Actuator and Contact Force Modeling of an Active Soft Brace for Scoliosis

Abstract

1. Introduction

2. Materials and Methods

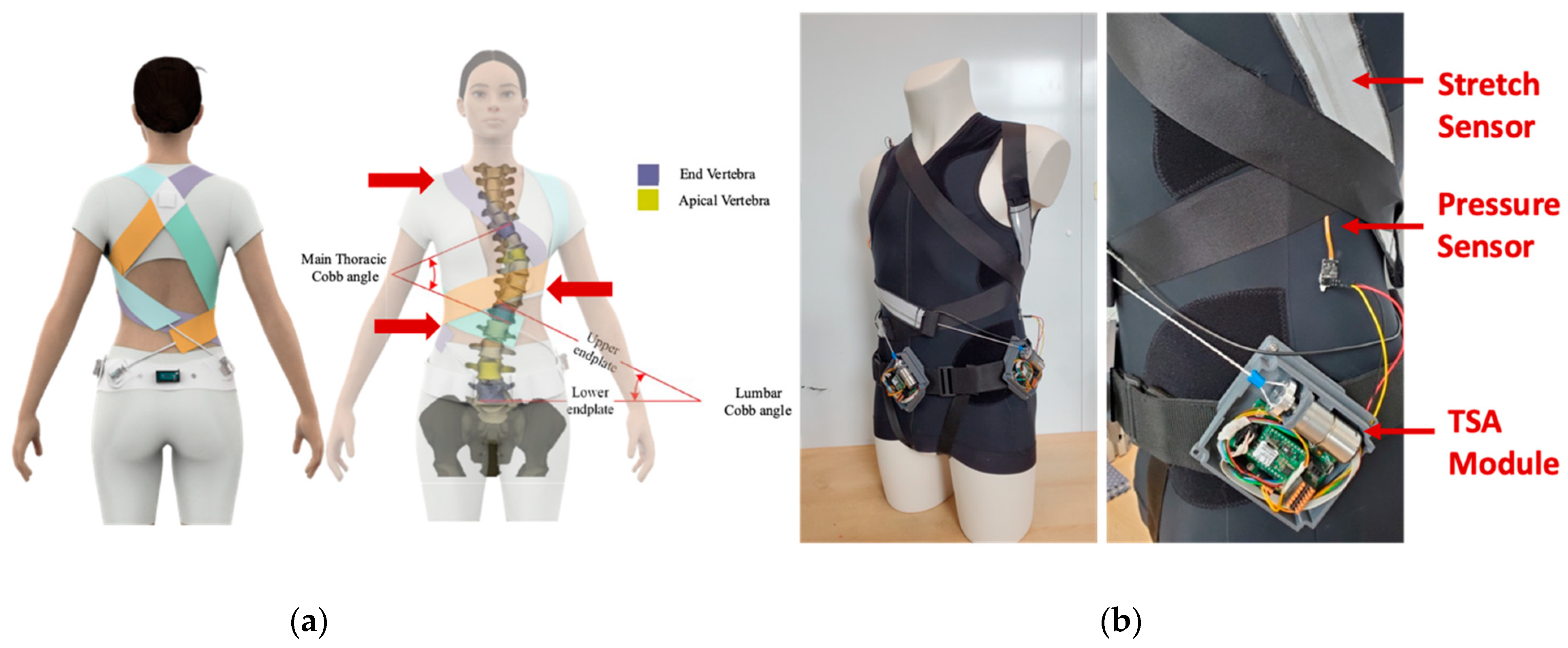

2.1. Device Working Principle and Design

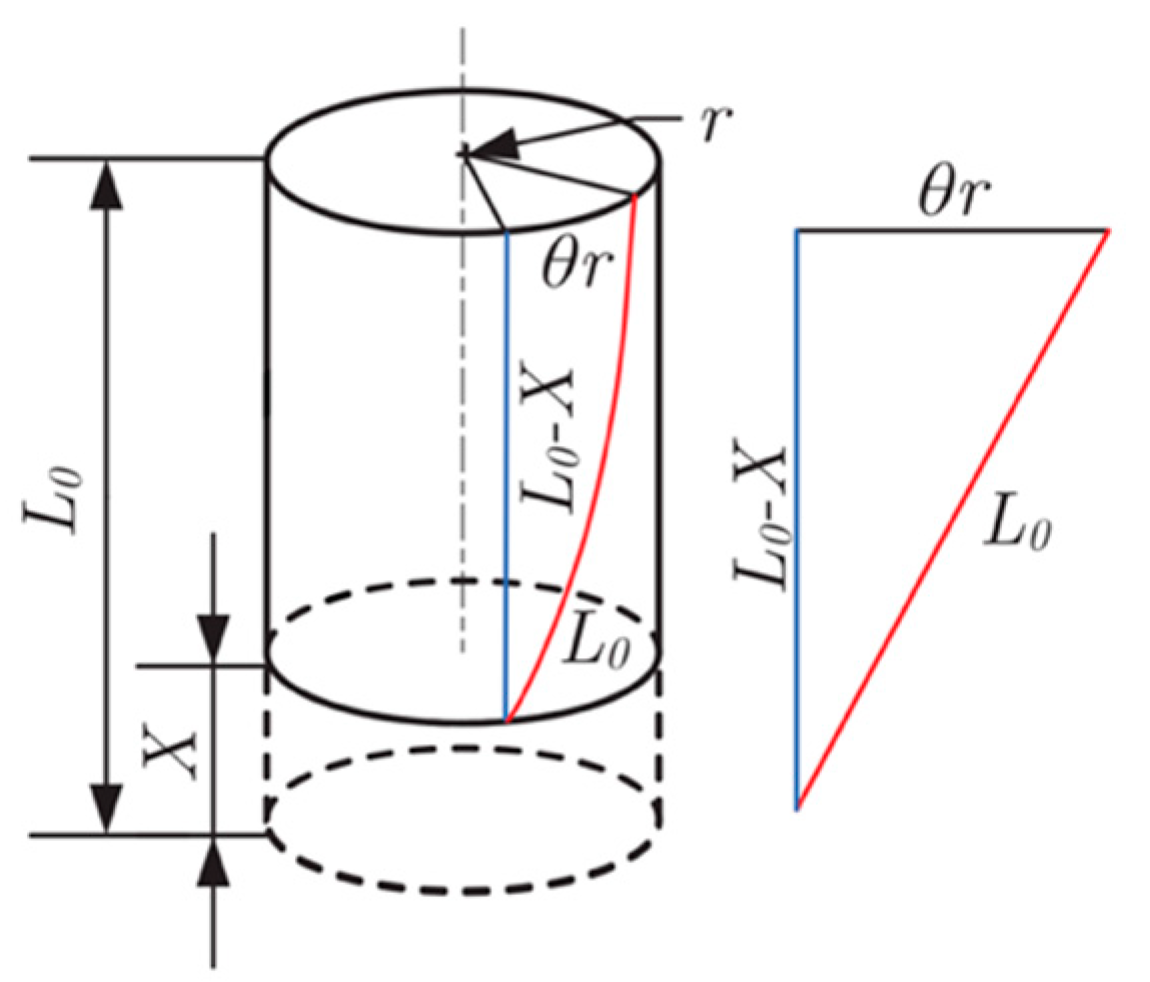

2.2. Actuation Module

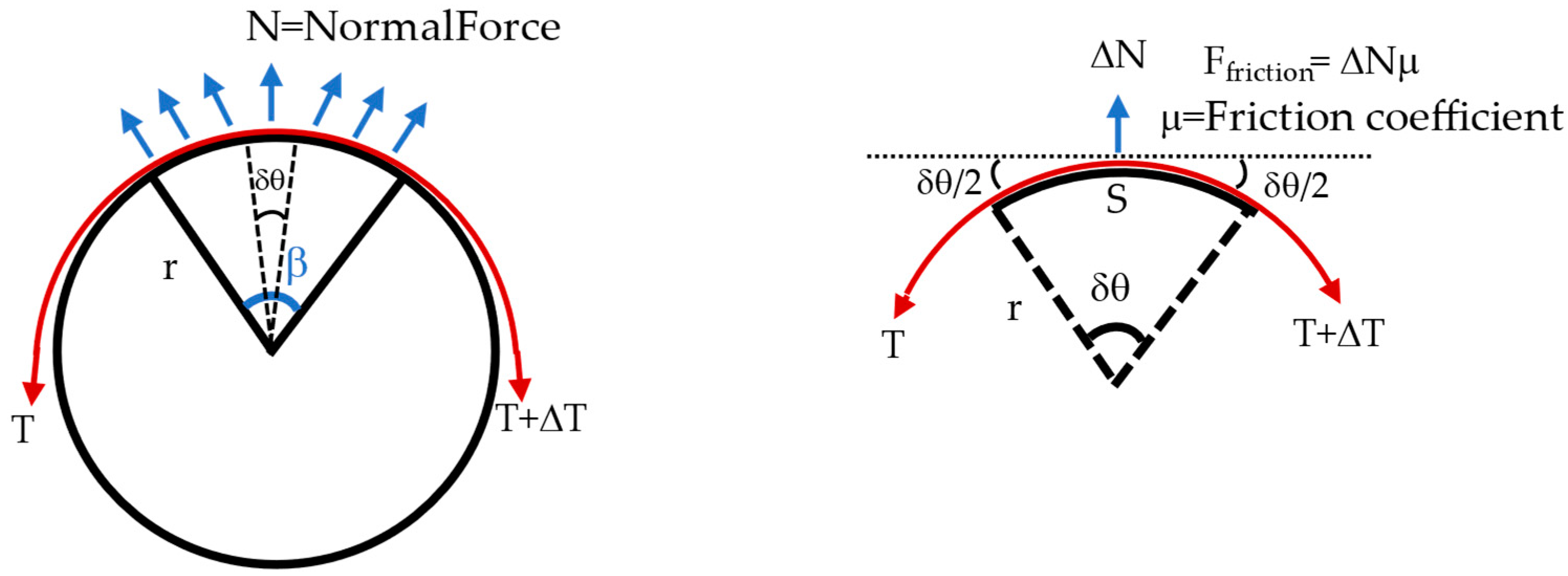

2.3. Contact Force Modeling

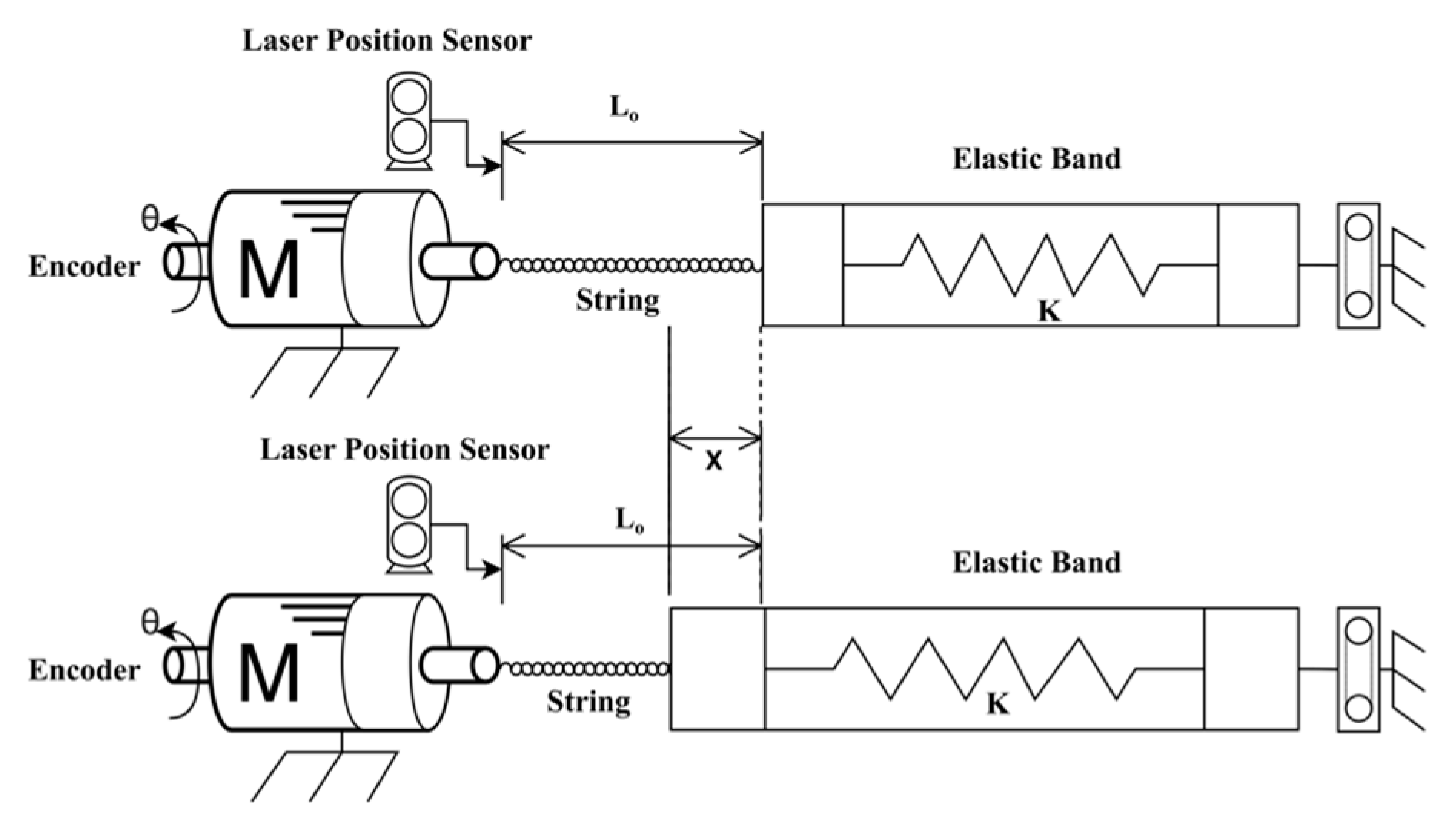

Testbed Setup

3. Results

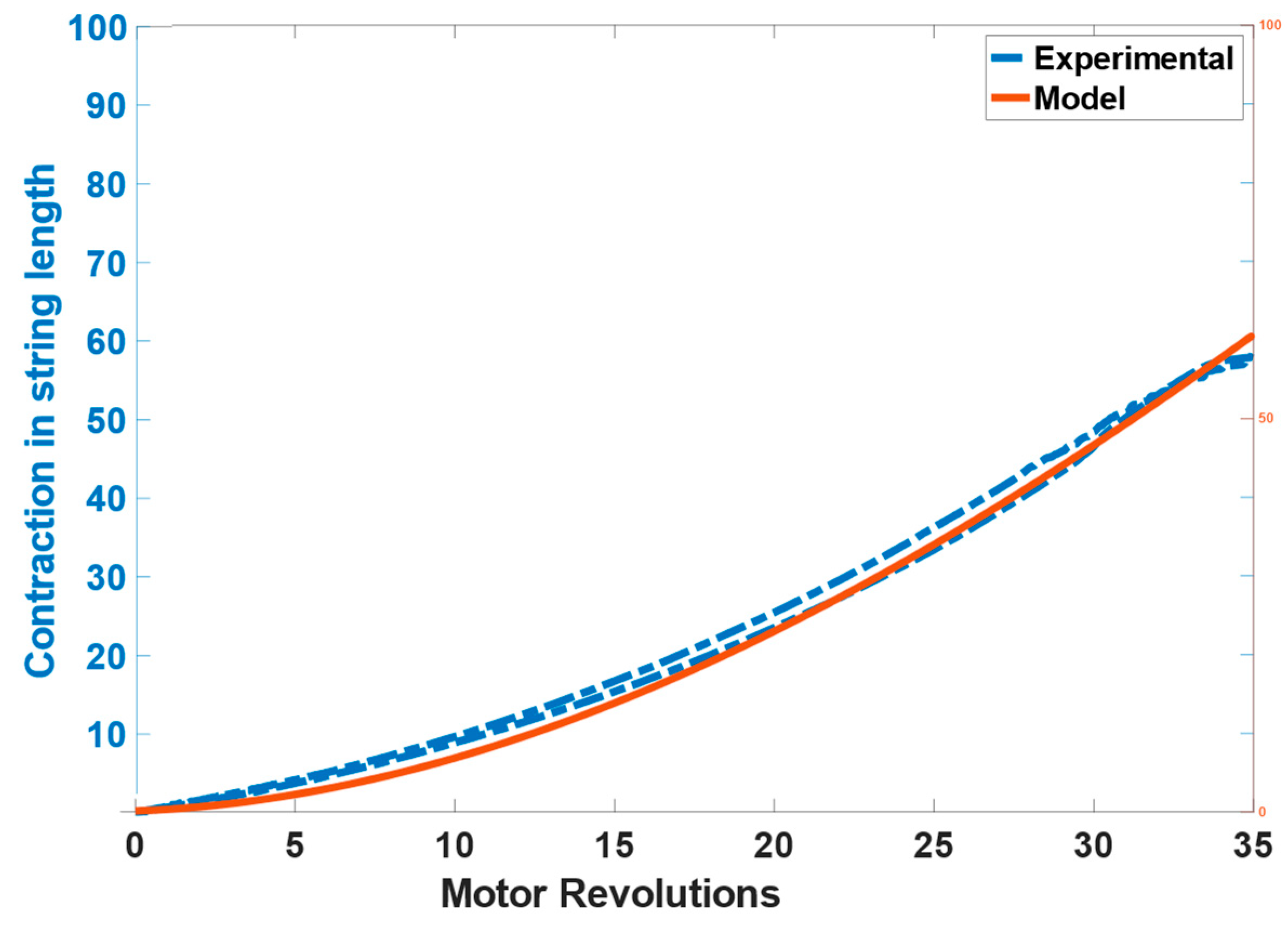

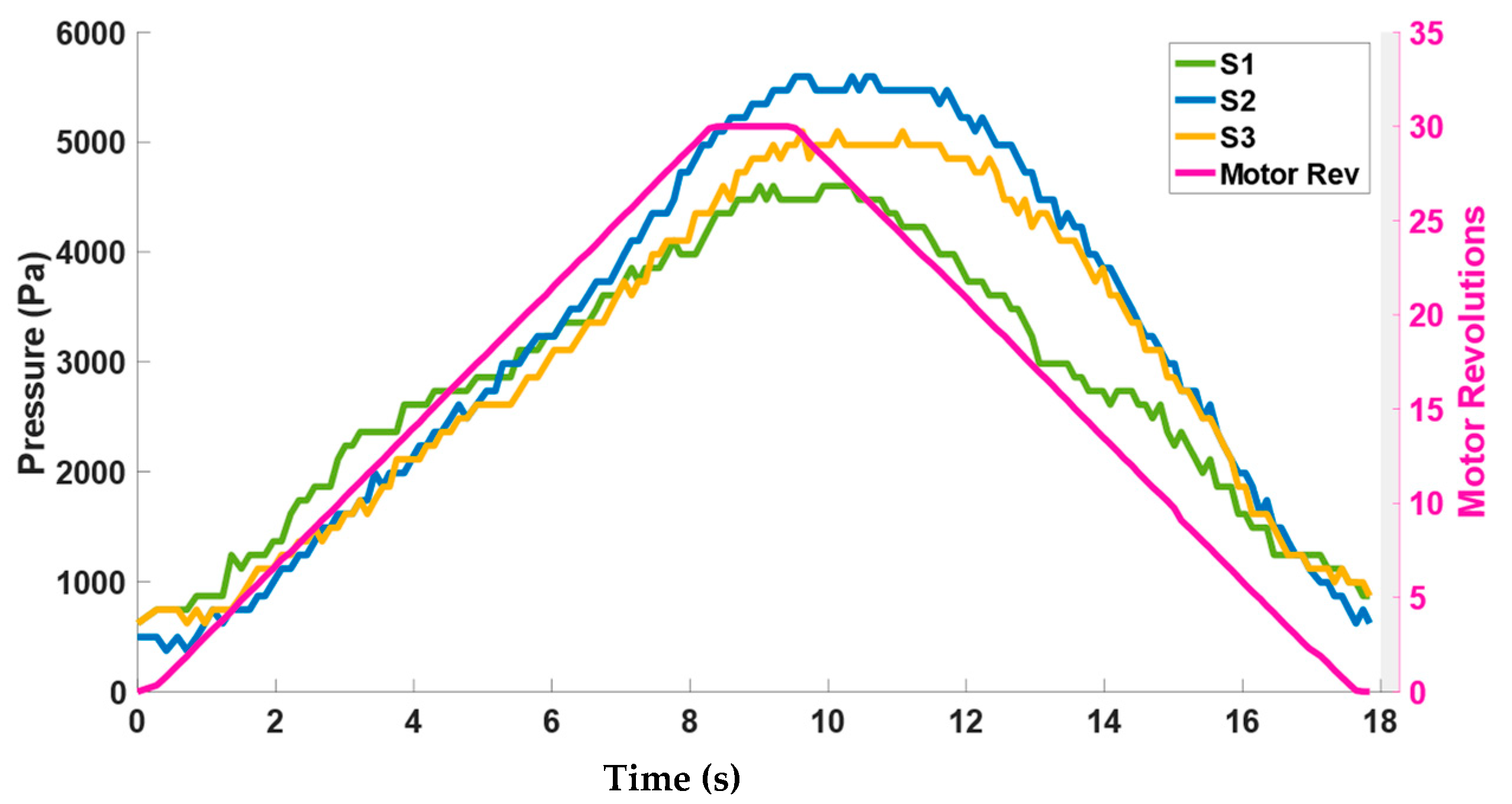

3.1. Actuator Modeling and Validation

3.2. Contact Force Modeling

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ogilvie, J. Adolescent idiopathic scoliosis and genetic testing. Curr. Opin. Pediatr. 2010, 22, 67–70. [Google Scholar] [CrossRef]

- Shakil, H.; Iqbal, Z.A.; Al-Ghadir, A.H. Scoliosis: Review of types of curves, etiological theories and conservative treatment. J. Back Musculoskelet. Rehabil. 2014, 27, 111–115. [Google Scholar] [CrossRef]

- Yaman, O.; Dalbayrak, S. Idiopathic scoliosis. Turk. Neurosurg. 2013, 24, 646–657. [Google Scholar] [CrossRef]

- Reamy, B.V.; Slakey, J.B. Adolescent idiopathic scoliosis: Review and current concepts. Am. Fam. Physician 2001, 64, 111. [Google Scholar]

- Vialle, R.; Thévenin-Lemoine, C.; Mary, P. Neuromuscular scoliosis. Orthop. Traumatol. Surg. Res. 2013, 99, S124–S139. [Google Scholar] [CrossRef]

- Janicki, A.J.; Alman, B. Scoliosis: Review of diagnosis and treatment. Paediatr. Child Health 2007, 12, 771–776. [Google Scholar] [CrossRef]

- Lee, G.B.; Priefer, D.T.; Priefer, R. Scoliosis: Causes and Treatments. Adolescents 2022, 2, 18. [Google Scholar] [CrossRef]

- Kotwicki, T.; Chowanska, J.; Kinel, E.; Czaprowski, D.; Janusz, P.; Tomaszewski, M. Optimal management of idiopathic scoliosis in adolescence. Adolesc. Health Med. Ther. 2013, 4, 59–73. [Google Scholar] [CrossRef][Green Version]

- Niu, X.; Yang, C.; Tian, B.; Li, X.; Zheng, S.; Cong, D.; Han, J.; Agrawal, S.K. Investigation of Robotic Braces of Patients with Idiopathic Scoliosis (IS)—Review of the Literature and Description of a Novel Brace. J. Mech. Med. Biol. 2018, 18, 1840038. [Google Scholar] [CrossRef]

- Lonstein, E.J.; Winter, R.B. The Milwaukee brace for the treatment of adolescent idiopathic scoliosis. A review of one thousand and twenty patients. J. Bone Jt. Surg. 1994, 76, 1207–1221. [Google Scholar] [CrossRef]

- Maruyama, T.; Takesita, K.; Kitagawa, T.; Nakao, Y. Milwaukee Brace. Physiother. Theory Pract 2011, 27, 43–46. [Google Scholar] [CrossRef]

- Noonan, K.J.; Weinstein, S.L.; Jacobson, W.C.; Dolan, L.A. Use of the Milwaukee Brace for Progressive Idiopathic Scoliosis. J. Bone Jt. Surg. 1996, 78, 557–567. [Google Scholar] [CrossRef]

- Blount, W.P.; Schmidt, A.C.; Keever, E.D.; Leonard, E.T. The Milwaukee Brace in the Operative Treatment of Scoliosis. J. Bone Jt. Surg. 1958, 40, 511–525. [Google Scholar] [CrossRef]

- Danielsson, A.J.; Hasserius, R.; Ohlin, A.; Nachemson, A.L. A Prospective Study of Brace Treatment versus Observation Alone in Adolescent Idiopathic Scoliosis: A Follow-up Mean of 16 Years after Maturity. Spine 2007, 32, 2198–2207. [Google Scholar] [CrossRef]

- Emans, J.B.; Kaelin, A.; Bancel, P.; Hall, J.E.; Miller, M.E. The Boston Bracing System for Idiopathic Scoliosis: Follow-up Results in 295 Patients. Spine 1986, 11, 792–801. [Google Scholar] [CrossRef]

- Heary, R.F.; Kumar, S.; Bono, C.M. Bracing for Scoliosis. Neurosurgery 2008, 63, A125–A130. [Google Scholar] [CrossRef]

- Negrini, S.; Marchini, G. Efficacy of the symmetric, patient-oriented, rigid, three-dimensional, active (SPoRT) concept of bracing for scoliosis: A prospective study of the Sforzesco versus Lyon brace. Eur. Med. 2006, 43, 171–181. [Google Scholar]

- Zaina, F.; Negrini, S.; Fusco, C.; Atanasio, S. How to improve aesthetics in patients with Adolescent Idiopathic Scoliosis (AIS): A SPoRT brace treatment according to SOSORT management criteria. Scoliosis 2009, 4, 18. [Google Scholar] [CrossRef]

- Hopf, C.; Heine, J. Long-Term Results of the Conservative Treatment of Scoliosis Using the Cheneau Brace. Z. Orthop. Ihre Grenzgeb. 1985, 123, 312–322. [Google Scholar] [CrossRef]

- Zaborowska-Sapeta, K.; Kowalski, I.M.; Kotwicki, T.; Protasiewicz-Fałdowska, H.; Kiebzak, W. Effectiveness of Chêneau brace treatment for idiopathic scoliosis: Prospective study in 79 patients followed to skeletal maturity. Scoliosis 2011, 6, 2. [Google Scholar] [CrossRef]

- De Giorgi, S.; Piazzolla, A.; Tafuri, S.; Borracci, C.; Martucci, A.; De Giorgi, G. Chêneau brace for adolescent idiopathic scoliosis: Long-term results. Can it prevent surgery? Eur. Spine J. 2013, 22, 815–822. [Google Scholar] [CrossRef] [PubMed]

- Dolan, L.A.; Donzelli, S.; Zaina, F.; Weinstein, S.L.; Negrini, S. Adolescent Idiopathic Scoliosis Bracing Success Is Influenced by Time in Brace: Comparative Effectiveness Analysis of BrAIST and ISICO Cohorts. Spine 2020, 45, 1193–1199. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.S.; Hwang, C.J.; Kim, D.-J.; Kim, J.H.; Kim, Y.-T.; Lee, M.Y.; Yoon, S.J.; Lee, D.-H. Effectiveness of the Charleston Night-time Bending Brace in the Treatment of Adolescent Idiopathic Scoliosis. J. Pediatr. Orthop. 2012, 32, 368–372. [Google Scholar] [CrossRef]

- Wiemann, J.M.; Shah, S.A.; Price, C.T. Nighttime Bracing Versus Observation for Early Adolescent Idiopathic Scoliosis. J. Pediatr. Orthop. 2014, 34, 603–606. [Google Scholar] [CrossRef]

- Coillard, C.; Leroux, M.A.; Zabjek, K.F.; Rivard, C. SpineCor—A non-rigid brace for the treatment of idiopathic scoliosis: Post-treatment results. Eur. Spine J. 2003, 12, 141–148. [Google Scholar] [CrossRef] [PubMed]

- Weiss, H.-R.; Werkmann, M. Retraction Note: Soft braces in the treatment of Adolescent Idiopathic Scoliosis (AIS)—Review of the literature and description of a new approach. Scoliosis 2013, 8, 7. [Google Scholar] [CrossRef]

- van Loon, P.J.M.; Kühbauch, B.A.G.; Thunnissen, F.B. Forced Lordosis on the Thoracolumbar Junction Can Correct Coronal Plane Deformity in Adolescents with Double Major Curve Pattern Idiopathic Scoliosis. Spine 2008, 33, 797–801. [Google Scholar] [CrossRef]

- Veldhuizen, A.; Cheung, J.; Bulthuis, G.; Nijenbanning, G. A new orthotic device in the non-operative treatment of idiopathic scoliosis. Med. Eng. Phys. 2002, 24, 209–218. [Google Scholar] [CrossRef]

- Weinstein, S.L.; Dolan, L.A.; Wright, J.G.; Dobbs, M.B. Effects of Bracing in Adolescents with Idiopathic Scoliosis. N. Engl. J. Med. 2013, 369, 1512–1521. [Google Scholar] [CrossRef]

- Park, J.-H.; Stegall, P.R.; Roye, D.P.; Agrawal, S.K. Robotic Spine Exoskeleton (RoSE): Characterizing the 3-D Stiffness of the Human Torso in the Treatment of Spine Deformity. IEEE Trans. Neural Syst. Rehabil. Eng. 2018, 26, 1026–1035. [Google Scholar] [CrossRef]

- Negrini, S.; Donzelli, S.; Aulisa, A.G.; Czaprowski, D.; Schreiber, S.; De Mauroy, J.C.; Diers, H.; Grivas, T.B.; Knott, P.; Kotwicki, T.; et al. 2016 SOSORT guidelines: Orthopaedic and rehabilitation treatment of idiopathic scoliosis during growth. Scoliosis Spinal Disord. 2018, 13, 3. [Google Scholar] [CrossRef] [PubMed]

- Wong, M.S.; Cheng, J.; Lam, T.P.; Ng, B.K.W.; Sin, S.W.; Lee-Shum, S.L.F.; Chow, H.K.D.; Tam, S.Y.P. The Effect of Rigid Versus Flexible Spinal Orthosis on the Clinical Efficacy and Acceptance of the Patients with Adolescent Idiopathic Scoliosis. Spine 2008, 33, 1360–1365. [Google Scholar] [CrossRef] [PubMed]

- Weiss, H.-R. SpineCor vs. Natural History—Explanation of the results obtained using a simple biomechanical model. In Research into Spinal Deformities 6; IOS Press: Amsterdam, The Netherlands, 2008. [Google Scholar] [CrossRef]

- Murray, R.C.; Ophaswongse, C.; Park, J.-H.; Agrawal, S.K. Characterizing Torso Stiffness in Female Adolescents with and without Scoliosis. IEEE Robot. Autom. Lett. 2020, 5, 1634–1641. [Google Scholar] [CrossRef]

- Igor, G.; Ryu, J.H.; Nedelchev, S. Twisted String Actuation Systems: Applications, Modelling, and Control; Elsevier Science: Oxford, UK, 2021; ISBN 9780128141953. [Google Scholar]

- Pham, V.M.; Houilliez, A.; Schill, A.; Carpentier, A.; Herbaux, B.; Thevenon, A. Study of the pressures applied by a Chêneau brace for correction of adolescent idiopathic scoliosis. Prosthet. Orthot. Int. 2008, 32, 345–355. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.; Fontanari, V.; Schmölz, W.; Agrawal, S.K. Active Soft Brace for Scoliotic Spine: A Finite Element Study to Evaluate in-Brace Correction. Robotics 2022, 11, 37. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, A.; Fontanari, V.; Schmoelz, W.; Fontana, M. Actuator and Contact Force Modeling of an Active Soft Brace for Scoliosis. Bioengineering 2022, 9, 303. https://doi.org/10.3390/bioengineering9070303

Ali A, Fontanari V, Schmoelz W, Fontana M. Actuator and Contact Force Modeling of an Active Soft Brace for Scoliosis. Bioengineering. 2022; 9(7):303. https://doi.org/10.3390/bioengineering9070303

Chicago/Turabian StyleAli, Athar, Vigilio Fontanari, Werner Schmoelz, and Marco Fontana. 2022. "Actuator and Contact Force Modeling of an Active Soft Brace for Scoliosis" Bioengineering 9, no. 7: 303. https://doi.org/10.3390/bioengineering9070303

APA StyleAli, A., Fontanari, V., Schmoelz, W., & Fontana, M. (2022). Actuator and Contact Force Modeling of an Active Soft Brace for Scoliosis. Bioengineering, 9(7), 303. https://doi.org/10.3390/bioengineering9070303