1. Introduction

Mechanical work is a cornerstone of classical physics and engineering, forming the basis for our understanding of energy transfer across a wide range of systems. Traditionally, it is defined as the integral of force over displacement:

where

F is the applied force and D the displacement along the force direction [

1]. This classical formulation implies that the total mechanical work depends solely on the magnitude of force and displacement, independent of the rate or timing of force application. In biological systems and biomaterials, especially the soft matter, however, this assumption often falls short. Biological tissues—including muscles, tendons, cartilage, and connective tissue—exhibit complex, rate-dependent mechanical behaviors due to their hierarchical, viscoelastic, and nonlinear microstructures [

2,

3,

4]. For example, muscle contraction follows a characteristic force–velocity relationship where rapid shortening reduces force output and affects both mechanical work and metabolic energy consumption [

5]. Tendons and ligaments display strain-rate sensitivity that influences stiffness and injury thresholds, critically shaping joint mechanics and movement safety [

6,

7]. These tissues dissipate energy differently depending on loading rate, reflecting intrinsic viscoelasticity and internal frictional mechanisms not accounted for by classical work definitions [

8].

Such rate-dependent phenomena are especially prominent in dynamic activities ranging from rapid muscle contractions in athletic performance to slow, sustained postural control, and are fundamental in rehabilitation science and biomaterial design [

9,

10]. For instance, high loading rates during impacts or sudden movements can elevate tissue damage risk, whereas controlled loading promotes healing and remodeling [

11,

12]. Moreover, emerging soft matter engineered to mimic or interface with biological tissues must account for time-dependent mechanical properties to ensure functional integration and durability [

13].

Despite their importance, classical mechanics frameworks rarely incorporate the explicit role of force application rate in defining and measuring mechanical work in biological contexts [

14,

15]. Most biomechanical models simplify work as force–displacement integrals, neglecting the temporal dynamics critical to physiological and pathological processes. This gap limits our understanding of energy transfer, efficiency, and injury mechanisms in living systems.

In this study, we revisit the work–energy relationship with an emphasis on biomechanics and biomaterials, exploring how varying force application rates influence mechanical work, energy partitioning, and functional outcomes in tissues exhibiting viscoelasticity and nonlinear response. Drawing on theoretical analyses, experimental case studies, and simulations, we demonstrate when and why classical work formulations fail in biological systems.

Our approach examines muscle models governed by Hill’s law, viscoelastic tissue behavior via standard mechanical analogs, and frictional energy dissipation in joint interfaces. We further propose experimental methodologies for quantifying rate-dependent mechanical work in biological tissues and biomimetic materials. By integrating classical mechanics with the rich temporal dynamics of biological systems, this work provides a more complete framework for understanding and optimizing biomechanical function, injury prevention, and biomaterial performance.

While prior studies have examined rate effects in isolated systems, no unified framework spanning muscle, tissue, and nano–bio interfaces currently exists—this study addresses that gap through complementary theoretical models, simulations, and proposed experiments.

In classical mechanics, work W done by a force F acting on a particle as it moves from an initial position x

i to x

f is defined as

For the special case of a constant force acting along the direction of displacement, this integral simplifies to the familiar expression:

where F is the constant magnitude of the force and D is the displacement in the direction of the force [

1,

2]. This formulation is foundational in physics and engineering and is widely taught in introductory courses and textbooks [

2,

3,

8].

Classical mechanics defines work under a set of simplifying assumptions: the applied force is constant in both magnitude and direction; the displacement occurs in a straight line along the direction of the force; the system is conservative, with no losses to friction, deformation, or thermal dissipation; and the only energy transfer is mechanical, arising from force acting over displacement. Under these idealized conditions, the classical work–energy theorem directly relates work done to the change in kinetic energy:

where m is the mass of the object, and v

i and v

f are the initial and final velocities, respectively [

1,

9]. However, it is important to note that in this classical framework, the duration or rate of force application—whether the force is applied slowly or rapidly—does not appear explicitly in the work equation. The absence of time-dependent terms reflects the Newtonian focus on instantaneous interactions and conservative systems [

9,

10].

This simplification works well for many physical systems, such as frictionless objects sliding on inclined planes or mass-spring oscillators obeying Hooke’s law. However, in practical and complex systems, energy dissipation, internal deformation, and time-dependent responses often render this formulation insufficient [

14]. These discrepancies motivate a deeper inquiry into whether and how the temporal dynamics of force application influence energy transfer, especially in systems exhibiting hysteresis, viscoelasticity, or irreversible processes. Such questions carry both theoretical significance and practical implications—from designing energy-efficient mechanical systems to understanding biological tissue responses—highlighting the need to revisit classical theory in light of modern experimental evidence.

In classical physics, mechanical work is defined as

. This formulation—a cornerstone of Newtonian mechanics—implies that the work done on an object depends solely on the applied force and the displacement along the force direction, with no explicit dependence on time or the rate at which the force is applied [

1,

2,

9]. Consequently, as long as the force-displacement relationship remains constant, classical theory predicts the same amount of work whether the motion occurs over milliseconds or minutes. However, a growing body of experimental evidence across diverse disciplines challenges this assumption of time-independence. In materials science, biomechanics, tribology, and mechanical engineering, the rate at which force is applied critically shapes energy transformation pathways, determining how mechanical work is divided between recoverable (elastic) energy and irreversible (dissipative) losses [

4,

5,

6,

12,

13].

Inelastic and Microstructural Responses: Rapid force application often triggers inelastic deformation, microcracking, and local heating, particularly in polymers, composites, metals, and biological tissues. These phenomena dissipate mechanical energy as heat or internal damage, reducing recoverable work [

3,

5,

6].

Wave Propagation and Shock Loading: At high strain rates, materials experience complex dynamic responses that significantly alter energy dissipation mechanisms. Stress waves and shock fronts propagate through the material, exciting transient vibrational modes and inertial effects that are not accounted for in classical work calculations [

11,

12]. These additional pathways can lead to increased energy loss, localized heating, and microstructural deformation, highlighting the need for rate-sensitive models when analyzing fast-loading scenarios in biological tissues, polymers, and engineered materials.

Relaxation and Recovery at Low Rates: Slow loading allows sufficient time for molecular or microstructural relaxation and energy redistribution within the material, thereby reducing hysteresis and damping losses commonly observed in viscoelastic and thermally sensitive systems [

4,

5]. This leads to a greater fraction of the input work being stored reversibly and a smaller fraction dissipated irreversibly.

These observations raise a fundamental theoretical question with direct practical implications: Is the classical work expression, W = ∫F⋅dx, truly complete for describing mechanical work in real, rate-dependent systems? Or does the temporal profile of force application fundamentally alter the effective work done and its partitioning between stored and dissipated energy?

Biomechanics:

Muscle-tendon units exhibit velocity-dependent force generation and associated metabolic costs, making contraction speed a critical factor for energy efficiency and injury risk [

6]. Faster contractions reduce force output per cycle while increasing the metabolic demand, and tendon elasticity further modulates force transmission and energy storage. Understanding these dynamics requires integrating rate-dependent biomechanical models that account for both muscle and tendon properties.

Polymeric and soft biomaterials often display time-temperature superposition and strain-rate sensitive modulus effects, which classical elasticity models cannot fully capture [

3,

5]. Accurate prediction of their behavior under varying loading rates requires constitutive models that account for viscoelasticity, microstructural relaxation, and thermal effects. Such models are essential for designing biomimetic materials and interpreting experimental results in biomechanics and tissue engineering.

Frictional contacts in biological and engineered systems exhibit stick-slip phenomena, velocity-dependent friction, and rate-sensitive heat generation, all of which directly influence energy dissipation and system stability [

12]. These effects can dominate local energy budgets in joints, nanoscale contacts, and mechanical interfaces, emphasizing the need to consider dynamic and rate-dependent friction in both experimental analysis and modeling.

Engineering Design: Dynamic loads applied over short timescales can cause failure modes and fatigue damage undetectable by static or quasi-static analyses, necessitating rate-aware design criteria [

13,

14].

Even within the relativistic regime, the explicit inclusion of time and frame-dependence in energy formulations via Lorentz transformations emphasizes that rate and temporal context are inseparable from an accurate energy description [

10]. The contrast between the simplicity of classical work integrals and the complexity of real-world, rate-sensitive materials highlights the need to reconsider how time-dependent forces influence mechanical work.

The microscopic mechanisms of energy dissipation underlie the observed rate-dependent effects in mechanical work. These include the roles of viscoelasticity, plasticity, friction, and biological processes in modulating energy transfer. This highlights the practical need for generalized or extended work–energy frameworks that incorporate temporal dynamics and material-specific constitutive behavior. Understanding how classical mechanics intersects with time-dependent and rate-sensitive behaviors in real materials provides the foundation for analyzing energy partitioning and dissipation in biological tissues and biomaterials.

In idealized conservative systems, the work–energy theorem remains the cornerstone for relating force to energy. Equation (4) asserts that the work done by a net force equals the change in kinetic energy of a particle of mass m, independent of the time duration over which the force is applied [

1,

2,

9]. While time does not explicitly appear in the total work expression, it enters indirectly through power, defined as the rate at which work is performed:

where p is power, F is force, and

is velocity. Total work can then be expressed as

However, the classical theorem rests on several key assumptions. (1) Forces are applied either instantaneously or sufficiently slowly (quasi-statically), such that inertial and dynamic effects are negligible. (2) The system exhibits no rate dependence or memory effects and behaves as an ideal elastic body. (3) Internal state variables—such as temperature changes, molecular relaxation, or deformation history—do not influence the mechanical response. (4) Energy losses via internal friction, plastic deformation, or other irreversible processes are absent.

When these assumptions are violated, as frequently occurs in real materials and complex systems, the clear-cut separation between force, displacement, and time breaks down. For example, in viscoelastic materials, the stress depends on both strain and strain rate, introducing hysteresis and energy dissipation that cannot be captured by purely elastic models. Similarly, plastic deformation involves irreversible structural changes dependent on loading rate, and frictional interfaces exhibit velocity-dependent forces that convert mechanical energy into heat or sound.

Under such conditions, the classical work–energy theorem remains mathematically valid but insufficient for capturing the complete energy transfer and dissipation mechanisms. The total mechanical work input no longer equals solely recoverable kinetic or potential energy changes but also includes rate-dependent dissipative losses distributed across microscopic degrees of freedom. Consequently, a more nuanced framework that incorporates temporal dynamics, material constitutive behavior, and internal state evolution is necessary to fully describe mechanical work in realistic systems.

While these classical and relativistic frameworks provide a rigorous basis for understanding mechanical work and energy in idealized systems, biological tissues and biomaterials frequently violate these assumptions due to their viscoelasticity, complex hierarchical structure, and active physiological processes. These characteristics introduce pronounced rate-dependent and dissipative behaviors that require extended theoretical treatment beyond the classical work–energy theorem.

Although, in practice, humans and even mechanical machines do not move at velocities approaching the speed of light, we include a brief discussion to provide a complete theoretical background in the introduction. At such extreme velocities, classical mechanics fails to accurately describe particle dynamics. In this regime, relativistic mechanics, governed by Einstein’s theory of Special Relativity, becomes the appropriate framework. The relativistic kinetic energy K

E is given by

where the Lorentz factor γ is

In the low-velocity limit (v ≪ c), this expression reduces to the classical kinetic energy,

. However, as the velocity approaches the speed of light (v → c), the required energy increases sharply, ultimately becoming infinite to accelerate a mass to c [

7,

10,

15]. The classical work–energy theorem relies on several key assumptions: (1) Forces are applied instantaneously or sufficiently slowly (quasi-statically), such that inertial and dynamic effects are negligible. (2) The system exhibits no rate dependence or memory effects, behaving as an ideal elastic body. (3) Internal state variables—such as temperature changes, molecular relaxation, or deformation history—do not influence the mechanical response. (4) Energy losses via internal friction, plastic deformation, or other irreversible processes are absent.

Relativistic dynamics also alters the relationship between force and acceleration. Specifically, as velocity increases, the effective inertia (or relativistic mass) grows, causing acceleration to diminish under constant force. The relativistic form of Newton’s second law becomes

This dependence introduces velocity into the force equation, which in turn affects the integration of work and energy. Nonetheless, the temporal profile of force application—whether the force is applied slowly or rapidly—does not fundamentally alter the total energy predicted by relativistic theory. Rather, the modifications to kinetic energy arise from the velocity-dependent geometry of spacetime and not from rate-of-application effects per se [

7,

10].

Thus, while relativistic mechanics provides significant corrections to classical kinetic energy and force interpretations at high velocities, it does not generalize the classical work–energy theorem to encompass rate-dependent material behaviors or dissipative processes. It presupposes idealized, conservative systems without friction or internal energy loss. This contrast highlights the essential need for separate theoretical treatment when addressing rate effects in real materials—where internal dissipation, hysteresis, and nonlinear responses dominate energy transformations.

Unlike the idealized assumptions of classical or relativistic mechanics, biological tissues and biomaterials are inherently non-conservative systems exhibiting complex, rate-dependent behaviors where mechanical energy is rarely fully conserved. Instead, the energy input into these systems partitions into multiple pathways involving irreversible dissipation driven by microstructural dynamics, fluid flow, biochemical processes, and thermomechanical interactions. The rate at which forces are applied profoundly influences how energy is stored, transformed, and lost, shaping physiological function, tissue adaptation, and injury risk.

Several key microscopic and mesoscopic mechanisms underlie these rate-dependent responses in biological and biomimetic materials:

Viscoelasticity and Tissue Microstructure: Biological tissues such as muscle, tendon, cartilage, and skin exhibit viscoelastic behavior where stress depends on both instantaneous strain and strain rate. This reflects the hierarchical organization of collagen fibers, extracellular matrix components, and interstitial fluids, producing time-dependent deformation and energy dissipation through internal friction, molecular rearrangement, and fluid flow within porous networks. Constitutive models like Maxwell, Kelvin–Voigt, and Standard Linear Solid analogs effectively describe these behaviors, capturing hysteresis loops observed in cyclic loading that directly relate to dissipated energy [

3,

4,

5,

16]. Such viscoelastic dissipation plays a critical role in protecting tissues from damage under dynamic loading and enables energy recycling during locomotion.

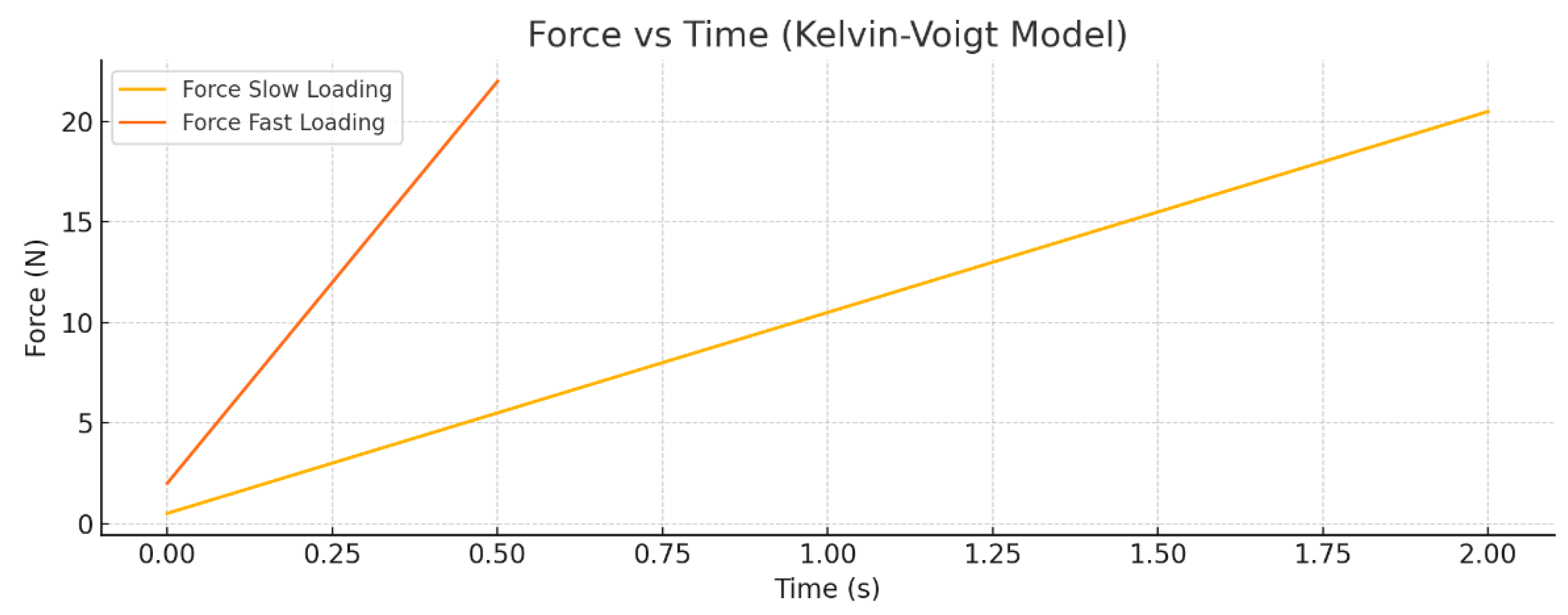

Many real materials—such as polymers, biological tissues, and damping composites exhibit viscoelastic behavior, in which force depends on both displacement and velocity. A simple representation is the Kelvin–Voigt model [

5]:

where η is the damping coefficient. The total work done becomes

The first term represents elastic storage, while the second corresponds to viscous dissipation. Faster displacement (

large) increases viscous losses, requiring greater total energy input [

6,

7]. This rate-dependence is critical in impact testing, where high strain rates significantly increase measured stiffness and damping [

8].

Rate-Dependent Plasticity and Remodeling: Although classical plasticity models apply mainly to metals and polymers, biological tissues undergo irreversible microstructural changes—such as microtears, collagen crosslinking, or cellular remodeling—that depend strongly on loading rate and magnitude. For example, tendon and ligament failure thresholds increase under rapid loading, a phenomenon akin to strain rate hardening seen in synthetic materials. These rate-dependent plastic and remodeling processes govern tissue durability, healing, and adaptation to mechanical stimuli, underscoring the need for constitutive laws that incorporate biological time scales and mechanotransduction pathways [

7,

13,

17].

Muscle

Biological muscles display velocity-dependent force generation, as described by Hill’s equation [

13]:

where F is the muscle force, v is the shortening velocity, and a and b are empirical constants. While these classical and relativistic frameworks provide a rigorous basis for understanding mechanical work and energy in idealized systems, biological tissues and biomaterials frequently violate these assumptions due to their viscoelasticity, complex hierarchical structure, and active physiological processes. These characteristics introduce pronounced rate-dependent and dissipative behaviors that require extended theoretical treatment beyond the classical work–energy theorem. In muscle mechanics, for example, the force–velocity relationship described by Hill’s law demonstrates that faster contractions produce less force, thereby reducing the mechanical work per cycle and altering the metabolic cost [

14,

15]. Conversely, slow, sustained contractions produce higher force but incur greater energy cost due to prolonged muscle activation. Rapid contractions, while metabolically efficient per unit time, may decrease mechanical efficiency, increase injury risk, and rely more heavily on elastic energy storage in tendons. Slow contractions, in contrast, generate higher total force but demand greater metabolic expenditure. This rate-dependence is central to sports biomechanics (e.g., optimizing sprint vs. endurance performance), rehabilitation engineering (e.g., selecting contraction speeds for safe and effective strengthening), and injury prevention (e.g., avoiding excessive eccentric loading during rapid movements) [

6,

7,

13,

14,

15].

These mechanisms necessitate extending the classical work–energy framework to explicitly consider rate-dependent energy partitioning. In biological contexts, the total mechanical work W can be expressed as

where W

stored represents recoverable elastic energy stored in tissues and biomaterials, and W

dissipated encompasses irreversible losses due to viscoelastic damping, plastic remodeling, frictional heating, fluid flow, and biochemical energy conversion. The proportions of stored versus dissipated energy are highly sensitive to the loading rate. For instance, a tendon stretched slowly allows molecular relaxation and fluid redistribution, minimizing dissipation, whereas rapid loading traps fluid and strains collagen networks, increasing energy loss and injury risk [

5,

6]. Similarly, skeletal muscle exhibits a well-characterized force-velocity relationship where rapid contractions reduce force output and metabolic efficiency, profoundly influencing mechanical work generation and physiological performance [

6,

18,

19].

These observations highlight a vital conclusion: while the classical expression W = ∫F⋅dx elegantly defines total mechanical energy transfer, it is incomplete for biological and biomimetic materials where internal dissipation, nonlinear mechanics, and rate effects are prominent. A more comprehensive energy balance must incorporate material-specific constitutive laws, temporal dynamics, and the complex partitioning of energy into reversible and irreversible components [

4,

7,

14].

It is important to emphasize that the classical work definition W = F × D remains valid in the non-relativistic regime when interpreted as the total mechanical energy transferred along a displacement path. Apparent discrepancies in energy conservation arise when experiments or models capture only partial energy pathways—such as kinetic energy or elastic strain energy—while neglecting microscale dissipative processes like heat generation, fluid flow, acoustic emissions, or biochemical energy transformations. When all relevant energy channels are accounted for, the total work matches the sum of all produced energy forms, regardless of loading rate. Thus, the critical role of force application rate lies not in violating the fundamental work equation but in governing how mechanical work partitions between recoverable storage and dissipative loss in biological and biomimetic systems.

Internal microstructural dynamics, phase transformations, thermal effects, and other irreversible processes cause a portion of the mechanical work input to be dissipated rather than fully recoverable. This results in energy losses that depend strongly on how quickly forces are applied. The following are some of the typical systems with recoverable elastic energy and irreversible losses.

When force is applied rapidly in complex materials—particularly in biological tissues and biomaterials (soft matter)—several energy loss mechanisms become especially significant. By integrating classical mechanics with rate-sensitive constitutive laws and time-dependent dynamics, we can build a predictive framework for mechanical work that reflects how biological tissues and biomaterials actually behave. The temporal profile of force—gradual rise, abrupt spike, oscillation, or sustained load—strongly influences viscoelastic damping, poroelastic flow, frictional heating, microdamage, and active metabolic processes.

Table 1 presents a selection of representative dynamic systems across biomechanics and related fields, illustrating how the rate of force application critically influences mechanical responses and energy transfer. Biological tissues, such as muscle and tendon, exhibit pronounced rate-dependent behaviors characterized by viscoelasticity and force-velocity relationships that significantly affect functional outcomes and injury risk [

2,

4,

5]. For example, skeletal muscle contractions follow Hill’s law, where increasing contraction velocity reduces force output and mechanical work per cycle, impacting metabolic cost and performance efficiency [

4,

8]. Similarly, connective tissues like tendons and cartilage demonstrate strain-rate dependent stiffness and damping properties, which are essential for load bearing and shock absorption during dynamic activities [

6,

11,

14]. These biomechanical systems operate within velocity regimes far below relativistic speeds but require constitutive models that account for temporal dynamics and dissipative mechanisms to accurately predict energy partitioning [

9,

10,

15].

3. Discussion

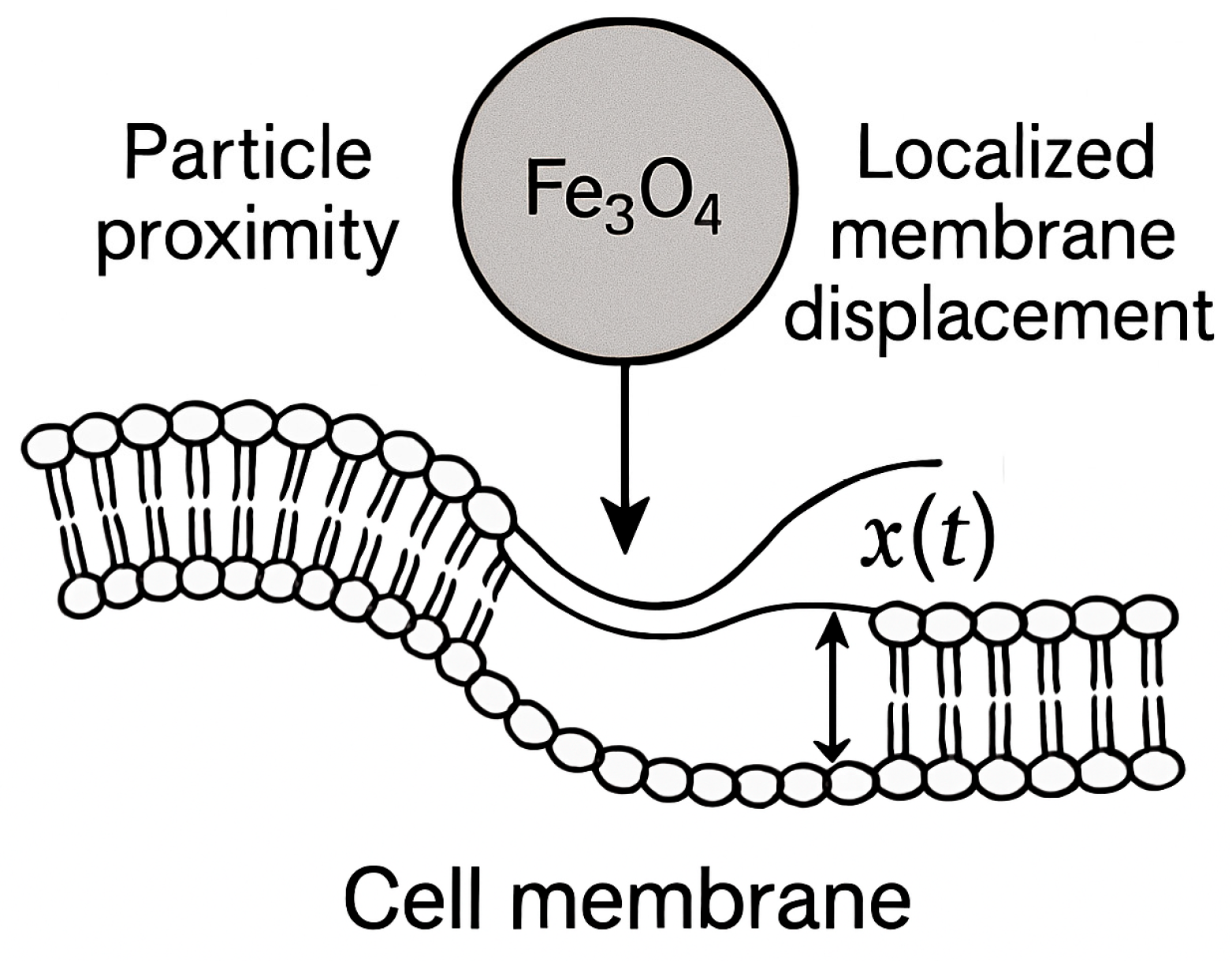

Nanoparticle interaction with cell membranes involves localized indentation until the particle is either fully engulfed or the membrane ruptures. Despite growing interest in nanoparticle delivery, a key gap in the literature is the lack of a unified framework that systematically examines how the rate of force application governs energy partitioning at the nano–bio interface. Most prior studies either focus on viscoelastic or strain-rate-sensitive behaviors independently, without integrating these effects in a controlled experimental and simulation platform.

This gap motivated our work, as understanding rate-dependent energy dissipation is essential for predicting mechanical stresses, membrane remodeling, and potential damage during nanoparticle uptake. The primary purpose of this research was to develop a combined theoretical, numerical, and experimental approach to quantify how nanoparticle size and entry velocity influence the partitioning of mechanical work into recoverable elastic energy and irreversible viscous dissipation. We hypothesize that nanoparticle size and entry velocity critically govern the partitioning of mechanical work into elastic and viscous components at the nano–bio interface, with faster loading and larger particles producing more viscous-dominated energy dissipation.

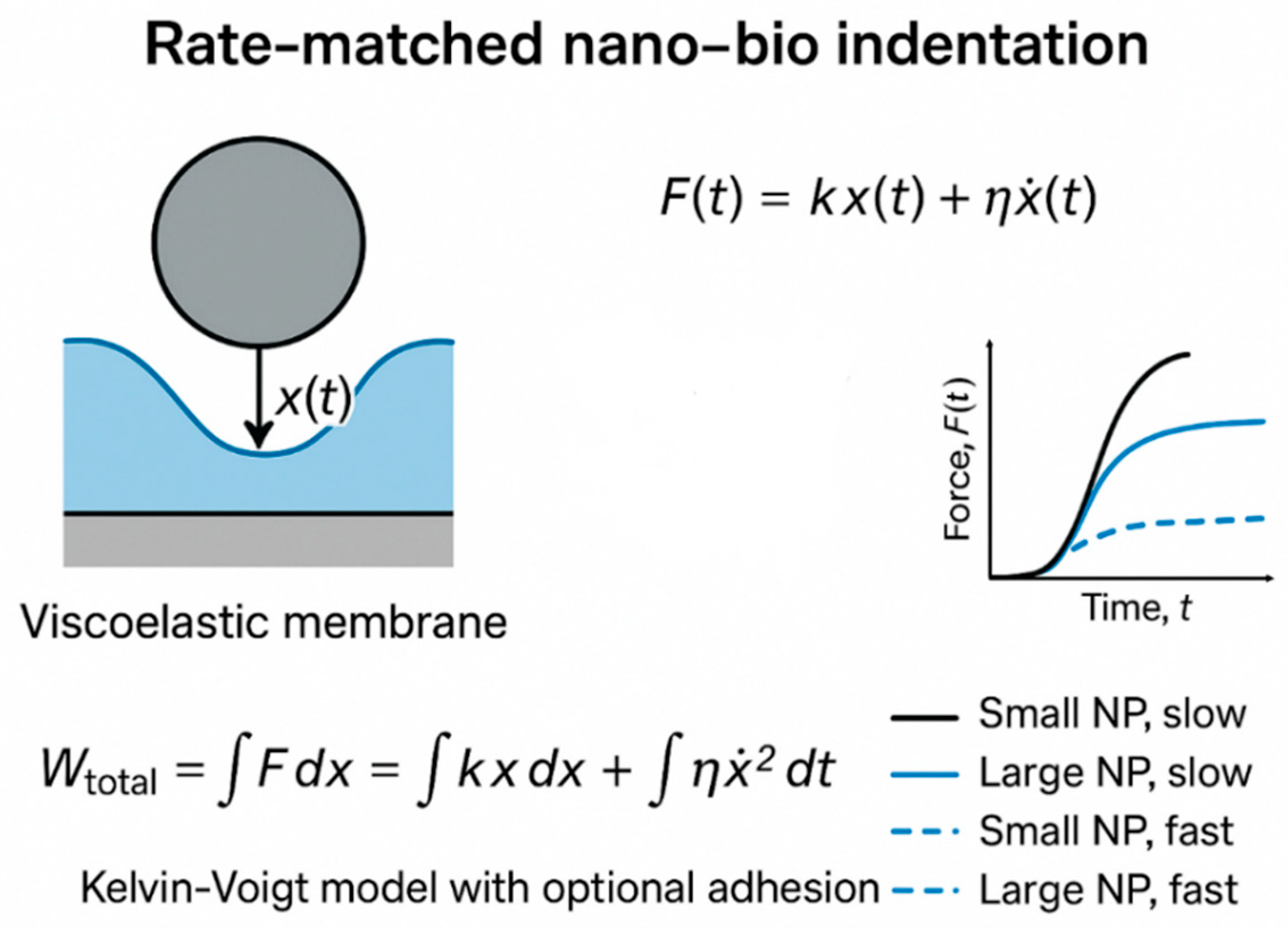

Our Kelvin–Voigt viscoelastic indentation model demonstrates that NP entry velocity crucially governs viscous dissipation and thereby modulates the mechanical energy partition between recoverable elastic storage and irreversible viscous loss.

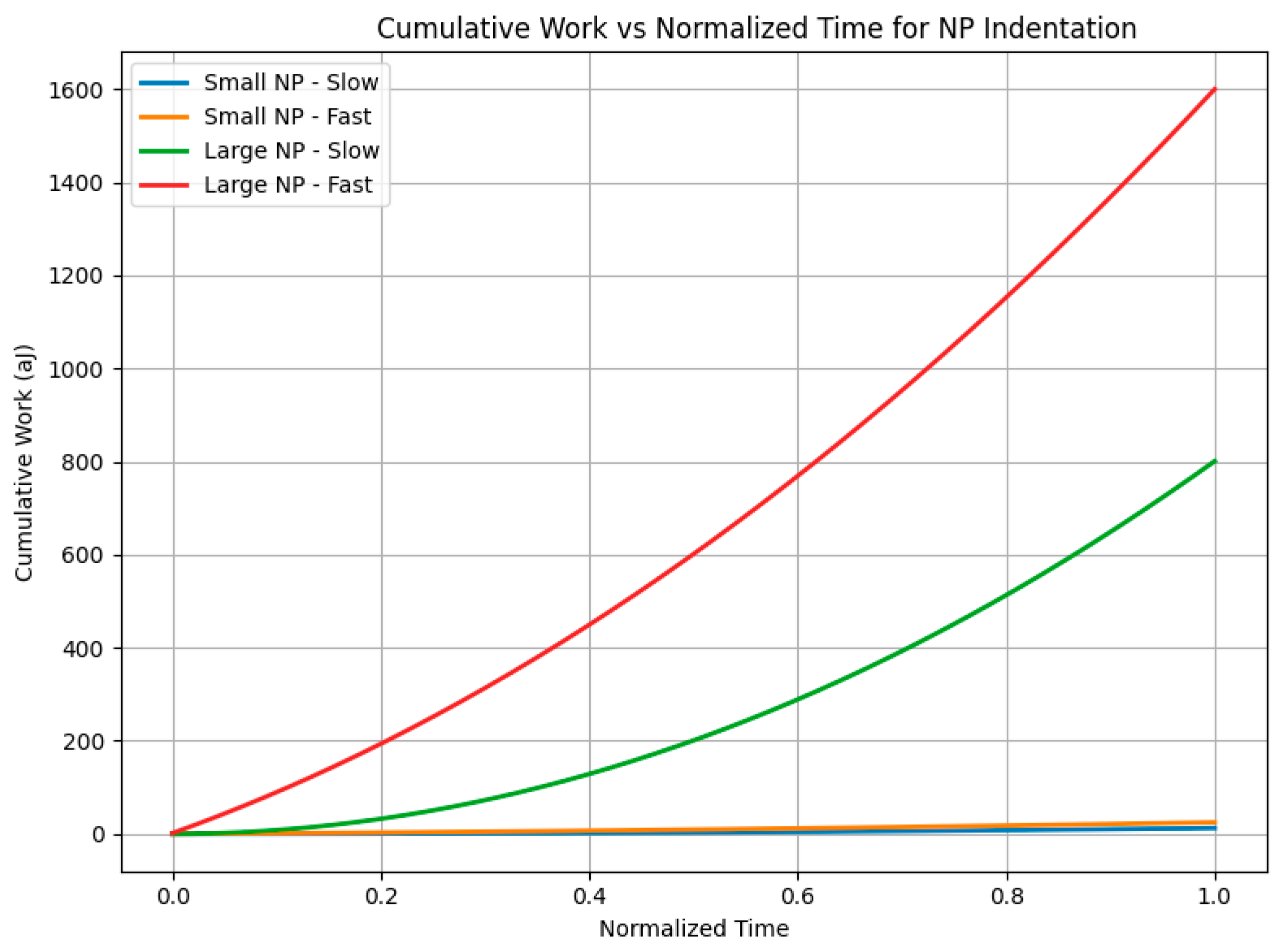

Figure 4 establishes the foundational role of loading rate by comparing slow and fast force ramps for a single nanoparticle scenario. Faster indentation ramps produce sharp force peaks due to viscous resistance, whereas slower loading yields smoother, predominantly elastic force responses. This comparison highlights how increasing entry velocity significantly amplifies viscous work relative to elastic energy, implying important considerations for delivery speed to balance effective transport while minimizing membrane damage or heating.

Extending these insights,

Figure 7 incorporates nanoparticle size as an additional key variable, presenting four representative cases (small and large nanoparticles at slow and fast loading rates). The results show that larger nanoparticles subjected to fast loading experience markedly sharper force rises and higher peak forces, underscoring a size-dependent amplification of viscous-dominated mechanical responses. This combined effect of particle size and rate deepens our understanding of biomechanical constraints influencing nanoparticle transport efficiency and membrane integrity.

Building further, our newly proposed rate-matched nano–bio indentation experiment and accompanying finite-element simulations (

Figure 7 and

Figure 8) quantitatively capture how force application rate directly dictates energy partitioning at the nano–bio interface for biologically relevant nanoparticle sizes and membrane properties. Rapid loading substantially increases total mechanical work primarily through viscous dissipation, which scales inversely with loading duration, while elastic energy storage remains relatively constant. This rate-dependent energy budget critically influences membrane remodeling, thermal effects, and potential damage during nanoparticle uptake.

Together, these results emphasize that both loading rate and nanoparticle size are critical parameters to optimize in nanodelivery design, balancing efficient cellular entry with the preservation of membrane function.

While more complex viscoelastic or multi-scale models could capture additional aspects of nanoparticle–membrane interactions, such models introduce greater computational cost, parameter uncertainty, and interpretive complexity. The choice of model should be guided by the specific research question. In many cases, simpler models—such as the Kelvin–Voigt framework employed here—provide sufficient insight into key mechanical behaviors, provided their limitations are acknowledged.

Regarding methodological limitations, our study considers single-particle indentation with idealized membrane properties and uniform loading conditions. Real biological membranes exhibit heterogeneity, nonlinear responses, and active remodeling, which are not fully captured in this framework. These simplifications may affect quantitative predictions of peak forces, energy partitioning, and viscous dissipation, though the qualitative trends and mechanistic insights remain valid. Researchers should interpret the results within these constraints, particularly when extending findings to in vivo nanoparticle delivery scenarios.

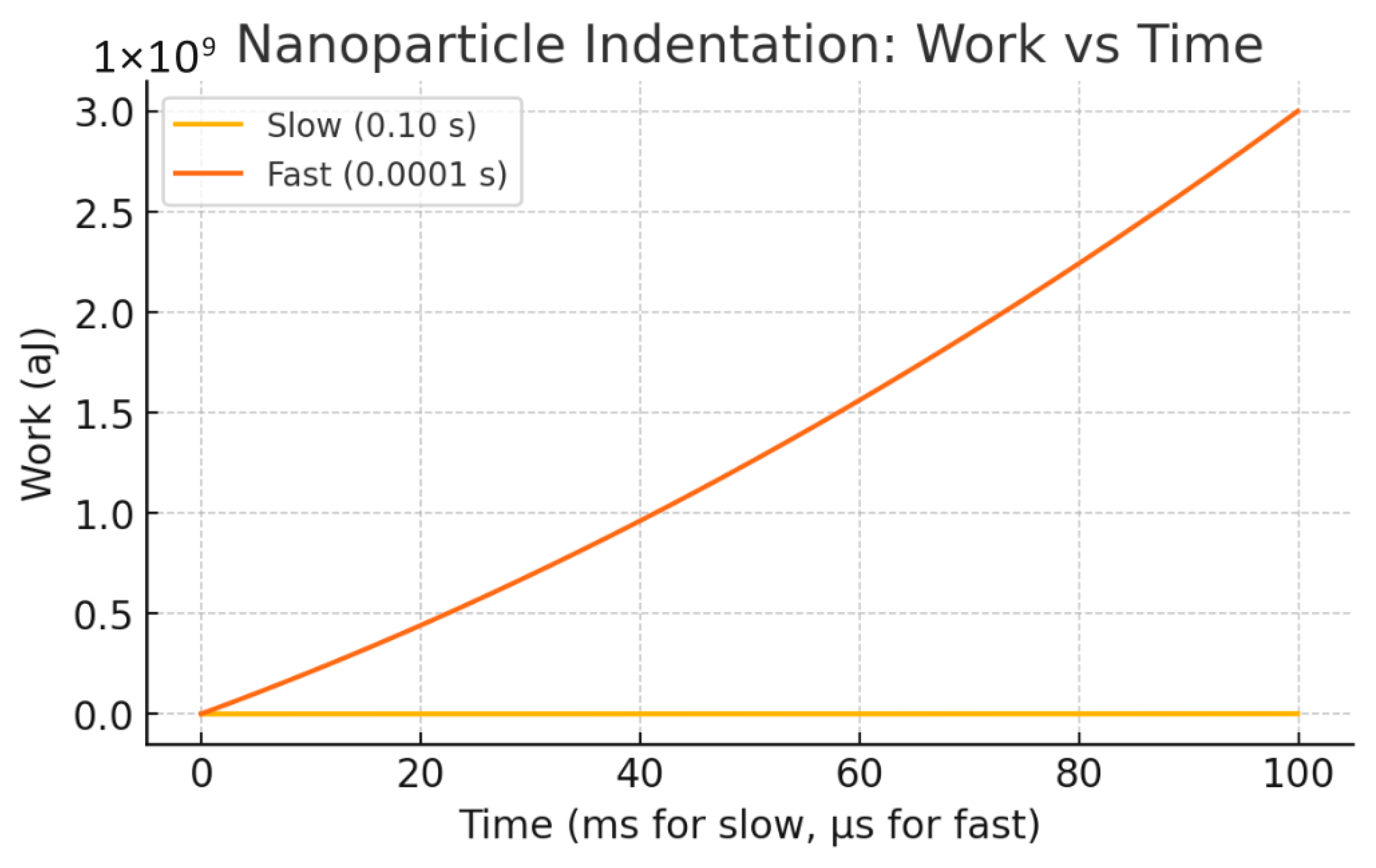

Simplifying to a Kelvin–Voigt indentation model with linear ramp loading, our simulations reveal that viscous dissipation, W

visc =

D

2/T, dominates total work for sufficiently fast indentation times T and larger particle sizes D.

Table 3 summarizes this effect: large nanoparticles (200 nm) under fast loading (0.0001 s) dissipate viscous energy on the order of their elastic storage energy, doubling total work input compared to slow loading cases.

Figure 7 and

Figure 8 illustrate these dynamics.

Figure 7 shows force–time curves for small and large NPs at slow and fast loading rates, highlighting how fast loading leads to sharper force spikes with larger viscous contributions.

Figure 8 demonstrates cumulative work over time, where the fast-large NP scenario accrues the greatest total mechanical work, confirming a shift from elastic- to viscous-dominated energy budgets. These results confirm the central hypothesis that NP size and loading rate critically govern energy partitioning at the membrane interface. Understanding this balance informs the design of nanoparticle delivery systems by delineating conditions favoring membrane remodeling (elastic energy-dominant) versus those increasing heating or mechanical damage risk (viscous energy-dominant).

Beyond nano–bio interfaces, our findings highlight why traditional, simplified models often fall short in practical biomechanics. Linear viscoelastic or purely elastic models can predict overall trends but fail to capture critical rate-dependent dissipation, peak forces, or energy partitioning that influence tissue damage, fatigue, and performance under dynamic loading. For example, tendon and cartilage responses under rapid stretch are underestimated by simple models, potentially misinforming injury risk predictions or rehabilitation protocols. Multiphysics, multiscale frameworks that incorporate nonlinear stiffness, adhesion, fluid pressurization, and active feedback are essential to realistically simulate tissue mechanics, guide biomaterials development, and predict physiological outcomes.

Our work also emphasizes the need for dynamic, time-resolved experiments that measure full force–time and displacement–time histories under physiologically relevant conditions. Reporting only peak forces obscures the role of rate-dependent energy dissipation and prevents accurate validation of biomechanical models. For biomaterials design, matching viscoelastic timescales to native tissue is critical: overly viscous materials risk excessive mechanical stress or heating under rapid loading, whereas overly compliant materials may dissipate energy inefficiently. By explicitly modeling viscous contributions, our approach provides actionable guidance for selecting nanoparticle sizes, delivery speeds, and tissue-mimetic material properties to maximize efficacy while minimizing damage.