1. Introduction

The North American pawpaw (

Asimina triloba) is an anomaly because it is the only temperate member of the tropical Annonaceae family. It produces a unique fruit (

Figure 1) with tropical characteristics [

1,

2]. Pawpaw harvest occurs once a year, from mid-summer to early fall, depending on location, which limits its access. The pawpaw industry is local and the average pawpaw grower oversees an annual production of just over 90 kg (200 lbs) per year [

3]. Most fresh whole fruits are sold at farms or farmers’ markets and almost all of the frozen pawpaw pulp supply goes to breweries for beer or the dairy industry [

3]. From a culinary or gastronomic point of view, pawpaw has been effectively incorporated into a wide variety of beverages, savory dishes, sauces, condiments, sweets, and desserts [

4]. Nutritionally, pawpaw is rich in fiber (19–25% of US Daily Value per serving) and potassium (5–6% of US Daily Value per serving), and is comparable in other nutritional areas to banana and mango, although banana has more potassium and mango has more Vitamin C [

5].

The global fruit juice market is worth approximately USD 160 billion in 2024 [

6]. In the US, orange juice and apple juice dominate sales, although cranberry juice is also a significant commodity. Tropical juices like mango, pineapple, and guava are gaining popularity, driven by increasing consumer interest in exotic flavors [

6]. Processed fruit such as juice accounts for one-quarter of total U.S. fruit consumption [

7].

Extraction techniques for fruit juices have been extensively reviewed [

8]. Traditional methods include pressing, centrifugation, and pulping, among others. For some fruits, these processes do not liberate the juice from the tissue efficiently, so the use of cellulases and pectinases has become a vital fruit processing technology to facilitate juice recovery by breaking down cell wall pectins and hemicelluloses [

9]. These enzymes have demonstrated increased juice yields from fruits that are difficult to process via traditional means, such as red and white pitaya [

10,

11], guava [

12], apple and banana [

13,

14], and sopadilla [

15]. In soursop (

A. muricata), an Annonaceae cousin to pawpaw, 0.05% Pectinex

® enzyme was used with a 120 min incubation time to optimize fruit juice yield [

16].

There is no research in the literature about developing juice from pawpaw. Therefore, the objective of this preliminary study was to identify pawpaw juice production parameters (enzyme percentage, extraction protocol, acidification) and assess consumer preferences.

2. Materials and Methods

Ripe whole fruits from different cultivars of pawpaw were obtained from Fox Paw Ridge Farm (Cincinnati, OH, USA). The fruit pulp from ripe and overripe whole fruits was separated from the skin and seeds, placed in vacuum-sealed bags and stored at −40 °C until extracted for juice. For juice extraction, pulp was thawed and pooled, resulting in a pooled pulp with pH 6.2 and 19.8 °BRIX. The pulp was placed in polyethylene bags with no attempt to exclude oxygen from the bag. A small amount of the pulp was stored at 4 °C for 14 days and then processed into juice. The remaining pulp was stored at −40 °C for less than 21 days until processed into juice. Juice processing was replicated four times except for the pawpaw pulp that was stored refrigerated for 14 days, which was extracted once.

For juice processing, the pooled pawpaw pulp first was mixed with water (1:1) in a food processor. The pH of the pulp slurry was adjusted to 4.0 ± 0.5 with either 25% citric or 25% tartaric acid solution, if necessary. For the single stage extraction, Pectinex® Ultra SP-L, a blend of pectinases, hemicellulases and beta-glucanases (enzyme activity: ≥3300 EGU/g), was added at 0, 0.05, and 0.1% (v/w). The slurry was incubated with constant shaking at room temperature (~20 °C) for 120 min, after which the slurry was centrifuged (2000× g) and the supernatant retained as the juice. For the two-stage extraction, juice directly was extracted first by incubating the slurry with constant shaking at room temperature (~20 °C) for 60 min, after which the slurry was centrifuged (2000× g) and the supernatant retained as the juice. Pectinex® Ultra SP-L was added to the pellet at 0, 0.05, and 0.1% (v/w) and incubated with constant shaking at room temperature (~20 °C) for 120 min, after which the slurry was centrifuged (2000× g) and the supernatant from the enzyme-aided second extraction was pooled with the juice from the first stage direct extraction. All juices were pasteurized at 80 °C.

Juices that were prepared for sampling all had pawpaw juice as the base. Four contained only pawpaw juice; two differed by acid type (citric, tartaric), one was sweetened with sucrose, and one was prepared with pawpaw stored refrigerated for 14 days. The others contained 90% pawpaw juice and either 10% of a fruit puree (pawpaw, banana, mango) or a fruit juice (apple, pineapple, orange). Juices for objective tests were sampled on the day they were prepared. Juices for sensory analysis were stored at −18 °C before use.

All objective analyses were performed in triplicate for each replicate. The pH of the juice and °BRIX (soluble solids) were measured using a calibrated pH meter and refractometer, respectively. CIE color values (L*, a*, b*) were measured using a calibrated colorimeter (Konica Minolta, NJ, USA). Clarity was measured directly by monitoring the absorbance at 660 nm. Juice yield was calculated as follows:

Initial sensory testing was performed using protocols approved by the Ohio University Institutional Review Board for the protection of human subjects (08-E-130) by a semi-trained panel (n = 12), five of whom had previously been trained for and participated in descriptive sensory analysis. The other seven panelists had little to no prior sensory analysis experience. Five, one hour training sessions were conducted, all in a group with a “conference room” setup:

Session 1: Identification and ranking of standardized solutions of basic tastes.

Session 2: Familiarization and identification sweet, sour, and bitter in fruit juices.

Session 3: Development of taste intensity rating against known standards.

Session 4: Identification and verbalization of fruit tastes, flavors, and textures.

Session 5: Familiarization with the ballot.

After the training sessions were completed, panelists sampled ~30 mL of juice at room temperature in a vessel labeled with a randomly generated 3-digit code. The sampling order for each participant was randomized. Sampling was conducted in a single session with a mandatory 30-min break after the fifth sample. Panelists were supplied with water and unsalted saltine crackers. Data was recorded on each panelist’s personal device (e.g., smartphone) using a ballot created and accessed via an online survey management platform (Qualtrics International Inc., Provo, UT, USA). Panelists rated the color, texture, flavor, and overall acceptability of each sample on a 9-point hedonic likeness scale (1 = dislike extremely, 2 = dislike very much, 3 = dislike moderately, 4 = dislike slightly, 5 = neither like nor dislike, 6 = like slightly, 7 = like moderately, 8 = like very much, 9 = like extremely). Panelists rated sweet, sour, smooth, and thick using a 5-point “Just About Right” scale. Panelists recorded ratings from 1 to 5, but to indicate visually the “just about right” midpoint at zero, these values were converted to −2 = not nearly _____ enough, −1 = not _____ enough, 0 = just about right, 1 = too _____, 2 = much too _____. Panelists also were instructed to list as many fruit tastes, flavors, and textures as they were able.

Consumer sensory testing was performed using protocols approved by the Ohio University Institutional Review Board for the protection of human subjects (23-E-194). Consumers were recruited from passers-by during the Ohio University fall commencement. Consumers were randomly assigned to use one of five tablets on which they indicated consent and performed the survey. The tablets linked to a survey created and accessed via an online survey management platform (Qualtrics International Inc., Provo, Utah, USA). The survey on the five tablets was identical except for the sample order of the juices. The survey consisted of demographic questions (

Table 1), five questions about juice consumption habits, and instructions for tasting and rating the juice samples. Each juice sample (~30 mL) was presented at room temperature. Consumers were instructed to rate how much they liked the aroma, texture, flavor, and overall acceptability on a nine-point hedonic scale. For each juice, consumers were given the option to “check all that apply” from a list of descriptors developed from the results of the semi-trained panel. The list included basic tastes (sweet, sour, bitter), fruity flavors (banana, mango, pineapple, melon, pear, citrus, papaya, orange), vegetable flavors (cucumber, raw pea pod, root vegetable), other flavors (creamsicle, cocoa, tapioca, vanilla, honey, nutty, burnt marshmallow, caramel, molasses), and biting flavors (green banana, horseradish, dirty/muddy, grassy, musty, plastic, fermented). A paper sheet that listed these descriptors was available during the evaluation.

Descriptive statistics and analysis of variance were performed using IBM SPSS Statistics software (version 29.0, Armonk, NY, USA), with a significance of p < 0.05 unless otherwise noted. Duncan’s Multiple Range test was performed post-hoc to determine significant differences between means.

3. Results

3.1. Effect of Enzyme, Extraction Protocol, and Acid on Pawpaw Juice

The effect of the addition of Pectinex

® Ultra SP-L (0.05% and 0.1%) on yield, pH, °BRIX, and color in pawpaw juice is shown in

Table 2. Significantly higher juice yields and lower pH values were observed in the juice extracted with the enzyme, but no differences was observed between 0.05% and 0.1%. No other variables exhibited significant differences, indicating that the enzyme did not affect these variables.

The effect of the presence and type of acid on yield, pH, °BRIX, color, and clarity in pawpaw juice is shown in

Table 3. The acid was added to the pawpaw/water slurry before extraction to achieve pH 4.0 ± 0.5, the optimum range for the enzyme. Compared to the juice prepared from pulp that was pH adjusted with citric or tartaric acid, lower clarity values were observed in the juice prepared from pawpaw stored for 14 days that did not require pH adjustment because its pH was within the active range of the enzyme. No other variables exhibited significant differences.

The effect of extraction process on yield, pH, °BRIX, color, and clarity in pawpaw juice is shown in

Table 4. For the single stage process, the enzyme is added directly to the pawpaw slurry before incubation and centrifugation, whereas in the two-stage process, the juice is first extracted via centrifugation (first stage) and the solids are treated with the enzyme and juice recovered with another centrifugation step (second stage). The two-stage process produced juice that was significantly lighter and more clear, and indicated by higher L* and lower clarity. No other variables exhibited significant differences, indicating that the enzyme did not affect these variables.

3.2. Sensory Analysis of Pawpaw Juice Using a Semi-Trained Panel

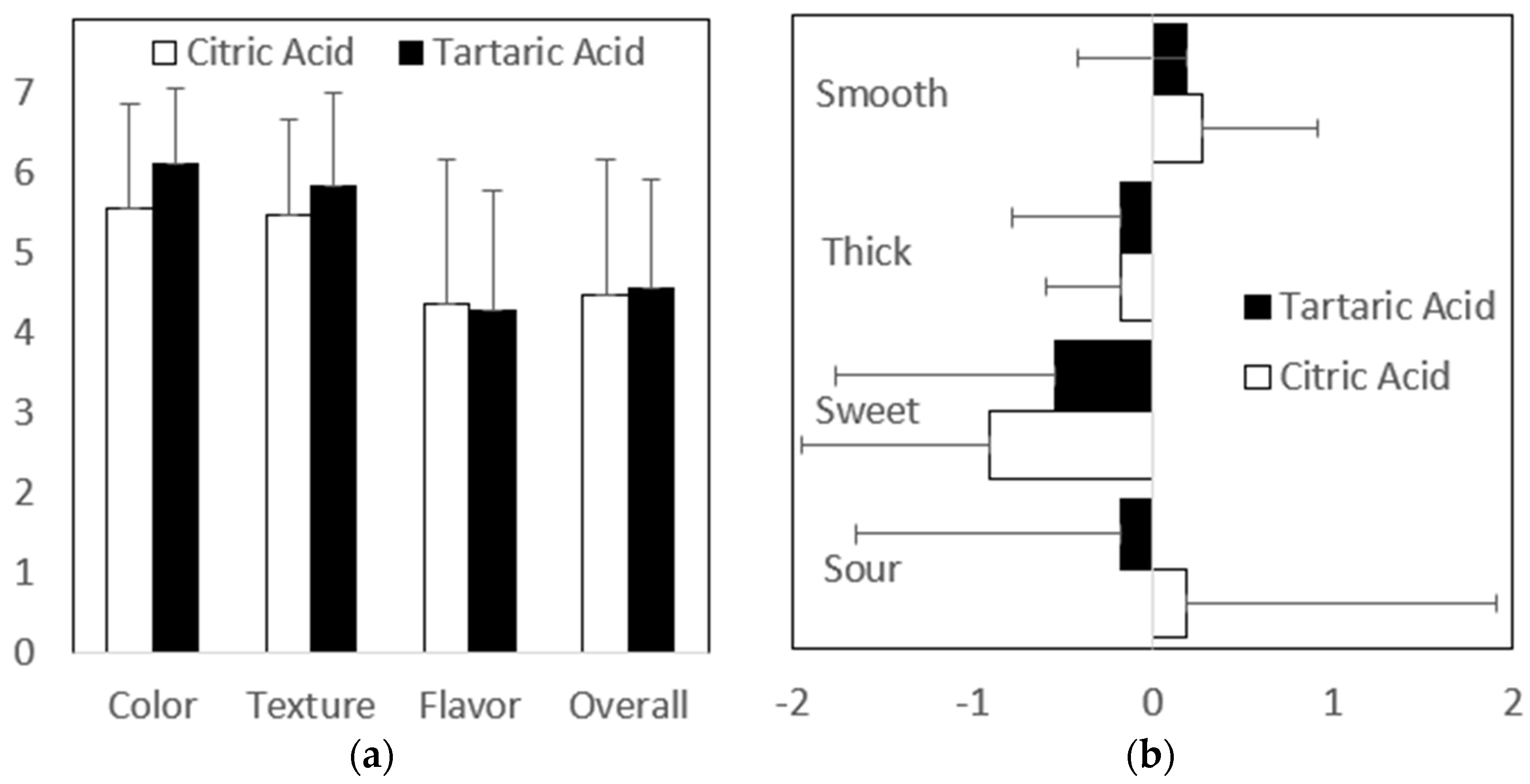

The semi-trained sensory panel rated pawpaw juice on a 9-point hedonic scale and a 5-point “Just About Right” scale for sweetness, sourness, smoothness, and thickness (

Figure 2). No significant differences were observed for any of the comparisons. A value of 5 on the hedonic scale indicates “neither like nor dislike” so values above and below indicate the juices were liked or disliked, respectively. The panel rated smoothness, thickness, sweetness, and sourness for both acids within one standard deviation of “just right”.

Pawpaw juice was compared to juice prepared from pawpaw stored refrigerated for 14 days as described above. The pawpaw juice was acidified with citric acid, whereas the juice from stored pawpaw did not need pH adjustment. No differences were observed for color (

p = 0.306), texture (

p = 0.891), flavor (

p = 0.132), or overall acceptability (

p = 0.196) on the 9-point hedonic scale. No differences were observed for smoothness (

p = 0.329), thickness (

p = 0.482), sweetness (

p = 0.416), and sourness (

p = 0.489) on the “Just About Right” rankings. The magnitude of the means and their trends were very similar to those shown in

Figure 2.

Six juices were compared that were comprised of 90:10 blends of pawpaw juice with other juices (apple, orange, pineapple juice) or fruit pulp (pawpaw, banana, mango). Pawpaw blends with juices were preferred significantly compared to those with purees for color (p = <0.001; juice M = 6.5, pulp M = 5.5), texture (p = <0.001, juice M = 6.7, pulp M = 4.3), flavor (p = 0.003, juice M = 6.2, pulp M = 4.7), and overall acceptability (p = <0.001, juice M = 6.5, pulp M = 4.4). All of the juice means were in the “like” range and all of the pulp means were in the “dislike” range. Pawpaw blends with juices were significantly more “just right” compared to those with purees for smoothness (p = <0.001, juice M = 0.00, pulp M = −1.0) and thickness (p = <0.001, juice M = 0.0, pulp M = 0.8), but no differences were observed for sweetness (p = 0.163) and sourness (p = 0.554).

The three 90:10 juice blends were compared to 100% pawpaw juice (

Table 5). Panelists liked the flavor of the blend with 10% pineapple significantly more than the 100% pawpaw juice and all three blends had significantly higher overall acceptability than the 100% pawpaw juice. No differences between the juices were observed based on the “just about right” scales.

The semi-trained panel was asked to provide tasting notes for each of the samples. Collectively, they identified a list of tastes and flavors that were used as the basis for the “Check all that apply” attributes discussed in

Section 3.3.

3.3. Consumer Sensory Analysis of Pawpaw Juice Blends

Thirty-one consumers were asked to rate how much they liked five pawpaw juices: 100% pawpaw juice, 100% pawpaw juice that was sweetened, and 90% pawpaw juice blended with either 10% apple, pineapple, or orange juice. No differences were observed between the five juices for aroma (p = 0.731), texture (p = 0.259), flavor (p = 0.079), or overall acceptability (p = 0.082). Within each of the five the pawpaw juices, there was at least one significant difference in sensory attributes between demographic categories; however, these differences did not provide much insight into the underlying drivers of their perceptions.

Within the juices with 10% juice added (pineapple, orange, apple), there was a single significant difference. In the pawpaw juice with 10% pineapple, a significant difference was observed between gender for texture (p = 0.014; male M = 6.2, female M = 7.4). In the pawpaw juice with 10% orange, a significant difference was observed between age groups for aroma (p = 0.001), with participants 18–24 and 25–34 exhibiting lower likeness (M = 5.1, 3.5, respectively) than for 35–44 (M = 7.7). In the pawpaw juice with 10% apple, a significant difference was observed between education level for overall acceptability (p = 0.036), with those with graduate or professional degrees exhibiting lower likeness (M = 4.0) than those with (M = 6.0) or without (M = 6.1) a bachelor’s degree.

Within the 100% pawpaw juice, there were two significant differences between educational level. Differences were observed for flavor (p = 0.011) and overall acceptability (p = 0.044). Means for flavor and overall acceptability, respectively, indicate that those with graduate or professional degrees exhibited lower likeness (M = 4.5, 4.7) than those with (M = 6.2, 6.3) or without (M = 6.6, 6.8) a bachelor’s degree.

There were significant differences in all of the sensory attributes between demographic categories within the sweetened pawpaw. Differences were observed between educational level in the sweetened pawpaw juice for texture (p = 0.003), flavor (p = 0.048), and overall acceptability (p = 0.011). Means for texture, flavor, and overall acceptability, respectively, indicate that those with graduate or professional degrees exhibited lower likeness (M = 5.4, 4.7, 5.0) than those with (M = 7.5, 6.8, 6.6) or without (M = 7.8, 6.8, 7.1) a bachelor’s degree. A difference also was observed between age groups in the sweetened pawpaw juice for aroma (p = 0.015), with participants 25–34 and 45–44 exhibiting lower likeness (M = 4.0, 5.0, respectively) than for 35–44 (M = 7.5).

The tastes and flavors that the semi-trained panel created in their tasting notes (

Section 3.2) served as the checkbox list for the “Check all that apply” attributes that participants were asked to identify (

Table 6). Eleven attributes were checked by at least one participant for all five of the juices, and two others (citrus flavor, sour taste) were checked for all but the sweetened pawpaw juice. Of the 31 participants, the percentage of participants who checked at least one attribute was in the order of: added orange juice (87%), added pineapple juice (81%), sweetened pawpaw juice (77%), added apple juice (74%), 100% pawpaw juice (68%)

Sweetened pawpaw juice had the most attributes checked (75) likely driven by the 19 panelists who checked sweet taste, which was seven more than those for the next highest (12, sweet taste in pawpaw juice with added pineapple juice). The percentage of the 23 attributes that was checked by at least one participant was in the order of: 100% pawpaw juice (85%), added orange juice (77%), added pineapple juice (69%), added apple juice (62%), and sweetened pawpaw juice (54%).

4. Discussion

The study’s design was constrained by the limited availability of pawpaw pulp for juice production. This limitation stems from several factors: pawpaw has a single annual harvest in late summer/fall, the industry remains niche with small-yield growers, harvest is susceptible to weather variability, and there exists a competitive wholesale market for pawpaw ingredients in products like beer and ice cream [

3]. Consequently, a phased design was employed. Processing parameters were established, followed by preliminary sensory characterization with a semi-trained panel. Finally, a consumer preference study was conducted that utilizing all available juice, although the sample size (

n = 31) was smaller than ideal.

The addition of pectinase, hemicellulase, and cellulase enzymes to assist juice extraction from fruits is not novel and has been in practice for nearly 100 years. Given that pawpaw exhibits typical Type I primary cell walls of flowering dicots, comprising pectic (homogalacturonan, rhamnogalacturonans I and II) and hemicellulose (arabinogalactan I and II, glucomannan, xylans) fractions [

17], a commercial enzyme preparation like Pectinex

® Ultra SP-L, containing pectinases, hemicellulases, and beta-glucanases, was expected to facilitate juice extraction. As shown in

Table 2, enzyme-treated juice yields were significantly higher compared to the juice extracted without enzyme. However, no significant differences were observed between 0.05% and 0.1% enzyme concentrations, leading to the selection of 0.05% for subsequent experiments.

The pH of pawpaw pulp is generally around 6.0 depending on cultivar [

18], so the pawpaw/water slurry was acidified before enzyme addition to reduce the pH to the optimum range for the enzyme 4.0 ± 0.5. As shown in

Table 3, there was no difference between citric and tartaric acid. Compared to the juice prepared from pulp that was pH adjusted with citric or tartaric acid, lower clarity values were observed in the juice prepared from pawpaw stored refrigerated for 14 days, which did not require pH adjustment because its pH was within the active range of the enzyme. Refrigerated storage is common for pawpaw pulp due to its high perishability at room temperature and 14 days of storage would simulate pulped pawpaw that likely could not be sold. Thus, the potential to upcycle pawpaw pulp was explored.

The juice yields reported herein (

Table 2,

Table 3 and

Table 4) assume a starting pawpaw/water slurry that is 50% pawpaw pulp and 50% added water. Because it was not known if the timing of enzyme addition would affect the extraction of water from the pulp, the enzyme was added directly to the slurry before incubation (single stage extraction) and to the solids after all of the recoverable water was extracted (two-stage extraction), the impact of which is shown in

Table 4. There were no differences between the two extraction methods except that the single state extraction produced juice that was statistically darker (lower L*) and less clear (higher ABS@660 nm). Because pawpaw pulp is approximately 70% water [

5,

18], the 50:50 pawpaw/water slurry would be expected to be about 85% water. Both extraction methods recovered about 82% of the moisture from the slurry, so both extractions were very efficient at juice recovery. Although the juice from the single stage extraction was darker and less clear, its convenience led to its selection for subsequent experiments.

The use of the semi-trained panel was two-fold. The panel provided preliminary sensory data for certain aspects of the juices and they also became familiar with identifying and verbalizing tastes and flavors, especially those in fruit, that were used to develop the consumer study. On their own, there were several important findings from these results. There were no differences observed between citric acid and tartaric acid, so citric acid was used to produce the juices for the subsequent consumer study because it is readily available and much more cost-effective than tartaric acid. However, it would be unwise to exclude juice prepared from pawpaw stored refrigerated for 14 days because this pawpaw juice did not need pH adjustment and no differences were observed between the juice extracted from this pawpaw and the acidified juices. Blending pawpaw juice with other purees (pawpaw, banana, mango) to produce a nectar-like product often seen commercially was not effective. On the other hand, blending pawpaw juice with other fruit juices (apple, orange, pineapple) produced overall acceptability scores that were liked and sweetness, sourness, smoothness, and thickness that were considered “just about right” by the panelists. The 3 taste and 23 flavor attributes identified were checked by at least one consumer.

Consumers showed no overall preference for any of the five juices across aroma, texture, flavor, and overall acceptability. Consequently, the observed variations in sensory attribute ratings between demographic groups for each juice lacked clear trends and were difficult to interpret. Consumers did reveal the complexity of pawpaw flavor (

Table 6), as evidenced by the fact that consumers who rated 100% pawpaw juice checked 85% (22/26) of the attributes developed by the semi-trained panel. Of those, all three of the basic tastes were selected and only caramel, molasses, horseradish, and plastic were not checked. Most often selected were sweet and bitter tastes and melon, papaya, and pear flavors. Banana flavor only was selected by 6% (2/31) of panelists even though it is often reported to be the dominant flavor in pawpaw pulp [

1,

2,

19], so more research would be required. Sweetening the pawpaw revealed caramel and molasses flavors but masked sour taste and citrus, creamsicle, fermented, grassy, green banana, musty, nutty, raw pea pod, and tapioca flavors.

5. Summary and Conclusions

This study aimed to optimize pawpaw juice production and assess consumer preferences. Due to limited pawpaw availability, a phased approach was used, focusing on processing parameters, sensory characterization, and consumer testing. Enzymatic extraction with Pectinex

® Ultra SP-L significantly increased juice yield compared to non-enzyme extraction, but enzyme concentration (0.05% vs. 0.1%) and acidification method (citric vs. tartaric acid) showed no significant differences. Single-stage enzyme addition, despite producing slightly darker and less clear juice, was selected for its convenience. Sensory panelists found no significant differences between citric and tartaric acid acidified juices, or between juices prepared from fresh pawpaw and pawpaw stored refrigerated for 14 days. Utilization of older pawpaw fruit for juice could help mitigate waste, especially in light of the fact that food loss and waste represent 30–40% of the food supply in the United States [

20].

Blending pawpaw juice with fruit juices improved overall acceptability compared to blending with fruit purees. Consumer testing revealed no overall preference among five juice formulations, but highlighted the complex flavor profile of pawpaw, with sweet and bitter tastes, and melon, papaya, and pear flavors being most frequently identified. Sweetening the juice altered the flavor profile, masking sourness and certain flavors.

Based on this preliminary study, challenges and opportunities exist for the development of a pawpaw-based juice on the market. Pawpaw has a complex and unique flavor but it is relatively unknown to many consumers and its unique flavor may be an acquired taste. Pawpaw has a local, wild-foraged, and native feel and research indicates that pawpaw has a robust antioxidant profile [

21,

22]. Taken together, pawpaw has the potential to appeal to consumers seeking novel and exotic tastes, those seeking authentic, sustainable and artisanal food products, and those that are health-conscious.

This preliminary study leaves many questions unanswered, so further study will be required to unlock the potential for pawpaw juice. It is unclear whether a reliable pawpaw fruit supply chain exists. Currently, the limited harvest season, small-scale growers, and weather dependence have created a seasonally variable supply chain. Further research is required to optimize processing that ensures consistent quality. The evidence that the flavor profile is easily altered with sweetening suggests that product development research would be needed. This research did not address storage and shelf life issues. Overall, pawpaw-based juice has potential, but not before research to optimize processing, extend shelf life, and understand consumer preferences for pawpaw-based juices is established.