Effect of Three Post-Harvest Methods at Different Altitudes on the Organoleptic Quality of C. canephora Coffee

Abstract

:1. Introduction

2. Materials and Methods

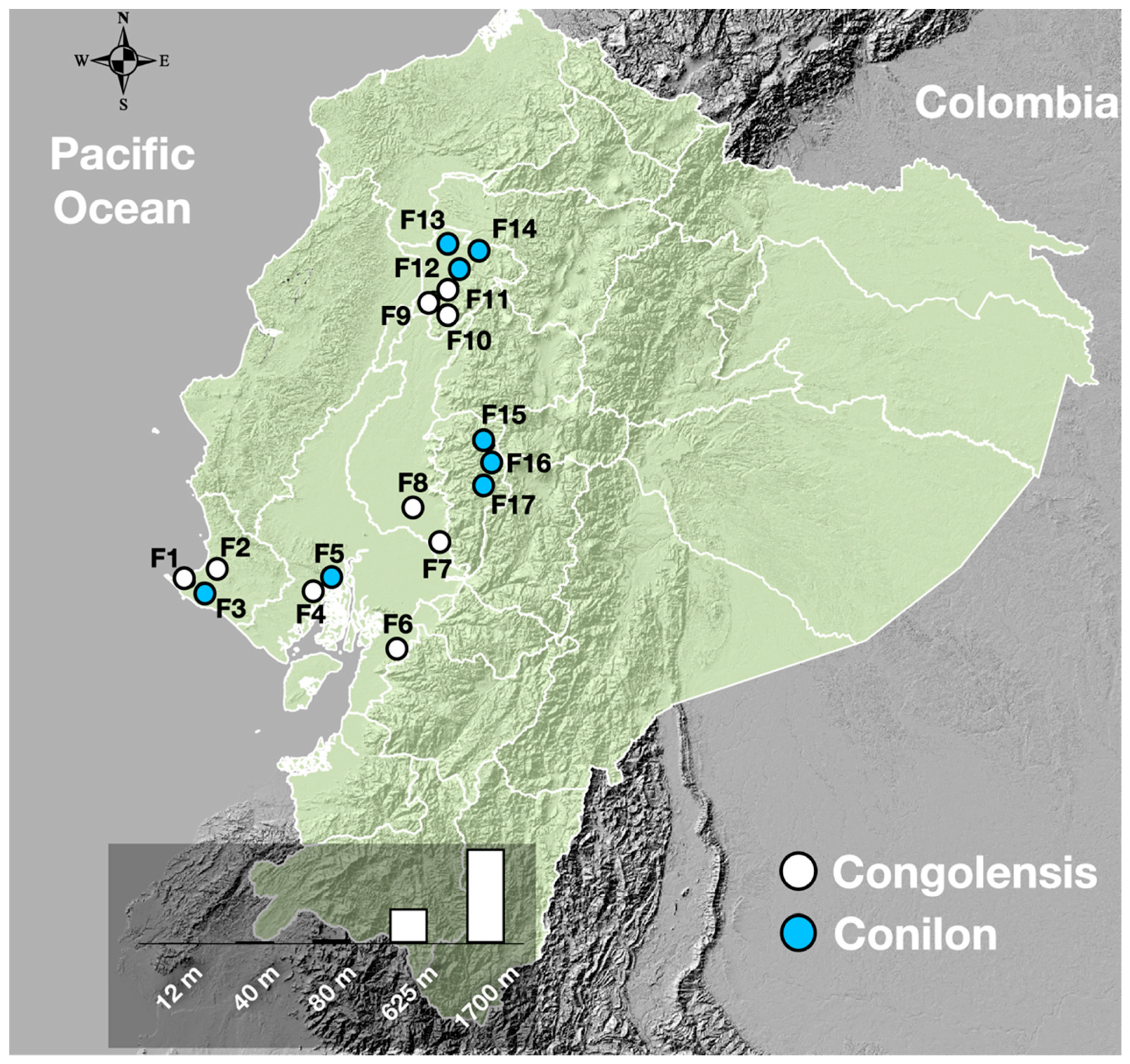

2.1. Sampling

2.2. Post-Harvest Treatment

2.3. Preparation of Coffee Samples

2.4. Sensorial Analysis

2.5. Statistical Analysis

3. Results

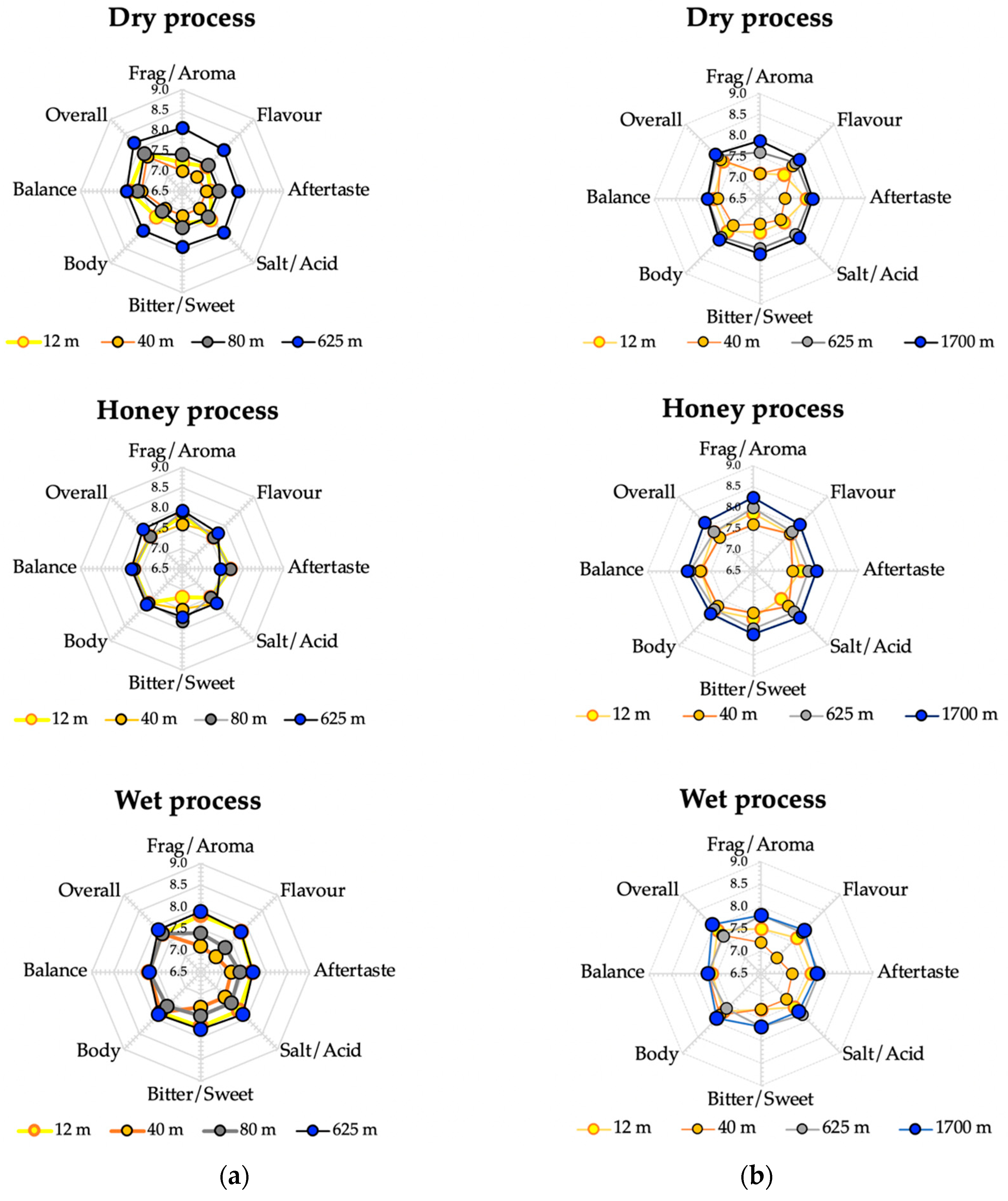

3.1. Effect of Post-Harvest Processes and Altitude on Coffee Cupping

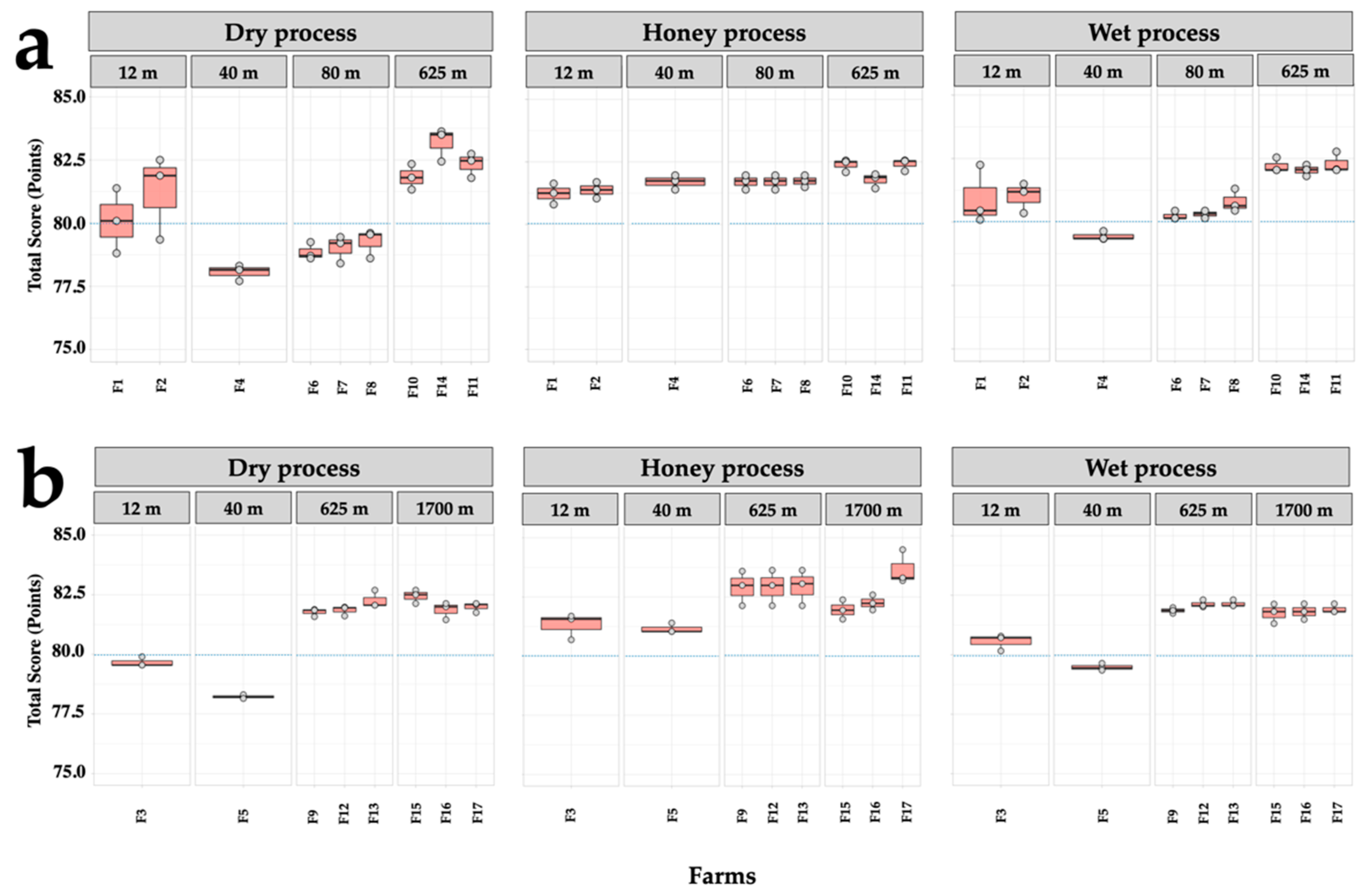

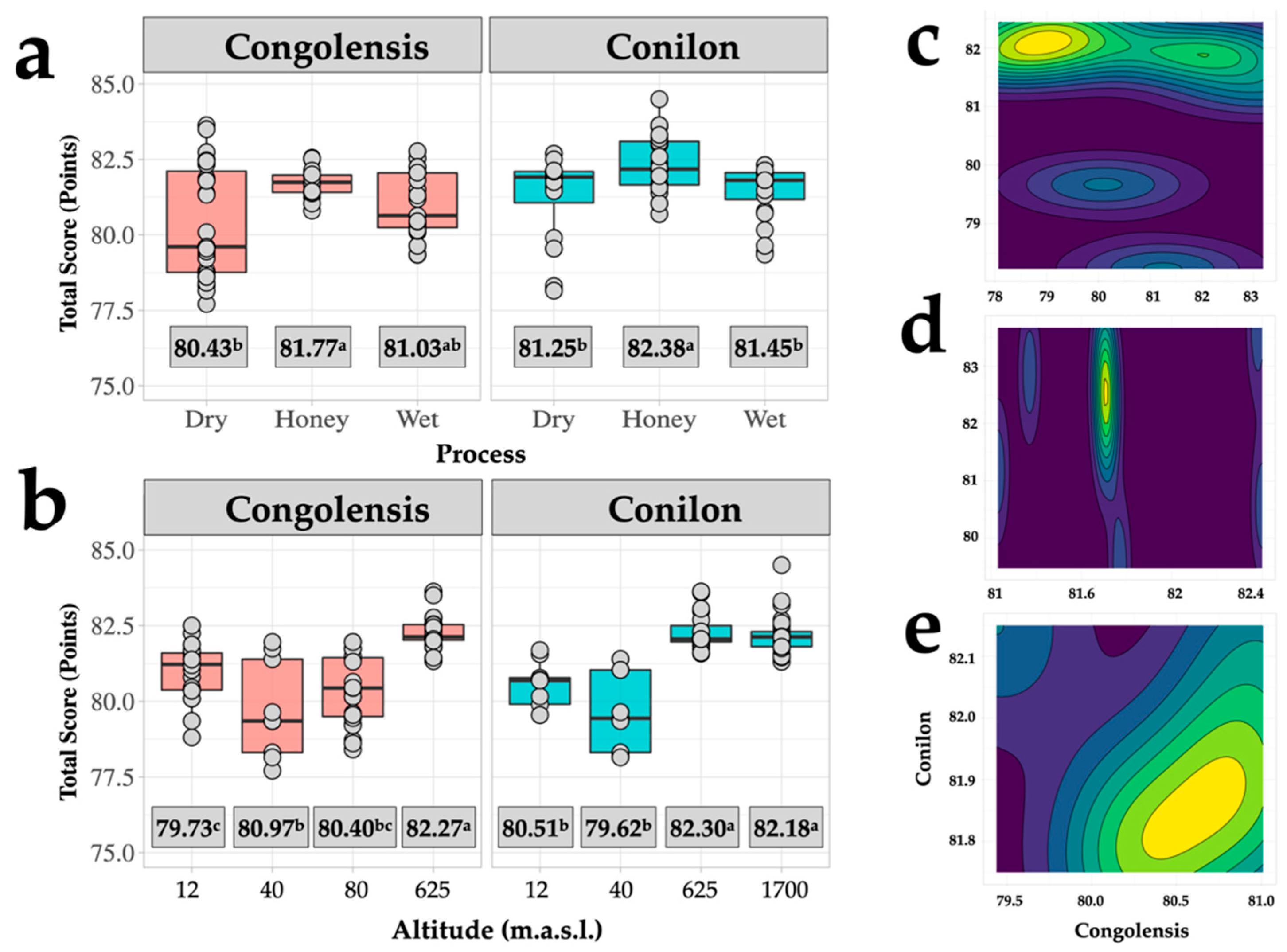

3.2. Effect of Post-Harvest Processes and Altitude on Total Score

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ICO. Monthly Coffee Market Report (2021/22); ICO: London, UK, 2021. [Google Scholar]

- Campuzano-Duque, L.F.; Herrera, J.C.; Ged, C.; Blair, M.W. Bases for the Establishment of Robusta Coffee (Coffea canephora) as a New Crop for Colombia. Agronomy 2021, 11, 2550. [Google Scholar] [CrossRef]

- Bunn, C.; Läderach, P.; Ovalle Rivera, O.; Kirschke, D. A Bitter Cup: Climate Change Profile of Global Production of Arabica and Robusta Coffee. Clim. Chang. 2015, 129, 89–101. [Google Scholar] [CrossRef] [Green Version]

- Byrareddy, V.; Kouadio, L.; Mushtaq, S.; Kath, J.; Stone, R. Coping with Drought: Lessons Learned from Robusta Coffee Growers in Vietnam. Clim. Serv. 2021, 22, 100229. [Google Scholar] [CrossRef]

- Kath, J.; Mittahalli Byrareddy, V.; Mushtaq, S.; Craparo, A.; Porcel, M. Temperature and Rainfall Impacts on Robusta Coffee Bean Characteristics. Clim. Risk Manag. 2021, 32, 100281. [Google Scholar] [CrossRef]

- Bosselmann, A.S.; Dons, K.; Oberthur, T.; Olsen, C.S. The Influence of Shade Trees on Coffee Quality in Small Holder Coffee 3 Agroforestry Systems in Southern Colombia. Agric. Ecosyst. Environ. 2009, 129, 8. [Google Scholar] [CrossRef]

- Ahmed, S.; Brinkley, S.; Smith, E.; Sela, A.; Theisen, M.; Thibodeau, C.; Warne, T.; Anderson, E.; Van Dusen, N.; Giuliano, P.; et al. Climate Change and Coffee Quality: Systematic Review on the Effects of Environmental and Management Variation on Secondary Metabolites and Sensory Attributes of Coffea arabica and Coffea canephora. Front. Plant Sci. 2021, 12, 708013. [Google Scholar] [CrossRef]

- Kittichotsatsawat, Y.; Jangkrajarng, V.; Tippayawong, K.Y. Enhancing Coffee Supply Chain towards Sustainable Growth with Big Data and Modern Agricultural Technologies. Sustainability 2021, 13, 4593. [Google Scholar] [CrossRef]

- Läderach, P.; Ramirez–Villegas, J.; Navarro-Racines, C.; Zelaya, C.; Martinez–Valle, A.; Jarvis, A. Climate Change Adaptation of Coffee Production in Space and Time. Clim. Chang. 2017, 141, 47–62. [Google Scholar] [CrossRef] [Green Version]

- Chemura, A.; Mudereri, B.T.; Yalew, A.W.; Gornott, C. Climate Change and Specialty Coffee Potential in Ethiopia. Sci. Rep. 2021, 11, 8097. [Google Scholar] [CrossRef]

- Hameed, A.; Hussain, S.A.; Ijaz, M.U.; Ullah, S.; Pasha, I.; Suleria, H.A.R. Farm to Consumer: Factors Affecting the Organoleptic Characteristics of Coffee. II: Postharvest Processing Factors: Farm to Consumer. Compr. Rev. Food Sci. Food Saf. 2018, 17, 1184–1237. [Google Scholar] [CrossRef]

- Rojas-Múnera, D.M.; Feijoo-Martínez, A.; Molina-Rico, L.J.; Zúñiga, M.C.; Quintero, H. Differential Impact of Altitude and a Plantain Cultivation System on Soil Macroinvertebrates in the Colombian Coffee Region. Appl. Soil Ecol. 2021, 164, 103931. [Google Scholar] [CrossRef]

- Gichuru, E.; Alwora, G.; Gimase, J.; Kathurima, C. Coffee Leaf Rust (Hemileia vastatrix) in Kenya—A Review. Agronomy 2021, 11, 2590. [Google Scholar] [CrossRef]

- Pereira, D.; Nadaleti, D.; Rodrigues, E.; Silva, A.; Malta, M.; Carvalho, S.; Carvalho, G. Genetic and Chemical Control of Coffee Rust (Hemileia vastatrix Berk et Br.): Impacts on Coffee (Coffea Arabica L.) Quality. J. Sci. Food Agric. 2021, 101, 2836–2845. [Google Scholar] [CrossRef] [PubMed]

- Wagner, S.; Jassogne, L.; Price, E.; Jones, M.; Preziosi, R. Impact of Climate Change on the Production of Coffea arabica at Mt. Kilimanjaro, Tanzania. Agriculture 2021, 11, 53. [Google Scholar] [CrossRef]

- Guerrero-Parra, H.A.; Calderón-Ezquerro, M.C.; Martínez-López, B. Environmental Factors That Modulate the Release and Transport of Airborne Urediniospores Hemileia vastatrix (Berk. & Broome) in Coffee Crops in Veracruz México. Aerobiologia 2022, 38, 123–143. [Google Scholar] [CrossRef]

- Mulindwa, J.; Kaaya, A.N.; Muganga, L.; Paga, M.; Musoli, P.; Sseremba, G.; Wagoire, W.W.; Bitalo, D.N. Cup Quality Profiles of Robusta Coffee Wilt Disease Resistant Varieties Grown in Three Agro-Ecologies in Uganda. J. Sci. Food Agric. 2021, 102, 1225–1232. [Google Scholar] [CrossRef]

- Pereira, L.; Moreli, A.; Moreira, T.; Caten, C.; Marcate, J.; Debona, D.; Guarçoni, R. Improvement of the Quality of Brazilian Conilon through Wet Processing: A Sensorial Perspective. AS 2019, 10, 395–411. [Google Scholar] [CrossRef] [Green Version]

- Pereira, L.; Guarçoni, R.; Pinheiro, P.; Osório, V.; Pinheiro, C.; Moreira, T.; Schwengber, C. New Propositions about Coffee Wet Processing: Chemical and Sensory Perspectives. Food Chem. 2020, 310, 125943. [Google Scholar] [CrossRef]

- do Livramento, K.G.; Borém, F.M.; José, A.C.; Santos, A.V.; do Livramento, D.E.; Alves, J.D.; Paiva, L.V. Proteomic Analysis of Coffee Grains Exposed to Different Drying Process. Food Chem. 2017, 221, 1874–1882. [Google Scholar] [CrossRef]

- Wei, F.; Tanokura, M. Chemical Changes in the Components of Coffee Beans during Roasting. In Coffee in Health and Disease Prevention; Elsevier: Amsterdam, The Netherlands, 2015; pp. 83–91. ISBN 978-0-12-409517-5. [Google Scholar]

- Waters, D.M.; Arendt, E.K.; Moroni, A.V. Overview on the Mechanisms of Coffee Germination and Fermentation and Their Significance for Coffee and Coffee Beverage Quality. Crit. Rev. Food Sci. Nutr. 2017, 57, 259–274. [Google Scholar] [CrossRef]

- Girma, B.; Sualeh, A. A Review of Coffee Processing Methods and Their Influence on Aroma. Int. J. Food Eng. Technol. 2022, 6, 7. [Google Scholar] [CrossRef]

- Campos, G.A.F.; Kruizenga, J.G.K.T.; Sagu, S.T.; Schwarz, S.; Homann, T.; Taubert, A.; Rawel, H.M. Effect of the Post-Harvest Processing on Protein Modification in Green Coffee Beans by Phenolic Compounds. Foods 2022, 11, 159. [Google Scholar] [CrossRef] [PubMed]

- Zakidou, P.; Plati, F.; Matsakidou, A.; Varka, E.-M.; Blekas, G.; Paraskevopoulou, A. Single Origin Coffee Aroma: From Optimized Flavor Protocols and Coffee Customization to Instrumental Volatile Characterization and Chemometrics. Molecules 2021, 26, 4609. [Google Scholar] [CrossRef]

- Bastian, F.; Hutabarat, O.S.; Dirpan, A.; Nainu, F.; Harapan, H.; Emran, T.B.; Simal-Gandara, J. From Plantation to Cup: Changes in Bioactive Compounds during Coffee Processing. Foods 2021, 10, 2827. [Google Scholar] [CrossRef] [PubMed]

- Schwan, R.; Fleet, G. Cocoa and Coffee Fermentations, 1st ed.; CRC Press: Boca Raton, FL, USA, 2014; Volume 1, ISBN 978-0-429-06292-6. [Google Scholar]

- Ribeiro, L.S.; Miguel, M.G.D.C.P.; Evangelista, S.R.; Martins, P.M.M.; van Mullem, J.; Belizario, M.H.; Schwan, R.F. Behavior of Yeast Inoculated during Semi-Dry Coffee Fermentation and the Effect on Chemical and Sensorial Properties of the Final Beverage. Food Res. Int. 2017, 92, 26–32. [Google Scholar] [CrossRef] [PubMed]

- Duarte, G.S.; Pereira, A.A.; Farah, A. Chlorogenic Acids and Other Relevant Compounds in Brazilian Coffees Processed by Semi-Dry and Wet Post-Harvesting Methods. Food Chem. 2010, 118, 851–855. [Google Scholar] [CrossRef]

- Lee, L.W.; Cheong, M.W.; Curran, P.; Yu, B.; Liu, S.Q. Coffee Fermentation and Flavor—An Intricate and Delicate Relationship. Food Chem. 2015, 185, 182–191. [Google Scholar] [CrossRef]

- Mahmud, M.M.C.; Shellie, R.A.; Keast, R. Unravelling the Relationship between Aroma Compounds and Consumer Acceptance: Coffee as an Example. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2380–2420. [Google Scholar] [CrossRef]

- Worku, M.; de Meulenaer, B.; Duchateau, L.; Boeckx, P. Effect of Altitude on Biochemical Composition and Quality of Green Arabica Coffee Beans Can Be Affected by Shade and Postharvest Processing Method. Food Res. Int. 2018, 105, 278–285. [Google Scholar] [CrossRef]

- Pinheiro, C.A.; Pereira, L.L.; Fioresi, D.B.; da Silva Oliveira, D.; Osório, V.M.; Silva, J.A.D.; Pereira, U.A.; Ferrão, M.A.G.; Souza, E.M.R.; da Fonseca, A.F.A.; et al. Physico-Chemical Properties and Sensory Profile of Coffea canephora Genotypes in High-Altitudes. Aust. J. Crop Sci. 2019, 13, 2046–2052. [Google Scholar] [CrossRef]

- Vargas-Pereira, P.; Silveira, D.; Schwan, R.; Assis Silva, S.; Coelho, J.; Bernardes, P. Effect of Altitude and Terrain Aspect on the Chemical Composition of Coffea canephora Cherries and Sensory Characteristics of the Beverage. J. Sci. Food Agric. 2021, 101, 2570–2575. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez, Y.; Guzman, N.; Hernandez, J. Effect of the Postharvest Processing Method on the Biochemical Composition and Sensory Analysis of Arabica Coffee. Eng. Agrícola 2020, 40, 177–183. [Google Scholar] [CrossRef] [Green Version]

- Barbosa, I.; de Oliveira, A.; Rosado, R.; Sakiyama, N.; Cruz, C.; Pereira, A. Sensory Analysis of Arabica Coffee: Cultivars of Rust Resistance with Potential for the Specialty Coffee Market. Euphytica 2020, 216, 165. [Google Scholar] [CrossRef]

- Bressani, A.P.P.; Martinez, S.J.; Batista, N.N.; Simão, J.B.P.; Dias, D.R.; Schwan, R.F. Co-Inoculation of Yeasts Starters: A Strategy to Improve Quality of Low Altitude Arabica Coffee. Food Chem. 2021, 361, 130133. [Google Scholar] [CrossRef] [PubMed]

- Elmacı, İ.; Gok, I. Effect of Three Post-harvest Methods and Roasting Degree on Sensory Profile of Turkish Coffee Assessed by Turkish and Brazilian Panelists. J. Sci. Food Agric. 2021, 101, 5368–5377. [Google Scholar] [CrossRef] [PubMed]

- Figueiredo, L.P.; Borém, F.M.; Ribeiro, F.C.; Giomo, G.S.; Malta, M.R. Coffee Cultivated in Different Environments. Coffee Sci. 2018, 13, 10. [Google Scholar] [CrossRef] [Green Version]

- Gamonal, L.E.; Vallejos-Torres, G.; López, L.A. Sensory Analysis of Four Cultivars of Coffee (Coffea arabica, L.), Grown at Different Altitudes in the San Martin Region—Peru. Ciência Rural. 2017, 47, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Gumecindo-Alejo, A.L.; Sánchez-Landero, L.A.; Ortiz-Ceballos, G.C.; Roberto Cerdán Cabrera, C.; Alvarado-Castillo, G. Factors Related to Coffee Quality, Based on the “Cup of Excellence” Contest in Mexico. Coffee Sci. 2021, 16, 1–10. [Google Scholar] [CrossRef]

- Evangelista, S.R.; Silva, C.F.; Miguel, M.G.P.D.C.; Cordeiro, C.D.S.; Pinheiro, A.C.M.; Duarte, W.F.; Schwan, R.F. Improvement of Coffee Beverage Quality by Using Selected Yeasts Strains during the Fermentation in Dry Process. Food Res. Int. 2014, 61, 183–195. [Google Scholar] [CrossRef] [Green Version]

- Wulandari, S.; Ainuri, M.; Sukartiko, A.C. Biochemical Content of Robusta Coffees under Fully-Wash, Honey, and Natural Processing Methods. IOP Conf. Ser. Earth Environ. Sci. 2021, 819, 012067. [Google Scholar] [CrossRef]

- Saloko, S.; Sulastri, Y.; Murad; Rinjani, M. The Effects of Temperature and Roasting Time on the Quality of Ground Robusta Coffee (Coffea rabusta) Using Gene Café Roaster. In Proceedings of the Bioscience, Biotechnology, and Biometrics, Lombok, Indonesia, 13–14 August 2019; AIP Publishing: Lombok, Indonesia, 2019; p. 060001. [Google Scholar]

- Folmer, B. (Ed.) The Craft and Science of Coffee; Academic Press—Elsevier: Amsterdam, The Netherlands; Boston, MA, USA, 2017; Volume 1, ISBN 978-0-12-803520-7. [Google Scholar]

- Pereira, L.; Cardoso, W.; Guarçoni, R.; da Fonseca, A.; Moreira, R.; Schwengber, C. The Consistency in the Sensory Analysis of Coffees Using Q-Graders. Eur. Food Res. Technol. 2017, 243, 1545–1554. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing. Available online: https://www.R-project.org/ (accessed on 1 October 2022).

- Wickham, H. Ggplot2: Elegant Graphics for Data Analysis, 1st ed.; Springer: New York, NY, USA, 2016; Volume 1, ISBN 978-3-319-24277-4. [Google Scholar]

- Avelino, J.; Barboza, B.; Davrieux, F.; Guyot, B. Shade Effects on Sensory and Chemical Characteristics of Coffee from Very High Altitude Plantations in Costa Rica. In Proceedings of the Conference: Second International Symposium on Multi-Strata Agroforestry Systems with Perennial Crops: Making Ecosystem Services Count for Farmers, Consumers and the Environment, Turrialba, Costa Rica, 17–21 September 2007; CATIE: Turrialba, Costa Rica, 2007. [Google Scholar]

- Silveira, A.; Pinheiro, A.; Ferreira, W.; Silva, L.; Rufino, J.; Sakiyama, N. Sensory Analysis of Specialty Coffee from Different Environmental Conditions in the Region of Matas de Minas, Minas Gerais, Brazil. Rev. Ceres 2016, 63, 436–443. [Google Scholar] [CrossRef] [Green Version]

- Tolessa, K.; D’heer, J.; Duchateau, L.; Boeckx, P. Influence of Growing Altitude, Shade and Harvest Period on Quality and Biochemical Composition of Ethiopian Specialty Coffee: Quality and Biochemical Composition of Ethiopian Specialty Coffee. J. Sci. Food Agric. 2017, 97, 2849–2857. [Google Scholar] [CrossRef] [PubMed]

- Louzada, L.; Rizzo, T. (Eds.) Quality Determinants In Coffee Production; Food Engineering Series; Springer International Publishing: Cham, Switzerland, 2021; ISBN 978-3-030-54436-2. [Google Scholar]

- Gebrekidan, M.; Redi-Abshiro, M.; Chandravanshi, B.; Ele, E.; Ahmed, M.; Mamo, H. Influence of Altitudes of Coffee Plants on the Alkaloids Contents of Green Coffee Beans. Chem. Int. 2019, 5, 247–257. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, D.; do Amaral, J.; Pereira, L.; Ferreira, J.; Guarçoni, R.; Moreira, T.; de Oliveira, A.; Rodrigues, W.; de Almeida, S.; Ribeiro, W.; et al. Physico-Chemical and Sensory Interactions of Arabica Coffee Genotypes in Different Water Regimes. J. Agric. Sci. 2021, 159, 50–58. [Google Scholar] [CrossRef]

- Sunarharum, W.B.; Williams, D.J.; Smyth, H.E. Complexity of Coffee Flavor: A Compositional and Sensory Perspective. Food Res. Int. 2014, 62, 315–325. [Google Scholar] [CrossRef]

- Velásquez, S.; Franco, A.P.; Peña, N.; Bohórquez, J.C.; Gutierrez, N. Effect of Coffee Cherry Maturity on the Performance of the Drying Process of the Bean: Sorption Isotherms and Dielectric Spectroscopy. Food Control. 2021, 123, 107692. [Google Scholar] [CrossRef]

- Joët, T.; Laffargue, A.; Descroix, F.; Doulbeau, S.; Bertrand, B.; de Kochko, A.; Dussert, S. Influence of Environmental Factors, Wet Processing and Their Interactions on the Biochemical Composition of Green Arabica Coffee Beans. Food Chem. 2010, 118, 693–701. [Google Scholar] [CrossRef]

- Banti, M.; Abraham, E. Coffee Processing Methods, Coffee Quality and Related Environmental Issues. J. Food Nutr. Sci. 2021, 9, 144. [Google Scholar] [CrossRef]

- Firdissa, E.; Mohammed, A.; Berecha, G.; Garedew, W. Coffee Drying and Processing Method Influence Quality of Arabica Coffee Varieties (Coffee arabica, L.) at Gomma I and Limmu Kossa, Southwest Ethiopia. J. Food Qual. 2022, 2022, 9184374. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, C.; Zhang, Y.; Zeng, W.; Cesarino, I. Coffee Cell Walls—Composition, Influence on Cup Quality and Opportunities for Coffee Improvements. Food Qual. Saf. 2021, 5, fyab012. [Google Scholar] [CrossRef]

- de Melo Pereira, G.V.; de Carvalho Neto, D.P.; Magalhães Júnior, A.I.; Vásquez, Z.S.; Medeiros, A.B.P.; Vandenberghe, L.P.S.; Soccol, C.R. Exploring the Impacts of Postharvest Processing on the Aroma Formation of Coffee Beans—A Review. Food Chem. 2019, 272, 441–452. [Google Scholar] [CrossRef] [PubMed]

- Selmar, D.; Bytof, G.; Knopp, S.-E.; Breitenstein, B. Germination of Coffee Seeds and Its Significance for Coffee Quality. Plant Biol. 2006, 8, 260–264. [Google Scholar] [CrossRef]

- Elhalis, H.; Cox, J.; Frank, D.; Zhao, J. The Role of Wet Fermentation in Enhancing Coffee Flavor, Aroma and Sensory Quality. Eur. Food Res. Technol. 2021, 247, 485–498. [Google Scholar] [CrossRef]

| Farm | Province | Coordinates | Altitude, m.a.m.s.l. | Precipitation a, mm | Temperature b, °C | Variety |

|---|---|---|---|---|---|---|

| F1 | Santa Elena | 2°13′36″ S 80°51′30″ W | 12 | 487 | 26 °C | Congolensis |

| F2 | Santa Elena | 2°13′36″ S 80°51′30″ W | 12 | 487 | 26 °C | Congolensis |

| F3 | Santa Elena | 2°13′36″ S 80°51′30″ W | 12 | 487 | 26 °C | Conilon |

| F4 | Guayas | 2°12′00″ S 79°58′00″ W | 40 | 4283 | 31 °C | Congolensis |

| F5 | Guayas | 2°12′00″ S 79°58′00″ W | 40 | 4283 | 31 °C | Conilon |

| F6 | Los Rios | 1°46′00″ S 79°27′00″ W | 80 | 6182 | 27 °C | Congolensis |

| F7 | Los Rios | 1°46′00″ S 79°27′00″ W | 80 | 6182 | 27 °C | Congolensis |

| F8 | Los Rios | 1°46′00″ S 79°27′00″ W | 80 | 6182 | 27 °C | Congolensis |

| F9 | Santo Domingo | 0°15′15″ S 79°10′19″ W | 625 | 4000 | 23 °C | Conilon |

| F10 | Santo Domingo | 0°15′15″ S 79°10′19″ W | 625 | 4000 | 23 °C | Congolensis |

| F11 | Santo Domingo | 0°15′15″ S 79°10′19″ W | 625 | 4000 | 23 °C | Congolensis |

| F12 | Santo Domingo | 0°15′15″ S 79°10′19″ W | 625 | 4000 | 23 °C | Conilon |

| F13 | Santo Domingo | 0°15′15″ S 79°10′19″ W | 625 | 4000 | 23 °C | Conilon |

| F14 | Santo Domingo | 0°15′15″ S 79°10′19″ W | 625 | 4000 | 23 °C | Congolensis |

| F15 | Bolivar | 1°36′ S 79°00′ W | 1700 | 4355 | 23 °C | Conilon |

| F16 | Bolivar | 1°36′ S 79°00′ W | 1700 | 4355 | 23 °C | Conilon |

| F17 | Bolivar | 1°36′ S 79°00′ W | 1700 | 4355 | 23 °C | Conilon |

| Source of Variation | Df | Frag/Aroma | Flavour | Aftertaste | Acidity | Sweetness | Body | Balance | Overall |

|---|---|---|---|---|---|---|---|---|---|

| Process | 2 | 40.19 (***) | 14.45 (***) | 25.50 (***) | 23.27 (***) | 14.34 (***) | 18.06 (***) | 2.00 (ns) | 42.90 (***) |

| Altitude | 3 | 39.37 (***) | 22.54 (***) | 21.88 (***) | 28.59 (***) | 30.93 (***) | 16.17 (***) | 15.97 (***) | 58.06 (***) |

| Process:Altitude | 6 | 6.40 (***) | 3.61 (***) | 5.37 (***) | 2.09 (.) | 14.23 (***) | 6.01 (***) | 10.54 (***) | 13.16 (***) |

| Altitude | Process | Frag/Aroma | Flavour | Aftertaste | Acidity | Sweetness | Body | Balance | Overall |

|---|---|---|---|---|---|---|---|---|---|

| 12 m | Dry | 7.53 (a) | 7.51 (a) | 7.41 (a) | 7.51 (a) | 7.52 (a) | 7.64 (a) | 7.64 (a) | 7.85 (a) |

| Honey | 7.76 (a) | 7.72 (a) | 7.56 (a) | 7.62 (a) | 7.58 (a) | 7.69 (a) | 7.70 (a) | 7.95 (a) | |

| Wet | 7.58 (a) | 7.55 (a) | 7.47 (a) | 7.59 (a) | 7.56 (a) | 7.68 (a) | 7.69 (a) | 7.89 (a) | |

| 40 m | Dry | 7.06 (b) | 7.13 (b) | 7.10 (b) | 7.13 (b) | 7.16 (c) | 7.20 (b) | 7.46 (a) | 7.53 (c) |

| Honey | 7.80 (a) | 7.70 (a) | 7.69 (a) | 7.61 (a) | 7.76 (a) | 7.72 (a) | 7.70 (a) | 8.00 (a) | |

| Wet | 7.20 (b) | 7.34 (ab) | 7.30 (b) | 7.47 (a) | 7.30 (b) | 7.50 (ab) | 7.52 (a) | 7.70 (b) | |

| 80 m | Dry | 7.34 (c) | 7.33 (c) | 7.22 (c) | 7.27 (b) | 7.28 (c) | 7.28 (c) | 7.50 (b) | 7.65 (c) |

| Honey | 7.81 (a) | 7.70 (a) | 7.69 (a) | 7.61 (a) | 7.76 (a) | 7.72 (a) | 7.70 (a) | 8.00 (a) | |

| Wet | 7.44 (b) | 7.50 (b) | 7.51 (b) | 7.52 (a) | 7.52 (b) | 7.50 (b) | 7.64 (a) | 7.83 (b) | |

| 625 m | Dry | 7.80 (a) | 7.78 (a) | 7.70 (a) | 7.67 (b) | 7.72 (b) | 7.70 (a) | 7.68 (b) | 8.04 (a) |

| Honey | 7.89 (a) | 7.85 (a) | 7.75 (a) | 7.83 (a) | 7.84 (a) | 7.75 (a) | 7.88 (a) | 8.05 (a) | |

| Wet | 7.83 (a) | 7.78 (a) | 7.70 (a) | 7.82 (ab) | 7.77 (ab) | 7.70 (a) | 7.68 (b) | 8.04 (a) |

| Source of Variation | Df | Frag/Aroma | Flavour | Aftertaste | Acidity | Sweetness | Body | Balance | Overall |

|---|---|---|---|---|---|---|---|---|---|

| Process | 2 | 61.29 (***) | 16.17 (***) | 12.27 (***) | 9.61 (***) | 16.97 (***) | 4.48 (*) | 19.80 (***) | 44.29 (***) |

| Altitude | 3 | 77.60 (***) | 35.42 (***) | 73.98 (***) | 62.36 (***) | 44.84 (***) | 12.80 (***) | 14.27 (***) | 104.63 (***) |

| Process:Altitude | 6 | 6.35 (***) | 3.64 (***) | 5.38 (***) | 4.29 (**) | 4.56 (***) | 2.55 (*) | 1.43 (ns) | 6.17 (***) |

| Altitude | Process | Frag/Aroma | Flavour | Aftertaste | Acidity | Sweetness | Body | Balance | Overall |

|---|---|---|---|---|---|---|---|---|---|

| 12 m | Dry | 7.10 (c) | 7.36 (b) | 7.58 (a) | 7.30 (b) | 7.37 (a) | 7.68 (a) | 7.56 (a) | 7.75 (b) |

| Honey | 7.81 (a) | 7.62 (a) | 7.65 (a) | 7.54 (a) | 7.62 (a) | 7.77 (a) | 7.66 (a) | 7.95 (a) | |

| Wet | 7.43 (b) | 7.60 (a) | 7.58 (a) | 7.54 (a) | 7.51 (a) | 7.70 (a) | 7.63 (a) | 7.85 (a) | |

| 40 m | Dry | 7.10 (b) | 7.13 (b) | 7.10 (b) | 7.16 (a) | 7.16 (b) | 7.30 (a) | 7.46 (a) | 7.55 (c) |

| Honey | 7.70 (a) | 7.70 (a) | 7.54 (a) | 7.47 (a) | 7.66 (a) | 7.72 (a) | 7.70 (a) | 7.93 (a) | |

| Wet | 7.23 (b) | 7.34 (ab) | 7.30 (b) | 7.49 (a) | 7.30 (b) | 7.50 (a) | 7.52 (a) | 7.71 (b) | |

| 625 m | Dry | 7.71 (b) | 7.72 (a) | 7.70 (b) | 7.72 (b) | 7.70 (b) | 7.76 (a) | 7.70 (b) | 8.01 (b) |

| Honey | 7.95 (a) | 7.85 (a) | 7.81 (a) | 7.85 (a) | 7.83 (a) | 7.81 (a) | 7.89 (a) | 8.12 (a) | |

| Wet | 7.79 (b) | 7.75 (a) | 7.72 (ab) | 7.77 (b) | 7.75 (ab) | 7.76 (a) | 7.70 (b) | 8.02 (b) | |

| 1700 m | Dry | 7.72 (b) | 7.74 (a) | 7.73 (a) | 7.68 (a) | 7.68 (a) | 7.70 (a) | 7.66 (b) | 8.01 (b) |

| Honey | 7.98 (a) | 7.85 (a) | 7.80 (a) | 7.79 (a) | 7.76 (a) | 7.77 (a) | 7.80 (a) | 8.09 (a) | |

| Wet | 7.91 (a) | 7.76 (a) | 7.73 (a) | 7.77 (a) | 7.70 (a) | 7.75 (a) | 7.72 (ab) | 8.01 (b) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Velásquez, S.; Banchón, C.; Chilán, W.; Guerrero-Casado, J. Effect of Three Post-Harvest Methods at Different Altitudes on the Organoleptic Quality of C. canephora Coffee. Beverages 2022, 8, 83. https://doi.org/10.3390/beverages8040083

Velásquez S, Banchón C, Chilán W, Guerrero-Casado J. Effect of Three Post-Harvest Methods at Different Altitudes on the Organoleptic Quality of C. canephora Coffee. Beverages. 2022; 8(4):83. https://doi.org/10.3390/beverages8040083

Chicago/Turabian StyleVelásquez, Sofía, Carlos Banchón, Willian Chilán, and José Guerrero-Casado. 2022. "Effect of Three Post-Harvest Methods at Different Altitudes on the Organoleptic Quality of C. canephora Coffee" Beverages 8, no. 4: 83. https://doi.org/10.3390/beverages8040083

APA StyleVelásquez, S., Banchón, C., Chilán, W., & Guerrero-Casado, J. (2022). Effect of Three Post-Harvest Methods at Different Altitudes on the Organoleptic Quality of C. canephora Coffee. Beverages, 8(4), 83. https://doi.org/10.3390/beverages8040083