A Safety Limit of the Number of Artificial Canals That Can Be Prepared by Two Rotary Endodontic Files Operated at Two Different Speeds: A Novel Approach

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Specifications

2.2. Preparation of the Simulated Canals

2.3. Irrigation Protocol

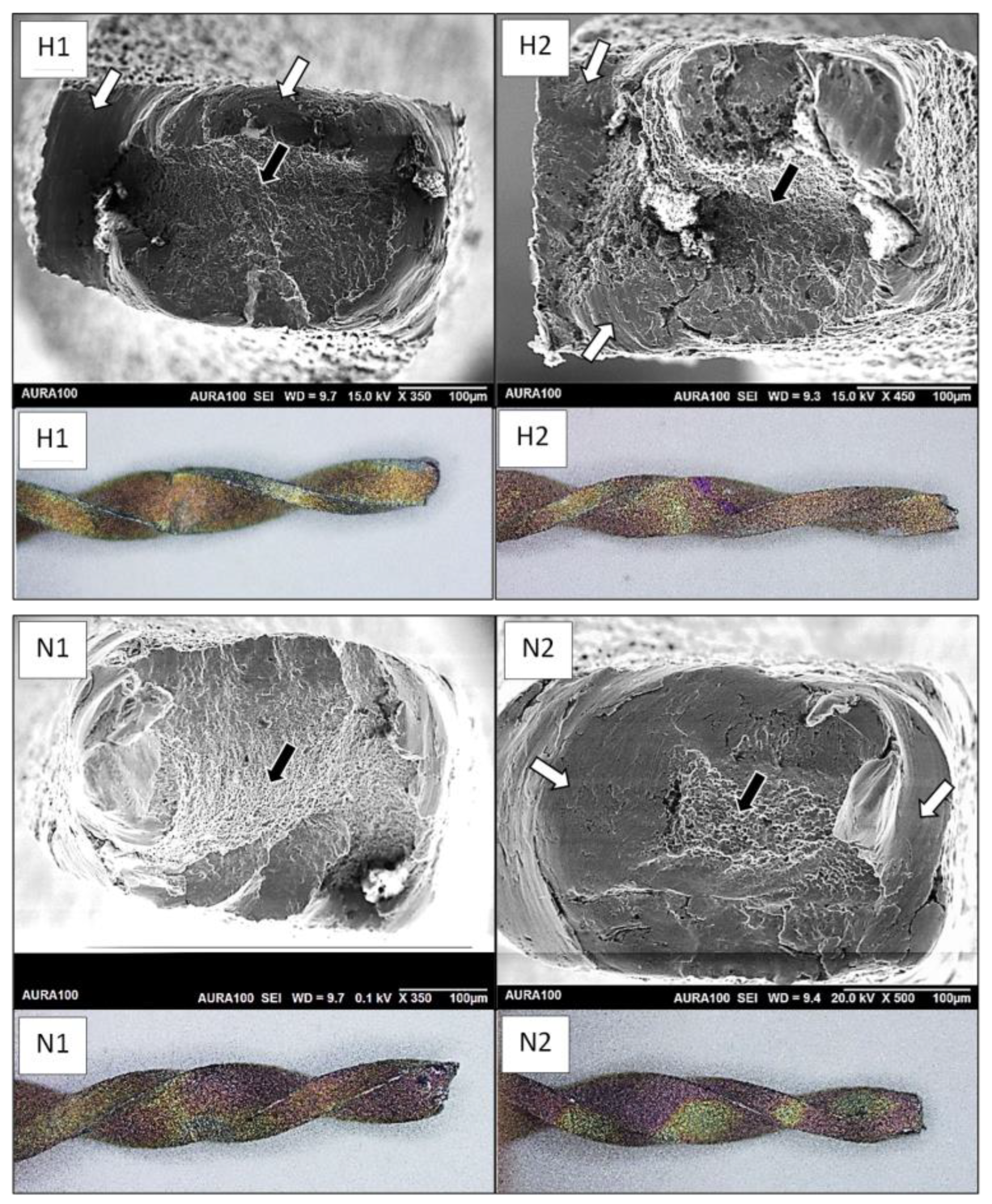

2.4. Fractography

2.5. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Walia, H.; Brantley, W.A.; Gerstein, H. An initial investigation of the bending and torsional properties of Nitinol root canal files. J. Endod. 1988, 14, 346–351. [Google Scholar] [CrossRef]

- Arias, A.; Peters, O.A. Present status and future directions: Canal shaping. Int. Endod. J. 2022, 55, 637–655. [Google Scholar] [CrossRef] [PubMed]

- Del Fabbro, M.; Afrashtehfar, K.I.; Corbella, S.; El-Kabbaney, A.; Perondi, I.; Taschieri, S. In vivo and in vitro effectiveness of rotary nickel-titanium vs manual stainless steel instruments for root canal therapy: Systematic review and meta-analysis. J. Evid. Based Dent. Pract. 2018, 18, 59–69. [Google Scholar] [CrossRef]

- Peralta-Mamani, M.; Rios, D.; Duarte, M.A.H.; Santiago Junior, J.F.; Honorio, H.M. Manual vs. rotary instrumentation in endodontic treatment of permanent teeth: A systematic review and meta-analysis. Am. J. Dent. 2019, 32, 311–324. [Google Scholar] [PubMed]

- Buerklein, S.; Arias, A. Effectiveness of root canal instrumentation for the treatment of apical periodontitis: A systematic review and meta-analysis. Int. Endod. J. 2023, 56, 395–421. [Google Scholar] [CrossRef] [PubMed]

- Sattapan, B.; Nervo, G.J.; Palamara, J.E.; Messer, H.H. Defects in rotary nickel-titanium files after clinical use. J. Endod. 2000, 26, 161–165. [Google Scholar] [CrossRef]

- Hülsmann, M.; Donnermeyer, D.; Schäfer, E. A critical appraisal of studies on cyclic fatigue resistance of engine-driven endodontic instruments. Int. Endod. J. 2019, 52, 1427–1445. [Google Scholar] [CrossRef]

- Kwak, S.W.; Shen, Y.; Liu, H.; Kim, H.-C.; Haapasalo, M. Torque generation of the endodontic instruments: A narrative review. Materials 2022, 15, 664. [Google Scholar] [CrossRef]

- Plotino, G.; Grande, N.M.; Cordaro, M.; Testarelli, L.; Gambarini, G. A review of cyclic fatigue testing of nickel-titanium rotary instruments. J. Endod. 2009, 35, 1469–1476. [Google Scholar] [CrossRef]

- Lee, J.Y.; Kwak, S.W.; Ha, J.-H.; Kim, H.-C. Ex-Vivo comparison of torsional stress on nickel–titanium instruments activated by continuous rotation or adaptive motion. Materials 2020, 13, 1900. [Google Scholar] [CrossRef]

- Orozco-Ocampo, Y.M.; Escobar-Rincón, D.; Jiménez-García, F.N.; Álvarez-Vargas, C.A.; Jaramillo-Gil, P.X. Factors influencing NiTi endodontic file separation: A thematic review. Dent. Med. Probl. 2024, 61, 269–278. [Google Scholar] [CrossRef] [PubMed]

- Lopes, H.P.; Ferreira, A.A.; Elias, C.N.; Moreira, E.J.; de Oliveira, J.C.M.; Siqueira, J.F., Jr. Influence of rotational speed on the cyclic fatigue of rotary nickel-titanium endodontic instruments. J. Endod. 2009, 35, 1013–1016. [Google Scholar] [CrossRef] [PubMed]

- Kwak, S.W.; Abu-Tahun, I.H.; Ha, J.-H.; Kim, H.-C. Torsional resistance of WaveOne Gold and Reciproc Blue according to the loading methods. J. Endod. 2021, 47, 88–93. [Google Scholar] [CrossRef]

- Theisen, W.; Schuermann, A. Electro discharge machining of nickel–titanium shape memory alloys. Mat. Sci. Eng. A 2004, 378, 200–204. [Google Scholar] [CrossRef]

- Pirani, C.; Iacono, F.; Generali, L.; Sassatelli, P.; Nucci, C.; Lusvarghi, L.; Gandolfi, M.G.; Prati, C. HyFlex EDM: Superficial features, metallurgical analysis and fatigue resistance of innovative electro discharge machined NiTi rotary instruments. Int. Endod. J. 2016, 49, 483–493. [Google Scholar] [CrossRef] [PubMed]

- Iacono, F.; Pirani, C.; Generali, L.; Bolelli, G.; Sassatelli, P.; Lusvarghi, L.; Gandolfi, M.; Giorgini, L.; Prati, C. Structural analysis of HyFlex EDM instruments. Int. Endod. J. 2017, 50, 303–313. [Google Scholar] [CrossRef]

- Kaval, M.E.; Capar, I.D.; Ertas, H. Evaluation of the cyclic fatigue and torsional resistance of novel nickel-titanium rotary files with various alloy properties. J. Endod. 2016, 42, 1840–1843. [Google Scholar] [CrossRef]

- Pedullà, E.; Savio, F.L.; Boninelli, S.; Plotino, G.; Grande, N.M.; La Rosa, G.; Rapisarda, E. Torsional and cyclic fatigue resistance of a new nickel-titanium instrument manufactured by electrical discharge machining. J. Endod. 2016, 42, 156–159. [Google Scholar] [CrossRef]

- Gündoğar, M.; Özyürek, T. Cyclic fatigue resistance of OneShape, HyFlex EDM, WaveOne Gold, and Reciproc Blue nickel-titanium instruments. J. Endod. 2017, 43, 1192–1196. [Google Scholar] [CrossRef]

- Goo, H.-J.; Kwak, S.W.; Ha, J.-H.; Pedullà, E.; Kim, H.-C. Mechanical properties of various heat-treated nickel-titanium rotary instruments. J. Endod. 2017, 43, 1872–1877. [Google Scholar] [CrossRef]

- Arias, A.; Macorra, J.C.; Govindjee, S.; Peters, O.A. Correlation between temperature-dependent fatigue resistance and differential scanning calorimetry analysis for 2 contemporary rotary instruments. J. Endod. 2018, 44, 630–634. [Google Scholar] [CrossRef]

- Moazzami, F.; Khojastepour, L.; Nabavizadeh, M.; Habashi, M.S. Cone-beam computed tomography assessment of root canal transportation by NeoNiTi and Reciproc single-file systems. Iran. Endod. J. 2016, 11, 96–100. [Google Scholar] [CrossRef]

- Aminsobhani, M.; Meraji, N.; Sadri, E. Comparison of cyclic fatigue resistance of five nickel titanium rotary file systems with different manufacturing techniques. J. Dent. 2015, 12, 636–646. [Google Scholar]

- Nabavizadeh, M.R.; Sedigh-Shams, M.; Abdolrasoulnia, S. Cyclic fatigue life of two single file engine-driven systems in simulated curved canals. Iran. Endod. J. 2018, 13, 61–65. [Google Scholar]

- Rubio, J.; Zarzosa, J.I.; Pallarés, A. A comparative study of cyclic fatigue of 10 different types of endodontic instruments: An in vitro study. Acta Stomatol. Croat. 2019, 53, 28–36. [Google Scholar] [CrossRef]

- Gayatri, K.; Tammineedi, S.; Bolla, N.; Vemuri, S.; Basam, R.C.; Sunil, C.R. Effect of autoclaving on the cyclic fatigue resistance of nickel-titanium rotary instruments: An in vitro study. J. Conserv. Dent. Endod. 2021, 24, 440–444. [Google Scholar] [CrossRef] [PubMed]

- Yum, H.-W.; Oh, S.; Perinpanayagam, H.; Gu, Y.; Chang, S.-W.; Yoo, Y.-J.; Kum, K.-Y. Phase transformation and mechanical behaviour of different heat-treated nickel-titanium rotary instruments. Int. Dent. J. 2025, 75, 1183–1193. [Google Scholar] [CrossRef] [PubMed]

- Silva, E.J.; Ajuz, N.C.; Martins, J.N.; Antunes, B.R.; Lima, C.O.; Vieira, V.T.; Braz-Fernandes, F.M.; Versiani, M.A. Multimethod analysis of three rotary instruments produced by electric discharge machining technology. Int. Endod. J. 2023, 56, 775–785. [Google Scholar] [CrossRef]

- Silva, E.J.; Martins, J.N.; Lima, C.O.; Vieira, V.T.; Fernandes, F.M.B.; De-Deus, G.; Versiani, M.A. Mechanical tests, metallurgical characterization, and shaping ability of nickel-titanium rotary instruments: A multimethod research. J. Endod. 2020, 46, 1485–1494. [Google Scholar] [CrossRef]

- Xu, J.; Shao, M.; Pan, H.; Lei, L.; Liu, T.; Cheng, L.; Hu, T.; Dummer, P. A proposal for using contralateral teeth to provide well-balanced experimental groups for endodontic studies. Int. Endod. J. 2016, 49, 1001–1008. [Google Scholar] [CrossRef]

- Johnsen, G.F.; Sunde, P.T.; Haugen, H.J. Validation of contralateral premolars as the substrate for endodontic comparison studies. Int. Endod. J. 2018, 51, 942–951. [Google Scholar] [CrossRef]

- Johnsen, G.F.; Haugen, H.; Nogueira, L.P.; Sevgi, U.; Jimenez, A.M.; DeLuca, J.T.; Mancuso, R.; Piasecki, L. Assessment of the root canal similarity in contralateral mandibular incisors. Int. Dent. J. 2023, 73, 71–78. [Google Scholar] [CrossRef] [PubMed]

- Sevgi, U.; Johnsen, G.F.; Hussain, B.; Piasecki, L.; Nogueira, L.P.; Haugen, H.J. Morphometric micro-CT study of contralateral mandibular incisors. Clin. Oral Investig. 2023, 28, 20. [Google Scholar] [CrossRef] [PubMed]

- Hülsmann, M. A critical appraisal of research methods and experimental models for studies on root canal preparation. Int. Endod. J. 2022, 55, 95–118. [Google Scholar] [CrossRef]

- Van Pham, K. Differential scanning calorimetric investigations of three rotary nickel-titanium instrument systems before and after simulated clinical uses. BMC Oral Health 2021, 21, 488. [Google Scholar] [CrossRef]

- Elnaghy, A.; Elsaka, S. Effect of sodium hypochlorite and saline on cyclic fatigue resistance of WaveOne Gold and Reciproc reciprocating instruments. Int. Endod. J. 2017, 50, 991–998. [Google Scholar] [CrossRef]

- Huang, X.; Shen, Y.; Wei, X.; Haapasalo, M. Fatigue resistance of nickel-titanium instruments exposed to high-concentration hypochlorite. J. Endod. 2017, 43, 1847–1851. [Google Scholar] [CrossRef]

- dos Reis-Prado, A.H.; Abreu, L.G.; de Arantes, L.C.; dos Santos de Paula, K.; de Castro Oliveira, S.; Goto, J.; Viana, A.C.D.; Benetti, F. Influence of sodium hypochlorite on cyclic fatigue resistance of nickel–titanium instruments: A systematic review and meta-analysis of in vitro studies. Clin. Oral Investig. 2023, 27, 6291–6319. [Google Scholar] [CrossRef]

- Palma, P.J.; Messias, A.; Cerqueira, A.R.; Tavares, L.D.; Caramelo, F.; Roseiro, L.; Santos, J.M. Cyclic fatigue resistance of three rotary file systems in a dynamic model after immersion in sodium hypochlorite. Odontology 2019, 107, 324–332. [Google Scholar] [CrossRef]

- Oh, S.; Kum, K.-Y.; Kim, H.-J.; Moon, S.-Y.; Kim, H.-C.; Chaniotis, A.; Perinpanayagam, H.; Pedullá, E.; Chang, S.W. Bending resistance and cyclic fatigue resistance of WaveOne Gold, Reciproc Blue, and HyFlex EDM instruments. J. Dent. Sci. 2020, 15, 472–478. [Google Scholar] [CrossRef]

- Dablanca-Blanco, A.-B.; Castelo-Baz, P.; Miguéns-Vila, R.; Alvarez-Novoa, P.; Martín-Biedma, B. Endodontic rotary files, what should an endodontist know? Medicina 2022, 58, 719. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Yue, L. Evolution and development: Engine-driven endodontic rotary nickel-titanium instruments. Int. J. Oral Sci. 2022, 14, 12. [Google Scholar] [CrossRef] [PubMed]

- HyFlex EDM. Available online: https://products.coltene.com/EN/GB/products/endodontics/shaping-files/rotary/hyflex-edm (accessed on 6 September 2025).

- Arias, A.; Macorra, J.C.; Govindjee, S.; Peters, O.A. Effect of gamma-ray sterilization on phase transformation behavior and fatigue resistance of contemporary nickel-titanium instruments. Clin. Oral Investig. 2020, 24, 3113–3120. [Google Scholar] [CrossRef]

- Kim, W.; Oh, S.; Ryu, G.J.; Kim, T.H.; Kim, S.J.; Kim, D.H.; Lee, B.N.; Kum, K.Y.; Chang, S.W.; Jang, J.H. Effect of autoclave sterilization on cyclic fatigue and torsional fracture resistance of NiTi rotary instruments. Odontology 2020, 108, 194–201. [Google Scholar] [CrossRef] [PubMed]

- Gomes, M.S.; Vieira, R.M.; Böttcher, D.E.; Plotino, G.; Celeste, R.K.; Rossi-Fedele, G. Clinical fracture incidence of rotary and reciprocating NiTi files: A systematic review and meta-regression. Aust. Endod. J. 2021, 47, 372–385. [Google Scholar] [CrossRef]

- Yared, G.; Bou Dagher, F.; Machtou, P. Influence of rotational speed, torque and operator’s proficiency on ProFile failures. Int. Endod. J. 2001, 34, 47–53. [Google Scholar] [CrossRef]

- Daugherty, D.W.; Gound, T.G.; Comer, T.L. Comparison of fracture rate, deformation rate, and efficiency between rotary endodontic instruments driven at 150 RPM and 350 RPM. J. Endod. 2001, 27, 93–95. [Google Scholar] [CrossRef] [PubMed]

- Pruett, J.P.; Clement, D.J.; Carnes, D.L., Jr. Cyclic fatigue testing of nickel-titanium endodontic instruments. J. Endod. 1997, 23, 77–85. [Google Scholar] [CrossRef]

- Shen, Y.; Cheung, G.S.-p.; Peng, B.; Haapasalo, M. Defects in nickel-titanium instruments after clinical use. Part 2: Fractographic analysis of fractured surface in a cohort study. J. Endod. 2009, 35, 133–136. [Google Scholar] [CrossRef]

- Abu-Tahun, I.H.; Ha, J.-H.; Kwak, S.W.; Kim, H.-C. Evaluation of dynamic and static torsional resistances of nickel-titanium rotary instruments. J. Dent. Sci. 2018, 13, 207–212. [Google Scholar] [CrossRef]

| Group | Total Files | p Value * | p Value ** | No. of Canals Prepared Until Separation | p Value * | p Value ** |

|---|---|---|---|---|---|---|

| Hyflex EDM RPM 300 | 12 | <0.001 * | 0.434 | 5.83 ± 1.85 a | 0.012 * | 0.525 ** |

| Hyflex EDM RPM 500 | 12 | 4.67 ± 1.23 | ||||

| NeoNiTi A1 RPM 300 | 12 | 4.25 ± 1.42 | ||||

| NeoNiTi A1 RPM 500 | 12 | 3.67 ± 1.72 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alzahrani, O.; Merdad, K.; Abuhaimed, T.; Natto, Z.S.; Siddiqui, A.Y.; Alothmani, O.S. A Safety Limit of the Number of Artificial Canals That Can Be Prepared by Two Rotary Endodontic Files Operated at Two Different Speeds: A Novel Approach. Bioengineering 2025, 12, 985. https://doi.org/10.3390/bioengineering12090985

Alzahrani O, Merdad K, Abuhaimed T, Natto ZS, Siddiqui AY, Alothmani OS. A Safety Limit of the Number of Artificial Canals That Can Be Prepared by Two Rotary Endodontic Files Operated at Two Different Speeds: A Novel Approach. Bioengineering. 2025; 12(9):985. https://doi.org/10.3390/bioengineering12090985

Chicago/Turabian StyleAlzahrani, Omar, Khalid Merdad, Tariq Abuhaimed, Zuhair S. Natto, Amna Y. Siddiqui, and Osama S. Alothmani. 2025. "A Safety Limit of the Number of Artificial Canals That Can Be Prepared by Two Rotary Endodontic Files Operated at Two Different Speeds: A Novel Approach" Bioengineering 12, no. 9: 985. https://doi.org/10.3390/bioengineering12090985

APA StyleAlzahrani, O., Merdad, K., Abuhaimed, T., Natto, Z. S., Siddiqui, A. Y., & Alothmani, O. S. (2025). A Safety Limit of the Number of Artificial Canals That Can Be Prepared by Two Rotary Endodontic Files Operated at Two Different Speeds: A Novel Approach. Bioengineering, 12(9), 985. https://doi.org/10.3390/bioengineering12090985