The Effect of Halloysite Addition on the Material Properties of Chitosan–Halloysite Hydrogel Composites

Abstract

1. Introduction

2. Results

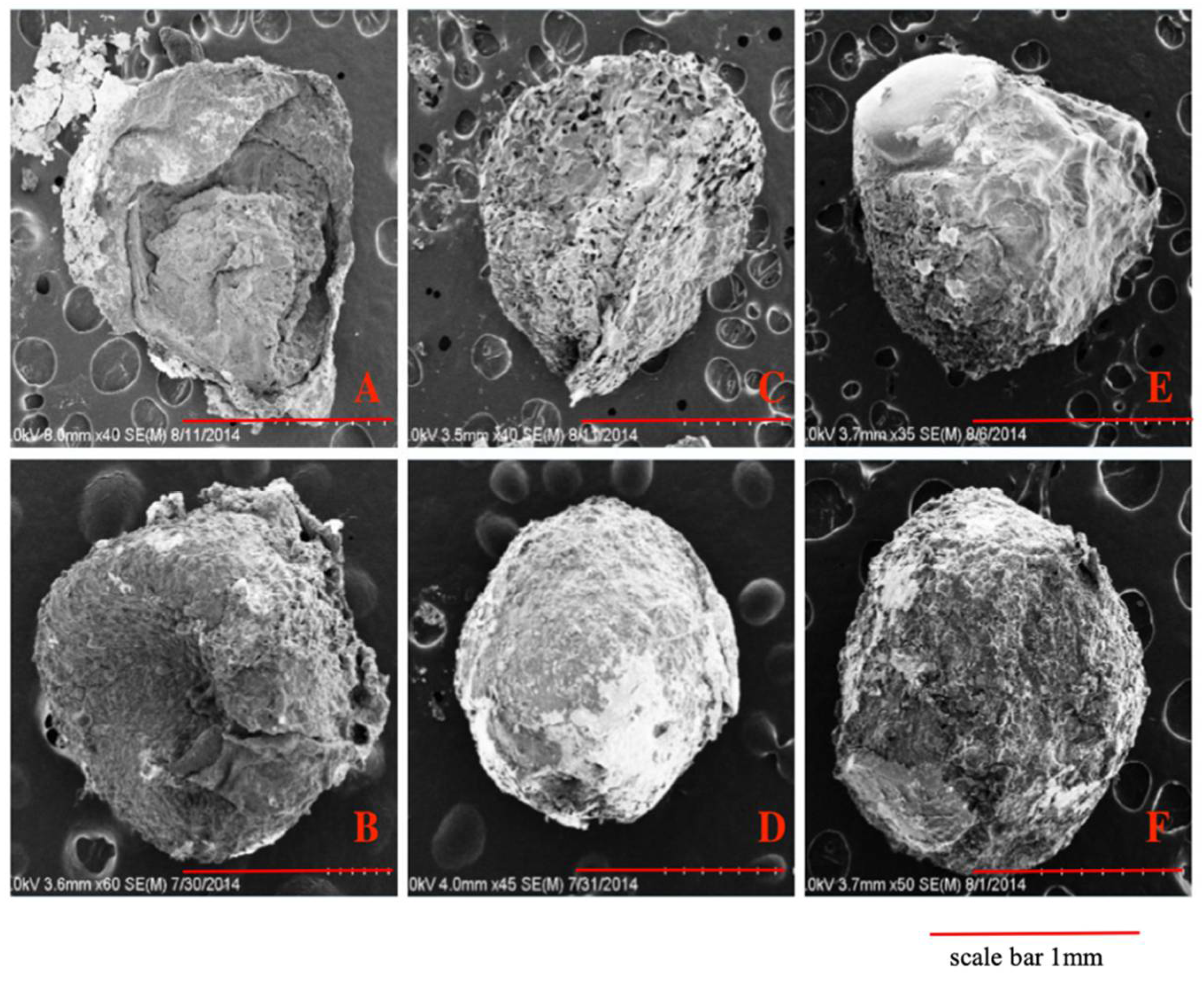

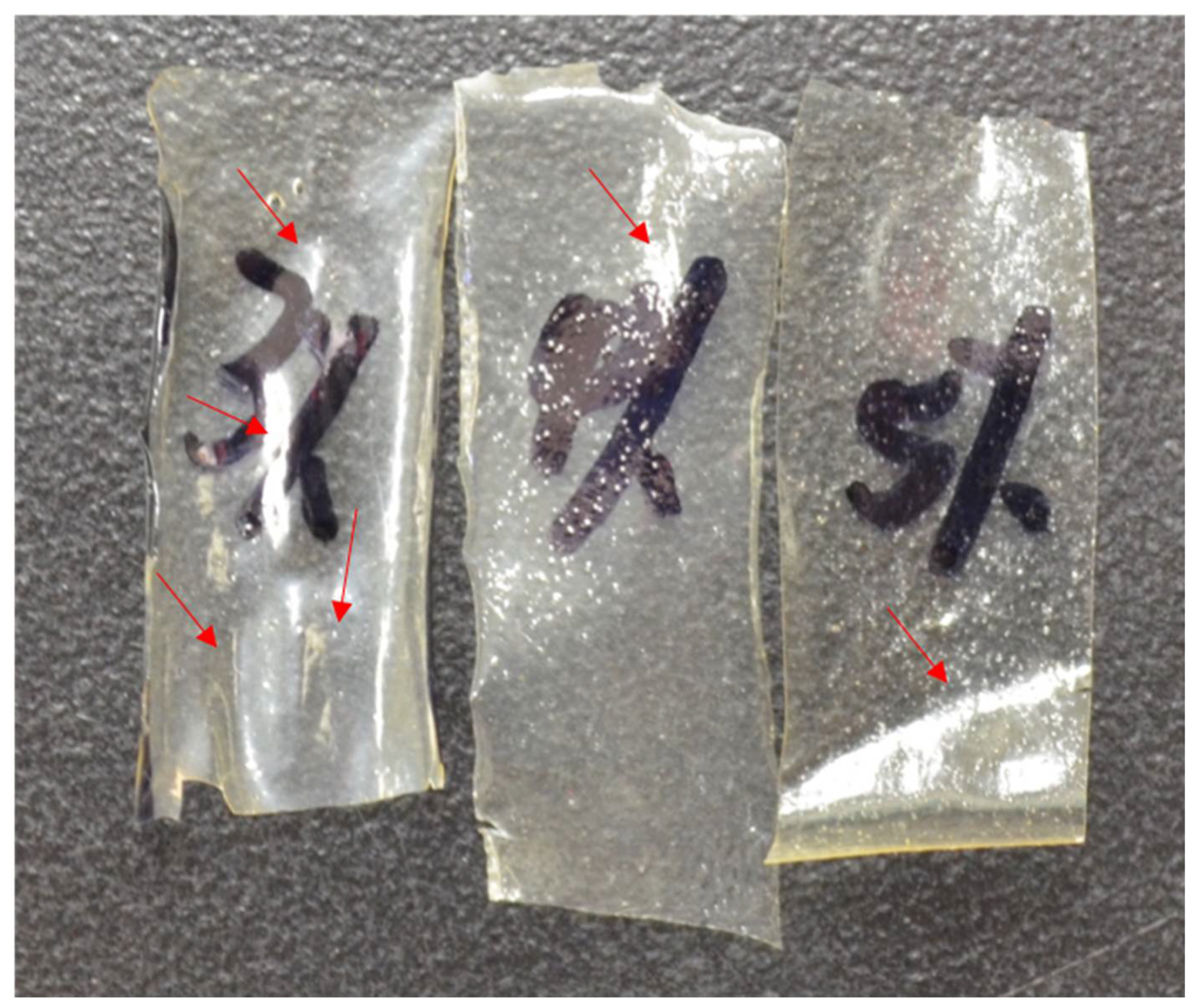

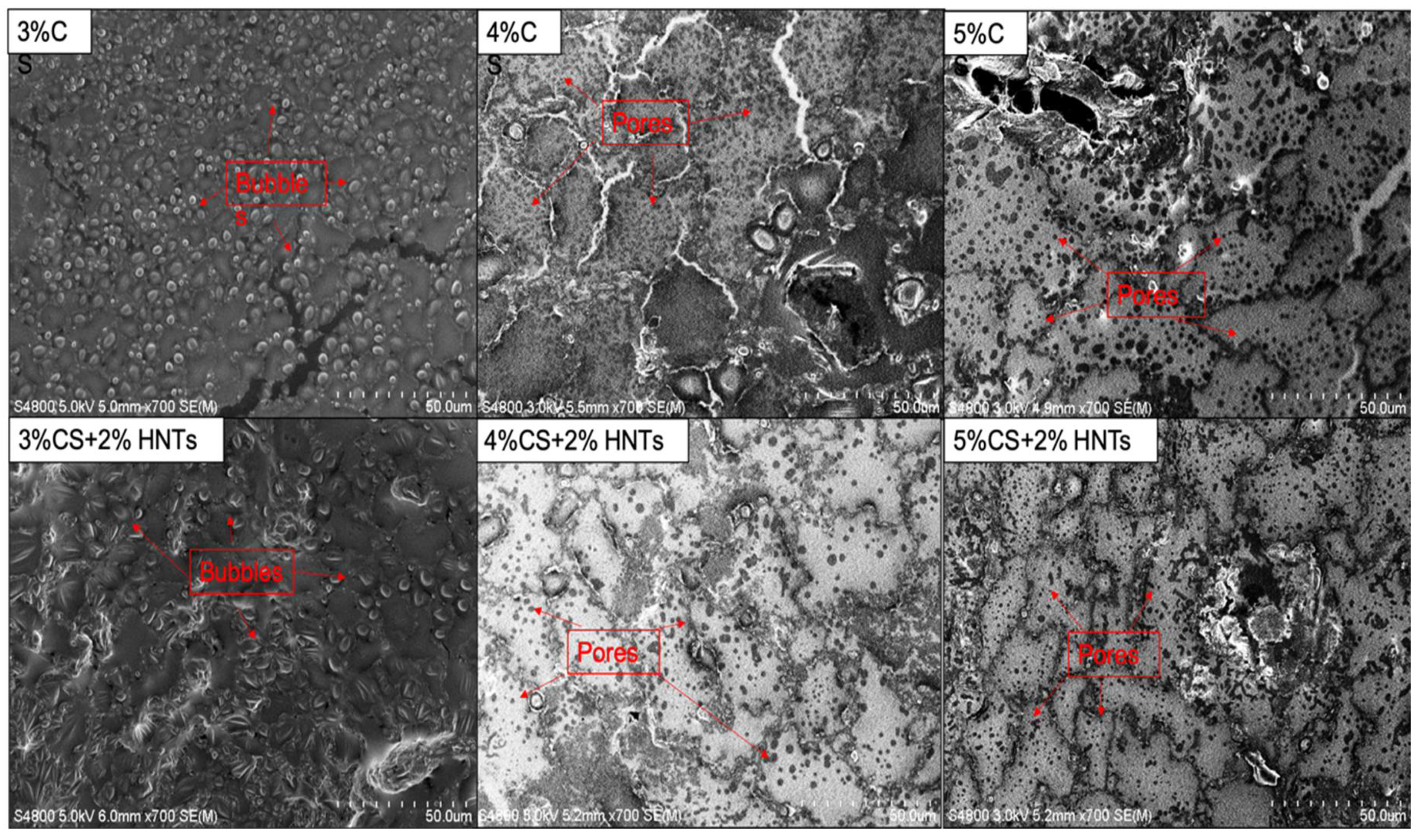

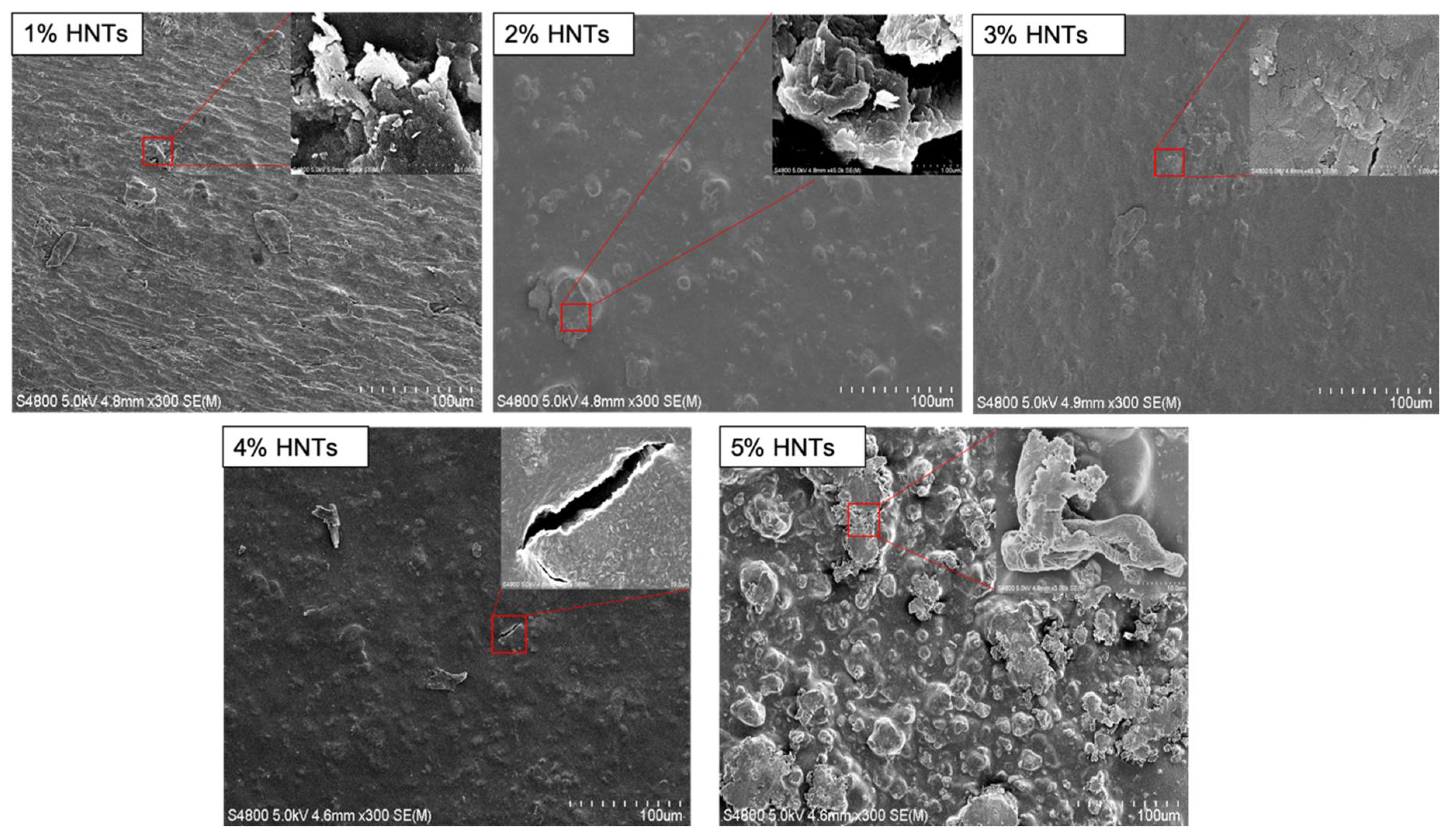

2.1. SEM

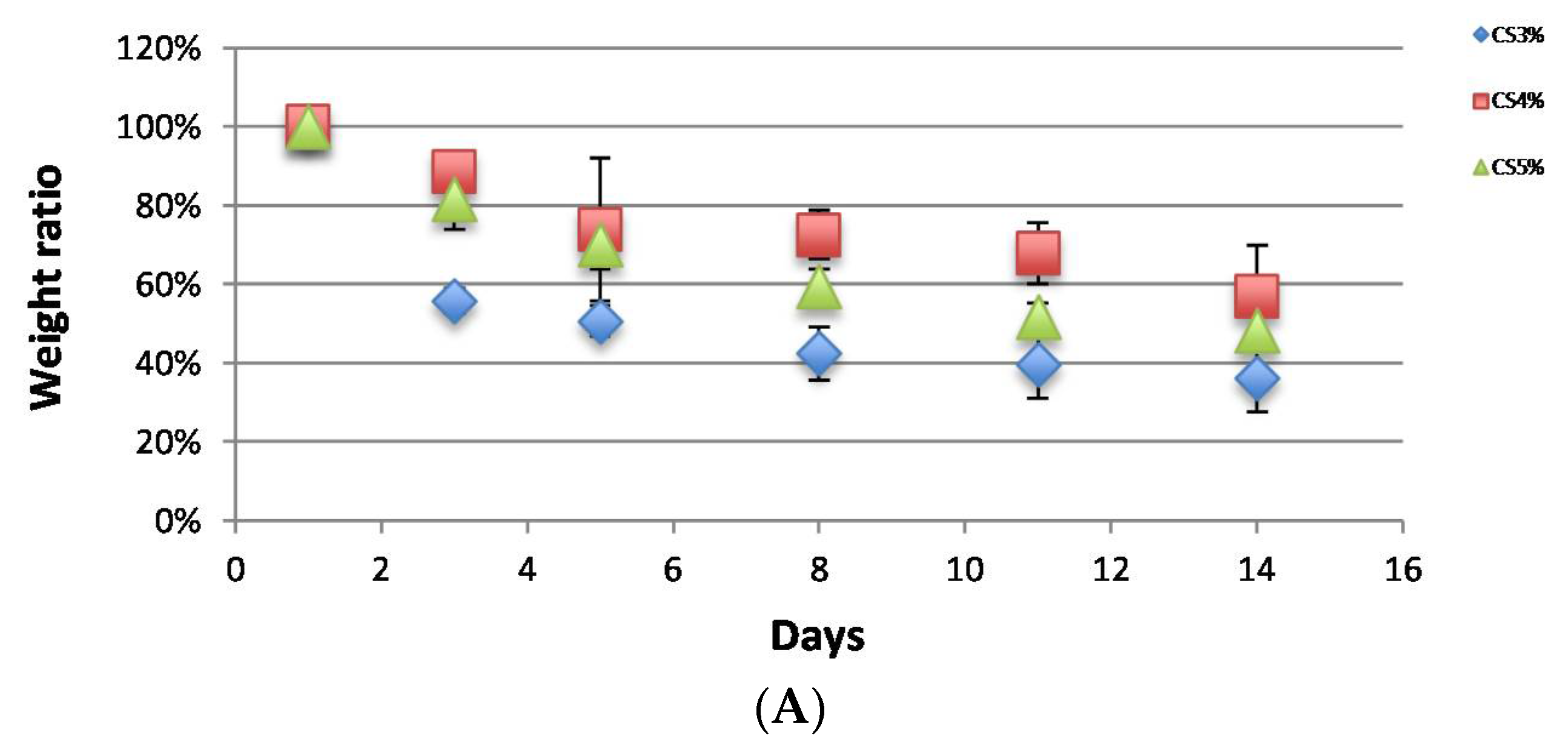

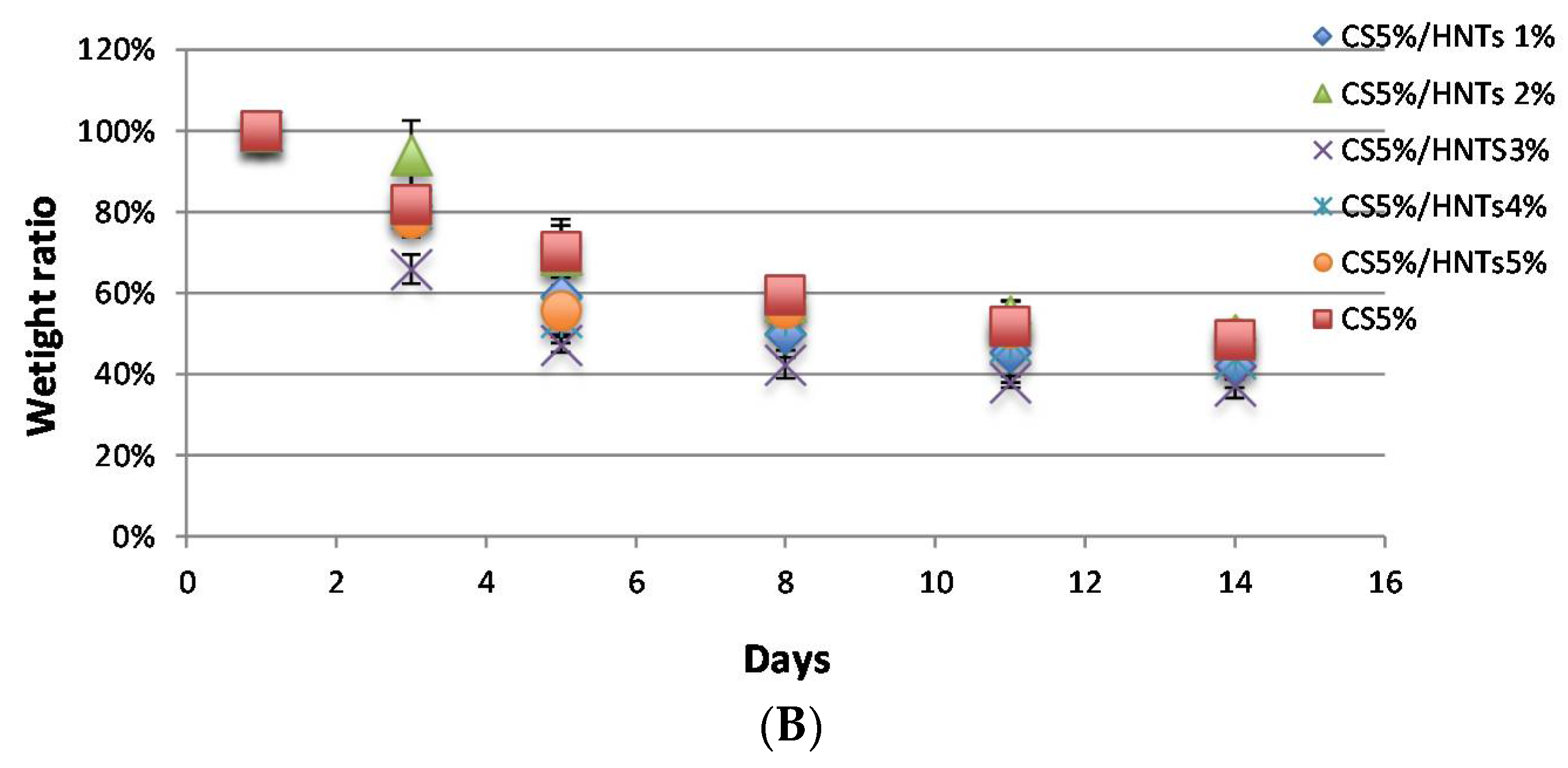

2.2. Degradation

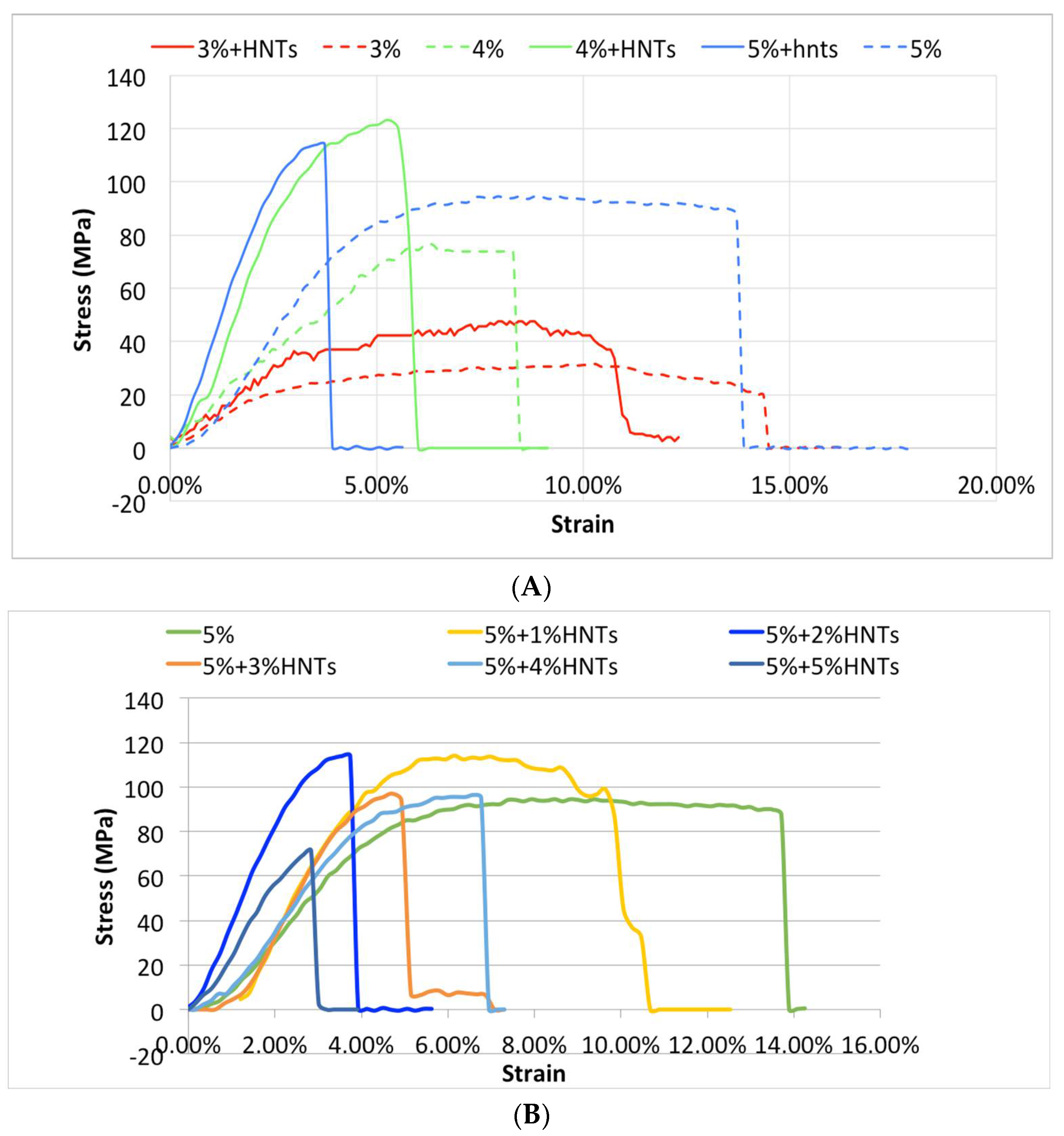

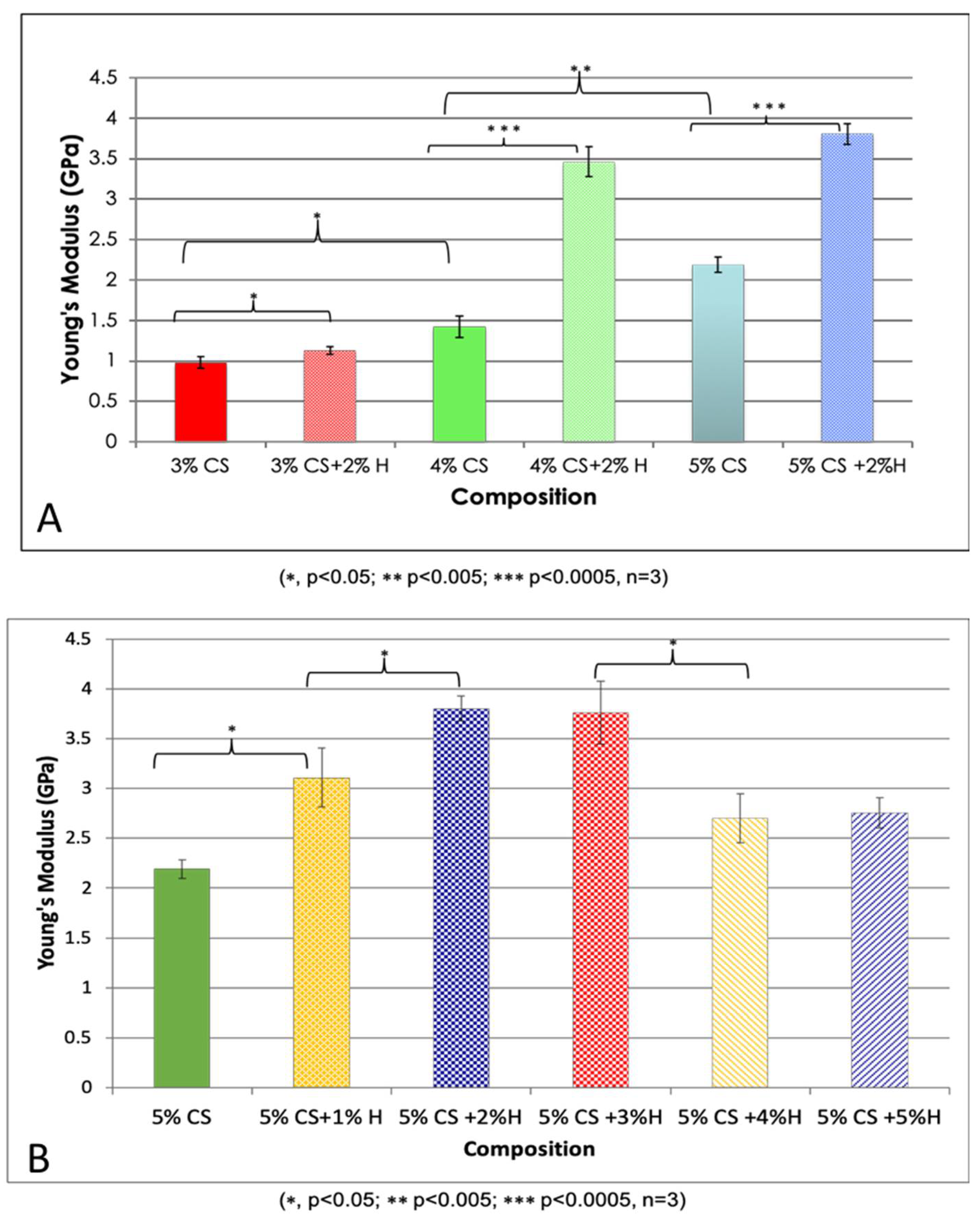

2.3. Tensile Property

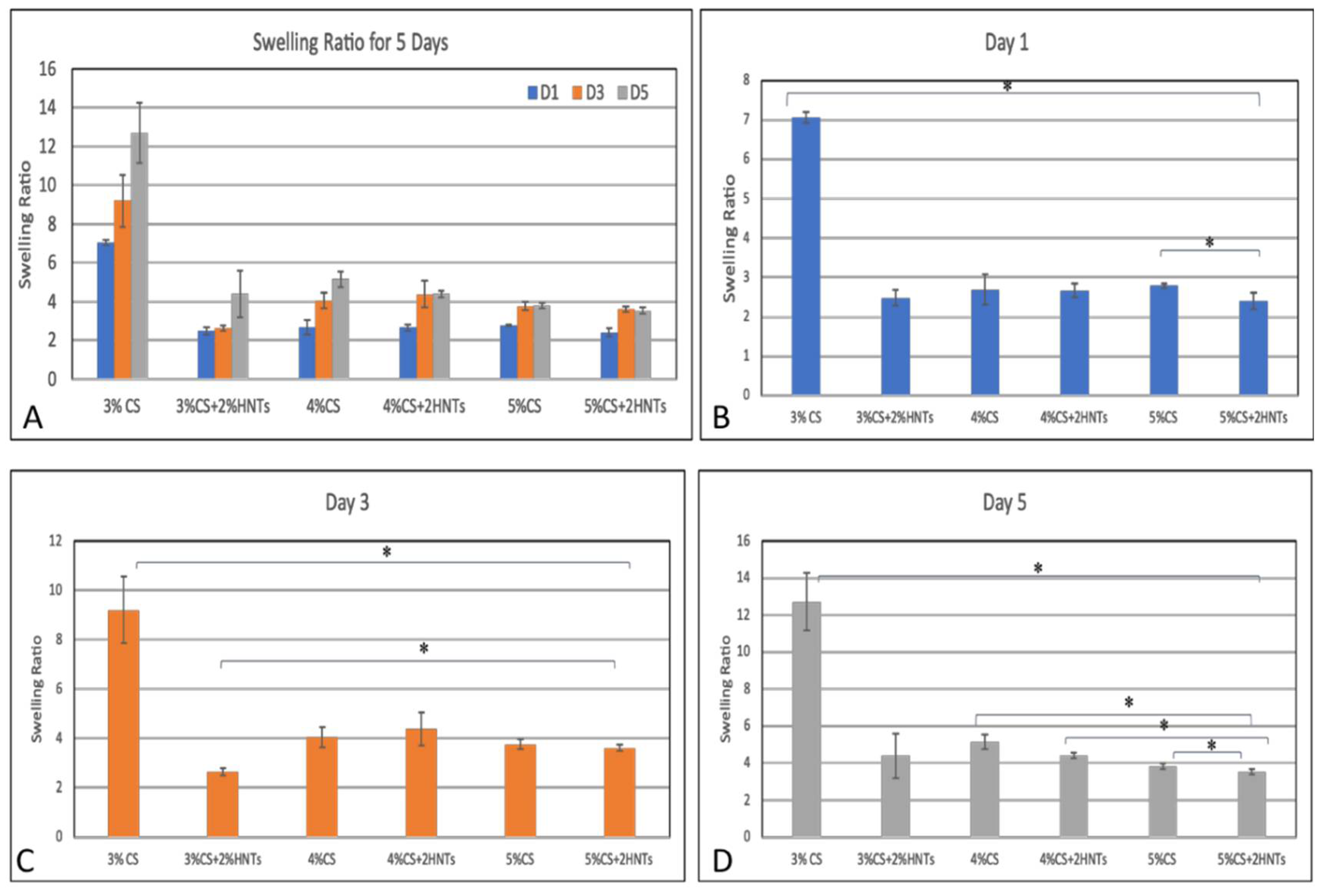

2.4. Swelling Ratio

2.5. Drug Release

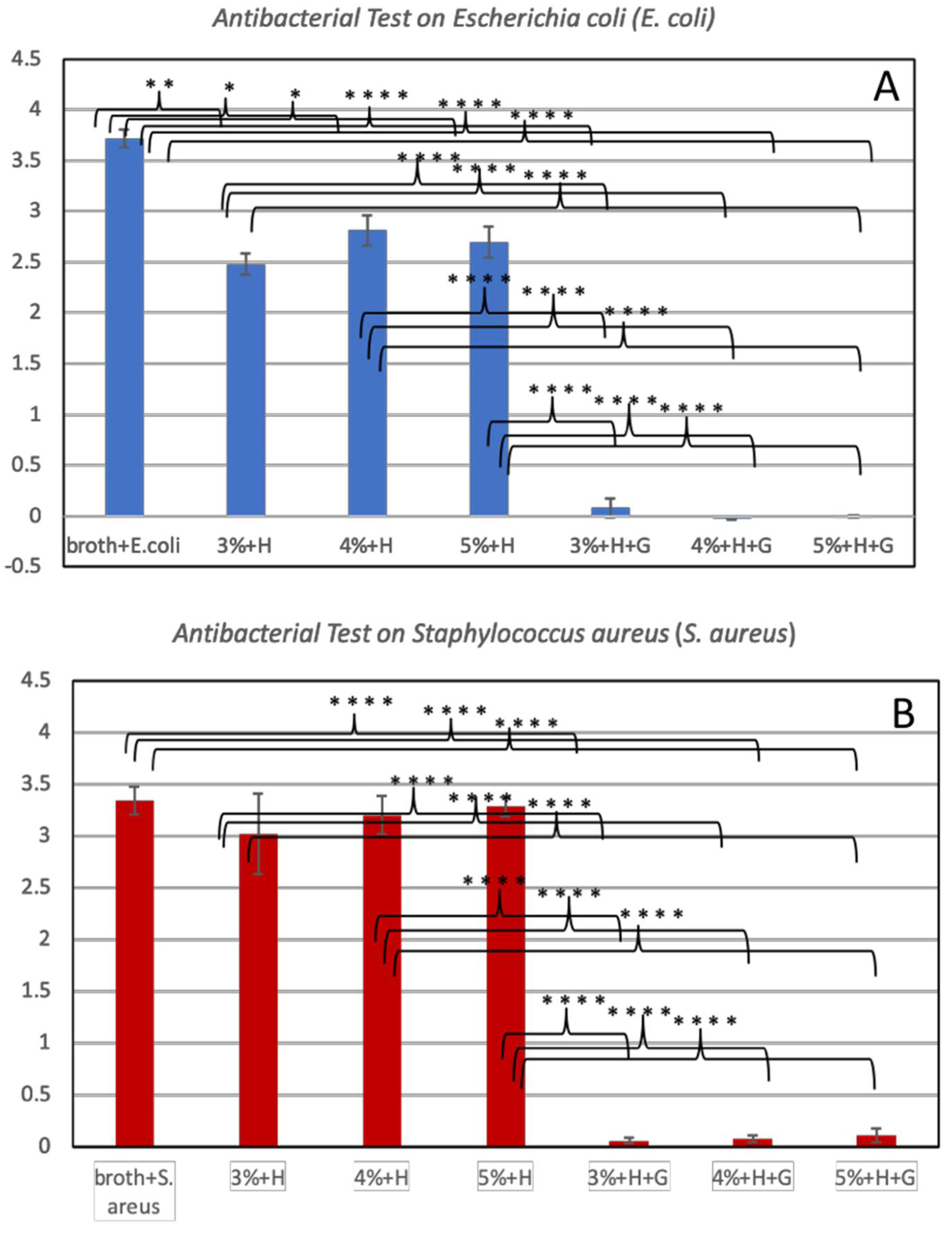

2.6. Bacterial Growth Inhibition Testing

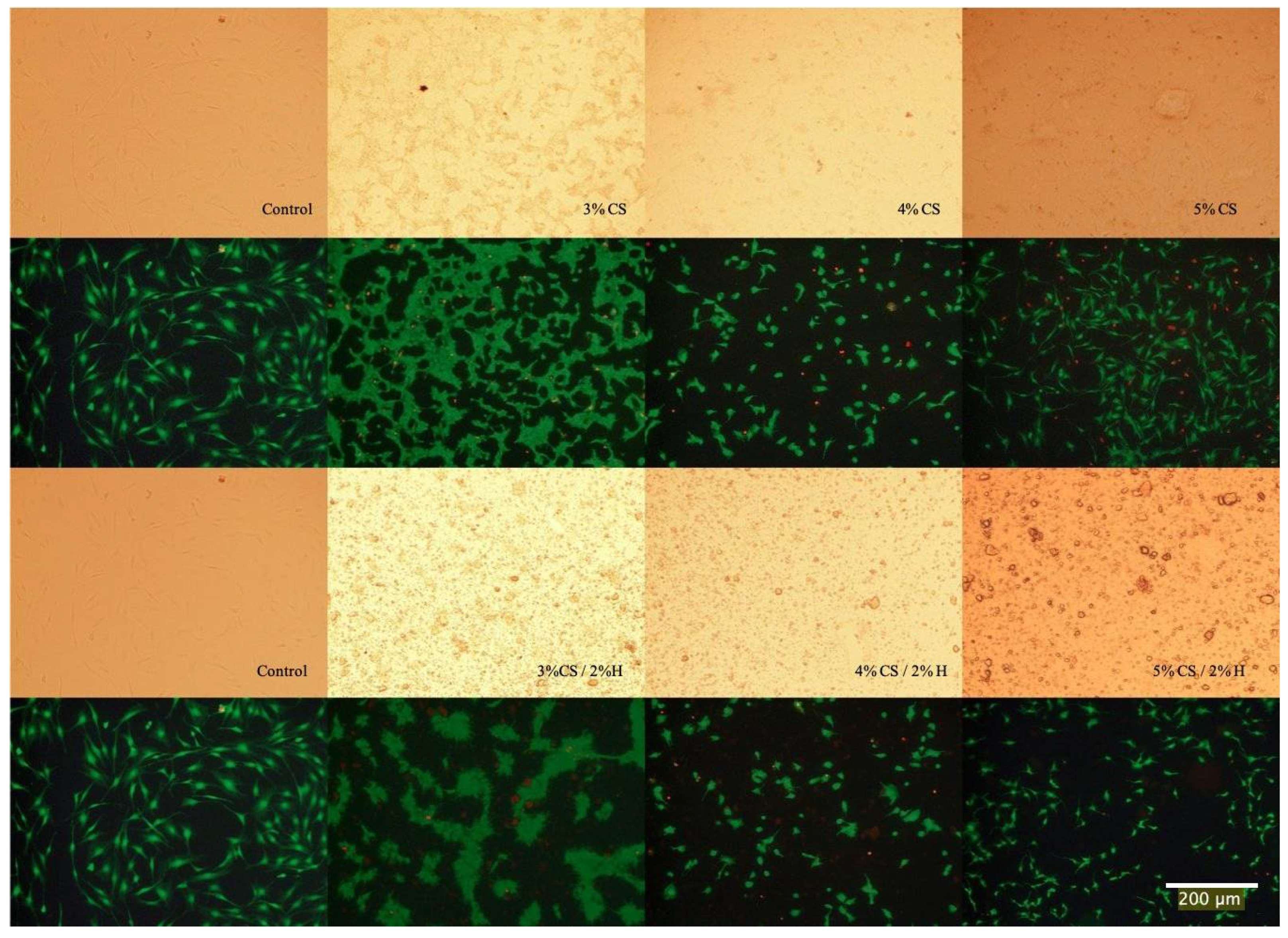

2.7. Live/Dead Assay

3. Discussion

4. Conclusions

5. Experimental Section

5.1. Drug Loading

5.2. HNTs-Chitosan Hydrogel Construct

5.3. Scanning Electron Microscopy (SEM) Study

5.4. Degradation Analysis

5.5. Tensile Properties

5.6. Drug Release Study

5.7. Swelling Ratio

5.8. Bacterial Inhibition Growth Test

5.9. Live/Dead Cytotoxicity Assay

5.10. Statistical Analysis

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Poveda-Roda, R.; Bagán, J.V.; Sanchis-Bielsa, J.M.; Carbonell-Pastor, E. Antibiotic use in dental practice. A review. Med. Oral Patol. Oral Cir. Bucal 2007, 12, 186–192. [Google Scholar]

- Chen, M.; Yu, Q.; Sub, H. Novel strategies for the prevention and treatment of biofilm related infections. Int. J. Mol. Sci. 2013, 14, 18488–18501. [Google Scholar] [CrossRef] [PubMed]

- Allahverdiyev, A.M.; Kon, K.V.; Abamor, E.S.; Bagirova, M.; Rafailovich, M. Copping with antibiotic resistance: Combining nanoparticles with antibiotics and other antimicrobial agents. Expert Rev. Anti Infect. Ther. 2011, 9, 1035–1052. [Google Scholar] [CrossRef] [PubMed]

- Rinaudo, M. Chitin and chitosan: Properties and applications. Prog. Polym. Sci. 2006, 31, 603–632. [Google Scholar] [CrossRef]

- Muzzarelli, R.A.A. Human enzymatic activities related to the therapeutic administration of chitin derivatives. Cell Mol. Life Sci. 1997, 53, 131–140. [Google Scholar] [CrossRef] [PubMed]

- Prabaharan, M.; Mano, J.F. Chitosan-based particles as controlled drug delivery systems. Drug Deliv. 2005, 12, 41–57. [Google Scholar] [CrossRef] [PubMed]

- Divya, K.; Vijayan, S.; George, T.K.; Jisha, M.S. Antimicrobial properties of chitosan nanoparticles: Mode of action and factors affecting activity. Fibers Polym 2017, 18, 221–230. [Google Scholar] [CrossRef]

- Dash, M.; Chiellini, F.; Ottenbrite, R.M.; Chiellini, E. Chitosan—A versatile semi-synthetic polymer in biomedical applications. Prog. Polym. Sci. 2011, 36, 981–1014. [Google Scholar] [CrossRef]

- Kashyap, M.; Archana, D.; Semwal, A.; Dutta, J.; Dutta, P.K. Chitosan: A Promising Substrate for Regenerative Medicine in Drug Formulation. In Chitin and Chitosan for Regenerative Medicine; Springer: New Delhi, India, 2016; pp. 261–277. [Google Scholar]

- Di Martino, A.; Sittinger, M.; Risbud, M.V. Chitosan: A versatile biopolymer for orthopaedic tissue-engineering. Biomaterials 2005, 26, 5983–5990. [Google Scholar] [CrossRef]

- Wu, T.; Li, Y.; Lee, D.S. Chitosan-based composite hydrogels for biomedical applications. Macromol. Res. 2017, 25, 480–488. [Google Scholar] [CrossRef]

- Yao, K.D.; Yao, A.L.; Yin, Y.J. Chitosan-Based Hydrogels: Functions and Application; CRC Press: London, UK, 2010. [Google Scholar]

- Wang, S.-F.; Shen, L.; Zhang, W.-D.; Tong, Y.-J. Preparation and mechanical properties of chitosan/carbon nanotubes composites. Biomacromolecules 2005, 6, 3067–3072. [Google Scholar] [CrossRef] [PubMed]

- Chatterjee, S.; Lee, M.W.; Woo, S.-H. Enhanced mechanical strength of chitosan hydrogel beads by impregnation with carbon nanotubes. Carbon 2009, 47, 2933–2936. [Google Scholar] [CrossRef]

- Hong, S.I.; Lee, J.H.; Bae, H.J.; Koo, S.Y.; Lee, H.S.; Choi, J.H.; Kim, D.H.; Park, S.H.; Park, H.J. Effect of shear rate on structural, mechanical, and barrier properties of chitosan/montmorillonite nanocomposite film. J. Appl. Polym. Sci. 2011, 119, 2742–2749. [Google Scholar] [CrossRef]

- Park, H.; Guo, X.; Temenoff, J.; Kasper, F.; Mikos, A. Effect of swelling ratio of intectable hydrogel composites on chondrongenix differentiation of encapsculated rabbit marrow mesenchymal stem cells in vitro. Biomacromolecules 2010, 10, 541–546. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Zhang, Y.; Wu, C.; Xiong, S.; Zhou, C. Chitosan/halloysite nanotubes bionanocomposites: Structure, mechanical properties and biocompatibility. Int. J. Biol. Macromol. 2012, 51, 566–575. [Google Scholar] [CrossRef]

- Chen, J.; Murphy, A.; Scholz, D.; Geever, L.; Lyson, J.; Devine, D. Surface-modified halloysite nanotubes reinforced poly(lactic acid) for use in biodegradable coronary stents. J. Appl. Polym. Sci. 2018, 135, 46521. [Google Scholar] [CrossRef]

- Karnik, S.; Hines, K.; Mills, D.K. Nanoenhanced hydrogel system with sustained release capabilities. J. Biomed. Mater. Res. Part A 2015, 103, 2416–2426. [Google Scholar] [CrossRef]

- Bordeepong, S.; Bhongsuwan, D.; Pungrassami, T.; Bongsuwan, T. Characterization of halloysite from Thung Yai District, Nahkon Si Thammarat Province, in Southern Thailand. Warasan Songkhla Nakharin 2011, 33, 599–607. [Google Scholar]

- Ahmed, F.R.; Shoaib, M.H.; Azhar, M.; Um, S.H.; Yousuf, R.I.; Hashmi, S.; Dar, A. Invitro assessment of cytotoxicity of halloysite nanotubes against HepG2, HCT116 and human peripheral blood lymphocytes. Colloids Surf. B 2015, 135, 50–55. [Google Scholar] [CrossRef]

- Fakhrullina, G.I.; Akhatova, F.S.; Lvov, Y.M.; Fakhrullin, R.F. Toxicity of halloysite clay nanotubes in vivo: A Caenorhabditis elegans study. Environ. Sci. Nano 2015, 2, 54–59. [Google Scholar] [CrossRef]

- Lai, X.; Agarwal, M.; Lvov, Y.M.; Pachpande, C.; Varahramyan, K.; Witzmann, F.A. Proteomic profiling of halloysite clay nanotube exposure in intestinal cell coculture. J. Appl. Toxicol. 2012, 33, 1316–1329. [Google Scholar]

- Albdiry, M.T.; Yousif, B.F. Role of silanized halloysite nanotubes on structural, mechanical properties and fracture toughness of thermoset nanocomposites. Mater. Des. 2014, 57, 279–288. [Google Scholar] [CrossRef]

- Deen, I.; Pang, X.; Zhitomirsky, I. Electrophoretic deposition of composite chitosan–halloysite nanotube–hydroxyapatite films. Colloids Surf. A Physicochem. Eng. Asp. 2012, 410, 38–44. [Google Scholar] [CrossRef]

- Garcia, F.J.; Rodriguez, S.G.; Kalytta, A.; Reller, A. Study of natural halloysite from the Dragon Mine. Z. Anorg. Allg. Chem. 2009, 635, 790–795. [Google Scholar] [CrossRef]

- Tappa, K.; Jammalamadaka, U.; Mills, D.K. Formulation and Evaluation of Nanoenhanced Anti-bacterial Calcium Phosphate Bone Cements. In Orthopedic Biomaterials; Springer: Cham, Switzerland, 2017; pp. 85–108. [Google Scholar]

- Liu, M.; Guo, B.; Du, M.; Cai, X.; Jia, D. Properties of halloysite nanotube–epoxy resin hybrids and the interfacial reactions in the systems. Nanotechnology 2007, 18, 455703. [Google Scholar] [CrossRef]

- Sun, L.; Boyer, C.; Grimes, R.; Mills, D.K. Drug coated clay nanoparticles for delivery of chemotherapeutics. Curr. Nanosci. 2016, 12, 207–214. [Google Scholar] [CrossRef]

- Wei, W.; Abdullayev, E.; Hollister, A.D.; Mills, D.; Lvov, Y.M. Clay nanotube/poly(methyl methacrylate) bone cement composites with sustained antibiotic release. Macromol. Mater. Eng. 2012, 297, 645–653. [Google Scholar] [CrossRef]

- Rooj, S.; Das, A.; Thakur, V.; Mahaling, R.N.; Bhowmick, A.K.; Heinrich, G. Preparation and properties of natural nanocomposites based on natural rubber and naturally occurring halloysite nanotubes. Mater. Des. 2010, 31, 2151–2156. [Google Scholar] [CrossRef]

- Kamble, R.; Ghag, M.; Gaikawad, S.; Panda, B.K. Halloysite nanotubes and applications: A review. J. Adv. Sci. Res. 2012, 3, 25–29. [Google Scholar]

- Shi, Y.-F.; Tian, Z.; Zhang, Y.; Shen, H.-B.; Jia, N.-Q. Functionalized halloysite nanotube-based carrier for intracellular delivery of antisense oligonucleotides. Nanoscale Res. Lett. 2011, 6, 608. [Google Scholar] [CrossRef]

- Liu, M.; Chang, Y.; Yang, J.; You, Y.; He, R.; Chen, T.; Zhou, C. Functionalized halloysite nanotube by chitosan grafting for drug delivery of curcumin to achieve enhanced anticancer efficacy. J. Mater. Chem. B 2016, 4, 2253–2263. [Google Scholar] [CrossRef]

- Lvov, Y.; Wang, W.; Zhang, L.; Fakhrullin, R. Halloysite clay nanotubes for loading and sustained release of functional compounds. Adv. Mater. 2016, 28, 1227–1250. [Google Scholar] [CrossRef] [PubMed]

- Patel, S.; Jammalamadaka, U.; Sun, L.; Tappa, K.; Mills, D.K. Sustained Release of Antibacterial Agents from Doped Halloysite Nanotubes. Bioengineering 2016, 3, 1. [Google Scholar] [CrossRef] [PubMed]

- Garcia, D.; Ferria, J.M.; Roplib, L.; Martineza, J.L.; Balart, R. Characterization of selectively etched halloysite nanotubes by acid treatment. Appl. Surf. Sci. 2017, 422, 616–625. [Google Scholar] [CrossRef]

- Shukla, S.K.; Mishra, A.K.; Arotiba, O.A.; Mamba, B.B. Chitosan-based nanomaterials: A state-of-the-art review. Int. J. Biol. Macromol. 2013, 59, 46–58. [Google Scholar] [CrossRef] [PubMed]

- Pishbin, F.; Mourino, V.; Gilchrist, J.B.; McComb, D.W.; Kreppel, S.; Salih, V.; Ryan, M.P.; Boccaccini, A.R. Single-step electrochemical deposition of antimicrobial orthopaedic coatings based on a bioactive glass/chitosan/nano-silver composite system. Acta Biomater. 2013, 9, 7469–7479. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Deen, I.; Zhitomirsky, I. Electrophoretic deposition of polyacrylic acid and composite films containing nanotubes and oxide particles. J. Colloid Interface Sci. 2011, 362, 367–374. [Google Scholar] [CrossRef]

- De Silva, R.T.; Pasbakhsh, P.; Goh, K.L.; Chai, S.P.; Ismail, H. Physico-chemical characterization of chitosan/halloysite composite membranes. Polym. Test. 2013, 32, 265–271. [Google Scholar] [CrossRef]

- Liu, M.; Wu, C.; Zhou, C. Chitosan–halloysite nanotubes nanocomposite scaffolds for tissue engineering. J. Mater. Chem. C 2013, 1, 2078–2089. [Google Scholar] [CrossRef]

- Massaro, M.; Giuseppe Colletti, C.; Lazzara, G.; Serena Riela, S. The use of some clay minerals as natural resources or drug carrier applications. J. Funct. Biomater. 2018, 9, 58. [Google Scholar] [CrossRef]

- Aguzzi, C.; Cerezo, P. Visreras, C.; Carmaella, C. Use of clays as drug delivery systems: Possibilities and limitations. Appl. Clay Sci. 2007, 36, 22–36. [Google Scholar] [CrossRef]

- Awad, M.E.; López-Galindo, A.; Setti, M.; El-Rahmany, M.M.; Iborra, C.V. Kaolinite in pharmaceutics and biomedicine. Int. J. Pharm. 2017, 533. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Long, M.; Huang, P.; Yang, H.; Chang, S.; Hu, Y.; Tang, A.; Mao, L. Emerging integrated nanoclay-facilitated drug delivery system for papillary thyroid cancer therapy. Sci. Rep. 2016, 6, 33335. [Google Scholar] [CrossRef] [PubMed]

- Holešováa, S.; Hundáková, M.; Pazdziorac, E. Antibacterial kaolinite based nanocomposites. Proc. Mater. Sci. 2016, 12, 124–129. [Google Scholar] [CrossRef]

- Llz, Y.; Long, M.; Huang, P.; Mao, L. Intercalated 2D nanoclay for emerging drug delivery in cancer therapy. Nano Res. 2017, 10. [Google Scholar] [CrossRef]

- Hun Kim, M.; Choi, G.; Elzatahry, A.; Vinu, A.; Bin Choy, Y.; Choy, J.-H. Review of clay-drug hybrid materials for biomedical applications: Administration routes. Clays Clay Miner. 2016, 64, 115–130. [Google Scholar] [CrossRef]

- Jayrajsinh, S.; Shankar, G.; Pharm, M.; Agrawal, Y.K.; Bakre, L. Montmorillonite nanoclay as a multifaceted drug-delivery carrier: A review. J. Drug Deliv. Sci. Technol. 2017, 39, 200–209. [Google Scholar] [CrossRef]

- Aguzzi, C.; Sandri, G.; Viseras, C.; Bonferoni, M.C.; Cerezo, P.; Rossi, S.; Ferrari, F.; Caramella, C.; Viseras, C. Solid state characterization of silver sulfadiazine loaded on montmorillonite/chitosan nanocomposite for wound healing. Colloids Surf. B Biointerfaces 2014, 113, 152–157. [Google Scholar] [CrossRef]

- Sharma, A.; Puri, V.; Kakkar, V.; Singh, I. Formulation and Evaluation of Silymarin-Loaded Chitosan-Montmorilloite Hydrogel beads for the Potential Treatment of Gastric Ulcers. J. Funct. Biomater. 2018, 9, 52. [Google Scholar] [CrossRef]

- Bothiraja, C.; Thorat, U.H.; Pawar, A.P.; Shaikh, K.S. Chitosan coated layered clay montmorillonite nanocomposites modulate oral delivery of paclitaxel in colonic cancer. Mater. Technol. 2014, 29, B120–B126. [Google Scholar] [CrossRef]

- Thakur, G.; Singh, A.; Singh, I. Chitosan-montmorillonite polymer composites: Formulation and evaluation of sustained release tablets of aceclofenac. Sci. Pharm. 2015, 84, 603–617. [Google Scholar] [CrossRef] [PubMed]

- Salcedo, I.; Aguzzi, C.; Sandri, S. In vitro biocompatibility and mucoadhesion of montmorillonite chitosan nanocomposite: A new drug delivery. Appl. Clay Sci. 2012, 55, 131–137. [Google Scholar] [CrossRef]

- Shchukin, D.G.; Sukhorukov, G.B.; Price, R.R.; Lvov, Y.M. Halloysite nanotubes as biomimetic nanoreactors. Small 2005, 1, 510–513. [Google Scholar] [CrossRef] [PubMed]

- Vergaro, V.; Abdullayev, E.; Lvov, Y.M.; Zeitoun, A.; Cingolani, R.; Rinaldi, R.; Leporatti, S. Cytocompatibility and uptake of halloysite clay nanotubes. Biomacromolecules 2010, 11, 820–826. [Google Scholar] [CrossRef] [PubMed]

- Wenbo, W.; Minullina, R.; Abdullayev, E.; Fakhrullin, R.; Mills, D.K.; Lvov, Y. Enhanced efficiency of antiseptics with sustained release from clay nanotubes. RSC Adv. 2014, 4, 488–494. [Google Scholar]

- Mingliang, D.; Baochun, G.; Demin, J. Newly emerging applications of halloysite nanotubes: A review. Polym. Int. 2008, 59, 574–582. [Google Scholar]

- Lvov, Y.M.; Shchukin, D.G.; Möhwald, H.; Price, R.R. Halloysite clay nanotubes for controlled release of protective agents. ACS Nano 2008, 2, 814–820. [Google Scholar] [CrossRef] [PubMed]

- Abdullayev, E.; Price, R.R.; Shchukin, D.G.; Lvov, T.M. Halloysite tubes as nanocontainers for anticorrosion coating with benzotriazole. Appl. Mater. Interfaces 2009, 1, 437–443. [Google Scholar] [CrossRef]

- Forsgren, J.; Mstorp, E.; Bredenberg, S.; Engqvist, H.; Stromme, M. A Ceramic drug delivery vehicle for oral administration of highly potent opioids. J. Pharm. Sci. 2010, 99, 219–226. [Google Scholar] [CrossRef]

- Srinatha, A.; Pandit, J.K.; Singh, S. Ionic Cross-linked Chitosan Beads for Extended Release of Ciprofloxacin: In vitro Characterization. Indian J. Pharm. Sci. 2008, 70, 16–21. [Google Scholar] [CrossRef]

- Vino, S.; Paryani, P.; Lulu, S.S.; Ghosh, A.R. Formulation and Evaluation of Chitosan Beads of Levocetirizine Dihydrochloride. J. Appl. Pharm. Sci. 2012, 2, 221–225. [Google Scholar] [CrossRef]

- Berger, J.; Reist, M.; Mayer, J.M.; Felt, O.; Peppas, N.A.; Gurny, R. Structure and interactions in covalently and ionically crosslinked chitosan hydrogels for biomedical applications. Eur. J. Pharm. Biopharm. 2004, 57, 19–34. [Google Scholar] [CrossRef]

- Huang, B.; Liu, M.; Zhou, C. Chitosan composite hydrogels reinforced with natural clay nanotubes. Carbohydr. Polym. 2017, 175, 689–698. [Google Scholar] [CrossRef] [PubMed]

- Chiu, Y.-C.; Kocagöz, S.; Larson, J.C.; Brey, E.M. Evaluation of Physical and Mechanical Properties of Porous Poly (Ethylene Glycol)-co-(L-Lactic Acid) Hydrogels during Degradation. PLoS ONE 2013, 8, e60728. [Google Scholar] [CrossRef] [PubMed]

- Fisher, J.P.; Holland, T.A.; Dean, D.; Mikos, A.G. Photoinitiated cross-linking of the biodegradable polyester poly(propylene fumarate). Part II. In vitro degradation. Biomacromolecules 2003, 4, 1335–1342. [Google Scholar] [CrossRef] [PubMed]

- Sokic, S.; Papavasiliou, G. Controlled proteolytic cleavage site presentation in biomimetic PEGDA hydrogels enhances neovascularization in vitro. Tissue Eng. Part A 2012, 18, 2477–2486. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, Y.; Mills, D.K. The Effect of Halloysite Addition on the Material Properties of Chitosan–Halloysite Hydrogel Composites. Gels 2019, 5, 40. https://doi.org/10.3390/gels5030040

Luo Y, Mills DK. The Effect of Halloysite Addition on the Material Properties of Chitosan–Halloysite Hydrogel Composites. Gels. 2019; 5(3):40. https://doi.org/10.3390/gels5030040

Chicago/Turabian StyleLuo, Yangyang, and David K. Mills. 2019. "The Effect of Halloysite Addition on the Material Properties of Chitosan–Halloysite Hydrogel Composites" Gels 5, no. 3: 40. https://doi.org/10.3390/gels5030040

APA StyleLuo, Y., & Mills, D. K. (2019). The Effect of Halloysite Addition on the Material Properties of Chitosan–Halloysite Hydrogel Composites. Gels, 5(3), 40. https://doi.org/10.3390/gels5030040