Exoskeletons: Contribution to Occupational Health and Safety

Abstract

:1. Introduction

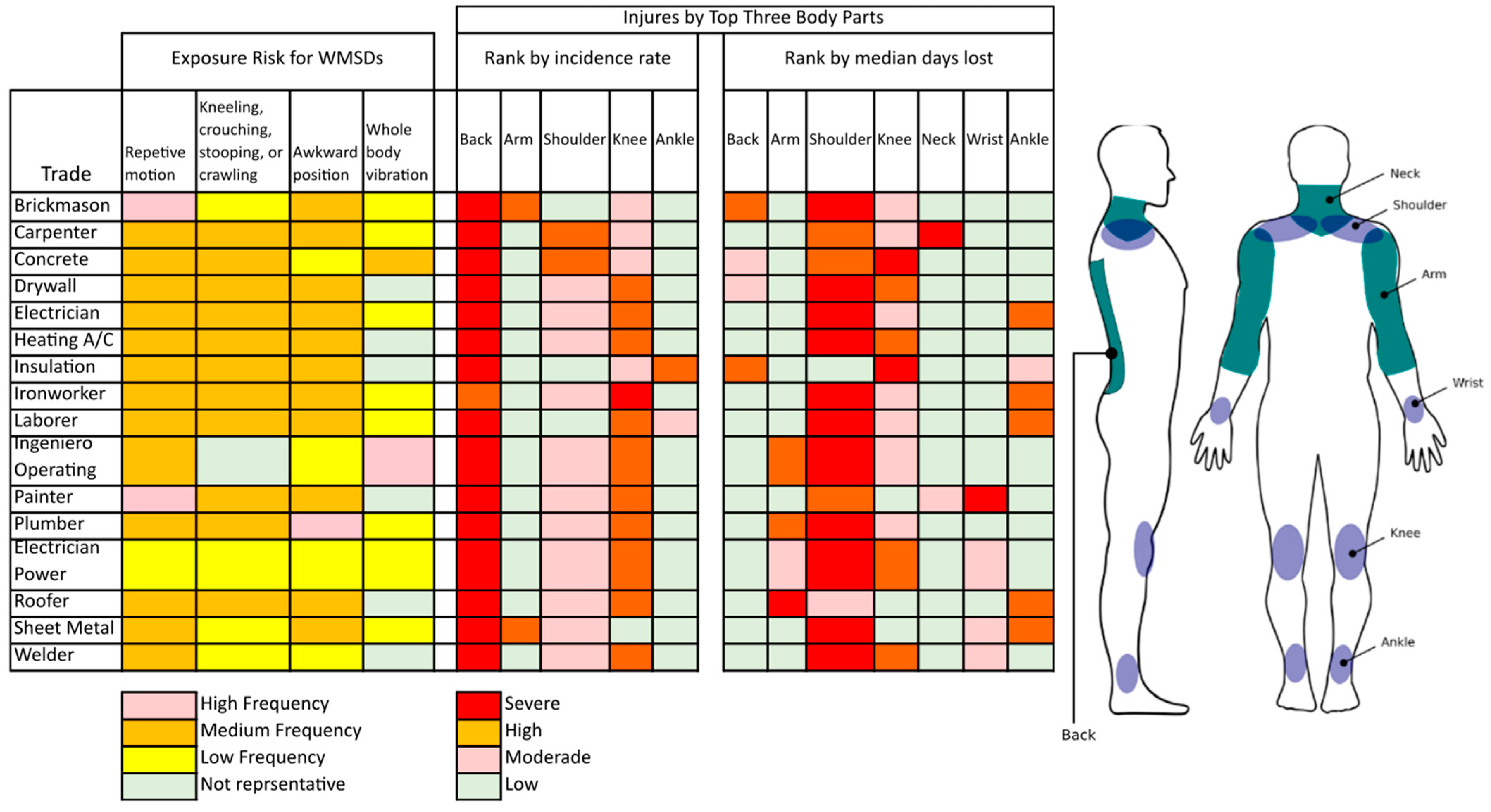

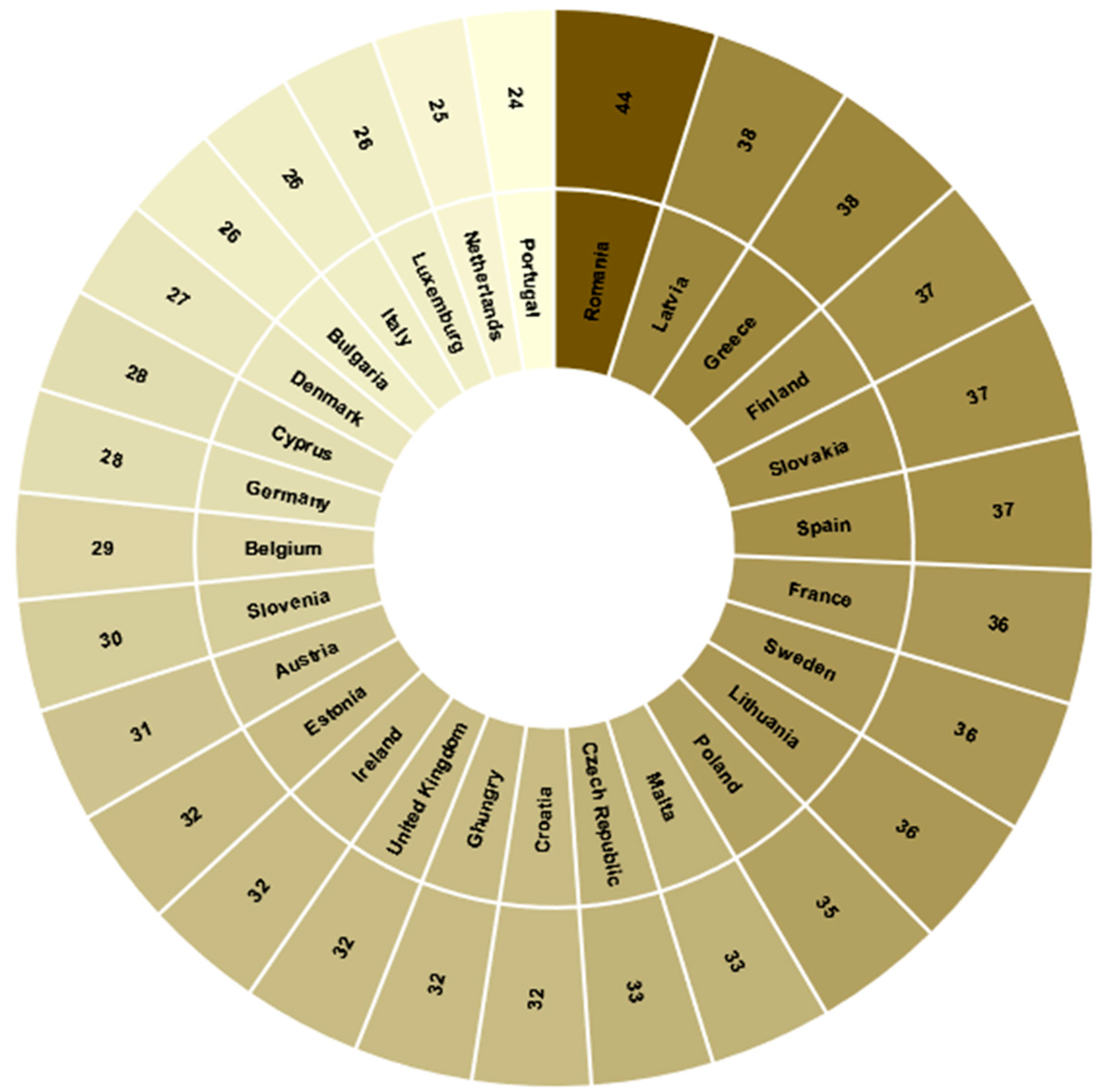

2. Musculoskeletal Risks in Workers

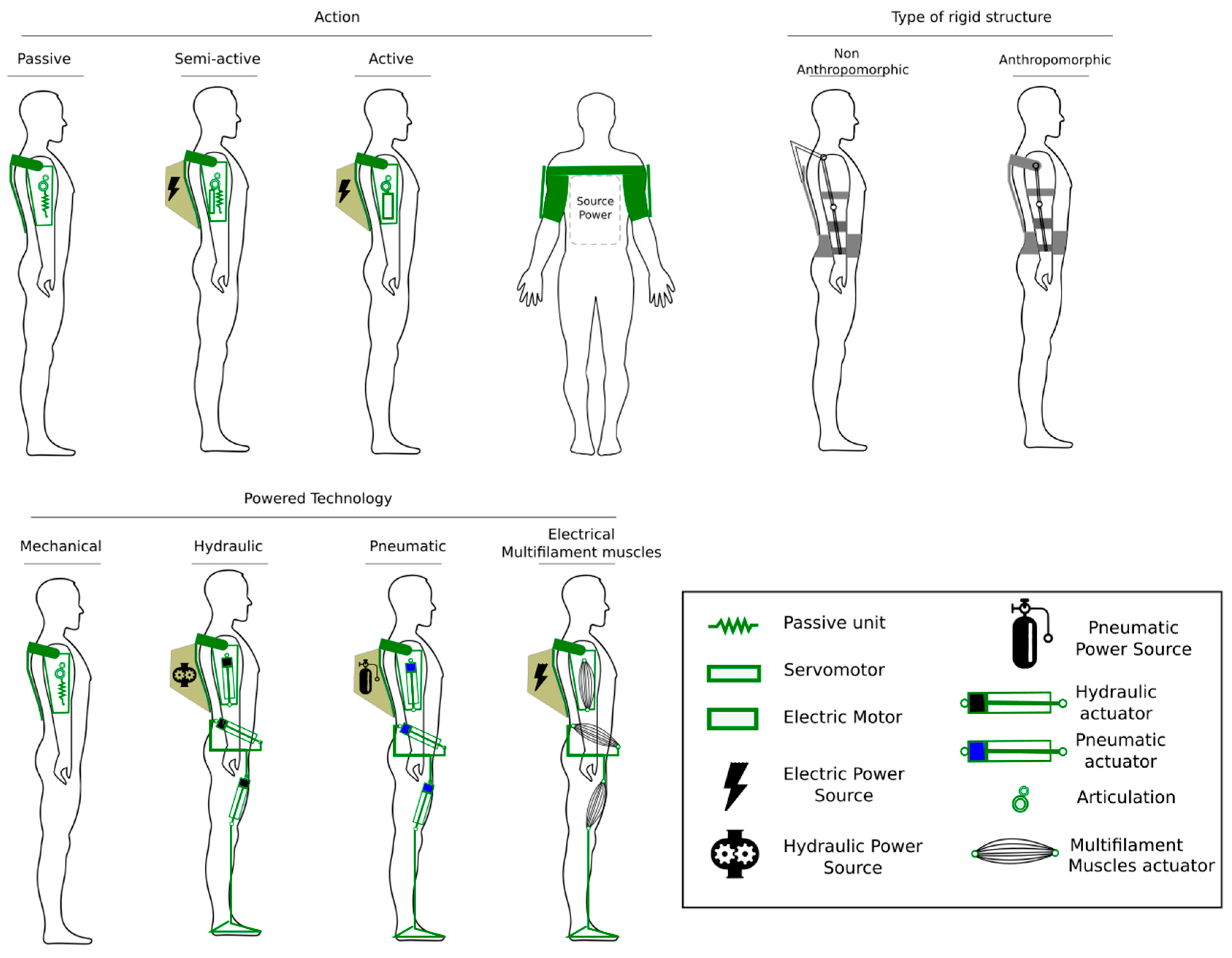

3. Use of Exoskeletons to Improve Occupational Health and Safety

4. Developments in Exoskeletons for Occupational Health and Safety

5. Exoskeletons as Support for the Health and Safety of Workers

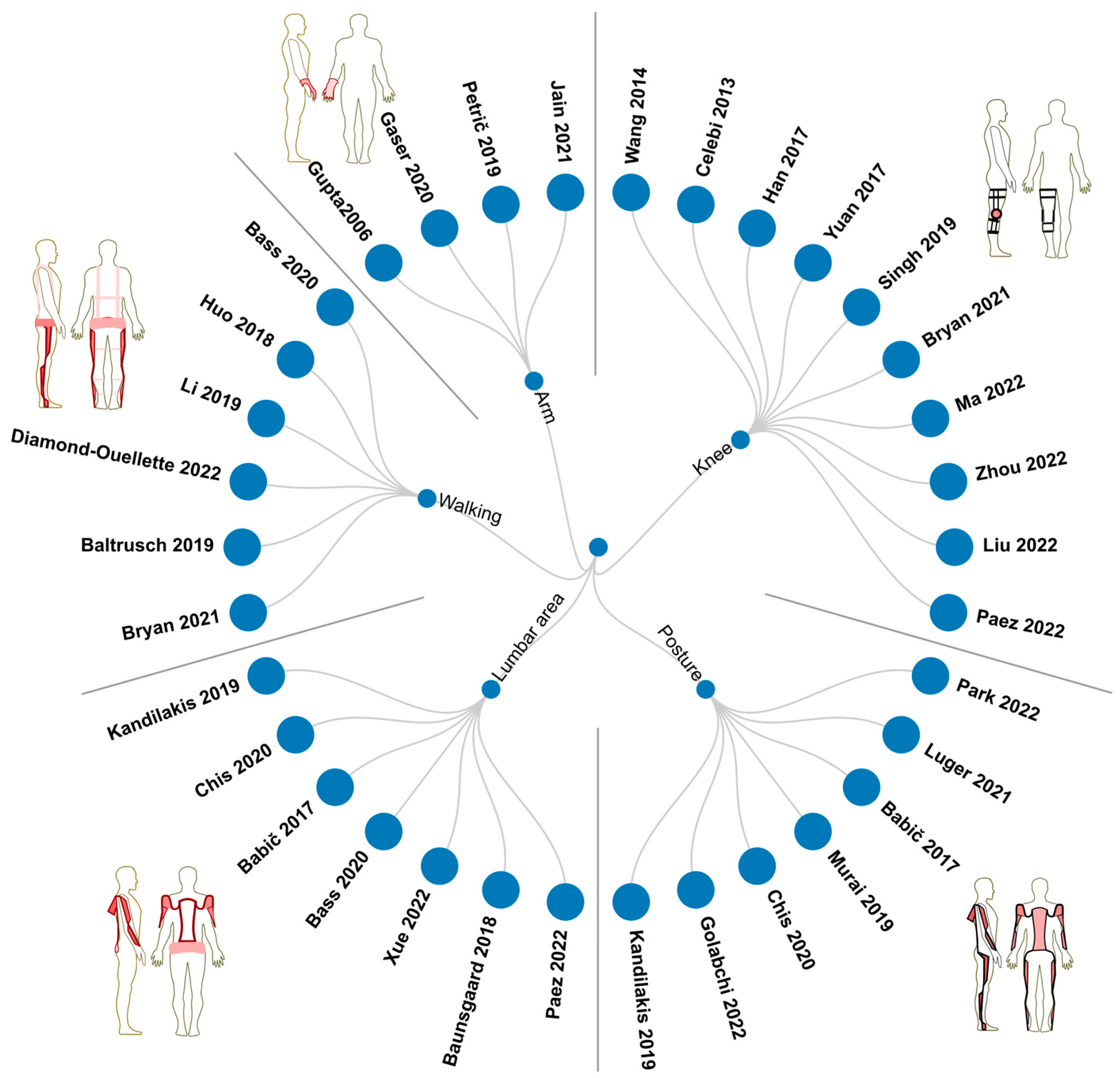

5.1. Assistance Exoskeletons

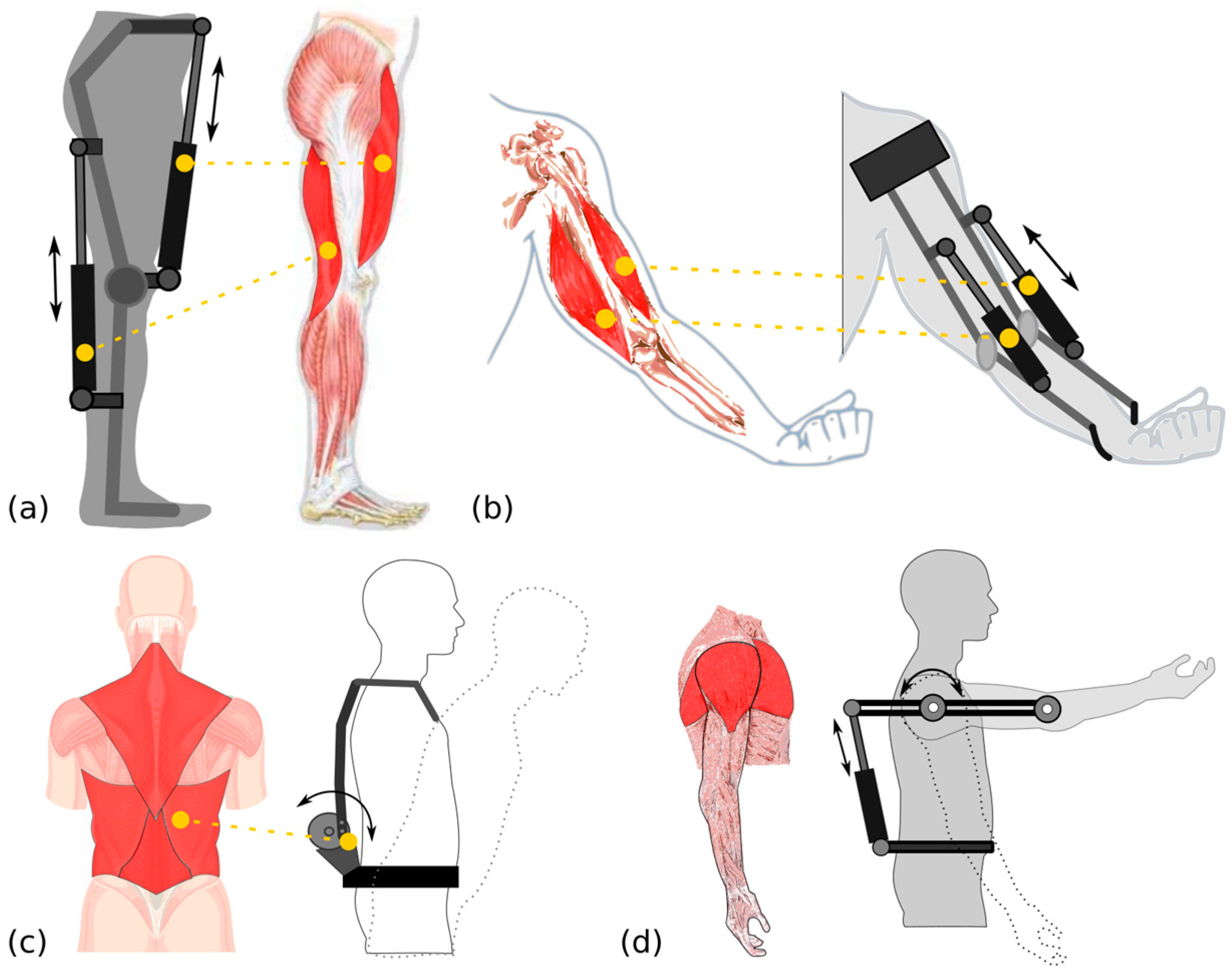

5.1.1. Exoskeletons for Knee Assistance

5.1.2. Exoskeletons for Walking Assistance

5.1.3. Exoskeletons for Posture Assistance

5.1.4. Exoskeletons for Less Effort in the Lumbar Area

5.1.5. Exoskeletons for Arm Loading Assistance

6. Methodology

7. Discussion

7.1. Limitations on the Use of Exoskeletons for Occupational Health and Safety

7.2. Future Directions

7.3. Environmental Impact in the Manufacturing of Exoskeletons

8. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Preferred Reporting Items for Systematic Reviews and Meta-Analyses Extension for Scoping Reviews (PRISMA-ScR) Checklist | |||

|---|---|---|---|

| Section | Item | PRISMA-ScR checklist item | Reported On page # |

| Title | |||

| Title | 1 | Identify the report as a scoping review. | 1 |

| Abstract | |||

| Structured summary | 2 | Provide a structured summary that includes (as applicable) background, objectives, eligibility criteria, sources of evidence, charting methods, results, and conclusions related to the review questions and objectives. | 1 |

| Introduction | |||

| Rationale | 3 | Describe the rationale for the review in the context of what is already known. Please explain why the review questions/objectives lend themselves to a scoping review approach. | 3 |

| Objectives | 4 | Provide an explicit statement of the questions and objectives being addressed concerning their key elements (e.g., population or participants, concepts, and context) or other relevant key elements used to conceptualize the review questions and/or objectives. | 1, 3, 15 |

| Methods | |||

| Protocol and registration | 5 | Indicate whether a review protocol exists; state if and where it can be accessed (e.g., a Web address); and provide registration information, including the registration number if available. | 14 |

| Eligibility criteria | 6 | Specify characteristics of the sources of evidence used as eligibility criteria (e.g., years considered, language, and publication status), and provide a rationale. | 15 |

| Information sources * | 7 | Describe all information sources in the search (e.g., databases with dates of coverage and contact with authors to identify additional sources) and the date the most recent search was executed. | 14 |

| Search | 8 | Present the full electronic search strategy for at least one database, including any limits used so that it could be repeated. | 16 |

| Selection of sources of evidence † | 9 | State the process for selecting sources of evidence (i.e., screening and eligibility) included in the scoping review. | 15, 16 |

| Data charting process ‡ | 10 | Describe the methods of charting data from the included sources of evidence (e.g., calibrated forms or forms that the team has tested before their use and whether data charting was done independently or in duplicate) and any processes for obtaining and confirming data from investigators. | 13 |

| Data items | 11 | List and define all variables for which data were sought and any assumptions and simplifications made. | - |

| Critical appraisal of individual sources of evidence § | 12 | If done, provide a rationale for conducting a critical appraisal of included sources of evidence; describe the methods used and how this information was used in any data synthesis (if appropriate). | - |

| Synthesis of results | 13 | Describe the methods of handling and summarizing the data that were charted. | 16 |

| Results | |||

| Selection of sources of evidence | 14 | Give the number of sources of evidence screened, assessed for eligibility, and included in the review, with reasons for exclusions at each stage, ideally using a flow diagram. | 16 |

| Characteristics of sources of evidence | 15 | For each source of evidence, present characteristics for which data were charted and provide the citations. | - |

| Critical appraisal within sources of evidence | 16 | If done, present data on critical appraisal of included sources of evidence (see item 12). | - |

| Results of individual sources of evidence | 17 | For each included source of evidence, present the relevant data that were charted that relate to the review questions and objectives. | - |

| Synthesis of results | 18 | Summarize and/or present the charting results related to the review questions and objectives. | 16 |

| Discussion | |||

| Summary of evidence | 19 | Summarize the main results (including an overview of concepts, themes, and types of evidence available), link to the review questions and objectives, and consider the relevance to key groups. | - |

| Limitations | 20 | Discuss the limitations of the scoping review process. | 16, 17, 18 |

| Conclusions | 21 | Provide a general interpretation of the results concerning the review questions, objectives, and potential implications and/or next steps. | 18 |

| Funding | |||

| Funding | 22 | Describe funding sources for the included sources of evidence and the scoping review. Describe the role of the funders of the scoping review. | 19 |

References

- Schwerha, D.J.; McNamara, N.; Nussbaum, M.A.; Kim, S. Adoption potential of occupational exoskeletons in diverse enterprises engaged in manufacturing tasks. Int. J. Ind. Ergon. 2021, 82, 103103. [Google Scholar] [CrossRef]

- Riccò, M.; Ranzieri, S.; Vezzosi, L.; Balzarini, F.; Bragazzi, N.L. Wearable Exoskeletons on the Workplaces: Knowledge, Attitudes and Perspectives of Health and Safety Managers on the implementation of exoskeleton technology in Northern Italy. Acta Biomed. 2021, 92, e2021310. [Google Scholar] [CrossRef]

- Deshpande, N.; Ortiz, J.; Sarakoglou, I.; Semini, C.; Tsagarakis, N.; Brygo, A.; Fernandez, J.; Frigerio, M.; Saccares, L.; Toxiri, S.; et al. Next-generation collaborative robotic systems for industrial safety and health. WIT Trans. Built Environ. 2018, 174, 187–200. [Google Scholar] [CrossRef]

- Zelik, K.E.; Nurse, C.A.; Schall, M.C.; Sesek, R.F.; Marino, M.C.; Gallagher, S. An ergonomic assessment tool for evaluating the effect of back exoskeletons on injury risk. Appl. Ergon. 2022, 99, 103619. [Google Scholar] [CrossRef]

- Upasani, S.; Franco, R.; Niewolny, K.; Srinivasan, D. The Potential for Exoskeletons to Improve Health and Safety in Agriculture-Perspectives from Service Providers. IISE Trans. Occup. Ergon. Hum. Factors 2019, 7, 222–229. [Google Scholar] [CrossRef]

- Lazzaroni, M.; Fanti, V.; Sposito, M.; Chini, G.; Draicchio, F.; Di Natali, C.; Caldwell, D.G.; Ortiz, J. Improving the Efficacy of an Active Back-Support Exoskeleton for Manual Material Handling Using the Accelerometer Signal. IEEE Robot. Autom. Lett. 2022, 7, 7716–7721. [Google Scholar] [CrossRef]

- Hoffmann, N.; Prokop, G.; Weidner, R. Methodologies for evaluating exoskeletons with industrial applications. Ergonomics 2022, 65, 276–295. [Google Scholar] [CrossRef]

- Di Natali, C.; Chini, G.; Toxiri, S.; Monica, L.; Anastasi, S.; Draicchio, F.; Caldwell, D.G.; Ortiz, J. Equivalent Weight: Connecting Exoskeleton Effectiveness with Ergonomic Risk during Manual Material Handling. Int. J. Environ. Res. Public Health 2021, 18, 2677. [Google Scholar] [CrossRef]

- van der Have, A.; Rossini, M.; Rodriguez-Guerrero, C.; Van Rossom, S.; Jonkers, I. The Exo4Work shoulder exoskeleton effectively reduces muscle and joint loading during simulated occupational tasks above shoulder height. Appl. Ergon. 2022, 103, 103800. [Google Scholar] [CrossRef] [PubMed]

- Howard, J.; Murashov, V.V.; Lowe, B.D.; Lu, M. Industrial exoskeletons: Need for intervention effectiveness research. Am. J. Ind. Med. 2020, 63, 201–208. [Google Scholar] [CrossRef]

- Steinhilber, B.; Luger, T.; Schwenkreis, P.; Middeldorf, S.; Bork, H.; Mann, B.; von Glinski, A.; Schildhauer, T.A.; Weiler, S.; Schmauder, M.; et al. The use of exoskeletons in the occupational context for primary, secondary, and tertiary prevention of work-related musculoskeletal complaints. IISE Trans. Occup. Ergon. Hum. Factors 2020, 8, 132–144. [Google Scholar] [CrossRef]

- Missiroli, F.; Lotti, N.; Tricomi, E.; Bokranz, C.; Alicea, R.; Xiloyannis, M.; Krzywinski, J.; Crea, S.; Vitiello, N.; Masia, L. Rigid, Soft, Passive, and Active: A Hybrid Occupational Exoskeleton for Bimanual Multijoint Assistance. IEEE Robot. Autom. Lett. 2022, 7, 2557–2564. [Google Scholar] [CrossRef]

- Schwerha, D.; McNamara, N.; Kim, S.; Nussbaum, M.A. Exploratory Field Testing of Passive Exoskeletons in Several Manufacturing Environments: Perceived Usability and User Acceptance. IISE Trans. Occup. Ergon. Hum. Factors 2022, 10, 71–82. [Google Scholar] [CrossRef] [PubMed]

- García, M.A.C. Evaluación de la carga física postural y su relación con los trastornos musculo esqueléticos. Rev. Colomb. De Salud Ocup. 2014, 4, 22–25. [Google Scholar] [CrossRef]

- Gupta, A.; O’Malley, M. Design of a haptic arm exoskeleton for training and rehabilitation. IEEE/ASME Trans. Mechatron. 2006, 11, 280–289. [Google Scholar] [CrossRef]

- Trastornos Musculoesqueléticos|Safety and Health at Work EU-OSHA. Available online: https://osha.europa.eu/es/themes/musculoskeletal-disorders (accessed on 24 December 2022).

- Christensen, S.; Rafique, S.; Bai, S. Design of a powered full-body exoskeleton for physical assistance of elderly people. Int. J. Adv. Robot. Syst. 2021, 18, 172988142110535. [Google Scholar] [CrossRef]

- Ogunseiju, O.; Olayiwola, J.; Akanmu, A.; Olatunji, O.A. Evaluation of postural-assist exoskeleton for manual material handling. ECAM 2021, 29, 1358–1375. [Google Scholar] [CrossRef]

- Kim, S.; Moore, A.; Srinivasan, D.; Akanmu, A.; Barr, A.; Harris-Adamson, C.; Rempel, D.M.; Nussbaum, M.A. Potential of Exoskeleton Technologies to Enhance Safety, Health, and Performance in Construction: Industry Perspectives and Future Research Directions. IISE Trans. Occup. Ergon. Hum. Factors 2019, 7, 185–191. [Google Scholar] [CrossRef]

- Zhu, Z.; Dutta, A.; Dai, F. Exoskeletons for manual material handling—A review and implication for construction applications. Autom. Constr. 2021, 122, 103493. [Google Scholar] [CrossRef]

- Fontana, M.; Vertechy, R.; Marcheschi, S.; Salsedo, F.; Bergamasco, M. The Body Extender: A Full-Body Exoskeleton for the Transport and Handling of Heavy Loads. IEEE Robot. Automat. Mag. 2014, 21, 34–44. [Google Scholar] [CrossRef]

- Kim, B.; Deshpande, A.D. An upper-body rehabilitation exoskeleton Harmony with an anatomical shoulder mechanism: Design, modeling, control, and performance evaluation. Int. J. Robot. Res. 2017, 36, 414–435. [Google Scholar] [CrossRef]

- Gasser, B.W.; Martinez, A.; Sasso-Lance, E.; Kandilakis, C.; Durrough, C.M.; Goldfarb, M. Preliminary Assessment of a Hand and Arm Exoskeleton for Enabling Bimanual Tasks for Individuals With Hemiparesis. IEEE Trans. Neural Syst. Rehabil. Eng. 2020, 28, 2214–2223. [Google Scholar] [CrossRef]

- Petrič, T.; Peternel, L.; Morimoto, J.; Babič, J. Assistive Arm-Exoskeleton Control Based on Human Muscular Manipulability. Front. Neurorobot. 2019, 13, 30. [Google Scholar] [CrossRef]

- Wang, D.; Lee, K.-M.; Guo, J.; Yang, C.-J. Adaptive Knee Joint Exoskeleton Based on Biological Geometries. IEEE/ASME Trans. Mechatron. 2014, 19, 1268–1278. [Google Scholar] [CrossRef]

- Choi, H.-J.; Kim, G.-S.; Chai, J.H.; Ko, C.-Y. Effect of Gait Training Program with Mechanical Exoskeleton on Body Composition of Paraplegics. JMDH 2020, 13, 1879–1886. [Google Scholar] [CrossRef]

- Ma, X.; Yuan, R.; Fang, Y.S. System study of pneumatic exoskeleton rehabilitation manipulator. J. Eng. 2019, 2019, 181–185. [Google Scholar] [CrossRef]

- Su, Q.; Pei, Z.; Tang, Z. Nonlinear Control of a Hydraulic Exoskeleton 1-DOF Joint Based on a Hardware-In-The-Loop Simulation. Machines 2022, 10, 607. [Google Scholar] [CrossRef]

- Kanzler, C.M.; Gomez, S.M.; Rinderknecht, M.D.; Gassert, R.; Lambercy, O. Exobuddy—A Non-Anthropomorphic Quasi-Passive Exoskeleton for Load Carrying Assistance. In Proceedings of the 2018 7th IEEE International Conference on Biomedical Robotics and Biomechatronics (Biorob), Enschede, The Netherlands, 26–29 August 2018; pp. 336–341. [Google Scholar] [CrossRef]

- Chen, Z.-J.; He, C.; Guo, F.; Xiong, C.-H.; Huang, X.-L. Exoskeleton-Assisted Anthropomorphic Movement Training (EAMT) for Poststroke Upper Limb Rehabilitation: A Pilot Randomized Controlled Trial. Arch. Phys. Med. Rehabil. 2021, 102, 2074–2082. [Google Scholar] [CrossRef] [PubMed]

- Meo, S.A.; Alsaaran, Z.F.; Alshehri, M.K.; Khashougji, M.A.; Almeterk, A.A.Z.; Almutairi, S.F.; Alsaeed, S.F. Work-Related musculoskeletal symptoms among building construction workers in Riyadh, Saudi Arabia. Pak. J. Med. Sci. 2013, 29, 1394–1399. [Google Scholar] [CrossRef] [PubMed]

- GopiReddy, M.M.; Nisha, B.; Prabhushankar, T.; Vishwambhar, V. Musculoskeletal morbidity among construction workers: A cross-sectional community-based study. Indian J. Occup. Environ. Med. 2016, 20, 144. [Google Scholar] [CrossRef]

- Instituto Nacional de Seguridad y Salud en el Trabajo. Exoesqueletos I: Definición y clasificación. Ministerio de Trabajo y Economía Social, Gobierno de España. 2021. Available online: https://www.insst.es/documents/94886/566858/NTP+1162+Exoesqueletos+I+Definici%C3%B3n+y+clasificaci%C3%B3n+-+A%C3%B1o+2021.pdf/6f074ccc-6e03-bb05-dd59-efb5fa4e1fc8?version=2.0&t=1643041463932 (accessed on 2 June 2023).

- Instituto Nacional de Seguridad y Salud en el Trabajo. Exoesqueletos II: Criterios para la selección e integración en la empresa. Ministerio de Trabajo y Economía Social, Gobierno de España. 2021. Available online: https://www.insst.es/documents/94886/566858/NTP+1163+Exoesqueletos+II+Criterios+para+la+selecci%C3%B3n+e+integraci%C3%B3n+en+la+empresa+-+A%C3%B1o+2021.pdf/cae53381-0965-c171-aff7-6355574dd989?t=1642080930199 (accessed on 2 June 2023).

- European Agency for Safety and Health at Work. Directive 89/391/EEC—OSH “Framework Directive”. Web Oficial de la Union Europea. 2021. Available online: https://osha.europa.eu/es/legislation/directives/the-osh-framework-directive/the-osh-framework-directive-introduction (accessed on 2 June 2023).

- Choi, S.D.; Yuan, L.; Borchardt, Y.J.G. Musculoskeletal Disorders in Construction: Practical Solutions From the Literature. Prof. Saf. 2016, 61, 26–32. [Google Scholar]

- Celebi, B.; Yalcin, M.; Patoglu, V. AssistOn-Knee: A self-aligning knee exoskeleton. In Proceedings of the en 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; pp. 996–1002. [Google Scholar] [CrossRef]

- Han, Y.; Zhu, S.; Zhou, Z.; Shi, Y.; Hao, D. Research on a multimodal actuator-oriented power-assisted knee exoskeleton. Robotica 2017, 35, 1906–1922. [Google Scholar] [CrossRef]

- Yuan, B.; Li, B.; Chen, Y.; Tan, B.; Jiang, M.; Tang, S.; Wei, Y.; Wang, Z.; Ma, B.; Huang, J. Designing of a Passive Knee-Assisting Exoskeleton for Weight-Bearing. In Intelligent Robotics and Applications; Huang, Y., Wu, H., Liu, H., Yin, Z., Eds.; Springer International Publishing: Cham, Switzerland, 2017; Volume 10463, pp. 273–285. [Google Scholar] [CrossRef]

- Singh, R.; Chaudhary, H.; Singh, A.K. Shape synthesis of an assistive knee exoskeleton device to support knee joint and rehabilitate gait. Disabil. Rehabil. Assist. Technol. 2019, 14, 462–470. [Google Scholar] [CrossRef]

- Bryan, G.M.; Franks, P.W.; Song, S.; Voloshina, A.S.; Reyes, R.; O’Donovan, M.P.; Gregorczyk, K.N.; Collins, S.H. Optimized hip–knee–ankle exoskeleton assistance at a range of walking speeds. J. Neuro. Eng. Rehabil. 2021, 18, 152. [Google Scholar] [CrossRef]

- Ma, L.; Leng, Y.; Jiang, W.; Qian, Y.; Fu, C. Design an Underactuated Soft Exoskeleton to Sequentially Provide Knee Extension and Ankle Plantarflexion Assistance. IEEE Robot. Autom. Lett. 2022, 7, 271–278. [Google Scholar] [CrossRef]

- Zhou, S.; Zhao, Z.; Liu, X.; Zhu, X.; Chen, J. A Real-Time Assistance Control Strategy for Active Knee Exoskeleton. In Proceedings of the 2021 Chinese Intelligent Systems Conference, Fuzhou, China, 16–17 October 2021; Jia, Y., Zhang, W., Fu, Y., Yu, Z., Zheng, S., Eds.; Springer: Singapore, 2022; Volume 804, pp. 621–633. [Google Scholar] [CrossRef]

- Yang, C.; Yu, L.; Xu, L.; Yan, Z.; Hu, D.; Zhang, S.; Yang, W. Current developments of robotic hip exoskeleton toward sensing, decision, and actuation: A review. Wearable Technol. 2022, 3, e15. [Google Scholar] [CrossRef]

- Sharifi, M.; Mehr, J.K.; Mushahwar, V.K.; Tavakoli, M. Adaptive CPG-Based Gait Planning With Learning-Based Torque Estimation and Control for Exoskeletons. IEEE Robot. Autom. Lett. 2021, 6, 8261–8268. [Google Scholar] [CrossRef]

- Sharifi, M.; Mehr, J.K.; Mushahwar, V.K.; Tavakoli, M. Autonomous Locomotion Trajectory Shaping and Nonlinear Control for Lower Limb Exoskeletons. IEEE/ASME Trans. Mechatron. 2022, 27, 645–655. [Google Scholar] [CrossRef]

- Baltrusch, S.J.; van Dieën, J.H.; Bruijn, S.M.; Koopman, A.S.; van Bennekom, C.A.M.; Houdijk, H. The effect of a passive trunk exoskeleton on metabolic costs during lifting and walking. Ergonomics 2019, 62, 903–916. [Google Scholar] [CrossRef]

- Diamond-Ouellette, G.; Telonio, A.; Karakolis, T.; Leblond, J.; Bouyer, L.J.; Best, K.L. Exploring the Change in Metabolic Cost of Walking before and after Familiarization with a Passive Load-Bearing Exoskeleton: A Case Series. IISE Trans. Occup. Ergon. Hum. Factors 2022, 10, 161–172. [Google Scholar] [CrossRef]

- Santos, C.; Gabriel, A.T.V.; Quaresma, C.; Nunes, I.L. Lower limb exoskeletons some examples of application. In Proceedings of the presentado en 13th International Conference on Applied Human Factors and Ergonomics (AHFE 2022), New York, NY, USA, 24–28 July 2022. [Google Scholar] [CrossRef]

- Keerthana, J.; Krishna, R.H.; Krishnamoorthy, M.; Hariharan, R.; Kumaresan, R. Design and Analysis of Lower Limb Assistive Exoskeleton. ARME 2022, 11, 18–28. [Google Scholar] [CrossRef]

- Wijegunawardana, I.; Kumara, M.; De Silva, H.; Viduranga, P.; Ranaweera, R.; Gopura, R.; Madusanka, D. ChairX: A Robotic Exoskeleton Chair for Industrial Workers. In Proceedings of the 2019 IEEE 16th International Conference on Rehabilitation Robotics (ICORR), Toronto, ON, Canada, 24–28 June 2019; pp. 587–592. [Google Scholar] [CrossRef]

- Li, Q.; Feng, Y.; Zhang, W.; Liu, R. Design and Research of Lower Limb Walking-assisted Exoskeleton Robot. In Proceedings of the 2019 4th International Conference on Control and Robotics Engineering (ICCRE), Nanjing, China, 20–23 April 2019; pp. 132–135. [Google Scholar] [CrossRef]

- Huo, W.; Mohammed, S.; Amirat, Y.; Kong, K. Fast Gait Mode Detection and Assistive Torque Control of an Exoskeletal Robotic Orthosis for Walking Assistance. IEEE Trans. Robot. 2018, 34, 1035–1052. [Google Scholar] [CrossRef]

- Golabchi, A.; Chao, A.; Tavakoli, M. A Systematic Review of Industrial Exoskeletons for Injury Prevention: Efficacy Evaluation Metrics, Target Tasks, and Supported Body Postures. Sensors 2022, 22, 2714. [Google Scholar] [CrossRef] [PubMed]

- Desbrosses, K.; Schwartz, M.; Theurel, J. Evaluation of two upper-limb exoskeletons during overhead work: Influence of exoskeleton design and load on muscular adaptations and balance regulation. Eur. J. Appl. Physiol. 2021, 121, 2811–2823. [Google Scholar] [CrossRef] [PubMed]

- Murai, S.; Ishizuka, Y.; Takahashi, Y. Power Assist Control Based on Posture Angles Estimation Using LPC and Motion Following using Interaction Force Between Wearer and Powered Exoskeleton. Proc. JSME Annu. Conf. Robot. Mechatron. (Robomech) 2019, 2019, 2A2-L01. [Google Scholar] [CrossRef]

- Mehr, J.K.; Sharifi, M.; Mushahwar, V.K.; Tavakoli, M. Intelligent Locomotion Planning With Enhanced Postural Stability for Lower-Limb Exoskeletons. IEEE Robot. Autom. Lett. 2021, 6, 7588–7595. [Google Scholar] [CrossRef]

- Liu, H.; Liu, X.; Yan, G.; Yuan, G.; Zeng, B. Human-Machine Attitude Deviation Identification of Knee Exoskeleton Based on PO-MOESP Algorithm. In Proceedings of the 2022 Chinese Intelligent Systems Conference, Beijing, China, 15–16 October 2022; Jia, Y., Zhang, W., Fu, Y., Zhao, S., Eds.; Springer Nature Singapore: Singapore, 2022; Volume 951, pp. 428–435. [Google Scholar] [CrossRef]

- Kiguchi, K.; Quan, Q. Muscle-model-oriented EMG-based control of an upper-limb power-assist exoskeleton with a neuro-fuzzy modifier. In Proceedings of the 2008 IEEE International Conference on Fuzzy Systems (IEEE World Congress on Computational Intelligence), Hong Kong, China, 1–6 June 2008; pp. 1179–1184. [Google Scholar] [CrossRef]

- Khan, A.M.; Ji, Y.H.; Ali, M.A.; Han, J.S.; Han, C.S. Passivity Based Adaptive Control and Its Optimization for Upper Limb Assist Exoskeleton Robot. J. Korean Soc. Precis. Eng. 2015, 32, 857–863. [Google Scholar] [CrossRef]

- Jamšek, M.; Babič, J. Human Trunk Stabilization with Hip Exoskeleton for Enhanced Postural Control. In Wearable Robotics: Challenges and Trends; Carrozza, M.C., Micera, S., Pons, J.L., Eds.; Springer International Publishing: Cham, Switzerland, 2019; Volume 22, pp. 450–454. [Google Scholar] [CrossRef]

- Paez-Granados, D.F.; Kadone, H.; Hassan, M.; Chen, Y.; Suzuki, K. Personal Mobility With Synchronous Trunk–Knee Passive Exoskeleton: Optimizing Human–Robot Energy Transfer. IEEE/ASME Trans. Mechatron. 2022, 27, 3613–3623. [Google Scholar] [CrossRef]

- Zhu, A.; Shen, Z.; Shen, H.; Song, J. Design and Preliminary Experimentation of Passive Weight-Support Exoskeleton. In Proceedings of the 2018 IEEE International Conference on Information and Automation (ICIA), Wuyishan, China, 11–13 August 2018; pp. 761–765. [Google Scholar] [CrossRef]

- Baunsgaard, C.B.; Nissen, U.V.; Brust, A.K.; Frotzler, A.; Ribeill, C.; Kalke, Y.-B.; León, N.; Gómez, B.; Samuelsson, K.; Antepohl, W.; et al. Gait training after spinal cord injury: Safety, feasibility and gait function following 8 weeks of training with the exoskeletons from Ekso Bionics. Spinal Cord 2018, 56, 106–116. [Google Scholar] [CrossRef] [PubMed]

- Xue, X.; Yang, X.; Tu, H.; Liu, W.; Kong, D.; Fan, Z.; Deng, Z.; Li, N. The improvement of the lower limb exoskeletons on the gait of patients with spinal cord injury: A protocol for systematic review and meta-analysis. Medicine 2022, 101, e28709. [Google Scholar] [CrossRef]

- Bass, A.; Morin, S.N.; Vermette, M.; Aubertin-Leheudre, M.; Gagnon, D.H. Incidental bilateral calcaneal fractures following overground walking with a wearable robotic exoskeleton in a wheelchair user with a chronic spinal cord injury: Is zero risk possible? Osteoporos Int. 2020, 31, 1007–1011. [Google Scholar] [CrossRef] [PubMed]

- Martin, W.B.; Boehler, A.; Hollander, K.W.; Kinney, D.; Hitt, J.K.; Kudva, J.; Sugar, T.G. Development and testing of the aerial porter exoskeleton. Wearable Technol. 2022, 3, e1. [Google Scholar] [CrossRef]

- Poliero, T.; Lazzaroni, M.; Toxiri, S.; Di Natali, C.; Caldwell, D.G.; Ortiz, J. Applicability of an Active Back-Support Exoskeleton to Carrying Activities. Front. Robot. AI 2020, 7, 579963. [Google Scholar] [CrossRef]

- Park, H.; Kim, S.; Nussbaum, M.A.; Srinivasan, D. Effects of using a whole-body powered exoskeleton during simulated occupational load-handling tasks: A pilot study. Appl. Ergon. 2022, 98, 103589. [Google Scholar] [CrossRef] [PubMed]

- Luger, T.; Bär, M.; Seibt, R.; Rimmele, P.; Rieger, M.A.; Steinhilber, B. A passive back exoskeleton supporting symmetric and asymmetric lifting in stoop and squat posture reduces trunk and hip extensor muscle activity and adjusts body posture—A laboratory study. Appl. Ergon. 2021, 97, 103530. [Google Scholar] [CrossRef] [PubMed]

- Babič, J.; Mombaur, K.; Lefeber, D.; van Dieën, J.; Graimann, B.; Russold, M.; Šarabon, N.; Houdijk, H. SPEXOR: Spinal Exoskeletal Robot for Low Back Pain Prevention and Vocational Reintegration. In Wearable Robotics: Challenges and Trends; González-Vargas, J., Ibáñez, J., Contreras-Vidal, J.L., van der Kooij, H., Pons, J.L., Eds.; Springer International Publishing: Cham, Switzerland, 2017; Volume 16, pp. 311–315. [Google Scholar] [CrossRef]

- De Bock, S.; Rossini, M.; Lefeber, D.; Rodriguez-Guerrero, C.; Geeroms, J.; Meeusen, R.; De Pauw, K. An Occupational Shoulder Exoskeleton Reduces Muscle Activity and Fatigue During Overhead Work. IEEE Trans. Biomed. Eng. 2022, 69, 3008–3020. [Google Scholar] [CrossRef]

- Chiș, L.C.; Copotoiu, M.; Moldovan, L. Different Types of Exoskeletons can Improve the Life of Spinal Cord Injury’s Patients—A Meta-Analysis. Procedia Manuf. 2020, 46, 844–849. [Google Scholar] [CrossRef]

- Jain, S.; Verma, H.; Khan, A.A. Ergonomic support system for construction worker’s hand arm for lifting tasks. J. Phys. Conf. Ser. 2021, 1950, 012051. [Google Scholar] [CrossRef]

- Ismail, R.; Ariyanto, M.; Perkasa, I.A.; Adirianto, R.; Putri, F.T.; Glowacz, A.; Caesarendra, W. Soft Elbow Exoskeleton for Upper Limb Assistance Incorporating Dual Motor-Tendon Actuator. Electronics 2019, 8, 1184. [Google Scholar] [CrossRef]

- Kandilakis, C.; Sasso-Lance, E. Exoskeletons for Personal Use After Spinal Cord Injury. Arch. Phys. Med. Rehabil. 2019, 102, 331–337. [Google Scholar] [CrossRef]

- Theurel, J.; Desbrosses, K. Occupational Exoskeletons: Overview of Their Benefits and Limitations in Preventing Work-Related Musculoskeletal Disorders. IISE Trans. Occup. Ergon. Hum. Factors 2019, 7, 264–280. [Google Scholar] [CrossRef]

- Mendeley Data. Available online: https://data.mendeley.com/datasets/bktzm7k664/1 (accessed on 2 June 2023).

- Bennett, S.T.; Han, W.; Mahmud, D.; Adamczyk, P.G.; Dai, F.; Wehner, M.; Veeramani, D.; Zhu, Z. Usability and Biomechanical Testing of Passive Exoskeletons for Construction Workers: A Field-Based Pilot Study. Buildings 2023, 13, 822. [Google Scholar] [CrossRef]

- TS2. The Environmental Impact of Robotic Exoskeletons: A Sustainable Solution? 2023. Available online: https://ts2.space/en/the-environmental-impact-of-robotic-exoskeletons-a-sustainable-solution/#google_vignette (accessed on 5 June 2023).

| Exoskeletons Shoulder-Arm Assistance | |||||

| Type | Exoskeleton | Muscle Activity and Movement | Joints’ Activity | Natural Movement | Lifting Speed on Arm |

| Passive | EKsoVest | X | |||

| Passive | H-VEX | X | |||

| Passive | Fawcett Exsovestᵀᴹ | X | |||

| Passive | Hombrox | X | |||

| Passive | PAEXO | X | X | ||

| Passive | EXHAUST | X | |||

| Passive | SkelEx | X | |||

| Active | EcoPick | X | |||

| Active | Lucy | X | X | ||

| Active | MuscleSuite | X | |||

| Exoskeletons Back Assistance | |||||

| Type | Exoskeleton | Muscle Activity and Movement | Lower Energy Expenditure | Lower Thoracic Strength | Less Strength in the Lower Back |

| Passive | BackX | X | |||

| Passive | BNDR | X | |||

| Passive | Laevo | X | X | ||

| Passive | PLAD | X | X | X | |

| Active | SPEDOR | X | X | X | |

| Active | HAL | X | X | ||

| Active | MeBot-EXO | X | X | X | |

| Active | MK2b | X | |||

| Exoskeletons Full-Body Assistance | |||||

| Type | Exoskeleton | Load Resistance | Arm Support | Physical Demands | Task Difficulty |

| Active | Fortisᵀᴹ | X | X | X | X |

| Exoskeleton Leg Assistance | |||||

| Type | Exoskeleton | Muscle Activity and Movement | Comfort Foot Position | Maintain Balance | Torsion Reduction |

| Passive | LegX | X | |||

| Passive | Silla sin silla | X | X | ||

| Active | Traje de ANGEL | X | X | ||

| Active | UMEx-oLEA | X | X | ||

| Database | String Search | Study Number |

|---|---|---|

| IEEE | ALL (exoskeletons AND occupational AND safety AND health) | 22 |

| Others | TITLE (exoskeletons AND occupational AND safety AND health) | 39 |

| Proquest | (exoskeleton) AND (occupational) AND (safety) AND (health) | 20 |

| PubMed | TITLE-ABS-KEY (exoskeletons AND occupational AND safety AND health) | 14 |

| Science Direct | All (exoskeletons AND occupational AND safety AND health) | 205 |

| Scopus | TITLE-ABS-KEY (exoskeletons AND occupational AND safety AND health) | 15 |

| Web of Science | All Fields (exoskeletons AND occupational AND safety AND health) | 29 |

| Total number of studies | 344 |

| N° | Quality Assessment Questions | Answer |

|---|---|---|

| QA1 | Does the paper describe devices or technologies for safety and occupational health? | (+1) Yes/(+0) No |

| QA2 | Does the document specify how technology improves working conditions? | (+1) Yes/(+0) No |

| QA3 | Does the paper describe the principles and technical characteristics of the operation of these technologies? | (+1) Yes/(+0) No |

| QA4 | Are the limitations of using these technologies described in the paper? | (+1) Yes/(+0) No |

| QA5 | Is the journal or conference in which the paper was published indexed in SJR? | (+1) if it is ranked Q1, (+0.75) if it is ranked Q2, (+0.50) if it is ranked Q3, (+0.25) if it is ranked Q4, (+0.0) if it is not ranked. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Flor-Unda, O.; Casa, B.; Fuentes, M.; Solorzano, S.; Narvaez-Espinoza, F.; Acosta-Vargas, P. Exoskeletons: Contribution to Occupational Health and Safety. Bioengineering 2023, 10, 1039. https://doi.org/10.3390/bioengineering10091039

Flor-Unda O, Casa B, Fuentes M, Solorzano S, Narvaez-Espinoza F, Acosta-Vargas P. Exoskeletons: Contribution to Occupational Health and Safety. Bioengineering. 2023; 10(9):1039. https://doi.org/10.3390/bioengineering10091039

Chicago/Turabian StyleFlor-Unda, Omar, Bregith Casa, Mauricio Fuentes, Santiago Solorzano, Fabián Narvaez-Espinoza, and Patricia Acosta-Vargas. 2023. "Exoskeletons: Contribution to Occupational Health and Safety" Bioengineering 10, no. 9: 1039. https://doi.org/10.3390/bioengineering10091039

APA StyleFlor-Unda, O., Casa, B., Fuentes, M., Solorzano, S., Narvaez-Espinoza, F., & Acosta-Vargas, P. (2023). Exoskeletons: Contribution to Occupational Health and Safety. Bioengineering, 10(9), 1039. https://doi.org/10.3390/bioengineering10091039