Stress Relaxation Properties of Five Orthodontic Aligner Materials: A 14-Day In-Vitro Study

Abstract

:1. Introduction

2. Materials and Methods

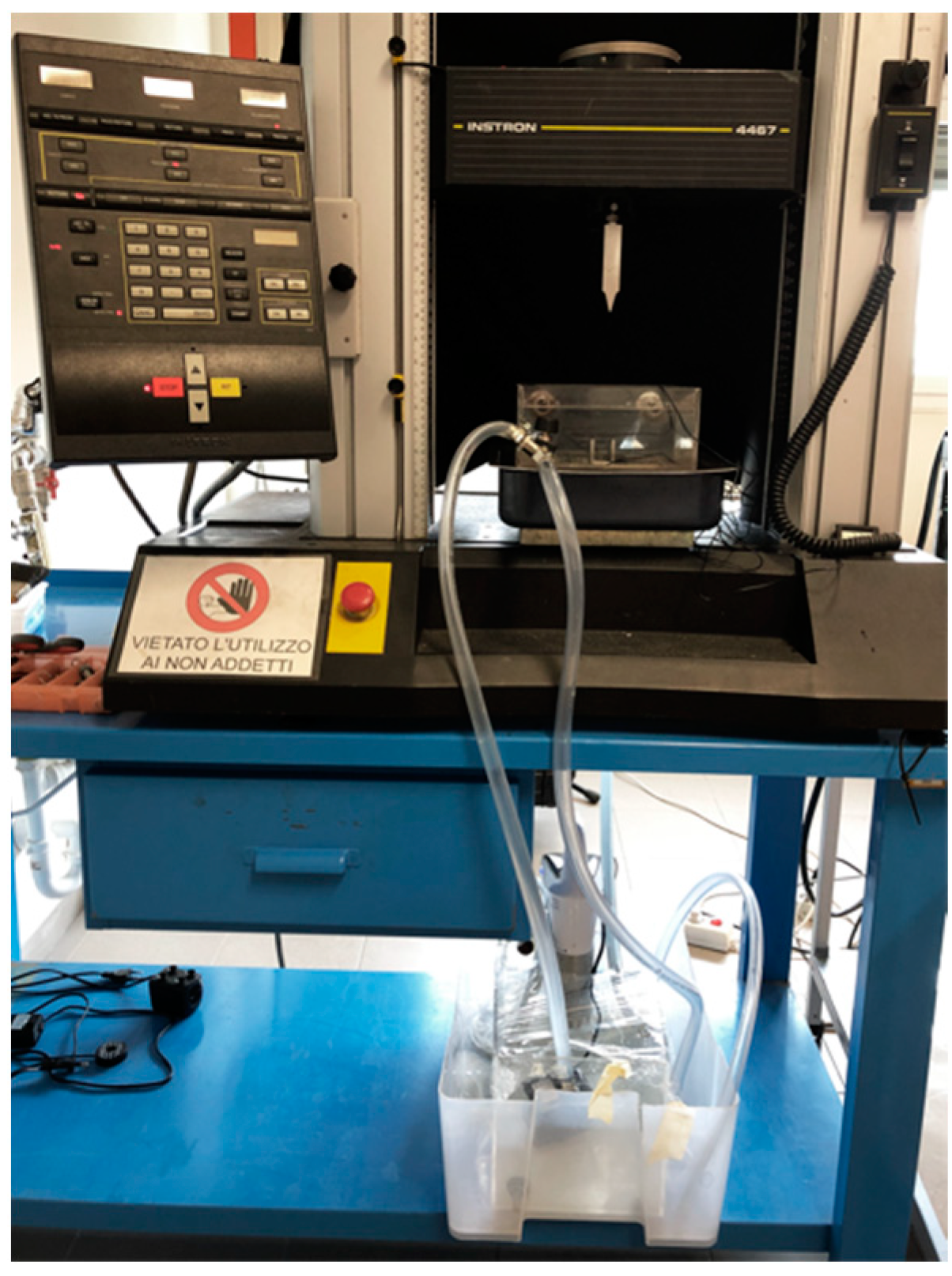

2.1. Yield Strength Testing

2.2. Stress Relaxation Testing

3. Results

3.1. Yield Strength Testing

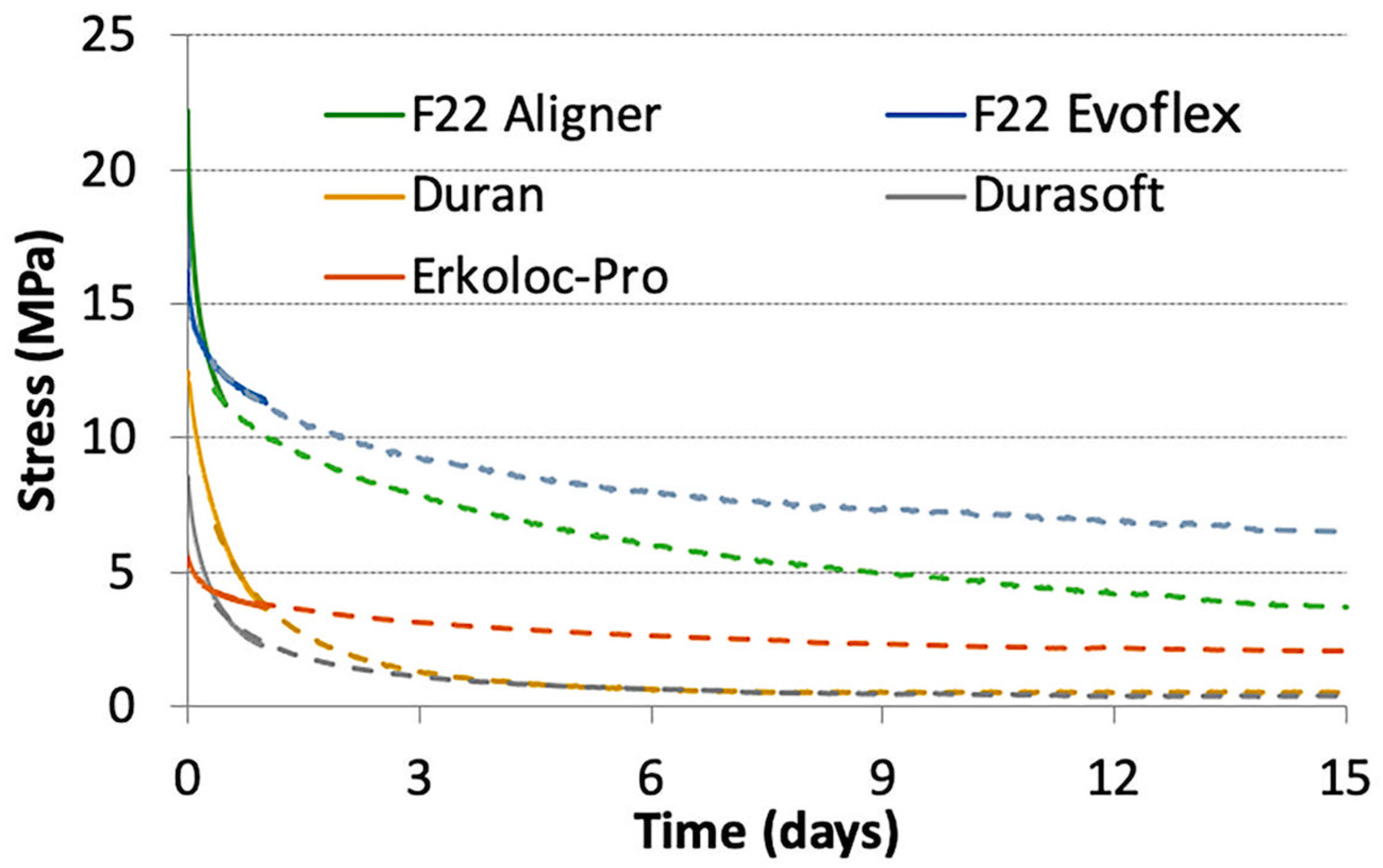

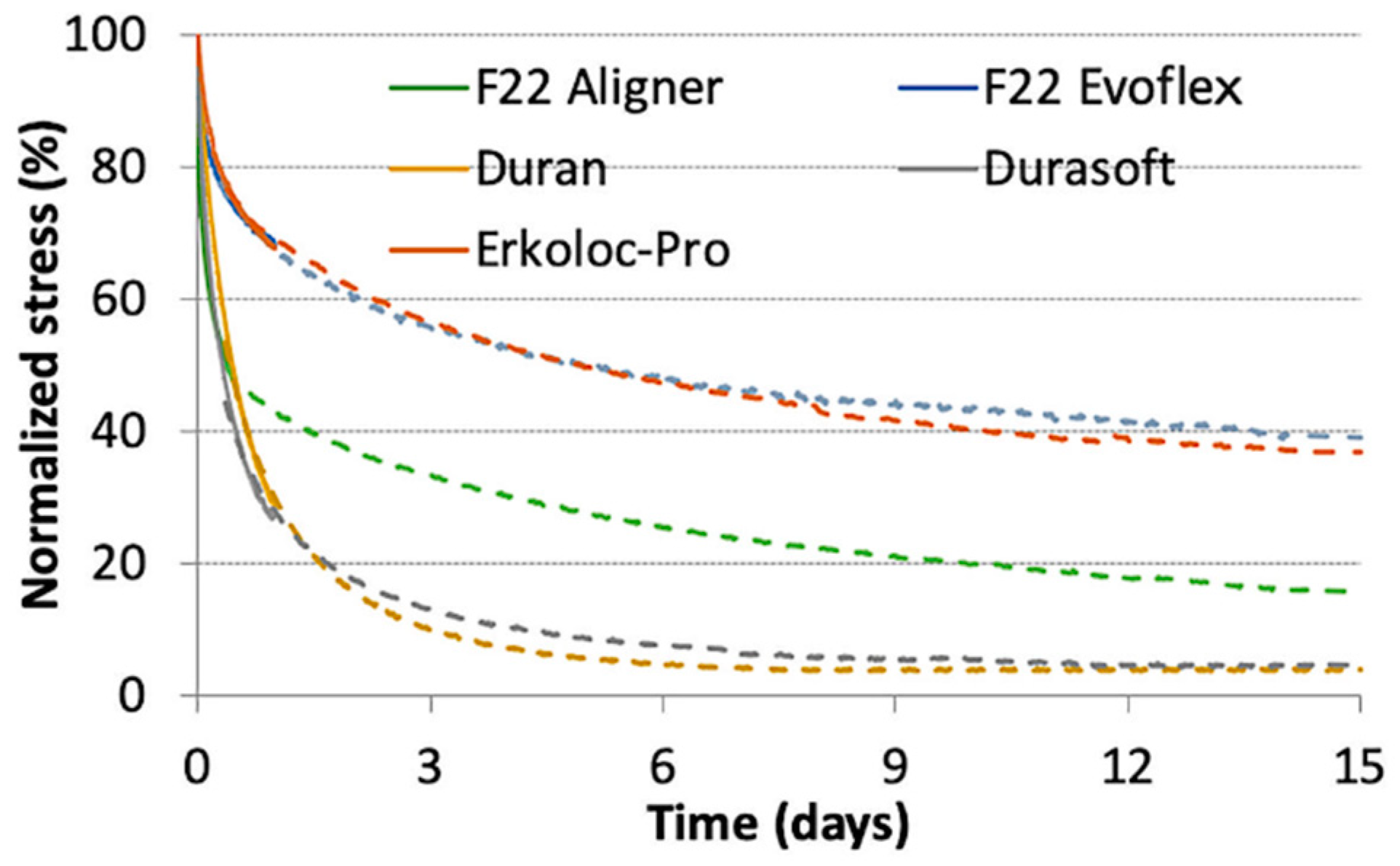

3.2. Stress Relaxation Testing

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rosvall, M.D.; Fields, H.W.; Ziuchkovski, J.; Rosenstiel, S.F.; Johnston, W.M. Attractiveness, acceptability, and value of orthodontic appliances. Am. J. Orthod. Dentofac. Orthop. 2009, 135, 276.e1–277. [Google Scholar] [CrossRef]

- Kwon, J.S.; Lee, Y.K.; Lim, B.S.; Lim, Y.K. Force delivery properties of thermoplastic orthodontic materials. Am. J. Orthod. Dentofac. Orthop. 2008, 133, 228–234. [Google Scholar] [CrossRef] [PubMed]

- Ryokawa, H.; Miyazaki, Y.; Fujishima, A.; Miyazaki, T.; Maki, K. The mechanical properties of dental thermoplastic materials in a simulated intraoral environment. Orthod. Waves 2006, 65, 64–72. [Google Scholar] [CrossRef]

- Dupaix, R.B.; Boyce, M.C. Finite strain behavior of polyethylene terephthalate (PET) and poly (ethylene terephthalate)- glycol (PETG). Polymer 2005, 46, 4827–4838. [Google Scholar] [CrossRef]

- Guarneri, M.P.; Lombardo, L.; Gracco, A.; Siciliani, G. The State of the Art of Clean Aligner Technique; Martina Editor: Bologna, Italy, 2013; pp. 15–24. (In Italian) [Google Scholar]

- Li, X.; Ren, C.; Wang, Z.; Zhao, P.; Wang, H.; Bai, Y. Changes in force associated with the amount of aligner activation and lingual bodily movement of the maxillary central incisor. Korean J. Orthod. 2016, 46, 65–72. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hahn, W.; Fialka-Fricke, J.; Dathe, H.; Fricke-Zech, S.; Zapf, A.; Gruber, R.; Kubein-Meesenburg, D.; Sadat-Khonsari, R. Initial forces generated by three types of thermoplastic appliances on an upper central incisor during tipping. Eur. J. Orthod. 2009, 31, 625–631. [Google Scholar] [CrossRef]

- Elkholy, F.; Panchaphongsaphak, T.; Kilic, F.; Schmidt, F.; Lapatki, B.G. Forces and moments delivered by PET-G aligners to an upper central incisor for labial and palatal translation. J. Orofac Orthop 2015, 76, 460–475. [Google Scholar] [CrossRef]

- Ren, Y.; Maltha, J.C.; Kuijpers-Jagtman, A.M. Optimum force magnitude for orthodontic tooth movement: A systematic literature review. Angle Orthod. 2003, 73, 86–92. [Google Scholar] [CrossRef]

- Lombardo, L.; Marafioti, M.; Stefanoni, F.; Mollica, F.; Siciliani, G. Load deflection characteristics and force level of nickel titanium initial archwires. Angle Orthod. 2012, 82, 507–521. [Google Scholar] [CrossRef] [Green Version]

- Boyd, R.; Miller, R.J.; Vlaskalic, V. The Invisalign system in adult orthodontics: Mild crowding and space closure cases. J. Clin. Orthod. 2000, 34, 13–15. [Google Scholar]

- Kim, T.W.; Echarri, P. Clear aligner: An efficient, esthetic, and comfortable option for an adult patient. World J. Orthod. 2007, 8, 13–18. [Google Scholar]

- Fang, D.; Zhang, N.; Chen, H.; Bai, Y. Dynamic stress relaxation of orthodontic thermoplastic materials in a simulated oral environment. Dent. Mater. J. 2013, 32, 946–951. [Google Scholar] [CrossRef] [Green Version]

- Kravitz, N.D.; Kusnoto, B.; BeGole, E.; Obrez, A.; Agran, B. How well does Invisalign work? A prospective clinical study evaluating the efficacy of tooth movement with Invisalign. Am. J. Orthod. Dentofac. Orthop. 2009, 135, 27–35. [Google Scholar] [CrossRef]

- Jamari, J.; Ammarullah, M.I.; Santoso, G.; Sugiharto, S.; Supriyono, T.; Prakoso, A.T.; Basri, H.; van der Heide, E. Computational Contact Pressure Prediction of CoCrMo, SS 316L and Ti6Al4V Femoral Head against UHMWPE Acetabular Cup under Gait Cycle. J. Funct. Biomater. 2022, 13, 64. [Google Scholar] [CrossRef]

- Schuster, S.; Eliades, G.; Zinelis, S.; Eliades, T.; Bradley, T.G. Structural conformation and leaching from in vitro aged and retrieved Invisalign appliances. Am. J. Orthod. Dentofac. Orthop. 2004, 126, 725–728. [Google Scholar] [CrossRef]

- Kohda, N.; Iijima, M.; Muguruma, T.; Brantley, W.A.; Ahluwalia, K.S.; Mizoguchi, I. Effects of mechanical properties of thermoplastic materials on the initial force of thermoplastic appliances. Angle Orthod. 2013, 83, 476–483. [Google Scholar] [CrossRef]

- Zhang, N.; Bai, Y.; Ding, X.; Zhang, Y. Preparation and characterization of thermoplastic materials for invisible orthodontics. Dent. Mater. J. 2011, 30, 954–959. [Google Scholar] [CrossRef] [Green Version]

- Lombardo, L.; Martines, E.; Mazzanti, V.; Arreghini, A.; Mollica, F.; Siciliani, G. Stress relaxation properties of four orthodontic aligner materials: A 24-hour in vitro study. Angle Orthod. 2017, 87, 11–18. [Google Scholar] [CrossRef] [Green Version]

- Iijima, M.; Kohda, N.; Kawaguchi, K.; Muguruma, T.; Ohta, M.; Naganishi, A.; Murakami, T.; Mizoguchi, I. Effects of temperature changes and stress loading on the mechanical and shape memory properties of thermoplastic materials with different glass transition behaviours and crystal structures. Eur. J. Orthod. 2015, 37, 665–670. [Google Scholar] [CrossRef]

- Wineman, A.S.; Rajagopal, K.R. Mechanical Response of Polymers; Cambridge University Press: Cambridge, UK, 2000; pp. 67–72. [Google Scholar]

- Zheng, M.; Liu, R.; Ni, Z.; Yu, Z. Efficiency, effectiveness and treatment stability of clear aligners: A systematic review and meta-analysis. Orthod. Craniofacial Res. 2017, 20, 127–133. [Google Scholar] [CrossRef]

- Proffit, W.R. Contemporary Orthodontics; Mosby-Year Book Inc.: St Louis, CA, USA, 1999; pp. 296–325. [Google Scholar]

- Inoue, S.; Yamaguchi, S.; Uyama, H.; Yamashiro, T.; Imazato, S. Orthodontic Aligner Incorporating Eucommia ulmoides Exerts Low Continuous Force: In Vitro Study. Materials 2020, 13, 4085. [Google Scholar] [CrossRef] [PubMed]

- Inoue, S.; Yamaguchi, S.; Uyama, H.; Yamashiro, T.; Imazato, S. Influence of constant strain on the elasticity of thermoplastic orthodontic materials. Dent. Mater. J. 2020, 39, 415–421. [Google Scholar] [CrossRef] [Green Version]

- Williams, M.L.; Landel, R.F.; Ferry, J.D. The temperature dependence of relaxation mechanisms in amorphous polymers and other glass forming liquids. J. Am. Chem. Soc. 1955, 77, 3701–3707. [Google Scholar]

- Mazzanti, V.; Mollica, F. Rheological behavior of wood flour filled poly(lactic acid): Temperature and concentration dependence. Polym Comp. 2019, 40, E169–E176. [Google Scholar] [CrossRef]

| Brand Name | Manufacter | Material | Thickness (mm) |

|---|---|---|---|

| F22 Evoflex | Sweden & Martina (Due Carrare, Padua, Italy) | TPU a | 0.76 |

| F22 Aligner | Sweden & Martina (Due Carrare, Padua, Italy) | TPU | 0.76 |

| Duran | SCHEU (Iserlohn, Germany) | PET-G b | 0.75 |

| Erkoloc-Pro | Erkodent (Pfalzgrafenweiler, Germany) | PET-G/TPU | 1 |

| Durasoft | SCHEU (Iserlohn, Germany) | TPU/PC c | 1.2 |

| Name | Yield Strength (MPa) | One-Fourth Yield Strength (MPa) | Yield Strain (mm/mm) | Young’s Modulus (MPa) | Deflection at One-Fourth Yield Strength (mm) |

|---|---|---|---|---|---|

| F22 Aligner | 81.36 | 20.34 | 0.0424 | 2770 | 1.26 |

| F22 Evoflex | 72.35 | 18.08 | 0.0537 | 2104 | 1.21 |

| Duran | 61.63 | 15.41 | 0.0371 | 2366 | 1.04 |

| Erkoloc-Pro | 31.53 | 7.88 | 0.0672 | 597 | 1.45 |

| Durasoft | 27.57 | 6.89 | 0.0730 | 583 | 1.1 |

| Name | σ1 (MPa) | σ2 (MPa) | Stress Decay σ1–σ2 (MPa) |

|---|---|---|---|

| F22 Aligner | 22.2 | 3.7 | 18.5 |

| F22 Evoflex | 15.8 | 6.5 | 9.3 |

| Duran | 12 | 0.5 | 11.5 |

| Erkoloc-Pro | 5.2 | 2.1 | 3.1 |

| Durasoft | 7.8 | 0.4 | 7.4 |

| Time (Days) | ||||

|---|---|---|---|---|

| 0 | 5 | 10 | 15 | |

| Normalized stress (%) | ||||

| F22 Aligner | 100 | 27.4 | 19.9 | 15.7 |

| F22 Evoflex | 100 | 50.3 | 43.7 | 39.2 |

| Duran | 100 | 5.6 | 3.9 | 3.9 |

| Erkoloc-Pro | 100 | 49.8 | 40.2 | 36.9 |

| Durasoft | 100 | 8.6 | 5.3 | 4.6 |

| Stress decay (%) | ||||

| F22 Aligner | 0 | 72.6 | 80.1 | 84.3 |

| F22 Evoflex | 0 | 49.7 | 56.3 | 60.8 |

| Duran | 0 | 94.4 | 96.1 | 96.1 |

| Erkoloc-Pro | 0 | 51.2 | 59.8 | 63.1 |

| Durasoft | 0 | 91.4 | 94.7 | 95.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Albertini, P.; Mazzanti, V.; Mollica, F.; Pellitteri, F.; Palone, M.; Lombardo, L. Stress Relaxation Properties of Five Orthodontic Aligner Materials: A 14-Day In-Vitro Study. Bioengineering 2022, 9, 349. https://doi.org/10.3390/bioengineering9080349

Albertini P, Mazzanti V, Mollica F, Pellitteri F, Palone M, Lombardo L. Stress Relaxation Properties of Five Orthodontic Aligner Materials: A 14-Day In-Vitro Study. Bioengineering. 2022; 9(8):349. https://doi.org/10.3390/bioengineering9080349

Chicago/Turabian StyleAlbertini, Paolo, Valentina Mazzanti, Francesco Mollica, Federica Pellitteri, Mario Palone, and Luca Lombardo. 2022. "Stress Relaxation Properties of Five Orthodontic Aligner Materials: A 14-Day In-Vitro Study" Bioengineering 9, no. 8: 349. https://doi.org/10.3390/bioengineering9080349

APA StyleAlbertini, P., Mazzanti, V., Mollica, F., Pellitteri, F., Palone, M., & Lombardo, L. (2022). Stress Relaxation Properties of Five Orthodontic Aligner Materials: A 14-Day In-Vitro Study. Bioengineering, 9(8), 349. https://doi.org/10.3390/bioengineering9080349