Micro and Macro Flooding Mechanism and Law of a Gel Particle System in Strong Heterogeneous Reservoirs

Abstract

1. Introduction

2. Results and Discussion

2.1. Study on Water Flooding Microscopic Channeling Mechanism and Remaining Oil Distribution Law

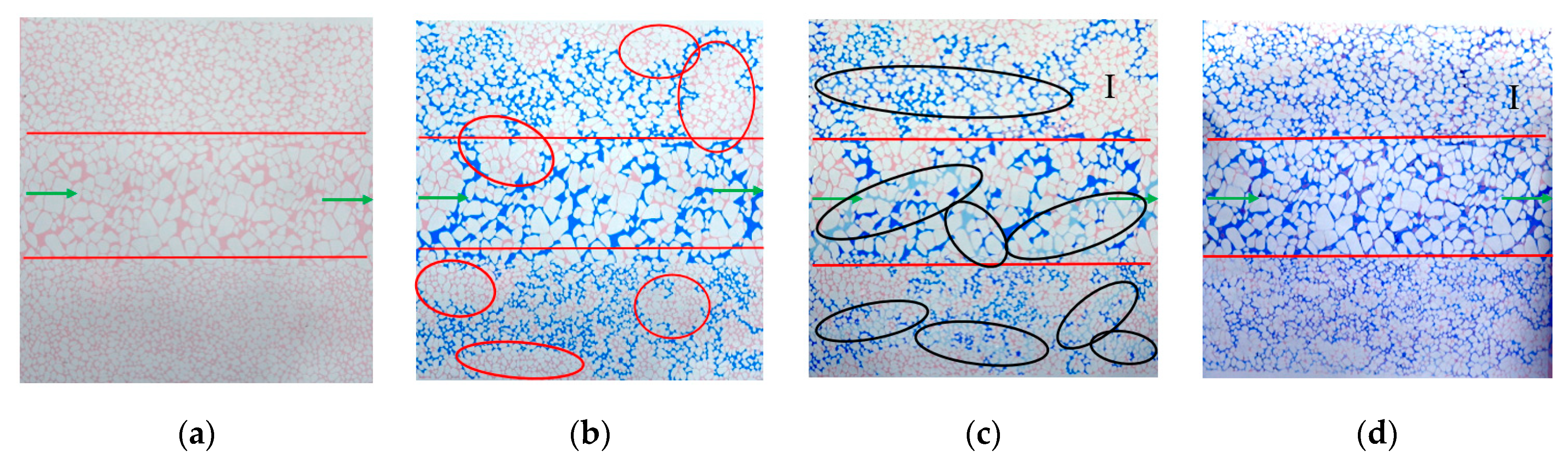

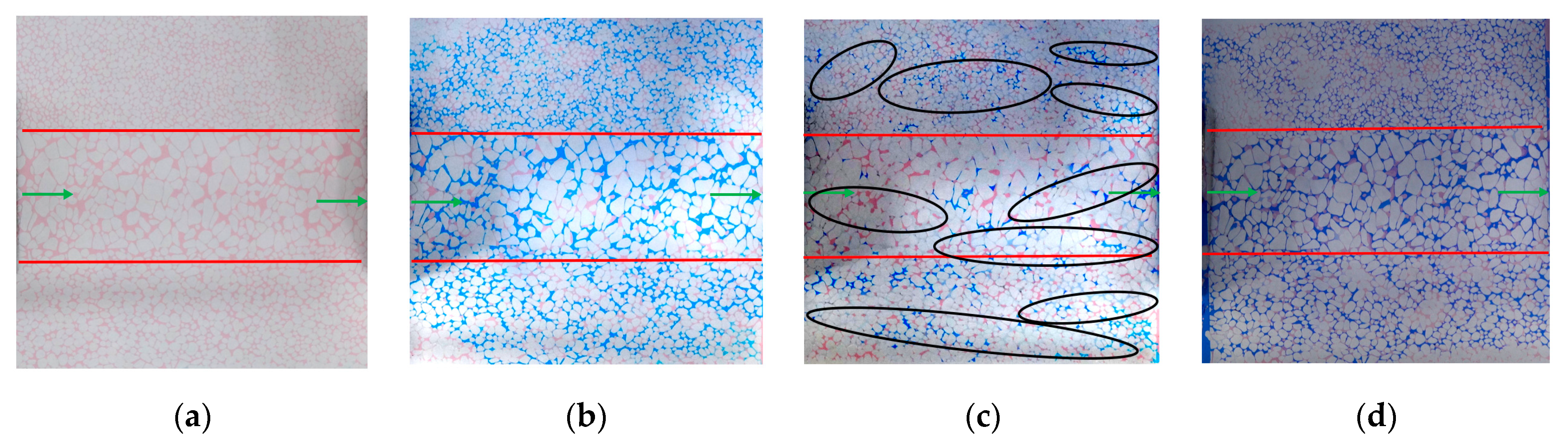

2.1.1. Mechanism Analysis of Water Flooding Channeling Path

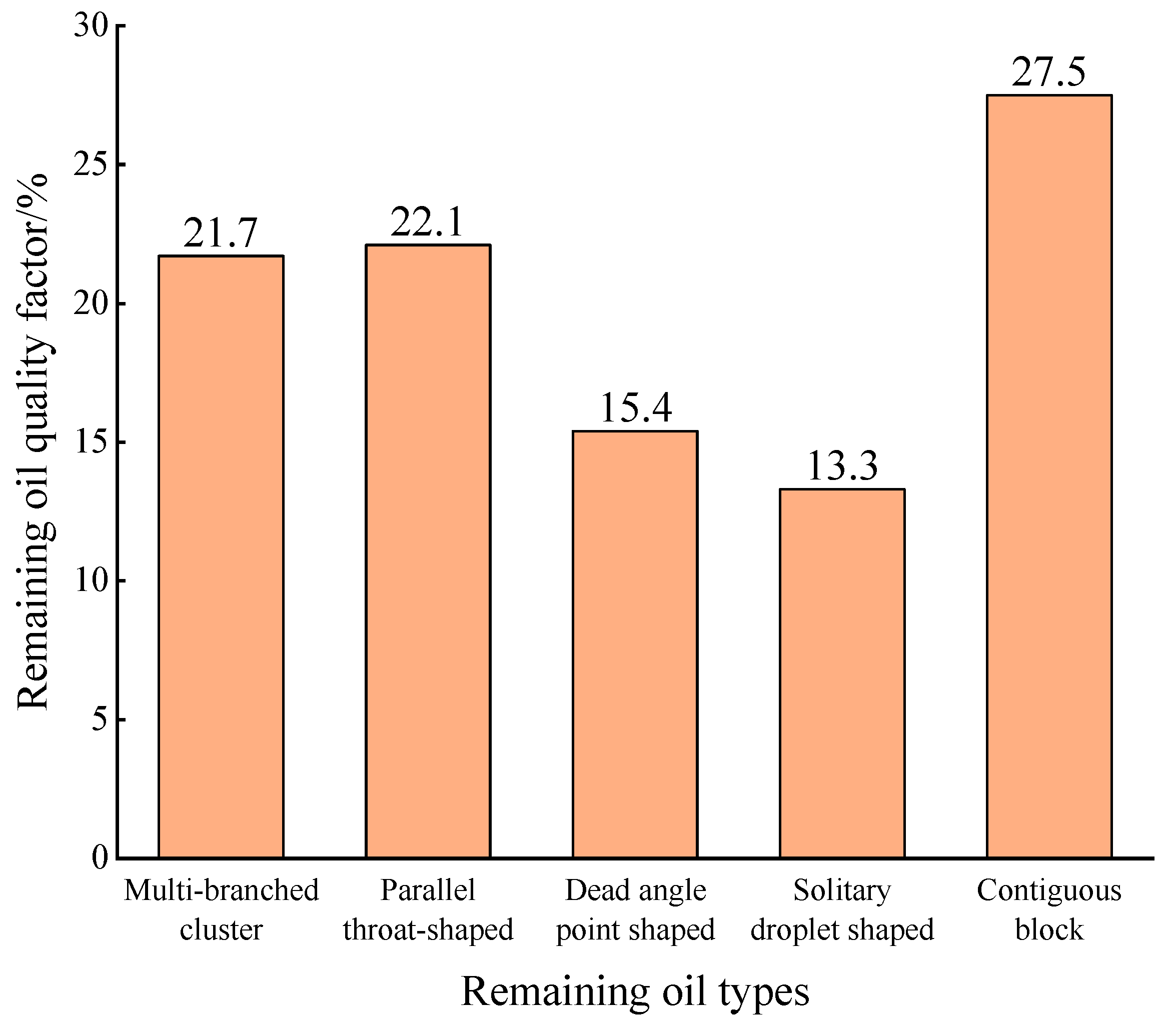

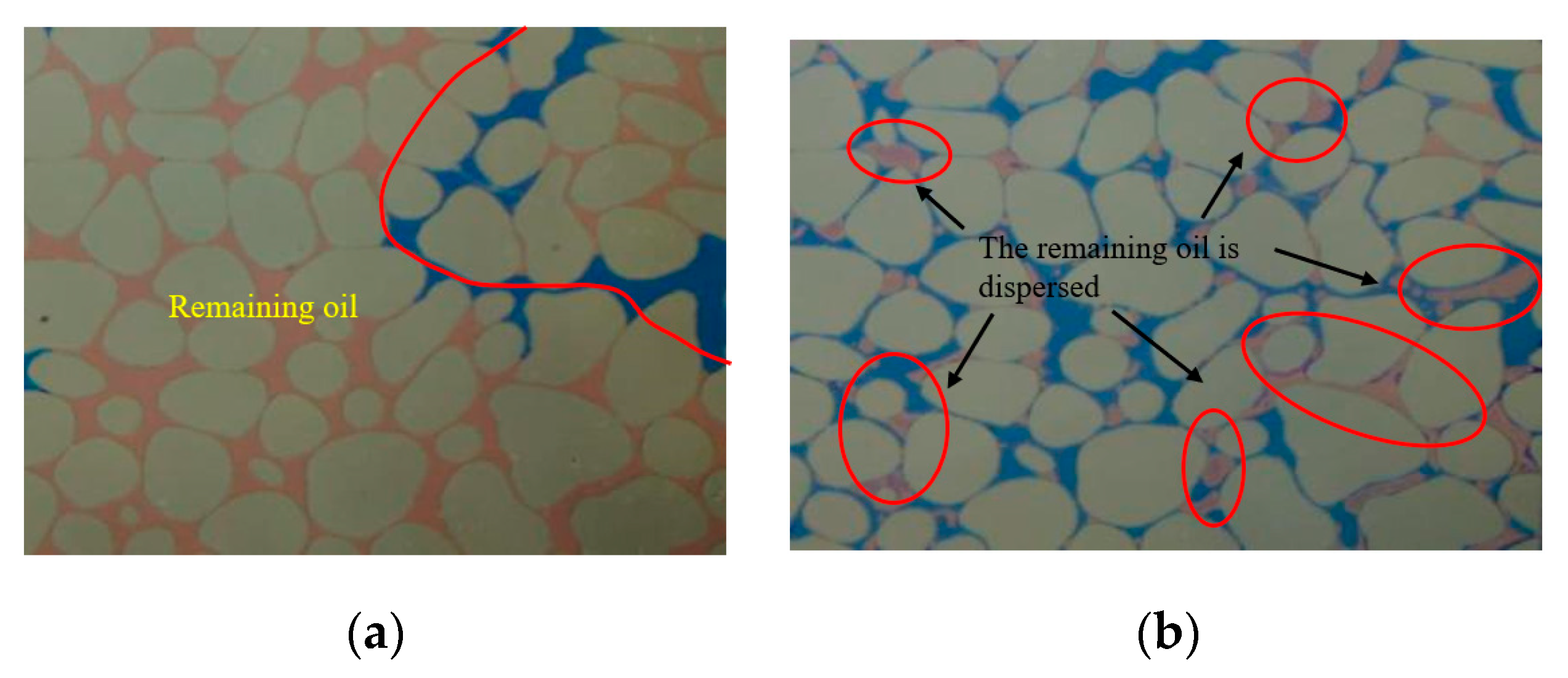

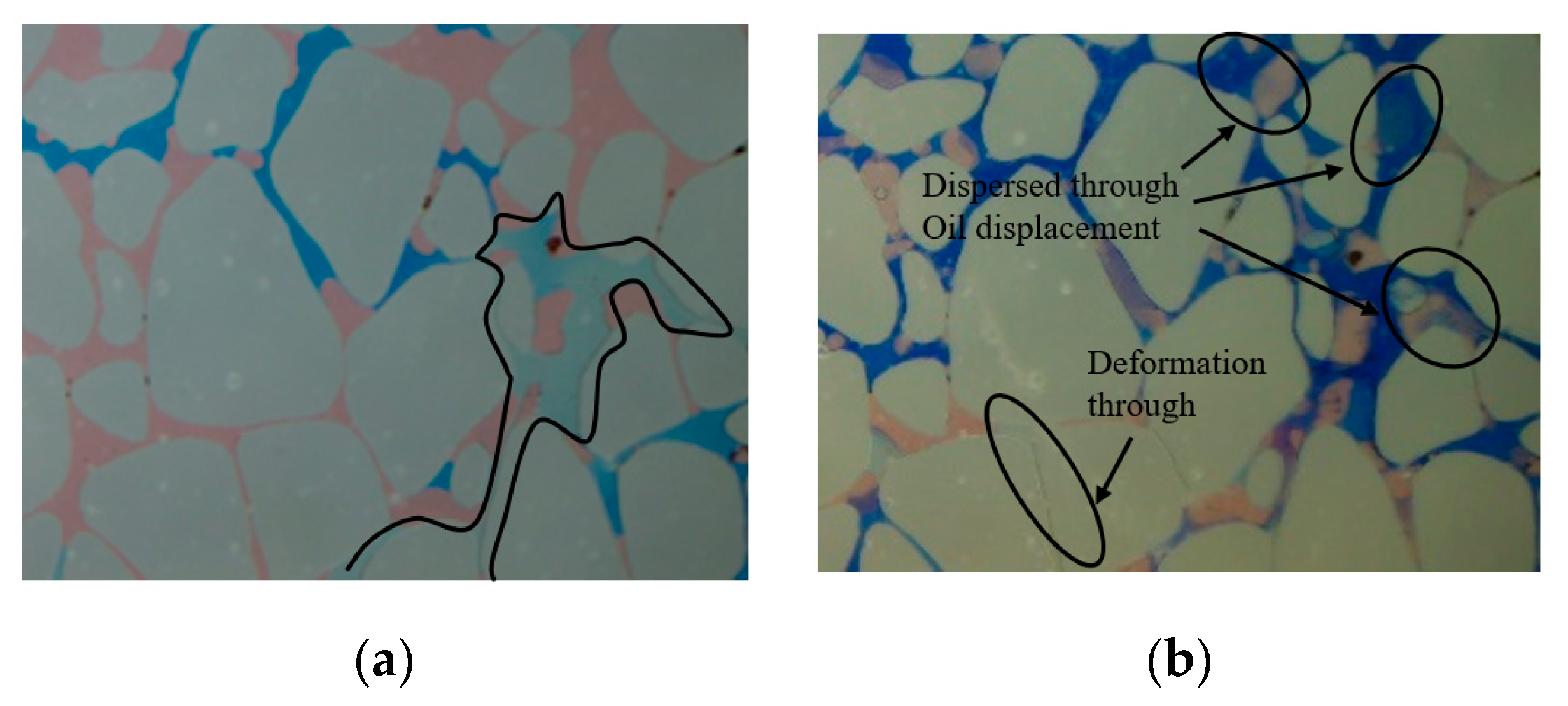

2.1.2. Remaining Oil Distribution

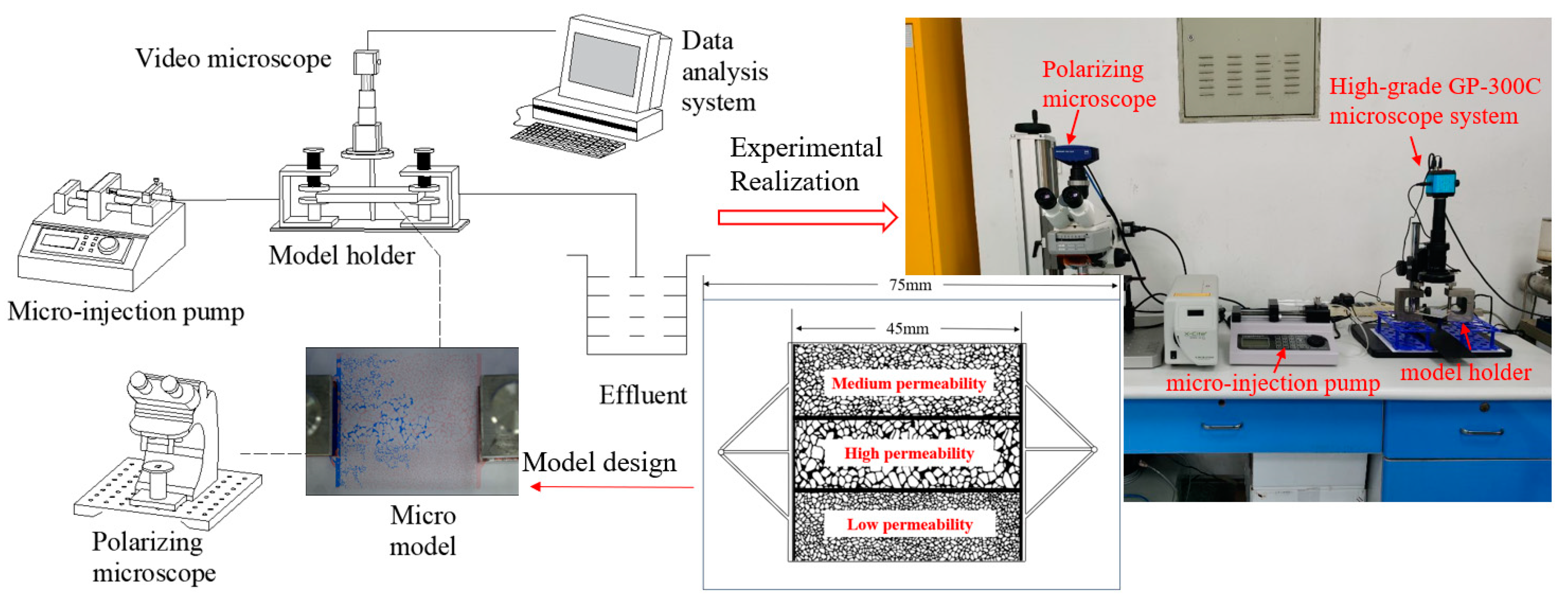

2.2. Study on Micro Flooding Mechanism of Key Parameters of Gel Particles

2.2.1. Heterogeneous Distribution Form of the Model

2.2.2. Different Injection Particle Sizes

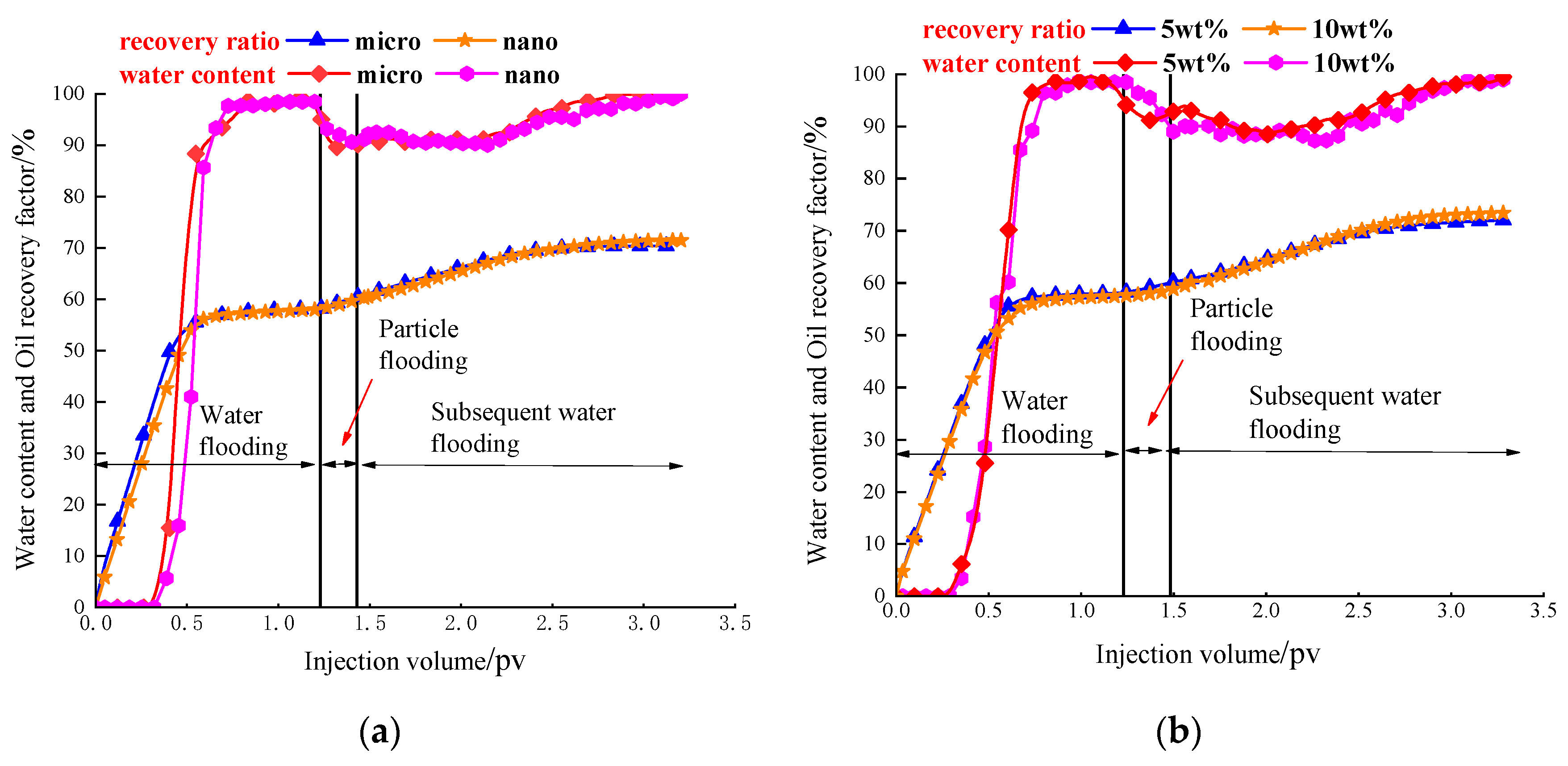

2.2.3. Different Injection Concentration

2.2.4. Analysis of Enhanced Oil Recovery (EOR) under Different Parameters

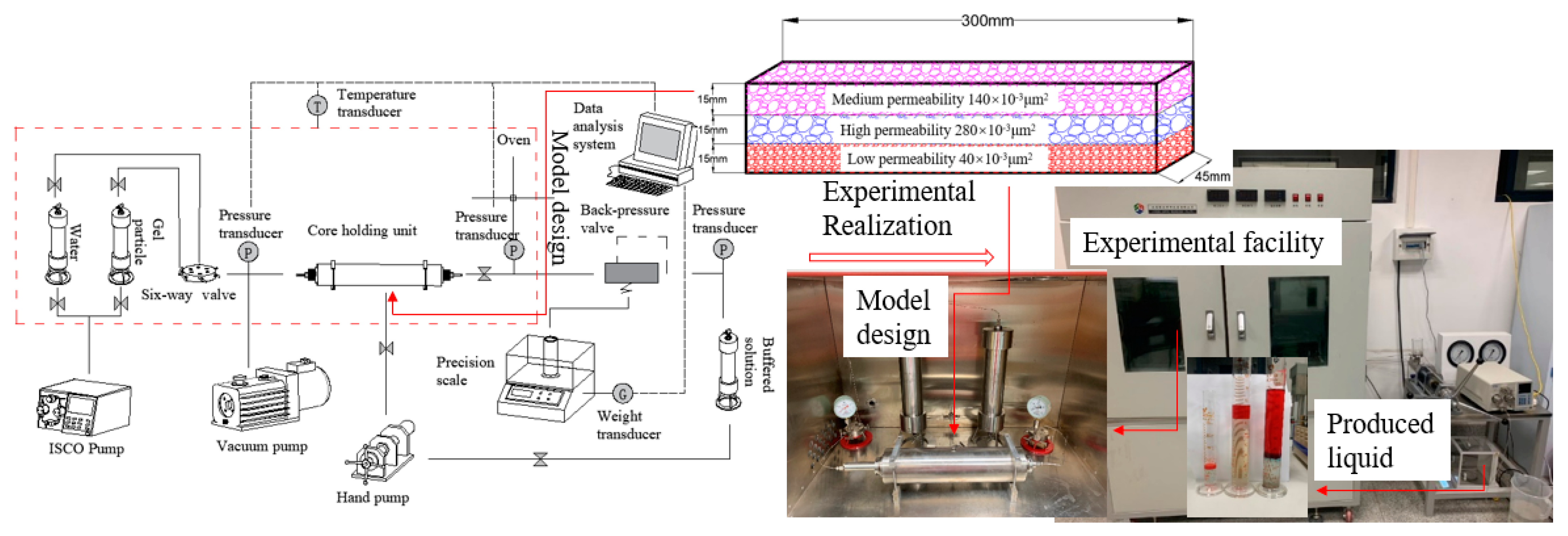

2.3. Evaluation of Flooding Effect of Gel Particle Macro Core

3. Conclusions

- (1)

- From the results of primary water flooding, the formation law of water flooding channels is determined by the heterogeneity distribution of the model and the connection between different permeability sections. There are five types of remaining oil after primary water flooding: contiguous block, multi-branch cluster, parallel throat, corner concave, and dispersed solitary drop, mainly focusing on the first three types;

- (2)

- The profile control effect of gel particles on reservoir vertical heterogeneity is better than that on reservoir lateral heterogeneity. The 10 wt% submicron particle (600 nm) can penetrate into the channel with a designed throat radius of 5–10 μm in the low-permeability section and the medium−high-permeability section to effectively plug it. The 10 wt% micron-sized particles (2.63 μm) can penetrate the channel with a designed throat radius of 20–30 μm in the high-permeability section to effectively plug it. However, it is nearly impossible for them to penetrate and cause plugging in sections with medium and low permeability. The 5 wt% micron-sized particles (2.63 μm) can penetrate into the channel with a designed throat radius of 10–20 μm in the medium-permeability section and high-permeability section, mainly forming weak plugging in the medium- and high-permeability section;

- (3)

- Both microscopic experiments and macroscopic core displacement experiments show that 10 wt% submicron particles have the best effect on profile control and flooding. The concentration parameters have a more significant impact on the effectiveness of profile control and flooding. The mechanism of action of gel particles is primarily characterized by the agent initially entering the dominant channel and subsequently expanding under the influence of high-temperature water. This process results in the phenomenon of plugging, migration and deformation, and re-plugging. Therefore, it has an efficient profile control and flooding effect on heterogeneous reservoirs.

4. Materials and Methods

4.1. Visual Microscopic Glass Etching Experiment

- The software was connected to the microscope and the parameters adjusted;

- The vacuum-saturated simulation of oil was modeled at room temperature;

- The simulated water was injected at a constant speed of 50 μL/min until the pressure stabilized, and the injection volume reached approximately 320 μL;

- According to the experimental scheme in Table 4, various particle sizes and concentrations of profile control and flooding agents were injected. Subsequently, the formation temperature was maintained for 72 h;

- Subsequent water flooding. The experiment was carried out at room temperature, and the injection pressure, injection volume, and injection speed were recorded. The displacement process and local feature images were taken.

4.2. Heterogeneous Rectangular Core Displacement Experiment

- The air tightness of the equipment was tested;

- Core drying, weighing, and vacuum pressure saturation simulation of the oil was carried out;

- Formation temperature aging for 24 h was conducted;

- Water flooding of the core was stopped when the water content reached 98% at the outlet end;

- According to the experimental scheme, the flooding agent was injected and maintained at the formation temperature for 72 h;

- Subsequent water flooding to the outlet end of the water content reached 98%. The experimental formation temperature was carried out, the pressure, produced water, and oil were recorded, and the change trend in water content and the oil recovery factor were then calculated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gao, Q.; Zhong, C.; Han, P.; Cao, R.; Jiang, G. Synergistic Effect of Alkali–Surfactant–Polymer and Preformed Particle Gel on Profile Control after Polymer Flooding in Heterogeneous Reservoirs. Energy Fuels 2020, 34, 15957–15968. [Google Scholar] [CrossRef]

- Lu, X.; Cao, B.; Xie, K.; Cao, W.; Liu, Y.; Zhang, Y.; Wang, X.; Zhang, J. Enhanced oil recovery mechanisms of polymer flooding in a heterogeneous oil reservoir. Pet. Explor. Dev. 2021, 48, 169–178. [Google Scholar] [CrossRef]

- Gong, W.; Liu, Y.; Xi, C.; Xi, C.; Yang, G.; Ju, Y.; Wang, M. Dynamic characterization of residual oil during long-term waterflooding experiments in heterogeneous porous structures. Fuel 2024, 356, 129567. [Google Scholar] [CrossRef]

- Du, Q. Variation law and microscopic mechanism of permeability in sandstone reservoir during long-term water flooding development. Acta Pet. Sin. 2016, 37, 1159–1164. [Google Scholar]

- Liao, H.; Xu, T.; Yu, H. Progress and prospects of EOR technology in deep, massive sandstone reservoirs with a strong bottom-water drive. Energy Geosci. 2023, 28, 100164. [Google Scholar] [CrossRef]

- Liu, L.; Cao, F.; Liu, X.; Tan, T.; Zheng, X.; Liu, R. Development Characteristics and Potential Tapping Strategies of Massive Sandstone Reservoirs With Bottom Water in Tahe Oilfield. Xinjiang Pet. Geol. 2023, 44, 450–455. [Google Scholar]

- Singh, V.; Ruwali, N.; Pandey, R.K.; Vaferi, B.; Wood, D.A. Applying a deep-learning surrogate model to simulate and compare achievable oil recovery by different waterflood scenarios. Pet. Sci. Technol. 2023, 1–19. [Google Scholar] [CrossRef]

- Peng, S.; Shi, Y.; Han, T.; Yao, T.; Huang, J.; Li, H.; Li, X.; Hu, H. A quantitative description method for channeling-path of reservoirs during high water cut period. Acta Pet. Sin. 2007, 28, 79–84. [Google Scholar]

- Wang, Q.; Ma, X.; Bi, Y.; He, H.; Gu, X.; Liu, T.; Zhao, L. Analysis of Channeling-Path Phenomena in a Complex Fault-Block Reservoir with Low Recovery Factor and High Water-Cut Ratio. Fluid Dyn. Mater. Process. 2023, 19, 361–377. [Google Scholar]

- Wei, P.; Zheng, L.; Yang, M.; Wang, C.; Chang, Q.; Zhang, W. Fuzzy-ball fluid self-selective profile control for enhanced oil recovery in heterogeneous reservoirs: The techniques and the mechanisms. Fuel 2020, 275, 117959. [Google Scholar] [CrossRef]

- Jin, F.; Li, Q.; He, Y.; Luo, Q.; Pu, W. Experimental Study on Enhanced Oil Recovery Method in Tahe High-Temperature and High-Salinity Channel Sand Reservoir: Combination of Profile Control and Chemical Flooding. ACS Omega 2020, 5, 5657–5665. [Google Scholar] [CrossRef]

- Cao, B.; Xie, K.; Lu, X.; Cao, W.; Cao, W.; He, X.; Xiao, Z.; Zhang, Y.; Wang, X.; Su, C. Effect and mechanism of combined operation of profile modification and water shutoff with in-depth displacement in high-heterogeneity oil reservoirs. Colloids Surf. A Physicochem. Eng. Asp. 2021, 631, 127673. [Google Scholar] [CrossRef]

- Cao, W.; Xie, K.; Lu, X.; Liu, Y.; Zhang, Y. Effect of Profile-Control Oil-Displacement Agent on Increasing Oil Recovery and Its Mechanism. Fuel 2019, 237, 1151–1160. [Google Scholar] [CrossRef]

- Cao, W.; Xie, K.; Cao, B.; Lu, X.; Tian, Z. Inorganic gel enhanced oil recovery in high temperature reservoir. J. Petrol. Sci. Eng. 2021, 196, 107691. [Google Scholar] [CrossRef]

- Altunina, L.K.; Bokserman, A.A.; Kuvshinov, V.A.; Polkovnikov, V.V. Inorganic gels for enhanced oil recovery at high temperature. Geol. Soc. Lond. Spec. Publ. 1995, 84, 219–223. [Google Scholar] [CrossRef]

- Zhao, X.; Chen, Z.; Chen, W.; Ma, H.; Zhai, D.; Ren, Z. The Current Research Situation And Development Trend Of Particle Profile-control Plugging Agents. Oil Drill. Prod. Technol. 2015, 37, 105–112. [Google Scholar]

- Zhao, F.; Sun, G.; Sun, M.; Xie, T.; Wang, F. Studies On Channel Plugging In A Reservoir By Using Clay As A Profile Control Agent In A Double-fluid Method. Acta Pet. Sin. 1994, 15, 56–65. [Google Scholar]

- Tran, T.V.; Civan, F.; Robb, I. Correlating Flowing Time and Condition For Perforation Plugging By Suspended Particles. SPE Drill. Complet. 2009, 24, 398–403. [Google Scholar] [CrossRef]

- Li, S.; Cheng, H.; Wei, Y.; Li, M.; Wang, Z. Two-Dimensional Visual Analysis of Three-Phase Foam Flooding under Different Reservoir Conditions. Energy Fuels 2023, 37, 17277–17289. [Google Scholar] [CrossRef]

- Wang, L.; Wang, T.; Wang, J.; Tian, H.; Chen, Y.; Song, W. Enhanced Oil Recovery Mechanism and Technical Boundary of Gel Foam Profile Control System for Heterogeneous Reservoirs in Changqing. Gels 2022, 8, 371. [Google Scholar] [CrossRef]

- Tao, J.; Dai, C.; Kang, W.; Zhao, G.; Liu, Y.; Fang, J.; Gao, M.; You, Q. Experimental Study on Low Interfacial Tension Foam for Enhanced Oil Recovery in High-Temperature and High-Salinity Reservoirs. Energy Fuels 2017, 31, 13416–13426. [Google Scholar] [CrossRef]

- Wang, Z.; Cao, Z.; Li, S.; Li, S. Investigation of the plugging capacity and enhanced oil recovery of flexible particle three-phase foam. J. Mol. Liq. 2023, 386, 122459. [Google Scholar] [CrossRef]

- Wu, W.; Hou, J.; Qu, M.; Wu, W.; Zhang, W.; Wen, Y.; Liang, T.; Xiao, L. Application of Phenolic Resin Crosslinked Polymer Gel in Fractured-Vuggy Carbonate Reservoir with High Temperature and High Salinity. In Proceedings of the International Petroleum Technology Conference, Riyadh, Saudi Arabia, 12–14 February 2022. [Google Scholar]

- Meng, X.; Zhang, G.; Wu, J.; Zhao, X.; Wang, L.; Zhang, F. Experimental Study on Phenol-Formaldehyde Resin Aggregates as In-Depth Conformance Control Agents Stabilized by Polymer. Polymers 2022, 14, 3159. [Google Scholar] [CrossRef]

- Ran, Y.; Zhang, G.; Jiang, P.; Pei, H. Study on Water-Soluble Phenolic Resin Gels for High-Temperature and High-Salinity Oil Reservoir. Gels 2023, 9, 489. [Google Scholar] [CrossRef]

- You, Q.; Tang, Y.; Dai, C.; Zhao, M.; Zhao, F.; Zhang, Y. A Study on the Morphology of a Dispersed Particle Gel Used as a Profile Control Agent for Improved Oil Recovery. J. Chem. 2014, 2014, 1–9. [Google Scholar] [CrossRef]

- Yang, H.; Zhou, B.; Zhu, T.; Wang, P.; Zhang, X.; Wang, T.; Wu, F.; Zhang, L.; Kang, W.; Ketova, Y.A.; et al. Conformance control mechanism of low elastic polymer microspheres in porous medium. J. Petrol. Sci. Eng. 2021, 196, 107708. [Google Scholar] [CrossRef]

- Zhao, G.; Dai, C.; You, Q. Characteristics and displacement mechanisms of the dispersed particle gel soft heterogeneous compound flooding system. Pet. Explor. Dev. 2018, 45, 481–490. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, D.; Wang, Z.; Cao, R. The formation and viscoelasticity of pore-throat scale emulsion in porous media. Pet. Explor. Dev. 2017, 44, 111–118. [Google Scholar] [CrossRef]

- Zhao, G.; Dai, C.; Zhao, M.; You, Q.; Chen, A. Investigation of preparation and mechanisms of a dispersed particle gel formed from a polymer gel at room temperature. PLoS ONE 2013, 8, e82651. [Google Scholar] [CrossRef]

- Wang, D.; Luo, Y.; Lai, R.; Cui, K.; Li, H.; Zhang, Z.; Zhang, Y.; Shi, R. New Technique for Enhancing Oil Recovery from Low-Permeability Reservoirs: The Synergy of Silica Nanoparticles and Biosurfactant. Energy Fuels 2021, 35, 318–328. [Google Scholar] [CrossRef]

- Kumar, G.; Mani, E.; Sangwai, J.S. Microfluidic Investigation of Surfactant-Assisted Functional Silica Nanofluids in Low-Salinity Seawater for Enhanced Oil Recovery Using Reservoir-on-a-Chip. Energy Fuels 2023, 37, 10329–10343. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, X.; Li, L.; Hao, Y.; Zhan, S.; Wang, W.; Wu, Z.; Zhang, W. Experimental study on microscopic mechanisms and displacement efficiency of N2 flooding in deep-buried clastic reservoirs. J. Petrol. Sci. Eng. 2022, 208, 109789. [Google Scholar] [CrossRef]

- Li, J.; Liu, Y.; Gao, Y.; Cheng, B.; Meng, F.; Xu, H. Effects of microscopic pore structure heterogeneity on the distribution and morphology of remaining oil. Pet. Explor. Dev. 2018, 45, 1112–1122. [Google Scholar] [CrossRef]

- Zhao, G.; You, Q.; Gu, C.; Lü, Y.; Dai, C. Preparation mechanism of multiscale dispersed particle gel. Acta Pet. Sin. 2017, 38, 821. [Google Scholar]

- He, Y.; Liao, K.; Bai, J.; Fu, L.; Ma, Q.; Zhang, X.; Ren, Z.; Wang, W. Study on a Nonionic Surfactant/Nanoparticle Composite Flooding System for Enhanced Oil Recovery. ACS Omega 2021, 6, 11068–11076. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Liu, H.; Xu, J. Mechanistic Simulation Studies on Viscous-Elastic Polymer Flooding in Petroleum Reservoirs. J. Dispers. Sci. Technol. 2013, 34, 417–426. [Google Scholar] [CrossRef]

- Yuan, C. Enhanced Oil Recovery Mechanism of Dispersion Gel-Surfactant Flooding for High Temperature and High Salinity Reservoirs. Ph.D. Thesis, Southwest Petroleum University, Nanchong, China, 2016. [Google Scholar]

- Jamaloei, B.Y.; Asghari, K.; Kharrat, R. The investigation of suitability of different capillary number definitions for flow behavior characterization of surfactant-based chemical flooding in heavy oil reservoirs. J. Pet. Sci. Eng. 2012, 90, 48–55. [Google Scholar] [CrossRef]

| Number | Placement Mode | Injection Particle Sized | Injection Concentration/wt% | Injection Volume/μL | Water Flooding Pressure /MPa | Particle Flooding Pressure /MPa | Subsequent Water Flooding Pressure /MPa |

|---|---|---|---|---|---|---|---|

| 1 | vertical | submicro | 10 | 100 | 0.005 | 0.006 | 0.016 |

| 2 | horizontal | submicro | 10 | 0.003 | 0.004 | 0.011 | |

| 3 | vertical | micron | 10 | 0.0035 | 0.0075 | 0.0165 | |

| 4 | vertical | micron | 5 | 0.0075 | 0.0075 | 0.0175 |

| Number | Experimental Parameters | Oil Recovery/% | Enhanced Oil Recovery (EOR)/% | ||||

|---|---|---|---|---|---|---|---|

| Water Flooding | Particle Flooding | Subsequent Water Flooding | Particle Flooding | Subsequent Water Flooding | Particle + Subsequent Water Flooding | ||

| 1 | vertical, 10 wt% submicron | 55.98 | 56.38 | 78.30 | 0.40 | 21.92 | 22.32 |

| 2 | horizontal, 10 wt% submicron | 59.43 | 59.84 | 78.36 | 0.41 | 18.51 | 18.92 |

| 3 | vertical, 10 wt% micron | 57.86 | 58.28 | 78.2 | 0.42 | 19.92 | 20.34 |

| 4 | vertical, 5 wt% micron | 56.28 | 56.6 | 74.27 | 0.32 | 17.67 | 17.99 |

| Condition | Parameters | Pressure/MPa | Oil Recovery/% | Ultimate Oil Recovery/% | EOR/% | ||||

|---|---|---|---|---|---|---|---|---|---|

| Water Flooding | Particle Flooding | Subsequent Water Flooding | Water Flooding | Particle Flooding | Subsequent Water Flooding | ||||

| Vertical heterogeneity, similar amount of profile control flooding | Micro particles | 0.06 | 0.31 | 0.45 | 58.25 | 2.26 | 9.86 | 70.37 | 12.12 |

| Submicro particles | 0.08 | 0.30 | 0.46 | 57.98 | 2.51 | 10.95 | 71.44 | 13.46 | |

| Vertical heterogeneity, submicron particles | 5 wt% | 0.07 | 0.31 | 0.55 | 58.02 | 2.78 | 11.25 | 71.44 | 14.03 |

| 10 wt% | 0.08 | 0.33 | 0.57 | 57.61 | 2.88 | 13.01 | 73.50 | 15.89 | |

| Number | Placement Mode | Injection Particle Type | Injection Concentration/wt% | Injection Volume/μL |

|---|---|---|---|---|

| 1 | vertical | submicron | 10 | 100 |

| 2 | horizontal | submicron | 10 | |

| 3 | vertical | micron | 10 | |

| 4 | vertical | micron | 5 |

| Condition | Parameters | Gas Permeability/10−3 μm2 | Liquid Permeability/10−3 μm2 | Porosity/% |

|---|---|---|---|---|

| Vertical heterogeneity, similar amount of profile control flooding | micro particles | 154 | 140.55 | 20.44 |

| submicron particles | 156 | 141.98 | 20.58 | |

| Vertical heterogeneity, submicron particles | 5 wt% | 156 | 140.36 | 20.24 |

| 10 wt% | 152 | 140.45 | 20.96 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, R.; Wang, L.; Xu, W.; Zhang, J.; Chen, Z. Micro and Macro Flooding Mechanism and Law of a Gel Particle System in Strong Heterogeneous Reservoirs. Gels 2024, 10, 151. https://doi.org/10.3390/gels10020151

Ye R, Wang L, Xu W, Zhang J, Chen Z. Micro and Macro Flooding Mechanism and Law of a Gel Particle System in Strong Heterogeneous Reservoirs. Gels. 2024; 10(2):151. https://doi.org/10.3390/gels10020151

Chicago/Turabian StyleYe, Rongjun, Lei Wang, Wenjun Xu, Jianpeng Zhang, and Zhengbang Chen. 2024. "Micro and Macro Flooding Mechanism and Law of a Gel Particle System in Strong Heterogeneous Reservoirs" Gels 10, no. 2: 151. https://doi.org/10.3390/gels10020151

APA StyleYe, R., Wang, L., Xu, W., Zhang, J., & Chen, Z. (2024). Micro and Macro Flooding Mechanism and Law of a Gel Particle System in Strong Heterogeneous Reservoirs. Gels, 10(2), 151. https://doi.org/10.3390/gels10020151