Coordinating Obstacle Avoidance of a Redundant Dual-Arm Nursing-Care Robot

Abstract

1. Introduction

- A capsule-based algorithm was used to model the volume of the robotic arms, and a gradient projecting method was utilized to calculate the shortest distances (among the left arm, the right arm, and the environment), which achieved the actual body’s self-collision avoidance.

- By introducing a distance threshold to assess the risk of collisions between obstacles and the robotic arms, the robotic arm movement speed was smoothly adjusted.

2. Materials and Methods

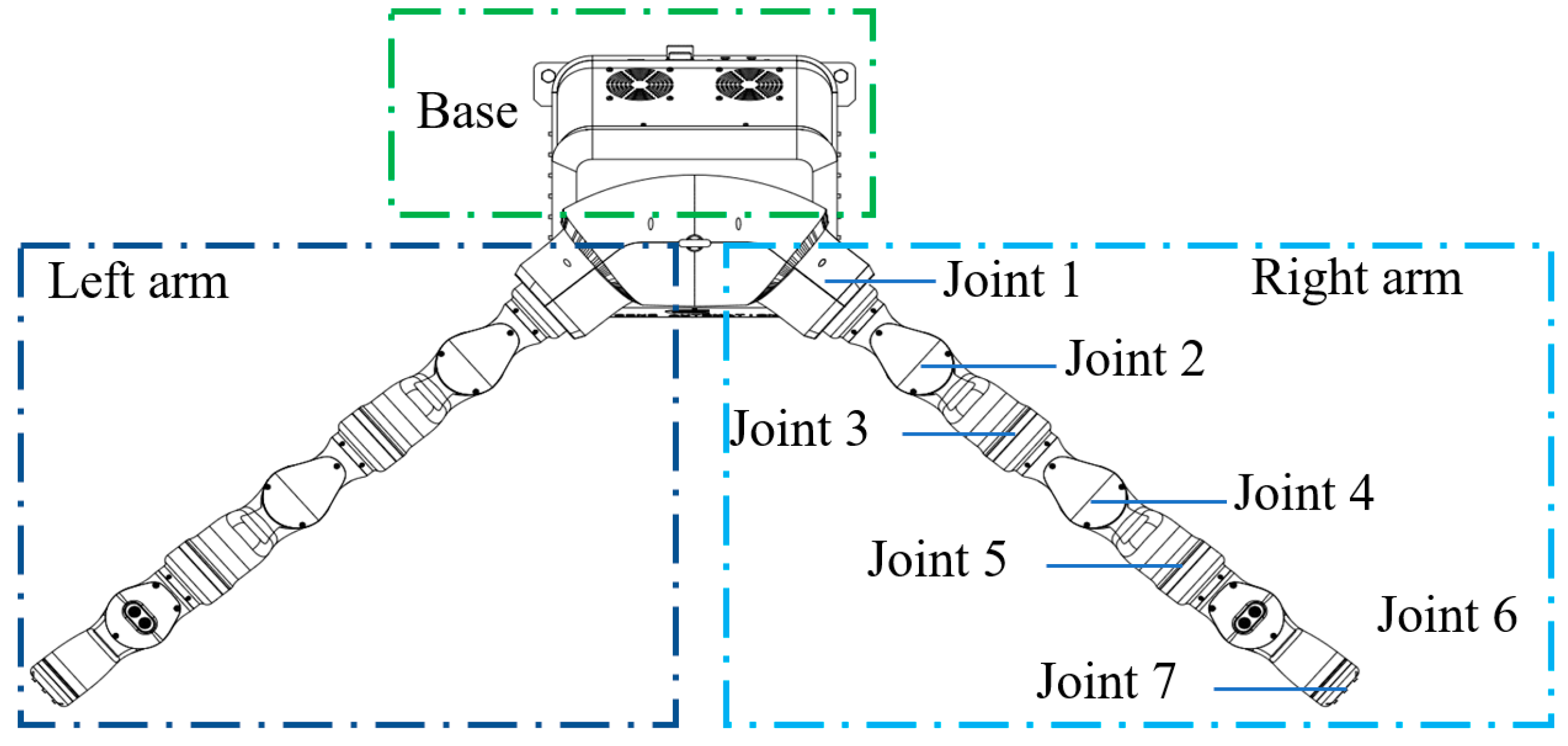

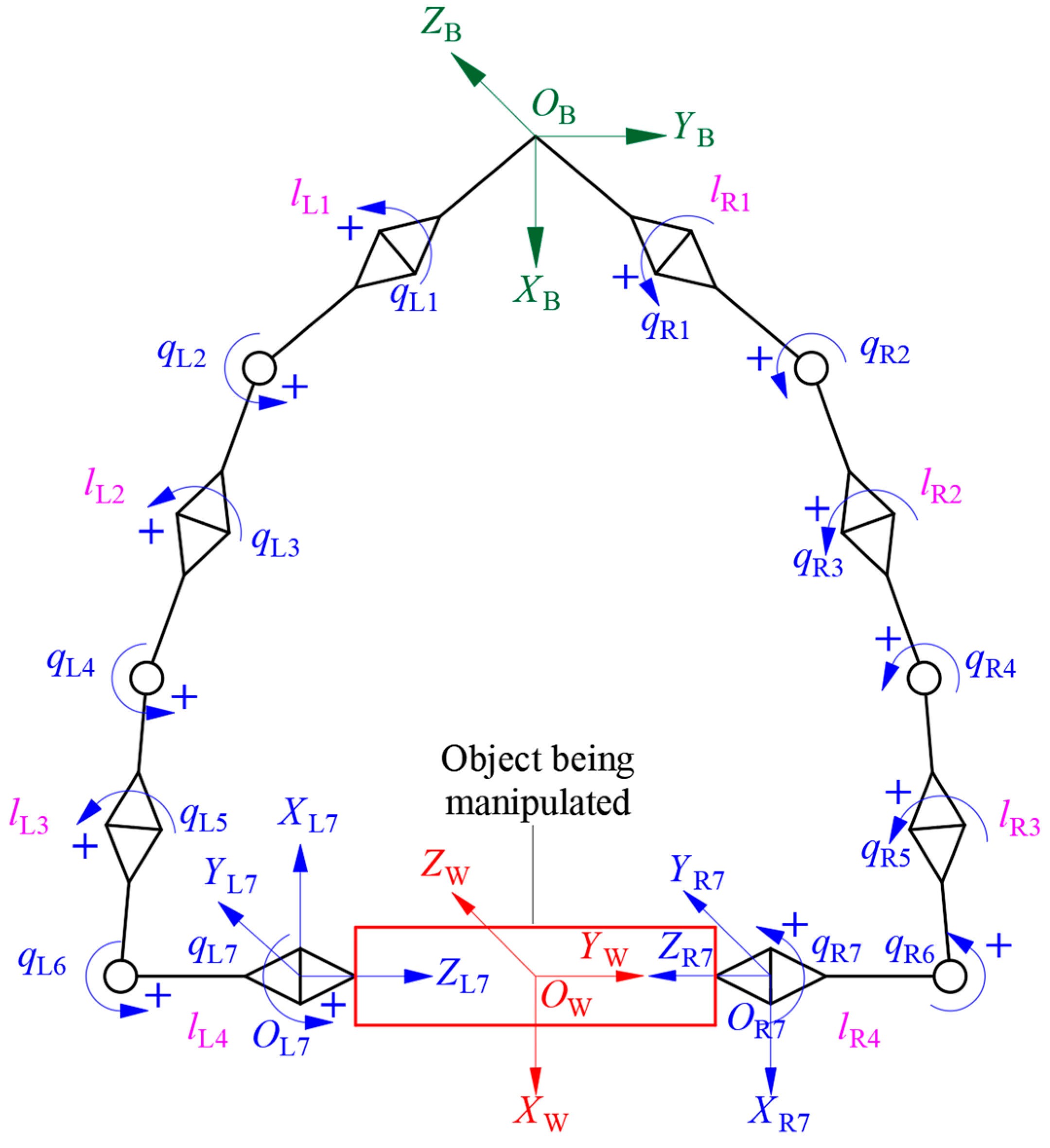

2.1. Kinematics of Coordinating Operation of Dual-Arm Robot

2.2. Shortest Distance Calculation Based on Gradient Projection Method

2.2.1. Simplified Model of Redundant Dual-Arm Robot

2.2.2. Shortest Distance between Left Arm and Obstacle k

2.2.3. Shortest Distance between Left Arm and Right Arm

2.3. Obstacle-Avoidance Algorithm in Coordinating Operation

2.3.1. Obstacle-Avoidance Motion Space

2.3.2. Obstacle-Avoidance Algorithm Theory

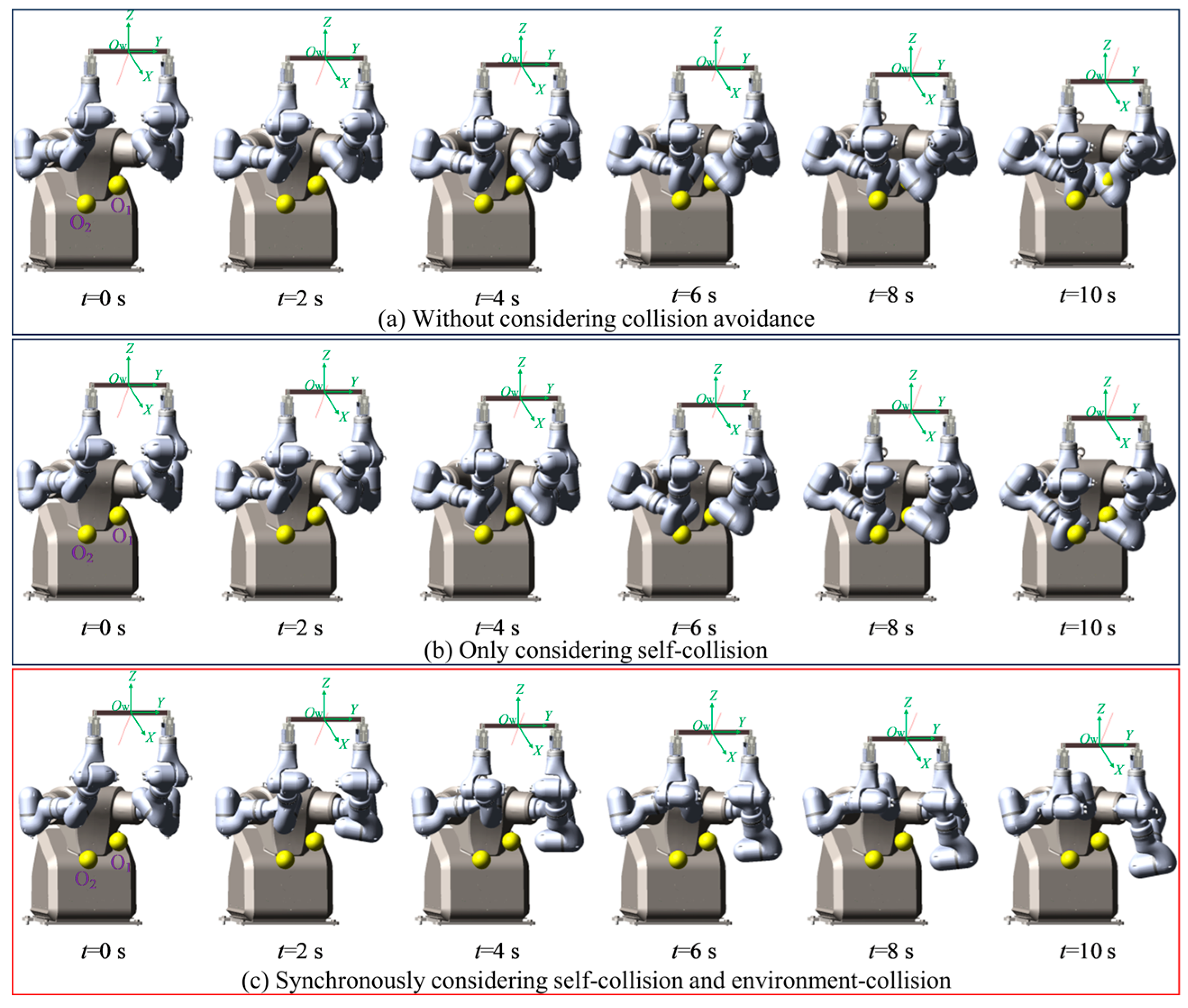

2.4. Simulation Analysis

3. Results and Discussion

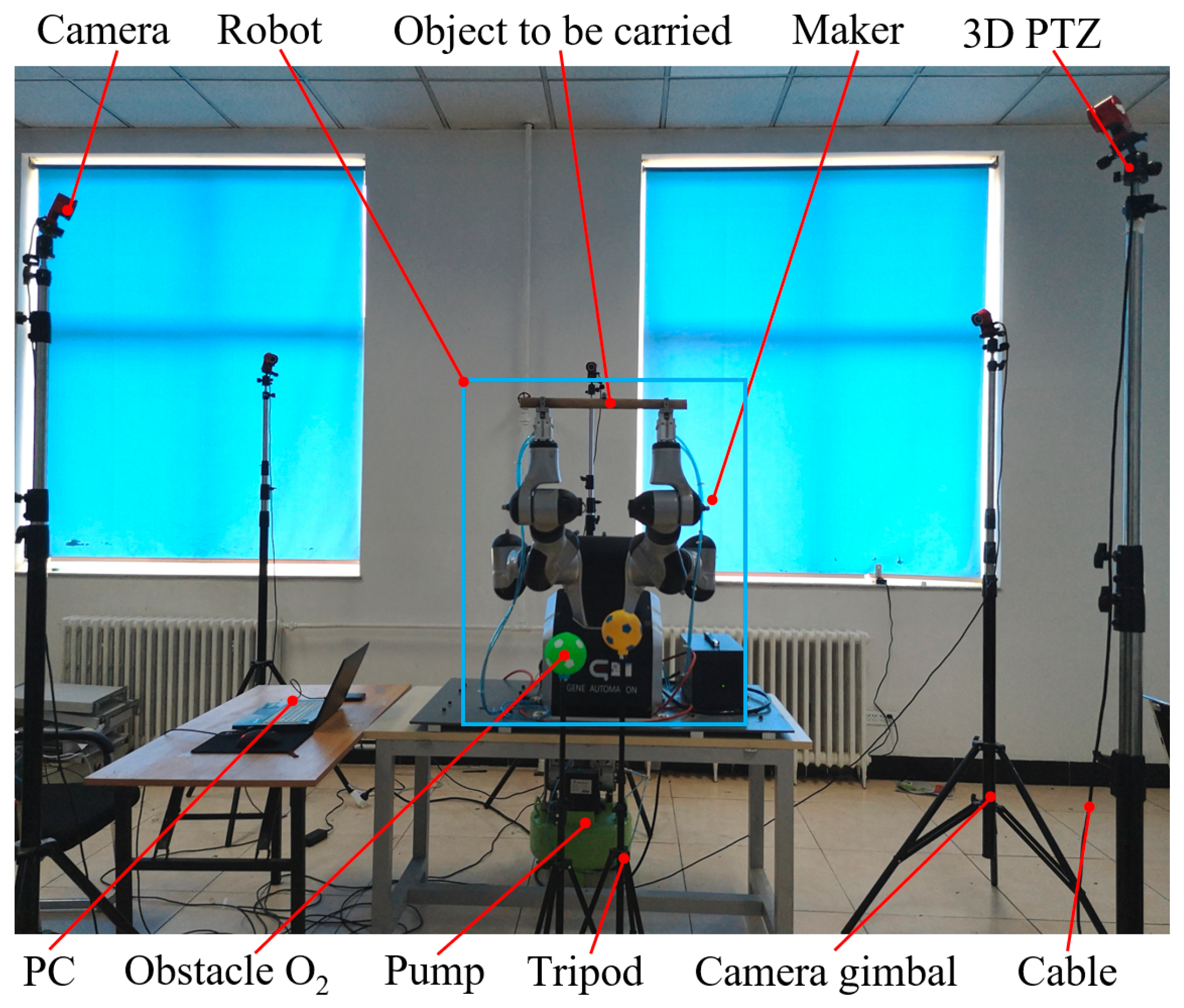

3.1. Experimental Scenario

3.2. Experimental Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, I. Service Robots: A Systematic Literature Review. Electronics 2021, 10, 2658. [Google Scholar] [CrossRef]

- Li, J.; Xie, J.; Wang, J.; Wen, Y.; Guo, S. Pyramid Transformer: A Multi-size Object Detection Model with Limited Device Requirements for the Nursing Robot. In Proceedings of the IEEE International Conference on Tools with Artificial Intelligence, New York, NY, USA, 31 October–2 November 2022. [Google Scholar]

- Wang, G.; Ye, F.; Zhang, N.; Wang, M. Design and Implementation of Medical Service Robot with Single Arm and Tracking Function. In Proceedings of the IEEE International Conference on Information and Automation (ICIA), Yinchuan, China, 26–28 August 2013. [Google Scholar]

- Tlach, V.; Kuric, I.; Ságová, Z.; Zajacko, I.; Bujnak, J.; Guagliano, M. Collaborative assembly task realization using selected type of a human-robot interaction. Transp. Res. Procedia 2019, 40, 541–547. [Google Scholar] [CrossRef]

- Chanthasopeephan, T.; Srikirin, P.; Srisap, M.; Rattapat, A. Flexure Design of a Compliant Modular Hyper-Redundant Manipulator. In Proceedings of the IEEE International Symposium on Robot and Human Interactive Communication (RO-MAN), Lisbon, Portugal, 28 August–1 September 2017. [Google Scholar]

- Su, H.; Sandoval, J.; Makhdoomi, M.; Ferrigno, G.; De Momi, E. Safety-enhanced Human-Robot Interaction Control of Redundant Robot for Teleoperated Minimally Invasive Surgery. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Brisbane, Australia, 21–25 May 2018. [Google Scholar]

- Wang, H.; Li, R.; Gao, Y.; Cao, C.; Ge, L. Comparative study on the redundancy of mobile single- and dual-arm robots. Int. J. Adv. Robot. Syst. 2017, 13, 1729881416666782. [Google Scholar] [CrossRef]

- Xie, J.; Zhu, D.; Wang, J.; Guo, S. A Training-Evaluation Method for Nursing Telerobot Operator with Unsupervised Trajectory Segmentation. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Kyoto, Japan, 23–27 October 2022. [Google Scholar]

- Peng, Y.; Carabis, D.; Wen, J. Collaborative manipulation with multiple dual-arm robots under human guidance. Int. J. Intell. Robot. 2018, 2, 252–266. [Google Scholar] [CrossRef]

- Lu, H.; Guo, S.; Yang, Z.; Chen, L.; Deng, F.; Wang, H. Research on Dynamic Modeling and Parameter Identification of 2R Coupling Drive Joint. J. Mech. Eng. 2022, 58, 51–64. [Google Scholar]

- Qu, J.; Zhang, F.; Wang, Y.; Fu, Y. Human-like coordination motion learning for a redundant dual-arm robot. Robot. Comput-Integr. Manuf. 2019, 57, 379–390. [Google Scholar] [CrossRef]

- Kavraki, L.; Svestka, P.; Latombe, J.; Overmars, M. Probabilistic roadmaps for path planning in high-dimensional configuration spaces. IEEE Trans. Robot. Autom. 1996, 12, 566–580. [Google Scholar] [CrossRef]

- Khatib, O. Real-time obstacle avoidance for manipulators and mobile robots. Int. J. Robot. Res. 1986, 5, 90–98. [Google Scholar] [CrossRef]

- Shen, H.; Wu, H.; Chen, B.; Yan, C.; Jiang, Y. Obstacle avoidance algorithm for coordinated motion of redundant dual-arm robot. Trans. Chin. Soc. Agric. Mach. 2015, 46, 356–361. [Google Scholar]

- Li, Y.; Xu, D. Cooperative path planning of dual-arm robot based on attractive force self-adaptive step size RRT. Robot 2020, 42, 606–616. [Google Scholar]

- Wang, J.; Liu, S.; Zhang, B.; Yu, C. Manipulation Planning with Soft Constraints by Randomized Exploration of the Composite Configuration Space. Int. J. Control Autom. Syst. 2021, 19, 1340–1351. [Google Scholar] [CrossRef]

- Wu, C.; Yue, Y.; Wei, B.; Liu, D. Self-collision detection and motion planning for dual-arm robot. J. Shanghai Jiaotong Univ. 2018, 52, 45–53. [Google Scholar]

- Shi, W.; Wang, K.; Zhao, C.; Tian, M. Obstacle Avoidance Path Planning for the Dual-Arm Robot Based on an Improved RRT Algorithm. Appl. Sci. 2022, 12, 4087. [Google Scholar] [CrossRef]

- Li, X.; Li, S.; Han, K.; Li, Z.; Xiong, Y.; Xie, Z. Real-time Self-collision Avoidance-oriented Torque Control Strategy for Dual-arm Robot. Inf. Control 2023, 52, 211–219. [Google Scholar]

- Siciliano, B.; Khatib, O.; Kröger, T. Springer Handbook of Robotics, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 701–708. [Google Scholar]

- Chiacchio, P.; Chiaverini, S.; Siciliano, B. Direct and inverse kinematics for coordinated motion tasks of a two-manipulator system. J. Dyn. Syst. Meas. Control-Trans. ASME 1996, 118, 691–697. [Google Scholar] [CrossRef]

- Chen, Y.; Ju, M.; Hwang, K. A virtual torque-based approach to kinematic control of redundant manipulators. IEEE Trans. Ind. Electron. 2016, 64, 1728–1736. [Google Scholar] [CrossRef]

- Li, Y.; Feng, S.; Zhu, D.; Guo, S.; Song, Y.; Tian, Q. Safety Control of a Redundant Dual-arm Robot for Transfer-care Task. J. Mech. Eng. 2023, 59, 76–89. [Google Scholar]

- Zhang, J.; Hu, P.; Zhang, X.; Liu, J.; Liu, X. Closed loop control obstacle avoidance based on the transformation of master and slave tasks. J. Mech. Eng. 2017, 53, 21–27. [Google Scholar] [CrossRef]

- Shen, H.; Wu, H.; Chen, B.; Yang, X. Obstacle avoidance algorithm for redundant robots based on transition between the primary and secondary tasks. Robot 2014, 36, 425–429. [Google Scholar]

- Zhao, J.; Lv, Y.; Zeng, Q.; Wan, L. Online Policy Learning Based Output-Feedback Optimal Control of Continuous-Time Systems. IEEE Trans. Circuits Syst. II Express Briefs 2024, 71, 652–656. [Google Scholar] [CrossRef]

- Dong, Y.; Hu, Z.; Wang, K.; Sun, Y.; Tang, J. Heterogeneous network representation learning. In Proceedings of the Twenty-Ninth International Joint Conference on Artificial Intelligence, Yokohama, Japan, 7–15 January 2021. [Google Scholar]

- Su, H.; Mariani, A.; Ovur, S.; Menciassi, A.; Ferrigno, G.; De Momi, E. Toward teaching by demonstration for robot-assisted minimally invasive surgery. IEEE Trans. Autom. Sci. Eng. 2021, 18, 484–494. [Google Scholar] [CrossRef]

| Angle | q1/(°) | q2/(°) | q3/(°) | q4/(°) | q5/(°) | q6/(°) | q7/(°) |

|---|---|---|---|---|---|---|---|

| Left | −5 | −80 | 45 | 40 | 56.3 | 59.2 | −2.5 |

| Right | 5 | 80 | −45 | −40 | −56.3 | −59.2 | 2.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Lu, H.; Wang, P.; Guo, S. Coordinating Obstacle Avoidance of a Redundant Dual-Arm Nursing-Care Robot. Bioengineering 2024, 11, 550. https://doi.org/10.3390/bioengineering11060550

Yang Z, Lu H, Wang P, Guo S. Coordinating Obstacle Avoidance of a Redundant Dual-Arm Nursing-Care Robot. Bioengineering. 2024; 11(6):550. https://doi.org/10.3390/bioengineering11060550

Chicago/Turabian StyleYang, Zhiqiang, Hao Lu, Pengpeng Wang, and Shijie Guo. 2024. "Coordinating Obstacle Avoidance of a Redundant Dual-Arm Nursing-Care Robot" Bioengineering 11, no. 6: 550. https://doi.org/10.3390/bioengineering11060550

APA StyleYang, Z., Lu, H., Wang, P., & Guo, S. (2024). Coordinating Obstacle Avoidance of a Redundant Dual-Arm Nursing-Care Robot. Bioengineering, 11(6), 550. https://doi.org/10.3390/bioengineering11060550