Modelling of Malt Mixture for the Production of Wort with Increased Biological Value

Abstract

:1. Introduction

2. Materials and Methods

2.1. Malt

2.2. Mixture Design

2.3. Wort Characteristics

2.3.1. Mashing Method

2.3.2. Wort Analysis

2.4. Extraction and Determination of Phenolic Compounds

2.4.1. Extraction of Phenolic Compounds from Malt and Wort

2.4.2. Determination of Phenolic Compounds Content

Content of Total Phenolic Compounds (TPC) with Folin–Ciocalteu (FC) Reagent

Content of Phenolic Compounds by the Glories Method

2.5. Antioxidant Activity (AOA) of Wort

2.5.1. AOA against the DPPH (2,2′-Diphenyl-1-picrylhydrazyl) Radical

2.5.2. AOA by the FRAP (Ferric Reducing Ability of Plasma) Method

2.5.3. AOA by the ABTS (2,2′-Azinobis- (3-ethylbenzothiazoline-6-sulfonate)) Method

2.5.4. AOA by the CUPRAC (Cupric Reducing Antioxidant Capacity) Method

2.5.5. AOA by the ORAC (Oxygen Radical Absorbance Capacity) Method

2.6. Statistical Analysis

3. Results and Discussion

3.1. Main Brewing Characteristics

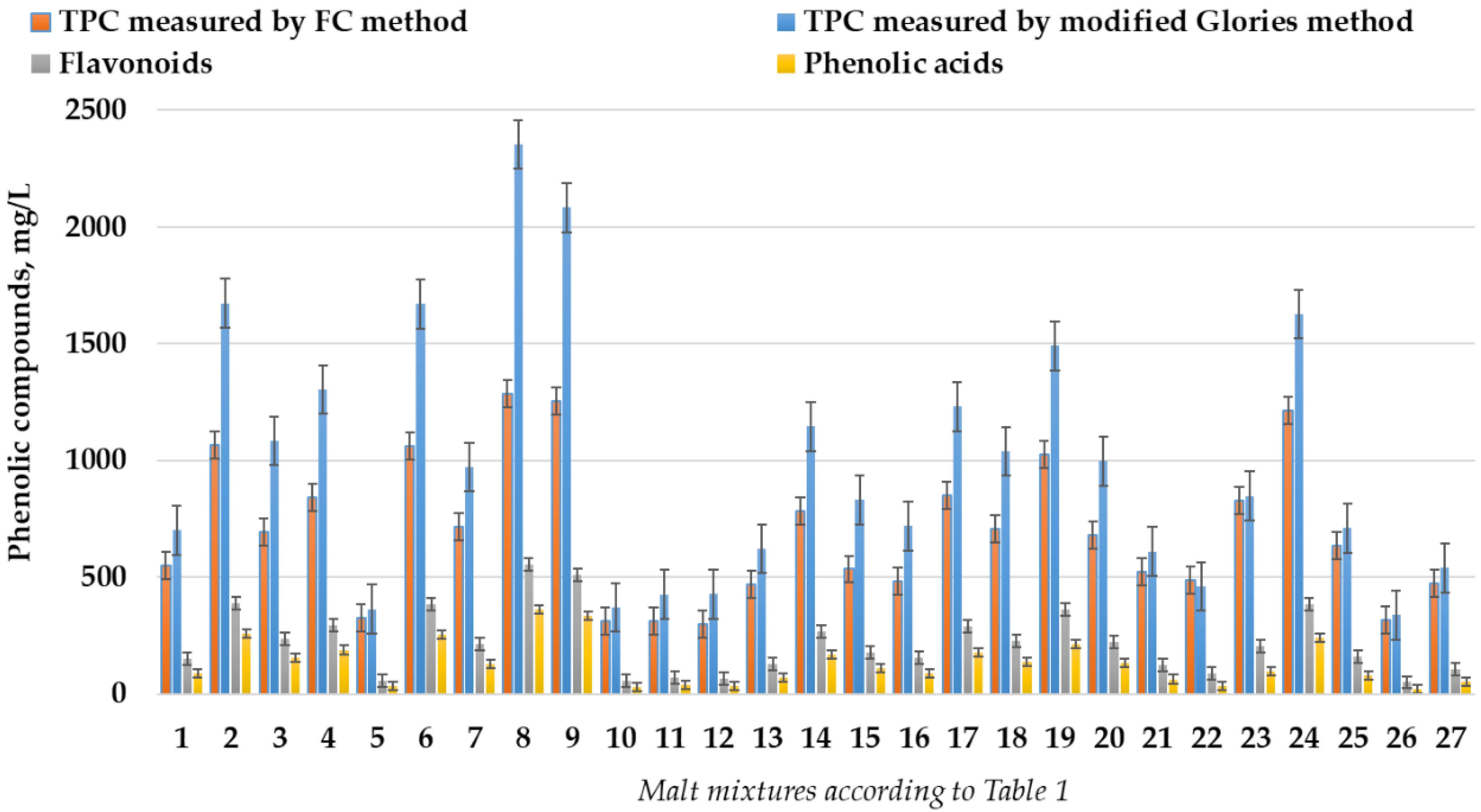

3.2. Phenolic Content and AOA of Malt Mixtures

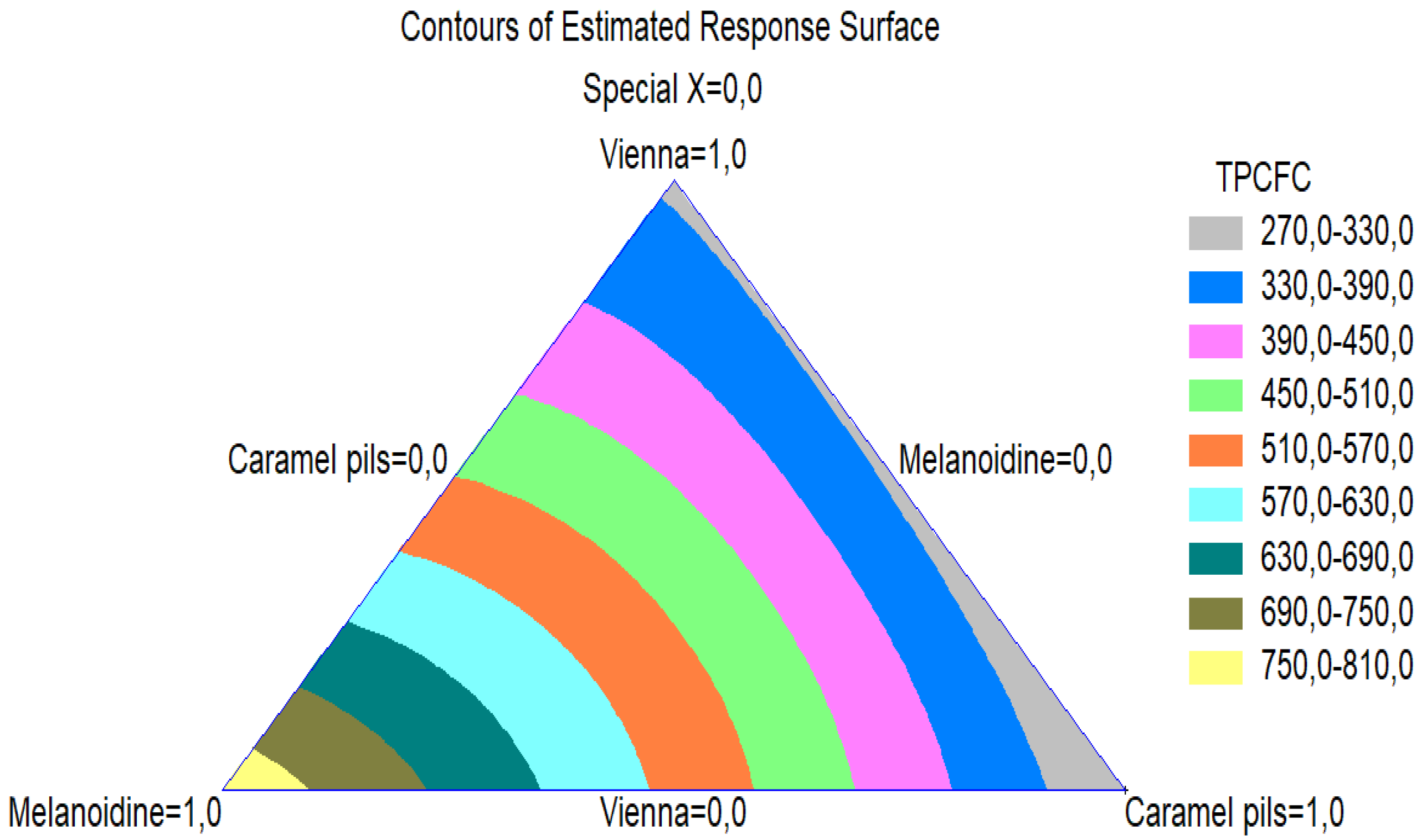

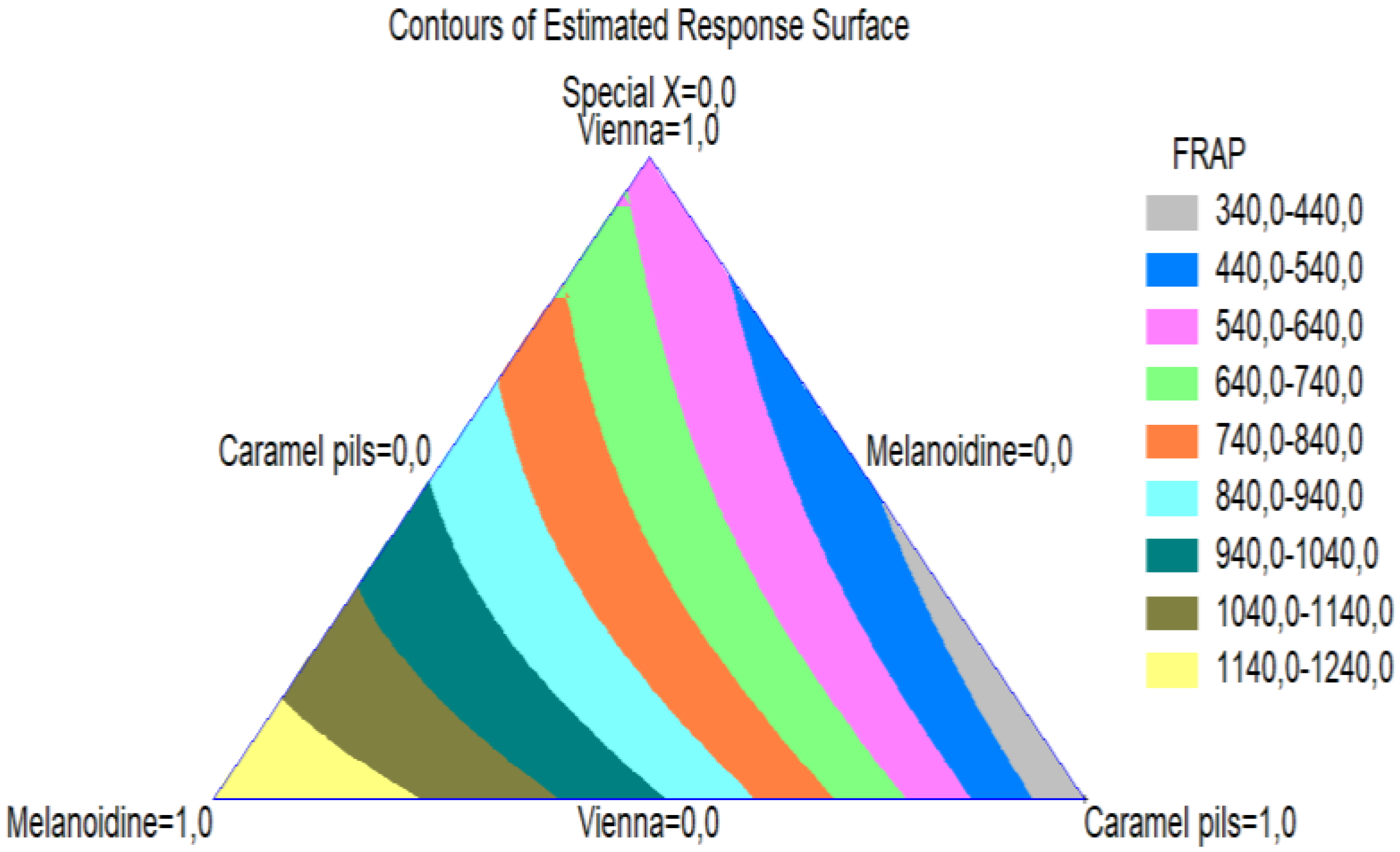

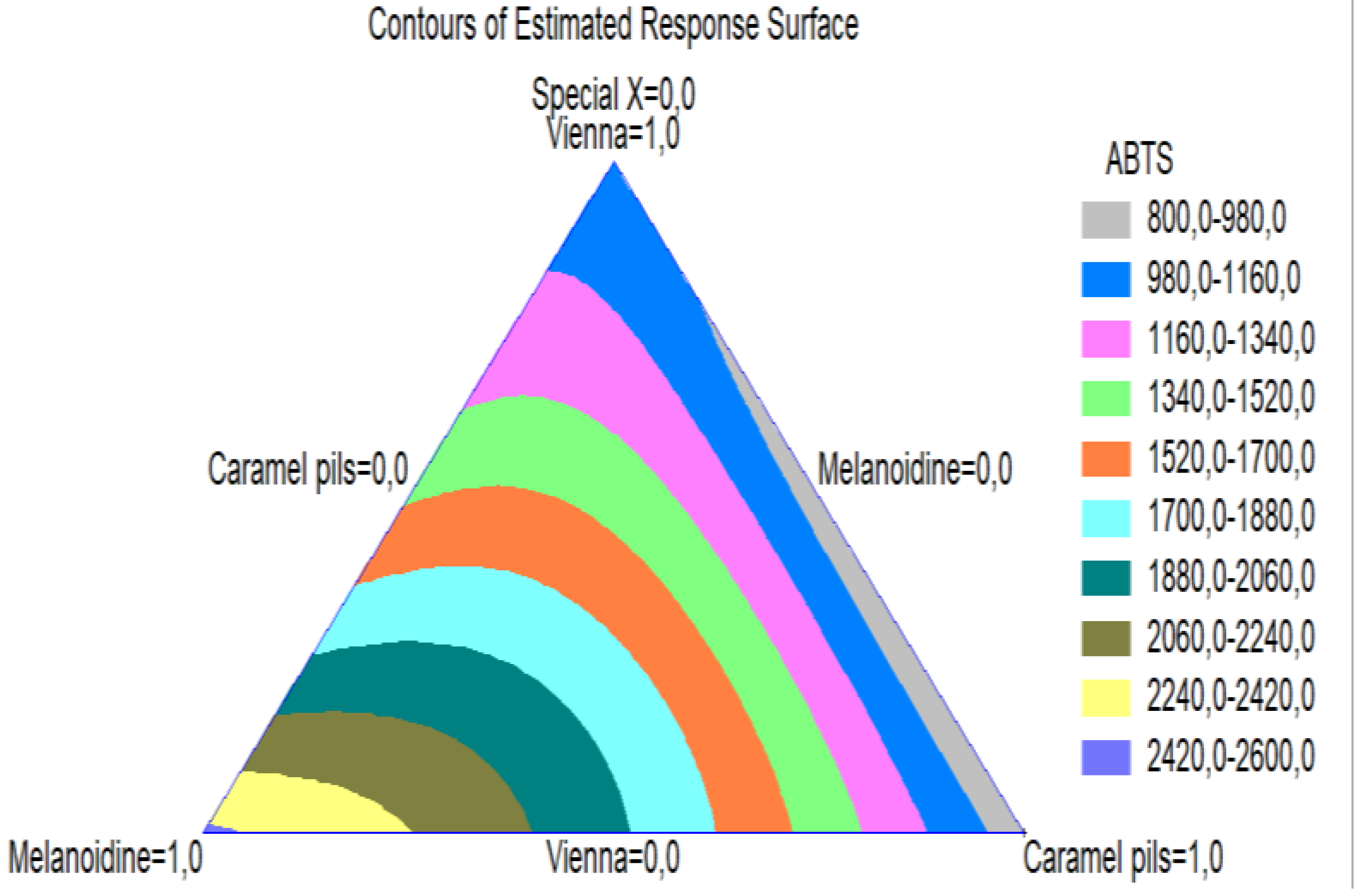

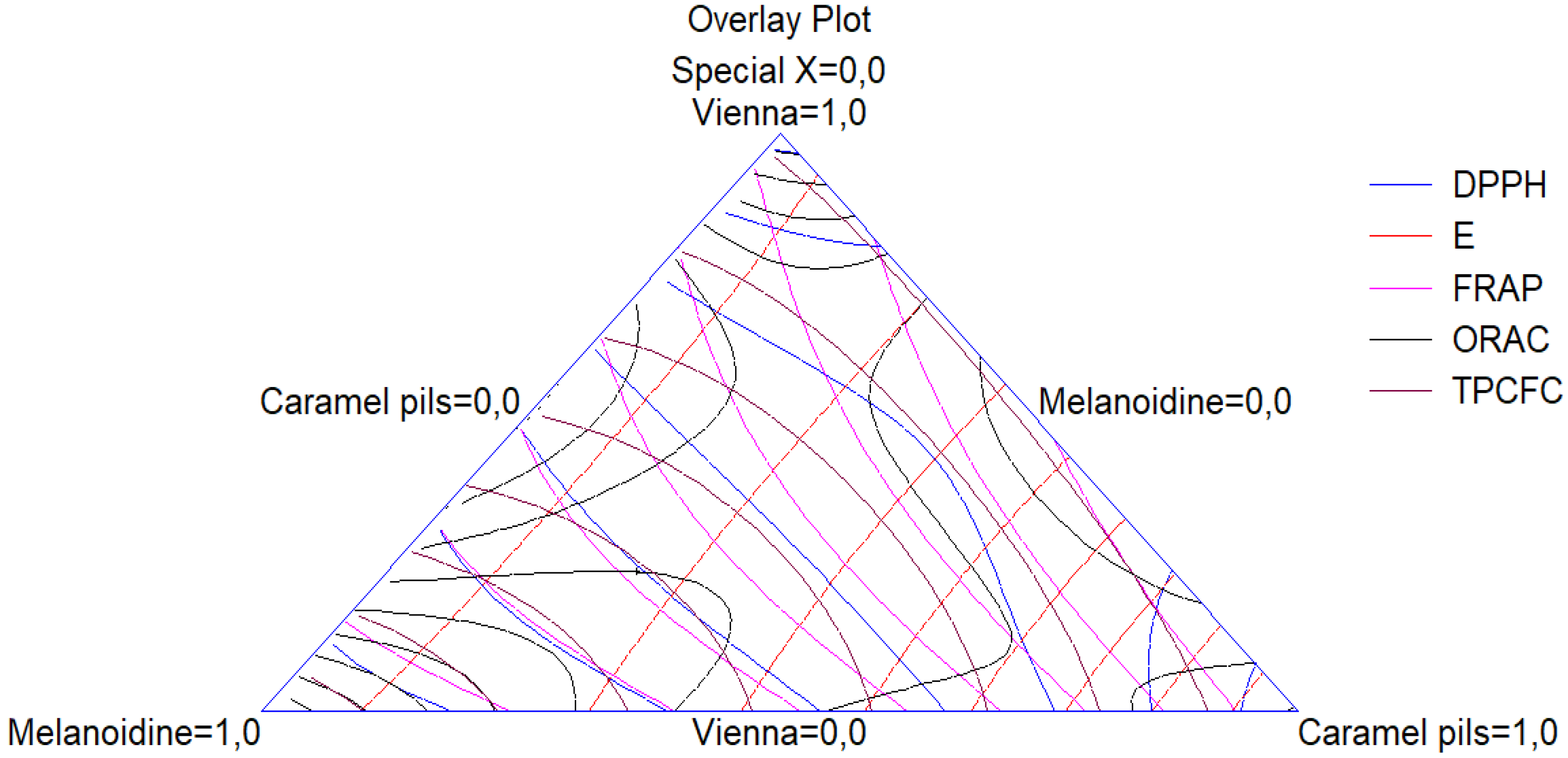

3.3. Mixture Optimization

R2 = 80.03%

R2 = 98.74%

R2 = 99.09%

R2 = 98.33%

R2 = 98.90%

R2 = 92.00%

R2 = 95.96%

R2 = 87.63%

R2 = 87.04%

R2 = 76.67%

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Martinez-Gomez, A.; Caballero, I.; Blanco, C.A. Phenols and melanoidins as natural antioxidants in beer. Structure, reactivity and antioxidant activity. Biomolecules 2020, 10, 400. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Palmer, G.H. Barley and malt. In Handbook of Brewing, 3rd ed.; Stewart, G.G., Russell, I., Anstruther, A., Eds.; CRC Press: Boca Raton, FL, USA, 2018; pp. 107–129. [Google Scholar]

- Čechovská, L.; Konečný, M.; Velíšek, J.; Cejpek, K. Effect of Maillard reaction on reducing power of malts and beers. Czech J. Food Sci. 2012, 30, 548–556. [Google Scholar] [CrossRef] [Green Version]

- Koren, D.; Kun, S.; Hegyesné Vecseri, B.; Kun-Farkas, G. Study of antioxidant activity during the malting and brewing process. J. Food Sci. Technol. 2019, 56, 3801–3809. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shopska, V.; Denkova-Kostova, R.; Dzhivoderova-Zarcheva, M.; Teneva, D.; Denev, P.; Kostov, G. Comparative study on phenolic content and antioxidant activity of different malt types. Antioxidants 2021, 10, 1124. [Google Scholar] [CrossRef] [PubMed]

- Ambra, R.; Pastore, G.; Lucchetti, S. The role of bioactive phenolic compounds on the impact of beer on health. Molecules 2021, 26, 486. [Google Scholar] [CrossRef] [PubMed]

- Nsogning Dongmo, S.; Sacher, B.; Kollmannsberger, H.; Becker, T. Key volatile aroma compounds of lactic acid fermented malt based beverages—Impact of lactic acid bacteria strains. Food Chem. 2017, 229, 565–573. [Google Scholar] [CrossRef]

- Tomova, T.; Petelkov, I.; Shopska, V.; Denkova-Kostova, R.; Kostov, G.; Denkova, Z. Production of probiotic wort-based beverages with grapefruit (Citrus paradisi L.) or tangerine (Citrus reticulata L.) zest essential oil addition. Acta Sci. Pol. Technol. Aliment. 2021, 20, 237–245. [Google Scholar] [CrossRef] [PubMed]

- Delgerzaya, P.; Shin, J.; Kim, K.; Park, J. Wort fermentation by Leuconostoc citreum originated from Kimchi and sensory properties of fermented wort. Food Sci. Biotechnol. 2009, 18, 1083–1090. [Google Scholar]

- Galvan, D.; Effting, L.; Cremasco, H.; Conte-Junior, C.A. Recent applications of mixture designs in beverages, foods, and pharmaceutical health: A systematic review and meta-analysis. Foods 2021, 10, 1941. [Google Scholar] [CrossRef] [PubMed]

- Shopska, V.; Denkova-Kostova, R.; Kostov, G. Modeling in brewing—A review. Processes 2022, 10, 267. [Google Scholar] [CrossRef]

- Myers, R.H.; Montgomery, D.C.; Anderson-Cook, C.M. Response Surface Methodology: Process and Product Optimization Using Designed Experiments, 4th ed.; John Wiley & Sons: New York, NY, USA, 2016; p. 856. [Google Scholar]

- Cornell, J.A. Experiments with Mixtures: Designs, Models, and the Analysis of Mixture Data, 3rd ed.; John Wiley & Sons: New York, NY, USA, 2020; p. 680. [Google Scholar]

- Analytica (Version 2019)—European Brewing Convention. Available online: https://brewup.eu/ebcanalytica (accessed on 20 April 2021).

- Dvoráková, M.; Guido, L.F.; Dostalek, P.; Skulilová, Z.; Moreira, M.M.; Barros, A.A. Antioxidant properties of free, soluble ester and insoluble-bound phenolic compounds in different barley varieties and corresponding malts. J. Inst. Brew. 2008, 114, 27–33. [Google Scholar] [CrossRef]

- Mazza, G.; Fukumoto, L.; Delaquis, P.; Girard, B.; Ewert, B. Anthocyanins, phenolics, and olor of Cabernet Franc, Merlot, and Pinot Noir wines from British Columbia. J. Agric. Food Chem. 1999, 47, 4009–4017. [Google Scholar] [CrossRef] [PubMed]

- Dinkova, R.; Heffels, P.; Shikov, V.; Weber, F.; Schieber, A.; Mihalev, K. Effect of enzyme-assisted extraction on the chilled storage stability of bilberry (Vaccinium myrtillus L.) anthocyanins in skin extracts and freshly pressed juices. Food Res. Int. 2014, 65, 35–41. [Google Scholar] [CrossRef]

- Benzie, I.F.F.; Strain, J.J. The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: The FRAP assay. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Iqbal, E.; Abu Salim, K.; Lim, L.B. Phytochemical screening, total phenolics and antioxidant activities of bark and leaf extracts of Goniothalamus velutinus (Airy Shaw) from Brunei Darussalam. J. King Saud Univ. Sci. 2015, 27, 224–232. [Google Scholar] [CrossRef] [Green Version]

- Apak, R.; Güçlü, K.; Özyürek, M.; Karademir, S.E.; Erçağ, E. The cupric ion reducing antioxidant capacity and polyphenolic content of some herbal teas. Int. J. Food Sci. Nutr. 2006, 57, 292–304. [Google Scholar] [CrossRef] [PubMed]

- Denev, P.; Ciz, M.; Ambrozova, G.; Lojek, A.; Yanakieva, I.; Kratchanova, M. Solid-phase extraction of berries’ anthocyanins and evaluation of their antioxidative properties. Food Chem. 2010, 123, 1055–1061. [Google Scholar] [CrossRef]

- Available online: https://bestmalz.de (accessed on 15 July 2022).

- O’Rourke, T. The role of pH in brewing. Brew. Int. 2002, 2, 21–23. [Google Scholar]

- Aron, P.M.; Shellhammer, T.H. A discussion of polyphenols in beer physical and flavour stability. J. Inst. Brew. 2010, 116, 369–380. [Google Scholar] [CrossRef]

- Amendola, D.; De Faveri, D.M.; Spigno, G. Grape marc phenolics: Extraction kinetics, quality and stability of extracts. J. Food Eng. 2010, 97, 384–392. [Google Scholar] [CrossRef]

- Dudonné, S.; Vitrac, X.; Coutiere, P.; Woillez, M.; Mérillon, J.-M. Comparative study of antioxidant properties and total phenolic content of 30 plant extracts of industrial interest using DPPH, ABTS, FRAP, SOD, and ORAC assays. J. Agric. Food Chem. 2009, 57, 1768–1774. [Google Scholar] [CrossRef] [PubMed]

| No. | Vienna (V) | Melanoidin (M) | Caramel Pils (CP) | Special X (SX) | Vienna (V) | Melanoidin (M) | Caramel Pils (CP) | Special X (SX) |

|---|---|---|---|---|---|---|---|---|

| ˗ | g | |||||||

| 1 | 0.333 | 0.667 | 0 | 0 | 16.67 | 33.33 | 0.00 | 0.00 |

| 2 | 0.125 | 0.125 | 0.125 | 0.625 | 6.25 | 6.25 | 6.25 | 31.25 |

| 3 | 0 | 0 | 0.667 | 0.333 | 0.00 | 0.00 | 33.33 | 16.67 |

| 4 | 0.333 | 0.333 | 0 | 0.333 | 16.67 | 16.67 | 0.00 | 16.67 |

| 5 | 0.333 | 0 | 0.667 | 0 | 16.67 | 0.00 | 33.33 | 0.00 |

| 6 | 0.333 | 0 | 0 | 0.667 | 16.67 | 0.00 | 0.00 | 33.33 |

| 7 | 0.125 | 0.625 | 0.125 | 0.125 | 6.25 | 31.25 | 6.25 | 6.25 |

| 8 | 0 | 0 | 0 | 1 | 0.00 | 0.00 | 0.00 | 50.00 |

| 9 | 0 | 0.333 | 0 | 0.667 | 0.00 | 16.67 | 0.00 | 33.33 |

| 10 | 0.667 | 0 | 0.333 | 0 | 33.33 | 0.00 | 16.67 | 0.00 |

| 11 | 1 | 0 | 0 | 0 | 50.00 | 0.00 | 0.00 | 0.00 |

| 12 | 0 | 0 | 1 | 0 | 0.00 | 0.00 | 50.00 | 0.00 |

| 13 | 0.667 | 0.333 | 0 | 0 | 33.33 | 16.67 | 0.00 | 0.00 |

| 14 | 0.25 | 0.25 | 0.25 | 0.25 | 12.50 | 12.50 | 12.50 | 12.50 |

| 15 | 0.625 | 0.125 | 0.125 | 0.125 | 31.25 | 6.25 | 6.25 | 6.25 |

| 16 | 0 | 0.333 | 0.667 | 0 | 0.00 | 16.67 | 33.33 | 0.00 |

| 17 | 0 | 0.333 | 0.333 | 0.333 | 0.00 | 16.67 | 16.67 | 16.67 |

| 18 | 0.333 | 0 | 0.333 | 0.333 | 16.67 | 0.00 | 16.67 | 16.67 |

| 19 | 0 | 0.667 | 0 | 0.333 | 0.00 | 33.33 | 0.00 | 16.67 |

| 20 | 0.667 | 0 | 0 | 0.333 | 33.33 | 0.00 | 0.00 | 16.67 |

| 21 | 0.125 | 0.125 | 0.625 | 0.125 | 6.25 | 6.25 | 31.25 | 6.25 |

| 22 | 0.333 | 0.333 | 0.333 | 0 | 16.67 | 16.67 | 16.67 | 0.00 |

| 23 | 0 | 1 | 0 | 0 | 0.00 | 50.00 | 0.00 | 0.00 |

| 24 | 0 | 0 | 0.333 | 0.667 | 0.00 | 0.00 | 16.67 | 33.33 |

| 25 | 0 | 0.667 | 0.333 | 0 | 0.00 | 33.33 | 16.67 | 0.00 |

| 26 | 1 | 0 | 0 | 0 | 50.00 | 0.00 | 0.00 | 0.00 |

| 27 | 0.667 | 0.333 | 0 | 0 | 33.33 | 16.67 | 0.00 | 0.00 |

| No. * | Wort Extract, °P | pH | Colour, EBC Units |

|---|---|---|---|

| 1 | 8.13 ± 0.16 | 5.19 ± 0.12 | 42.03 ± 0.43 |

| 2 | 7.64 ± 0.11 | 4.82 ± 0.09 | 205.00 ± 2.21 |

| 3 | 6.80 ± 0.13 | 5.11 ± 0.14 | 101.03 ± 1.13 |

| 4 | 7.99 ± 0.12 | 5.07 ± 0.08 | 130.63 ± 1.43 |

| 5 | 7.25 ± 0.09 | 5.59 ± 0.13 | 11.50 ± 0.21 |

| 6 | 7.86 ± 0.11 | 4.87 ± 0.08 | 206.38 ± 21.42 |

| 7 | 7.96 ± 0.10 | 5.04 ± 0.12 | 82.00 ± 7.95 |

| 8 | 3.11 ± 0.08 | 4.58 ± 0.03 | 450.00 ± 43.44 |

| 9 | 7.29 ± 0.11 | 4.86 ± 0.05 | 233.20 ± 22.23 |

| 10 | 7.77 ± 0.12 | 5.99 ± 0.09 | 11.73 ± 0.25 |

| 11 | 8.38 ± 0.17 | 5.94 ± 0.13 | 12.35 ± 0.54 |

| 12 | 6.62 ± 0.11 | 5.79 ± 0.08 | 8.38 ± 0.82 |

| 13 | 8.39 ± 0.17 | 5.81 ± 0.02 | 30.70 ± 3.13 |

| 14 | 7.75 ± 0.09 | 5.60 ± 0.04 | 97.88 ± 10.12 |

| 15 | 8.15 ± 0.14 | 5.86 ± 0.01 | 57.25 ± 6.23 |

| 16 | 7.26 ± 0.10 | 5.72 ± 0.05 | 26.90 ± 2.44 |

| 17 | 7.51 ± 0.09 | 4.95 ± 0.03 | 130.13 ± 10.34 |

| 18 | 7.71 ± 0.12 | 5.27 ± 0.05 | 116.00 ± 12.01 |

| 19 | 7.98 ± 0.12 | 5.13 ± 0.08 | 151.13 ± 16.21 |

| 20 | 7.99 ± 0.11 | 5.38 ± 0.06 | 110.13 ± 9.87 |

| 21 | 7.34 ± 0.09 | 5.51 ± 0.05 | 48.45 ± 5.98 |

| 22 | 7.83 ± 0.10 | 5.57 ± 0.06 | 28.10 ± 3.45 |

| 23 | 8.39 ± 0.12 | 5.29 ± 0.03 | 76.50 ± 6.32 |

| 24 | 8.40 ± 0.13 | 4.97 ± 0.02 | 213.75 ± 19.95 |

| 25 | 7.87 ± 0.11 | 5.39 ± 0.11 | 47.53 ± 5.33 |

| 26 | 8.18 ± 0.16 | 5.85 ± 0.07 | 14.13 ± 0.98 |

| 27 | 8.22 ± 0.11 | 5.65 ± 0.05 | 29.90 ± 3.07 |

| Target Function | Min | Max | Hit | Target |

|---|---|---|---|---|

| Variant 1 | ||||

| DPPH | – | – | ✓ | 974 |

| TPCFC | – | – | ✓ | 300 |

| FRAP | – | – | ✓ | 1882 |

| ORAC | – | ✓ | – | – |

| Variant 2 | ||||

| E | – | – | ✓ | 8 |

| DPPH | – | – | ✓ | 974 |

| FRAP | – | – | ✓ | 1500 |

| ORAC | – | – | ✓ | 10,000 |

| TPCFC | ✓ | – | – | – |

| Variant 3 | ||||

| E | – | ✓ | – | – |

| DPPH | – | ✓ | – | – |

| FRAP | – | ✓ | – | – |

| ORAC | – | ✓ | – | – |

| TPCFC | ✓ | – | – | – |

| Variant 4 | ||||

| E | – | ✓ | – | – |

| DPPH | – | ✓ | – | – |

| FRAP | – | ✓ | – | – |

| ORAC | – | ✓ | – | – |

| TPCFC | ✓ | – | – | – |

| Variant 5 | ||||

| E | – | ✓ | – | – |

| DPPH | – | ✓ | – | – |

| FRAP | – | ✓ | – | – |

| ORAC | – | ✓ | – | – |

| TPCFC | ✓ | – | – | – |

| Malt | Content | Content | Optimum Values of Target Functions(Determined Experimentally) | ||||

|---|---|---|---|---|---|---|---|

| Extract | TPCFC | DPPH | FRAP | ORAC | |||

| % | g | °P | mg/L | μM TE/L | |||

| Variant 1 | |||||||

| Vienna | 27 | 13.5 | 7.71 ± 0.09 | 943.16 ± 33 | 1005.46 ± 23 | 2335.42 ± 179 | 12,283.5 ± 147 |

| Melanoidin | 26 | 13.0 | |||||

| Caramel pils | 1 | 0.50 | |||||

| Special X | 46 | 23.0 | |||||

| Variant 2 | |||||||

| Vienna | 27 | 13.5 | 7.68 ± 0.10 | 888.06 ± 24 | 966.24 ± 18 | 2222.92 ± 151 | 12,543.0 ± 94 |

| Melanoidin | 34 | 17.0 | |||||

| Caramel pils | 1 | 0.50 | |||||

| Special X | 38 | 19.0 | |||||

| Variant 3 | |||||||

| Vienna | 31 | 15.5 | 7.66 ± 0.09 | 707.45 ± 13 | 770.13 ± 11 | 1697.92 ± 127 | 7735.5 ± 347 |

| Melanoidin | 34 | 17.0 | |||||

| Caramel pils | 10 | 5.00 | |||||

| Special X | 25 | 12.5 | |||||

| Variant 4 | |||||||

| Vienna | 22.6 | 11.3 | 7.71 ± 0.11 | 686.06 ± 12 | 770.13 ± 11 | 1731.25 ± 154 | 7611.0 ± 135 |

| Melanoidin | 31.2 | 15.6 | |||||

| Caramel pils | 21 | 10.6 | |||||

| Special X | 24.9 | 12.5 | |||||

| Variant 5 | |||||||

| Vienna | 24.2 | 12.1 | 7.80 ± 0.10 | 598.27 ± 9 | 631.35 ± 15 | 1277.08 ± 111 | 7523 ± 23 |

| Melanoidin | 51.8 | 25.9 | |||||

| Caramel pils | 20 | 10.0 | |||||

| Special X | 4 | 2.0 | |||||

| Optimum Value = 0.305878 | Response | Optimum | |||

|---|---|---|---|---|---|

| Factor | Low | High | Optimum | DPPH | 448.509 |

| Vienna | 0.2 | 1.0 | 0.241239 | E | 7.97982 |

| Melanoidine | 0.2 | 1.0 | 0.517119 | FRAP | 990.009 |

| Caramel pils | 0.2 | 1.0 | 0.2 | ORAC | 4482.95 |

| Special X | 0.0 | 0.15 | 0.0416422 | TPCFC | 617.527 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shopska, V.; Teneva, D.; Denkova-Kostova, R.; Ivanova, K.; Denev, P.; Kostov, G. Modelling of Malt Mixture for the Production of Wort with Increased Biological Value. Beverages 2022, 8, 44. https://doi.org/10.3390/beverages8030044

Shopska V, Teneva D, Denkova-Kostova R, Ivanova K, Denev P, Kostov G. Modelling of Malt Mixture for the Production of Wort with Increased Biological Value. Beverages. 2022; 8(3):44. https://doi.org/10.3390/beverages8030044

Chicago/Turabian StyleShopska, Vesela, Desislava Teneva, Rositsa Denkova-Kostova, Kristina Ivanova, Petko Denev, and Georgi Kostov. 2022. "Modelling of Malt Mixture for the Production of Wort with Increased Biological Value" Beverages 8, no. 3: 44. https://doi.org/10.3390/beverages8030044

APA StyleShopska, V., Teneva, D., Denkova-Kostova, R., Ivanova, K., Denev, P., & Kostov, G. (2022). Modelling of Malt Mixture for the Production of Wort with Increased Biological Value. Beverages, 8(3), 44. https://doi.org/10.3390/beverages8030044