The Simulation of Ester Lubricants and Their Application in Weak Gel Drilling Fluids

Abstract

:1. Introduction

2. Results and Discussion

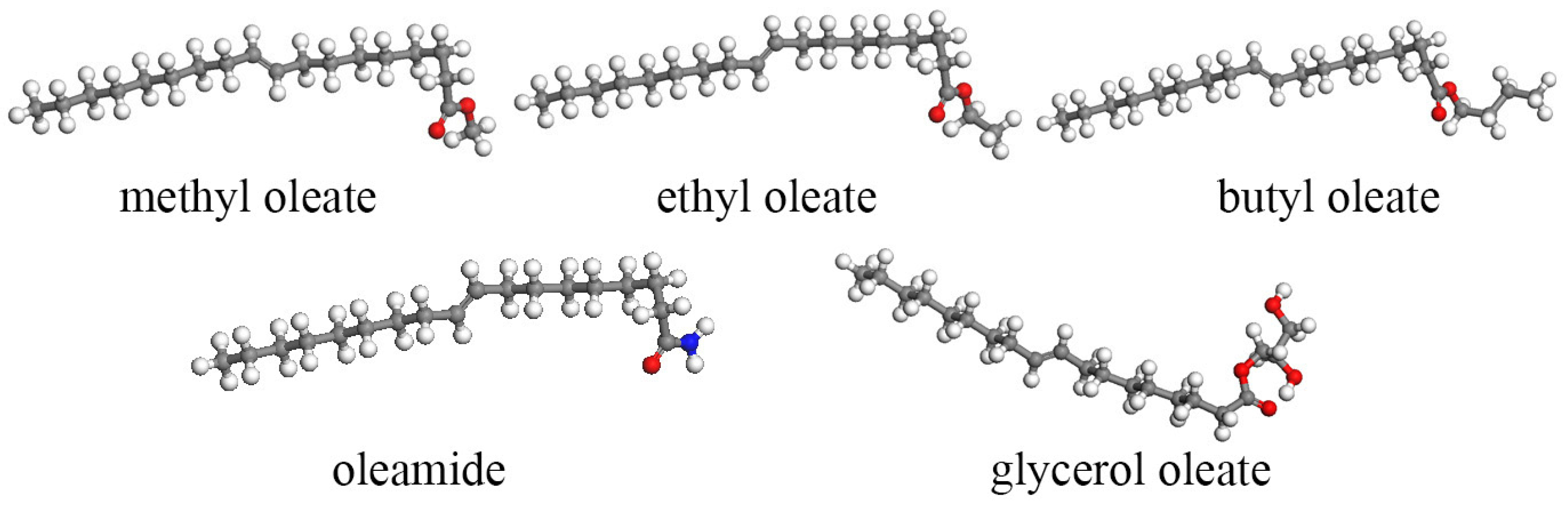

2.1. Shear Simulation and Model Validation of Ester Base Oil

2.2. Selection of Extreme-Pressure Components and Simulation of Efficient Lubricant

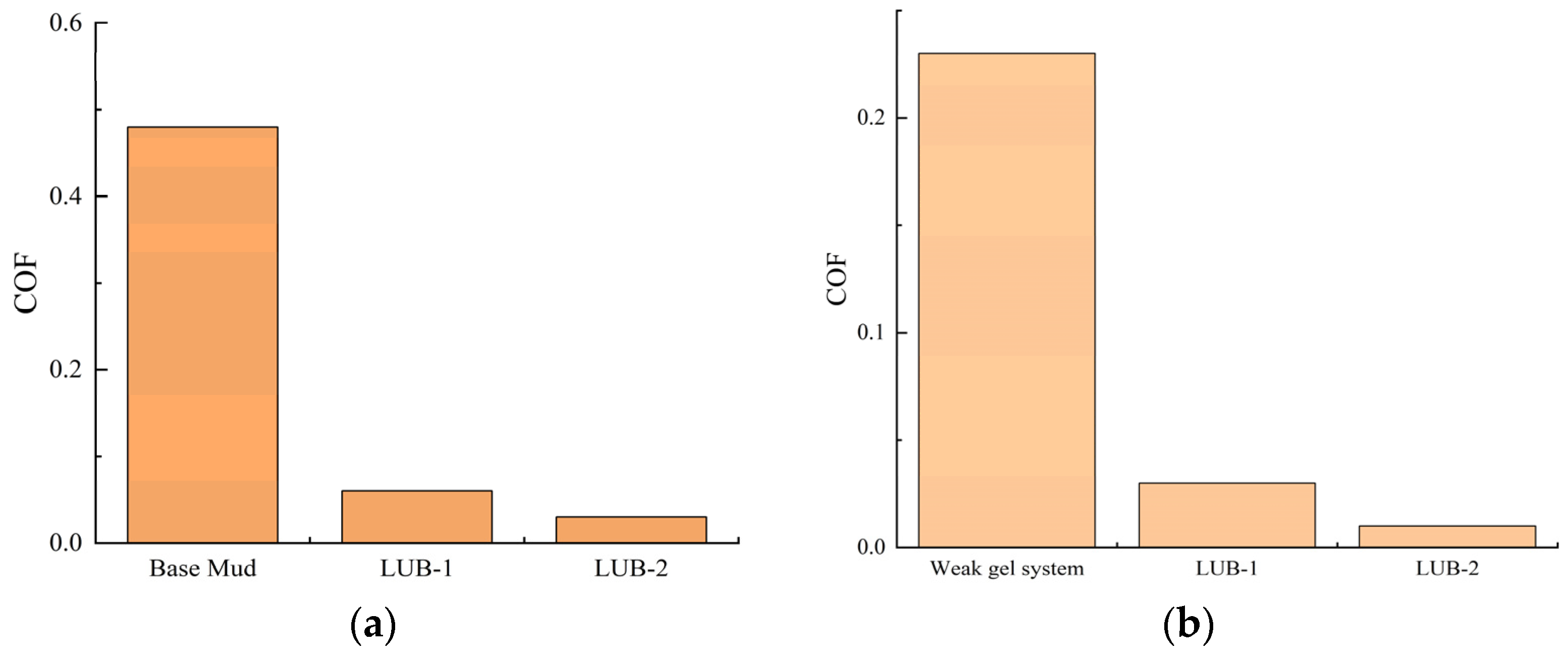

2.3. Performance Testing of Ester Lubricants

2.4. Field Application of LUB-2

3. Conclusions

- (1)

- Methyl oleate and oleamide are selected as the base oil of the ester lubricant and the extreme-pressure lubricant additive through molecular dynamics shear simulation under extreme pressure. The ratio of oleamide and methyl oleate is optimized, and the ester lubricant LUB-2 is formed when 10% oleamide is added to methyl oleate. LUB-2 can effectively balance the lubricating performance and cost of the lubricant.

- (2)

- The results of the evaluation of the lubricant show that the lubricity coefficient of the drilling fluid is reduced by 95.65% when 0.5% LUB-2 is added to the weak gel drilling fluid. This reduction is more than the reduction in most of the ester lubricants in the market. LUB-2 is not hydrolyzed in the weak gel at pH 8.0 and is compatible with the drilling fluid. This feature does not affect the gel performance of the drilling fluid.

- (3)

- The results of the field application show that LUB-2 can reduce the friction resistance by 33% when 1% of LUB-2 is added to the drilling fluid in the field, and the lubrication performance remains unchanged after a total horizontal displacement of 1194 m from the opening of the window side drilling to the completion of the well. The addition of 10% oleic acid amide to methyl ester can greatly improve the economy of ester lubricants and increase the application prospect of ester lubricants.

4. Materials and Methods

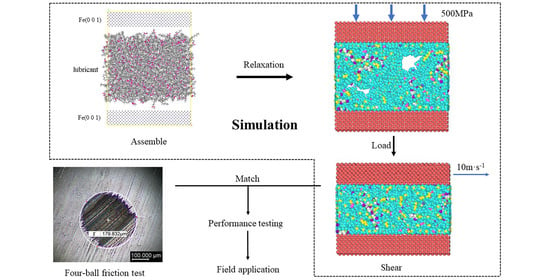

4.1. Shear Simulation of Ester Lubricants

4.1.1. Structure Models

4.1.2. Shear Simulation of Single Lubricant Structure

- (1)

- Structural optimization: After the establishment of the ‘sandwich model’, the positions of the upper and lower iron layers were fixed, and molecular dynamics simulations were used to optimize the overall structure of the lubricant system in the middle layer.

- (2)

- Load process: The simulation system adopted the NVT system, fixed the lower iron wall, and applied a pressure of 500 MPa to the upper iron wall. The system’s temperature was set to 298 K, the step size was 1.0 fs, and the simulation time was 50 ps, thereby allowing the system to reach a stable state [25]. The structural changes in the ‘sandwich model’ before and after loading are shown in Figure 13.

- (3)

- Shear process: After the completion of the load iron wall surface, the system continued using the NVT system, namely, the lubricant system using the NVE system, to simulate the lubricant in the shear process and produce the shear heat phenomenon [28,29]. The NVT ensemble is a canonical ensemble, which is a collection of systems with the same number of molecules N, the same volume V, and the same temperature T, represented by the symbol (N, V, T). The NVE ensemble is a microcanonical ensemble, which is a collection of systems with the same number of molecules N, the same volume V, and the same energy E. The lower iron wall surface was fixed, and the upper iron wall surface of the upper-most layer of iron atoms was set at a speed of 10–30 m/s along the x-axis direction of the shear. The initial temperature of the system was set to 298–398 K. The step size was 1.0 fs, and the simulation time was 2000 ps.

4.1.3. Shear Simulation for Lubricant Structure Optimization

4.2. Experimental Materials and Apparatus

4.3. Friction and Wear Experiment

4.4. Evaluation of Lubrication Property in Weak Gel Drilling Fluids

4.4.1. Preparation of Drilling Fluids

- (1)

- Base mud

- (2)

- Weak gel drilling fluid

4.4.2. Evaluation of Lubrication Performance

- (1)

- Evaluation of extreme-pressure lubrication performance

- (2)

- Determination of drilling fluid compatibility

- (3)

- Performance test after a long time of aging

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sonmez, A.; Kok, M.V.; Bal, B.; Bagatir, G.; Gucuyener, I.H. Comprehensive Approach to Torque and Lost Circulation Problems in Geothermal Wells in Terms of Drilling Fluid. Geothermics 2021, 95, 102126. [Google Scholar] [CrossRef]

- Zhang, Y.; Mian, C.; Jin, Y.; Lu, Y.; Liang, C.; Wang, D.; Du, X.; Li, W. The Influence of Oil-Based Drilling Fluid on the Wellbore Instability and Fracturing in Complex Shale Formation. In Proceedings of the 50th U.S. Rock Mechanics/Geomechanics Symposium, Houston, TX, USA, 26–29 June 2016. [Google Scholar]

- Rojas, D.; Soruco, A.; Jimenez, C.; Soriano, V.; Ahmed, R. High Performance Water-Based Fluid Replaces Oil-Based Mud on the Execution of a Complex 3D Well Trajectory. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Port of Spain, Trinidad and Tobago, 14–15 June 2023. [Google Scholar] [CrossRef]

- Heikal, A.; Banna, M.E.; Manescu, G.; Mulaifi, M.A.; Mohammed, I. High-Performance Water-Base Fluid Performs as an Environmentally Friendly Alternative to Oil-Base for Drilling Challenging. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Brisbane, Australia, 23–25 October 2018. [Google Scholar] [CrossRef]

- Dye, W.; Daugereau, K.; Hansen, N.A.; Otto, M.J.; Shoults, L.; Leaper, R.; Clapper, D.K.; Xiang, T. New Water-Based Mud Balances High-Performance Drilling and Environmental Compliance. SPE Drill. Complet. 2006, 21, 255–267. [Google Scholar] [CrossRef]

- Liu, J.; Li, G.; Xia, Y. Technical Progress on Environmental-Friendly, High-Performance Water-Based Drilling Fluids. Environ. Earth Sci. Res. J. 2020, 7, 121–126. [Google Scholar] [CrossRef]

- Zhang, L.; Hou, S.; Wu, Y.; You, F.; Zhang, J. Research Progress and Development Trend of Environmentally Friendly Lubricants for Drilling Fluids. Oilfield Chem. 2022, 39, 163–169. [Google Scholar] [CrossRef]

- Kania, D.; Yunus, R.; Omar, R.; Abdul Rashid, S.; Mohamad Jan, B. A Review of Biolubricants in Drilling Fluids: Recent Research, Performance, and Applications. J. Petrol. Sci. Eng. 2015, 135, 177–184. [Google Scholar] [CrossRef]

- Amanullah, M.; Ramasamy, J.; Alouhali, R. HSE-Friendly Lubricants to Safeguard Environment and Enhance Operational Excellence. In Proceedings of the International Petroleum Technology Conference, Dhahran, Saudi Arabia, 13–15 January 2020. [Google Scholar]

- Zhao, X.; Li, D.; Zhu, H.; Ma, J.; An, Y. Advanced Developments in Environmentally Friendly Lubricants for Water-Based Drilling Fluid: A Review. RSC Adv. 2022, 12, 22853–22868. [Google Scholar] [CrossRef] [PubMed]

- Raof, N.A.; Hamid, H.A.; Aziz, N.; Yunus, R. Prospects of Plant-Based Trimethylolpropane Esters in the Biolubricant Formulation for Various Applications: A Review. Front. Mech. Eng. 2022, 8, 833438. [Google Scholar] [CrossRef]

- Nehal, S. Ahmed Citric Acid-Based Esters as Potential Synthetic Lubricants: A Study of Their Synthesis, Rheological Properties and Thermal Stability. Tribol. Trans. 2023, 66, 095–1104. [Google Scholar] [CrossRef]

- Li, W.; Zhao, X.; Peng, H.; Guo, J.; Ji, T.; Chen, B.; You, Z.; Liu, L. A Novel Environmentally Friendly Lubricant for Water-Based Drilling Fluids as a New Application of Biodiesel. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference, Singapore, 22–24 August 2016. [Google Scholar] [CrossRef]

- Liu, F. Study on Mechanism of Shear Response Gel and Strong Adsorption Water-Based Lubricant. Ph.D. Thesis, China University of Petroleum, Beijing, China, 2019. [Google Scholar]

- Qian, x.; Xuan, Y.; Lin, Y.; Yang, X. Development and Application of an Environmental-Friendly Drilling Fluid Lubricant SMLUB-E. Pet. Drill. Tech. 2020, 48, 34–39. [Google Scholar]

- Dong, X.; Wang, L.; Yang, X.; Lin, Y.; Xue, Y. Effect of Ester Based Lubricant SMJH-1 on the Lubricity Properties of Water Based Drilling Fluid. J. Petrol. Sci. Eng. 2015, 135, 161–167. [Google Scholar] [CrossRef]

- Liu, Y.; Qiu, Z.; Zhong, H.; Meng, M.; Zhao, X.; Nie, Z.; Huang, W. Development of a Novel Anti-Temperature, Anti-Wear and Ecofriendly Lubricant SDL-1 for Water-Based Drilling Fluid. In Proceedings of the International Petroleum Technology Conference, Beijing, China, 26–28 March 2019. [Google Scholar] [CrossRef]

- Shan, K.; Qiu, Z.; Zhang, W.; Zhong, H.; Zhao, X.; Mo, J. Preparation and Performance Evaluation of an Environmentally Friendly Lubricant for Water-Based Drilling Fluid. IOP Conf. Ser. Earth Environ. 2021, 787, 012008. [Google Scholar] [CrossRef]

- Amanullah, M. Coefficient of Friction Reducing Efficiency of ARC Eco-Lube. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference, Singapore, 22–24 August 2016. [Google Scholar] [CrossRef]

- Fereidounpour, A.; Mohammad, H.; Hosseini, M. A Field Study, Laboratory Test and Cost Estimation of Solid and Liquid Lubricants in Directional Wells to Reduce Friction Coefficient and Improve ROP. SN Appl. Sci. 2020, 2, 1495. [Google Scholar] [CrossRef]

- Everhard, I.; Willis, S.; Villalobos, M.; Clapper, D.; Salem, H.A.; Hughes, B. Reduced Drilling Days and Low Friction Factors Hallmark Eagle Ford Water-Based Fluid Performance. In Proceedings of the 2014 AADE Fluids Technical Conference and Exhibition, Houston, TX, USA, 15–16 April 2014. [Google Scholar]

- Akaighe, N.; Zeilinger, S.; Cutler, J.; Bhandari, D.; Bunquin, J.; Bharadwaj, N. Low Friction Drilling Fluid Additive Technology. In Proceedings of the SPE/IADC International Drilling Conference and Exhibition, Stavanger, Norway, 7–9 March 2023. [Google Scholar] [CrossRef]

- Guo, J.; Zhou, J.; Lu, F.; Li, Y.; Wang, Z.; Huang, C.; Tian, Z.; Kong, Y. Simulation of Adsorption of Lubricant Base Oil on the Surface of Drilling Tools. Drill. Fluid Complet. Fluid 2018, 35, 27–30. [Google Scholar] [CrossRef]

- Zhang, S.; Dai, Y.; Xu, H.; Wang, J.; Lu, F.; Liu, G. Friction Reduction of Oleamide Lubricants on Iron Surface. Drill. Fluid Complet. Fluid 2022, 39, 596–600. [Google Scholar] [CrossRef]

- Wang, W. Design of Base Oil Molecular Structure for Diesel Engine and the Study of Lubricating Mechanism. Ph.D. Thesis, Dalian Maritime University, Dalian, China, 2018. [Google Scholar]

- Zhang, S.; Yan, Z.; Liu, Z.; Jiang, Y.; Sun, H.; Wu, S. Experimental and Numerical Study of the Mixed Lubrication Considering Boundary Film Strength. Materials 2023, 16, 1035. [Google Scholar] [CrossRef] [PubMed]

- Khormali, A.; Ahmadi, S. Prediction of Barium Sulfate Precipitation in Dynamic Tube Blocking Tests and Its Inhibition for Waterflooding Application Using Response Surface Methodology. J. Pet. Explor. Prod. Technol. 2023, 13, 2267–2281. [Google Scholar] [CrossRef]

- Stephan, S.; Dyga, M.; Alhafez, I.A.; Lenhard, J.; Urbassek, H.M.; Hasse, H. Reproducibility of Atomistic Friction Computer Experiments: A Molecular Dynamics Simulation Study. Mol. Simul. 2021, 47, 1509–1521. [Google Scholar] [CrossRef]

- Liu, D.; Li, H.; Huo, L.; Wang, K.; Sun, K.; Wei, J.; Chen, F. Molecular Dynamics Simulation of the Lubricant Conformation Changes and Energy Transfer of the Confined Thin Lubricant Film. Chem. Eng. Sci. 2023, 270, 118541. [Google Scholar] [CrossRef]

- NB/SH/T 0189-2017; Li, T.; Lei, A.; Ding, F.; Yang, H.; Hu, G. Determination of Anti-wear Performance of Lubricant (four-ball machine method). 2017. Available online: https://www.plusstd.com/1551097592.html (accessed on 29 February 2024).

- Q/SH CG0182—2023; Zhang, X.; Shan, H.; Li, B.; Zhang, Y.; Ji, M.; Cao, Z.; Liu, J.; Li, Q. Technical requirements of non fluorescent biomass lubricant for drilling fluids. 2023. Available online: http://www.jxsyzj.com/product_view.asp?id=376 (accessed on 29 February 2024).

| Test Conditions | AV/ mPa·s | PV/ mPa·s | YP/ Pa | FLAPI/mL | ρ/ (g·cm−3) | |

|---|---|---|---|---|---|---|

| Base mud | before hot rolling | 7.0 | 6.0 | 1.0 | 23.2 | 1.03 |

| 120 °C 16 h | 7.5 | 5.5 | 2.0 | 28.4 | 1.03 | |

| +0.5% LUB-1 | before hot rolling | 10.0 | 7.0 | 3.0 | 18.9 | 0.98 |

| 120 °C 16 h | 9.0 | 6.5 | 2.5 | 24.5 | 0.95 | |

| +0.5% LUB-2 | before hot rolling | 7.5 | 6.0 | 1.5 | 18.5 | 1.025 |

| 120 °C 16 h | 8.5 | 6.5 | 2.0 | 23.9 | 1.02 |

| Test Conditions | AV/ mPa·s | PV/ mPa·s | YP/ Pa | FLAPI/ mL | |

|---|---|---|---|---|---|

| Weak gel drilling fluid | before hot rolling | 43.0 | 35.0 | 8.0 | 2.8 |

| 120 °C 16 h | 36.5 | 32.0 | 4.5 | 3.4 | |

| +0.5% LUB-1 | before hot rolling | 46.0 | 38.5 | 7.5 | 2.6 |

| 120 °C 16 h | 38.0 | 34.0 | 4.0 | 3.0 | |

| +0.5% LUB-2 | before hot rolling | 42.0 | 35.0 | 7.0 | 2.4 |

| 120 °C 16 h | 34.5 | 31.0 | 3.5 | 3.1 |

| Test Conditions | Gel/Pa | AV/mPa·s | PV/mPa·s | YP/Pa | ρ/(g·cm−3) | |

|---|---|---|---|---|---|---|

| 10 s | 10 min | |||||

| before hot rolling | 3 | 6 | 42.0 | 35.0 | 7.0 | 1.20 |

| Day 1 | 1.5 | 4.5 | 34.5 | 31.0 | 3.5 | 1.19 |

| Day 2 | 1.5 | 4 | 34.0 | 31.0 | 3.0 | 1.19 |

| Day 3 | 1.5 | 4.5 | 34.0 | 30.5 | 3.5 | 1.19 |

| Day 4 | 1.5 | 4.5 | 33.0 | 30.5 | 2.5 | 1.19 |

| Day 5 | 2 | 4 | 33.5 | 30.5 | 3.0 | 1.19 |

| Day 6 | 1.5 | 4 | 33.0 | 30.5 | 2.5 | 1.19 |

| Day 7 | 1.5 | 4 | 33.0 | 30.0 | 3.0 | 1.19 |

| Well Depth/ m | AV/ mPa·s | PV/ mPa·s | YP/ Pa | FLHTHP/120 °C | Drilling Resistances/T | Note |

|---|---|---|---|---|---|---|

| 2143 | 47 | 33 | 14 | 14.8 | 14 | Without Lubricants |

| 2337 | 50 | 35 | 15 | 14.0 | 15 | Adding 1% LUB-2 |

| 2428 | 47.5 | 33 | 14.5 | 12.8 | 10 | |

| 2713 | 48.5 | 33 | 14.5 | 14.2 | 10 | |

| 3160 | 48.5 | 33 | 14.5 | 14.0 | 11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, Y.; Lu, F.; Tang, Y.; Wang, Y.; He, X.; Wang, T.; Wu, J. The Simulation of Ester Lubricants and Their Application in Weak Gel Drilling Fluids. Gels 2024, 10, 178. https://doi.org/10.3390/gels10030178

Dai Y, Lu F, Tang Y, Wang Y, He X, Wang T, Wu J. The Simulation of Ester Lubricants and Their Application in Weak Gel Drilling Fluids. Gels. 2024; 10(3):178. https://doi.org/10.3390/gels10030178

Chicago/Turabian StyleDai, Yao, Fuwei Lu, Yuhua Tang, Yuanyuan Wang, Xinyi He, Tengfei Wang, and Juan Wu. 2024. "The Simulation of Ester Lubricants and Their Application in Weak Gel Drilling Fluids" Gels 10, no. 3: 178. https://doi.org/10.3390/gels10030178

APA StyleDai, Y., Lu, F., Tang, Y., Wang, Y., He, X., Wang, T., & Wu, J. (2024). The Simulation of Ester Lubricants and Their Application in Weak Gel Drilling Fluids. Gels, 10(3), 178. https://doi.org/10.3390/gels10030178