Injectable Cryogels in Biomedicine

Abstract

1. Introduction

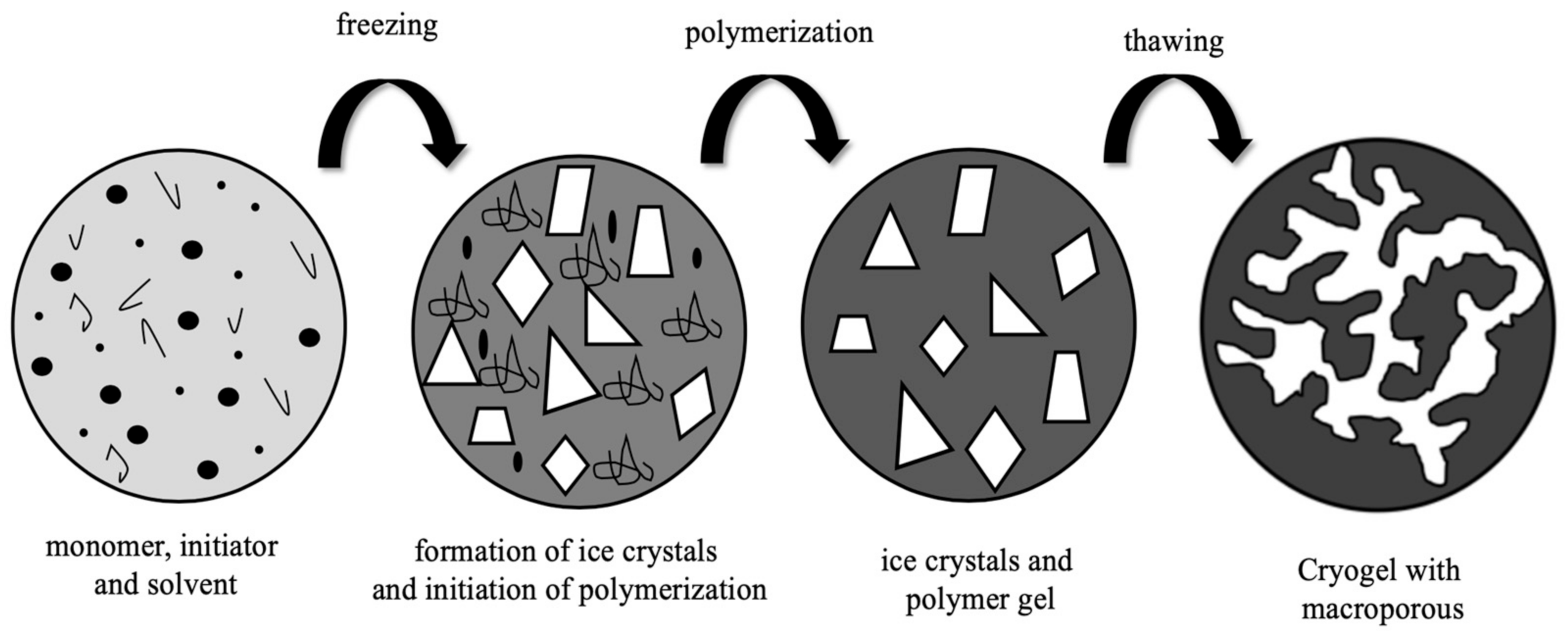

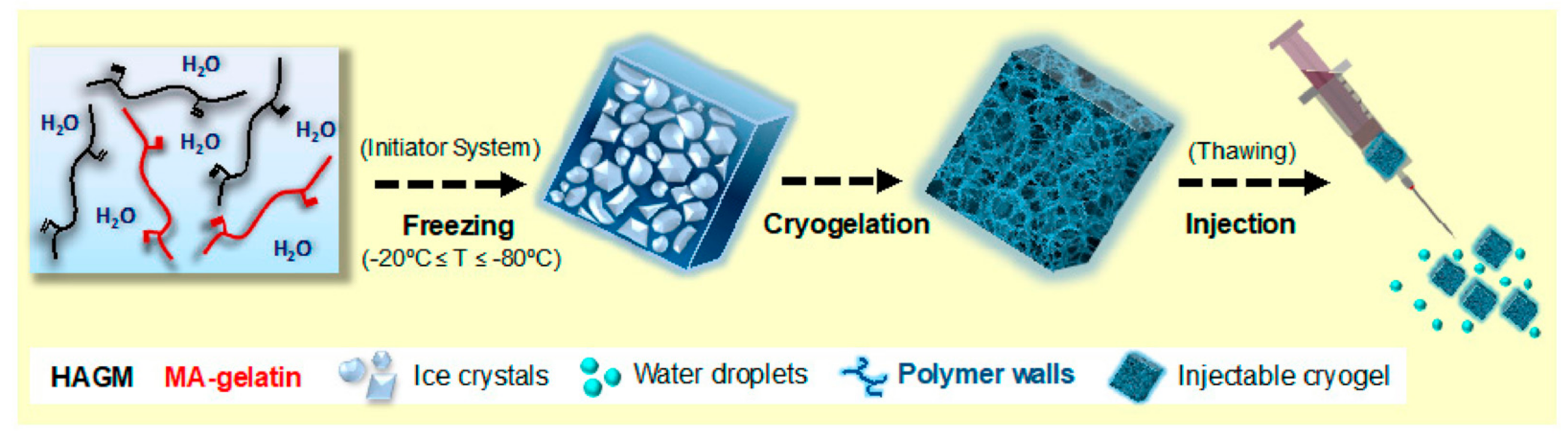

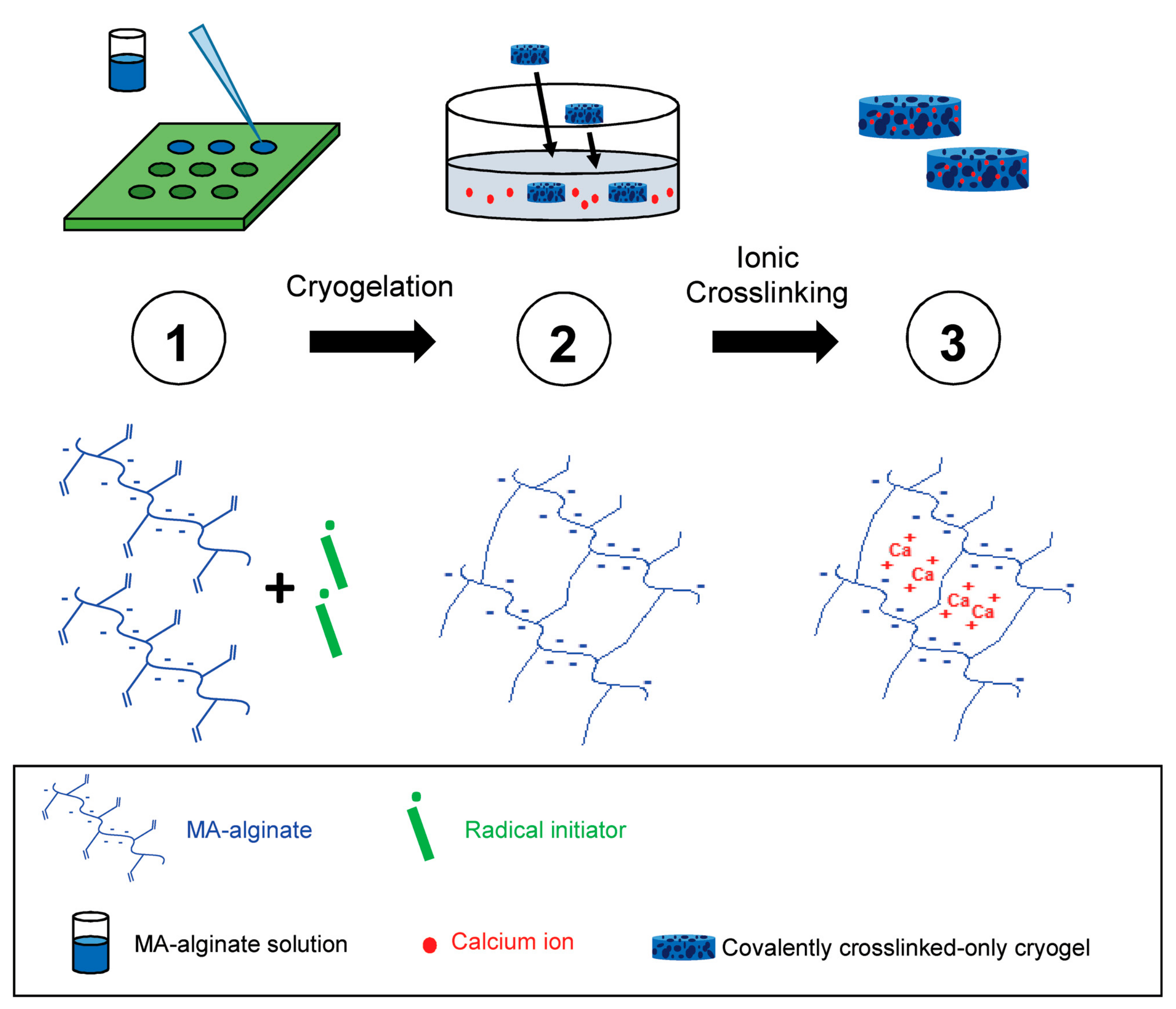

2. Cryogels

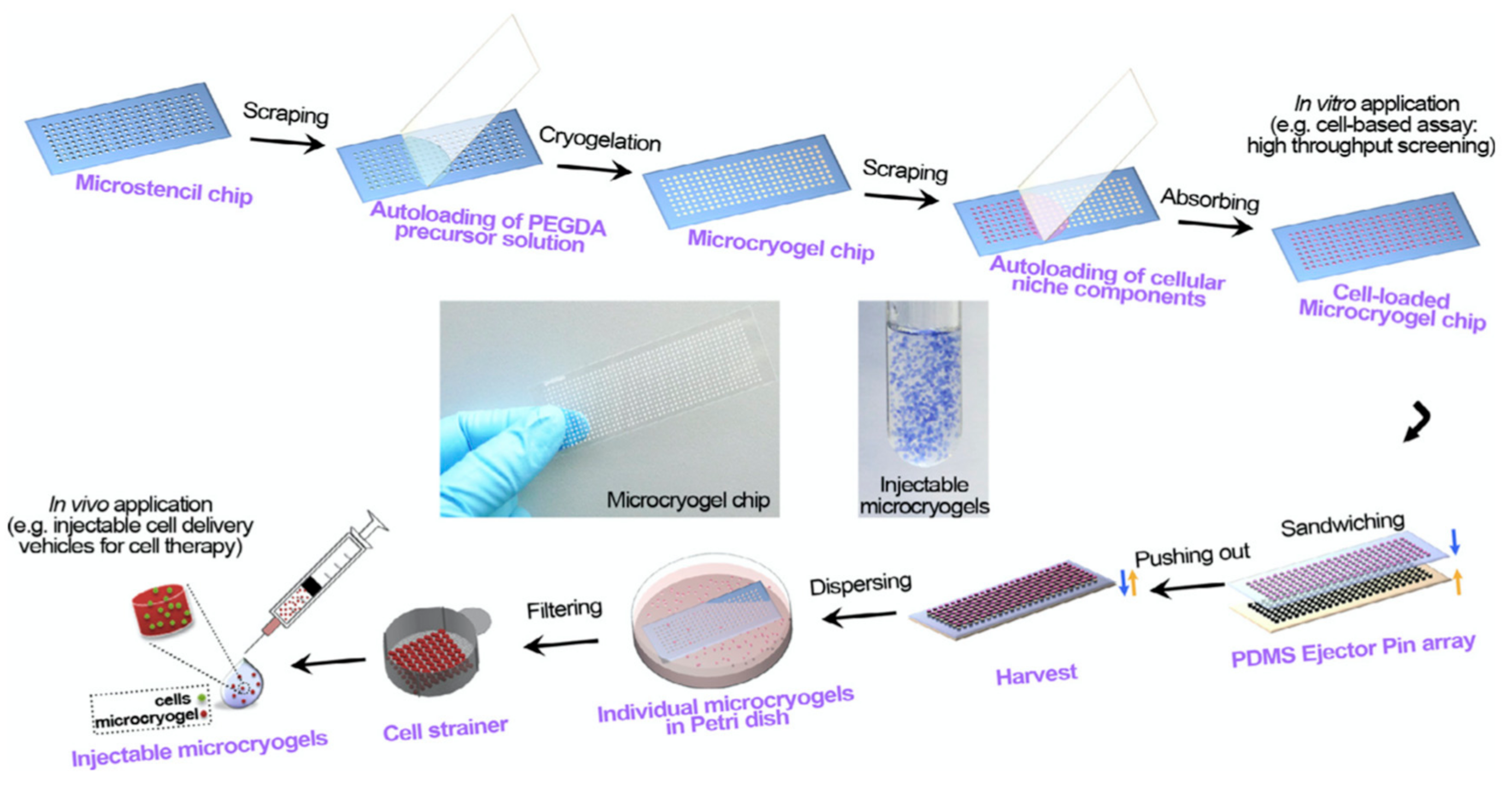

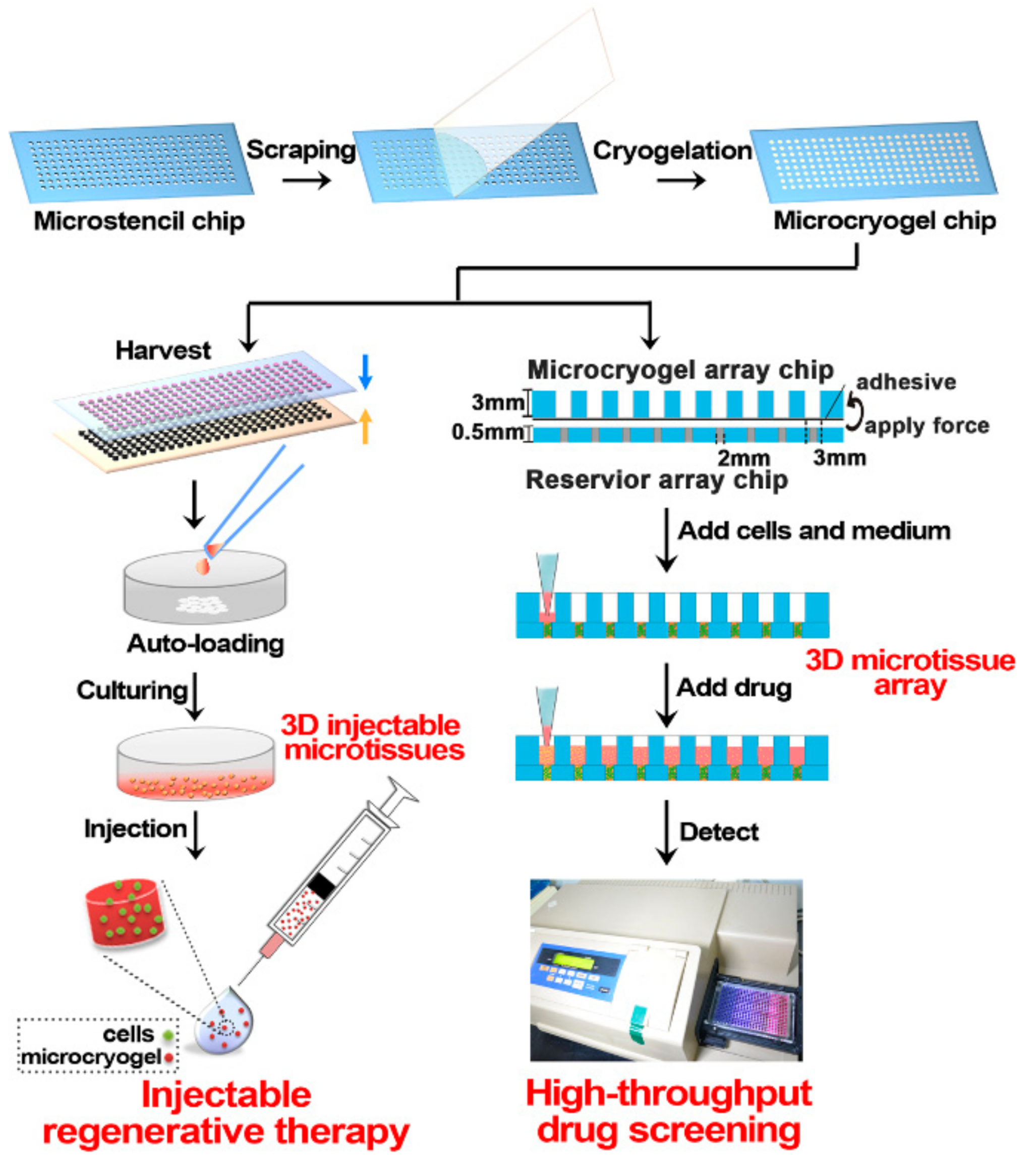

3. Injectable Cryogels

4. Injectable Cryogels in Biomedicine Applications

4.1. Wound Repair Applications of Injectable Cryogels in Tissue Engineering

4.2. Cell and Drug Delivery Applications of Injectable Cryogels in Tissue Engineering

4.3. Other Applications of Injectable Cryogels

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bencherif, S.A.; Sands, R.W.; Bhatta, D.; Arany, P.; Verbeke, C.S.; Edwards, D.A.; Mooney, D.J. Injectable preformed scaffolds with shape-memory properties. Proc. Nalt. Acad. Sci. USA 2012, 109, 19590–19595. [Google Scholar] [CrossRef] [PubMed]

- Plieva, F.M.; Galaev, I.Y.; Mattiasson, B. Macroporous gels prepared at subzero temperatures as novel materials for chromatography of particulate-containing fluids and cell culture applications. J Sep. Sci. 2007, 30, 1657–1671. [Google Scholar] [CrossRef] [PubMed]

- Mikhalovsky, S.V.; Savina, I.N.; Dainiak, M.; Ivanov, A.E.; Galaev, I.Y. 5.03-Biomaterials/Cryogels, Comprehensive Biotechnology, 2nd ed.; Moo-Young, M., Ed.; Academic Press: Burlington, MA, USA, 2011; pp. 11–22. [Google Scholar]

- Plieva, F.M.; Galaev, I.Y.; Noppe, W.; Mattiasson, B. Cryogel applications in microbiology. Trends Microbiol. 2008, 16, 543–551. [Google Scholar] [CrossRef] [PubMed]

- Dainiak, M.B.; Galaev, I.Y.; Kumar, A.; Plieva, F.M.; Mattiasson, B. Chromatography of living cells using supermacroporous hydrogels, cryogels. Adv. Biochem. Eng. Biotechnol. 2007, 106, 101–127. [Google Scholar]

- Lozinsky, V.I. Cryostructuring of polymeric systems. 50.† cryogels and cryotropic gel-formation: Terms and definitions. Gels 2018, 4, 77. [Google Scholar] [CrossRef]

- Shih, T.Y.; Blacklow, S.O.; Li, A.W.; Freedman, B.R.; Bencherif, S.; Koshy, S.T.; Darnell, M.C.; Mooney, D.J. Injectable, tough alginate cryogels as cancer vaccines. Adv. Healthc. Mater. 2018, 7, 1701469–1701482. [Google Scholar] [CrossRef]

- Kang, H.W.; Lee, S.J.; Ko, I.K.; Kengla, C.; Yoo, J.J.; Atala, A. A 3D bioprinting system to produce human-scale tissue constructs with structural integrity. Nat. Biotechnol. 2016, 34, 312. [Google Scholar] [CrossRef]

- Dhandayuthapani, B.; Yoshida, Y.; Maekawa, T.; Kumar, D.S. Polymeric scaffolds in tissue engineering application: A review. Int. J. Polym. Sci. 2011, 1–19. [Google Scholar] [CrossRef]

- Eggermont, L.J.; Rogers, Z.J.; Colombani, T.; Memic, A.; Bencherif, S.A. Injectable Cryogels for Biomedical Applications. Trends Biotechnol. 2020, 38, 418–431. [Google Scholar] [CrossRef]

- Uzunoğlu, G.; Çimen, D.; Bereli, N.; Çetin, K.; Denizli, A. Removal of Low-Density Lipoprotein Cholesterol from Blood Plasma via Heparin Modified Cryogels. J. Biomater. Sci. Polym. Ed. 2019, 30, 1276–1290. [Google Scholar] [CrossRef]

- Çimen, D.; Göktürk, I.; Yılmaz, F. Removal of Iron by Chelation with Molecularly Imprinted Supermacroporous Cryogel. Artif. Cells Nanomed. Biotechnol. 2016, 44, 1158–1166. [Google Scholar]

- Çetin, K.; Denizli, A. 5-Fluorouracil delivery from metal-ion mediated molecularly imprinted cryogel discs. Colloids Surf. B 2015, 126, 401–406. [Google Scholar] [CrossRef]

- Saylan, Y.; Denizli, A. Supermacroporous Composite Cryogels in Biomedical Applications. Gels 2019, 5, 20. [Google Scholar] [CrossRef]

- Plieva, F.; Huiting, X.; Galaev, I.Y.; Bergenståhl, B.; Mattiasson, B. Macroporous elastic polyacrylamide gels prepared at subzero temperatures: Control of porous structure. J. Mater. Chem. 2006, 16, 4065–4073. [Google Scholar] [CrossRef]

- Okay, O.; Lozinsky, V.I. Synthesis and structure–property relationships of cryogels. In Polymeric Cryogels: Macroporous Gels with Remarkable Properties; Okay, O., Ed.; Springer International Publishing: Basel, Switzerland, 2014; Volume 263, pp. 103–157. [Google Scholar]

- Asliyüce, S.; Bereli, N.; Uzun, L.; Onur, M.A.; Say, R.; Denizli, A. Ion-imprinted supermacroporous cryogel, for in vitro removal of iron out of human plasma with beta thalassemia. Sep. Purif. Technol. 2010, 73, 243–249. [Google Scholar] [CrossRef]

- Çimen, D.; Denizli, A. Immobilize Metal Affinity Monolithic Cryogels for Cytochrome C Purification. Colloids Surf. B. 2012, 93, 29–35. [Google Scholar] [CrossRef]

- Kumari, J.; Kumar, A. Development of polymer based cryogel matrix for transportation and storage of mammalian cells. Sci. Rep. 2017, 7, 41551. [Google Scholar]

- Jain, E.; Karande, A.A.; Kumar, A. Supermacroporous polymer-based cryogel bioreactor for monoclonal antibody production in continuous culture using hybridoma cells. Biotechnol. Prog. 2011, 27, 170–180. [Google Scholar] [CrossRef]

- Carvalho, B.M.A.; Da Silva, S.L.; Da Silva, L.H.M.; Minim, V.P.R.; Da Silva, M.C.H.; Carvalho, L.M. Cryogel Poly(acrylamide): Synthesis, Structure and Applications. Sep. Purif. Rev. 2014, 43, 241–262. [Google Scholar] [CrossRef]

- Çimen, D.; Bereli, N.; Andaç, M.; Denizli, A. Molecularly imprinted cryogel columns for Concanavalin A purification from jack bean extract. Sep. Sci. Plus. 2018, 1, 454–463. [Google Scholar] [CrossRef]

- Plieva, F.M.; Karlsson, M.; Aguilar, M.R.; Gomez, D.; Mikhalovsky, S.; Galaev, I.Y. Pore structure in supermacroporous polyacrylamide based cryogels. Soft Matter. 2005, 1, 303–309. [Google Scholar] [CrossRef]

- Gun’ko, V.M.; Savina, I.N.; Mikhalovsky, S.V. Cryogels: Morphological, structural and adsorption characterisation. Adv. Coll. Int. Sci. 2013, 187, 1–46. [Google Scholar] [CrossRef]

- Bereli, N.; Saylan, Y.; Uzun, L.; Say, R.; Denizli, A. L-Histidine imprinted supermacroporous cryogels for protein recognition. Sep. Purif. Technol. 2011, 82, 28–35. [Google Scholar] [CrossRef]

- Inanan, T.; Tüzmen, N.; Karipcin, F. Oxime-functionalized cryogel disks for catalase immobilization. Int. J. Biol. Macromol. 2018, 114, 812–820. [Google Scholar] [CrossRef]

- Koshy, S.T.; Ferrante, T.C.; Lewin, S.A.; Mooney, D.J. Injectable, Porous, and Cell-Responsive Gelatin Cryogels. Biomaterials 2014, 35, 2477–2487. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.K.; Dsouza, R.N.; Grasselli, M.; Fernández-Lahore, M. High capacity cryogel-type adsorbents for protein purification. J. Chromatogr. A 2014, 1355, 143–148. [Google Scholar] [CrossRef]

- Kuo, C.Y.; Chen, C.H.; Hsiao, C.Y.; Chen, J.P. Incorporation of chitosan in biomimetic gelatin/chondroitin- 6-sulfate/hyaluronan cryogel for cartilage tissue engineering. Carbohydr. Polym. 2015, 117, 722–730. [Google Scholar] [CrossRef]

- Baydemir, G.; Bereli, N.; Andaç, M.; Say, R.; Galaev, I.Y.; Denizli, A. Supermacroporous poly(hydroxyethyl methacrylate) based cryogel with embedded bilirubin imprinted particles. React. Funct. Polym. 2009, 69, 36–42. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, D.; Zhu, S.; Liu, X.; Zhang, H. 3D cryogel composites as adsorbent for isolation of protein and small molecules. Talanta 2019, 191, 229–234. [Google Scholar] [CrossRef]

- Çimen, D.; Yılmaz, F.; Perçin, I.; Türkmen, D.; Denizli, A. Dye affinity cryogels for plasmid DNA purification. Mater. Sci. Eng. C 2015, 56, 318–324. [Google Scholar] [CrossRef]

- Wang, B.H.; Campbell, G. Campbell, G. Formulations of polyvinyl alcohol cryogel that mimic the biomechanical properties of soft tissues in the natural lumbar intervertebral disc. Spine 2009, 34, 2745–2753. [Google Scholar] [CrossRef]

- O’Brien, F.J. Biomaterials scaffolds for tissue engineering. Mater. Today 2011, 14, 88–95. [Google Scholar] [CrossRef]

- Bakhshpour, M.; Idil, N.; Perçin, I.; Adil Denizli, A. Biomedical Applications of Polymeric Cryogels. Appl. Sci. 2019, 9, 553. [Google Scholar] [CrossRef]

- Bereli, N.; Yavuz, H.; Denizli, A. Protein chromatography by molecular imprinted cryogels. J. Liq Chrom. Relat. Tech. 2020, 43, 657–670. [Google Scholar] [CrossRef]

- Lozinsky, V.I.; Galaev, I.Y.; Plieva, F.M.; Savina, I.N.; Jungvid, H.; Mattiasson, B. Polymeric cryogels as promising materials of biotechnological interest. Trends Biotechnol. 2003, 21, 445–451. [Google Scholar] [CrossRef] [PubMed]

- Hacker, M.C.; Nawaz, H.A. Multi-functional macromers for hydrogel design in biomedical engineering and regenerative medicine. Int. J. Mol. Sci. 2015, 16, 27677–27706. [Google Scholar] [CrossRef] [PubMed]

- Erdem, A.; Ngwabebhoh, F.A.; Yildiz, U. Fabrication and characterization of soft macroporous Jeffamine cryogels as potential materials for tissue applications. RSC Adv. 2016, 6, 111872–111881. [Google Scholar] [CrossRef]

- Konovalova, M.V.; Markov, P.A.; Durnev, E.A.; Kurek, D.V.; Popov, S.V.; Varlamov, V.P. Preparation and biocompatibility evaluation of pectin and chitosan cryogels for biomedical application. J. Biomed. Mater. Res. 2017, 105, 547–556. [Google Scholar] [CrossRef] [PubMed]

- Savina, I.N.; Ingavle, G.C.; Cundy, A.B.; Mikhalovsky, S.V. A simple method for the production of large volume 3D macroporous hydrogels for advanced biotechnological, medical and environmental applications. Sci. Rep. 2016, 6, 1–9. [Google Scholar] [CrossRef]

- Yavuz, H.; Bereli, N.; Baydemir, G.; Andaç, M.; Türkmen, D.; Denizli, A. Cryogels: Applications in Extracorporeal Affinity Therapy. In Supermacroporous Cryogels: Biomedical and Biotechnological Applications; Kumar, A., Ed.; CRC Press: Boca Raton, FL, USA, 2016; pp. 397–416. [Google Scholar]

- Bhat, S.; Kumar, A. Biomaterials and bioengineering tomorrow’s healthcare. Biomatter. 2013, 3, e24717. [Google Scholar] [CrossRef]

- Cheng, L.; Ji, K.; Shih, T.Y.; Haddad, A.; Giatsidis, G.; Mooney, D.J.; Orgill, D.P.; Nabzdyk, C.S. Injectable shape-memorizing three-dimensional hyaluronic acid cryogels for skin sculpting and soft tissue reconstruction. Tissue Eng. Part A 2017, 23, 243–251. [Google Scholar] [CrossRef]

- Kim, I.; Lee, S.S.; Bae, S.; Lee, H.; Hwang, N.S. Heparin functionalized injectable cryogel with rapid shape-recovery property for neovascularization. Biomacromolecules 2018, 19, 2257–2269. [Google Scholar] [CrossRef]

- Chew, S.A.; Danti, S. Biomaterial-based implantable devices for cancer therapy. Adv. Healthc. Mater. 2017, 6, 1600766. [Google Scholar] [CrossRef]

- Kearney, C.J.; Mooney, D.J. Macroscale delivery systems for molecular and cellular payloads. Nat. Mater. 2013, 12, 1004–1017. [Google Scholar] [CrossRef]

- Chen, M.H.; Wang, L.L.; Chung, J.J.; Kim, Y.H.; Atluri, P.; Burdick, J.A. Methods to assess shear-thinning hydrogels for application as injectable biomaterials. ACS Biomater. Sci. Eng. 2017, 3, 3146–3160. [Google Scholar] [CrossRef]

- Willerth, S.M.; Sakiyama-Elbert, S.E. Combining stem cells and biomaterial scaffolds for constructing tissues and cell delivery. StemJournal. 2019, 1, 1–25. [Google Scholar] [CrossRef]

- Tan, H.; Marra, K.G. Injectable, biodegradable hydrogels for tissue engineering applications. Materials 2010, 3, 1746–1767. [Google Scholar] [CrossRef]

- Rezaeeyazdi, M.; Colombani, T.; Memic, A.; Bencherif, S.A. Injectable hyaluronic acid-co-gelatin cryogels for tissue-engineering applications. Materials 2018, 11, 1374. [Google Scholar] [CrossRef] [PubMed]

- Demir, D.; Boelgen, N. Synthesis and characterization of injectable chitosan cryogel microsphere scaffolds. Int. J. Polym. Mater. Pol. 2017, 66, 686–696. [Google Scholar] [CrossRef]

- Lei, K.; Tang, L. Surgery-free injectable macroscale biomaterials for local cancer immunotherapy. Biomater. Sci. 2019, 7, 733. [Google Scholar] [CrossRef]

- Patenaude, M.; Smeets, N.M.; Hoare, T. Designing injectable, covalently cross-linked hydrogels for biomedical applications. Macromol. Rapid Commun. 2014, 35, 598–617. [Google Scholar] [CrossRef] [PubMed]

- Cloyd, J.M.; Malhotra, N.R.; Weng, L.; Chen, W.; Mauck, R.L.; Elliott, D.M. Material Properties in Unconfined Compression of Human Nucleus Pulposus, Injectable Hyaluronic Acid-Based Hydrogels and Tissue Engineering Scaffolds. Eur. Spine J. 2007, 16, 1892–1898. [Google Scholar] [CrossRef] [PubMed]

- Schirmer, L.; Hoornaert, C.; Le Blon, D.; Eigel, D.; Neto, C.; Gumbleton, M.; Welzel, P.B.; Rosser, A.E.; Werner, C.; Ponsaerts, P.; et al. Heparin-based, injectable microcarriers for controlled delivery of interleukin-13 to the brain. Biomater. Sci. 2020, 8, 4997. [Google Scholar] [CrossRef] [PubMed]

- Goodarzi, K.; Shariatzadeh, F.J.; Solouk, A.; Akbari, S.; Mirzadeh, H. Injectable drug loaded gelatin based scaffolds as minimally invasive approach for drug delivery system: CNC/PAMAM nanoparticles. Eur. Polym. J. 2020, 139, 109992. [Google Scholar] [CrossRef]

- Nikolova, M.P.; Chavali, M.S. Recent advances in biomaterials for 3D scaffolds: A review. Bioact. Mater. 2019, 4, 271–292. [Google Scholar] [CrossRef]

- Hixon, K.R.; Eberlin, C.T.; Kadakia, P.U.; McBride-Gagyi, S.H.; Jain, E.; Sell, S.A. A comparison of cryogel scaffolds to identify an appropriate structure for promoting bone regeneration. Biomed. Phys. Eng. Exp. 2018, 4, 035014. [Google Scholar] [CrossRef]

- Koshy, S.T.; Zhang, D.K.Y.; Grolman, J.M.; Stafford, A.G.; Mooney, D.J. Injectable nanocomposite cryogels for versatile protein drug delivery. Acta Biomater. 2018, 65, 36–43. [Google Scholar] [CrossRef]

- Bencherif, S.A.; Sands, R.W.; Ali, O.A.; Li, W.A.; Lewin, S.A.; Braschler, T.M.; Shih, T.Y.; Verbeke, C.S.; Bhatta, D.; Dranoff, G.; et al. Injectable cryogel-based whole-cell cancer vaccines. Nat. Commun. 2015, 6, 7556. [Google Scholar] [CrossRef]

- Hixon, K.R.; Lu, T.; Sell, S.A. A comprehensive review of cryogels and their roles in tissue engineering applications. Acta Biomater. 2017, 62, 29–41. [Google Scholar] [CrossRef] [PubMed]

- Cao, J.; Wang, P.; Liu, Y.; Zhu, C.; Fan, D. Double crosslinked HLC-CCS hydrogel tissue engineering scaffold for skin wound healing. Int. J. Biol. Macromol. 2020, 155, 625–635. [Google Scholar] [CrossRef]

- Shiekh, P.A.; Andrabi, S.M.; Singh, A.; Majumder, S.; Kumar, A. Designing cryogels through cryostructuring of polymeric matrices for biomedical applications. Eur. Polym. J. 2021, 144, 110234. [Google Scholar] [CrossRef]

- Sener, G.; Hilton, S.A.; Osmond, M.J.; Zgheib, C.; Newsom, J.P.; Dewberry, L.; Singh, S.; Sakthivel, T.S.; Seal, S.; Liechty, K.W.; et al. Injectable, self-healable zwitterionic cryogels with sustained microRNA-cerium oxide nanoparticle release promote accelerated wound healing. Acta Biomater. 2020, 101, 262–272. [Google Scholar] [CrossRef]

- Zhao, X.; Guo, B.; Wu, H.; Liang, Y.; Ma, P.X. Injectable antibacterial conductive nanocomposite cryogels with rapid shape recovery for noncompressible hemorrhage and wound healing. Nat. Commun. 2018, 9, 2784. [Google Scholar] [CrossRef]

- Çetin, K.; Aslıyüce, S.; Idil, N.; Denizli, A. Preparation of lysozyme loaded gelatin microcryogels and investigation of their antibacterial properties. J. Biomater. Sci. Polym. Ed. 2020. [Google Scholar] [CrossRef]

- Zhao, X.; Liang, Y.; Guo, B.; Yin, Z.; Zhu, D.; Han, Y. Injectable dry cryogels with excellent blood-sucking expansion and blood clotting to cease hemorrhage for lethal deep-wounds, coagulopathy and tissue regeneration. Chem. Eng. J. 2021, 403, 126329. [Google Scholar] [CrossRef]

- Navare, K.J.; Colombani, T.; Rezaeeyazdi, M.; Bassous, N.; Rana, D.; Webster, T.; Memic, A.; Bencherif, S.A. Needle-injectable microcomposite cryogel scafolds with antimicrobial properties. Sci. Rep. 2020, 10, 18370. [Google Scholar]

- Larsson, E.; Boujemaoui, A.; Malmstrom, E.; Carlmark, A. Thermoresponsive cryogels reinforced with cellulose nanocrystals. RSC Adv. 2015, 5, 77643–77650. [Google Scholar] [CrossRef]

- Demir, D.; Özdemir, S.; Yalçın, M.S.; Bölgen, N. Chitosan cryogel microspheres decorated with silver nanoparticles as injectable and antimicrobial scaffolds. Int. J. Polym. Mater. Polym. Biomater. 2020, 69, 919–927. [Google Scholar] [CrossRef]

- Dimatteo, R.; Darling, N.J.; Segura, T. In situ forming injectable hydrogels for drug delivery and wound repair. Adv. Drug Delivery Rev. 2018, 127, 167–184. [Google Scholar] [CrossRef] [PubMed]

- Radhouani, H.; Bicho, D.; Gonçalves, C.; Maia, F.R.; Reis, R.L.; Oliveira, J.M. Kefiran cryogels as potential scaffolds for drug delivery and tissue engineering applications. Mater. Today Commun. 2019, 20, 100554. [Google Scholar] [CrossRef]

- Memic, A.; Colombani, T.; Eggermont, L.J.; Rezaeeyazdi, M.; Steingold, J.; Rogers, Z.J.; Navare, K.J.; Mohammed, H.S.; Bencherif, S.A. Latest advances in cryogel technology for biomedical applications. Adv. Therap. 2019, 2, 1800114. [Google Scholar] [CrossRef]

- Zeng, Y.; Chen, C.; Liu, W.; Fu, Q.; Han, Z.; Li, Y.; Feng, S.; Li, X.; Qi, C.; Wu, J.; et al. Injectable microcryogels reinforced alginate encapsulation of mesenchymal stromal cells for leak-proof delivery and alleviation of canine disc degeneration. Biomaterials 2015, 59, 53–65. [Google Scholar] [CrossRef]

- Flippova, A.; Bonini, F.; Efremova, L.; Locatelli, M.; Preynat-Seauve, O.; Béduer, A.; Krause, K.H.; Braschler, T. Neurothreads: Development of supportive carriers for mature dopaminergic neuron differentiation and implantation. Biomaterials 2021, 270, 120707. [Google Scholar]

- Bruns, J.; McBride-Gagyi, S.; Zustiak, S.P. Injectable and cell-adhesive polyethylene glycol cryogel scaffolds: Independent control of cryogel microstructure and composition. Macromol. Mater. Eng. 2018, 303, 1800298. [Google Scholar] [CrossRef]

- Liu, W.; Li, Y.; Zeng, Y.; Zhang, X.; Wang, J.; Xie, L.; Li, X.; Du, Y. Microcryogels as injecTable 3-D cellular microniches for site-directed and augmented cell delivery. Acta Biomater. 2014, 10, 1864–1875. [Google Scholar] [CrossRef]

- Zeng, Y.; Zhu, L.; Han, Q.; Liu, W.; Mao, X.; Li, Y.; Yu, N.; Feng, S.; Fu, Q.; Wang, X.; et al. Preformed gelatin microcryogels as injectable cell carriers for enhanced skin wound healing. Acta Biomater. 2015, 25, 291–303. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Yan, X.; Liu, W.; Zhou, L.; You, Z.; Du, Y. 3D microtissues for injectable regenerative therapy and high-throughput drug screening. J. Vis. Exp. 2017, 128, e55982. [Google Scholar] [CrossRef] [PubMed]

- Villard, P.; Rezaeeyazdi, M.; Colombani, T.; Joshi-Navare, K.; Rana, D.; Memic, A.; Bencherif, S.A. Autoclavable and injectable cryogels for biomedical applications. Adv. Healthc. Mater. 2019, 8, 1900679. [Google Scholar] [CrossRef] [PubMed]

- Béduer, A.; Piacentini, N.; Aeberli, L.; Da Silva, A.; Verheyen, C.A.; Bonini, F.; Rochat, A.; Filippova, A.; Serex, L.; Renaud, P.; et al. Additive manufacturing of hierarchical injectable scaffolds for tissue engineering. Acta Biomater. 2018, 76, 71–79. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Çimen, D.; Özbek, M.A.; Bereli, N.; Mattiasson, B.; Denizli, A. Injectable Cryogels in Biomedicine. Gels 2021, 7, 38. https://doi.org/10.3390/gels7020038

Çimen D, Özbek MA, Bereli N, Mattiasson B, Denizli A. Injectable Cryogels in Biomedicine. Gels. 2021; 7(2):38. https://doi.org/10.3390/gels7020038

Chicago/Turabian StyleÇimen, Duygu, Merve Asena Özbek, Nilay Bereli, Bo Mattiasson, and Adil Denizli. 2021. "Injectable Cryogels in Biomedicine" Gels 7, no. 2: 38. https://doi.org/10.3390/gels7020038

APA StyleÇimen, D., Özbek, M. A., Bereli, N., Mattiasson, B., & Denizli, A. (2021). Injectable Cryogels in Biomedicine. Gels, 7(2), 38. https://doi.org/10.3390/gels7020038