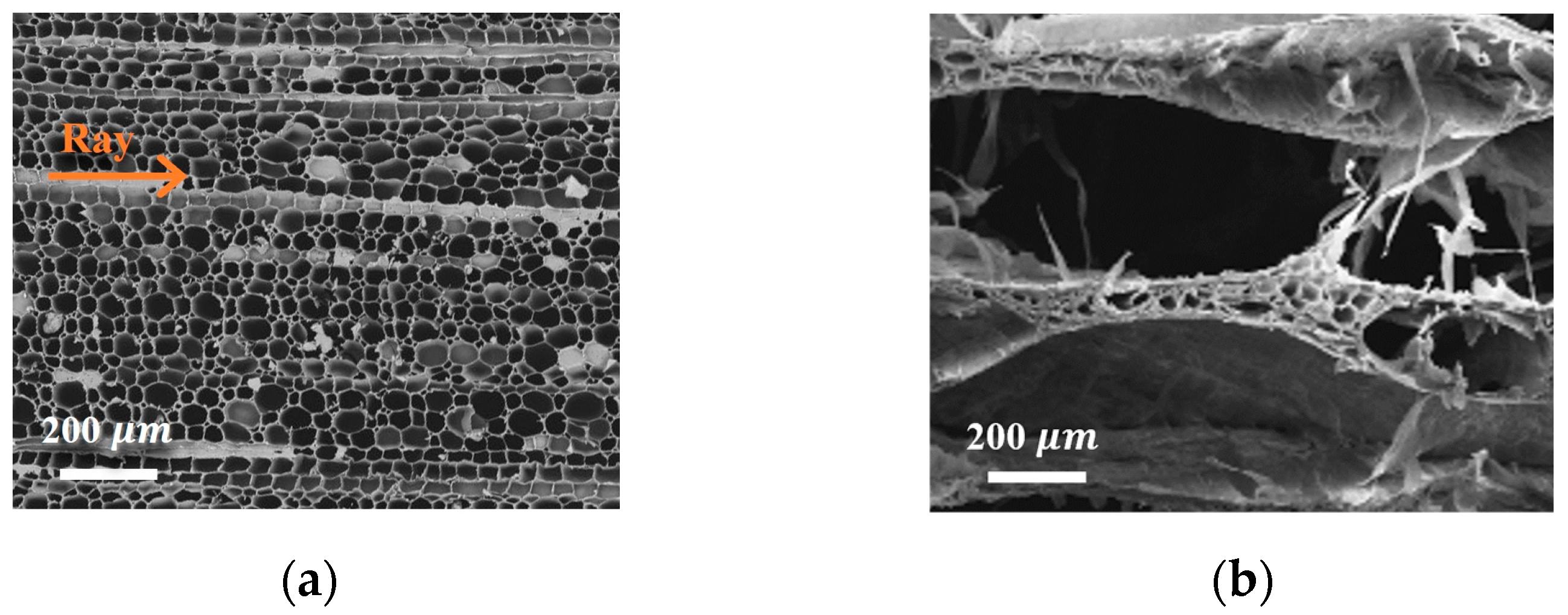

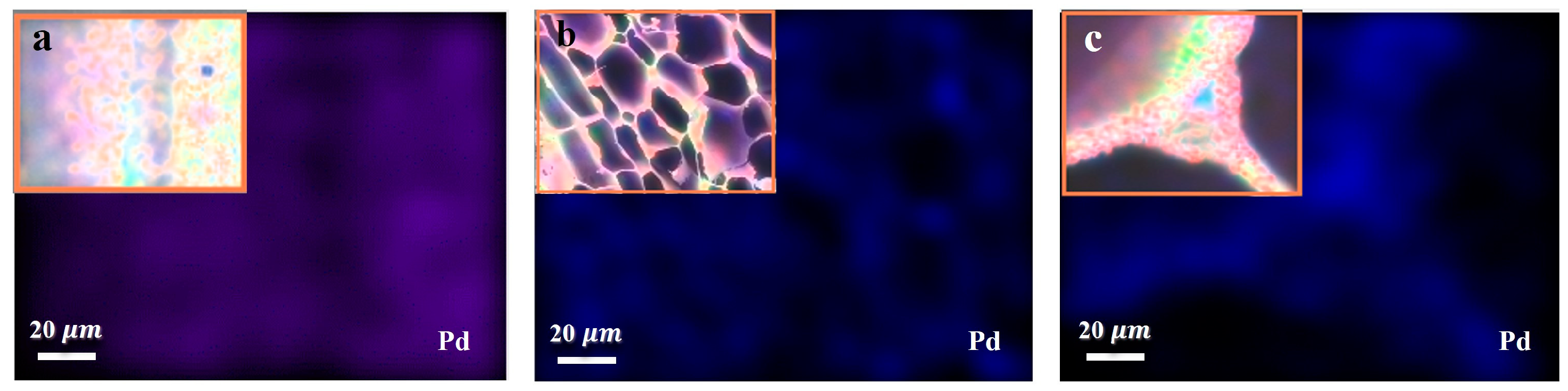

2.1. Morphological Characterization

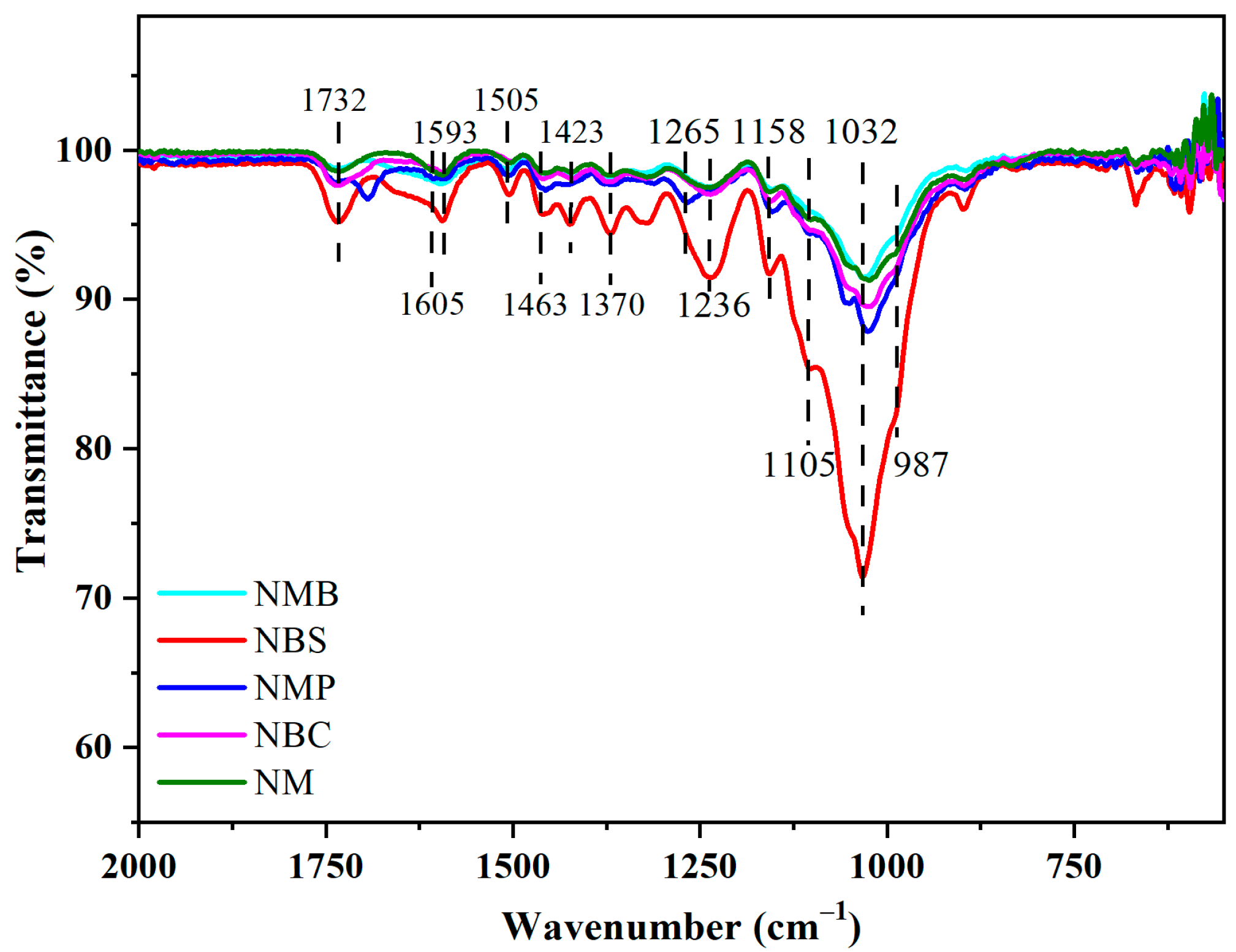

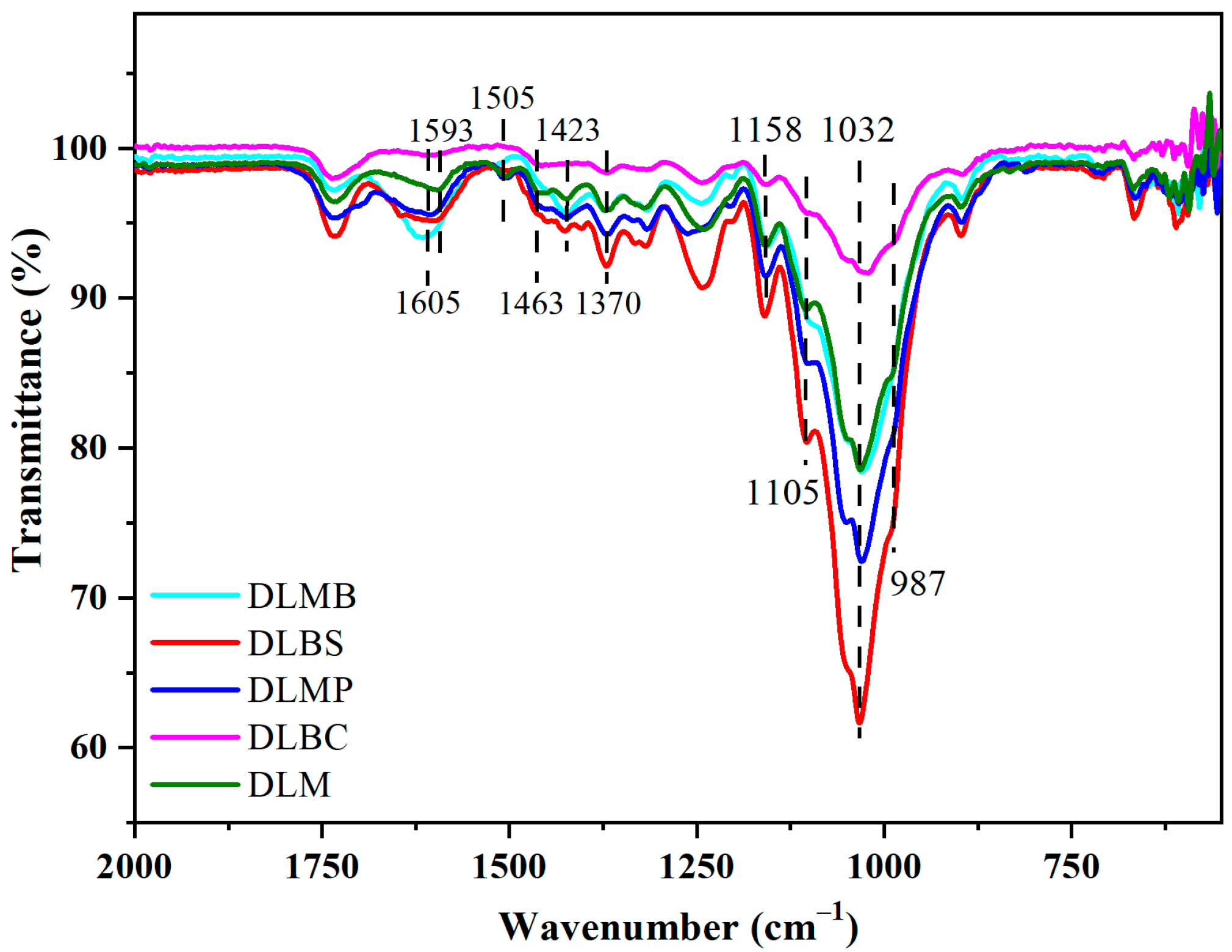

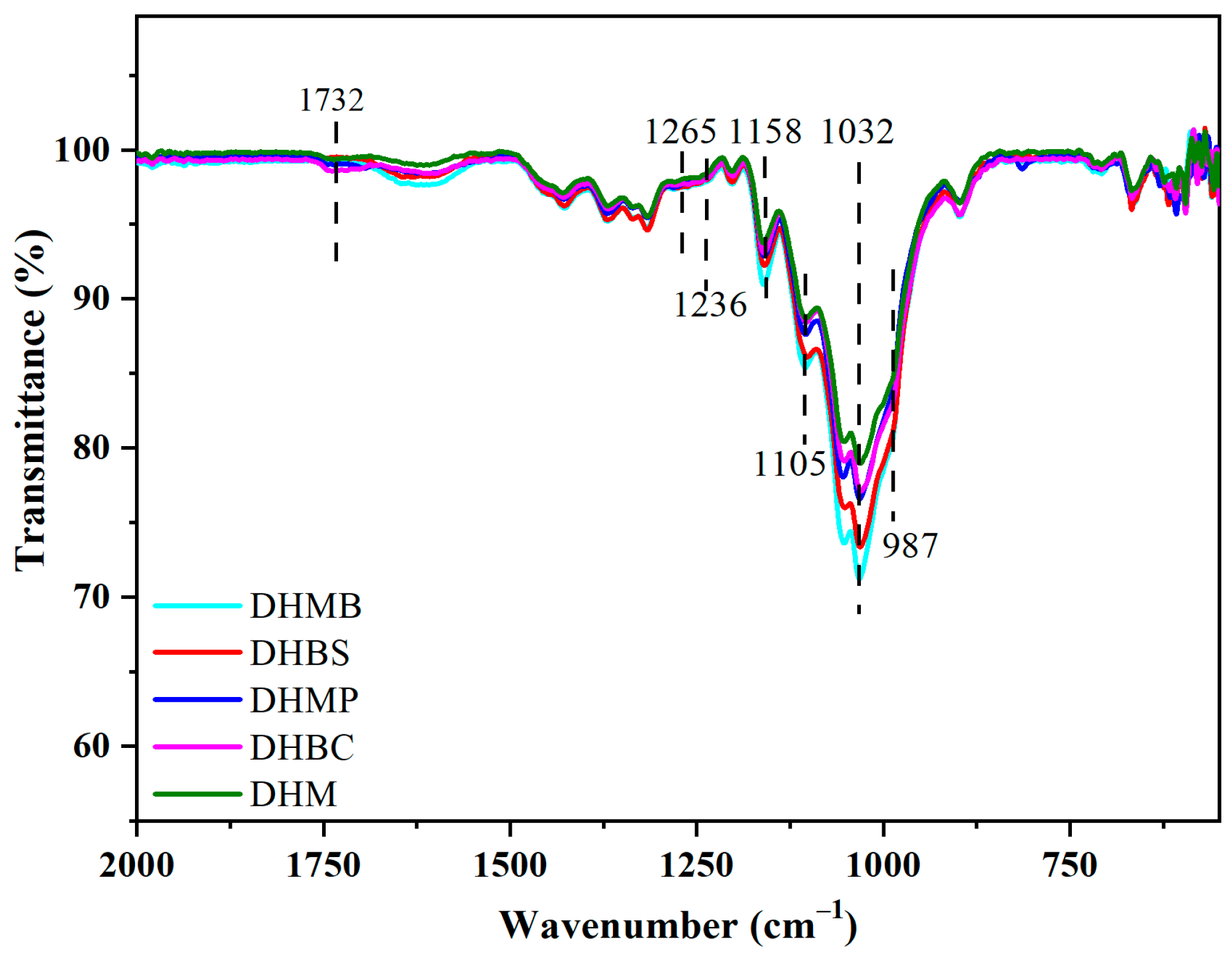

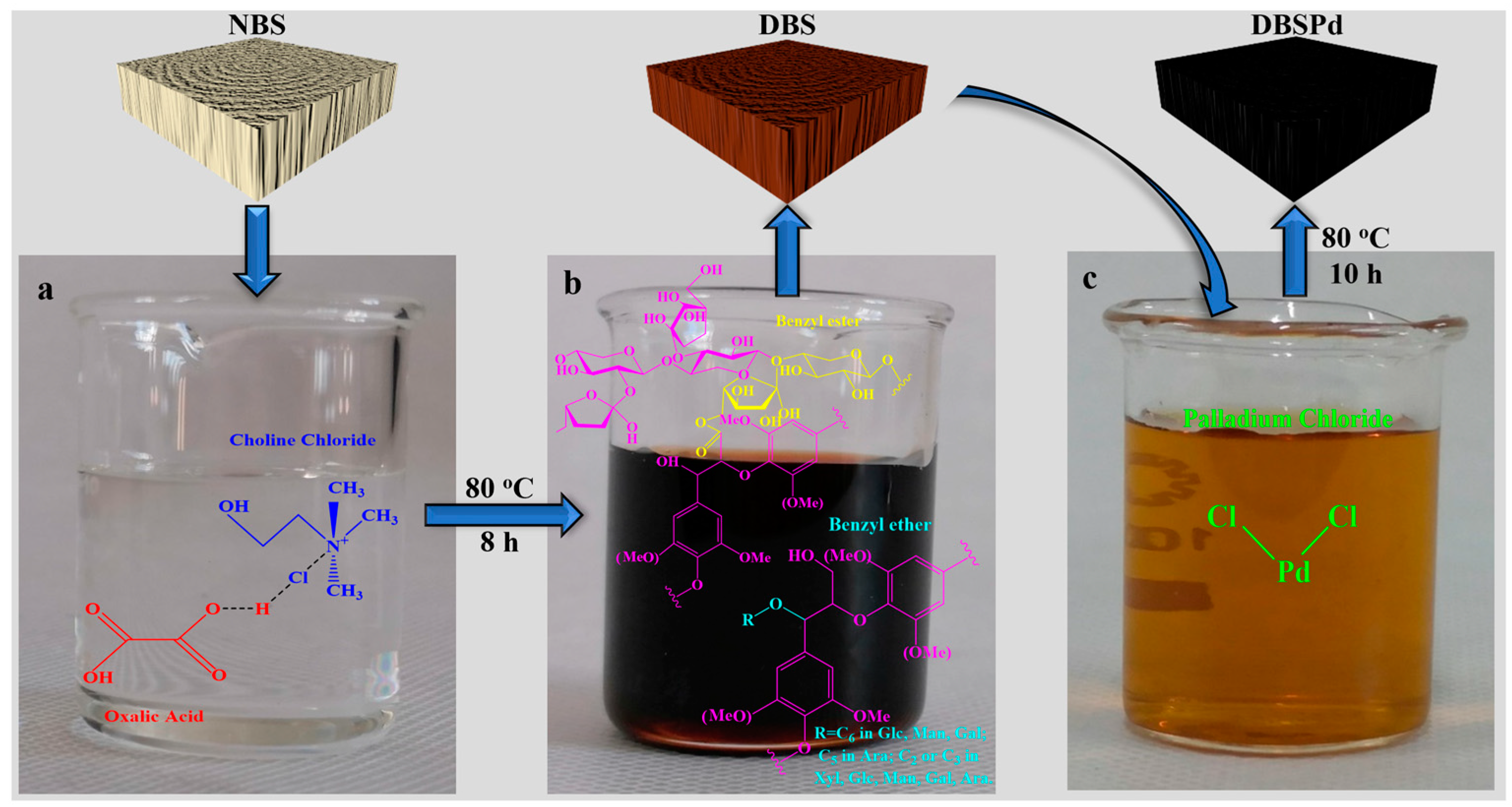

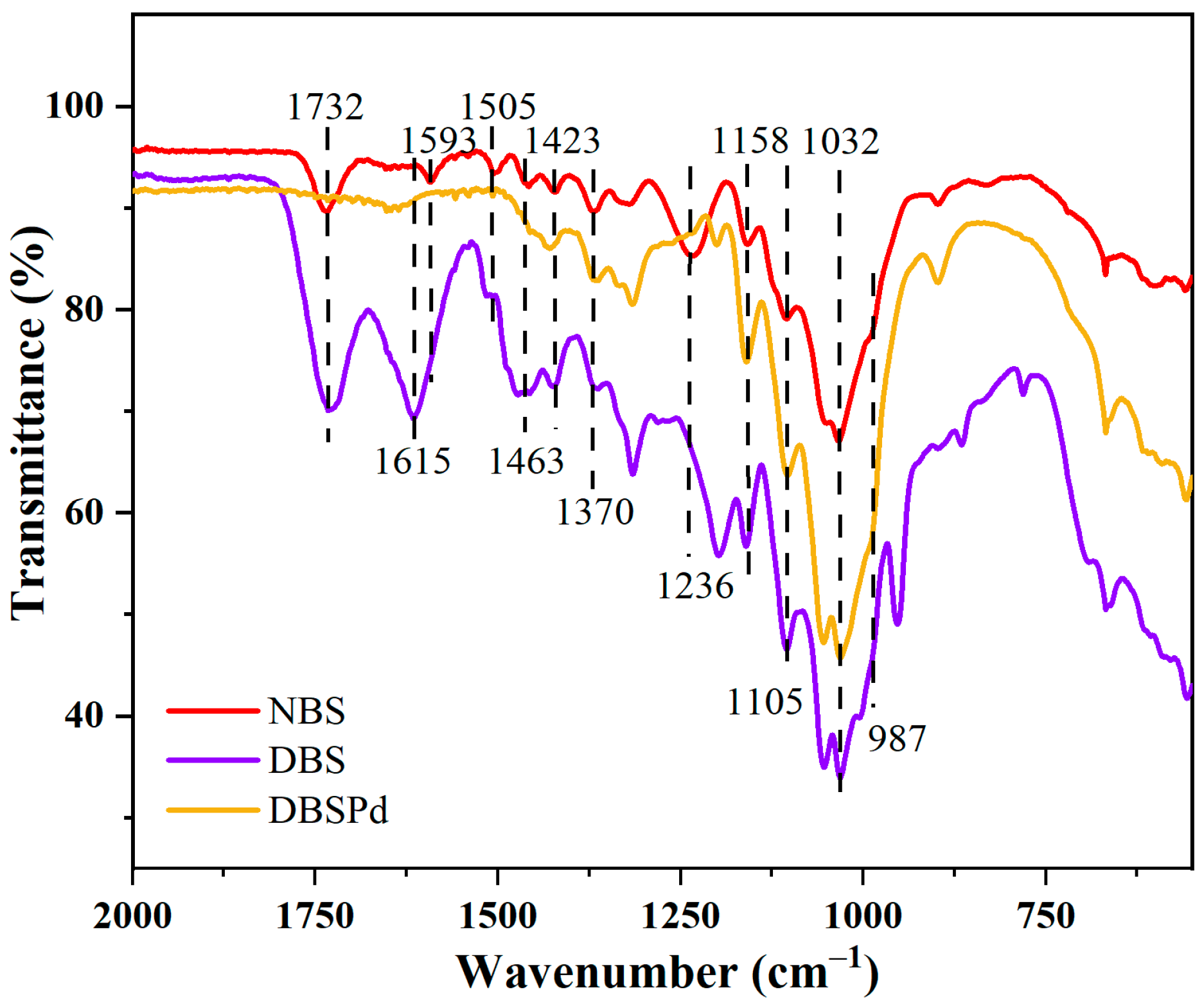

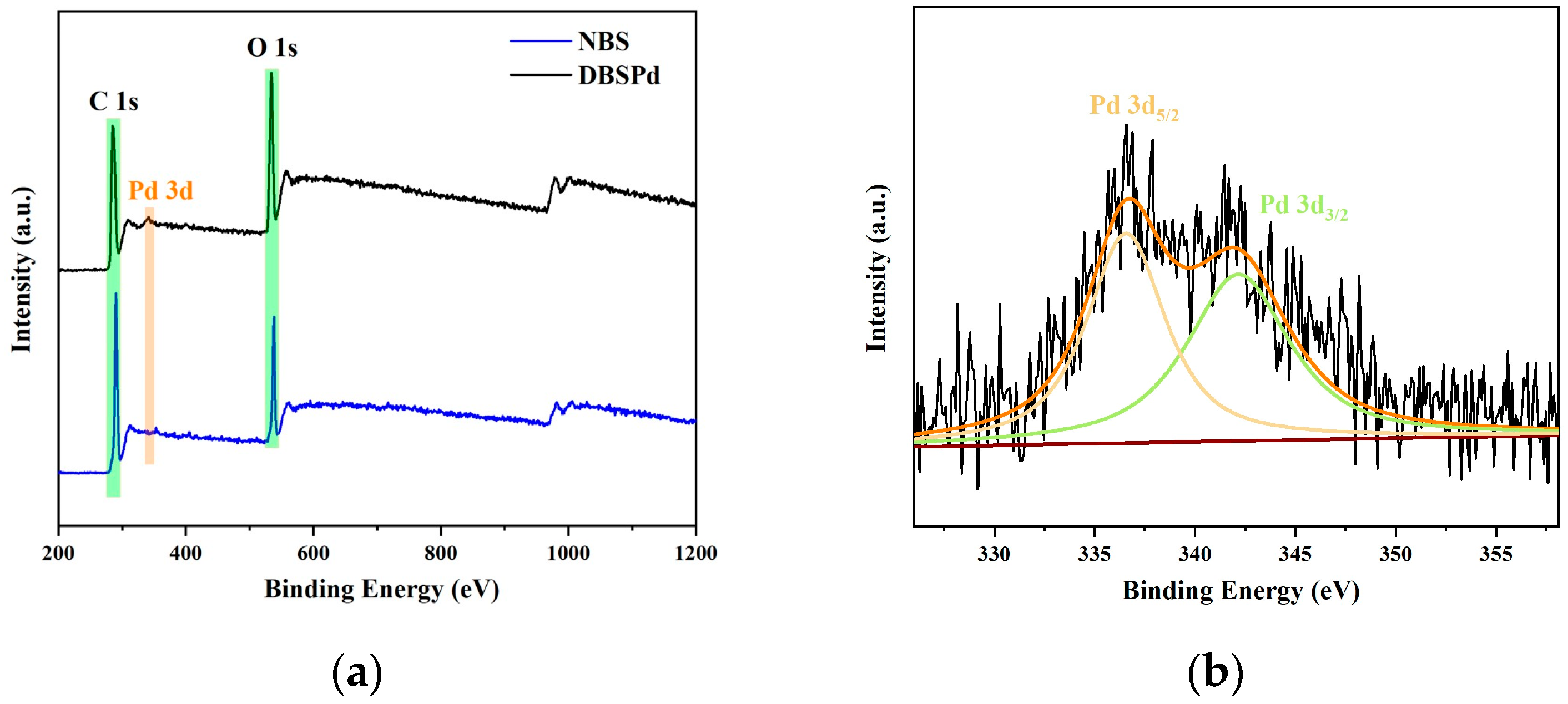

2.2. Chemical Functional Groups Characterization

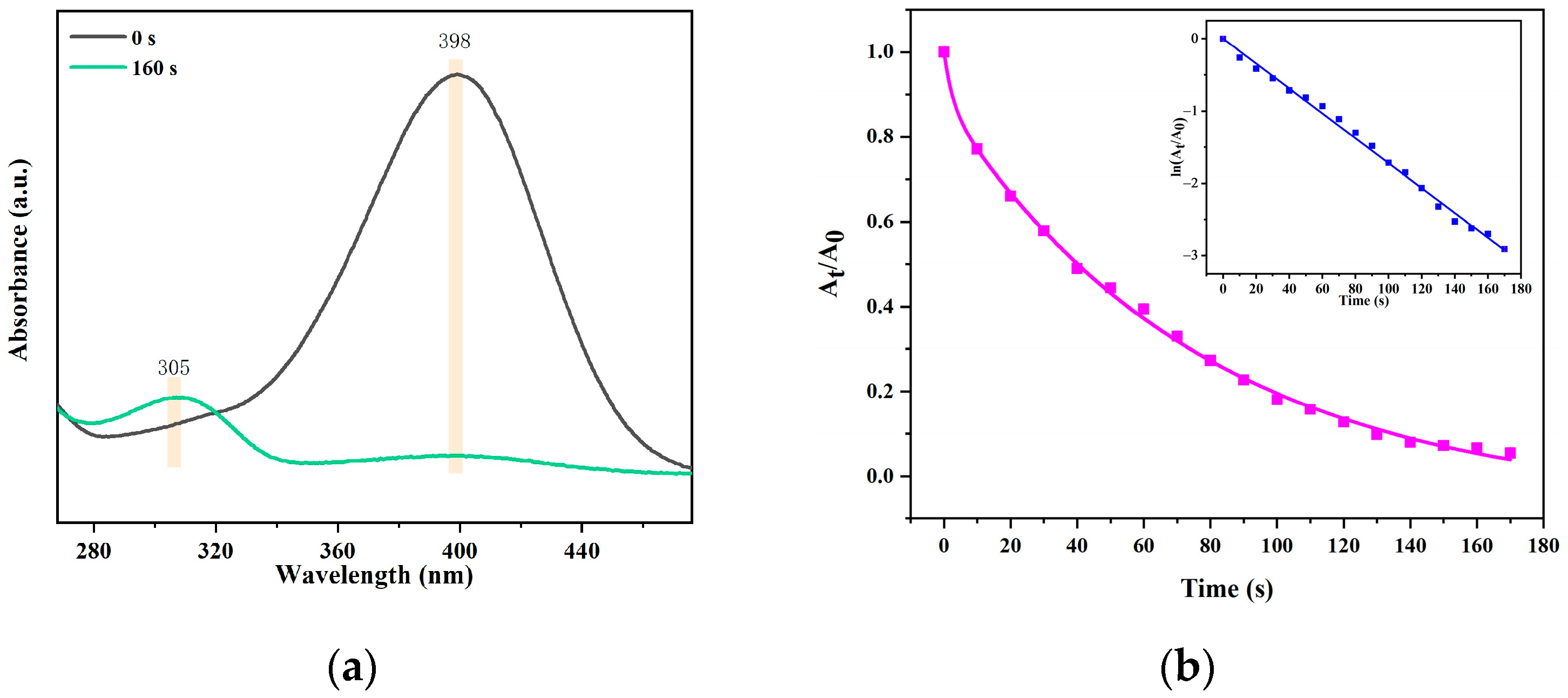

2.3. Applications in Dye Reduction

3. Conclusions

4. Materials and Methods

4.1. Materials

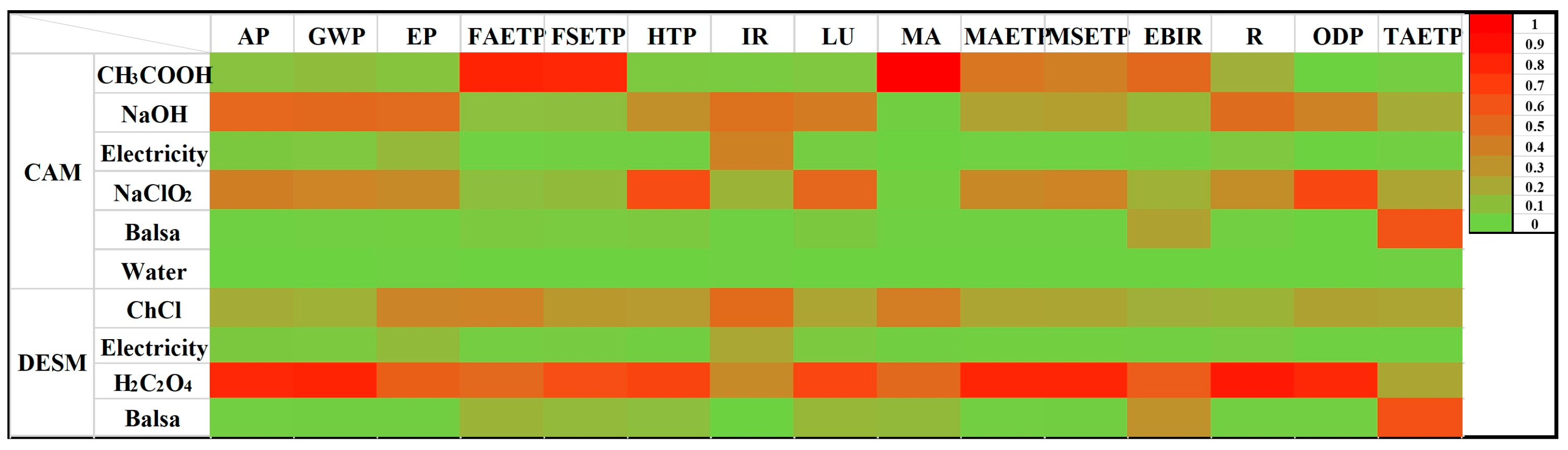

4.2. Life Cycle Assessment

4.2.1. Aim of LCA

4.2.2. Inventory of Life Cycle

4.2.3. LCA

4.2.4. Uncertainty Analysis

4.3. Material Preparation

4.3.1. Preparation of DBS and DBSPd

4.3.2. Fabrication of Delignification Wood and De-Hemicellulose

- (1)

- Preparation of delignification (DL) wood. On the basis of the diverse cell structure and chemical composition among the different wood species, MP, BS, BC, M, and MB were selected for delignification. The wood was placed in an aqueous solution of 2% sodium chlorite (NaClO2) buffered by acetic acid (pH = 4.6) and reacted at 100 °C for 6 h, the delignification of the wood was achieved and labeled as DL before the wood species;

- (2)

- Preparation of de-hemicellulose (DH) wood. The abovementioned delignified wood was placed in an 8% NaOH solution, reacted at 80 °C for 8 h, washed with deionized water after cooling to room temperature, and labeled as DH before the wood species.

4.4. Catalytic Behavioral Test

4.5. Characterizations

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khatri, A.; Peerzada, M.H.; Mohsin, M.; White, M. A review on developments in dyeing cotton fabrics with reactive dyes for reducing effluent pollution. J. Clean. Prod. 2015, 87, 50–57. [Google Scholar] [CrossRef]

- Wei, Y.; Ding, A.; Chen, Y. A novel titanium sulfate modified poly-magnesium-silicate coagulant with improved pH range for dye removal. J. Environ. Manag. 2023, 343, 118168. [Google Scholar] [CrossRef] [PubMed]

- Tripathi, P.; Tiwari, S.; Tiwari, H.; Sonwani, R.K.; Singh, R.S. Techno-economic assessment of coupling ozonation and biodegradation process for the dye wastewater treatment. J. Water. Process. Eng. 2023, 56, 104286. [Google Scholar] [CrossRef]

- Waliullah, R.; Rehan, A.I.; Awual, M.E.; Rasee, A.I.; Sheikh, M.C.; Salman, M.S.; Hossain, M.S.; Hasan, M.M.; Kubra, K.T.; Hasan, M.N. Optimization of toxic dye removal from contaminated water using chitosan-grafted novel nanocomposite adsorbent. J. Mol. Liq. 2023, 388, 122763. [Google Scholar] [CrossRef]

- Bae, S.; Gim, S.; Kim, H.; Hanna, K. Effect of NaBH4 on properties of nanoscale zero-valent iron and its catalytic activity for reduction of p-nitrophenol. Appl. Catal. B 2016, 182, 541–549. [Google Scholar] [CrossRef]

- Yang, L.; Jiao, Y.; Xu, X.; Pan, Y.; Su, C.; Duan, X.; Sun, H.; Liu, S.; Wang, S.; Shao, Z. Superstructures with Atomic-Level Arranged Perovskite and Oxide Layers for Advanced Oxidation with an Enhanced Non-Free Radical Pathway. ACS Sustain. Chem. Eng. 2022, 10, 1899–1909. [Google Scholar] [CrossRef]

- Chu, C.; Rao, S.; Ma, Z.; Han, H. Copper and cobalt nanoparticles doped nitrogen-containing carbon frameworks derived from CuO-encapsulated ZIF-67 as high-efficiency catalyst for hydrogenation of 4-nitrophenol. Appl. Catal. B 2019, 256, 117792. [Google Scholar] [CrossRef]

- Shahwan, T.; Sirriah, S.A.; Nairat, M.; Boyacı, E.; Eroğlu, A.E.; Scott, T.B.; Hallam, K.R. Green synthesis of iron nanoparticles and their application as a Fenton-like catalyst for the degradation of aqueous cationic and anionic dyes. Chem. Eng. J. 2011, 172, 258–266. [Google Scholar] [CrossRef]

- Xu, Y.; Shi, X.; Hua, R.; Zhang, R.; Yao, Y.; Zhao, B.; Liu, T.; Zheng, J.; Lu, G. Remarkably catalytic activity in reduction of 4-nitrophenol and methylene blue by Fe3O4@ COF supported noble metal nanoparticles. Appl. Catal. B 2020, 260, 118142. [Google Scholar] [CrossRef]

- Mallikarjuna, K.; Bathula, C.; Reddy, G.D.; Shrestha, N.K.; Kim, H.; Noh, Y.-Y. Au-Pd bimetallic nanoparticles embedded highly porous Fenugreek polysaccharide based micro networks for catalytic applications. Int. J. Biol. Macromol. 2019, 126, 352–358. [Google Scholar] [CrossRef]

- Jahdi, M.; Mishra, S.B.; Nxumalo, E.N.; Mhlanga, S.D.; Mishra, A.K. Smart pathways for the photocatalytic degradation of sulfamethoxazole drug using F-Pd co-doped TiO2 nanocomposites. Appl. Catal. B 2020, 267, 118716. [Google Scholar] [CrossRef]

- Elias, W.C.; Heck, K.N.; Guo, S.; Yazdi, S.; Ayala-Orozco, C.; Grossweiler, S.; Domingos, J.B.; Ringe, E.; Wong, M.S. Indium-decorated Pd nanocubes degrade nitrate anions rapidly. Appl. Catal. B 2020, 276, 119048. [Google Scholar] [CrossRef]

- Zhang, P.; Shao, C.; Zhang, Z.; Zhang, M.; Mu, J.; Guo, Z.; Liu, Y. In situ assembly of well-dispersed Ag nanoparticles (AgNPs) on electrospun carbon nanofibers (CNFs) for catalytic reduction of 4-nitrophenol. Nanoscale 2011, 3, 3357–3363. [Google Scholar] [CrossRef] [PubMed]

- Hu, H.; Xin, J.H.; Hu, H.; Wang, X.; Miao, D.; Liu, Y. Synthesis and stabilization of metal nanocatalysts for reduction reactions—A review. J. Mater. Chem. A 2015, 3, 11157–11182. [Google Scholar] [CrossRef]

- Feng, H.; Zhu, X.; Chen, R.; Liao, Q.; Liu, J.; Li, L. High-performance gas-liquid-solid microreactor with polydopamine functionalized surface coated by Pd nanocatalyst for nitrobenzene hydrogenation. Chem. Eng. J. 2016, 306, 1017–1025. [Google Scholar] [CrossRef]

- Bi, F.; Zhang, X.; Chen, J.; Yang, Y.; Wang, Y. Excellent catalytic activity and water resistance of UiO-66-supported highly dispersed Pd nanoparticles for toluene catalytic oxidation. Appl. Catal. B 2020, 269, 118767. [Google Scholar] [CrossRef]

- Pinto, R.J.; Marques, P.A.; Martins, M.A.; Neto, C.P.; Trindade, T. Electrostatic assembly and growth of gold nanoparticles in cellulosic fibres. J. Colloid. Interface Sci. 2007, 312, 506–512. [Google Scholar] [CrossRef]

- Bokare, A.D.; Chikate, R.C.; Rode, C.V.; Paknikar, K.M. Iron-nickel bimetallic nanoparticles for reductive degradation of azo dye Orange G in aqueous solution. Appl. Catal. B 2008, 79, 270–278. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, H.; House, S.D.; Jin, R.; Yang, J.C.; Jin, R. Ultrasmall Palladium Nanoclusters as Effective Catalyst for Oxygen Reduction Reaction. Chemelectrochem 2016, 3, 1225–1229. [Google Scholar] [CrossRef]

- Wang, J.; Wu, Z.; Li, T.; Ye, J.; Shen, L.; She, Z.; Liu, F. Catalytic PVDF membrane for continuous reduction and separation of p-nitrophenol and methylene blue in emulsified oil solution. Chem. Eng. J. 2018, 334, 579–586. [Google Scholar] [CrossRef]

- Sun, D.; Yang, J.; Li, J.; Yu, J.; Xu, X.; Yang, X. Novel Pd-Cu/bacterial cellulose nanofibers: Preparation and excellent performance in catalytic denitrification. Appl. Surf. Sci. 2010, 256, 2241–2244. [Google Scholar] [CrossRef]

- Kaushik, M.; Friedman, H.M.; Bateman, M.; Moores, A. Cellulose nanocrystals as non-innocent supports for the synthesis of ruthenium nanoparticles and their application to arene hydrogenation. RSC Adv. 2015, 5, 53207–53210. [Google Scholar] [CrossRef]

- Yang, Z.; Smetana, A.B.; Sorensen, C.M.; Klabunde, K.J. Synthesis and characterization of a new tiara Pd(II) thiolate complex, [Pd(SC12H25)2]6, and its solution-phase thermolysis to prepare nearly monodisperse palladium sulfide nanoparticles. Inorg. Chem. Commun. 2007, 46, 2427–2431. [Google Scholar] [CrossRef] [PubMed]

- Yu, Q.; Jiang, Z.; Yu, Y.; Yang, H.; Sun, X.; Wang, C.; Ho, S.-H. Synchronous removal of emulsions and organic dye over palladium nanoparticles anchored cellulose-based membrane. J. Environ. Manag. 2021, 288, 112402. [Google Scholar] [CrossRef]

- Plomion, C.; Leprovost, G.; Stokes, A. Wood formation in trees. Plant. Physiol. 2001, 127, 1513–1523. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Zou, Y.; Li, J.; Zhang, K.; Xia, Y.; Hui, B.; Yang, D. Wood aerogel-derived sandwich-like layered nanoelectrodes for alkaline overall seawater electrosplitting. Appl. Catal. B 2021, 293, 120215. [Google Scholar] [CrossRef]

- Zhao, L.; Chen, J.; Pan, D.; Hou, Y. Robust, Fire-Retardant, and Water-Resistant Wood/Polyimide Composite Aerogels with a Hierarchical Pore Structure for Thermal Insulation. Gels 2023, 9, 467. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Zhu, Y.; Tian, G.; Wang, A. In situ generation of silver nanoparticles within crosslinked 3D guar gum networks for catalytic reduction. Int. J. Biol. Macromol. 2015, 73, 39–44. [Google Scholar] [CrossRef]

- Meng, T.; Jiang, B.; Li, Z.; Xu, X.; Li, D.; Henzie, J.; Nanjundan, A.K.; Yamauchi, Y.; Bando, Y. Programmed design of selectively-functionalized wood aerogel: Affordable and mildew-resistant solar-driven evaporator. Nano Energy 2021, 87, 106146. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, W.; Xia, Q.; Guo, B.; Wang, Q.; Liu, S.; Liu, Y.; Li, J.; Yu, H. Efficient Cleavage of Lignin-Carbohydrate Complexes and Ultrafast Extraction of Lignin Oligomers from Wood Biomass by Microwave-Assisted Treatment with Deep Eutectic Solvent. Chemsuschem 2017, 10, 1692–1700. [Google Scholar] [CrossRef] [PubMed]

- Alvarez-Vasco, C.; Ma, R.; Quintero, M.; Guo, M.; Geleynse, S.; Ramasamy, K.K.; Wolcott, M.; Zhang, X. Unique low-molecular-weight lignin with high purity extracted from wood by deep eutectic solvents (DES): A source of lignin for valorization. Green Chem. 2016, 18, 5133–5141. [Google Scholar] [CrossRef]

- Yang, J.; Lu, X.; Yao, X.; Li, Y.; Yang, Y.; Zhou, Q.; Zhang, S. Inhibiting degradation of cellulose dissolved in ionic liquids via amino acids. Green Chem. 2019, 21, 2777–2787. [Google Scholar] [CrossRef]

- Francisco, M.; Van Den Bruinhorst, A.; Kroon, M.C. New natural and renewable low transition temperature mixtures (LTTMs): Screening as solvents for lignocellulosic biomass processing. Green Chem. 2012, 14, 2153–2157. [Google Scholar] [CrossRef]

- Xu, G.-C.; Ding, J.-C.; Han, R.-Z.; Dong, J.-J.; Ni, Y. Enhancing cellulose accessibility of corn stover by deep eutectic solvent pretreatment for butanol fermentation. Bioresour. Technol. 2016, 203, 364–369. [Google Scholar] [CrossRef] [PubMed]

- Hansen, R.N.; Rasmussen, F.N.; Ryberg, M.; Birgisdóttir, H. A systematic review of consequential LCA on buildings: The perspectives and challenges of applications and inventory modelling. Inter. J. Life Cycle Assess. 2023, 28, 131–145. [Google Scholar] [CrossRef]

- Owen, N.; Thomas, D. Infrared studies of “hard” and “soft” woods. Appl. Spectrosc. 1989, 43, 451–455. [Google Scholar] [CrossRef]

- Emandi, A.; Ileana Vasiliu, C.; Budrugeac, P.; Stamatin, I. Quantitative investigation of wood composition by integrated FT-IR and thermogravimetric methods. Cell. Chem. Technol. 2011, 45, 579. [Google Scholar]

- Lun, L.W.; Gunny, A.A.N.; Kasim, F.H.; Arbain, D. Fourier transform infrared spectroscopy (FTIR) analysis of paddy straw pulp treated using deep eutectic solvent. AIP Conf. Proc. 2017, 1835, 1. [Google Scholar]

- Zhuang, Z.; Yang, Q.; Chen, W. One-Step Rapid and Facile Synthesis of Subnanometer-Sized Pd6(C12H25S)11 Clusters with Ultra-High Catalytic Activity for 4-Nitrophenol Reduction. ACS Sustain. Chem. Eng. 2019, 7, 2916–2923. [Google Scholar] [CrossRef]

- Islam, M.T.; Dominguez, N.; Ahsan, M.A.; Dominguez-Cisneros, H.; Zuniga, P.; Alvarez, P.J.J.; Noveron, J.C. Sodium rhodizonate induced formation of gold nanoparticles supported on cellulose fibers for catalytic reduction of 4-nitrophenol and organic dyes. J. Environ. Chem. Eng. 2017, 5, 4185–4193. [Google Scholar] [CrossRef]

- Fageria, P.; Uppala, S.; Nazir, R.; Gangopadhyay, S.; Chang, C.-H.; Basu, M.; Pande, S. Synthesis of Monometallic (Au and Pd) and Bimetallic (AuPd) Nanoparticles Using Carbon Nitride (C3N4) Quantum Dots via the Photochemical Route for Nitrophenol Reduction. Langmuir 2016, 32, 10054–10064. [Google Scholar] [CrossRef] [PubMed]

- Guan, H.; Cheng, Z.; Wang, X.J. Highly compressible wood sponges with a spring-like lamellar structure as effective and reusable oil absorbents. ACS Nano 2018, 12, 10365–10373. [Google Scholar] [CrossRef] [PubMed]

- Arvidsson, R.; Nguyen, D.; Svanström, M.J. Life cycle assessment of cellulose nanofibrils production by mechanical treatment and two different pretreatment processes. Environ. Sci. Technol. 2015, 49, 6881–6890. [Google Scholar] [CrossRef]

- Wu, Z.; Lin, H.; Wang, Y.; Yu, X.; Li, J.; Xiong, Z.; Wang, Y.; Huang, Y.; Chen, T.; Liu, F. Enhanced catalytic degradation of 4-NP using a superhydrophilic PVDF membrane decorated with Au nanoparticles. RSC. Adv. 2016, 6, 62302–62309. [Google Scholar] [CrossRef]

- Gao, S.; Zhang, Z.; Liu, K.; Dong, B. Direct evidence of plasmonic enhancement on catalytic reduction of 4-nitrophenol over silver nanoparticles supported on flexible fibrous networks. Appl. Catal. B Environmental. 2016, 188, 245–252. [Google Scholar] [CrossRef]

| Input | Amount | |

|---|---|---|

| CAM | DESM | |

| NBS | 1.96 kg | 1.86 kg |

| NaClO2 | 8.73 kg | / |

| Acetic acid | 0.9813 kg | / |

| NaOH | 10.4672 kg | / |

| Deionized water | 124.2980 kg | / |

| Oxalic acid | / | 4.4072 kg |

| ChCl | / | 0.9762 kg |

| Electricity for heat | 7.6880 kWh | 4.9600 kWh |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Q.; Sun, X.; Liu, F.; Yang, Z.; Wei, S.; Wang, C.; Li, X.; He, Z.; Li, X.; Li, Y. Eco-Friendly Method for Wood Aerogel Preparation with Efficient Catalytic Reduction of 4-Nitrophenol. Gels 2023, 9, 978. https://doi.org/10.3390/gels9120978

Yu Q, Sun X, Liu F, Yang Z, Wei S, Wang C, Li X, He Z, Li X, Li Y. Eco-Friendly Method for Wood Aerogel Preparation with Efficient Catalytic Reduction of 4-Nitrophenol. Gels. 2023; 9(12):978. https://doi.org/10.3390/gels9120978

Chicago/Turabian StyleYu, Qianqian, Xiaohan Sun, Feng Liu, Zhaolin Yang, Shulei Wei, Chengyu Wang, Xin Li, Zechen He, Xiaodong Li, and Yudong Li. 2023. "Eco-Friendly Method for Wood Aerogel Preparation with Efficient Catalytic Reduction of 4-Nitrophenol" Gels 9, no. 12: 978. https://doi.org/10.3390/gels9120978

APA StyleYu, Q., Sun, X., Liu, F., Yang, Z., Wei, S., Wang, C., Li, X., He, Z., Li, X., & Li, Y. (2023). Eco-Friendly Method for Wood Aerogel Preparation with Efficient Catalytic Reduction of 4-Nitrophenol. Gels, 9(12), 978. https://doi.org/10.3390/gels9120978