A Study on Gel/Space Ratio Development in Binary Mixture Containing Portland Cement and Meta-Illite Calcined Clay/Rice Husk Ash

Abstract

:1. Introduction

2. Materials and Methods

2.1. Binders

2.2. Fine Aggregate

2.3. Superplasticiser

2.4. SAP

2.5. Water

2.6. The Design Strength of HPC

2.7. Compressive Strength

2.8. Degree of Hydration

2.9. Computation of the Gel/Space Ratio of the PC

2.9.1. Integrating MCC and RHA SCMs into Powers’ Model as in Equation (7)

2.9.2. Air Content Estimation Following Bolomey’s Equation

2.9.3. Curve Fitting of Compressive Strength and Gel/Space Ratio

3. Results and Discussion

3.1. Degree of Hydration and Early Strength of MCC- or RHA-Based HPC Mortar

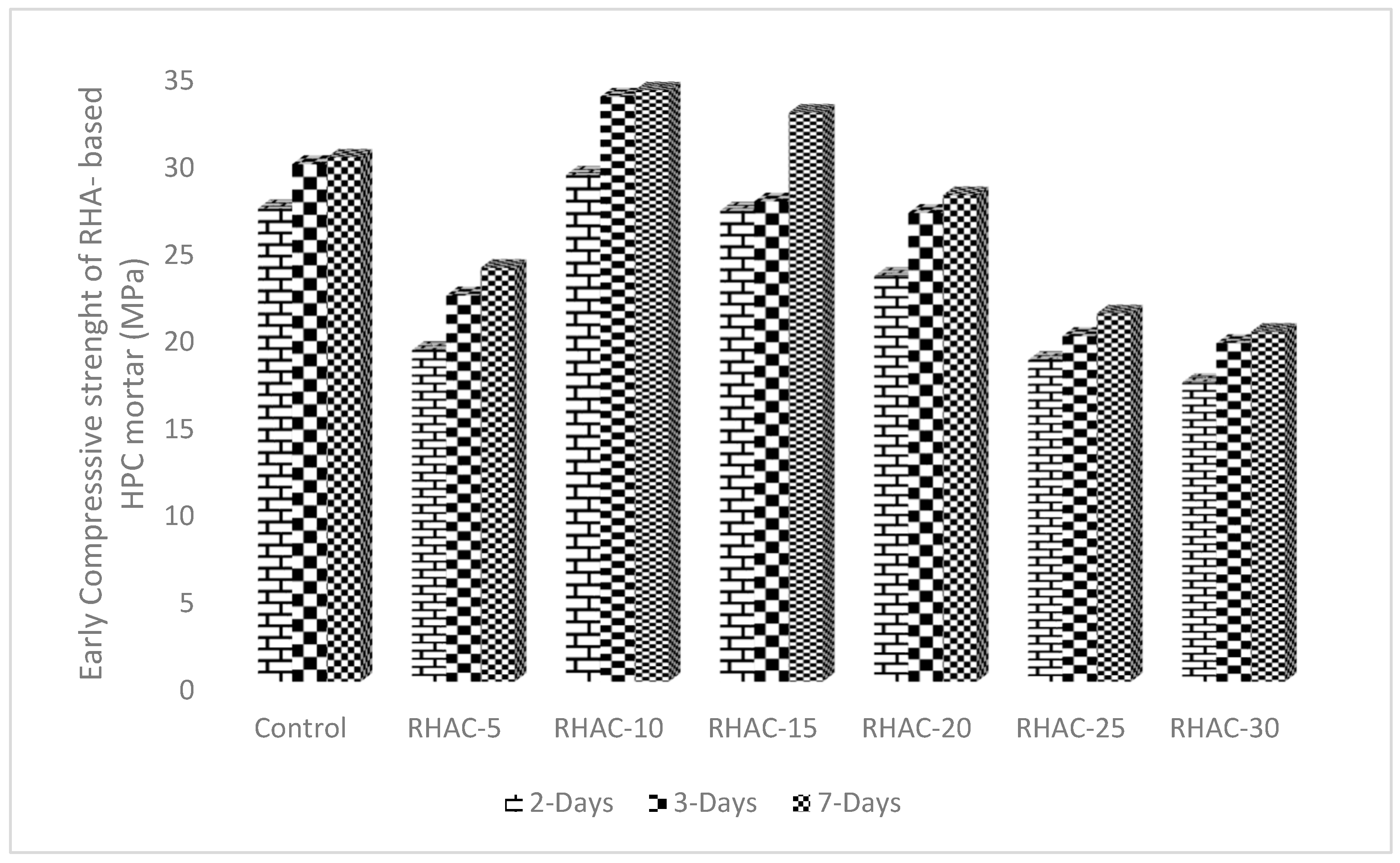

3.2. Early Age Strength Development of HPC Mortar

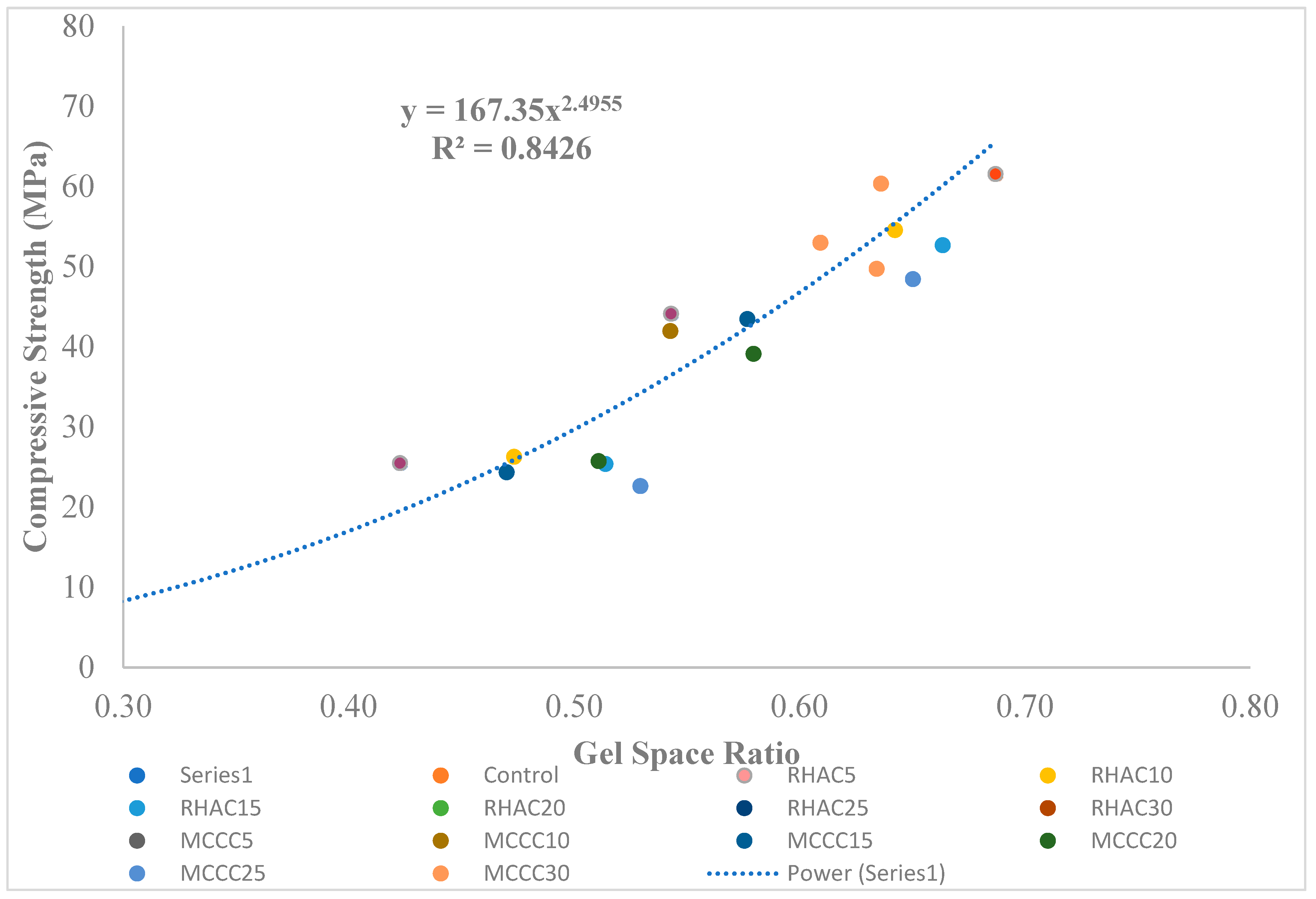

3.3. Curve-Fitting and Modelling of the Compressive Strength Behaviours

4. Conclusions

- The degree of hydration enhances with hydration age for entirely MCC-blended HPC mortar mixes.

- There is a noticeable gradual decline in the degree of hydration values for higher MCC replacements.

- The blend of RHA cement retards plain cement’s hydration at an early age for all HPC mixes.

- There is a comparative early compressive strength of MCC-based HPC mortar with control measured up to 7 days.

- The compressive strength of only RHAC-10 and RHAC-15 mortars improved over the control for 7 days curing age.

- The MCC or RHA addition led to about 17% reduction in the compressive strength of the low W/B HPC.

- The combined use of Bolomey’s void volume correction and Powers gel/space equations are suitable models for predicting the effect of MCC and RHA on the compressive strength of the low W/B HPCs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, D.; Wang, R.; Tyrer, M.; Wong, H.; Cheeseman, C. Sustainable infrastructure development through use of calcined excavated waste clay as a supplementary cementitious material. J. Clean. Prod. 2017, 168, 1180–1192. [Google Scholar] [CrossRef]

- Mosaberpanah, M.A.; Umar, S.A. Utilising Rice Husk Ash as Supplement to Cementitious Materials on Performance of Ultra High Performance Concrete—A review. Mater. Today Sustain. 2020, 7, 100030. [Google Scholar] [CrossRef]

- Laidani ZE, A.; Benabed, B.; Abousnina, R.; Gueddouda, M.K.; Kadri, E.H. Experimental investigation on effects of calcined bentonite on fresh, strength and durability properties of sustainable self-compacting concrete. Constr. Build. Mater. 2020, 230, 117062. [Google Scholar] [CrossRef]

- Marchetti, G.; Rahhal, V.; Pavlík, Z.; Pavlíková, M.; Irassar, E.F. Assessment of packing, flowability, hydration kinetics, and strength of blended cements with illitic calcined shale. Constr. Build. Mater. 2020, 254, 119042. [Google Scholar] [CrossRef]

- Nduka, D.O.; Ameh, J.; Joshua, O.; Ojelabi, R. Awareness and Benefits of Self-Curing Concrete in Construction Projects: Builders and Civil Engineers Perceptions. Buildings 2018, 8, 109. [Google Scholar] [CrossRef] [Green Version]

- Global Cement. Ota Pozzolana Cement Plant Ready for Commercialisation. 2017. Available online: https://www.globalcement.com/news/item/6870-ota-pozzolana-cement-plant-ready-for-commercialisation (accessed on 3 September 2021).

- Olawale, S.O.A.; Tijani, M.A.; Alabi, O. The Effect of Cement-NBRRI Pozzolanic Material Blend on the Mechanical Properties of Glass Fibre Reinforced Concrete. ABUAD J. Eng. Res. Dev. (AJERD) 2018, 1, 371–379. Available online: http://www.ajerd.abuad.edu.ng/ (accessed on 12 November 2021).

- Golafshani, E.M.; Behnood, A.; Arashpour, M. Predicting the compressive strength of normal and High-Performance Concretes using ANN and ANFIS hybridised with Grey Wolf Optimizer. Constr. Build. Mater. 2020, 232, 117266. [Google Scholar] [CrossRef]

- Oyebisi, S.; Ede, A.; Olutoge, F.; Omole, D. Geopolymer concrete incorporating agro-industrial wastes: Effects on mechanical properties, microstructural behaviour and mineralogical phases. Constr. Build. Mater. 2020, 256, 119390. [Google Scholar] [CrossRef]

- Malik, M.; Bhattacharyya, S.K.; Barai, S.V. Thermal and mechanical properties of concrete and its constituents at elevated temperatures: A review. Constr. Build. Mater. 2020, 270, 121398. [Google Scholar] [CrossRef]

- Wu, M.; Li, C.; Yao, W. Gel/space ratio evolution in ternary composite system consisting of Portland Cement, silica fume, and fly ash. Materials 2017, 10, 59. [Google Scholar] [CrossRef] [Green Version]

- Aïtcin, P.C. High-Performance Concrete; Taylor & Francis e-Library: New York, NY, USA, 2004; Available online: https://books.google.com.ng/books?hl=en&lr=&id=d_yojcvXOf4C&oi=fnd&pg=PP1&dq=12.%09A%C3%AFtcin,+P.+C.+(2004).+High-Performance+Concrete.+Taylor+%26+Francis+e-Lbrary.+New+York,+USA.&ots=JmH4mhbT8X&sig=JekjYus5gV7zw4VwmukejXu0O4Q&redir_esc=y#v=onepage&q&f=false (accessed on 20 November 2021).

- Powers, T.C.; Brownyard, T.L. Studies of the physical properties of hardened Portland cement paste. J. Proc. 1946, 43, 101–132. Available online: https://www.concrete.org/publications/internationalconcreteabstractsportal/m/details/id/8745 (accessed on 20 November 2021).

- Powers, T.C. Structure and physical properties of hardened Portland cement paste. J. Am. Ceram. Soc. 1958, 41, 1–6. [Google Scholar] [CrossRef]

- Lam, L.; Wong, Y.L.; Poon, C.S. Degree of hydration and gel/space ratio of high-volume fly ash/cement systems. Cem. Concr. Res. 2000, 30, 747–756. [Google Scholar] [CrossRef]

- Hasholt, M.T.; Jespersen, M.H.S.; Jensen, O.M. Mechanical properties of concrete with SAP part I: Development of compressive strength. In Proceedings of the International RILEM Conference on Use of Superabsorbent Polymers and Other New Additives in Concrete, Lynbgy, Demark, 15–18 August 2010; Available online: https://orbit.dtu.dk/en/publications/mechanical-properties-of-concrete-with-sap-part-i-development-of (accessed on 20 November 2021).

- Heikal, M.; Ismail, M.N.; Ibrahim, N.S. Physico-mechanical, microstructure characteristics and fire resistance of cement pastes containing Al2O3 nano-particles. Constr. Build. Mater. 2015, 91, 232–242. [Google Scholar] [CrossRef]

- Park, B.; Choi, Y.C. Hydration and pore-structure characteristics of high-volume fly ash cement pastes. Constr. Build. Mater. 2021, 278, 122390. [Google Scholar] [CrossRef]

- Bolomey, J. Granulation and forecasting the resistance of concrete. Granulation et pr’evision de la r’esistance probable des b’etons. Travaux 1935, 30, 228–232. [Google Scholar]

- Nigeria Industrial Standard [NIS] 444-1 Composition, Specification and Conformity Criteria for Common Cements. Standards Organisation of Nigeria. 2018. Available online: https://standards.lawnigeria.com/cgi-sys/suspendedpage.cgi (accessed on 22 November 2021).

- Neville, A.M. Properties of Concrete, 5th ed.; Pearson Educational Limited: London, UK, 2012; Available online: https://www.pearson.com/uk/educators/higher-education-educators/program/Neville-Properties-of-Concrete-Properties-of-Concrete-5th-Edition/PGM1001873.html (accessed on 10 November 2021).

- Olawuyi, B.J.; Babafemi, A.J.; Boshoff, W.P. Early-age and long-term strength development of high-performance concrete with SAP. Constr. Build. Mater. 2021, 267, 121798. [Google Scholar] [CrossRef]

- BS EN 1008; Mixing Water for Concrete: Specification for Sampling, Testing and Assessing the Suitability of Water, Including Water Recovered from Processes in the Concrete industry as Mixing Water for Concrete. British Standards Institution: London, UK, 2002.

- EN, B. 12390-3: 2019; Testing Hardened Concrete. Compressive Strength of Test Specimens. British Standard Institute: London, UK, 2019.

- International Union of Testing and Research Laboratories for Materials and Structures (RILEM). CPC4-Compressive Strength of Concrete 1975, TC14-CPC, RILEM Technical Recommendations for the Testing and Use of Construction Materials; E & FN, Spon: London, UK, 1994; pp. 17–18. Available online: https://www.rilem.net/publication/publication/4 (accessed on 10 November 2021).

- Hasholt, M.T.; Jensen, O.M. Chloride migration in concrete with superabsorbent polymers. Cem. Concr. Compos. 2015, 55, 290–297. [Google Scholar] [CrossRef] [Green Version]

- Olawuyi, B.J. The Mechanical Behaviour of High-Performance Concrete with Superabsorbent Polymers (SAP). Ph.D. Thesis, University of Stellenbosch, Stellenbosch, South Africa, 2016. Available online: http://scholar.sun.ac.za/handle/10019.1/98352 (accessed on 20 November 2021).

- Bullard, J.W.; Jennings, H.M.; Livingston, R.A.; Nonat, A.; Scherer, G.W.; Schweitzer, J.S.; Thomas, J.J. Mechanisms of cement hydration. Cem. Concr. Res. 2011, 41, 1208–1223. [Google Scholar] [CrossRef]

- Mohsen, A.; Aiad, I.; El-Hossiny, F.I.; Habib, A.O. Evaluating the mechanical properties of admixed blended cement pastes and estimating its kinetics of hydration by different techniques. Egypt. J. Pet. 2020, 29, 171–186. [Google Scholar] [CrossRef]

- Wang, J.; Xiao, J.; Zhang, Z.; Han, K.; Hu, X.; Jiang, F. Action mechanism of rice husk ash and the effect on main performances of cement-based materials: A review. Constr. Build. Mater. 2021, 288, 123068. [Google Scholar] [CrossRef]

| Constituents | Mix Blends (kg/m3) | ||||||

|---|---|---|---|---|---|---|---|

| Control | MCCC-5/RHAC-5 | MCCC-10/RHAC-10 | MCCC-15/RHAC-15 | MCCC-20/RHAC-20 | MCCC-25/RHAC-25 | MCCC-30/RHAC-30 | |

| Water | 156 | 156 | 156 | 156 | 156 | 156 | 156 |

| Cement (CEM II) | 540 | 513 | 486 | 459 | 432 | 405 | 378 |

| MCC | 0 | 27 | 54 | 81 | 108 | 135 | 162 |

| Coarse aggregate | 1050 | 1050 | 1050 | 1050 | 1050 | 1050 | 1050 |

| Sand (≥300 um) | 700 | 700 | 700 | 700 | 700 | 700 | 700 |

| SAP (0.3% bwob) | 1.62 | 1.62 | 1.62 | 1.62 | 1.62 | 1.62 | 1.62 |

| Superplasticiser (1.5% bwob) | 8.10 | 8.10 | 8.10 | 8.10 | 8.10 | 8.10 | 8.10 |

| Water/binder (W/B) | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Additional water | 20.30 | 20.30 | 20.30 | 20.30 | 20.30 | 20.30 | 20.30 |

| Degree of Hydration (%) | RH7 Factor | |||||

|---|---|---|---|---|---|---|

| MIX ID | 2 Days | 3 Days | 7 Days | 2 Days | 3 Days | 7 Days |

| Control | 30.79 | 32.67 | 51.30 | 0.60 | 0.64 | 1.00 |

| MCCC-5 | 28.99 | 38.40 | 50.29 | 0.57 | 0.75 | 0.98 |

| MCCC-10 | 20.87 | 34.98 | 44.15 | 0.41 | 0.68 | 0.86 |

| MCCC-15 | 20.30 | 33.46 | 36.22 | 0.40 | 0.65 | 0.71 |

| MCCC-20 | 20.45 | 32.61 | 41.47 | 0.40 | 0.64 | 0.81 |

| MCCC-25 | 18.85 | 30.26 | 40.62 | 0.37 | 0.59 | 0.79 |

| MCCC-30 | 18.79 | 31.58 | 33.42 | 0.37 | 0.62 | 0.65 |

| RHAC-5 | 21.24 | 29.24 | 36.77 | 0.41 | 0.57 | 0.72 |

| RHAC-10 | 21.90 | 31.86 | 45.47 | 0.43 | 0.62 | 0.89 |

| RHAC-15 | 21.15 | 32.10 | 43.89 | 0.41 | 0.63 | 0.86 |

| RHAC-20 | 15.60 | 25.27 | 33.84 | 0.30 | 0.49 | 0.66 |

| RHAC-25 | 15.21 | 23.37 | 33.07 | 0.30 | 0.46 | 0.64 |

| RHAC-30 | 15.33 | 21.60 | 32.21 | 0.30 | 0.42 | 0.63 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nduka, D.O.; Olawuyi, B.J.; Joshua, O.O.; Omuh, I.O. A Study on Gel/Space Ratio Development in Binary Mixture Containing Portland Cement and Meta-Illite Calcined Clay/Rice Husk Ash. Gels 2022, 8, 85. https://doi.org/10.3390/gels8020085

Nduka DO, Olawuyi BJ, Joshua OO, Omuh IO. A Study on Gel/Space Ratio Development in Binary Mixture Containing Portland Cement and Meta-Illite Calcined Clay/Rice Husk Ash. Gels. 2022; 8(2):85. https://doi.org/10.3390/gels8020085

Chicago/Turabian StyleNduka, David O., Babatunde J. Olawuyi, Opeyemi O. Joshua, and Ignatius O. Omuh. 2022. "A Study on Gel/Space Ratio Development in Binary Mixture Containing Portland Cement and Meta-Illite Calcined Clay/Rice Husk Ash" Gels 8, no. 2: 85. https://doi.org/10.3390/gels8020085

APA StyleNduka, D. O., Olawuyi, B. J., Joshua, O. O., & Omuh, I. O. (2022). A Study on Gel/Space Ratio Development in Binary Mixture Containing Portland Cement and Meta-Illite Calcined Clay/Rice Husk Ash. Gels, 8(2), 85. https://doi.org/10.3390/gels8020085