Anaerobic Digestion of Pig-Manure Solids at Low Temperatures: Start-Up Strategies and Effects of Mode of Operation, Adapted Inoculum, and Bedding Material

Abstract

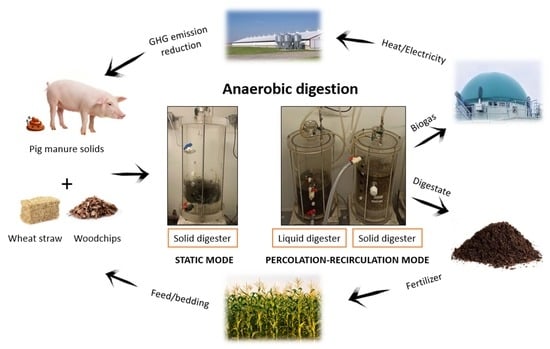

:1. Introduction

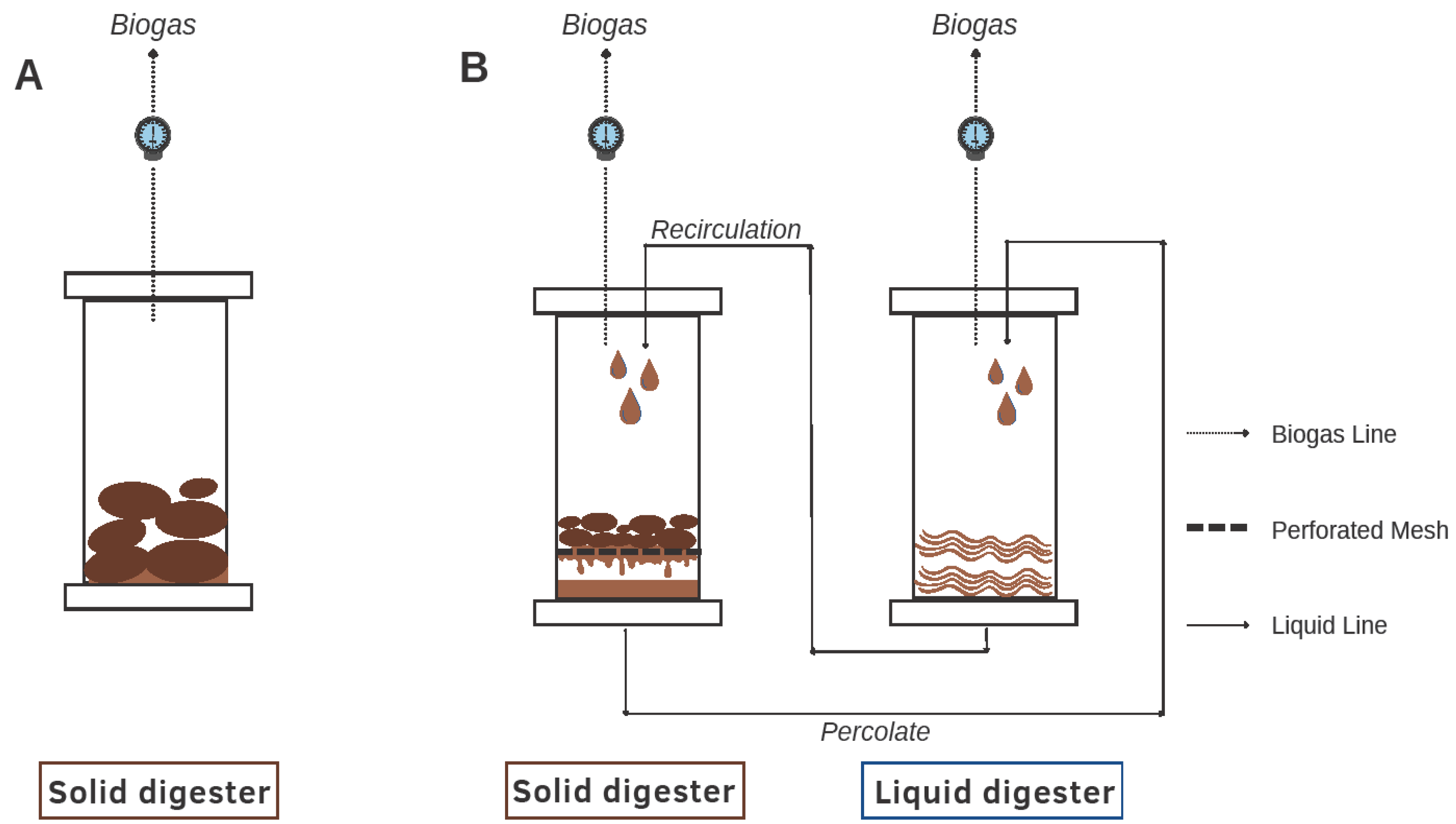

2. Materials and Methods

2.1. Inoculum and Substrates

2.2. Physico-Chemical and Biogas Measurements

2.3. Experimental Set-Up

3. Results and Discussion

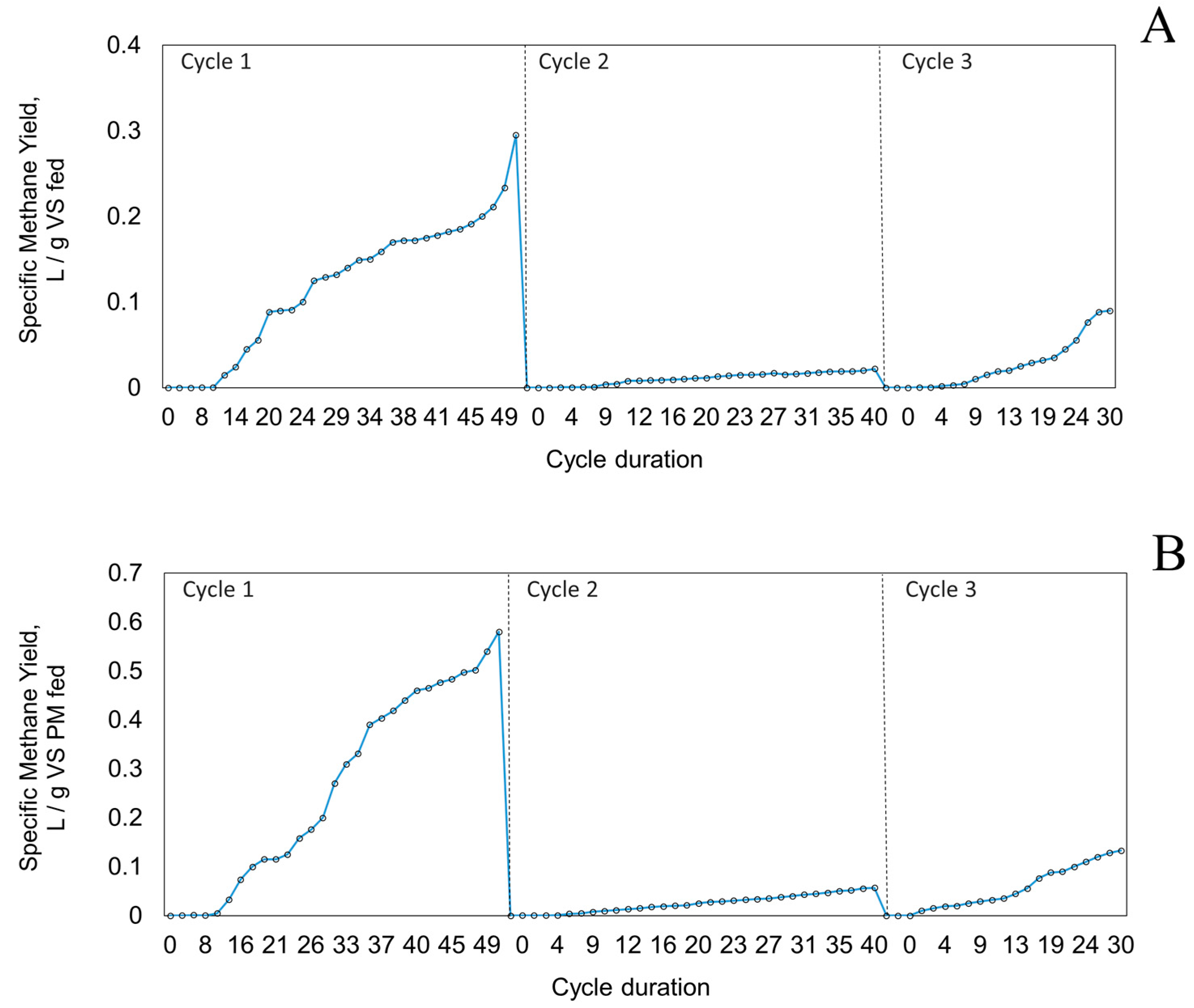

3.1. Specific Methane Yield from the Static Mode of Operation

3.2. Specific Methane Yield from the Two-Stage Percolation–Recirculation Mode of Operation

3.3. Effect of Adapted Inoculum

3.4. Effect of Mode of Operation

3.5. Bedding Material and Post-Treatment Digestate Quality

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AD | Anaerobic Digestion |

| PM | Pig Manure (solids) |

| WS | Wheat Straw |

| WC | Wood Chips |

| DAD | Dry Anaerobic Digestion (static) |

| P-R | Percolation–Recirculation or Percolate–Recirculation |

| SMY | Specific Methane Yield |

| FAN | Free Ammonia Nitrogen |

| TAN | Total Ammonia Nitrogen |

| VFA | Volatile Fatty Acids |

| TCOD | Total Chemical Oxygen Demand (COD) |

| TKN | Total Kjeldahl Nitrogen |

| C/N ratio S:I ratio | Carbon-to-Nitrogen ratio Substrate-to-Inoculum ratio |

References

- Agriculture and Agri-Food Canada, Quick Facts 2020. Available online: https://agriculture.canada.ca/en/canadas-agriculture-sectors/animal-industry/red-meat-and-livestock-market-information/hogs-pork (accessed on 20 April 2022).

- Charron-Doucet, F.; Léger Dionne, A. Streamlined Environmental Life Cycle Assessment of Canadian Pork Production; GROUPE AGÉCO: Montreal, Canada, 2018. [Google Scholar]

- Abalos, D.; Recous, S.; Butterbach-Bahl, K.; De Notaris, C.; Rittl, T.F.; Topp, C.F.E.; Petersen, S.O.; Hansen, S.; Bleken, M.A.; Rees, R.M.; et al. A Review and Meta-Analysis of Mitigation Measures for Nitrous Oxide Emissions from Crop Residues. Sci. Total Environ. 2022, 828, 154388. [Google Scholar] [CrossRef] [PubMed]

- Bourque, L.; Koroluk, R. Manure Storage in Canada; Statistics Canada, Agriculture Division: Ottawa, ON, Canada, 2003; ISBN 978-0-662-34832-0.

- Shapovalov, Y.; Zhadan, S.; Bochmann, G.; Salyuk, A.; Nykyforov, V. Dry Anaerobic Digestion of Chicken Manure: A Review. Appl. Sci. 2020, 10, 7825. [Google Scholar] [CrossRef]

- A Healthy Environment and a Healthy Economy: Canada’s Strengthened Climate Plan to Create Jobs and Support People, Communities, and the Planet. Canadian Climate Plan. Available online: https://www.canada.ca/en/services/environment/weather/climatechange/climate-plan/climate-plan-overview/healthy-environment-healthy-economy.html (accessed on 3 July 2022).

- Rajagopal, R.; Massé, D.I. Start-up of Dry Anaerobic Digestion System for Processing Solid Poultry Litter Using Adapted Liquid Inoculum. Process Saf. Environ. Prot. 2016, 102, 495–502. [Google Scholar] [CrossRef]

- Mahato, P.; Goyette, B.; Rahaman, M.S.; Rajagopal, R. Processing High-Solid and High-Ammonia Rich Manures in a Two-Stage (Liquid-Solid) Low-Temperature Anaerobic Digestion Process: Start-Up and Operating Strategies. Bioengineering 2020, 7, 80. [Google Scholar] [CrossRef] [PubMed]

- Mahdy, A.; Fotidis, I.A.; Mancini, E.; Ballesteros, M.; González-Fernández, C.; Angelidaki, I. Ammonia Tolerant Inocula Provide a Good Base for Anaerobic Digestion of Microalgae in Third Generation Biogas Process. Bioresour. Technol. 2017, 225, 272–278. [Google Scholar] [CrossRef]

- Yao, Y.; Huang, G.; An, C.; Chen, X.; Zhang, P.; Xin, X.; Shen, J.; Agnew, J. Anaerobic Digestion of Livestock Manure in Cold Regions: Technological Advancements and Global Impacts. Renew. Sustain. Energy Rev. 2020, 119, 109494. [Google Scholar] [CrossRef]

- Beaulieu, M.S.; Statistics Canada; Agriculture Division. Manure Management in Canada; Statistics Canada, Agriculture Division: Ottawa, ON, Canada, 2004; ISBN 978-0-662-37067-3.

- VanderZaag, A.C.; Glenn, A.; Balde, H. Manure Methane Emissions over Three Years at a Swine Farm in Western Canada. J. Environ. Qual. 2022, 51, 301–311. [Google Scholar] [CrossRef]

- Zhong, B.; An, X.; Shen, F.; An, W.; Zhang, Q. Anaerobic Co-Digestion of Rice Straw and Pig Manure Pretreated With a Cellulolytic Microflora: Methane Yield Evaluation and Kinetics Analysis. Front. Bioeng. Biotechnol. 2021, 8, 579405. [Google Scholar] [CrossRef]

- Orfanoudaki, A.; Makridakis, G.; Maragkaki, A.; Fountoulakis, M.S.; Kallithrakas-Kontos, N.G.; Manios, T. Anaerobic Co-Digestion of Pig Manure and Spent Coffee Grounds for Enhanced Biogas Production. Waste Biomass Valorization 2020, 11, 4613–4620. [Google Scholar] [CrossRef]

- Abudi, Z.N.; Hu, Z.; Abood, A.R. Anaerobic Co-Digestion of Mango Leaves and Pig Manure: Performance Assessment and Kinetic Analysis. Biomass Conv. Bioref. 2022, 12, 275–285. [Google Scholar] [CrossRef]

- Pezzolla, D.; Di Maria, F.; Zadra, C.; Massaccesi, L.; Sordi, A.; Gigliotti, G. Optimization of Solid-State Anaerobic Digestion through the Percolate Recirculation. Biomass Bioenergy 2017, 96, 112–118. [Google Scholar] [CrossRef]

- Xie, S.; Wu, G.; Lawlor, P.G.; Frost, J.P.; Zhan, X. Methane Production from Anaerobic Co-Digestion of the Separated Solid Fraction of Pig Manure with Dried Grass Silage. Bioresour. Technol. 2012, 104, 289–297. [Google Scholar] [CrossRef] [PubMed]

- Sutaryo, S.; Ward, A.J.; Møller, H.B. Anaerobic Digestion of Acidified Slurry Fractions Derived from Different Solid–Liquid Separation Methods. Bioresour. Technol. 2013, 130, 495–501. [Google Scholar] [CrossRef] [PubMed]

- González-Fernández, C.; León-Cofreces, C.; García-Encina, P.A. Different Pretreatments for Increasing the Anaerobic Biodegradability in Swine Manure. Bioresour. Technol. 2008, 99, 8710–8714. [Google Scholar] [CrossRef] [PubMed]

- Campos, E.; Almirall, M.; Martinez Almela, J.; Flotats, X. Anaerobic Digestion of Solid Fraction of Pig Slurry. 2002. Available online: https://www.researchgate.net/publication/228513124_Anaerobic_digestion_of_solid_fraction_of_pig_slurry (accessed on 3 July 2022).

- Møller, H.; Hansen, J.; Sørensen, C. Nutrient Recovery by Solid-Liquid Separation and Methane Productivity of Solids. Trans. ASABE 2007, 50, 193–200. [Google Scholar] [CrossRef]

- Møller, H.B.; Sommer, S.G.; Ahring, B.K. Methane Productivity of Manure, Straw and Solid Fractions of Manure. Biomass Bioenergy 2004, 26, 485–495. [Google Scholar] [CrossRef]

- Ameen, F.; Ranjitha, J.; Ahsan, N.; Shankar, V. Co-Digestion of Microbial Biomass with Animal Manure in Three-Stage Anaerobic Digestion. Fuel 2021, 306, 121746. [Google Scholar] [CrossRef]

- Shu, Q.; Cheng, H.; Chen, X.; Wang, J.; Du, Z.; Hong, J.; Zheng, Z.; Luo, X. Effects of Increasing Concentrations of Enrofloxacin on Co-Digestion of Pig Manure and Corn Straw. Sustainability 2022, 14, 5894. [Google Scholar] [CrossRef]

- Astals, S.; Nolla-Ardèvol, V.; Mata-Alvarez, J. Anaerobic Co-Digestion of Pig Manure and Crude Glycerol at Mesophilic Conditions: Biogas and Digestate. Bioresour. Technol. 2012, 110, 63–70. [Google Scholar] [CrossRef]

- Rajagopal, R.; Massé, D.I.; Singh, G. A Critical Review on Inhibition of Anaerobic Digestion Process by Excess Ammonia. Bioresour. Technol. 2013, 143, 632–641. [Google Scholar] [CrossRef]

- Eaton, A.D.; Clesceri, L.S.; Greenberg, A.E. Standard Methods for the Examination of Water and Wastewater; American Public Health Association (APHA): Washington, DC, USA, 2005; pp. 20001–23710. [Google Scholar]

- Saady, N.M.C.; Massé, D.I. High Rate Psychrophilic Anaerobic Digestion of High Solids (35%) Dairy Manure in Sequence Batch Reactor. Bioresour. Technol. 2015, 186, 74–80. [Google Scholar] [CrossRef] [PubMed]

- Janesch, E.; Pereira, J.; Neubauer, P.; Junne, S. Phase Separation in Anaerobic Digestion: A Potential for Easier Process Combination? Front. Chem. Eng. 2021, 3, 711971. [Google Scholar] [CrossRef]

- Baldi, F.; Pecorini, I.; Iannelli, R. Comparison of Single-Stage and Two-Stage Anaerobic Co-Digestion of Food Waste and Activated Sludge for Hydrogen and Methane Production. Renew. Energy 2019, 143, 1755–1765. [Google Scholar] [CrossRef]

- Gonzalez-Martinez, A.; Garcia-Ruiz, M.J.; Rodriguez-Sanchez, A.; Osorio, F.; Gonzalez-Lopez, J. Archaeal and Bacterial Community Dynamics and Bioprocess Performance of a Bench-Scale Two-Stage Anaerobic Digester. Appl. Microbiol. Biotechnol. 2016, 100, 6013–6033. [Google Scholar] [CrossRef] [PubMed]

- Fotidis, I.A.; Treu, L.; Angelidaki, I. Enriched Ammonia-Tolerant Methanogenic Cultures as Bioaugmentation Inocula in Continuous Biomethanation Processes. J. Clean. Prod. 2017, 166, 1305–1313. [Google Scholar] [CrossRef] [Green Version]

| Manure Type | Separation Method | TS (%) | Temperature (°C) | SMY | Remarks | Reference |

|---|---|---|---|---|---|---|

| Pig manure (co-digestion with mango leaves) | Sieved through 2 mm pore size | 28.29 ± 0.08 | 37 ± 1 | 465 mL/gVS (at mango leaves:pig manure mix ratio 1:3) 281 mL/gVS (only pig manure) |

| [15] |

| Pig slurry and straw | None | 20.7 ± 1.3 | 35 ± 2 | 120 mL/gVs (static mode–no recirculation) 240.8 mL/gVS (P-R mode) |

| [16] |

| Liquid pig manure (co-digestion with spent coffee grounds) | None | 26.5 ± 5.3 g/L | 37 | 323 ± 29 mL/gVS (co-digestion) |

| [14] |

| Pig-manure solids (co-digestion with dried grass) | Decanter centrifuge, alum, and polyacrylamide flocculant (PAM) diluted with water | 28.2 | 35 ± 1 | 252.5 mL CH4/g VS |

| [17] |

| Pig-manure solids (acidified) | Drum screen separation 1 mm screen size and 7 rpm speed | 10.60 | 35 | 319.3 ± 1.9 L/kg VS | Retention time = 90 days | [18] |

| Sow manure solids (acidified) | Screw press separation with mm screen size and mm plate tension | |||||

| Pig manure (co-digestion with rice straw) | None | N.A. | 35 ± 0.5 | ≈342 mL/gVS (pre-treated) ≈236 mL/gVS (not pretreated) |

| [13] |

| Pig manure | Mechanical sieve 0.25 mm pore size | 11.4 | 35 | 251 L CH4/kg CODfed | [19] | |

| Pig manure | Flocculation with coagulant aid | 13.6 | 35 | 110 L CH4/kg VS | [20] | |

| 155 L CH4/kg CODfed | ||||||

| 135 L CH4/kg vs. fed | ||||||

| 9.9 | 157 L CH4/kg COD fed | |||||

| Pig manure | Centrifugation | 32 | 161 to 186 L CH4/kg VS | Retention time = 60 days | [21] | |

| Pig manure | Coagulation and flocculation | 12.2 | 392 to 404 L CH4/kg VS | Retention time = 60 days | ||

| Pig manure | Centrifugation | 29 | 35 | 261 L CH4/kg VS | Biodegradability = 51% | [22] |

| Pig manure | Centrifugation | 31 | 35 | 159 L CH4/kg VS | Biodegradability = 30% | |

| Pig manure | Chemical treatment | 28.5 | 35 | 247 L CH4/kg VS | Biodegradability = 48% |

| Parameters | Pig-Manure Solids | Wheat Straw | Woodchips |

|---|---|---|---|

| Dry matter (DM, %) | 26.9 | 90 | 90 |

| Volatile solids (VS, %) | 23 | 85 | 85 |

| Fixed solids (FS, %) | -- | 15 | 15 |

| Total volatile fatty acids (TVFA, g/L) | 23.1 | NA | NA |

| pH | 6.6 | NA | NA |

| Total chemical oxygen demand (TCOD, g/L) | 216.3 | 1079 | NA |

| Total Kjedahl nitrogen (TKN, g/L) | 38.5 | NA | NA |

| Ammonia (NH3, g/L) | 10.1 | NA | NA |

| Cycle 1 | Cycle 2 | Cycle 3 | ||||

| Substrates used | PM solids + WS | PM solids + WS | PM solids + WC | PM solids + WC | PM solids + WS | PM solids + WC |

| Mode of operation | Static DAD | 2-stage P-R | Static DAD | 2-stage P-R | Static DAD | 2-stage P-R |

| Inoculum used | Yes * | Yes * | Yes * | Yes ** | Yes * | Yes * |

| PM solids + co-substrate (kg) | 2.32 + 0.61 | 2.32 + 0.61 | 2.32 + 0.95 | 2.32 + 0.95 | 2.38 + 0.31 | 2.38 + 0.66 |

| Liquid inoculum (kg) | 12 | 36 | 12 | 36 | 6 | 6 |

| OLR (g VS/kg inoculum/day) | 3.1 | 1.0 | 4.12 | 1.4 | 4.5 | 4.3 |

| S:I ratio | 0.24 | 0.08 | 0.27 | 0.09 | 0.45 | 0.51 |

| Feedstock TS (%) | 40.0 | 40.0 | 45.9 | 45.9 | 34.3 | 33.3 |

| Inoculum TS (%) | 6 | 2 | 6 | 2 | 6 | 6 |

| Operation period (days) | 49 | 49 | 40 | 40 | 30 | 30 |

| Single-Stage AD with Static Mode | Two-Stage AD with P-R Mode | |||||

| Cycle number (duration in days) | 1 (49) | 2 (40) | 3 (30) | 1 (49) | 2 (40) | 3 (30) |

| Total biogas production (L) | NA | 100 | 170 | NA | 550 | 410 |

| Biogas production rate (L/d) * | NA | 2.5 | 5.7 | NA | 13.8 | 13.7 |

| Biogas production (L/kg raw feedstock) ** | NA | 30.58 | 63.19 | NA | 168.19 | 134.86 |

| SMY (L/g VSfed) | 0.295 | 0.022 | 0.090 | 0.249 | 0.213 | 0.210 |

| SMY (L/g VSPM fed) | 0.580 | 0.057 | 0.133 | 0.500 | 0.535 | 0.423 |

| Remarks | WS required longer time, and its contribution to CH4 production began later. | Non-adapted inoculum use explains low SMY. | 50% less WS and inoculum volume were used compared to cycle 1. | WS required longer time to contribute to CH4 production. | Adapted inoculum improved the SMY value. | Inoculum recirculation stopped after 20 days which explains the slight drop in SMY. 30% less WC used compared to cycle 2. |

| Mode | Static | P-R | |||||

|---|---|---|---|---|---|---|---|

| Cycle | 1 | 2 | 3 | 1 | 2 | 3 | |

| Co-substrate | WS | X | X | X | |||

| WC | X | X | X | ||||

| Inoculum | Adapted | X | |||||

| Non-adapted | X | X | X | X | X | ||

| SMY | L/g VSPM fed up to 30 days | 0.28 | 0.05 | 0.13 | 0.40 | 0.48 | 0.42 |

| Physico–Chemical Parameters | Digestate (from Static Mode of Operation) | Digestate (from P-R Mode of Operation) |

|---|---|---|

| Dry matter (DM, %) | 12.4 | 12 |

| Volatile solids (VS, %) | 10 | 9.87 |

| Fixed solids (FS, %) | 2.4 | - |

| Total volatile fatty acids (TVFA, g/L) | 744 | 841 |

| pH | 8.2 | 8.1 |

| Total chemical oxygen demand (TCOD, g/L) | 66.96 | 117.72 |

| Ammonia (NH3-N, g/L) | 8.18 | - |

| Ammonium (NH4, g/L) | 12.3 | 4.99 |

| TKN (g/L) | 48.1 | 34.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajagopal, R.; Bele, V.; Saady, N.M.C.; Hickmann, F.M.W.; Goyette, B. Anaerobic Digestion of Pig-Manure Solids at Low Temperatures: Start-Up Strategies and Effects of Mode of Operation, Adapted Inoculum, and Bedding Material. Bioengineering 2022, 9, 435. https://doi.org/10.3390/bioengineering9090435

Rajagopal R, Bele V, Saady NMC, Hickmann FMW, Goyette B. Anaerobic Digestion of Pig-Manure Solids at Low Temperatures: Start-Up Strategies and Effects of Mode of Operation, Adapted Inoculum, and Bedding Material. Bioengineering. 2022; 9(9):435. https://doi.org/10.3390/bioengineering9090435

Chicago/Turabian StyleRajagopal, Rajinikanth, Vaibhavi Bele, Noori M. Cata Saady, Felipe M. W. Hickmann, and Bernard Goyette. 2022. "Anaerobic Digestion of Pig-Manure Solids at Low Temperatures: Start-Up Strategies and Effects of Mode of Operation, Adapted Inoculum, and Bedding Material" Bioengineering 9, no. 9: 435. https://doi.org/10.3390/bioengineering9090435

APA StyleRajagopal, R., Bele, V., Saady, N. M. C., Hickmann, F. M. W., & Goyette, B. (2022). Anaerobic Digestion of Pig-Manure Solids at Low Temperatures: Start-Up Strategies and Effects of Mode of Operation, Adapted Inoculum, and Bedding Material. Bioengineering, 9(9), 435. https://doi.org/10.3390/bioengineering9090435