Phenolic Composition and Related Properties of Aged Wine Spirits: Influence of Barrel Characteristics. A Review

Abstract

1. Introduction

- Direct extraction of wood constituents;

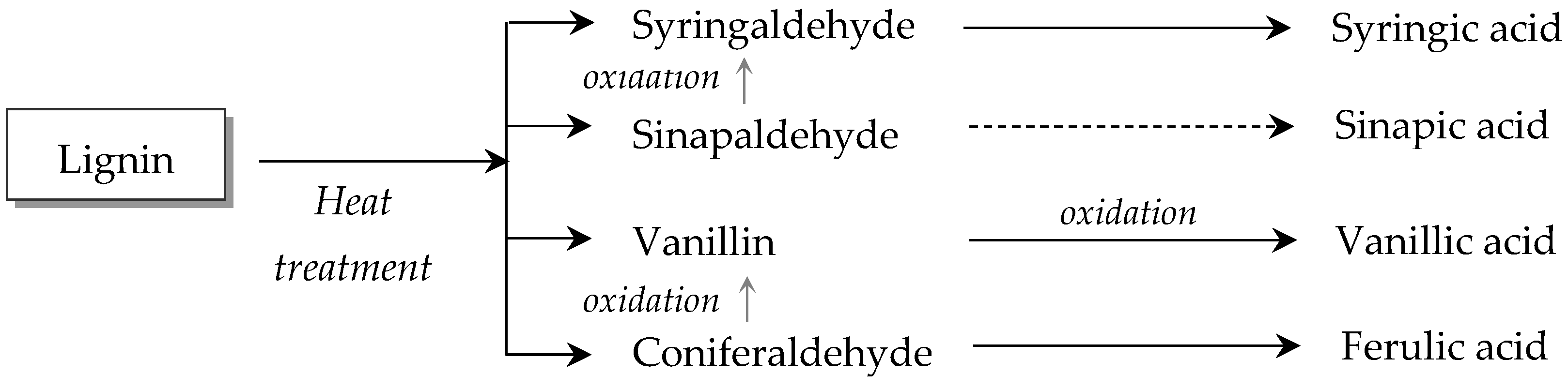

- Decomposition of wood biopolymers (lignin, hemicelluloses and cellulose) followed by the release of derived compounds into the distillate;

- Chemical reactions involving only the wood extractable compounds;

- Chemical reactions involving only the distillate compounds;

- Chemical reactions between the wood extractable compounds and the distillate compounds;

- Evaporation of volatile compounds and concentration of volatile and non-volatile compounds;

- Formation of a hydrogen-bonded network between ethanol and water.

- (i)

- The wooden barrel characteristics—the wood botanical species used, and the characteristics imparted by the cooperage technology (especially the seasoning/maturation of the wood and the heat treatment of the barrel), and the barrel size [33];

- (ii)

- (iii)

- The technological operations performed during the ageing period, such as the refilling with the same wine distillate to offset the loss by evaporation [18,20,36], the addition of water to decrease the alcoholic strength [37], and stirring to homogenize the wine spirit and to enhance the extraction of wood compounds [38].

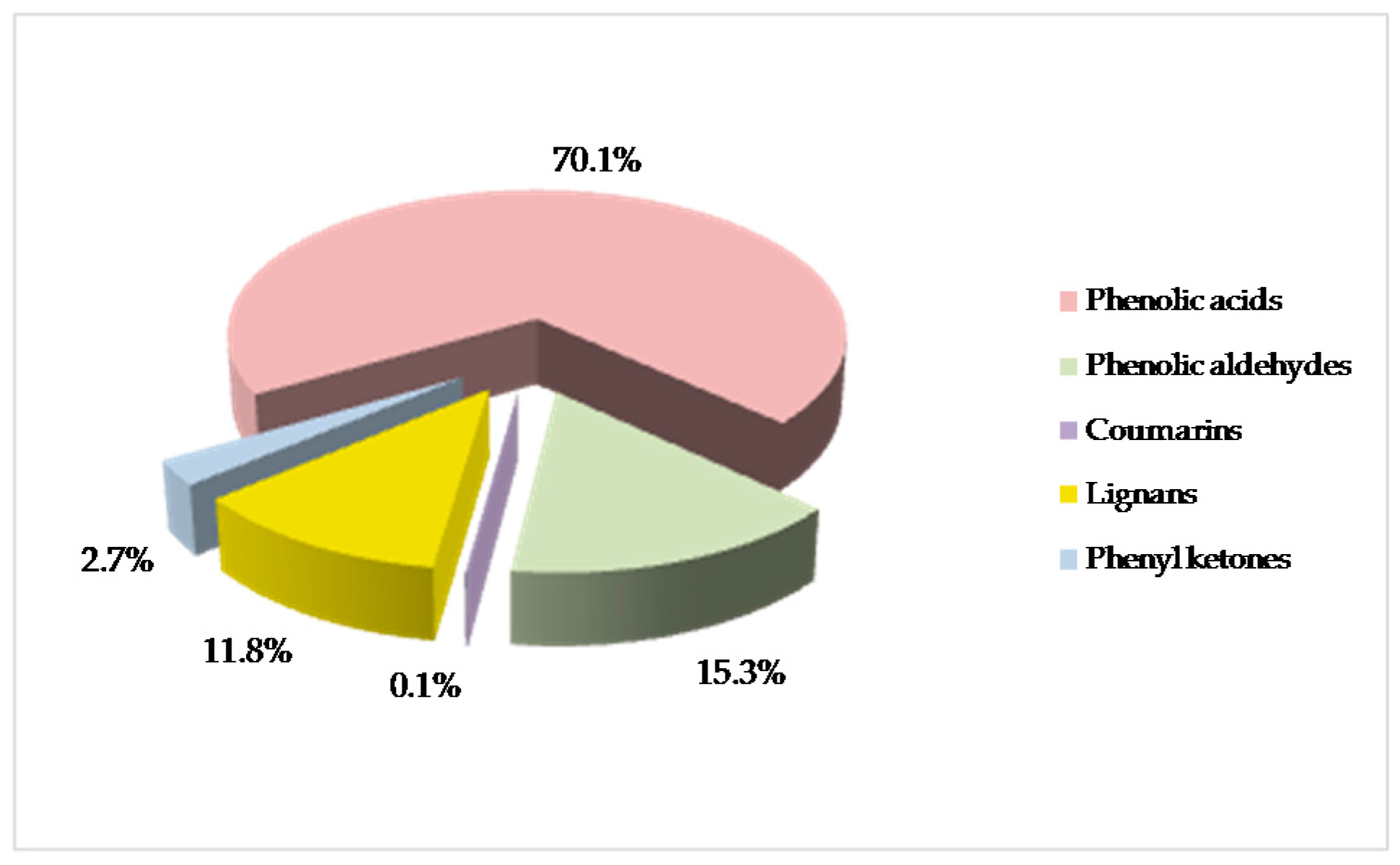

2. Phenolic Compounds Found in Aged Wine Spirits

3. Influence of the Wood Botanical Species

3.1. Phenolic Composition

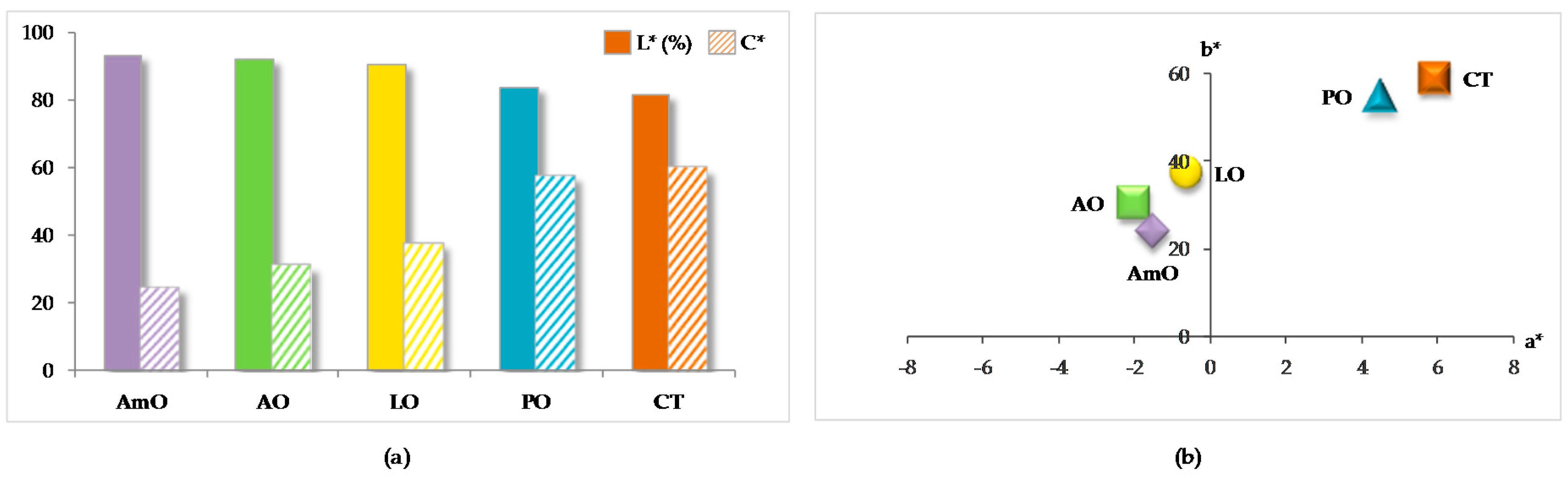

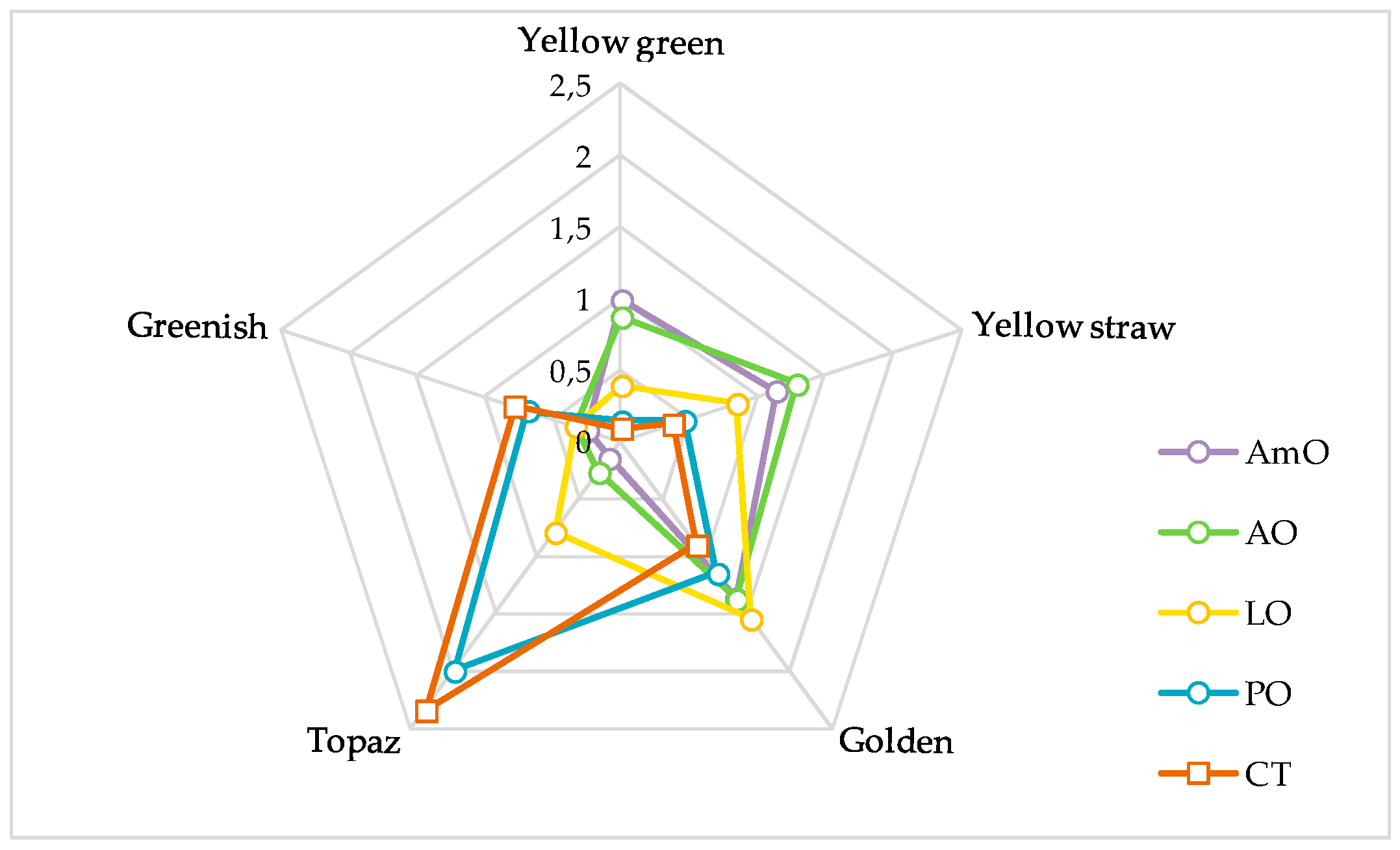

3.2. Chromatic Characteristics and Sensory Properties

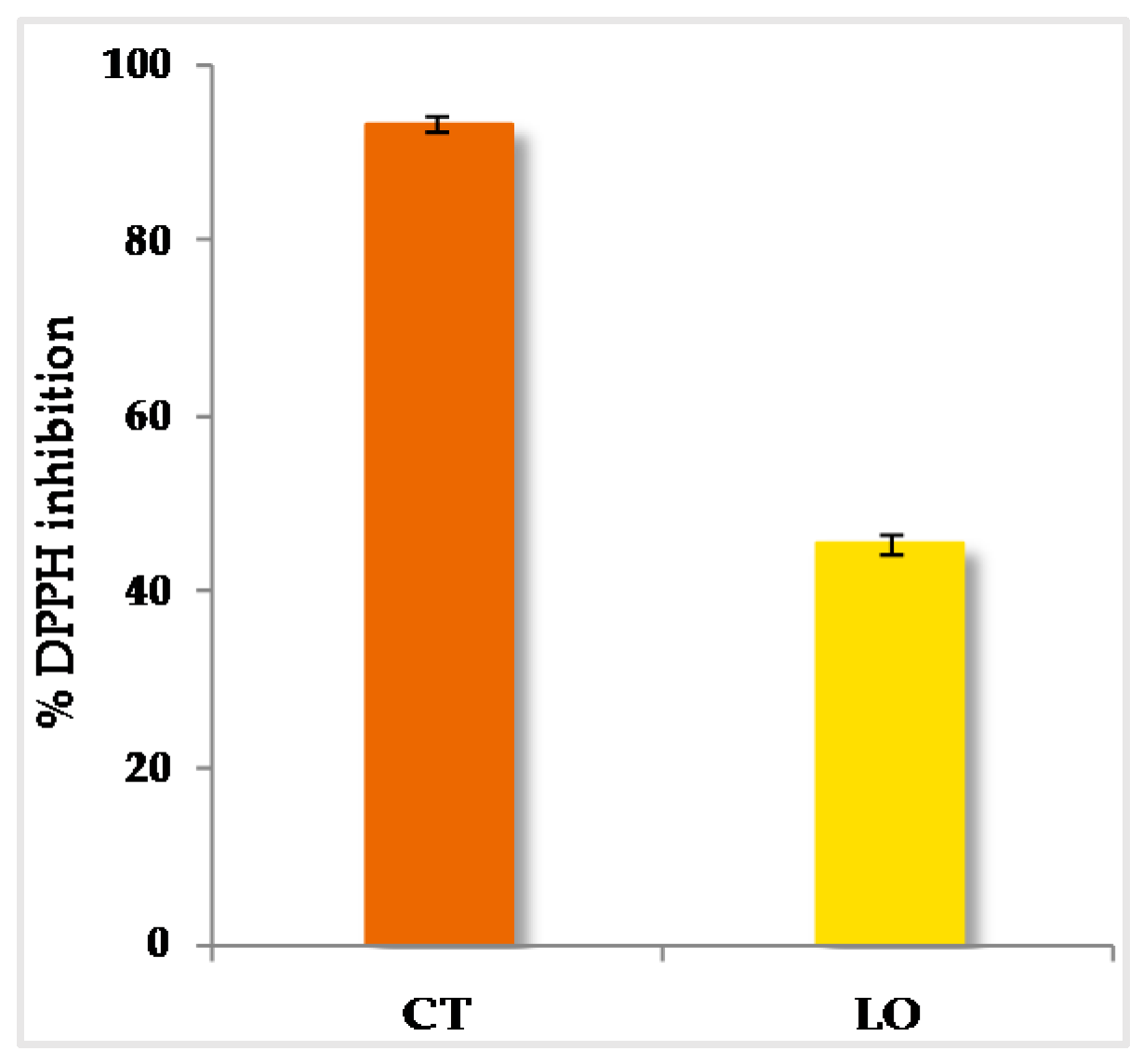

3.3. Antioxidant Activity

4. Influence of the Heat Treatment of the Barrel

4.1. Phenolic Composition

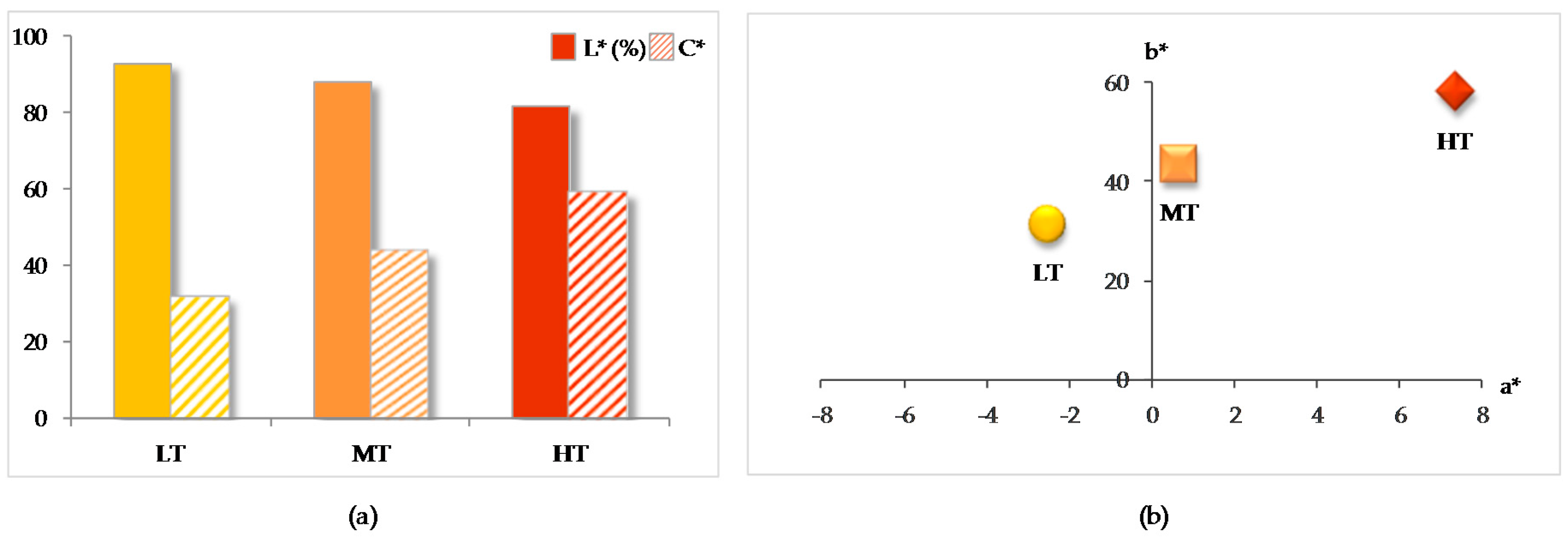

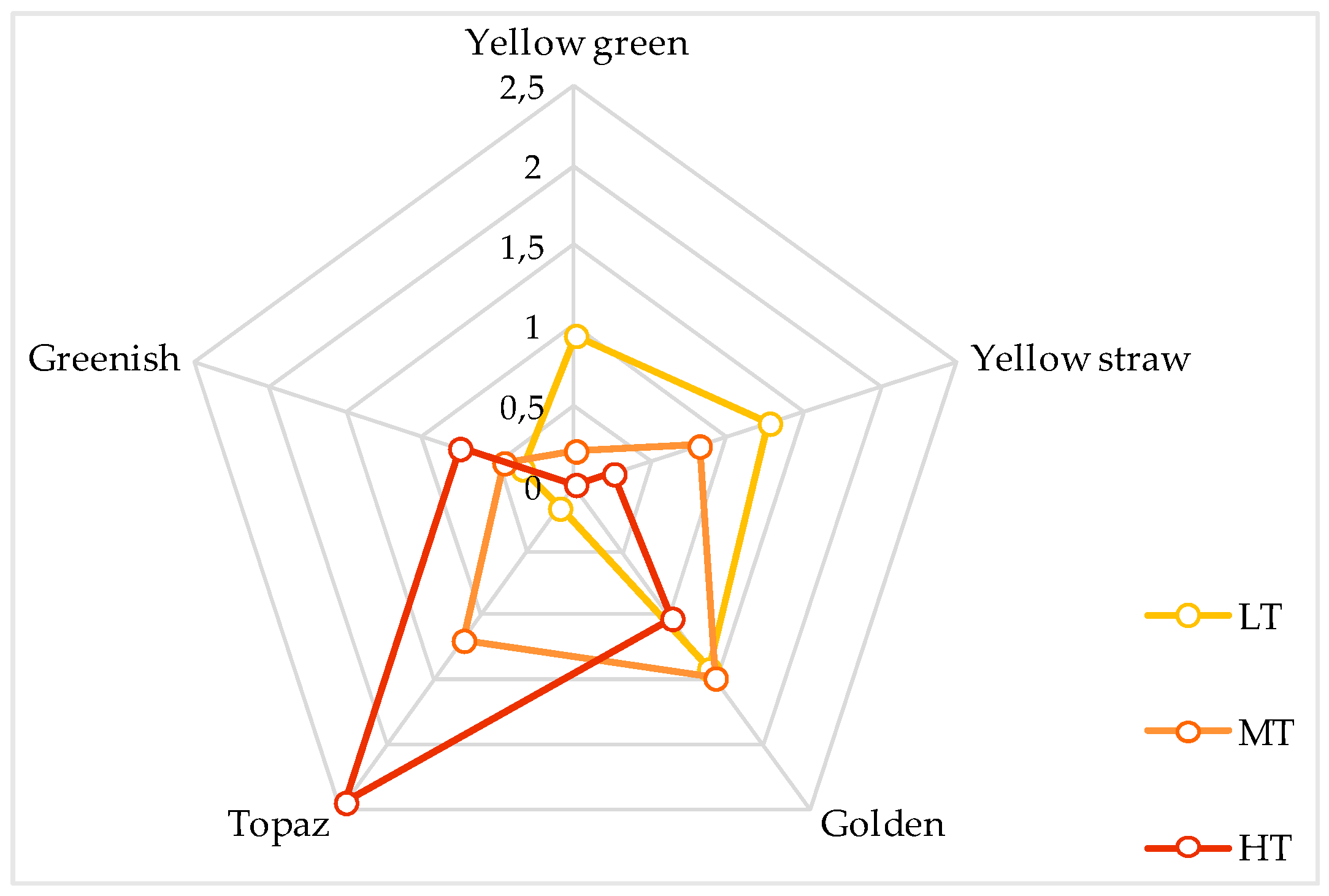

4.2. Chromatic Characteristics and Sensory Properties

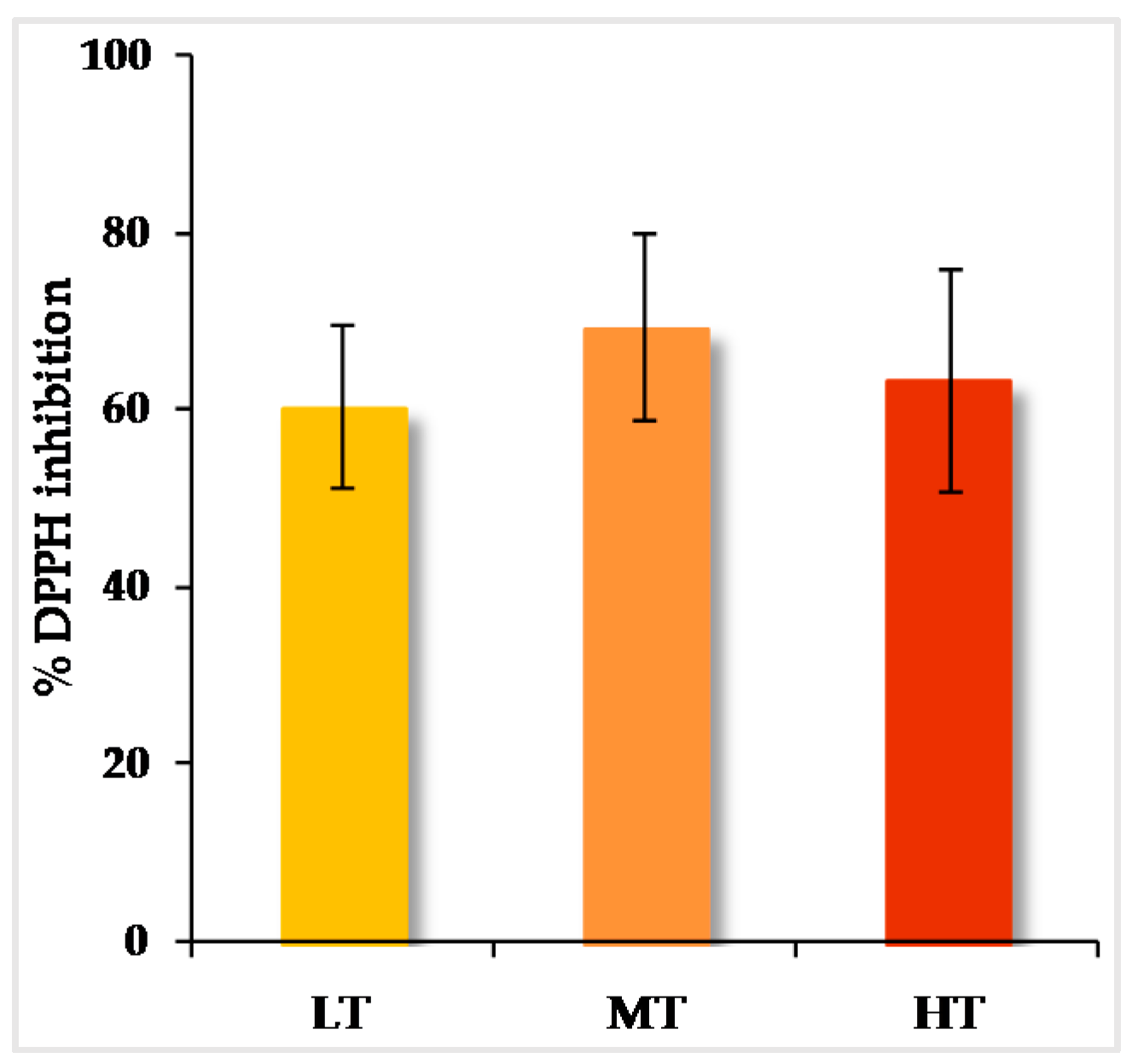

4.3. Antioxidant Activity

5. Concluding Remarks

Acknowledgments

Conflicts of Interest

References

- IBIS World Industry Report 2010. Global Spirits Manufacturing: C1122-GL. Available online: https://www.just-drinks.com/store/samples/2010_ibisworld (accessed on 27 August 2017).

- Grigg, D. Wine, Spirits and Beer: World Patterns of Consumption. Geography 2004, 89, 99–110. [Google Scholar]

- Léauté, R. Distillation in alambic. Am. J. Enol. Vitic. 1990, 41, 90–103. [Google Scholar]

- Cantagrel, R. La qualité et le renom du Cognac dans le monde, sa place dans l’histoire. In Les Eaux-De-Vie Traditionnelles D’origine Viticole; Bertrand, A., Ed.; Lavoisier—Tec & Doc: Paris, France, 2008; pp. 15–38. ISBN 978-2-7430-1040-9. [Google Scholar]

- Garreau, C. L’Armagnac. In Les Eaux-De-Vie Traditionnelles D’origine Viticole; Bertrand, A., Ed.; Lavoisier—Tec & Doc: Paris, France, 2008; pp. 39–62. ISBN 978-2-7430-1040-9. [Google Scholar]

- Belchior, A.P.; Caldeira, I.; Costa, S.; Tralhão, G.; Ferrão, A.; Mateus, A.M.; Carvalho, E. Evolução das características fisico-químicas e organolépticas de aguardentes Lourinhã ao longo de cinco anos de envelhecimento em madeiras de carvalho e de castanheiro. Ciência e Técnica Vitivinícola 2001, 16, 81–94. [Google Scholar]

- Regulation (EC) No. 110/2008. Definition, description, presentation, labelling and protection of geographical indications of spirit drinks. Off. J. Eur. Union 2008, L39, 16–54.

- Décret No. 2009-1285. Appellations d’origine contrôlée “Armagnac”, “Blanche Armagnac”, “Bas Armagnac”, “Haut Armagnac” et “Armagnac-Ténarèze”. Journal Officiel de la République Française 2009, 247, 17916–17927.

- Décret No. 2009-1146. Appellation d’origine contrôlée “Cognac” ou “Eau-de-vie de Cognac” ou “Eau-de-vie des Charentes”. Journal Officiel de la République Française 2009, 221, 15619–15628.

- Decreto-Lei No. 323/94. Estatuto da Região Demarcada das Aguardentes Vínicas da Lourinhã. Diário da República I Série A 1994, 29, 7486–7489.

- Caldeira, I.; Santos, R.; Ricardo-da-Silva, J.; Anjos, O.; Belchior, A.P.; Canas, S. Kinetics of odorant compounds in wine brandies aged in different systems. Food Chem. 2016, 211, 937–946. [Google Scholar] [CrossRef] [PubMed]

- Canas, S. Aguardentes vínicas envelhecidas. In Química Enológica—Métodos Analíticos. Avanços Recentes No Controlo da Qualidade de Vinhos e de Outros Produtos Vitivinícolas; Curvelo-Garcia, A.S., Barros, P., Eds.; Publindústria, Edições Técnicas: Porto, Portugal, 2015; Capítulo 18.2; pp. 741–771. ISBN 978-989-723-118-6. [Google Scholar]

- Baldwin, S.; Black, R.A.; Andreasen, A.A.; Adams, S.L. Aromatic congener formation in maturation of alcoholic distillates. J. Agric. Food Chem. 1967, 15, 381–385. [Google Scholar] [CrossRef]

- Nishimura, K.; Ohnishi, M.; Masahiro, M.; Kunimasa, K.; Ryuichi, M. Reactions of wood components during maturation. In Flavour of Distilled Beverages: Origin and Development; Piggott, J.R., Ed.; Ellis Horwood Limited: Chichester, UK, 1983; pp. 241–255. ISBN 0-85312-546-5. [Google Scholar]

- Puech, J.-L.; Leauté, R.; Clot, G.; Momdedeu, L.; Mondies, H. Évolution de divers constituants volatils et phénoliques des eaux-de-vie de Cognac au cours de leur vieillissement. Sci. Aliments 1984, 4, 65–80. [Google Scholar]

- Nykanen, L. Formation and occurence of flavor compounds in wine and distilled alcoholic beverages. Am. J. Enol. Vitic. 1986, 37, 84–96. [Google Scholar]

- Piggott, J.R.; Conner, J.M.; Clayne, J.; Peterson, A. The influence of non-volatile constituents on the extraction of ethyl esters from brandies. J. Sci. Food Agric. 1992, 59, 477–482. [Google Scholar] [CrossRef]

- Singleton, V.L. Maturation of wines and spirits: Comparisons, facts and hypotheses. Am. J. Enol. Vitic. 1995, 46, 98–115. [Google Scholar]

- Parke, S.A.; Birch, G.G. Solution properties of ethanol in water. Food Chem. 1999, 67, 241–246. [Google Scholar] [CrossRef]

- Canas, S.; Belchior, A.P.; Mateus, A.M.; Spranger, M.I.; Bruno de Sousa, R. Kinetics of impregnation/evaporation and release of phenolic compounds from wood to brandy in experimental model. Ciência e Técnica Vitivinícola 2002, 17, 1–14. [Google Scholar]

- Aronson, J.; Ebeler, S.E. Effect of polyphenol compounds on the headspace volatility of flavours. Am. J. Enol. Vitic. 2004, 55, 13–21. [Google Scholar]

- Puech, J.-L.; Jouret, C.; Goffinet, B. Évolution des composés phénoliques du bois de chêne au cours du vieillissement de l’Armagnac. Sci. Aliments 1985, 5, 379–392. [Google Scholar]

- Canas, S.; Belchior, A.P.; Caldeira, I.; Spranger, M.I.; Bruno de Sousa, R. La couleur et son évolution dans les eaux-de-vie Lourinhã pendant les trois premières années du vieillissement. Ciência e Técnica Vitivinícola 2000, 15, 1–14. [Google Scholar]

- Caldeira, I.; Bruno de Sousa, R.; Belchior, A.P.; Clímaco, M.C. A sensory and chemical approach to the aroma of wooden aged Lourinhã wine brandy. Ciência e Técnica Vitivinícola 2008, 23, 97–110. [Google Scholar]

- Belchior, A.P.; San-Romão, V. Influence de l’oxygène et de la lumière sur l’évolution de la composition phénolique des eaux-de-vie vieillis en bois de chêne. Bull. Liaison Groupe Polyphenols 1982, 11, 598–604. [Google Scholar]

- Avakiants, S. Régulation des processus de vieillissement des eaux-de-vie. In Élaboration et Connaissance des Spiritueux; Cantagrel, R., Ed.; Lavoisier—Tec & Doc: Paris, France, 1992; pp. 595–600. ISBN 2-87777-3574. [Google Scholar]

- Mosedale, J.R.; Puech, J.-L. Wood maturation of distilled beverages. Trends Food Sci. Technol. 1998, 9, 95–101. [Google Scholar] [CrossRef]

- Canas, S.; Caldeira, I.; Belchior, A.P. Comparison of alternative systems for the ageing of wine brandy. Oxygenation and wood shape effect. Ciência e Técnica Vitivinícola 2009, 24, 33–40. [Google Scholar]

- Cernîsev, S. Analysis of lignin-derived phenolic compounds and their transformations in aged wine distillates. Food Control 2017, 73, 281–290. [Google Scholar] [CrossRef]

- Moutounet, M.; Mazauric, J.P.; Saint-Pierre, B.; Hanocq, J.F. Gaseous exchange in wines stored in barrels. J. Sci. Tech. Tonnellerie 1998, 4, 115–129. [Google Scholar]

- Del Álamo-Sanza, M.; Nevares, I. Recent advances in the evaluation of the oxygen transfer rate in oak barrels. J. Agric. Food Chem. 2014, 62, 8892–8899. [Google Scholar] [CrossRef] [PubMed]

- Del Álamo-Sanza, M.; Nevares, I.; Mayr, T.; Baro, J.A.; Martínez-Martínez, V.; Ehgartner, J. Analysis of the role of wood anatomy on oxygen diffusivity in barrel staves using luminescent imaging. Sens. Actuators B Chem. 2016, 237, 1035–1043. [Google Scholar] [CrossRef]

- Canas, S.; Vaz, M.; Belchior, A.P. Influence de la dimension du fût dans les cinétiques d’extraction/oxydation des composés phénoliques du bois pour les eaux-de-vie Lourinhã. In Les Eaux-de-vie Traditionnelles D’origine Viticole; Bertrand, A., Ed.; Lavoisier—Tec & Doc: Paris, France, 2008; pp. 143–146. ISBN 978-2-7430-1040-9. [Google Scholar]

- Philp, J.M. Cask quality and warehouse conditions. In The Science and Technology of Whiskies; Piggott, J.R., Sharp, R., Duncan, R.E.B., Eds.; Longman Scientific & Technical: Essex, UK, 1989; pp. 264–294. ISBN 978-0582044289. [Google Scholar]

- Cantagrel, R.; Mazerolles, G.; Vidal, J.P.; Galy, B.; Boulesteix, J.M.; Lablanquie, O.; Gaschet, J. Evolution analytique et organoleptique des eaux-de-vie de Cognac au cours du vieillissement. 2a partie: Incidence de la température et de l’hygrométrie des lieux de stockage. In Élaboration et Connaissance des Spiritueux; Cantagrel, R., Ed.; Lavoisier—Tec & Doc: Paris, France, 1992; pp. 573–576. ISBN 2-87777-3574. [Google Scholar]

- Feuillat, F.; Perrin, J.R.; Keller, R. Simulation expérimentale del’interface tonneau. mesure des cinétiques d’imprégnation du liquide dans le bois et d’évaporation de surface. OENO One 1994, 28, 227–245. [Google Scholar] [CrossRef]

- Puech, J.-L.; Léauté, R.; Mosedale, J.R.; Mourgues, J. Barrique et vieillissement des eaux-de-vie. In Enologie Fondements Scientifiques et Technologiques; Flanzy, C., Ed.; Lavoisier Tec & Doc: Paris, France, 1998; pp. 1110–1142. ISBN 978-2743002435. [Google Scholar]

- Patrício, I.; Canas, S.; Belchior, A.P. Effect of brandies’ agitation on the kinetics of extraction/oxidation and diffusion of wood extractable compounds in experimental model. Ciência e Técnica Vitivinícola 2005, 20, 1–15. [Google Scholar]

- Belchior, A.P.; Carvalho, E. A cor em aguardentes vínicas envelhecidas: Método espectrofotométrico de determinação e relação com os teores em fenólicas totais. Ciência e Técnica Vitivinícola 1983, 2, 29–37. [Google Scholar]

- Escolar, D.; Haro, M.; Saucedo, A.; Gòmes, J.; Alvàrez, J.A. Evolution de quelques paramètres physico-chimiques des brandies pendant leur vieillissement. Doc. Blanc OIV 1993, 2023, 1–9. [Google Scholar]

- Bakker, J.; Bridle, P.; Timberlake, C.F. Tristimulus measurements (CIELab 76) of port wine colour. Vitis 1993, 25, 67–78. [Google Scholar]

- Negueruela, A.I.; Echávarri, J.F.; Pérez, M.M. A study of correlation between enological colorimetric indexes and CIE colorimetric parameters in red wines. Am. J. Enol. Vitic. 1995, 46, 353–356. [Google Scholar]

- Chassaing, S.; Lefeuvre, D.; Jacquet, R.; Jourdes, M.; Ducasse, L.; Galland, S.; Grelard, A.; Saucier, C.; Teissedre, P.-L.; Dangles, O.; et al. Physicochemical studies of new anthocyan-ellagitannin hybrid pigments: About the origin of the influence of oak C-glycosidic ellagitannins on wine color. Eur. J. Org. Chem. 2015, 1, 55–63. [Google Scholar]

- Gambuti, A.; Capuano, R.; Lisanti, M.T.; Strollo, D.; Mioi, L. Effect of aging in new oak, one-year-used oak, chestnut barrels and bottle on color, phenolics and gustative profile of three monovarietal red wines. Eur. Food Res. Technol. 2010, 231, 455–465. [Google Scholar] [CrossRef]

- Chinnici, F.; Natali, N.; Sonni, F.; Bellachiona, A.; Riponi, C. Comparative changes in color features and pigment composition of red wines aged in oak and cherry wood casks. J. Agric. Food Chem. 2011, 59, 6575–6582. [Google Scholar] [CrossRef] [PubMed]

- Baiano, A.; De Gianni, A.; Mentana, A.; Quinto, M.; Centonze, D.; Del Nobile, M.A. Effects of the heat treatment with oak chips on color-related phenolics, volatile composition, and sensory profile of red wines: The case of Aglianico and Montepulciano. Eur. Food Res. Technol. 2016, 242, 745–767. [Google Scholar] [CrossRef]

- Louw, L.; Oelofse, S.; Naes, T.; Lambrechts, M.; van Rensburg, P.; Nieuwoudt, H. Optimisation of the partial napping approach for the sucessful capturing of mouthfeel differentiation between brandy products. Food Qual. Preference 2015, 41, 245–253. [Google Scholar] [CrossRef]

- Michel, J.; Albertin, W.; Jourdes, M.; Le Floch, A.; Giodanengo, T.; Mourey, N.; Teissedre, P.-L. Variations in oxygen and ellagitannins, and organoleptic properties of red wine aged in French oak barrels classified by a near infrared system. Food Chem. 2016, 204, 381–390. [Google Scholar] [CrossRef] [PubMed]

- Canas, S.; Leandro, M.C.; Spranger, M.I.; Belchior, A.P. Phenolic compounds in a Lourinhã brandy extracted from different woods. In Polyphenols Communications 98, Proceedings of the XIXth International Conference on Polyphenols, Lille, France, 1–4 September 1998; Charbonnier, F., Delacotte, J.-M., Rolando, C., Eds.; Groupe Polyphénols: Bordeaux, France, 1998; Volume 1, pp. 373–374. [Google Scholar]

- Lee, K.-Y.M.; Paterson, A.; Piggott, J.R.; Richardson, G.D. Origins of flavour in whiskies and revised flavour wheel: Review. J. Inst. Brew. 2001, 107, 287–313. [Google Scholar] [CrossRef]

- Herve du Penhoat, C.L.M.; Michon, V.M.F.; Peng, S.; Viriot, C.; Scalbert, A.; Gage, D. Structural elucidation of new dimeric ellagitannins from Quercus robur L. Roburins A-E. J. Chem. Soc. Perkin Trans. 1993, I, 1653–1660. [Google Scholar] [CrossRef]

- Edelmann, A.; Lendl, B. Toward the optical tongue: Flow-through sensing of tannin-protein interactions based on FTIR spectroscopy. J. Am. Chem. Soc. 2002, 124, 14741–14747. [Google Scholar] [CrossRef] [PubMed]

- Glabasnia, A.; Hofmann, T. Sensory-directed identification of taste-active ellagitannins in American (Quercus alba L.) and European oak wood (Quercus robur L.) and quantitative analysis in bourbon whiskey and oak-matured red wines. J. Agric. Food Chem. 2006, 54, 3380–3390. [Google Scholar] [CrossRef] [PubMed]

- Hufnagel, J.C.; Hofmann, T. Orosensory-directed identification of astringent mouthfeel and bitter-tasting compounds in red wine. J. Agric. Food Chem. 2008, 56, 1376–1386. [Google Scholar] [CrossRef] [PubMed]

- Marchal, A.; Cretin, B.N.; Sindt, L.; Waffo-Téguo, P.; Dubourdieu, D. Contribution of oak lignans to wine taste: Chemical identification, sensory characterization and quantification. Tetrahedron 2015, 71, 3148–3156. [Google Scholar] [CrossRef]

- Sindt, L.; Gammacurta, M.; Waffo-Teguo, P.; Dubourdieu, D.; Marchal, A. Taste-guided isolation of bitter lignans from Quercus petraea and their identification in wine. J. Nat. Prod. 2016, 79, 2432–2438. [Google Scholar] [CrossRef] [PubMed]

- Puech, J.-L. Vieillissement Des Eaux-de-vie en Futs de Chene. Extraction et Evolution de la Lignine et de ses Produits de Degradation. Ph.D. Thesis, Université Paul Sabatier de Toulouse, Toulouse, France, 1978. [Google Scholar]

- Canas, S. Study of the Extractable Compounds of Woods (Oak and Chestnut) and the Extraction Processes in the Enological Perspective. Ph.D.Thesis, Instituto Superior de Agronomia, Universidade Técnica de Lisboa, Lisbon, Portugal, 2003. [Google Scholar]

- Caldeira, I. The Aroma of Wine Brandies Aged in Wood. Cooperage Technology Relevance. Ph.D. Thesis, Instituto Superior de Agronomia, Universidade Técnica de Lisboa, Lisbon, Portugal, 2004. [Google Scholar]

- Chen, J.H.; Ho, C.-T. Antioxidant activities of caffeic acid and its related hydroxycinnamic acid compounds. J. Agric. Food Chem. 1997, 45, 2374–2378. [Google Scholar] [CrossRef]

- Priyadarsini, K.I.; Khopde, S.M.; Kumar, S.S.; Mohan, H. Free radical studies of ellagic acid, a natural phenolic antioxidant. J. Agric. Food Chem. 2002, 50, 2200–2206. [Google Scholar] [CrossRef] [PubMed]

- Sroka, Z.; Cisowski, W. Hydrogen peroxide scavenging, antioxidant and anti-radical activity of some phenolic acids. Food Chem. Toxicol. 2003, 41, 753–758. [Google Scholar] [CrossRef]

- Ou, S.; Kwok, K.C. Ferulic acid: Pharmaceutical functions, preparation and applications in foods. J. Sci. Food Agric. 2004, 84, 1261–1269. [Google Scholar] [CrossRef]

- Soobrattee, M.A.; Neergheen, V.S.; Luximon-Ramma, A.; Arouma, O.I.; Bahorun, T. Phenolics as potential antioxidant therapeutic agents: Mechanisms and actions. Mutat. Res. 2005, 579, 200–213. [Google Scholar] [CrossRef] [PubMed]

- Bakkalbasi, E.; Mentes, O.; Artik, N. Food—Occurence, effects of processing and storage. Crit. Rev. Food Sci. Nutr. 2009, 49, 283–298. [Google Scholar] [CrossRef] [PubMed]

- Alañón, M.E.; Castro-Vázquez, L.C.; Diáz-Maroto, M.C.; Gordon, M.H.; Pérez-Coello, M.S. A study of the antioxidant capacity of oak wood used in wine ageing and the correlation with polyphenol composition. Food Chem. 2011, 128, 997–1002. [Google Scholar] [CrossRef]

- Alañón, M.E.; Castro-Vázquez, L.; Díaz-Maroto, M.C.; Hermosín-Gutiérrez, I.; Gordon, M.H. Antioxidant capacity and phenolic composition of different woods used in cooperage. Food Chem. 2011, 129, 1584–1590. [Google Scholar] [CrossRef]

- Kumar, K.N.; Raja, S.B.; Vidhya, N.; Devaraj, S.N. Ellagic acid modulates antioxidant status, ornithine decarboxylase expression, and aberrant crypt foci progression in 1,2-dimethylhydrazine-instigated colon preneoplastic lesions in rats. J. Agric. Food Chem. 2012, 60, 3665–3672. [Google Scholar] [CrossRef] [PubMed]

- Heleno, S.A.; Martins, A.; Queiroz, M.J.R.P.; Ferreira, I.C.F.R. Bioactivity of phenolic acids: Metabolites versus parent compounds: A review. Food Chem. 2015, 173, 501–513. [Google Scholar] [CrossRef] [PubMed]

- Bountagkidou, O.G.; Ordoudi, S.A.; Tsimidou, M.Z. Structure-antioxidant activity relationship of natural hydroxybenzaldehydes using in vitro assays. Food Res. Int. 2010, 43, 2014–2019. [Google Scholar] [CrossRef]

- Ibrahim, M.N.M.; Sriprasanthi, R.B.; Shamsudeen, S.; Adam, F.; Bhawani, S.A. A concise review of the natural existance, synthesis, properties, and applications of syringaldehyde. BioResources 2012, 7, 4377–4399. [Google Scholar]

- Skalicka-Wozniaka, K.; Erdogan Orhanb, I.A.; Cordellc, G.; Mohammad Nabavie, S.; Budzynska, B. Implication of coumarins towards central nervous system disorders. Pharmacol. Res. 2016, 103, 188–203. [Google Scholar] [CrossRef] [PubMed]

- Hagerman, A.E.; Riedl, K.M.; Jones, G.A.; Sovik, K.N.; Ritchard, N.T.; Hartzfeld, P.W.; Riechel, T.L. High molecular weight plant polyphenolics (tannins) as biological antioxidants. J. Agric. Food Chem. 1998, 46, 1887–1892. [Google Scholar] [CrossRef] [PubMed]

- Da Porto, C.; Calligaris, S.; Celotti, E.; Nicoli, M.C. Antiradical properties of commercial cognacs assessed by the DPPH test. J. Agric. Food Chem. 2000, 48, 4241–4245. [Google Scholar] [CrossRef] [PubMed]

- Jordão, A.M.; Correia, A.C.; DelCampo, R.; SanJosé, M.L.G. Antioxidant capacity, scavenger activity, and ellagitannins content from commercial oak pieces used in winemaking. Eur. Food Res. Technol. 2012, 235, 817–825. [Google Scholar] [CrossRef]

- Saleem, M.; Kim, J.H.; Alic, M.S.; Lee, Y.S. An update on bioactive plant lignans. Nat. Prod. Rep. 2005, 22, 696–716. [Google Scholar] [CrossRef] [PubMed]

- Marteau, C.; Nardello-Rajat, V.; Favier, V.; Aubry, J.-M. Dual role of phenols as fragances and antioxidants: Mechanism, kinetics and drastic solvent effect. Flavour Frag. J. 2013, 28, 30–38. [Google Scholar] [CrossRef]

- Goldberg, D.M.; Hoffman, B.; Yang, J.; Soleas, G.J. Phenolic constituents, furans, and total antioxidant status of distilled spirits. J. Agric. Food Chem. 1999, 47, 3978–3985. [Google Scholar] [CrossRef] [PubMed]

- Duriez, P.; Cren, C.; Luc, G.; Fruchart, J.C.; Rolando, C.; Teissier, E. Ingestion of cognac significantly increases plasma phenolic and ellagic acid concentrations and plasma antioxidant capacity in humans. In Proceedings of the 26th World Congress (81st Assembly of OIV)—Section Wine and Health, Adelaide, Australia, 11–17 October 2001; OIV: Adelaide, Australia, 2001; pp. 358–369. [Google Scholar]

- Umar, A.; Boisseau, M.; Segur, M.-C.; Begaud, B.; Moore, N. Effect of age of Armagnac extract and duration of treatment on antithrombotic effects in a rat thrombosis model. Thromb. Res. 2003, 111, 185–189. [Google Scholar] [CrossRef] [PubMed]

- Al Awwadi, N.A.; Borrot-Bouttefroy, A.; Umar, A.; Saucier, C.; Segur, M.-C.; Garreau, C.; Canal, M.; Glories, Y.; Moore, N. Effect of Armagnac fractions on human platelet aggregation in vitro and on rat arteriovenous shunt thrombosis in vivo probably not related only to polyphenols. Thromb. Res. 2007, 119, 407–412. [Google Scholar] [CrossRef] [PubMed]

- Schwarz, M.; Rodríguez, M.C.; Martínez, C.; Bosquet, V.; Guillén, D.; Barroso, C.G. Antioxidant activity of Brandy de Jerez and other distillates, and correlation with their polyphenolic content. Food Chem. 2009, 116, 29–33. [Google Scholar] [CrossRef]

- Ziyatdinova, G.; Salikhova, I.; Budnikov, H. Chronoamperometric estimation of cognac and brandy antioxidant capacity using MWNT modified glassy carbon electrode. Talanta 2014, 125, 378–384. [Google Scholar] [CrossRef] [PubMed]

- Muresan, B.; Cimpoiu, C.; Hosu, A.; Bischin, C.; Gal, E.; Damian, G.; Fischer-Fodor, E.; Silaghi-Dumitrescu, R. Antioxidant content in Romanian traditional distilled alcoholic beverages. Studia Ubb Chemia 2015, 60, 355–370. [Google Scholar]

- Garrido, J.; Borges, F. Wine and grape polyphenols—A chemical perspective. Food Res. Int. 2013, 54, 1844–1858. [Google Scholar] [CrossRef]

- Botelho, G.; Canas, S.; Lameiras, J. Development of phenolic compounds encapsulation techniques as a major challenge for food industry and for health and nutrition fields. In Nanotechnology in Agri-Food Industry; Grumezescu, A.M., Ed.; Elsevier: London, UK, 2017; Chapter 14; Volume 5, pp. 535–586. ISBN 978-0-12-804304-2. [Google Scholar]

- Deibner, L.; Jouret, C.; Puech, J.-L. Substances phénoliques des eaux-de-vie d’Armagnac. I. La lignin d’extraction et les produits de sa dégradation. Ind. Aliment. Agricoles 1976, 93, 401–414. [Google Scholar]

- Puech, J.-L.; Jouret, C.; Deibner, L.; Alibert, G. Substances phénoliques des eaux-de-vie d’Armagnac et de rhum. II. Produits de la degradation de la lignin: Les aldéhydes et les acides aromatiques. Ind. Aliment. Agricoles 1977, 94, 483–493. [Google Scholar]

- Puech, J.-L. Extraction and evolution of lignin products in Armagnac matured in oak. Am. J. Enol. Vitic. 1981, 32, 111–114. [Google Scholar]

- Puech, J.-L.; Jouret, C. Dosage des aldéhydes aromatiques des eaux-de-vie conservées en fûts de chêne: Détection d’adultération. Ann. Falsif. Exp. Chim. 1982, 805, 81–90. [Google Scholar]

- Belchior, A.P.; Puech, J.-L.; Carvalho, E.; Mondies, H. Caractéristiques de la composition phénolique du bois de chêne portugais et de quelques eaux-de-vie de vin. Ciência e Técnica Vitivinícola 1984, 2, 57–65. [Google Scholar]

- Nabeta, K.; Yonekubo, J.; Miyake, M. Phenolic compounds from the heartwood of European oak (Quercus robur L.) and brandy. Mokuzai Gakkaishi 1987, 33, 408–415. [Google Scholar]

- Salagoity-Auguste, M.H.; Tricard, C.; Sudraud, P. Dosage simultané des aldéhydes aromatiques et des coumarines par chromatographie liquide haute performance. J. Chromatogr. 1987, 392, 379–387. [Google Scholar] [CrossRef]

- Tricard, C.; Salagoity, M.H.; Sudraud, P. La scopolétine: Un marqueur de la conservation en fûts de chêne. OENO One 1987, 21, 33–41. [Google Scholar] [CrossRef]

- Puech, J.-L.; Moutounet, M. Liquid chromatographic determination of scopoletin in hydroalcoholic extract of oak wood and in matured distilled alcoholic beverages. J. Assoc. Off. Anal. Chem. 1988, 71, 512–514. [Google Scholar] [PubMed]

- Artajona, J.; Barbero, E.; Llobet, M.; Marco, J.; Parente, F. Influence du “bousinage” de la barrique sur les qualités organoleptiques des brandies vieillies en fûts de chêne. In Les Eaux-de-Vie Traditionnelles D’origine Viticole; Bertrand, A., Ed.; Lavoisier—Tec & Doc: Paris, France, 1991; pp. 197–205. ISBN 2-85206-765-X. [Google Scholar]

- Rabier, P.; Moutounet, M. Evolution d’extractibles de bois de chêne dans une eau-de-vie de vin. Incidence du thermotraitement des barriques. In Les Eaux-de-vie Traditionnelles D’origine Viticole; Bertrand, A., Ed.; Lavoisier—Tec & Doc: Paris, France, 1991; pp. 220–230. ISBN 2-85206-765-X. [Google Scholar]

- Calvo, A.; Caumeil, M.; Pineau, J. Extraction des polyphénols et des aldéhydes aromatiques pendant le vieillissement du cognac, en fonction du titre alcoolique et du degré d’épuisement des fûts. In Élaboration et Connaissance des Spiritueux; Cantagrel, R., Ed.; Lavoisier—Tec & Doc: Paris, France, 1992; pp. 562–566. ISBN 2-87777-3574. [Google Scholar]

- Puech, J.-L.; Moutounet, M. Phenolic compounds in an ethanol-water extract of oak wood and in brandy. Food Sci. Technol. 1992, 25, 350–352. [Google Scholar]

- Puech, J.-L.; Maga, J. Influence du brûlage du fût sur la composition des substances volatiles et non volatiles d’une eau-de-vie. Rev. Oenol. 1993, 70, 13–16. [Google Scholar]

- Viriot, C.; Scalbert, A.; Lapierre, C.; Moutounet, M. Ellagitannins and lignins in aging of spirits in oak barrels. J. Agric. Food Chem. 1993, 41, 1872–1879. [Google Scholar] [CrossRef]

- Canas, S.; Leandro, M.C.; Spranger, M.I.; Belchior, A.P. Low molecular weight organic compounds of chestnut wood (Castanea sativa L.) and corresponding aged brandies. J. Agric. Food Chem. 1999, 47, 5023–5030. [Google Scholar] [CrossRef] [PubMed]

- Panosyan, A.G.; Mamikonyan, G.V.; Torosyan, M.; Gabrielyan, E.S.; Mkhitaryan, S.A.; Tirakyan, M.R.; Ovanesyan, A. Determination of the composition of volatiles in Cognac (brandy) by headspace gas chromatography—Mass spectrometry. J. Anal. Chem. 2001, 56, 1078–1085. [Google Scholar] [CrossRef]

- Savchuk, S.A.; Vlasov, V.N.; Appolonova, S.S.; Arbuzov, V.N.; Vedenin, A.N.; Mezinov, A.B.; Grigor’yan, B.R. Application of chromatography and spectrometry to the authentication of alcoholic beverages. J. Anal. Chem. 2001, 56, 214–231. [Google Scholar] [CrossRef]

- Canas, S.; Belchior, A.P.; Spranger, M.I. Bruno de Sousa R.High-performance liquid chromatography method for analysis of phenolic acids, phenolic aldehydes and furanic derivatives in brandies. Development and validation. J. Sep. Sci. 2003, 26, 496–502. [Google Scholar] [CrossRef]

- Canas, S.; Silva, V.; Belchior, A.P. Wood related chemical markers of aged wine brandies. Ciência e Técnica Vitivinícola 2008, 23, 45–52. [Google Scholar]

- Cretin, B.N.; Dubourdieu, D.; Marchal, A. Development of a quantitation method to assay both lyoniresinol enatiomers in wines, spirits, and oak wood by liquid chromatography-high resolution mass spectrometry. Anal. Bioanal. Chem. 2016, 408, 3789–3799. [Google Scholar] [CrossRef] [PubMed]

- Canas, S.; Leandro, M.C.; Spranger, M.I.; Belchior, A.P. Influence of botanical species and geographical origin on the content of low molecular weight phenolic compounds of woods used in Portuguese cooperage. Holzforschung 2000, 54, 255–261. [Google Scholar] [CrossRef]

- Canas, S.; Grazina, N.; Spranger, M.I.; Belchior, A.P. Modelisation of heat treatment of Portuguese oak wood (Quercus pyrenaica Willd.). Analysis of the behaviour of low molecular weight phenolic compounds. Ciência e Técnica Vitivinícola 2000, 15, 75–94. [Google Scholar]

- Canas, S.; Belchior, A.P.; Falcão, A.; Gonçalves, J.A.; Spranger, M.I.; Bruno de Sousa, R. Effect of heat treatment on the thermal and chemical modifications of oak and chestnut wood used in brandy ageing. Ciência e Técnica Vitivinícola 2007, 22, 5–14. [Google Scholar]

- Alañón, M.E.; Rubio, H.; Díaz-Maroto, M.C.; Pérez-Coello, M.S. Monosaccharide anhydrides, new markers of toasted oak wood used for ageing wines and distillates. Food Chem. 2010, 119, 505–512. [Google Scholar] [CrossRef]

- Sanz, M.; Cadahía, E.; Esteruelas, E.; Muñoz, A.M.; Fernández de Simón, B.; Hernández, T.; Estrella, I. Phenolic compounds in chestnut (Castanea sativa Mill.) heartwood. Effect of toasting at cooperage. J. Agric. Food Chem. 2010, 58, 9631–9640. [Google Scholar] [CrossRef] [PubMed]

- Le Floch, A.; Jourdes, M.; Teissedre, P.-L. Polysaccharides and lignin from oak wood used in cooperage: Composition, interest, assays: A review. Carbohydr. Res. 2015, 417, 94–102. [Google Scholar] [CrossRef] [PubMed]

- Hale, M.D.; McCafferty, K.; Larmie, E.; Newton, J.; Swan, J.S. The influence of oak seasoning and toasting parameters on the composition and quality of wine. Am. J. Enol. Vitic. 1999, 50, 495–502. [Google Scholar]

- Acuña, L.; Gonzalez, D.; de la Fuente, J.; Moya, L. Influence of toasting treatment on permeability of six wood species for enological use. Holzforschung 2014, 68, 447–454. [Google Scholar] [CrossRef]

- Puech, J.-L. Characteristics of oak wood and biochemical aspects of Armagnac aging. Am. J. Enol. Vitic. 1984, 35, 77–81. [Google Scholar]

- Sarni, F.; Moutounet, M.; Puech, J.-L.; Rabier, P. Effect of heat treatment of oak wood extractable compounds. Holzforschung 1990, 44, 461–466. [Google Scholar] [CrossRef]

- Chatonnet, P. Influence des Procédés de Tonnellerie et des Conditions D’élevage sur la Composition et la Qualité des Vins Elevés en Fûts de Chêne. Ph.D. Thesis, Institut d’Oenologie, Université de Bordeaux II, Bordeaux, France, 1995. [Google Scholar]

- Cretin, B.N.; Sallembien, Q.; Sindt, L.; Daugey, N.; Buffeteau, T.; Waffo-Teguo, P.; Dubourdieu, D.; Marchal, A. How stereochemistry influences the taste of wine: Isolation, characterization and sensory evaluation of lyoniresinol stereoisomers. Anal. Chim. Acta 2015, 888, 191–198. [Google Scholar] [CrossRef] [PubMed]

- Caldeira, I.; Clímaco, M.C.; Bruno de Sousa, R.; Belchior, A.P. Volatile composition of oak and chestnut woods used in brandy ageing: Modification induced by heat treatment. J. Food Eng. 2006, 76, 202–211. [Google Scholar] [CrossRef]

- Chatonnet, P.; Boidron, J.N.; Pons, M. Incidence du traitement thermique du bois de chêne sur sa composition chimique. 2e partie: Évolution de certains composés en fonction de l’intensité de brûlage. Définition des paramètres thermiques de la chauffe des fûts en tonnellerie. OENO One 1989, 4, 223–250. [Google Scholar] [CrossRef]

- Canas, S.; Casanova, V.; Belchior, A.P. Antioxidant activity and phenolic content of Portuguese wine aged brandies. J. Food Compos. Anal. 2008, 21, 626–633. [Google Scholar] [CrossRef]

- Canas, S.; Spranger, M.I.; Belchior, A.P.; Bruno-de-Sousa, R. Isolation and identification by LC-ESI-MS of hydrolyzable tannins from Quercus pyrenaica Willd and Castanea sativa Mill heartwoods. In Proceedings of the 228th ACS National Meeting, Abstracts of the 4th Tannin Conference, Philadelphia, PA, USA, 22–26 August 2004; Gatenholm, P., Ed.; American Chemical Society: Philadelphia, PA, USA, 2004. [Google Scholar]

- Fernández de Simón, B.F.; Sanz, M.; Cadahía, E.; Poveda, P.; Broto, M. Chemical characterization of oak heartwood from Spain forests of Quercus pyrenaica (Willd.) Ellagitannins, low molecular weight phenolic, and volatile compounds. J. Agric. Food Chem. 2006, 54, 8314–8321. [Google Scholar] [CrossRef] [PubMed]

- Prida, A.; Boulet, J.-C.; Ducousso, A.; Nepveu, G.; Puech, J.-L. Effect of species and ecological conditions on ellagitannins content in oak wood from na even-aged and mixed stand of Quercus robur L. and Quercus petraea Liebl. Ann. For. Sci. 2006, 63, 415–424. [Google Scholar] [CrossRef]

- Jordão, A.M.; Ricardo da Silva, J.M.; Laureano, O. Ellagitannins from Portuguese oak wood (Quercus pyrenaica Willd.) used in cooperage: Influence of geographical origin, coarseness of the grain and toasting level. Holzforschung 2007, 61, 155–160. [Google Scholar] [CrossRef]

- Mammela, P.; Savolainen, H.; Lindroos, L.; Kangas, J.; Vartiainen, T. Analysis of oak tannins by liquid chromatography-electrospray ionisation mass spectrometry. J. Chromatogr. A 2001, 891, 75–83. [Google Scholar] [CrossRef]

- Garcia, R.; Soares, B.; Dias, C.B.; Freitas, A.M.C.; Cabrita, M.J. Phenolic and furanic compounds of Portuguese chestnut and French, American and Portuguese oak wood chips. Eur. Food Res. Technol. 2012, 235, 457–467. [Google Scholar] [CrossRef]

- Matricardi, L.; Waterhouse, A. Influence of toasting technique on color and ellagitannins of oak wood in barrel making. Am. J. Enol. Vitic. 1999, 50, 519–526. [Google Scholar]

- Doussot, F.; De Jeso, B.; Quideau, S.; Pardon, P. Extractives content in cooperage oak wood during natural seasoning and toasting; influence of tree species, geographic location, and single-tree effects. J. Agric. Food Chem. 2002, 50, 5955–5961. [Google Scholar] [CrossRef] [PubMed]

- Chira, K.; Teissedre, P.-L. Relation between volatile composition, ellagitannin content and sensory perception of oak wood chips representing different toasting processes. Eur. Food Res. Technol. 2013, 236, 735–746. [Google Scholar] [CrossRef]

- García-Estévez, I.; Alcalde-Eon, C.; Le Grottaglie, L.; Rivas-Gonzalo, J.C.; Escribano-Bailón, M.T. Understanding the ellagitannin extraction process from oak wood. Tetrahedron 2015, 71, 3089–3094. [Google Scholar] [CrossRef]

- Jourdes, M.; Michel, J.; Saucier, C.; Quideau, S.; Teissedre, P.-L. Identification, amounts, and kinetics of extraction of C-glucosidic ellagitannins during wine aging in oak barrels or in stainless steel tanks with oak chips. Anal. Bioanal. Chem. 2011, 401, 1531–1539. [Google Scholar] [CrossRef] [PubMed]

- Lurton, L.; Ferrari, G.; Snakkers, G. Cognac: Production and aromatic characteristics. In Alcoholic beverages. Sensory Evaluation and Consumer Research; Piggott, J., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2012; pp. 242–266. ISBN 978-0-85709-051-5. [Google Scholar]

- Snakkers, G.; Nepveu, G.; Guilley, E.; Cantagrel, R. Variabilités géographique, sylvicole et individuelle de la teneur en extractibles de chênes sessiles français (Quercus petraea Liebl.): Polyphénols, octalactones et phénols volatils. Ann. For. Sci. 2000, 57, 251–260. [Google Scholar] [CrossRef]

- Marchal, A.; Prida, A.; Dubourdieu, D. New approach for differentiating sessile and pedunculate oak: Development of a LC-HRMS method to quantitate triterpenoids in wood. J. Agric. Food Chem. 2016, 64, 618–628. [Google Scholar] [CrossRef] [PubMed]

- Cadahía, E.; Munoz, L.; Simón, B.F.; Garcia-Vallejo, M.C. Changes in low molecular weight phenolic compounds in Spanish, French, and American oak woods during natural seasoning and toasting. J. Agric. Food Chem. 2001, 49, 1790–1798. [Google Scholar] [CrossRef] [PubMed]

- Canas, S.; Caldeira, I.; Belchior, A.P.; Spranger, M.I.; Clímaco, M.C.; Bruno de Sousa, R. Chestnut wood: A sustainable alternative for the aging of wine brandies. In Food Quality: Control, Analysis and Consumer Concerns; Medina, D.A., Laine, A.M., Eds.; Nova Science Publishers Inc.: New York, NY, USA, 2011; pp. 181–228. ISBN 978-1-61122-917-2. [Google Scholar]

- Canas, S.; Caldeira, I.; Mateus, A.M.; Belchior, A.P.; Clímaco, M.C.; Bruno de Sousa, R. Effect of natural seasoning on the chemical composition of chestnut wood used for barrel making. Ciência e Técnica Vitivinícola 2006, 21, 1–16. [Google Scholar]

- De Rosso, M.; Cancian, D.; Panighel, A.; Vedova, A.D.; Flamini, R. Chemical compounds release from five different woods used to make barrels for aging wines and spirits. Volatile compounds and polyphénols. Wood Sci. Technol. 2009, 43, 375–385. [Google Scholar] [CrossRef]

- Castellari, M.; Piermattei, B.; Arfelli, G.; Amati, A. Influence of aging conditions on the quality of red sangiovese wine. J. Agric. Food Chem. 2001, 49, 3672–3676. [Google Scholar] [CrossRef] [PubMed]

- Alañón, M.E.; Schumacher, R.; Castro-Vásquez, L.; Díaz-Maroto, M.C.; Hermosín-Gutiérrez, I.; Pérez-Coello, M.S. Enological potential of chestnut wood for aging Tempranillo wines. Part II: Phenolic compounds and chromatic characteristics. Food Res. Int. 2013, 51, 536–543. [Google Scholar] [CrossRef]

- Rodríguez Madrera, R.; Suárez Valles, B.; Diñeiro García, Y.; del Valle Arguelles, P.; Picinelli Lobo, A. Alternative woods for aging distillates—An insight into their phenolic profiles and antioxidant activities. Food Sci. Biotechnol. 2010, 19, 1129–1134. [Google Scholar] [CrossRef]

- Canas, S.; Quaresma, H.; Belchior, A.P.; Spranger, M.I.; Bruno de Sousa, R. Evaluation of wine brandies authenticity by the relationships between benzoic and cinnamic aldehydes and between furanic aldehydes. Ciência e Técnica Vitivinícola 2004, 19, 13–27. [Google Scholar]

- Doussot, F.; Pardon, P.; Dedier, J.; De Jeso, B. Individual, species and geographic origin influence on cooperage oak extractible content (Quercus robur L. and Quercus petraea Liebl.). Analusis 2000, 28, 960–965. [Google Scholar] [CrossRef]

- Quaglieri, C.; Jourdes, M.; Waffo-Teguo, P.; Teissedre, P.-L. Updated knowledge about pyranoanthocyanins: Impact of oxygen on their contents, and contribution in the winemaking process to overall wine color. Trends Food Sci. Technol. 2017, 67, 139–149. [Google Scholar] [CrossRef]

- Christensen, C.M. Effects of colour on aroma, flavour and texture judgements of foods. J. Food Sci. 1983, 48, 787–790. [Google Scholar] [CrossRef]

- Schwarz, M.; Rodríguez, M.C.; Guillén, D.A.; Barroso, C.G. Analytical charactisation of a Brandy de Jerez during its ageing. Eur. Food Res. Technol. 2011, 232, 813–819. [Google Scholar] [CrossRef]

- Rodríguez-Solana, R.; Salgado, J.M.; Domínguez, J.M.; Cortés-Diéguez, S. First approach to the analytical characterization of barrel-aged grape marc distillates using phenolic compounds and colour parameters. Food Technol. Biotechnol. 2014, 52, 391–402. [Google Scholar] [CrossRef] [PubMed]

- Es-Safi, N.; Cheynier, V.; Moutounet, M. Study of the reactions between (+)-catechin and furfural derivatives in the presence or absence of anthocyanins and their implication in food color change. J. Agric. Food Chem. 2002, 48, 5946–5954. [Google Scholar] [CrossRef]

- Es-Safi, N.; Cheynier, V.; Moutounet, M. Role of aldehydes in the condensation of phenolic compounds with emphasis on food organoleptic properties. J. Agric. Food Chem. 2002, 50, 5571–5585. [Google Scholar] [CrossRef] [PubMed]

- Sousa, C.; Mateus, N.; Perez-Alonso, J.; Santos-Buelga, C.; De Freitas, V. Preliminary study of oaklins, a new class of brick-red catechinpyrylium pigments resulting from the reaction between catechin and wood aldehydes. J. Agric. Food Chem. 2005, 53, 9249–9256. [Google Scholar] [CrossRef] [PubMed]

- Caldeira, I.; Mateus, A.M.; Belchior, A.P. Flavour and odour profile modifications during the first five years of Lourinhã brandy maturation on different wooden barrels. Anal. Chim. Acta 2006, 563, 264–273. [Google Scholar] [CrossRef]

- Renaud, S.; De Lorgeril, M. Wine, alcohol, platelets and The French Paradox for coronary heart disease. Lancet 1992, 339, 1523–1526. [Google Scholar] [CrossRef]

- Tunstall-Pedoe, H.; Kuulasmaa, K.; Mahonen, M.; Tolonen, H.; Ruokokoski, E.; Amouyed, P. Contribution of trends in survival and coronary-event rates to changes in coronary heart disease mortality: 10-year results from 37 WHO MONICA project populations. Monitoring trends and determinants in cardiovascular disease. Lancet 1999, 353, 1547–1557. [Google Scholar] [CrossRef]

- Alonso, A.M.; Castro, R.; Rodriguez, M.C.; Guillen, D.A.; Barroso, C.G. Study of the antioxidant power of brandies and vinegars derived from Sherry wines and correlation with their content in polyphenols. Food Res. Int. 2004, 37, 715–721. [Google Scholar] [CrossRef]

- Pecic, S.; Veljovic, M.; Despotovic, S.; Leskosek-Cukalovic, I.; Jadranin, M.; Tesevic, V.; Niksic, M.; Nikicevic, N. Effect of maturation conditions on sensory and antioxidant properties of old Serbian plum brandies. Eur. Food Res.Technol. 2012, 235, 479–487. [Google Scholar] [CrossRef]

- Psarra, E.; Makris, D.P.; Kallithraka, S.; Kefalas, P. Evaluation of the antiradical and reducing properties of selected Greek white wines: Correlation with polyphenolic composition. J. Sci. Food Agric. 2002, 82, 1014–1020. [Google Scholar] [CrossRef]

- Ávila-Reyes, J.; Almarz-Abarca, N.; Delgado-Alvarado, E.A.; González-Valdez, L.; Del Toro, G.V.; Páramo, E.D. Phenol profile and antioxidant capacity of mescal aged in oak wood barrels. Food Res. Int. 2010, 43, 296–300. [Google Scholar] [CrossRef]

- Yeh, C.-T.; Yen, G.-C. Modulation of hepatic phase II phenol sulfotransferase and antioxidant status by phenolic acids in rats. J. Nutr. Biochem. 2006, 17, 561–569. [Google Scholar] [CrossRef] [PubMed]

- Chatonnet, P.; Boindron, J.N. Incidence du traitement thermique du bois de chêne sur sa composition chimique. 1ere partie: Définition des paramètres thermiques de la chauffe des fûts en tonnellerie. OENO One 1989, 23, 77–87. [Google Scholar] [CrossRef]

- Sanz, M.; Fernández de Simón, B.; Cadahía, E.; Esteruelas, E.; Muñoz, A.M.; Hernández, M.T.; Estrella, I. Polyphenolic profile as a useful tool to identify the wood used in wine aging. Anal. Chim. Acta 2012, 732, 33–45. [Google Scholar] [CrossRef] [PubMed]

- Duval, C.J.; Sok, N.; Laroche, J.; Gourrat, K.; Prida, A.; Lequin, S.; Chassagne, D.; Gougeon, R.D. Dry vs soaked wood: Modulating the volatile extractible fraction of oak wood by heat treatments. Food Chem. 2013, 138, 270–277. [Google Scholar] [CrossRef] [PubMed]

- Cantagrel, R.; Mazerolles, G.; Vidal, J.P.; Galy, B. Evolution analytique et organoleptique des eaux-de-vie de cognac au cours du vieillissement. 1ère partie: Incidence des techniques de tonnelleries. In Élaboration et Connaissance des Spiritueux; Cantagrel, R., Ed.; Lavoisier—Tec & Doc: Paris, France, 1992; pp. 567–572. ISBN 2-87777-3574. [Google Scholar]

- Puech, J.-L.; Lepoutre, J.-P.; Baumes, R.; Bayonove, C.; Moutounet, M. Influence du thermotraitement des barriques sur l’évolution de quelques composants issus du bois de chêne dans les eaux-de-vie. In Élaboration et Connaissance des Spiritueux; Cantagrel, R., Ed.; Lavoisier—Tec & Doc: Paris, France, 1992; pp. 583–594. ISBN 2-87777-3574. [Google Scholar]

- Sanz, M.; Cadahia, E.; Esteruelas, E.; Muñoz, A.M.; Fernández de Simon, B.; Hernández, T.; Estrella, I. Effect of toasting intensity at cooperage on phenolic compounds in acacia (Robinia pseudoacacia) heartwood. J. Agric. Food Chem. 2011, 59, 3135–3145. [Google Scholar] [CrossRef] [PubMed]

- Chira, K.; Teissedre, P.-L. Chemical and sensory evaluation of wine matured in oak barrel: Effect of oak species involved and toasting process. Eur. Food Res. Technol. 2015, 240, 533–547. [Google Scholar] [CrossRef]

- Híc, P.; Soural, I.; Balík, J.; kulichová, J.; Vrchotová, N.; Tríska, J. Antioxidant capacities of extracts in relation to toasting oak and acacia wood. J. Food Nutr. Res. 2017, 56, 129–137. [Google Scholar]

| Class | Compound | Concentration Range * | References | Wine Spirits ** |

|---|---|---|---|---|

| Phenolic aldehydes | Sinapaldehyde | 0.05–42.31 | [13,15,29,38,74,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105] | a,b,c,d,e,j,l |

| Syringaldehyde | 0.20–34.20 | [13,15,17,29,38,74,87,88,89,90,91,92,93,94,98,99,100,101,102,103,104,105] | a,b,c,d,e,j,l | |

| Vanillin | 0.10–18.40 | [13,15,17,29,38,87,88,89,90,91,92,93,94,97,98,99,100,101,102,103,104,105] | a,b,c,d,e,j,k,l | |

| Coniferaldehyde | 0.05–12.94 | [13,15,29,38,74,87,88,89,91,92,93,98,99,100,102,103,105] | a,b,c,d,e,j,l | |

| Phenolic acids | Gallic acid | 1.00–168.67 | [15,17,38,74,96,97,99,101,102,105] | a,c,f,k,l |

| Ellagic acid | 3.90–104.00 | [38,74,97,99,101,102,105] | a,c,k,l | |

| Syringic acid | 0.40–17.18 | [15,17,29,38,74,88,89,99,100,101,102,105] | a,b,c,d,l | |

| Vanillic acid | 0.20–10.95 | [15,17,29,38,74,88,89,99,100,101,102,105] | a,b,c,d,l | |

| Ferulic acid | 0.05–9.94 | [15,88,89,102,105] | a,b,c | |

| Protocatechuic acid | 0.12–2.27 | [15] | a | |

| Coumaric acid | 0.02–1.20 | [15,88] | a,b | |

| Coumarins | Scopoletin | 6.00–301.10 | [38,74,93,94,95,99,102] | a,b,c,e,f,g,h,i,l |

| Umbelliferone | 0.11–7.00 | [38,93,102] | a,b,c | |

| Lignans | Lyoniresinol | 3.40–17.50 | [92,99,106] | c,j,l |

| Phenyl ketones | Acetovanillone | 0.51–6.21 | [107] | a |

| Class | Compound | Concentration Range |

|---|---|---|

| Ellagitannins | Castalagin | 2.81–20.75 |

| Vescalagin | 0.03–0.24 | |

| Roburin E | 0.08–0.19 | |

| Grandinin | 0.06–0.16 | |

| Gallotannins | Monogalloyl-glucose | 0.47–5.95 |

| Compound | American oak | Allier Oak | Limousin Oak | Portuguese Oak | Chestnut |

|---|---|---|---|---|---|

| Ellagic acid | 32.45 a | 37.19 a | 49.38 b | 81.16 c | 91.27 d |

| Gallic acid | 10.49 a | 13.46 a | 11.52 a | 37.80 b | 218.19 c |

| Vanillic acid | 2.97 b | 2.04 a | 2.62 a,b | 2.96 b | 6.15 c |

| Syringic acid | 3.56 a | 3.58 a,b | 4.09 a,b,c | 5.03 c | 19.77 d |

| Ferulic acid | 2.97 a | 2.85 a | 3.03 a | 6.06 b | 6.39 c |

| Vanillin | 6.21 a,b | 5.50 a | 6.33 b | 6.41 b | 8.28 c |

| Syringaldehyde | 15.06 b | 11.73 a | 15.02 b | 14.94 b | 15.89 b |

| Coniferaldehyde | 9.04 | 8.27 | 9.12 | 8.75 | 7.78 |

| Sinapaldehyde | 16.71 b | 14.63 a,b | 16.76 b | 19.65 c | 11.94 a |

| Umbelliferone | 1.48 c | 0.78 a | 0.95 b | 0.98 b | 0.92 b |

| Scopoletin | 164.77 d | 19.74 b | 37.12 c | 10.33 a | 8.63 a |

| ΣLMW | 122.68 a | 127.68 a | 144.03 a | 224.0 b | 395.93 c |

| Compound | Limousin Oak | Chestnut |

|---|---|---|

| Castalagin | 12.07 | 6.33 |

| Vescalagin | 0.11 | 0.17 |

| Roburin E | 0.14 | 0.12 |

| Grandinin | 0.12 | 0.14 |

| Monogalloyl-glucose | nd | 5.16 |

| Compound | Light Toasting | Medium Toasting | Heavy Tosating |

|---|---|---|---|

| Ellagic acid | 38.85 a | 57.69 b | 87.36 c |

| Gallic acid | 42.27 a | 55.44 b | 54.22 b |

| Vanillic acid | 2.05 a | 3.20 b | 4.48 c |

| Syringic acid | 5.08 a | 6.00 b | 8.64 c |

| Ferulic acid | 4.30 a | 4.49 a | 5.00 b |

| Vanillin | 2.94 a | 6.43 b | 10.07 c |

| Syringaldehyde | 4.31 a | 13.00 b | 26.28 c |

| Coniferaldehyde | 3.25 a | 8.64 b | 13.55 c |

| Sinapaldehyde | 3.99 a | 14.49 b | 30.60 c |

| Umbelliferone | 0.47 a | 0.92 b | 1.64 c |

| Scopoletin | 37.36 | 39.42 | 36.58 |

| ΣLMW | 117.82 a | 197.10 b | 295.08 c |

© 2017 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Canas, S. Phenolic Composition and Related Properties of Aged Wine Spirits: Influence of Barrel Characteristics. A Review. Beverages 2017, 3, 55. https://doi.org/10.3390/beverages3040055

Canas S. Phenolic Composition and Related Properties of Aged Wine Spirits: Influence of Barrel Characteristics. A Review. Beverages. 2017; 3(4):55. https://doi.org/10.3390/beverages3040055

Chicago/Turabian StyleCanas, Sara. 2017. "Phenolic Composition and Related Properties of Aged Wine Spirits: Influence of Barrel Characteristics. A Review" Beverages 3, no. 4: 55. https://doi.org/10.3390/beverages3040055

APA StyleCanas, S. (2017). Phenolic Composition and Related Properties of Aged Wine Spirits: Influence of Barrel Characteristics. A Review. Beverages, 3(4), 55. https://doi.org/10.3390/beverages3040055