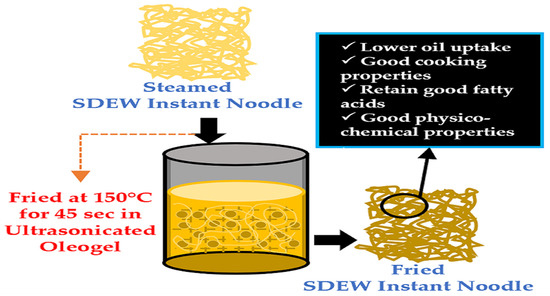

Effect of Palm Oil–Carnauba Wax Oleogel That Processed with Ultrasonication on the Physicochemical Properties of Salted Duck Egg White Fortified Instant Noodles

Abstract

:1. Introduction

2. Results and Discussion

2.1. Color Characteristics

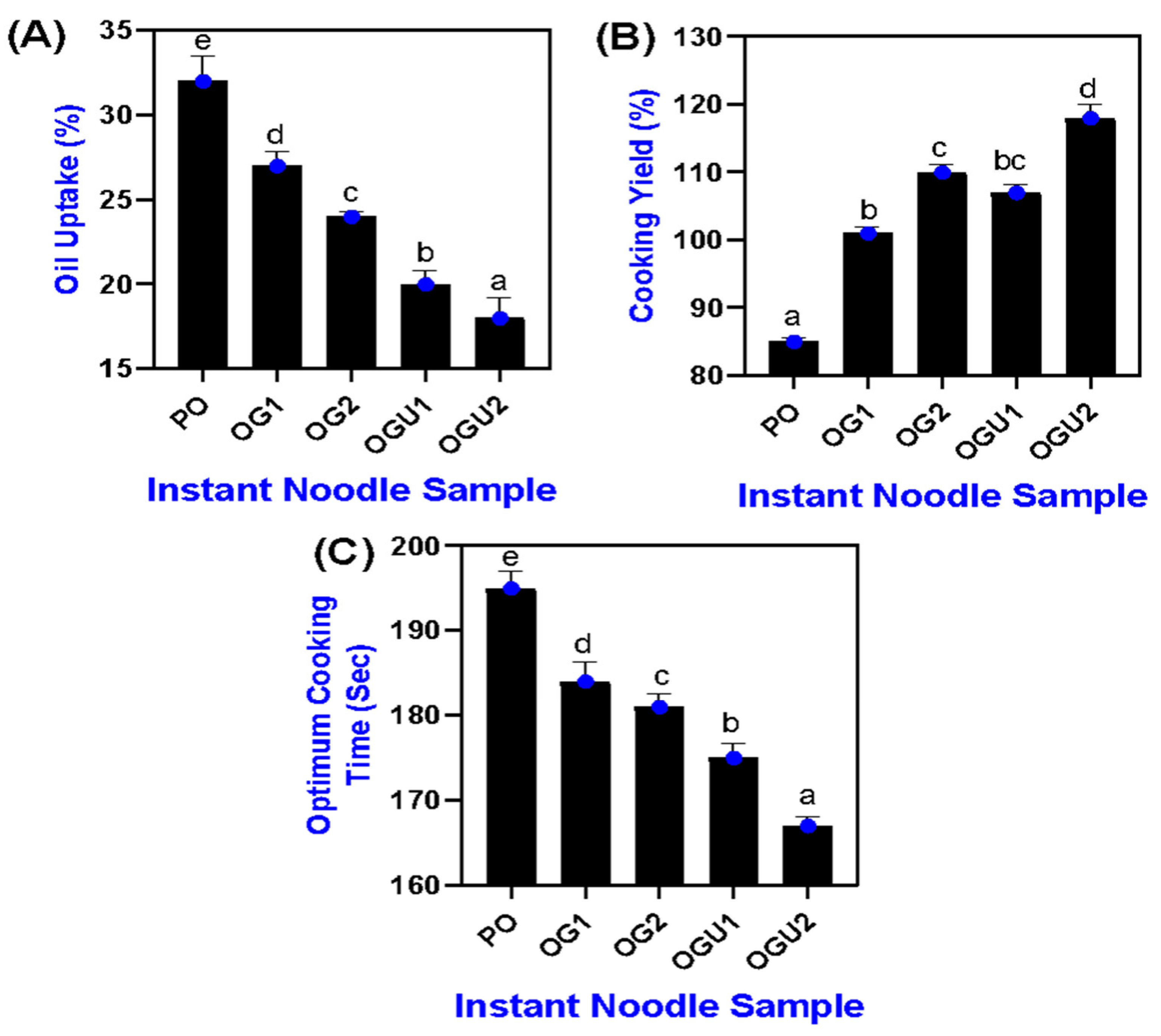

2.2. Cooking Properties

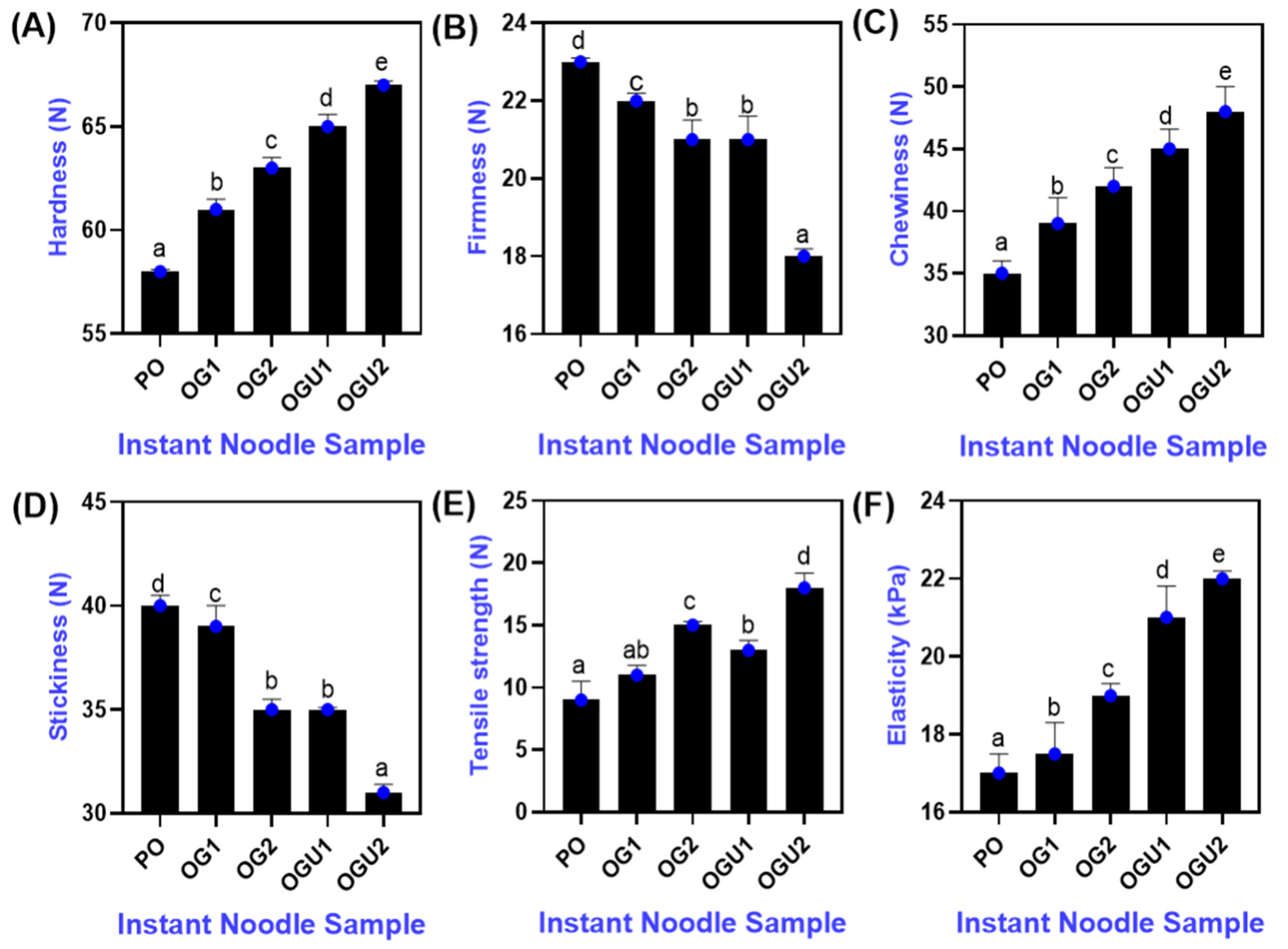

2.3. Textural Profile

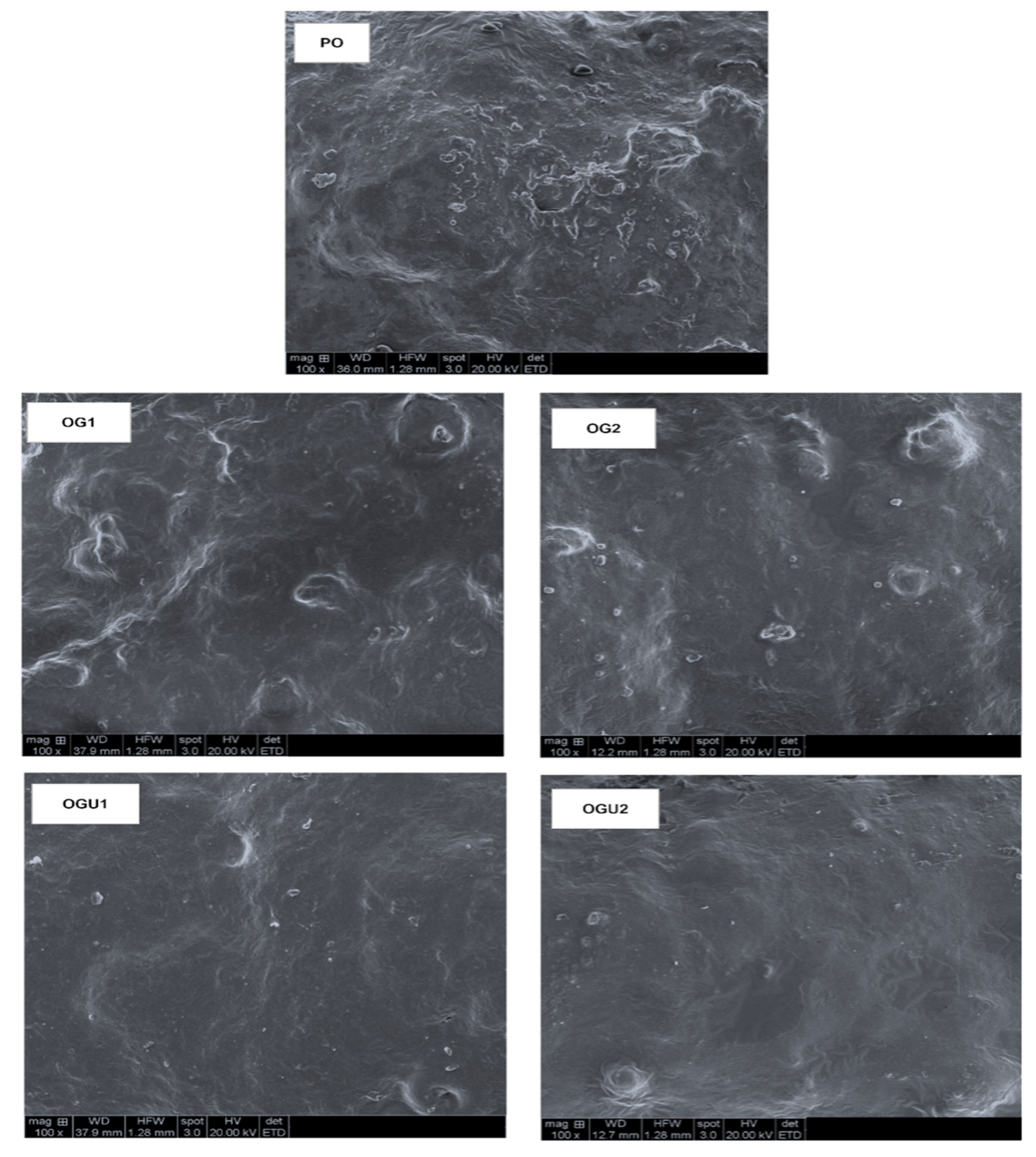

2.4. Microstructural Observation

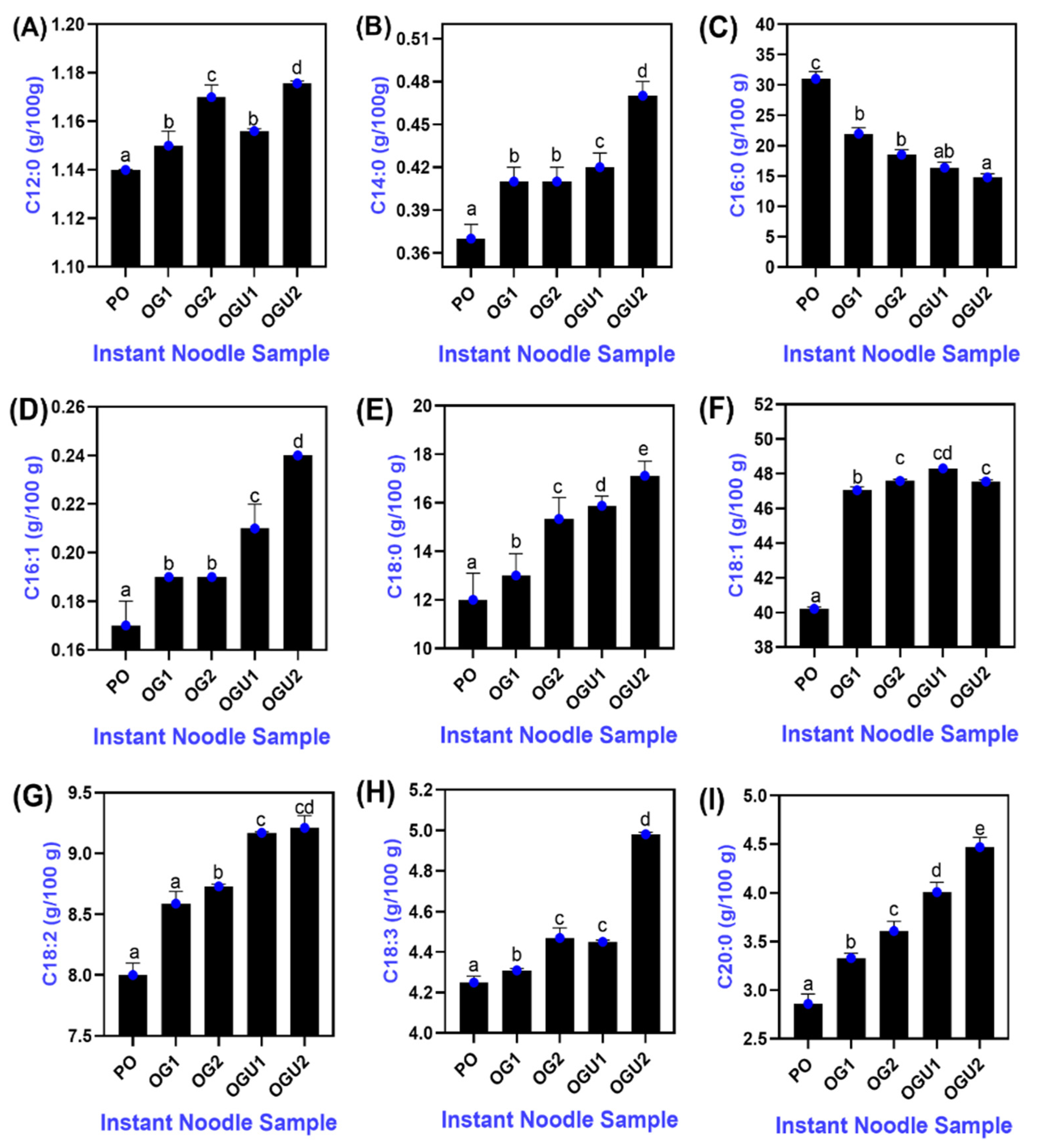

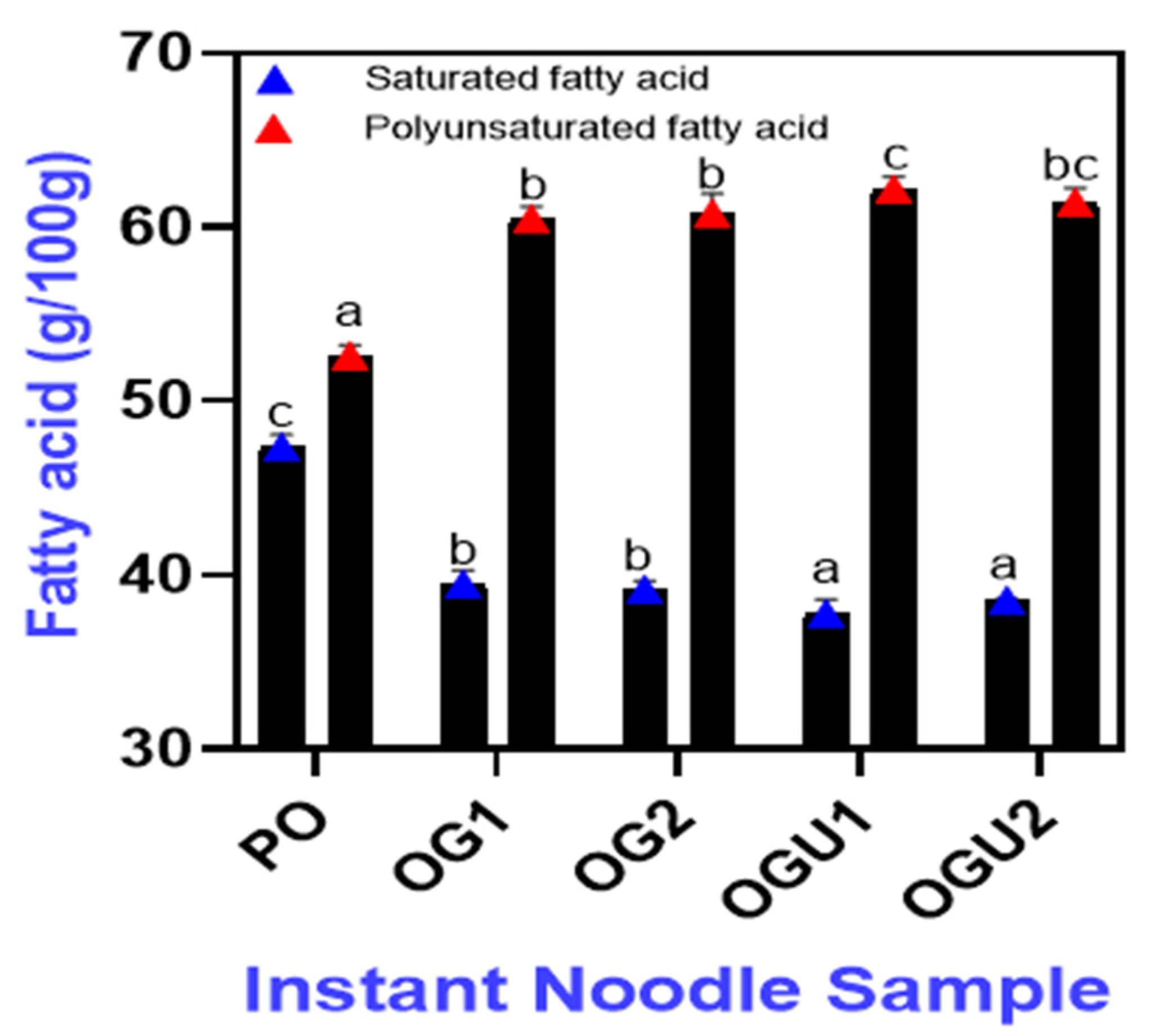

2.5. Fatty Acid Profile

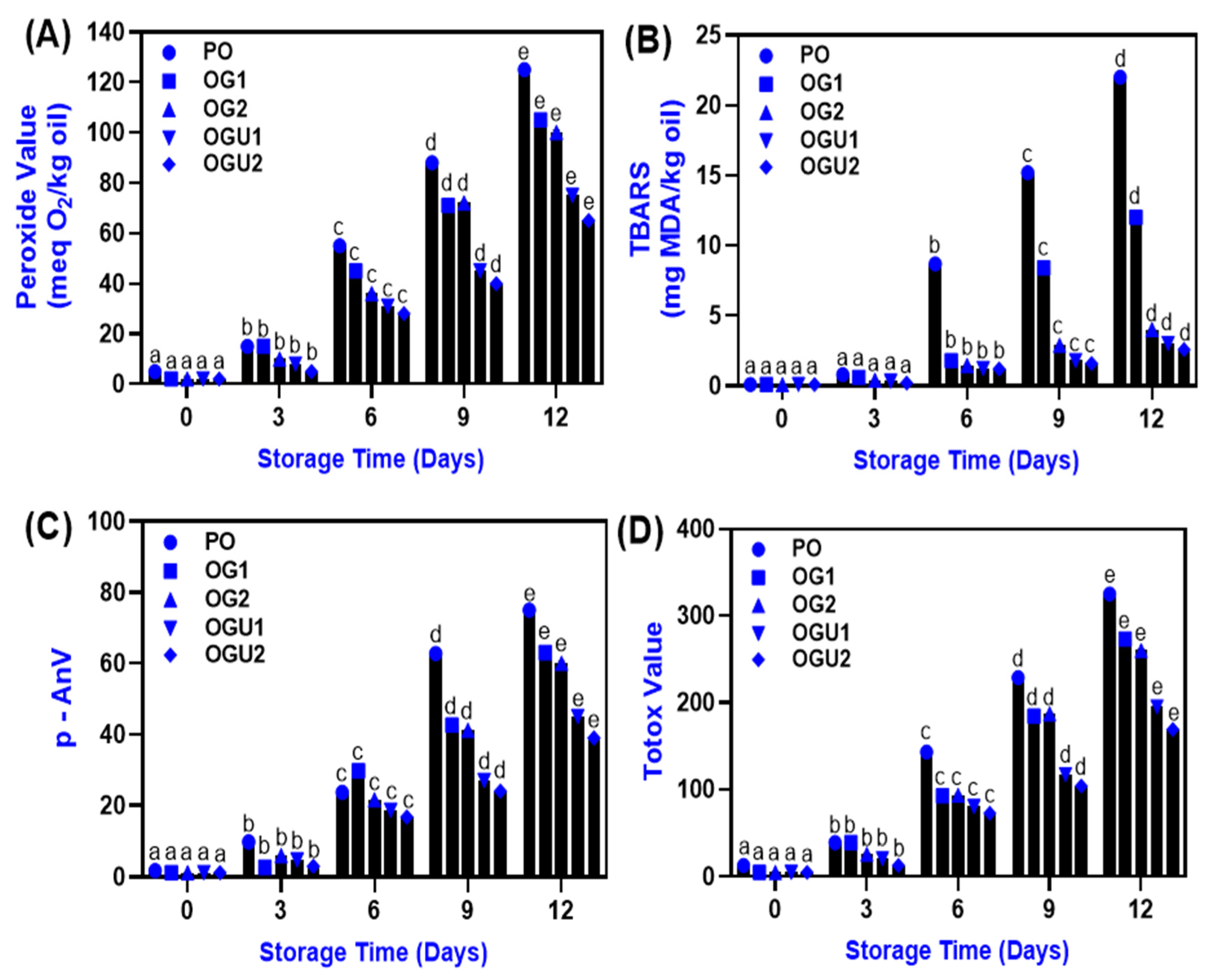

2.6. Lipid Oxidation

3. Conclusions

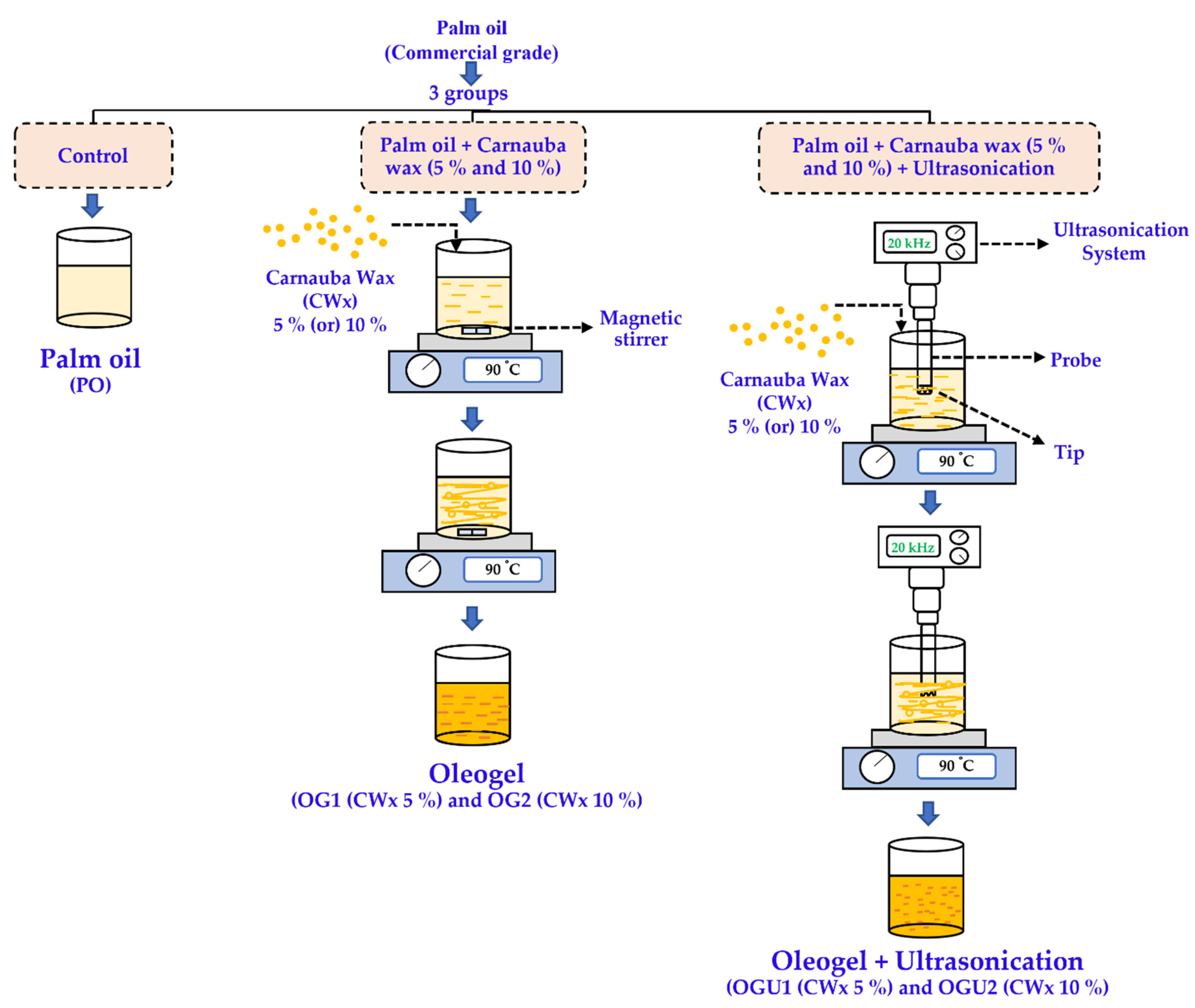

4. Materials and Methods

4.1. Raw Material, Chemicals, and Reagents

4.2. Oleogel Preparation

4.3. Preparation of SDEW Instant Noodle

4.4. Quality Analysis

4.4.1. Color Characteristics

4.4.2. Cooking Properties

4.4.3. Texture Analysis

4.4.4. Microstructure

4.4.5. Fatty Acid Analysis

4.4.6. Oxidation Stability of Oleogels

Thiobarbituric Acid Reactive Substance (TBARS)

Peroxide Value (PV)

p-Anisidine Value (p-AnV)

Totox Value

4.5. Statistics

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Adrah, K.; Adegoke, S.C.; Nowlin, K.; Tahergorabi, R. Study of oleogel as a frying medium for deep-fried chicken. Food Measur. 2022, 16, 1114–1123. [Google Scholar] [CrossRef]

- Doan, C.D.; Patel, A.R.; Tavernier, I.; De Clercq, N.; Van Raemdonck, K.; Van de Walle, D.; Delbaere, C.; Dewettinck, K. The feasibility of wax-based oleogel as a potential co-structurant with palm oil in low-saturated fat confectionery fillings. Eur. J. Lipid Sci. Technol. 2016, 118, 1903–1914. [Google Scholar] [CrossRef]

- Beaudry, G.; Macklin, C.; Roknich, E.; Sears, L.; Wiener, M.; Gheewala, S.H. Greenhouse gas assessment of palm oil mill biorefinery in Thailand from a life cycle perspective. Biomass Conv. Bioref. 2018, 8, 43–58. [Google Scholar] [CrossRef]

- Adrah, K.; Adegoke, S.C.; Tahergorabi, R. Physicochemical and microbial quality of coated raw and oleogel-fried chicken. LWT 2022, 154, 112589. [Google Scholar] [CrossRef]

- Lim, J.; Jeong, S.; Oh, I.K.; Lee, S. Evaluation of soybean oil-carnauba wax oleogels as an alternative to high saturated fat frying media for instant fried noodles. LWT 2017, 84, 788–794. [Google Scholar] [CrossRef]

- Venkatachalam, K. Influence of prolonged salting on the physicochemical properties of duck egg white. Braz. Arch. Biol. Technol. 2018, 61, e18180314. [Google Scholar] [CrossRef] [Green Version]

- Lekjing, S.; Venkatachalam, K. Physicochemical, volatile, amino acid, and sensory profiles of instant noodles incorporated with salted duck egg white from various salting durations. Int. Food Res. J. 2022, 29, 283–299. [Google Scholar] [CrossRef]

- Moghtadaei, M.; Soltanizadeh, N.; Goli, S.A.H. Production of sesame oil oleogels based on beeswax and application as partial substitutes of animal fat in beef burger. Food Res. Int. 2018, 108, 368–377. [Google Scholar] [CrossRef] [PubMed]

- Aydeniz Guneser, B.; Yılmaz, E.; Uslu, E.K. Sunflower oil–beeswax oleogels are promising frying medium for potato strips. Eur. J. Lipid Sci. Technol. 2021, 123, 2100063. [Google Scholar] [CrossRef]

- Li, L.; Taha, A.; Geng, M.; Zhang, Z.; Su, H.; Xu, X.; Pan, S.; Hu, H. Ultrasound-assisted gelation of β-carotene enriched oleogels based on candelilla wax-nut oils: Physical properties and in-vitro digestion analysis. Ultrason. Sonochem. 2021, 79, 105762. [Google Scholar] [CrossRef]

- de Freitas, C.A.S.; de Sousa, P.H.M.; Soares, D.J.; da Silva, J.Y.G.; Benjamin, S.R.; Guedes, M.I.F. Carnauba wax uses in food—A review. Food Chem. 2019, 291, 38–48. [Google Scholar] [CrossRef] [PubMed]

- Natarajan, S.; Ponnusamy, V. A review on the applications of ultrasound in food processing. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Yi, B.; Kim, M.-J.; Lee, S.Y.; Lee, J. Physicochemical properties and oxidative stability of oleogels made of carnauba wax with canola oil or beeswax with grapeseed oil. Food Sci. Biotechnol. 2017, 26, 79–87. [Google Scholar] [CrossRef] [PubMed]

- Awad, T.S.; Moharram, H.A.; Shaltout, O.E.; Asker, D.; Youssef, M.M. Applications of ultrasound in analysis, processing and quality control of food: A review. Food Res. Int. 2012, 48, 410–427. [Google Scholar] [CrossRef]

- Agregán, R.; Barba, F.J.; Gavahian, M.; Franco, D.; Khaneghah, A.M.; Carballo, J.; Ferreira, I.C.; da Silva Barretto, A.C.; Lorenzo, J.M. Fucus vesiculosus extracts as natural antioxidants for improvement of physicochemical properties and shelf life of pork patties formulated with oleogels. J. Sci. Food Agric. 2019, 99, 4561–4570. [Google Scholar] [CrossRef] [Green Version]

- Khazaei, N.; Esmaiili, M.; Emam-Djomeh, Z. Effect of active edible coatings made by basil seed gum and thymol on oil uptake and oxidation in shrimp during deep-fat frying. Carb. Polym. 2016, 137, 249–254. [Google Scholar] [CrossRef]

- Asenstorfer, R.E.; Appelbee, M.J.; Mares, D.J. Impact of protein on darkening in yellow alkaline noodles. J. Agric. Food Chem. 2010, 58, 4500–4507. [Google Scholar] [CrossRef]

- Hanabusa, K.; Suzuki, M. Development of low-molecular-weight gelators and polymer-based gelators. Polym. J. 2014, 46, 776–782. [Google Scholar] [CrossRef]

- Sadiq, U.; Gill, H.; Chandrapala, J. Casein micelles as an emerging delivery system for bioactive food components. Foods 2021, 10, 1965. [Google Scholar] [CrossRef]

- Rajasekaran, B.; Subbiah, B.; Stephen, N.M.; Nagarajan, M.; Muniasamy, S. Design, fabrication, and validation of ohmic heater to process green mussel meat. J. Food Proc. Preserv. 2021, 45, e15511. [Google Scholar] [CrossRef]

- Oh, I.; Lee, S. Rheological, microstructural, and tomographical studies on the rehydration improvement of hot air-dried noodles with oleogel. J. Food Eng. 2020, 268, 109750. [Google Scholar] [CrossRef]

- Mellema, M. Mechanism and reduction of fat uptake in deep-fat fried foods. Trends Food Sci. Technol. 2003, 14, 364–373. [Google Scholar] [CrossRef]

- Thammathongchat, S.; Fukuoka, M.; Watanabe, H. An innovative noodle: Gelatinized at the core, leaving the surface ungelatinized. J. Food Eng. 2005, 70, 27–33. [Google Scholar] [CrossRef]

- Chandra, S.; Singh, S.; Kumari, D. Evaluation of functional properties of composite flours and sensorial attributes of composite flour biscuits. J. Food Sci. Technol. 2015, 52, 3681–3688. [Google Scholar] [CrossRef] [PubMed]

- Sozer, N.; Dalgic, A.C.; Kaya, A. Thermal, textural and cooking properties of spaghetti enriched with resistant starch. J. Food Eng. 2007, 81, 476–484. [Google Scholar] [CrossRef]

- Kumalarasi, R.; Sholichah, E.; Haryanto, A.; Hanifah, U.; Mayasti, I.K.N.; Yuniar, D.A. Evaluation of uniformity of physical and texture quality in manufacture of gluten-free noodles using single-screw extruders: A case study on local SMEs in Subang district-Indonesia. Food Sci. Technol. Campinas 2022, 42, e82241. [Google Scholar] [CrossRef]

- Marciniak-Lukasiak, K.; Zbikowska, A.; Kupiec, M.; Brzezinska, M.; Szymanska, I.; Lukasiak, P. The influence of rice protein, hemp protein and transglutaminase addition on the quality of instant fried noodles. Appl. Sci. 2021, 11, 9070. [Google Scholar] [CrossRef]

- Wang, J.; Li, A.; Hu, J.; Zhang, B.; Liu, J.; Zhang, Y.; Wang, S. Effect of frying process on nutritional property, physicochemical quality, and in vitro digestibility of commercial instant noodles. Front. Nutr. 2022, 9, 823432. [Google Scholar] [CrossRef]

- Barak, S.; Mudgil, D.; Khatkar, B.S. Effect of compositional variation of gluten proteins and rheological characteristics of wheat flour on the textural quality of white salted noodles. Int. J. Food Prop. 2014, 17, 731–740. [Google Scholar] [CrossRef]

- Jung, D.; Oh, I.; Lee, J.; Lee, S. Utilization of butter and oleogel blends in sweet pan bread for saturated fat reduction: Dough rheology and baking performance. LWT 2020, 125, 109194. [Google Scholar] [CrossRef]

- Adhikari, B.; Howes, T.; Bhandari, B.R.; Truong, V. Stickiness in foods: A review of mechanisms and test methods. Int. J. Food Prop. 2001, 4, 1–33. [Google Scholar] [CrossRef]

- Jang, A.; Kim, Y.J.; Lee, S. Rheological, thermal conductivity, and microscopic studies on porous-structured noodles for shortened cooking time. LWT 2016, 74, 1–6. [Google Scholar] [CrossRef]

- Khatkar, B.A.; Kaur, A. Effect of protein incorporation on functional, thermal, textural and overall quality characteristics of instant noodles. J. Food Measure. Charact. 2018, 12, 2218–2229. [Google Scholar] [CrossRef]

- Thanatuksorn, P.; Pradistsuwana, C.; Jantawat, P.; Suzuki, T. Effect of Surface Roughness on Post-Frying Oil Absorption in Wheat Flour and Water Food Model. J. Sci. Food Agric. 2005, 85, 2574–2580. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, M.; Wang, W.; Teng, A.; Liu, A.; Ye, R.; Liu, Y.; Wang, K.; Ding, J.; Wu, X. An attempt of using β-sitosterol-corn oil oleogels to improve water barrier properties of gelatin film. J. Food Sci. 2019, 84, 1447–1455. [Google Scholar] [CrossRef]

- Da Silva, T.L.T.; Danthine, S. Effect of high-intensity ultrasound on the oleogelation and physical properties of high melting point monoglycerides and triglycerides oleogels. J. Food Sci. 2021, 86, 343–365. [Google Scholar] [CrossRef]

- Fradique, M.; Batista, A.P.; Nunes, M.C.; Gouveia, L.; Bandarra, N.M.; Raymundo, A. Isochrysis galbana and diacronema vlkianum biomass incorporation in pasta products as PUFA’S source. LWT 2013, 50, 312–319. [Google Scholar] [CrossRef] [Green Version]

- Mahmud, A.; Girmatsion, M.; Abraha, B.; Mohammed, J.K.; Yang, F.; Xia, W. Fatty acid and amino acid profiles and digestible indispensable amino acid score of grass carp (Ctenopharyngodon Idella) protein concentrate supplemented noodles. Food Meas. 2020, 14, 2370–2379. [Google Scholar] [CrossRef]

- Liu, L.-Y.; Yang, M.-H.; Lin, J.-H.; Lee, M.-H. Lipid Profile and Oxidative Stability of Commercial Egg Products. J. Food Drug Anal. 2020, 13, 7. [Google Scholar] [CrossRef]

- Arendt, E.K.; Zannini, E. Cereal Grains for the Food and Beverage Industries; Elsevier: Amsterdam, The Netherlands, 2013; ISBN 978-0-85709-892-4. [Google Scholar]

- Ganesan, P.; Kaewmanee, T.; Benjakul, S.; Baharin, B.S. Comparative study on the nutritional value of pidan and salted duck egg. Korean J. Food Sci. Anim. Resour. 2014, 34, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Kaewmanee, T.; Benjakul, S.; Visessanguan, W. Changes in chemical composition, physical properties and microstructure of duck egg as influenced by salting. Food Chem. 2009, 112, 560–569. [Google Scholar] [CrossRef]

- Rodrigues, V.P. Copernicia cerifera Mart.: Aspectos Químicos e Farmacológicos de uma Palmeira Brasileira; Universidade Federal do Rio de Janeiro: Rio de Janeiro, Brazil, 2004; p. 155. [Google Scholar]

- Perez-Alvarez, A.J.; Roldan-Verdu, A.; Martinez-Mayoral, A.; Sayas-Barbera, E.; de Vera, N.C.; Viruda-Martos, M.; Fernandez-Lopez, J. Chia oleogel as a potential new ingredient for healthy cooked meat sausages. Proceedings 2021, 70, 76. [Google Scholar]

- Park, C.; Bemer, L.H.; Maleky, F. Oxidative stability of rice bran wax oleogels and an oleogel cream cheese product. J. Am. Oil Chem. Soc. 2018, 95, 1267–1275. [Google Scholar] [CrossRef]

- Aliasl Khiabani, A.; Tabibiazar, M.; Roufegarinejad, L.; Hamishehkar, H.; Alizadeh, A. Preparation and characterization of carnauba wax/adipic acid oleogel: A new reinforced oleogel for application in cake and beef burger. Food Chem. 2020, 333, 127446. [Google Scholar] [CrossRef] [PubMed]

- Rajasekaran, B.; Singh, A.; Nagarajan, M.; Benjakul, S. Effect of chitooligosaccharide and α-tocopherol on physical properties and oxidative stability of shrimp oil-in-water emulsion stabilized by bovine serum albumin-chitosan complex. Food Control 2022, 137, 108899. [Google Scholar] [CrossRef]

- Öğütcü, M.; Arifoğlu, N.; Yılmaz, E. Storage stability of cod liver oil organogels formed with beeswax and carnauba wax. Int. J. Food Sci. Technol. 2015, 50, 404–412. [Google Scholar] [CrossRef]

- Lim, J.; Hwang, H.; Lee, S. Oil-structuring characterization of natural waxes in canola oil oleogels: Rheological, thermal, and oxidative properties. Appl. Biol. Chem. 2017, 60, 17–22. [Google Scholar] [CrossRef]

- Wei, F.; Miao, J.; Tan, H.; Feng, R.; Zheng, Q.; Cao, Y.; Lan, Y. Oleogel-structured emulsion for enhanced oxidative stability of perilla oil: Influence of crystal morphology and cooling temperature. LWT 2021, 139, 110560. [Google Scholar] [CrossRef]

- Hu, Y.; Zhao, G.; Yin, F.; Liu, Z.; Wang, J.; Qin, L.; Zhou, D.; Shahidi, F.; Zhu, B. Effects of roasting temperature and time on aldehyde formation derived from lipid oxidation in scallop (Patinopecten yessoensis) and the deterrent effect by antioxidants of bamboo leaves. Food Chem. 2022, 369, 130969. [Google Scholar] [CrossRef]

- Nagarajan, M.; Rajasekaran, B.; Benjakul, S.; Venkatachalam, K. Influence of chitosan-gelatin edible coating incorporated with longkong pericarp extract on refrigerated black tiger shrimp (penaeus monodon). Curr. Res. Food Sci. 2021, 4, 345–353. [Google Scholar] [CrossRef]

- Zahran, H.; Bat, H.; Şahineşilçubuk, N. Influence of wall material combination on the lipid oxidation of the hazelnut oil microcapsules. Discov. Food 2022, 2, 17. [Google Scholar] [CrossRef]

- Pan, J.; Tang, L.; Dong, Q.; Li, Y.; Zhang, H. Effect of oleogelation on physical properties and oxidative stability of camellia oil-based oleogels and oleogel emulsions. Food Res. Int. 2021, 140, 110057. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Wang, T.; Gong, Y.; Wang, W.; Wang, X.; Yu, D.; Wu, F.; Wang, L. Effect of ultrasound on the structural characteristics and oxidative stability of walnut oil oleogel coated with soy protein isolate-phosphatidylserine. Ultrason. Sonochem. 2022, 83, 105945. [Google Scholar] [PubMed]

- Tiga, H.B.; Hwang, H.; Lee, S. Thermal and pasting properties of Quinoa—Wheat flour blends and their effects on production of extruded instant noodles. J. Cereal Sci. 2021, 60, 17–22. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC International; AOAC International: Washongton, DC, USA, 2005. [Google Scholar]

- American Association of Cereal Chemists (AACC). Approved Methods of the American Association of Cereal Chemists, 13th ed.; AACC: Saint Paul, MN, USA, 2003. [Google Scholar]

- Ahmed, S.Z.; Abozed, S.S. Functional and antioxidant properties of novel snack crackers incorporated with Hibiscus sabdariffa by-product. J. Adv. Res. 2015, 6, 79–87. [Google Scholar] [CrossRef] [Green Version]

- Pudtikajorn, K.; Benjakul, S. Simple Wet Rendering Method for Extraction of Prime Quality Oil from Skipjack Tuna Eyeballs. Eur. J. Lipid Sci. Technol. 2020, 122, 2000077. [Google Scholar] [CrossRef]

- Okpala, C.O.R. Investigation of quality attributes of ice-stored Pacific white shrimp (Litopenaeus vannamei) as affected by sequential minimal ozone treatment. LWT 2014, 57, 538–547. [Google Scholar] [CrossRef]

- Sun-Waterhouse, D.; Zhou, J.; Miskelly, G.M.; Wibisono, R.; Wadhwa, S.S. Stability of encapsulated olive oil in the presence of caffeic acid. Food Chem. 2011, 126, 1049–1056. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Noonim, P.; Rajasekaran, B.; Venkatachalam, K. Effect of Palm Oil–Carnauba Wax Oleogel That Processed with Ultrasonication on the Physicochemical Properties of Salted Duck Egg White Fortified Instant Noodles. Gels 2022, 8, 487. https://doi.org/10.3390/gels8080487

Noonim P, Rajasekaran B, Venkatachalam K. Effect of Palm Oil–Carnauba Wax Oleogel That Processed with Ultrasonication on the Physicochemical Properties of Salted Duck Egg White Fortified Instant Noodles. Gels. 2022; 8(8):487. https://doi.org/10.3390/gels8080487

Chicago/Turabian StyleNoonim, Paramee, Bharathipriya Rajasekaran, and Karthikeyan Venkatachalam. 2022. "Effect of Palm Oil–Carnauba Wax Oleogel That Processed with Ultrasonication on the Physicochemical Properties of Salted Duck Egg White Fortified Instant Noodles" Gels 8, no. 8: 487. https://doi.org/10.3390/gels8080487