Development and Performance Evaluation of a New Conformance Control Agent Gel

Abstract

1. Introduction

2. Results and Discussion

2.1. Properties of Gels

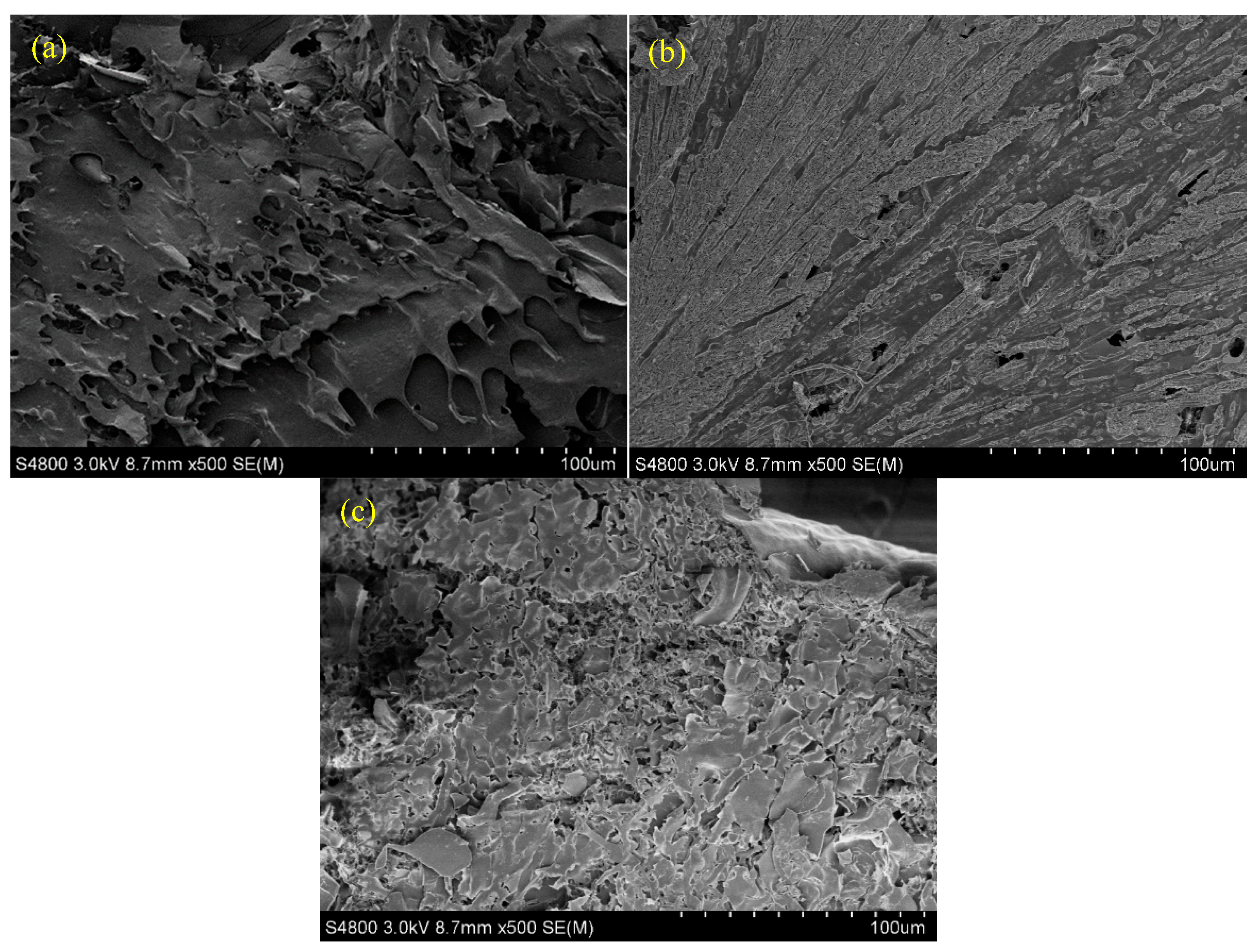

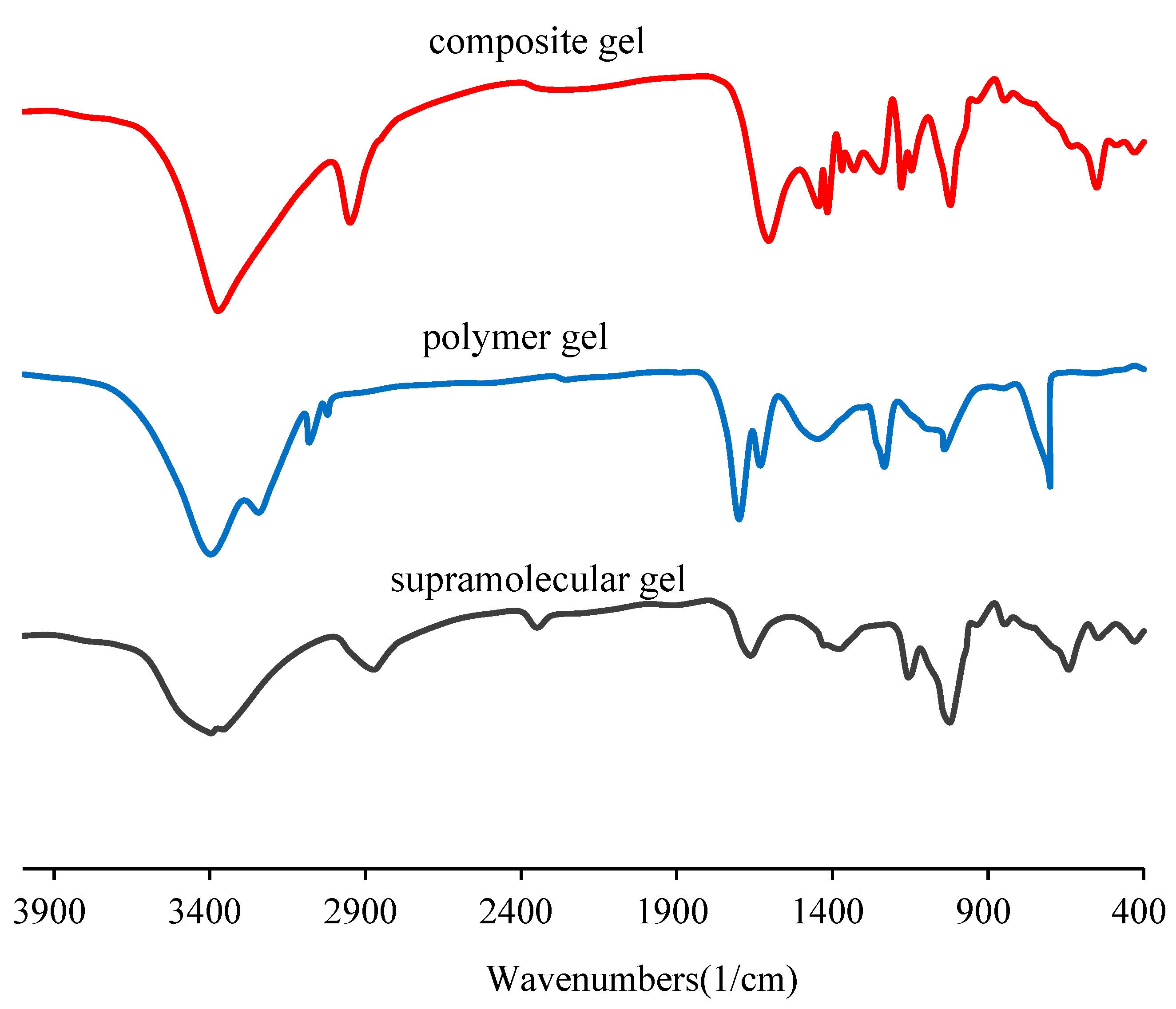

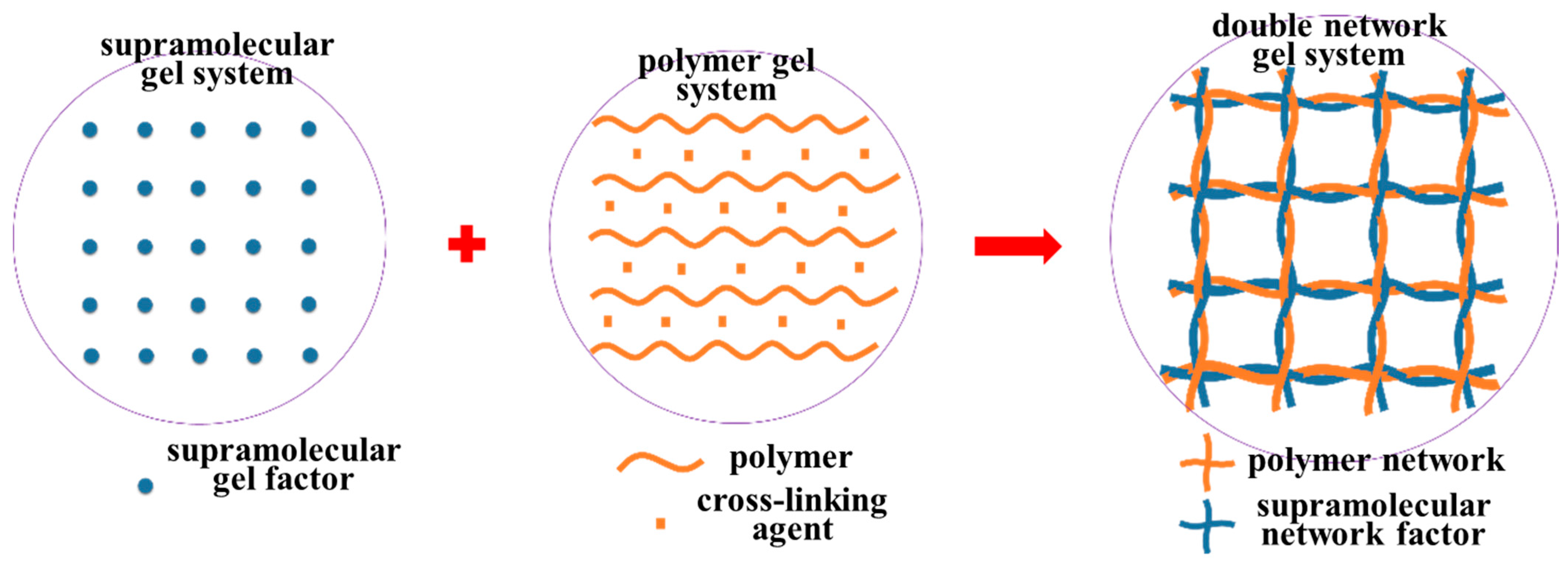

2.2. Microstructure and Cross-Linking Reaction Mechanism of the Gels

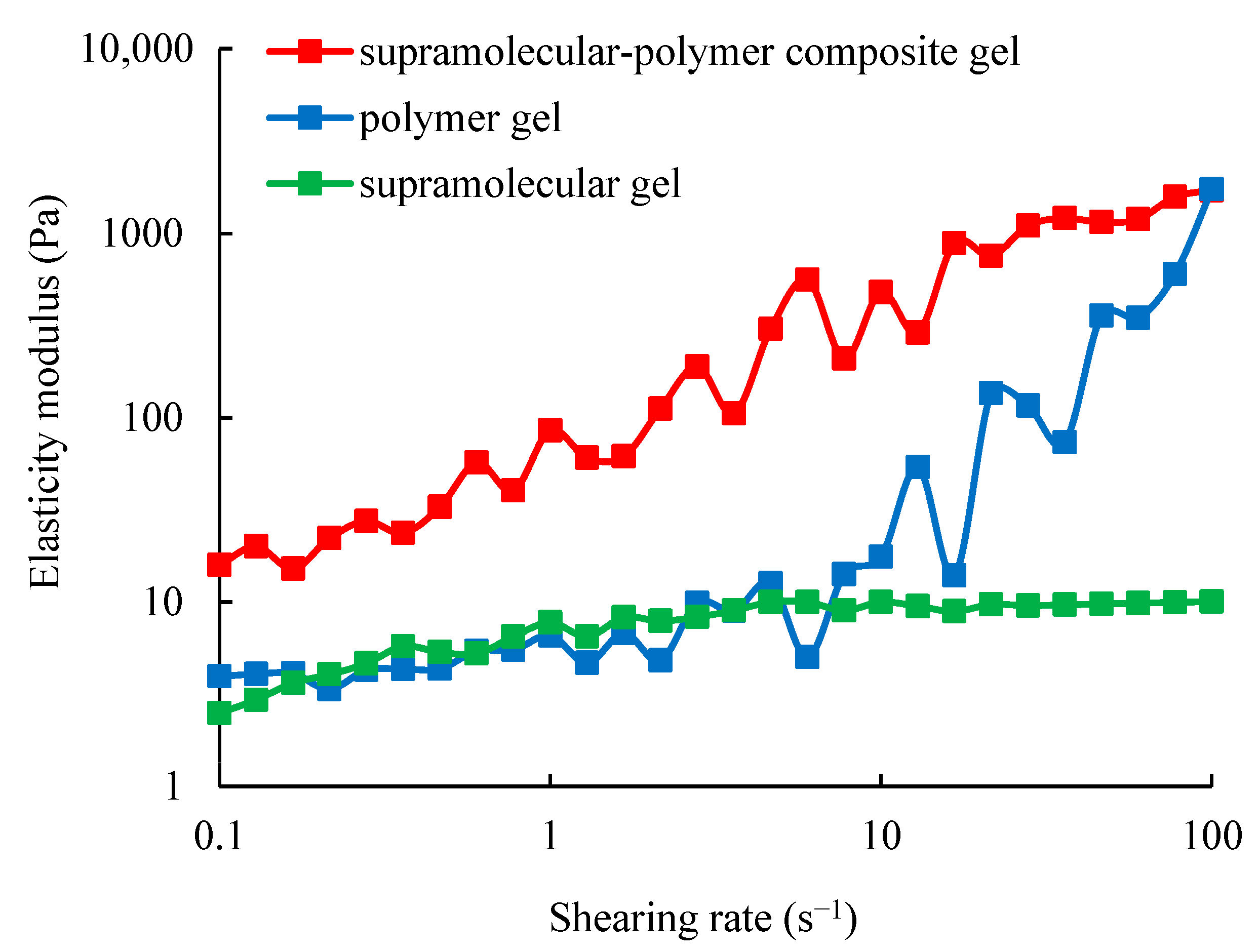

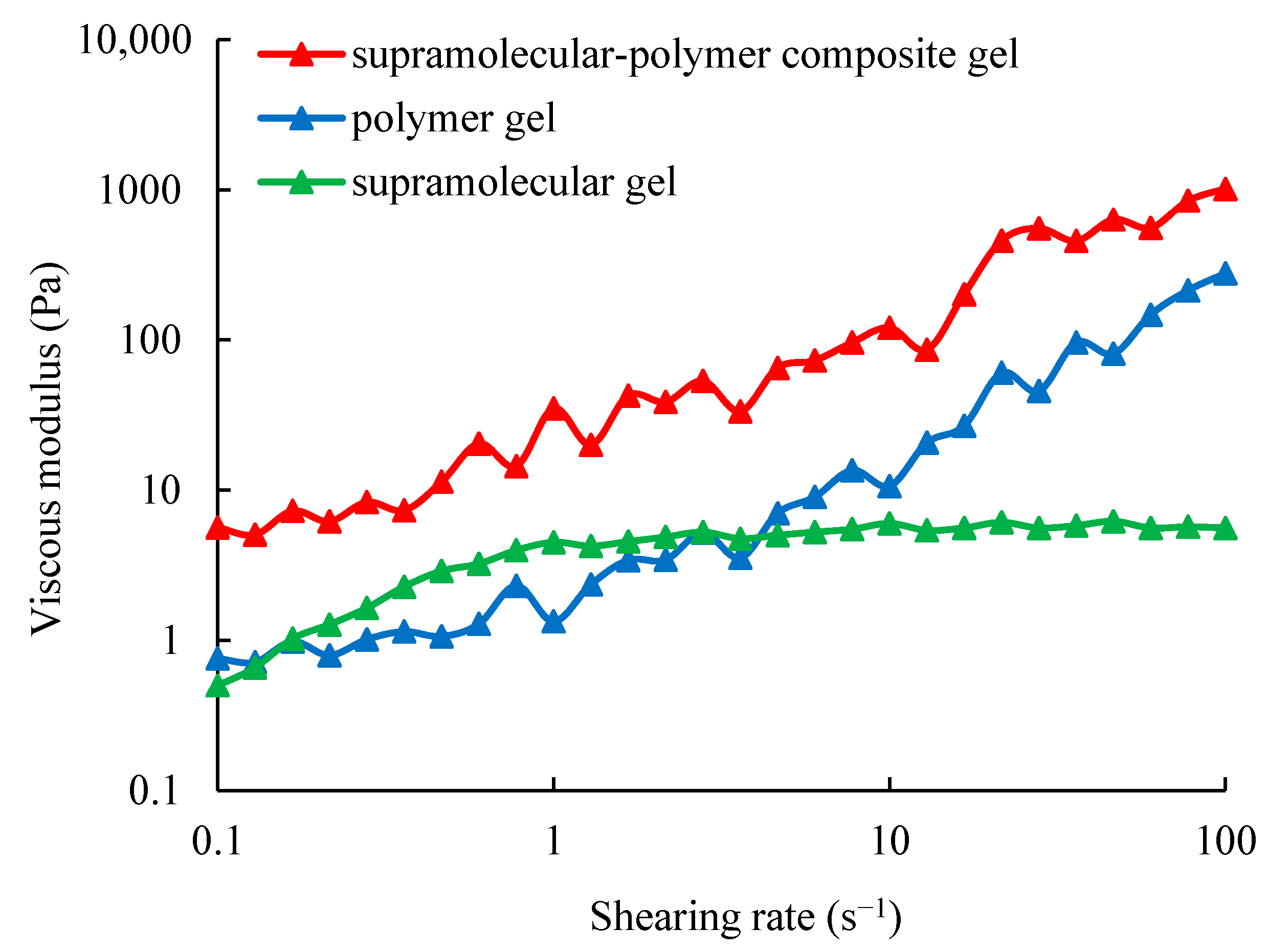

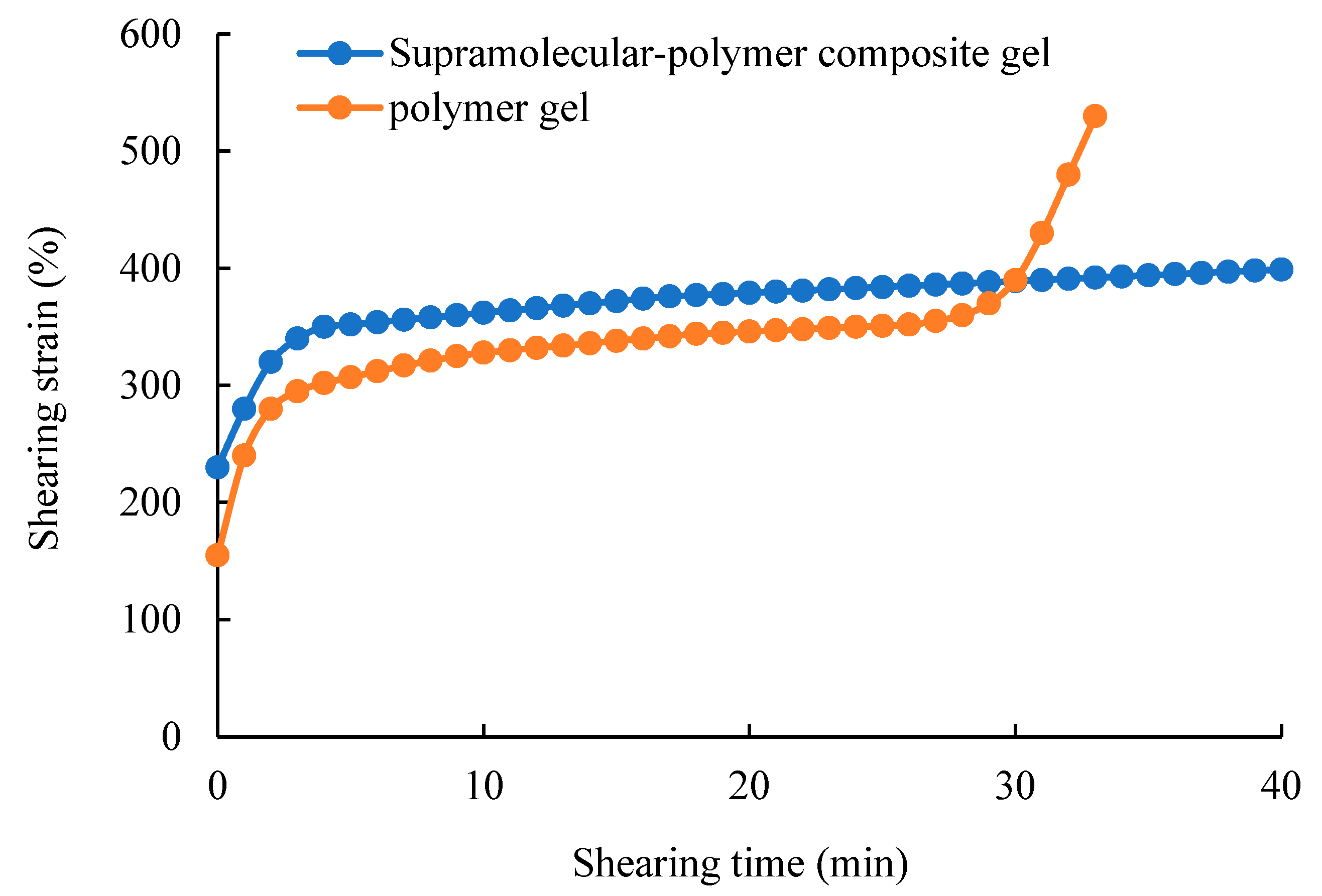

2.3. Rheological Characteristics of the Supramolecular–Polymer Composite Gel System

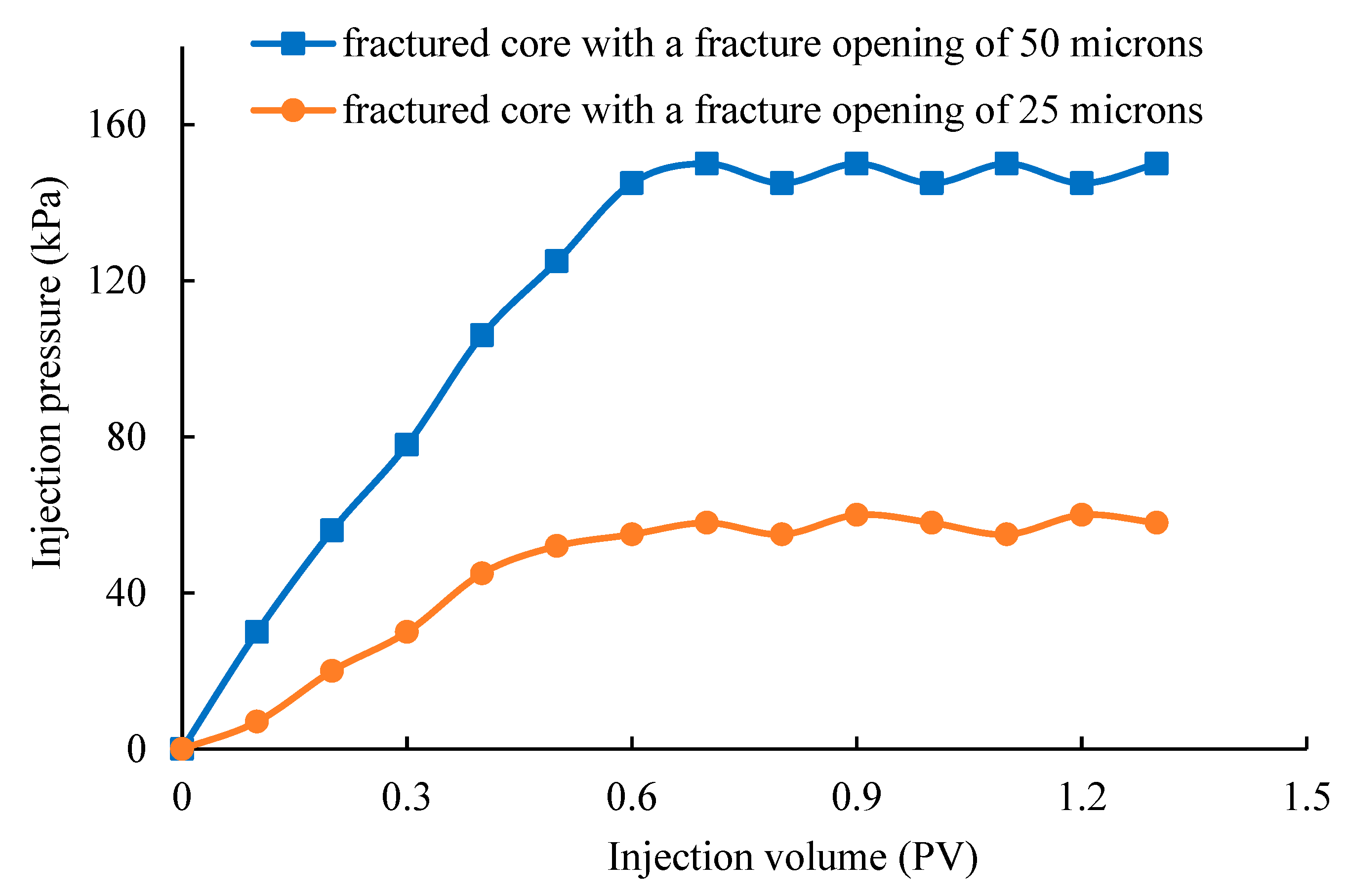

2.4. Flow Ability of the Supramolecular–Polymer Composite Gel System at the Initial State in Micro-Scale Fractures

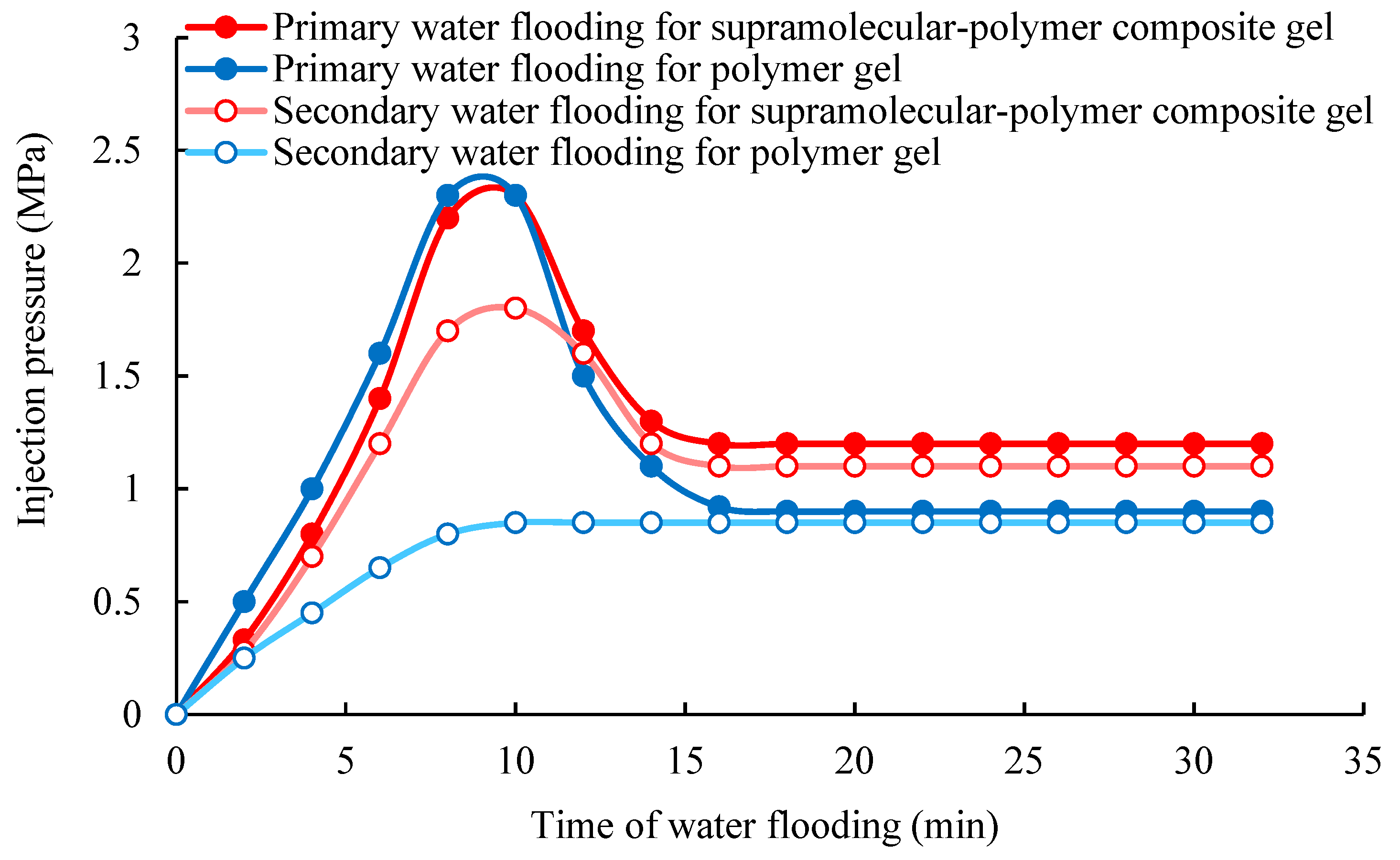

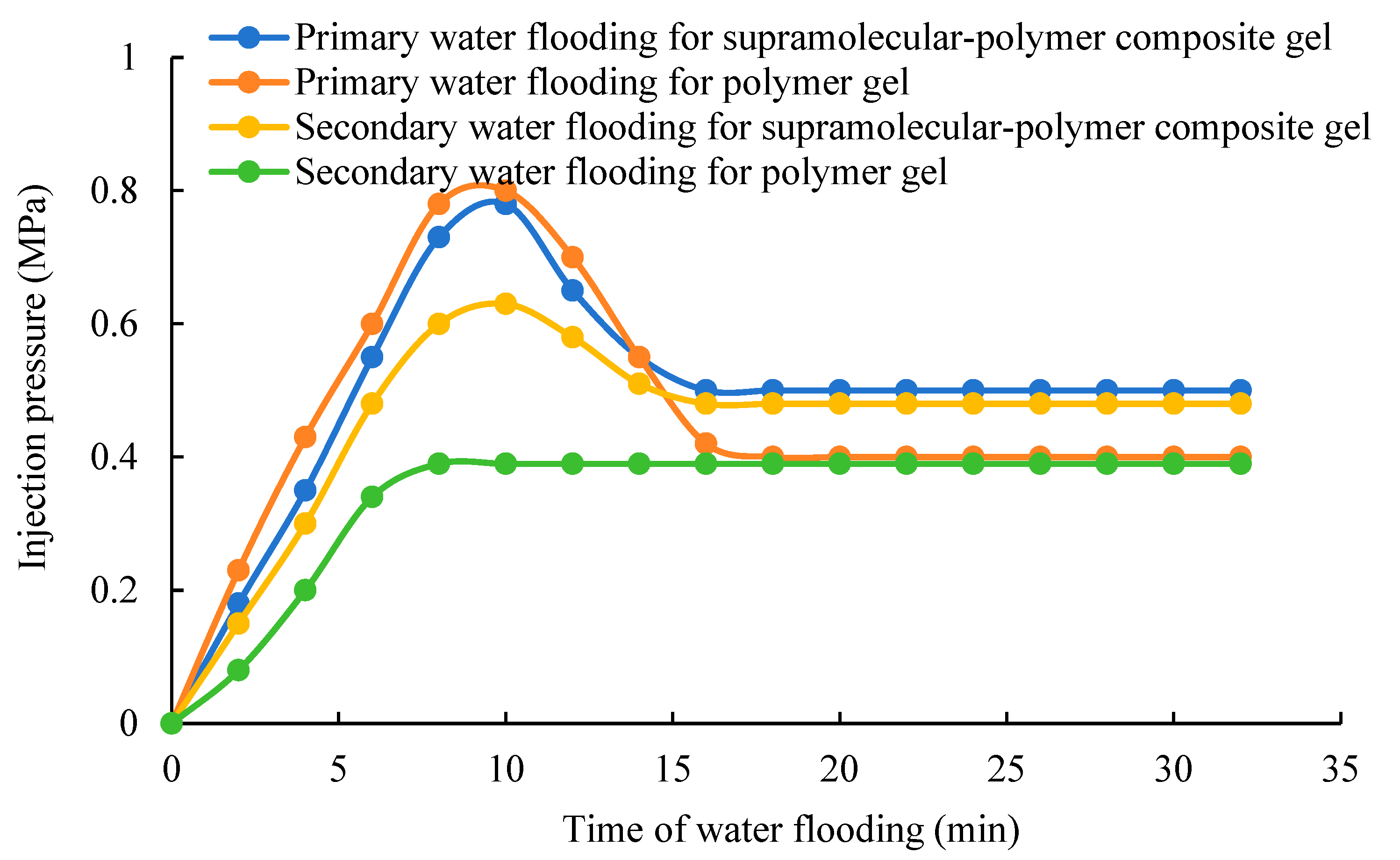

2.5. Plugging Performance of the Gels in the Large Millimeter-Scale Fractures after Gelation

3. Conclusions

4. Experiment

4.1. Materials and Instruments

4.2. Experiment Methods

4.2.1. Preparation and Performance Test of Gels

- (1)

- Preparation and performance test of the supramolecular gel

- (2)

- Preparation and performance test of the polymer gel

- (3)

- Preparation and performance test of the supramolecular–polymer composite gel

4.2.2. Evaluation of Injection Performance of Conformance Control Agent at the Initial State

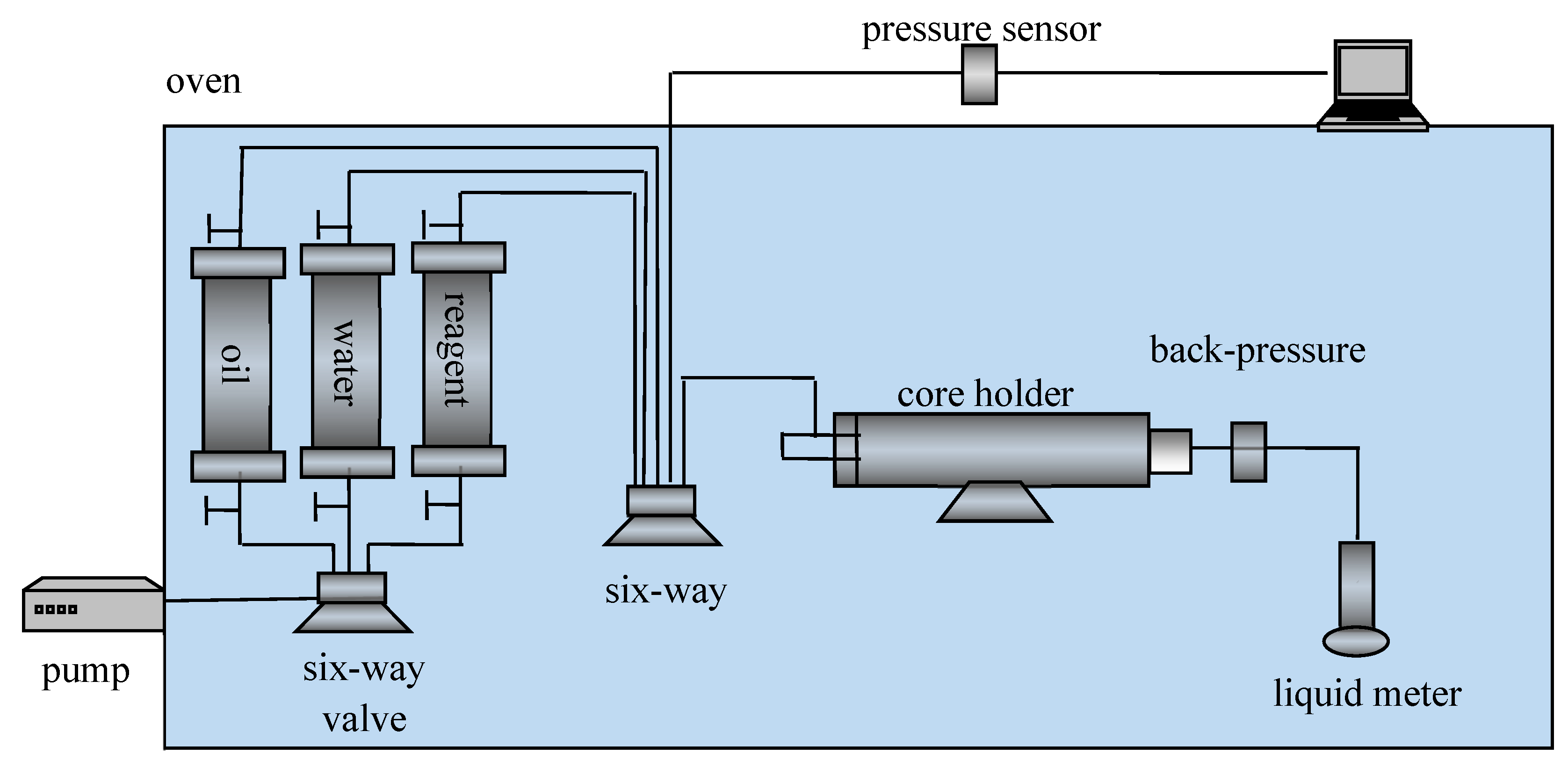

4.2.3. Evaluation of Plugging Performance of Conformance Control Agent after Gelation

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, J.; Liu, J.G.; Li, Z.G.; Li, H.C.; Zhang, J.S.; Li, W.Q.; Zhang, Y.L.; Ping, Y.; Yang, H.Y.; Wang, P. Synchronous injection-production energy replenishment for a horizontal well in an ultra-low permeability sandstone reservoir: A case study of Changqing oilfield in Ordos Basin, NW China. Pet. Explor. Dev. 2020, 47, 827–835. [Google Scholar] [CrossRef]

- Wang, X.Z.; Dang, H.L.; Gao, T. Method of moderate water injection and its application in ultra-low permeability oil reservoirs of Yanchang Oilfield, NW China. Pet. Explor. Dev. 2018, 45, 1094–1102. [Google Scholar] [CrossRef]

- Xiao, W.L.; Yang, Y.B.; Li, M.; Li, N.; You, J.X.; Zhao, J.Z.; Zheng, L.L.; Zhou, K.M.; Ren, J.T.; Wang, Y. Experimental study on the oil production characteristics during the waterflooding of different types of reservoirs in Ordos Basin, NW China. Pet. Explor. Dev. 2021, 48, 935–945. [Google Scholar] [CrossRef]

- Zhang, L.; Khan, N.; Pu, C. A new method of plugging the fracture to enhance oil production for fractured oil reservoir by using gel particles and HPAM/Cr3+ system. Polymers 2019, 11, 446. [Google Scholar] [CrossRef] [PubMed]

- An, Z.B.; Zhou, K.; Wu, D.J.; Hou, J. Production characteristics and displacement mechanisms of infilling polymer-surfactant-preformed particle gel flooding in post-polymer flooding reservoirs: A review of practice in Ng3 block of Gudao Oilfield. Pet. Sci. 2023, 20, 2354–2371. [Google Scholar] [CrossRef]

- Bai, L.; Shi, C.Y.; Tang, K.; Xie, H.; Yang, S.L.; Zhu, D.Y. Study on migration and plugging performance of polymer gel in fractured cores using nuclear magnetic resonance technology. Geoenergy Sci. Eng. 2023, 227, 211891. [Google Scholar] [CrossRef]

- Hao, H.D.; Li, J.X.; Deng, S.; Xian, B.H.; Tang, Z.; Yang, S.; Hou, J.R. N2 Foam Flooding Combined with Gel Plugging for Enhanced Oil Recovery in High-Temperature Reservoirs: Laboratory Experiments and Numerical Simulations. ACS Omega 2023, 8, 23913–23924. [Google Scholar] [CrossRef]

- Li, Y.K.; Hou, J.R.; Wu, W.P.; Qu, M.; Liang, T.; Zhong, W.X.; Wen, Y.C.; Sun, H.T.; Pan, Y.N. A novel profile modification HPF-Co gel satisfied with fractured low permeability reservoirs in high temperature and high salinity. Pet. Sci. 2024, 21, 683–693. [Google Scholar] [CrossRef]

- Liu, S.Q.; Jia, H.; Wang, H.S.; Liang, Y.B.; Shi, D.S.; Lu, Z.C.; Wu, J.Y. The ternary combination of polymer gel, microsphere and surfactant for conformance control and oil displacement to improve oil recovery in strong heterogeneous reservoir. Pet. Res. 2023, 8, 151–166. [Google Scholar] [CrossRef]

- Liu, T.Y.; Ye, Z.B.; Liu, D. Preparation and Performance Evaluation of P(St-AM) Microencapsulated Gel-Breaking Agents with Core-Shell Structure. Chem. Tech. Fuels Oils 2024, 60, 309–314. [Google Scholar] [CrossRef]

- Afsharpour, S.; Fatemi, M.; Ghazanfari, M.H. Microfluidics investigation of the fracture/matrix interaction mechanisms during preformed particle gel (PPG) treatment in fractured porous media. Geoenergy Sci. Eng. 2024, 234, 212611. [Google Scholar] [CrossRef]

- Ali, A.; Al Ramadan, M.; Aljawad, M.S.; Elsayed, M.; Almohsin, A. Experimental Study of Nanosilica Gel as a Water Shut-Off Agent in Fractured Reservoirs. Energy Fuels 2024, 38, 7167–7180. [Google Scholar] [CrossRef]

- Zhang, L.; Zheng, L.; Pu, J.; Pu, C.; Cui, S. Influence of Hydrolyzed Polyacrylamide (HPAM) Molecular Weight on the Cross-Linking Reaction of the HPAM/Cr3+ System and Transportation of the HPAM/Cr3+ System in Micro-fractures. Energy Fuels 2016, 30, 9351–9361. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, R.B.; Liu, J.; Yu, Y.Y.; Zhu, K.L. Development and field application of strongly resilient temporary plugging diversion agent for fracturing. J. Pet. Explor. Prod. Technol. 2024, 14, 2073–2088. [Google Scholar] [CrossRef]

- Long, W.J.; Wei, Z.J.; Zhou, F.S.; Li, S.H.; Yin, K.; Zhao, Y.; Yu, S.T.; Qi, H. Alkaline Hydrolysis of Waste Acrylic Fibers Using the Micro-Water Method and Its Application in Drilling Fluid Gel Systems. Gels 2023, 9, 974. [Google Scholar] [CrossRef]

- Pandit, Y.K.; Mahto, V.; Udayabhanu, G.; Ravishankar, B.; Dhandi, M. Preparation, characterization, and evaluation of a nanomaterial reinforced particle gel system for the control of excessive water production in the mature oil fields. Geoenergy Sci. Eng. 2024, 235, 212707. [Google Scholar] [CrossRef]

- Pu, J.Y.; Bai, B.J.; Geng, J.M.; Zhang, N.; Schuman, T. Dual crosslinked poly(acrylamide-co-N-vinylpyrrolidone) microspheres with re-crosslinking ability for fossil energy recovery. Geoenergy Sci. Eng. 2023, 224, 211604. [Google Scholar] [CrossRef]

- Tan, X.J.; Zhang, J.H.; Wang, Y.A.; Li, M.; Liu, J.M.; Zhu, Z.J. Application of a Salt-Resistant In Situ Cross-Linked Terpolymer Gel for the Daqing Oilfield. ACS Omega 2023, 8, 22223–22229. [Google Scholar] [CrossRef]

- Xin, X.K.; Liu, Q.; Liu, S.J.; Yu, G.M.; Wan, Q.S. Optimization of Gel Flooding during the High Water Cut Stage in a Conglomerate Reservoir of the Xinjiang Oilfield. Polymers 2023, 15, 1809. [Google Scholar] [CrossRef]

- Xu, Q.J.; Wu, R.; Yuan, Z.Y.; Liang, H.; Shi, Y.; Xu, H.; Wu, H.T.; Zheng, J.; Wu, J.R. Tough, Notch-Insensitive, Heat-Resistant Hydrogels Constructed by Vinylated Polylysine for Temporary Oilfield Water Plugging. Ind. Eng. Chem. Res. 2023, 62, 18484–18492. [Google Scholar] [CrossRef]

- Zhang, L.; Yu, W.; Ma, P.; Zheng, L.; Zhang, Y. Study on long-term rheological characteristics of polymer gel and prediction of its creep fracture time. J. Pet. Sci. Eng. 2021, 201, 108445. [Google Scholar] [CrossRef]

- Zhang, L.; Zhuang, W.; Khan, N.; Zheng, L. Effect of stress relaxation and creep recovery on transportation in porous medium and fracture of the millimeter-scale polymer gel particles for conformance control of heterogeneous oil reservoir. J. Pet. Sci. Eng. 2020, 185, 106648. [Google Scholar] [CrossRef]

- Zou, H.J.; Wang, Y.G.; Xu, Y.; Li, J.A.; Wu, L.; Su, G.S.; Yu, X.R.; Yang, H. Synthesis and Performance Study of Self-Degradable Gel Plugging Agents Suitable for Medium- and Low-Temperature Reservoirs. ACS Omega 2024, 9, 33702–33709. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Ge, J.; Wu, H.; Guo, H.B.; Shan, J.L.; Zhang, G.C. Phase behavior of colloidal nanoparticles and their enhancement effect on the rheological properties of polymer solutions and gels. RSC Adv. 2024, 14, 8513–8525. [Google Scholar] [CrossRef]

- Zhi, J.Q.; Liu, Y.K.; Chen, J.F.; Bo, L.F.; Qu, G.H.; Jiang, N.; He, W.Z. Preparation and Performance Evaluation of a Temperature and Salt Resistant Hydrophobic Associative Weak Polymer Gel System. Molecules 2023, 28, 3125. [Google Scholar] [CrossRef]

- Du, X.W.; Zhou, J.; Shi, J.F.; Xu, B. Supramolecular Hydrogelators and Hydrogels: From Soft Matter to Molecular Biomaterials. Chem. Rev. 2015, 115, 13165–13307. [Google Scholar] [CrossRef]

- Hong, W.; Zhao, X.H.; Zhou, J.X.; Suo, Z.G. A theory of coupled diffusion and large deformation in polymeric gels. J. Mech. Phys. Solids 2008, 56, 1779–1793. [Google Scholar] [CrossRef]

- Sun, D.L.; Yang, Y.; Ma, W.J.; Ye, S.X.; Zhang, H.; Zhang, J.; Yang, B. Heat-Resistant Hydrogel for Temporary Plugging in High-Temperature and High-Pressure Fractured Reservoirs. ACS Appl. Polym. Mater. 2023, 5, 7746–7754. [Google Scholar] [CrossRef]

- Hu, J.M.; Liu, S.Y. Responsive Polymers for Detection and Sensing Applications: Current Status and Future Developments. Macromolecules 2010, 43, 8315–8330. [Google Scholar] [CrossRef]

- Ali, O.; Okumura, B.; Shintani, Y.; Sugiura, S.; Shibata, A.; Higashi, S.L.; Ikeda, M. Oxidation-Responsive Supramolecular Hydrogels Based on Glucosamine Derivatives with an Aryl Sulfide Group. Chembiochem 2024, 25, e202400459. [Google Scholar] [CrossRef]

- Chen, S.J.; Li, L.; Gu, Y.Q.; Luo, F.; Chen, K.Y.; Lou, Y.; Huang, Q.; Hu, J.J.; Cheng, Y.Y. A Supramolecular Bifunctional Hydrogel with Zero-Order Release Kinetics to Resist Bacterial Infection and Foreign Body Response of Implants. Ccs Chem. 2024, 1–16. [Google Scholar] [CrossRef]

- Yang, J.B.; Sun, J.S.; Bai, Y.R.; Lv, K.H.; Li, J.; Li, M.C.; Zhu, Y.C. Preparation and characterization of supramolecular gel suitable for fractured formations. Pet. Sci. 2023, 20, 2324–2342. [Google Scholar] [CrossRef]

- Dimmito, M.P.; Marinelli, L.; Cacciatore, I.; Toto, E.C.; Albertini, B.; Fontana, A.; Pilato, S.; Reale, M.; Costantini, E.; Pesce, C.; et al. From self-Assembly to healing: Engineering ultra-Small peptides into supramolecular hydrogels for controlled drug release. Int. J. Pharm. 2024, 663, 124562. [Google Scholar] [CrossRef] [PubMed]

- Kubota, R. Supramolecular Polymer Composite Hydrogels: From in Situ Network Observation to Functional Properties. Bull. Chem. Soc. Jpn. 2023, 96, 802–812. [Google Scholar] [CrossRef]

- Ginesi, R.E.; Draper, E.R. Methods of changing low molecular weight gel properties through gelation kinetics. Soft Matter 2024, 20, 3887–3896. [Google Scholar] [CrossRef]

- Wu, C.F.; Liao, W.J.; Zhang, Y.J.; Yan, Y.F. Peptide-based supramolecular hydrogels and their biotherapeutic applications. Biomater. Sci. 2024. [Google Scholar] [CrossRef]

- Wei, Q.; Chang, Y.; Ma, G.; Zhang, W.; Wang, Q.; Hu, Z. One-pot preparation of double network hydrogels via enzyme-mediated polymerization and post-self-assembly for wound healing. J. Mater. Chem. B 2019, 7, 6195–6201. [Google Scholar] [CrossRef]

- Zheng, J.; Xiao, P.; Liu, W.; Zhang, J.; Huang, Y.; Chen, T. Mechanical robust and self-healable supramolecular hydrogel. Macromol. Rapid Commun. 2016, 37, 265–270. [Google Scholar] [CrossRef]

- Ramya, K.A.; Reddy, S.M.M.; Shanmugam, G.; Deshpande, A.P. Fibrillar Network Dynamics during Oscillatory Rheology of Supramolecular Gels. Langmuir 2020, 36, 13342–13355. [Google Scholar] [CrossRef]

- Yu, G.C.; Yan, X.Z.; Han, C.Y.; Huang, F.H. Characterization of supramolecular gels. Chem. Soc. Rev. 2013, 42, 6697–6722. [Google Scholar] [CrossRef]

- Kavanagh, G.M.; Ross-Murphy, S.B. Rheological characterisation of polymer gels. Prog. Polym. Sci. 1998, 23, 533–562. [Google Scholar] [CrossRef]

| No. | Length (cm) | Diameter (cm) | Fracture Aperture (mm) | Permeability of Rock Matrix for the Fracture Cores (10−3 μm2) | Porosity of Rock Matrix for the Fracture Cores (%) |

|---|---|---|---|---|---|

| 1# | 10 | 2.5 | 0.025 | 15 | 15.66 |

| 2# | 10 | 2.5 | 0.050 | 15 | 15.82 |

| 3# | 10 | 2.5 | 1.00 | 15 | 15.58 |

| 4# | 10 | 2.5 | 2.00 | 15 | 15.64 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, B.; Wang, H.; Jiang, S.; Chen, M.; Zhang, L. Development and Performance Evaluation of a New Conformance Control Agent Gel. Gels 2024, 10, 618. https://doi.org/10.3390/gels10100618

Ma B, Wang H, Jiang S, Chen M, Zhang L. Development and Performance Evaluation of a New Conformance Control Agent Gel. Gels. 2024; 10(10):618. https://doi.org/10.3390/gels10100618

Chicago/Turabian StyleMa, Bin, He Wang, Shu Jiang, Mengyu Chen, and Lei Zhang. 2024. "Development and Performance Evaluation of a New Conformance Control Agent Gel" Gels 10, no. 10: 618. https://doi.org/10.3390/gels10100618

APA StyleMa, B., Wang, H., Jiang, S., Chen, M., & Zhang, L. (2024). Development and Performance Evaluation of a New Conformance Control Agent Gel. Gels, 10(10), 618. https://doi.org/10.3390/gels10100618