Transcription of Nanofibrous Cerium Phosphate Using a pH-Sensitive Lipodipeptide Hydrogel Template

Abstract

:1. Introduction

2. Results and Discussion

2.1. Characterization of Self-Assembled Nanofibrous Hydrogel Template

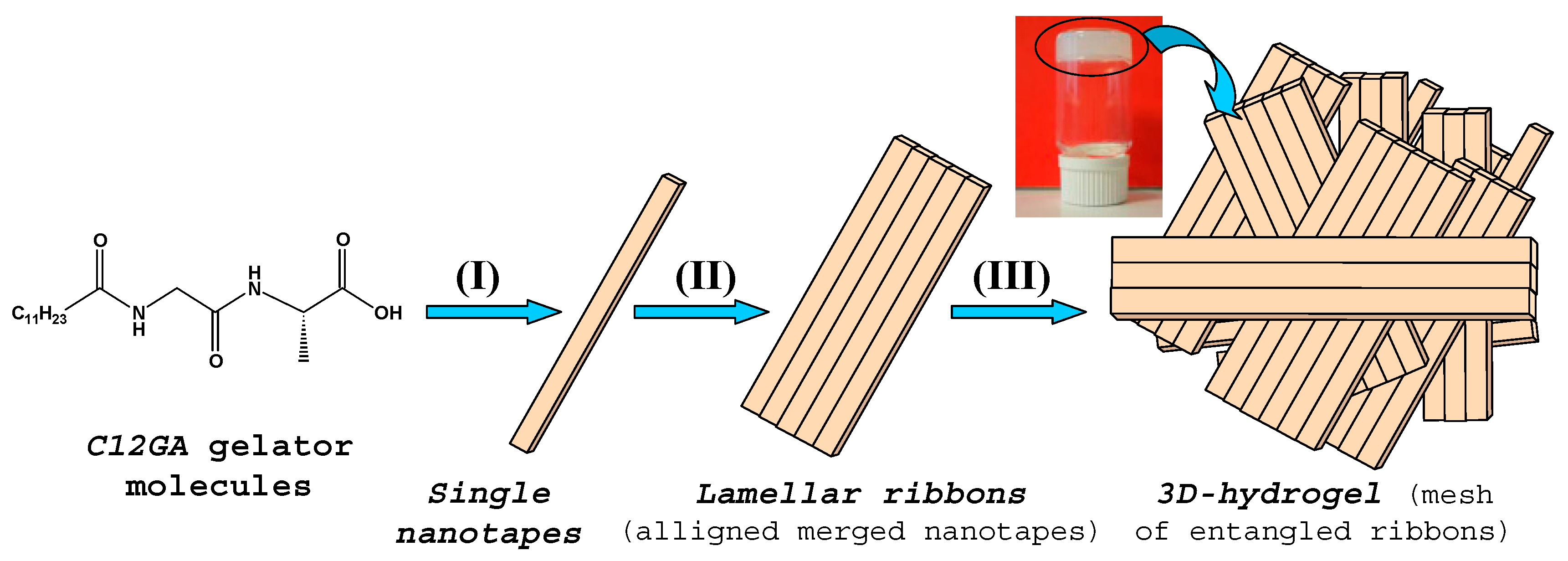

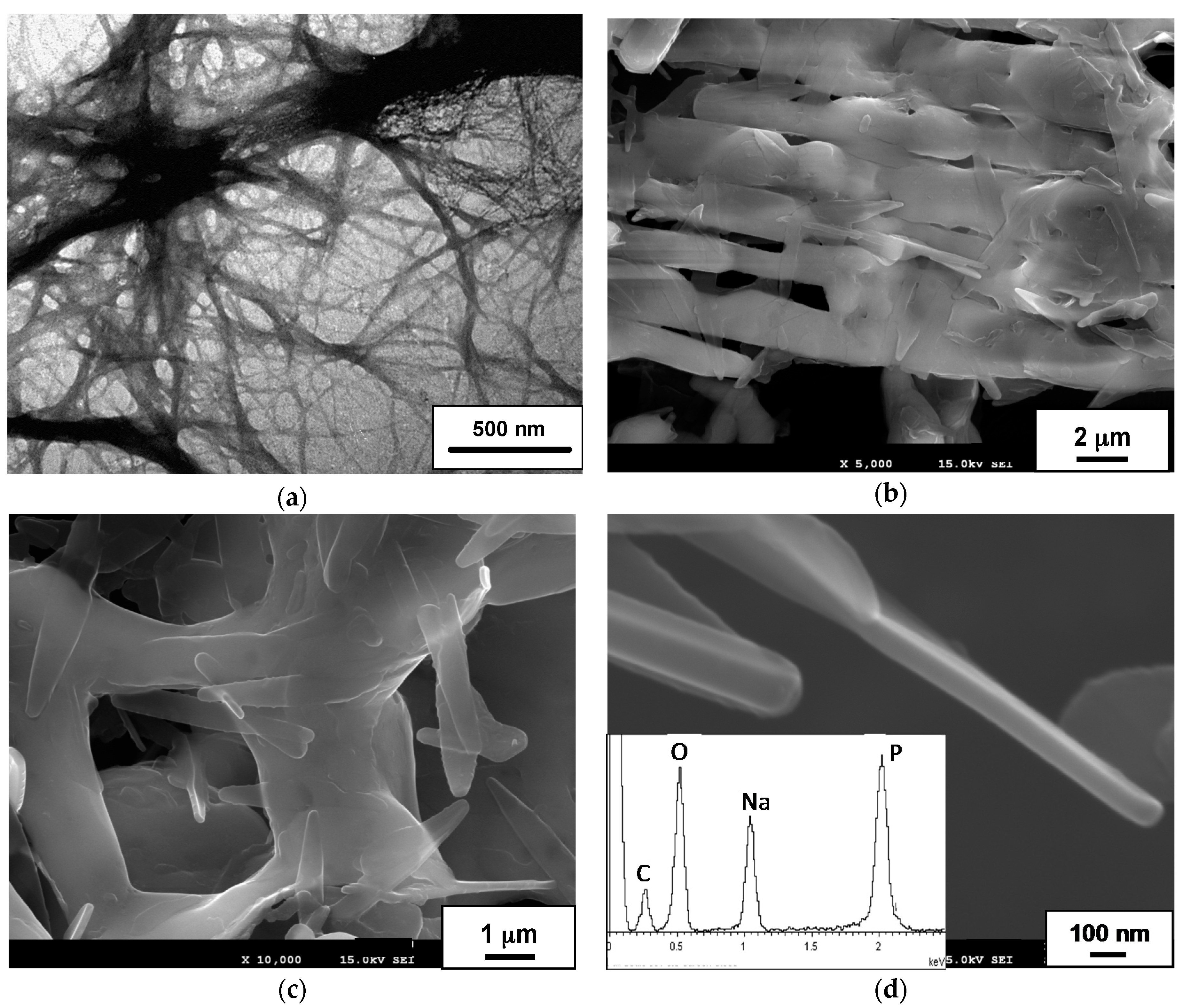

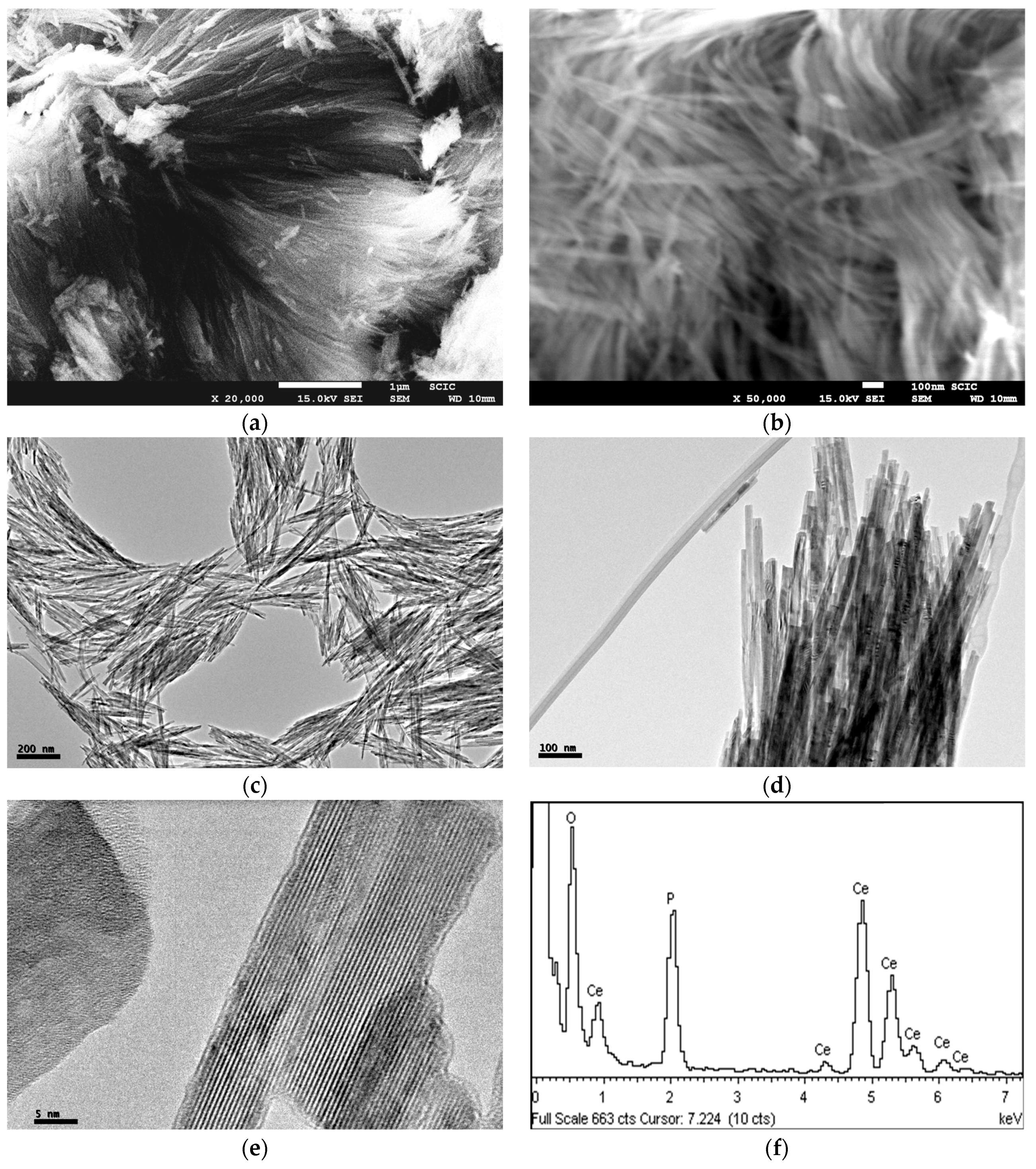

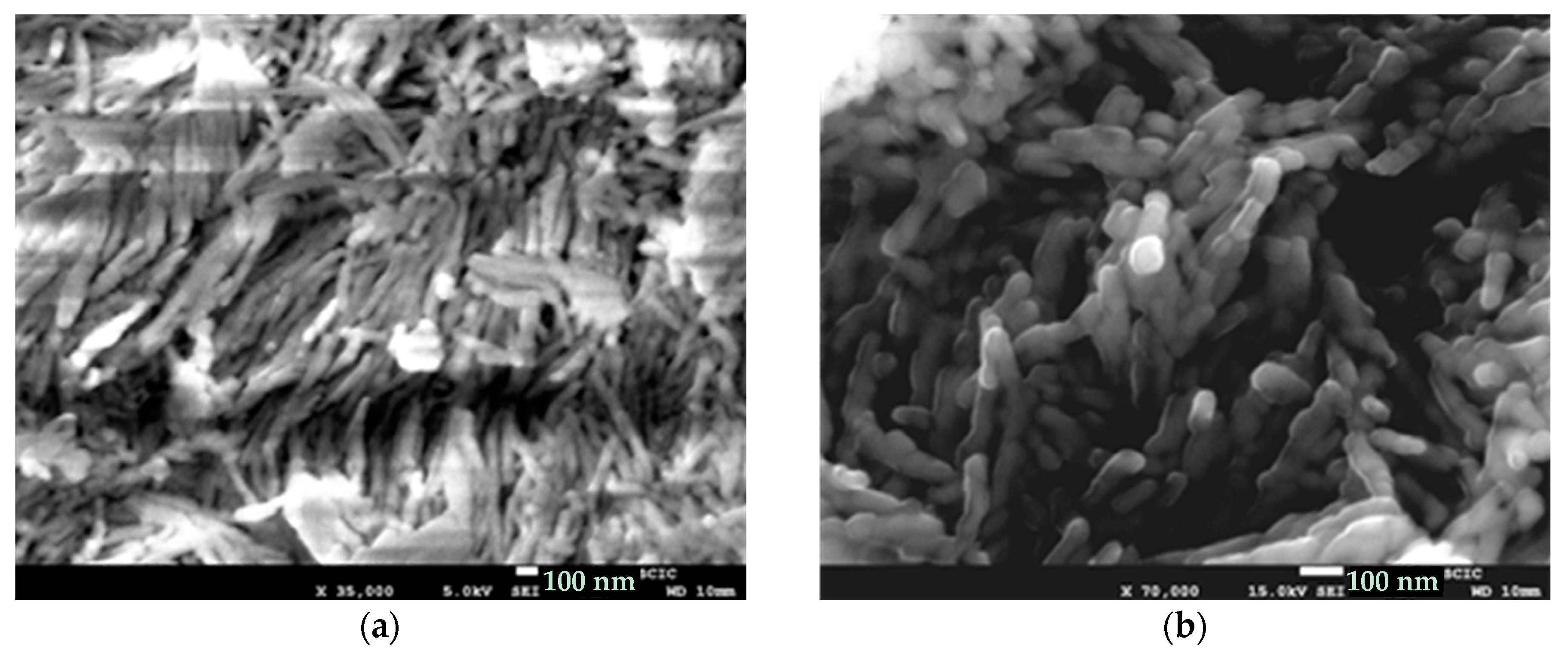

2.1.1. Aggregation Behavior and Morphology (SEM/EDX + TEM) of Nanofibrous C12GA Hydrogel

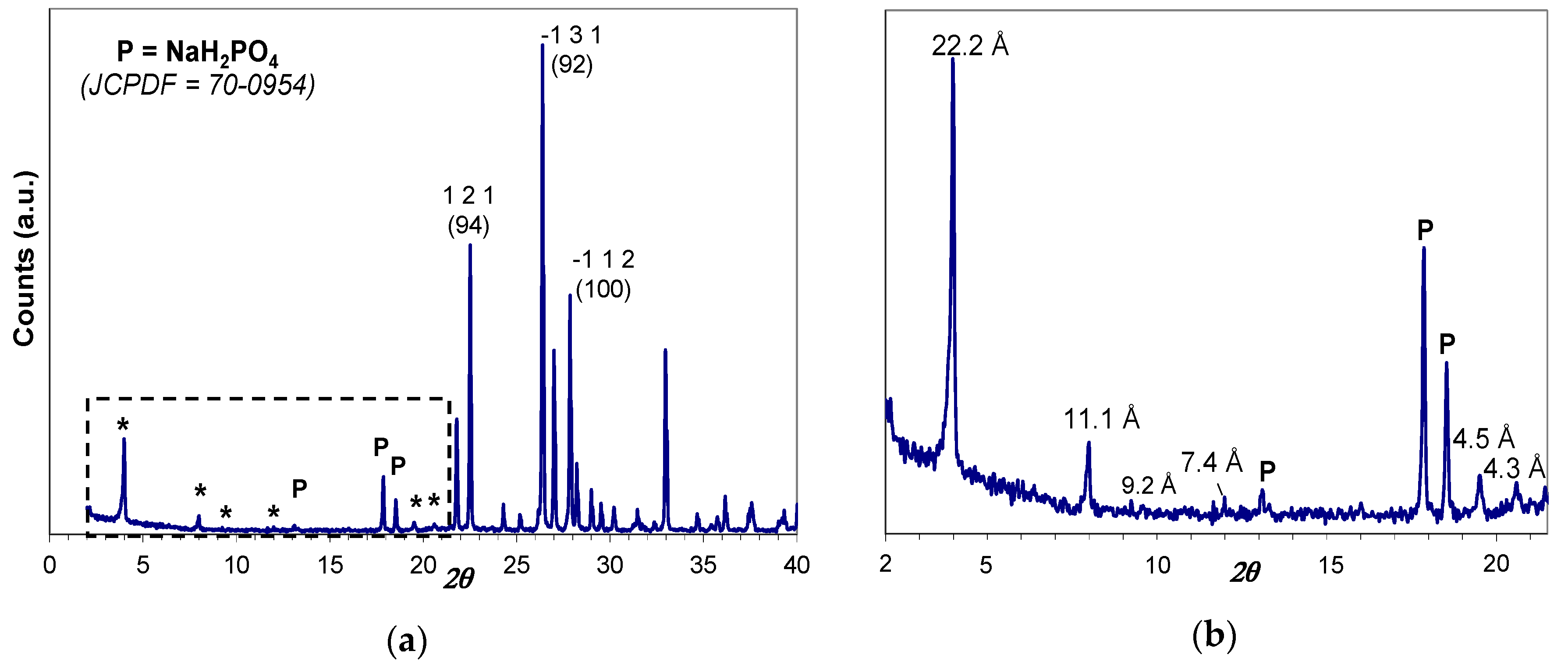

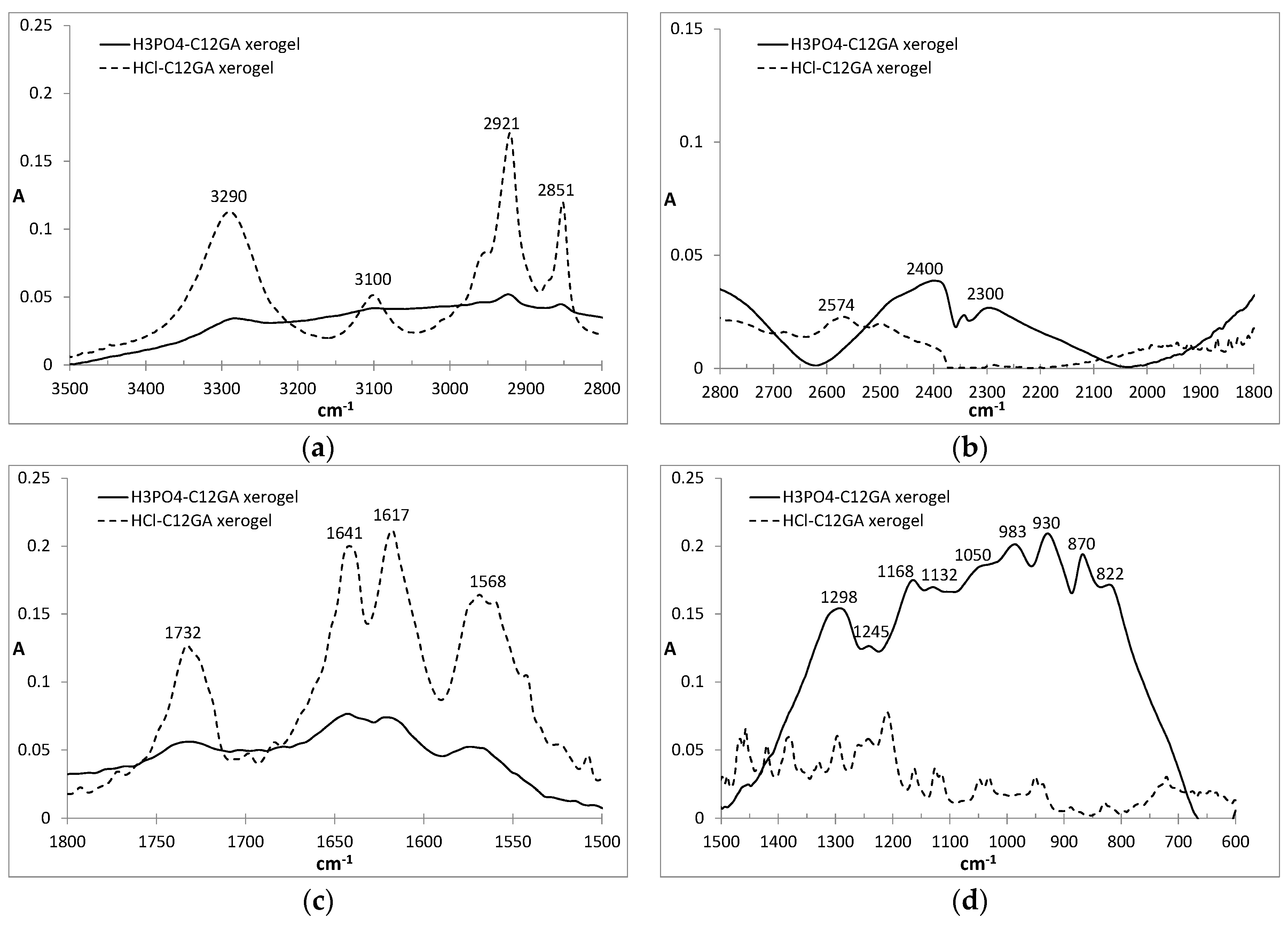

2.1.2. Crystal-Chemical Characterization (by WAXD and FTIR) of Hydrogel Template

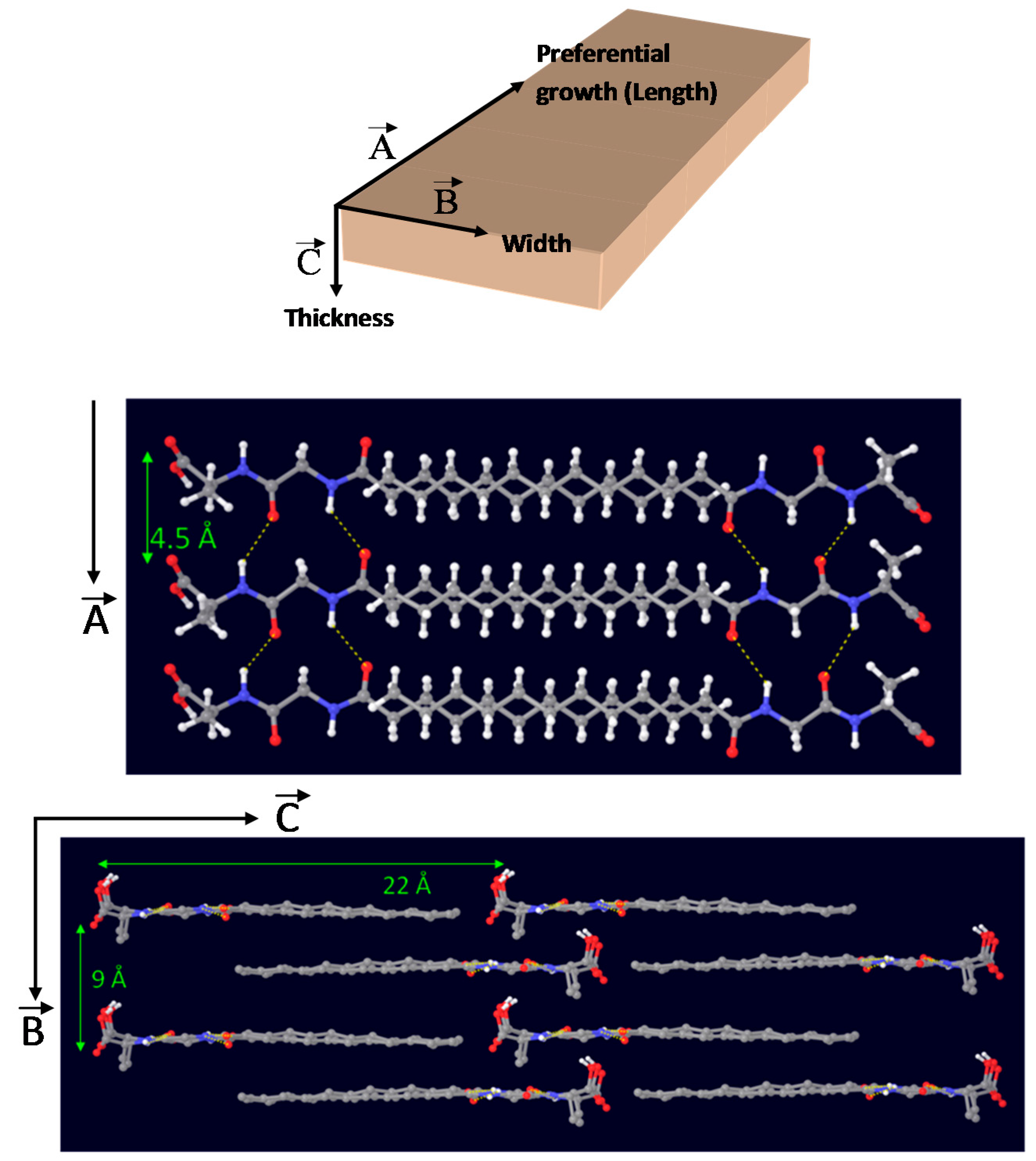

2.1.3. Proposed Model for the Packing of C12GA Gelator in Self-Assembled Hydrogel

2.2. Templated-Based Synthesis and Characterization of Hybrid C12GA-CePO4 Xerogel (60 °C)

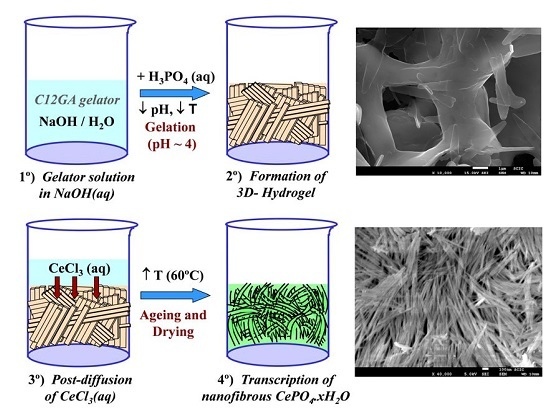

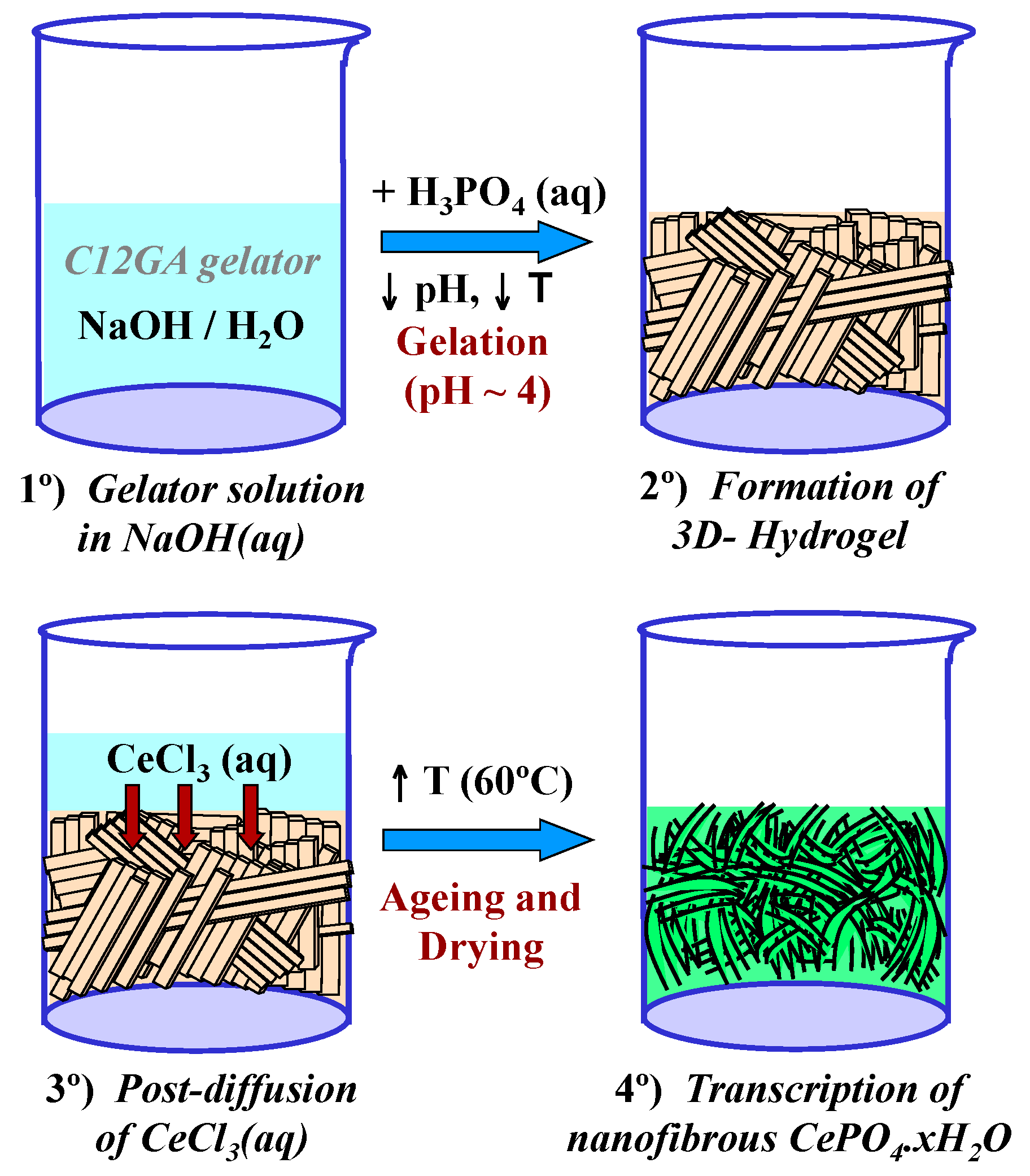

2.2.1. Transcription Strategy for the Preparation of C12GA-Templated Nanofibrous CePO4

2.2.2. Characterization of Templated Nanofibrous C12GA-CePO4 Xerogel (60 °C)

2.3. Morphology and Crystal-Chemical Characterization of Annealed CePO4 Samples (250, 600 and 900 °C)

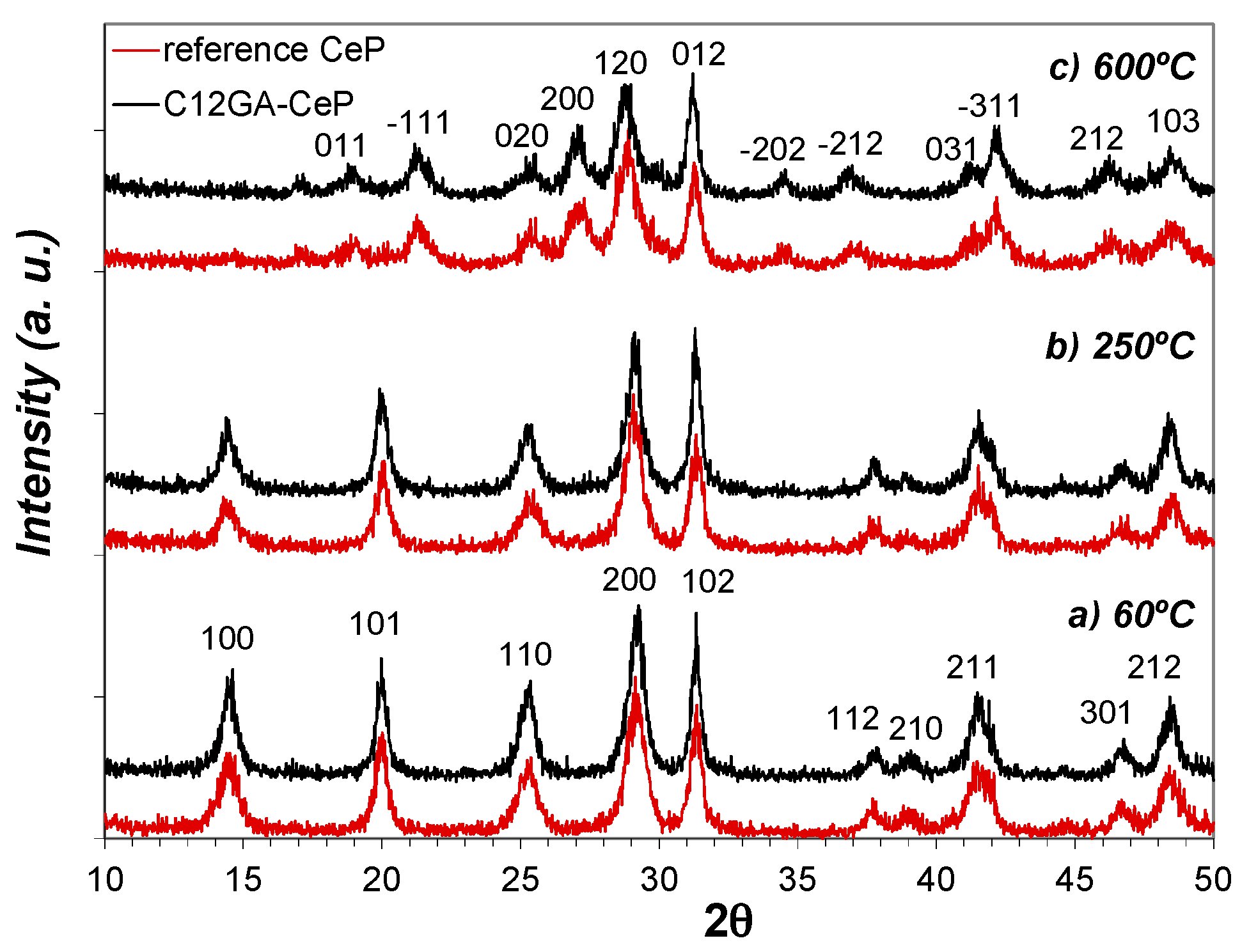

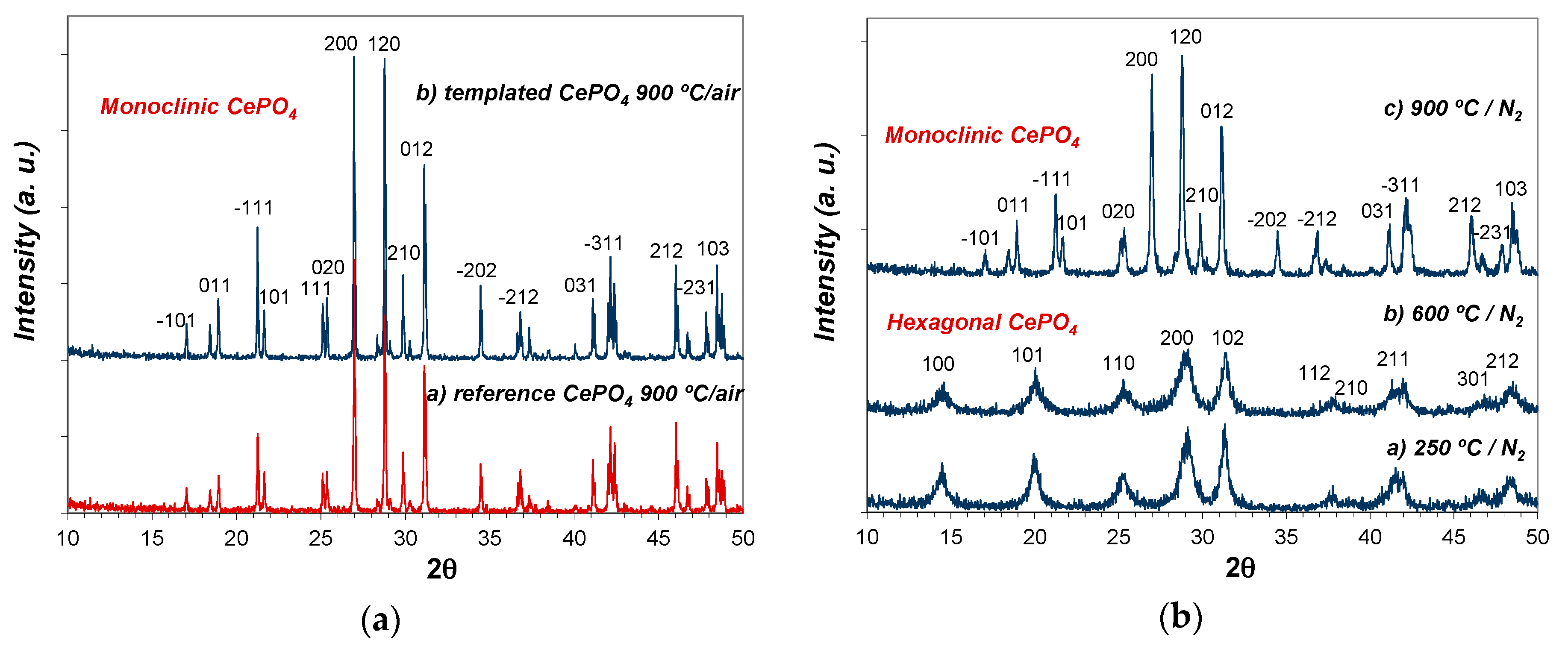

2.3.1. Crystalline Phase Evolution (XRD) after Annealing Treatments at 250, 600 and 900 °C

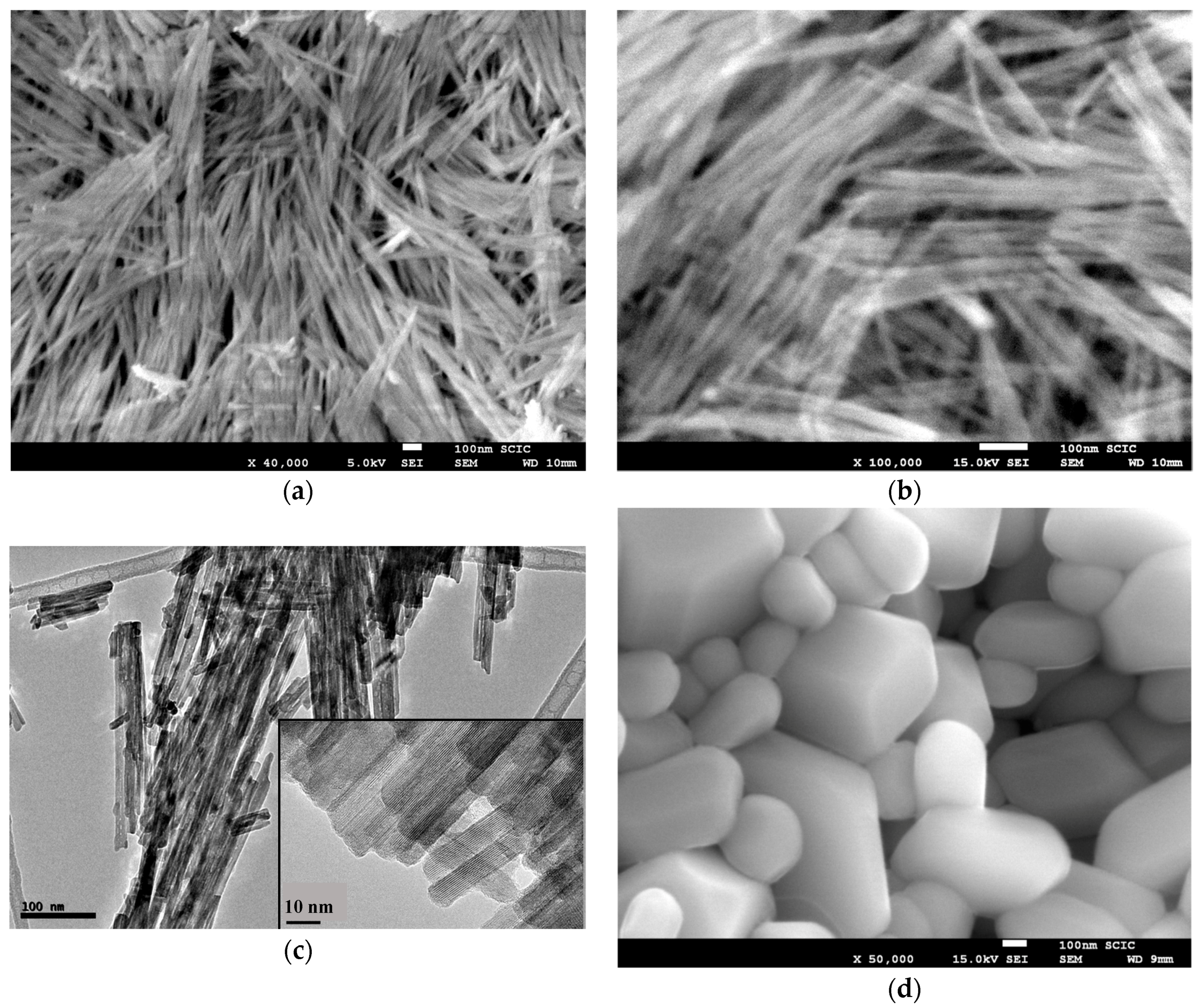

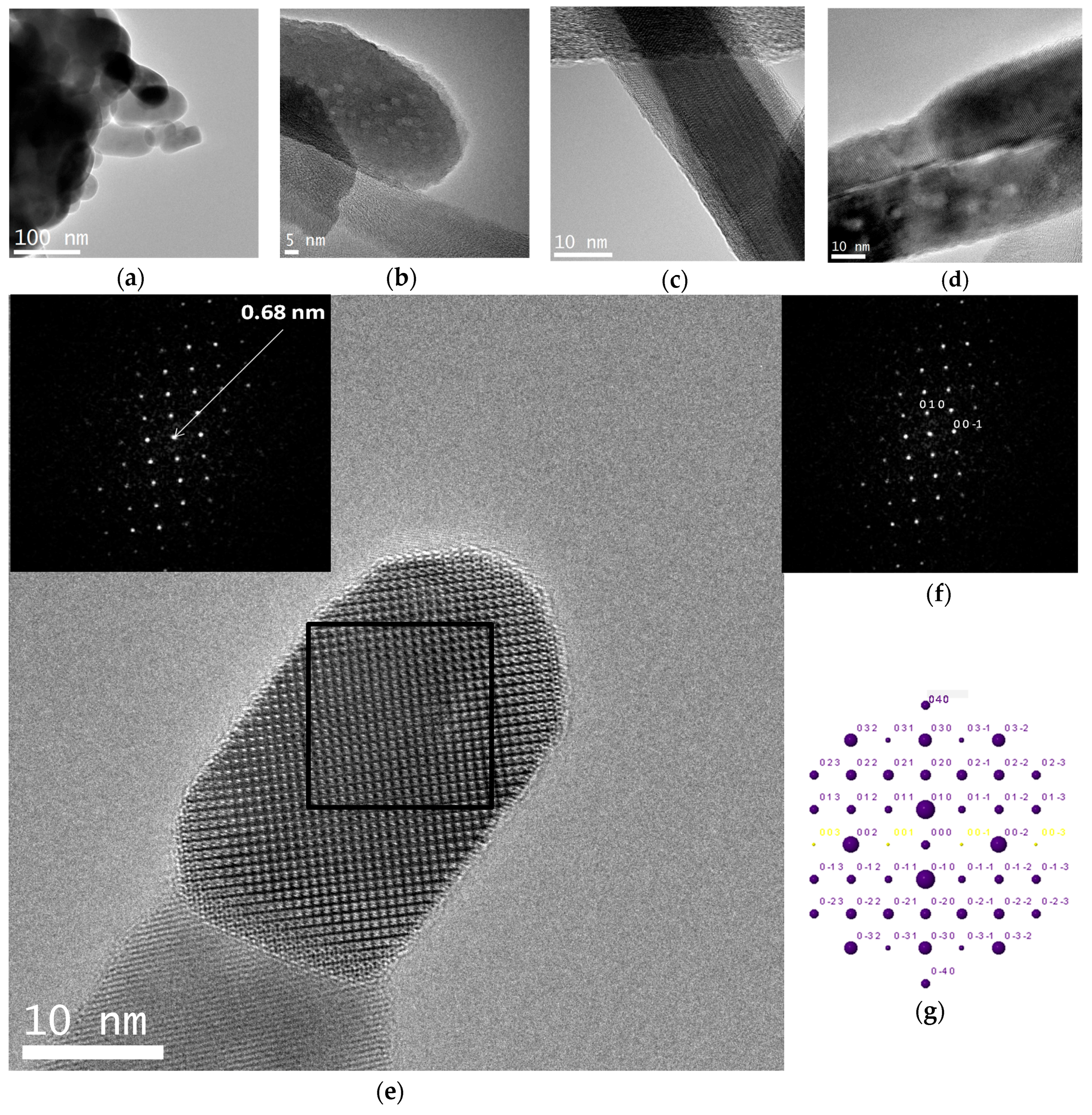

2.3.2. Morphology and Crystal-Chemical Evolution (FE-SEM, TEM and HRTEM)

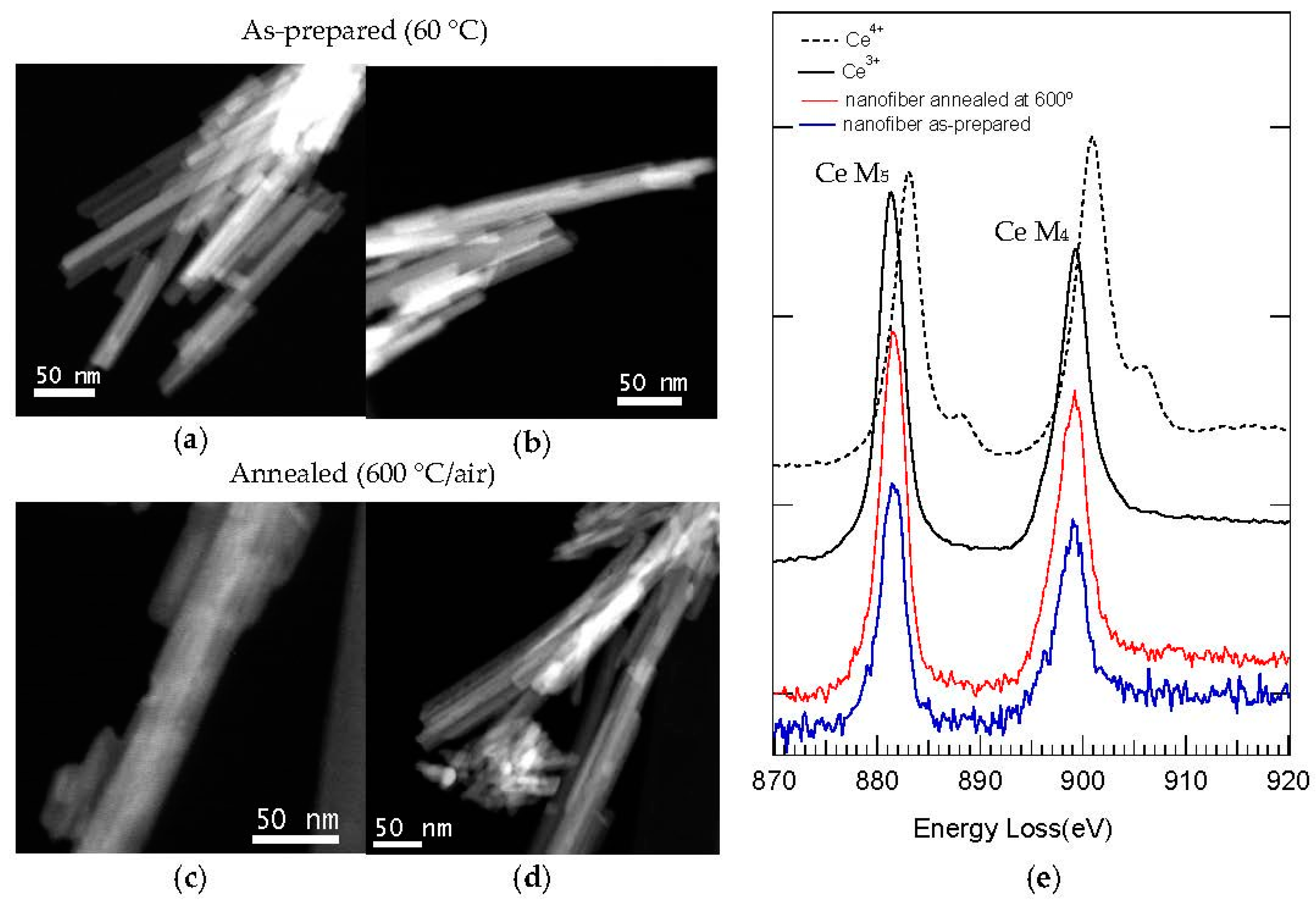

2.4. Elucidation of Ce Oxidation State (Ce3+ vs. Ce4+) in CePO4 Samples by STEM-EELS Spectroscopy

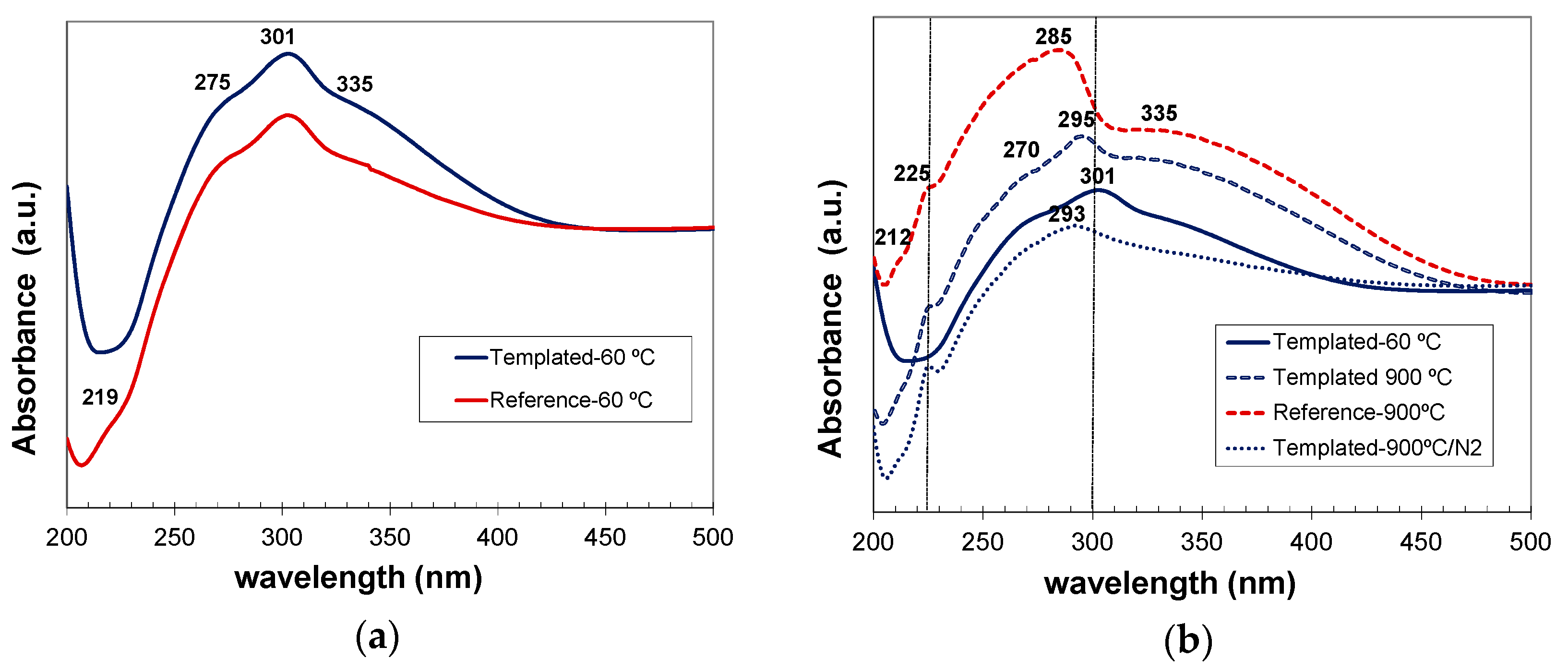

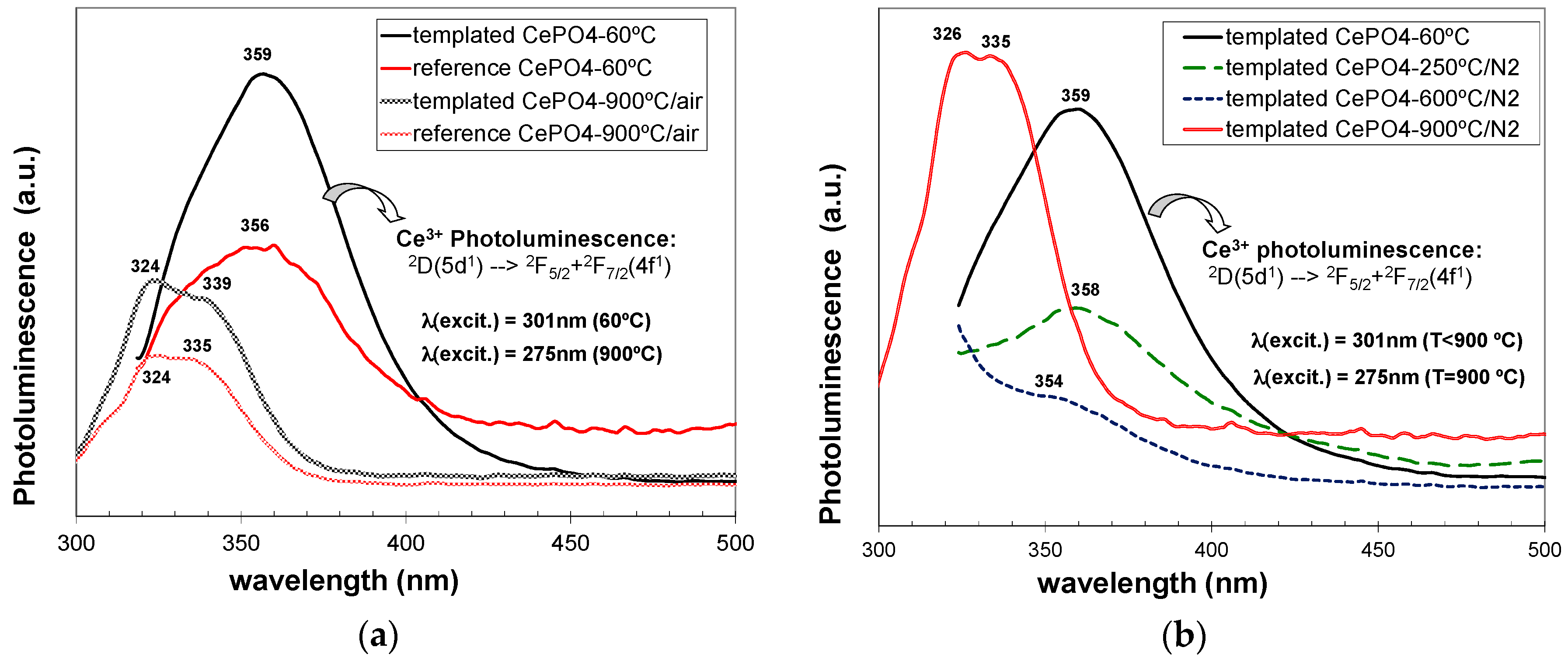

2.5. Optical Absorption and Photo-Luminescence Properties of CePO4 Samples

3. Conclusions

4. Materials and Methods

4.1. Preparation of C12GA Lipodipeptide Gelator and of HCl-C12GA and H3PO4-C12GA Hydrogels/Xerogels

4.2. Transcription of Nanofibrous CePO4·xH2O Using the H3PO4-C12GA Hydrogel as Nanofibrous Template

4.3. Preparation of a Non-Templated Reference Sample of CePO4·xH2O (Reference-CePO4)

4.4. Characterization of C12GA Xerogels and of as-Prepared (60 °C) and Annealed CePO4 Samples

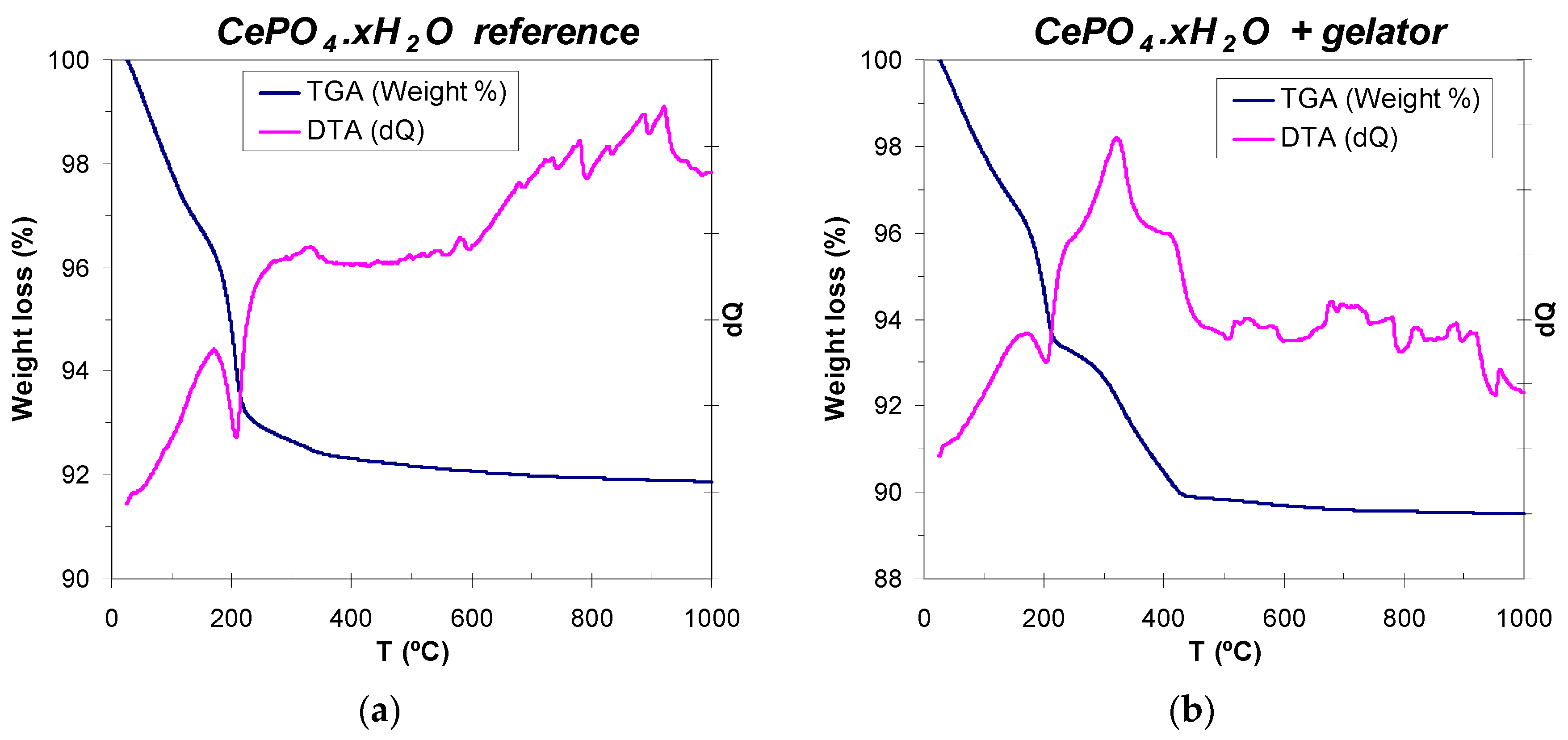

4.4.1. Thermal Analysis

4.4.2. X-ray Powder Diffraction (WA)XRD

4.4.3. Fourier-Transformed Infrarred (FTIR) Spectroscopy

4.4.4. Electron Microscopy Characterization (FE-SEM, TEM, HRTEM and STEM-HAADF)

4.4.5. Determination of Ce4+/Ce3+ Ratio from STEM-EELS Spectroscopy

4.4.6. Optical Absorption and Photo-Luminescence Spectra

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bu, W.; Chen, H.; Hua, Z.; Liu, Z.; Huang, W.; Zhang, L.; Shi, J. Surfactant-assisted synthesis of Tb(III)-doped cerium phosphate single-crystalline nanorods with enhanced green emission. Appl. Phys. Lett. 2004, 85, 4307–4309. [Google Scholar] [CrossRef]

- Bu, W.; Hua, Z.; Chen, H.; Shi, J. Epitaxial Synthesis of Uniform Cerium Phosphate One-Dimensional Nanocable Heterostructures with Improved Luminescence. J. Phys. Chem. B 2005, 109, 14461–14464. [Google Scholar] [CrossRef] [PubMed]

- Fang, Y.-P.; Xu, A.-W.; Song, R.-Q.; Zhang, H.-X.; You, L.-P.; Yu, J.C.; Liu, H.-Q. Systematic Synthesis and Characterization of Single-Crystal Lanthanide Orthophosphate Nanowires. J. Am. Chem. Soc. 2003, 125, 16025–16034. [Google Scholar] [CrossRef] [PubMed]

- Tang, C.; Bando, Y.; Golberg, D.; Ma, R. Cerium phosphate nanotubes: Synthesis, valence state, and optical properties. Angew. Chem. Int. Ed. 2005, 44, 576–579. [Google Scholar] [CrossRef]

- Bao, J.; Yu, R.; Zhang, J.; Wang, D.; Deng, J.; Chen, J.; Xing, X. Oxalate-induced hydrothermal synthesis of CePO4:Tb nanowires with enhanced photoluminescence. Scr. Mater. 2010, 62, 133–136. [Google Scholar] [CrossRef]

- Li, G.; Chao, K.; Peng, H.; Chen, K.; Zhang, Z. Facile synthesis of CePO4 nanowires attached to CeO2 octahedral micrometer crystals and their enhanced photoluminescence properties. J. Phys. Chem. C 2008, 112, 16452–16456. [Google Scholar] [CrossRef]

- Ma, L.; Chen, W.X.; Zheng, Y.F.; Xu, Z.-D. Hydrothermal growth and morphology evolution of CePO4 aggregates by a complexing method. Mater. Res. Bull. 2008, 43, 2840–2849. [Google Scholar] [CrossRef]

- Yang, M.; You, H.; Zheng, Y.; Liu, K.; Jia, G.; Song, Y.; Huang, Y.; Zhang, L.; Zhang, H. Hydrothermal Synthesis and Luminescent Properties of Novel Ordered Sphere CePO4 Hierarchical Architectures. Inorg. Chem. 2009, 48, 11559–11565. [Google Scholar] [CrossRef] [PubMed]

- Komban, R.; Beckmann, R.; Rode, S.; Ichilmann, S.; Kühnle, A.; Beginn, U.; Haase, M. Surface Modification of Luminescent Lanthanide Phosphate Nanorods with Cationic “Quat-primer” Polymers. Langmuir 2011, 27, 10174–10183. [Google Scholar] [CrossRef] [PubMed]

- Yang, R.; Qin, J.; Li, M.; Liu, Y.; Li, F. Redox hydrothermal synthesis of cerium phosphate microspheres with different architectures. CrystEngComm 2011, 13, 7284. [Google Scholar] [CrossRef]

- Fang, J.; Evans, C.W.; Willis, G.J.; Sherwood, D.; Guo, Y.; Lu, G.; Raston, C.L.; Iyer, K.S.; Li, Y. Sequential microfluidic flow synthesis of CePO4 nanorods decorated with emission tunable quantum dots. Lab Chip 2010, 10, 2579. [Google Scholar] [CrossRef] [PubMed]

- Kitsuda, M.; Fujihara, S. Quantitative Luminescence Switching in CePO4:Tb by Redox Reactions. J. Phys. Chem. C 2011, 115, 8808–8815. [Google Scholar] [CrossRef]

- Fujihara, S.; Takano, Y.; Kitsuda, M. Microstructural Aspects of the CePO4:Tb3+ Phosphor for Luminescence Sensing. Int. J. Appl. Ceram. Technol. 2015, 12, 411–417. [Google Scholar] [CrossRef]

- Chen, H.; Ren, J. Selective detection of Fe2+ by combination of CePO4:Tb3+ nanocrystal–H2O2 hybrid system with synchronous fluorescence scan technique. Analyst 2012, 137, 1899. [Google Scholar] [CrossRef] [PubMed]

- Di, W.; Shirahata, N.; Zeng, H.; Sakka, Y. Fluorescent sensing of colloidal CePO4:Tb nanorods for rapid, ultrasensitive and selective detection of vitamin C. Nanotechnology 2010, 21, 365501. [Google Scholar] [CrossRef] [PubMed]

- Di, W.; Wang, X.; Ren, X. Nanocrystalline CePO4:Tb as a novel oxygen sensing material on the basis of its redox responsive reversible luminescence. Nanotechnology 2010, 21, 75709. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Yuan, F.; Xu, J.; Zhang, Y.; Wu, Y.; Wang, L. Simple and sensitive detection method for Cobalt(II) in water using CePO4:Tb3+ nanocrystals as fluorescent probes. Spectrochim. ACTA PART A Mol. Biomol. Spectrosc. 2013, 107, 151–155. [Google Scholar] [CrossRef] [PubMed]

- Dezfuli, A.S.; Ganjali, M.R.; Norouzi, P. Facile sonochemical synthesis and morphology control of CePO4 nanostructures via an oriented attachment mechanism: Application as luminescent probe for selective sensing of Pb2+ ion in aqueous solution. Mater. Sci. Eng. C 2014, 42, 774–781. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Jiang, X.; Chen, K. CePO4:Tb,Gd hollow nanospheres as peroxidase mimic and magnetic–fluorescent imaging agent. Chem. Commun. 2012, 48, 6839–6841. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Wong, S.S. Ambient Large-Scale Template-Mediated Synthesis of High-Aspect Ratio Single-Crystalline, Chemically Doped Rare-Earth Phosphate Nanowires for Bioimaging. ACS Nano 2010, 4, 99–112. [Google Scholar] [CrossRef] [PubMed]

- Ye, C.; Guo, H.; Zhang, M.; Zhu, H.; Hu, J.; Lai, X.; Li, A. Synthesis and enhanced electrochemical property of Au-doped cerium phosphate nanowires. Mater. Lett. 2014, 131, 141–144. [Google Scholar] [CrossRef]

- Rodriguez-Liviano, S.; Aparicio, F.J.; Becerro, A.I.; García-Sevillano, J.; Cantelar, E.; Rivera, S.; Hernández, Y.; De La Fuente, J.M.; Ocaña, M. Synthesis and functionalization of biocompatible Tb:CePO4 nanophosphors with spindle-like shape. J. Nanopart. Res. 2013, 15, 1402. [Google Scholar] [CrossRef]

- Liu, H.; Xi, P.; Xie, G.; Chen, F.; Li, Z.; Bai, D.; Zeng, Z. Biocompatible hydroxyapatite nanoparticles as a redox luminescence switch. J. Biol. Inorg. Chem. 2011, 16, 1135–1140. [Google Scholar] [CrossRef] [PubMed]

- Rajesh, K.; Mukundan, P.; Krishna Pillai, P.; Nair, V.R.; Warrier, K.G.K. High-Surface-Area Nanocrystalline Cerium Phosphate through Aqueous Sol–Gel Route. Chem. Mater. 2004. [Google Scholar] [CrossRef]

- Dhaouadi, H.; Fadhalaoui, A.; Mdani, A.; Rsaigui, M. Structural and electrical properties of nanostructured cerium phosphate. Ionics (Kiel) 2013, 20, 857–866. [Google Scholar] [CrossRef]

- Kang, J.; Byun, S.; Nam, S.; Kang, S.; Moon, T.; Park, B. Synergistic improvement of oxygen reduction reaction on gold/cerium-phosphate catalysts. Int. J. Hydrogen Energy 2014, 39, 10921–10926. [Google Scholar] [CrossRef]

- Uy, D.; O’Neill, A.E.; Xu, L.; Weber, W.H.; McCabe, R.W. Observation of cerium phosphate in aged automotive catalysts using Raman spectroscopy. Appl. Catal. B Environ. 2003, 41, 269–278. [Google Scholar] [CrossRef]

- Wang, L.; Yuan, F.; Niu, X.; Kang, C.; Li, P.; Li, Z.; Zhu, Y. Effect of cerous phosphates with different crystal structures on their acidity and catalytic activity for the dehydration of glucose into 5-(hydroxymethyl)furfural. RSC Adv. 2016, 6, 40175–40184. [Google Scholar] [CrossRef]

- Romero-Sarria, F.; Domínguez, M.I.; Centeno, M.A.; Odriozola, J.A. CO oxidation at low temperature on Au/CePO4: Mechanistic aspects. Appl. Catal. B Environ. 2011, 107, 268–273. [Google Scholar] [CrossRef]

- Ho, L.-N.; Nishiguchi, H.; Nagaoka, K.; Takita, Y. Preparation of mesoporous nanocrystalline cerium phosphate with controllable pore size by using chelating agent. Mater. Chem. Phys. 2006, 97, 494–500. [Google Scholar] [CrossRef]

- Pusztai, P.; Haspel, H.; Tóth, I.Y.; Tombácz, E.; László, K.; Kukovecz, Á.; Kónya, Z. Structure-independent proton transport in cerium(III) phosphate nanowires. ACS Appl. Mater. Interfaces 2015, 7, 9947–9956. [Google Scholar] [CrossRef] [PubMed]

- Masui, T.; Tategaki, H.; Furukawa, S.; Imanaka, N. Synthesis and Characterization of New Environmentally-Friendly Pigments Based on Cerium Phosphate. J. Ceram. Soc. Jpn. 2004, 112, 646–649. [Google Scholar] [CrossRef]

- Imanaka, N.; Masui, T.; Itaya, M. Synthesis of an Environmentally Friendly and Nontoxic New Pigment Based on Rare Earth Phosphate. Chem. Lett. 2003, 32, 400–401. [Google Scholar] [CrossRef]

- Sumaletha, N.; Rajesh, K.; Mukundan, P.; Warrier, K.G.K. Environmentally benign sol-gel derived nanocrystalline rod shaped calcium doped cerium phosphate yellow-green pigment. J. Sol-Gel Sci. Technol. 2009, 52, 242–250. [Google Scholar] [CrossRef]

- Seixas, V.C.; Serra, O.A. Stability of sunscreens containing CePO4: Proposal for a new inorganic UV filter. Molecules 2014, 19, 9907–9925. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Duan, X.; Wei, Q.; Lieber, C.M. Directed Assembly of One-Dimensional Nanostructures into Functional Networks. Science 2001, 291, 630–633. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Odom, T.W.; Lieber, C.M. Chemistry and Physics in One Dimension: Synthesis and Properties of Nanowires and Nanotubes. Acc. Chem. Res. 1999, 32, 435–445. [Google Scholar] [CrossRef]

- Bu, W.-B.; Hua, Z.-L.; Chen, H.-R.; Zhang, L.-X.; Shi, J.-L. Hydrothermal Synthesis of Ultraviolet-Emitting Cerium Phosphate Single-Crystal Nanowires. Chem. Lett. 2004, 33, 612–613. [Google Scholar] [CrossRef]

- Zhang, Y.; Guan, H. Hydrothermal synthesis and characterization of hexagonal and monoclinic CePO4 single-crystal nanowires. J. Cryst. Growth 2003, 256, 156–161. [Google Scholar] [CrossRef]

- Xing, Y.; Li, M.; Davis, S.A.; Mann, S. Synthesis and Characterization of Cerium Phosphate Nanowires in Microemulsion Reaction Media. J. Phys. Chem. B 2006, 110, 1111–1113. [Google Scholar] [CrossRef] [PubMed]

- Lin, X.; Guo, B.; Qiu, Y.; Xu, P.; Fan, H. Surfactant-free hydrothermal synthesis of CePO4 microbundles assembled by aligned nanorods. Mater. Lett. 2017, 194, 49–52. [Google Scholar] [CrossRef]

- Ma, L.; Xu, L.-M.; Chen, W.-X.; Xu, Z.-D. Microwave-assisted synthesis and characterization of LaPO4:Re (Re = Ce3+, Eu3+, Tb3+) nanorods. Mater. Lett. 2009, 63, 1635–1637. [Google Scholar] [CrossRef]

- Ma, M.G.; Zhu, J.F.; Sun, R.C.; Zhu, Y.J. Hydrothermal synthesis and characterization of CePO4/C core-shell nanorods. Mater. Lett. 2009, 63, 2513–2515. [Google Scholar] [CrossRef]

- Meng, L.; Yang, L.; Zhou, B.; Cai, C. Cerium phosphate nanotubes: Synthesis, characterization and biosensing. Nanotechnology 2009, 20, 35502. [Google Scholar] [CrossRef] [PubMed]

- Yin, Y.B.; Shao, X.; Zhao, L.M.; Li, W.Z. Synthesis and characterization of CePO4 nanowires via microemulsion method at room temperature. Chin. Chem. Lett. 2009, 20, 857–860. [Google Scholar] [CrossRef]

- Di, W.; Li, J.; Shirahata, N.; Sakka, Y. An efficient and biocompatible fluorescence resonance energy transfer system based on lanthanide-doped nanoparticles. Nanotechnology 2010, 21, 455703. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Sun, Z.; Ma, L.; Zhang, X.; Yao, M.; Joly, A.G.; Liu, Z.; Chen, W. Synthesis and luminescence of CePO4:Tb/LaPO4 core/sheath nanowires. Nanotechnology 2010, 21, 125604. [Google Scholar] [CrossRef] [PubMed]

- Ekthammathat, N.; Thongtem, T.; Phuruangrat, A.; Thongtem, S. Facile hydrothermal synthesis and optical properties of monoclinic CePO4 nanowires with high aspect ratio. J. Nanomater. 2012, 2012, 1–6. [Google Scholar] [CrossRef]

- Wen, X.; Li, C.; Meng, F. Synthesis and characterization of CePO4 nanorods via solvothermal process. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2014, 29, 229–232. [Google Scholar] [CrossRef]

- Kirubanithy, M.; Irudayaraj, A.A.; Raj, A.D.; Manikandan, S. Synthesis, Characterization and Photoluminescence Behaviours of CePO4 and Tb-doped CePO4 Nanostructures. Mater. Today Proc. 2015, 2, 4344–4347. [Google Scholar] [CrossRef]

- Fan, Y.; Hu, Z.; Yang, J.; Zhang, C.; Zhu, L. Ultrasonic-assisted synthesis of core–shell structure CePO4:Tb/GdPO4 and GdPO4/CePO4:Tb nanophosphors and their photoluminescence properties. Appl. Surf. Sci. 2013, 266, 22–26. [Google Scholar] [CrossRef]

- Qian, L.; Du, W.; Gong, Q.; Qian, X. Controlled synthesis of light rare earth phosphate nanowires via a simple solution route. Mater. Chem. Phys. 2009, 114, 479–484. [Google Scholar] [CrossRef]

- Pusztai, P.; Tóth-Szeles, E.; Horváth, D.; Tóth, Á.; Kukovecz, Á.; Kónya, Z. A simple method to control the formation of cerium phosphate architectures. CrystEngComm 2015, 17, 8477–8485. [Google Scholar] [CrossRef]

- Pusztai, P.; Kukovecz, Á.; Kónya, Z. Green synthesis of biomimetic CePO4:Tb nanostructures using the simplest morphology control. RSC Adv. 2014, 4, 49879–49887. [Google Scholar] [CrossRef]

- Bao, J.; Zhu, X.; Liu, Y.; Li, W.; Yu, R. N,N-Dimethylformamide-induced synthesis and photoluminescence of CePO4 and Ce0.95PO4:Tb0.05 with sphere-like nanostructures. Mater. Lett. 2014, 124, 97–100. [Google Scholar] [CrossRef]

- Palma-Ramírez, D.; Domínguez-Crespo, M.A.; Torres-Huerta, A.M.; Dorantes-Rosales, H.; Ramírez-Meneses, E.; Rodríguez, E. Microwave-assisted hydrothermal synthesis of CePO4 nanostructures: Correlation between the structural and optical properties. J. Alloys Compd. 2015, 643, S209–S218. [Google Scholar] [CrossRef]

- Bao, J.; Yu, R.; Zhang, J.; Yang, X.; Wang, D.; Deng, J.; Chen, J.; Xing, X. Low-temperature hydrothermal synthesis and structure control of nano-sized CePO4. CrystEngComm 2009, 11, 1630. [Google Scholar] [CrossRef]

- Bao, J.R.; Zhu, X.W.; Yu, R.B.; Zhang, J.Y.; Xing, X.R. Hydrothermal Synthesis of Neodymium Orthophosphate with Controlled Structure and Morphology. Adv. Mater. Res. 2012, 399–401, 635–640. [Google Scholar] [CrossRef]

- Guan, M.; Sun, J.; Shang, T.; Zhou, Q.; Han, J.; Ji, A. A facile synthesis of cerium phosphate nanofiber by solution-solid method. J. Mater. Sci. Technol. 2010, 26, 45–48. [Google Scholar] [CrossRef]

- Cao, M.; Hu, C.; Wu, Q.; Guo, C.; Qi, Y.; Wang, E. Controlled synthesis of LaPO4 and CePO4 nanorods/nanowires. Nanotechnology 2005, 16, 282–286. [Google Scholar] [CrossRef] [PubMed]

- Brown, S.S.; Im, H.J.; Rondinone, A.J.; Dai, S. Facile, alternative synthesis of lanthanum phosphate nanocrystals by ultrasonication. J. Colloid Interface Sci. 2005, 292, 127–132. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Liu, X.; Liu, X.; Li, Q.; Li, J.; Zhang, S.; Meng, J.; Cao, X. Facile sonochemical synthesis of CePO4:Tb/LaPO4 core/shell nanorods with highly improved photoluminescent properties. Nanotechnology 2006, 17, 4217–4222. [Google Scholar] [CrossRef] [PubMed]

- Onoda, H.; Nariai, H.; Maki, H.; Motooka, I. Addition of urea or biuret on synthesis of Rhabdophane-type neodymium and cerium phosphates. J. Mater. Synth. Process. 2002, 10, 121–126. [Google Scholar] [CrossRef]

- Ono, Y.; Nakashima, K.; Sano, M.; Kanekiyo, Y.; Inoue, K.; Shinkai, S.; Sano, M.; Hojo, J.; Schüth, F.; Stucky, G.D.; et al. Organic gels are useful as a template for the preparation of hollow fiber silica. Chem. Commun. 1998, 368, 1477–1478. [Google Scholar] [CrossRef]

- Ono, Y.; Nakashima, K.; Sano, M.; Hojo, J.; Shinkai, S. Organogels are useful as a template for the preparation of novel helical silica fibers. J. Mater. Chem. 2001, 11, 2412–2419. [Google Scholar] [CrossRef]

- Van Bommel, K.J.C.; Friggeri, A.; Shinkai, S. Organic templates for the generation of inorganic materials. Angew. Chem.-Int. Ed. 2003, 42, 980–999. [Google Scholar] [CrossRef] [PubMed]

- Jung, J.H.; Shinkai, S. Gels as Templates for Nanotubes. In Templates in Chemistry I, Topics in Current Chemistry 248; Springer: Berlin/Heidelberg, Germany, 2005; pp. 223–260. [Google Scholar]

- Friggeri, A.; van Bommel, K.J.C.; Shinkai, S. Molecular Gels. In Molecular Gels; Weiss, R.G., Terech, P., Eds.; Springer: New York, NY, USA, 2006; pp. 857–893. [Google Scholar]

- Llusar, M.; Sánchez, C. Inorganic and Hybrid Nanofibrous Materials Templated with Organogelators. Chem. Mater. 2008, 20, 782–820. [Google Scholar] [CrossRef]

- Jung, J.H.; Kobayashi, H.; van Bommel, K.J.C.; Shinkai, S.; Shimizu, T. Creation of novel helical ribbon and double-layered nanotube TiO2 structures using an organogel template. Chem. Mater. 2002, 14, 1445–1447. [Google Scholar] [CrossRef]

- Jung, J.H.; Amaike, M.; Nakashima, K.; Shinkai, S. Preparation of novel silica structures, using a library of carbohydrate gel assemblies as templates for sol-gel transcription. J. Chem. Soc. Trans. 2 2001, 1938–1943. [Google Scholar] [CrossRef]

- Llusar, M.; Pidol, L.; Roux, C.; Pozzo, J.L.; Sanchez, C. Templated Growth of Alumina-Based Fibers through the Use of Anthracenic Organogelators. Chem. Mater. 2002, 14, 5124–5133. [Google Scholar] [CrossRef]

- Roy, G.; Miravet, J.F.; Escuder, B.; Sanchez, C.; Llusar, M. Morphology templating of nanofibrous silica through pH-sensitive gels: “In situ” and “post-diffusion” strategies. J. Mater. Chem. 2006, 16, 1817–1824. [Google Scholar] [CrossRef]

- Suzuki, M.; Nakajima, Y.; Sato, T.; Shirai, H.; Hanabusa, K. Fabrication of TiO2 using L-lysine-based organogelators as organic templates: control of the nanostructures. Chem. Commun. 2006, 377–379. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, M.; Sato, T.; Shirai, H.; Hanabusa, K. Powerful low-molecular-weight gelators based on L-valine and L-isoleucine with various terminal groups. New J. Chem. 2006, 30, 1184–1191. [Google Scholar] [CrossRef]

- Escuder, B.; Marti, S.; Miravet, J.F. Organogel formation by coaggregation of adaptable amidocarbamates and their tetraamide analogues. Langmuir 2005, 21, 6776–6787. [Google Scholar] [CrossRef] [PubMed]

- Escuder, B.; Miravet, J.F. Silk-inspired low-molecular-weight organogelator. Langmuir 2006, 22, 7793–7797. [Google Scholar] [CrossRef] [PubMed]

- Pozzo, J.L.; Clavier, G.M.; Desvergne, J.P. Rational design of new acid-sensitive organogelators. J. Mater. Chem. 1998, 8, 2575–2577. [Google Scholar] [CrossRef]

- Suzuki, M.; Yumoto, M.; Kimura, M.; Shirai, H.; Hanabusa, K. New low-molecular-mass gelators based on L-lysine: Amphiphilic gelators and water-soluble organogelators. Helv. Chim. Acta 2004, 87, 1–10. [Google Scholar] [CrossRef]

- Suzuki, M.; Nakajima, Y.; Yumoto, M.; Kimura, M.; Shirai, H.; Hanabusa, K. Effects of hydrogen bonding and van der Waals interactions on organogelation using designed low-molecular-weight gelators and gel formation at room temperature. Langmuir 2003, 19, 8622–8624. [Google Scholar] [CrossRef]

- Hartgerink, J.D.; Beniash, E.; Stupp, S.I. Peptide-amphiphile nanofibers: a versatile scaffold for the preparation of self-assembling materials. Proc. Natl. Acad. Sci. USA 2002, 99, 5133–5138. [Google Scholar] [CrossRef] [PubMed]

- Iqbal, S.; Miravet, J.F.; Escuder, B. Biomimetic Self-Assembly of Tetrapeptides into Fibrillar Networks and Organogels. Eur. J. Org. Chem. 2008, 2008, 4580–4590. [Google Scholar] [CrossRef]

- Miravet, J.F.; Escuder, B. Reactive organogels: Self-assembled support for functional materials. Org. Lett. 2005, 7, 4791–4794. [Google Scholar] [CrossRef] [PubMed]

- Hartgerink, J.D.; Beniash, E.; Stupp, S.I. Self-Assembly and Mineralization of Peptide-Amphiphile Nanofibers. Science 2001, 294, 1684–1688. [Google Scholar] [CrossRef] [PubMed]

- Hosseinkhani, H.; Hosseinkhani, M.; Kobayashi, H. Design of Tissue-engineered Nanoscaffold Through Self-assembly of Peptide Amphiphile. J. Bioact. Compat. Polym. 2006, 21, 277–296. [Google Scholar] [CrossRef]

- Semino, C.E. Self-assembling Peptides: From Bio-inspired Materials to Bone Regeneration. J. Dent. Res. 2008, 87, 606–616. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.G.; Suzuki, M.; Kimura, M.; Shirai, H.; Hanabusa, K. Preparation of cotton-like silica. Chem. Commun. 2004, 1332–1333. [Google Scholar] [CrossRef] [PubMed]

- Delbecq, F. Supramolecular gels from lipopeptide gelators: Template improvement and strategies for the in-situ preparation of inorganic nanomaterials and for the dispersion of carbon nanomaterials. Adv. Colloid Interface Sci. 2014, 209, 98–108. [Google Scholar] [CrossRef] [PubMed]

- Aoki, K.; Nagano, K.; Iitaka, Y. The crystal structure of L-arginine phosphate monohydrate. Acta Crystallogr. Sect. B Struct. Crystallogr. Cryst. Chem. 1971, 27, 11–23. [Google Scholar] [CrossRef]

- Heinemann, S.; Heinemann, C.; Jäger, M.; Neunzehn, J.; Wiesmann, H.P.; Hanke, T. Effect of Silica and Hydroxyapatite Mineralization on the Mechanical Properties and the Biocompatibility of Nanocomposite Collagen Scaffolds. ACS Appl. Mater. Interfaces 2011, 3, 4323–4331. [Google Scholar] [CrossRef] [PubMed]

- Smolin, Y.I.; Lapshin, A.E.; Pankova, G.A. Crystal structure of L-alanine phosphate. Crystallogr. Rep. 2003, 48, 283–285. [Google Scholar] [CrossRef]

- Iqbal, S. Biomimetic Self-Assembly of Peptides into Fibrillar Networks. Ph.D. Thesis, Universitat Jaume I, Castellón, Spain, 2011. [Google Scholar]

- Bouas-Laurent, H.; Desvergne, J.P. Optical Spectroscopic Methods as Tools to Investigate Gel Structures. In Molecular Gels. Materials with Self-Assembled Fibrillar Networks; Weiss, R.G., Terech, P., Eds.; Springer: New York, NY, USA, 2006; pp. 363–429. [Google Scholar]

- Abraham, S.; Lan, Y.; Lam, R.S.H.; Grahame, D.A.S.; Kim, J.J.H.; Weiss, R.G.; Rogers, M.A. Influence of positional isomers on the macroscale and nanoscale architectures of aggregates of racemic hydroxyoctadecanoic acids in their molecular gel, dispersion, and solid states. Langmuir 2012, 28, 4955–4964. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, M.; Yumoto, M.; Shirai, H.; Hanabusa, K. Supramolecular gels formed by amphiphilic low-molecular-weight gelators of N-alpha, N-epsilon-diacyl-L-lysine derivatives. Chem. Eur. J. 2008, 14, 2133–2144. [Google Scholar] [CrossRef] [PubMed]

- Miller, F.A.; Wilkins, C.H. Infrared Spectra and Characteristic Frequencies of Inorganic Ions. Anal. Chem. 1952, 24, 1253–1294. [Google Scholar] [CrossRef]

- De Jager, H.J.; Prinsloo, L.C. The dehydration of phosphates monitored by DSC/TGA and in situ Raman spectroscopy. Thermochim. Acta 2001, 376, 187–196. [Google Scholar] [CrossRef]

- Mohamadi, F.; Richards, N.G.J.; Guida, W.C.; Liskamp, R.; Lipton, M.; Caufield, C.; Chang, G.; Hendrickson, T.; Still, W.C. Macromodel—An integrated software system for modeling organic and bioorganic molecules using molecular mechanics. J. Comput. Chem. 1990, 11, 440–467. [Google Scholar] [CrossRef]

- Mooney, R.C.L. X-Ray diffraction study of cerous phosphate and related crystals. I. Hexagonal modification. Acta Crystallogr. 1950, 3, 337–340. [Google Scholar] [CrossRef]

- Bowles, J.F.W.; Morgan, D.J. The composition of rhabdophane. Mineral. Mag. 1984, 48, 146–148. [Google Scholar] [CrossRef]

- Mooney, R.C.L. Crystal Structures of a Series of Rare Earth Phosphates. J. Chem. Phys. 1948, 16, 1003. [Google Scholar] [CrossRef]

- Rodríguez-Luque, M.P.; Hernández, J.C.; Yeste, M.P.; Bernal, S.; Cauqui, M.A.; Pintado, J.M.; Pérez-Omil, J.A.; Stéphan, O.; Calvino, J.J.; Trasobares, S. Preparation of Rhodium/CexPr1-xO2 Catalysts: A Nanostructural and Nanoanalytical Investigation of Surface Modifications by Transmission and Scanning-Transmission Electron Microscopy. J. Phys. Chem. C 2008, 112, 5900–5910. [Google Scholar] [CrossRef]

- Garvie, L.A.J.; Buseck, P.R. Determination of Ce4+/Ce3+ in electron-beam-damaged CeO2 by electron energy-loss spectroscopy. J. Phys. Chem. Solids 1999, 60, 1943–1947. [Google Scholar] [CrossRef]

- Luwang, M.N.; Ningthoujam, R.S.; Srivastava, J.S.K.; Vatsa, R.K. Effects of Ce3+ codoping and annealing on phase transformation and luminescence of Eu3+-doped YPO4 nanorods: D2O solvent effect. J. Am. Chem. Soc. 2010, 132, 2759–2768. [Google Scholar] [CrossRef] [PubMed]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Llusar, M.; Escuder, B.; López-Castro, J.D.D.; Trasobares, S.; Monrós, G. Transcription of Nanofibrous Cerium Phosphate Using a pH-Sensitive Lipodipeptide Hydrogel Template. Gels 2017, 3, 23. https://doi.org/10.3390/gels3020023

Llusar M, Escuder B, López-Castro JDD, Trasobares S, Monrós G. Transcription of Nanofibrous Cerium Phosphate Using a pH-Sensitive Lipodipeptide Hydrogel Template. Gels. 2017; 3(2):23. https://doi.org/10.3390/gels3020023

Chicago/Turabian StyleLlusar, Mario, Beatriu Escuder, Juan De Dios López-Castro, Susana Trasobares, and Guillermo Monrós. 2017. "Transcription of Nanofibrous Cerium Phosphate Using a pH-Sensitive Lipodipeptide Hydrogel Template" Gels 3, no. 2: 23. https://doi.org/10.3390/gels3020023