Investigation of the Mechanical Response of the Foot Structure Considering Push-Off Angles in Speed Skating

Abstract

:1. Introduction

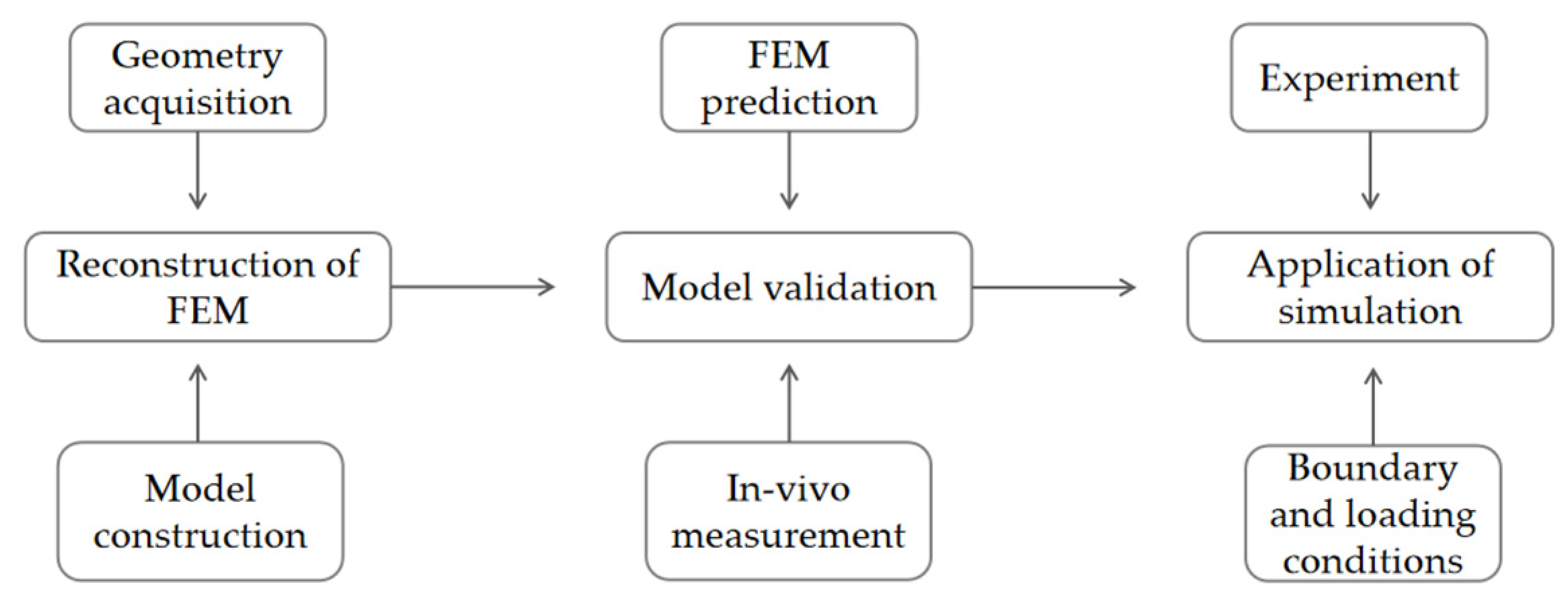

2. Materials and Methods

2.1. Subject and Speed Skate

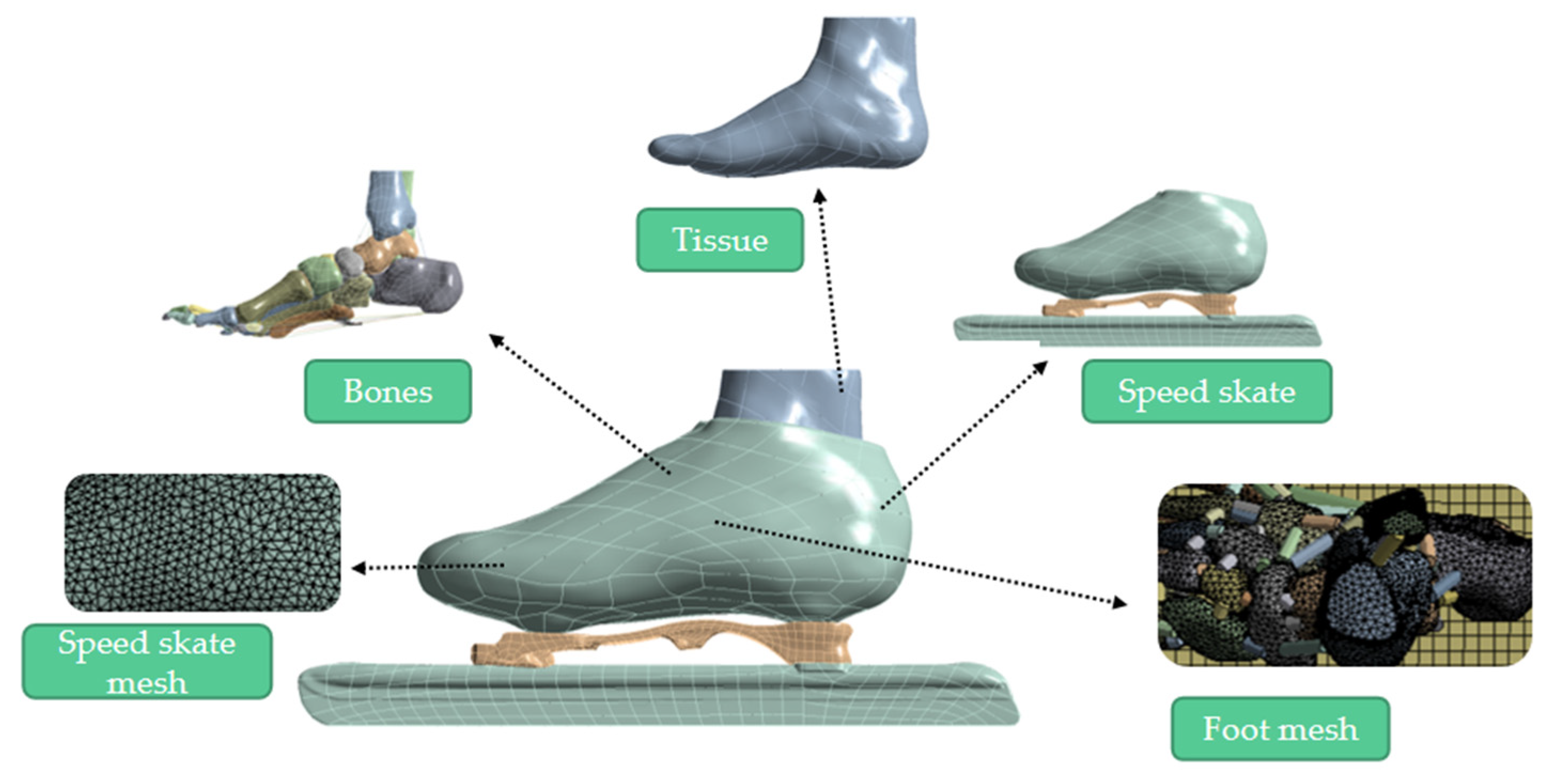

2.2. The Reconstruction of the FEM

2.2.1. Geometry Acquisition

2.2.2. Model Construction

2.3. Model Validation

2.4. Application of Simulation

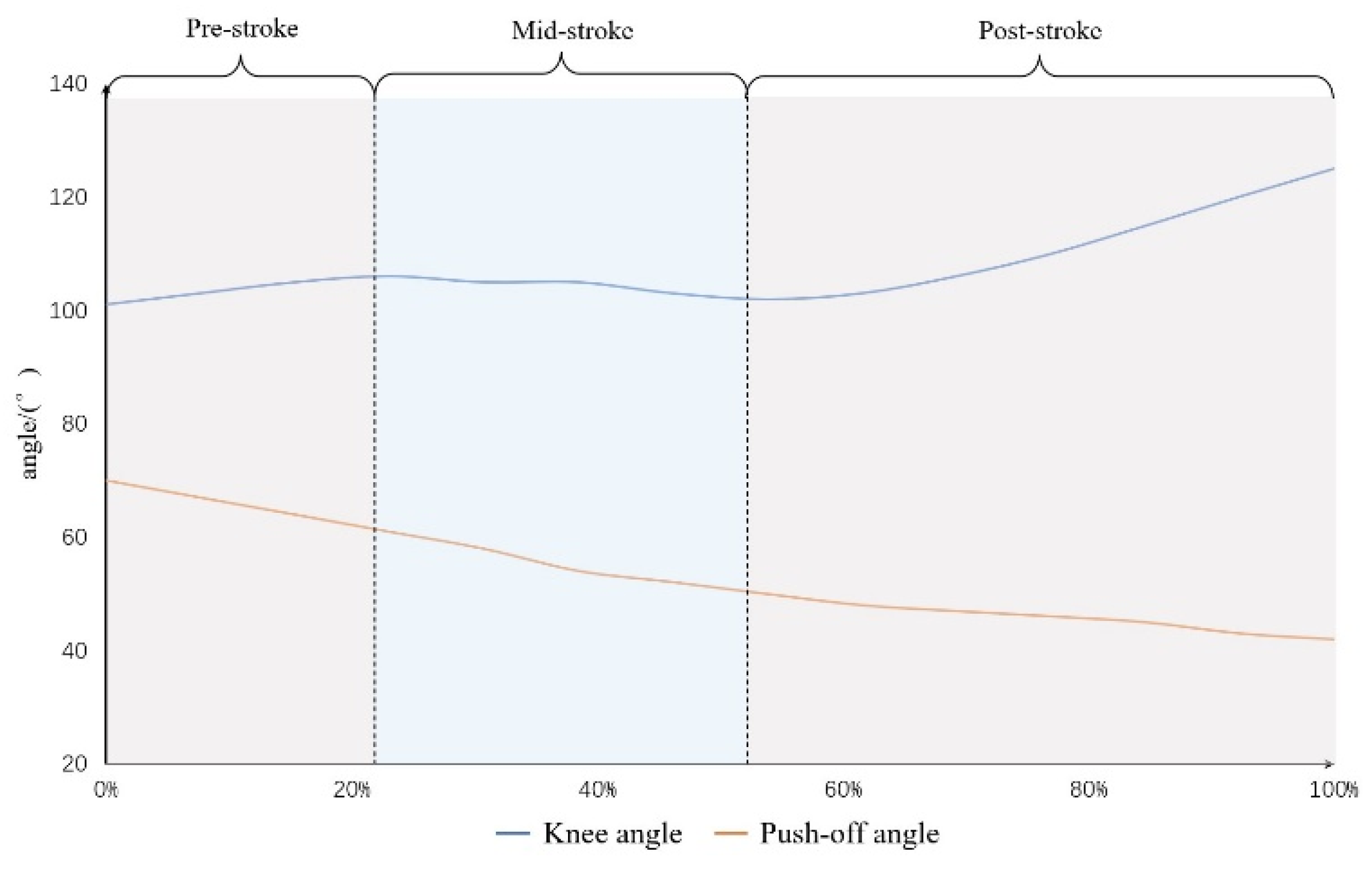

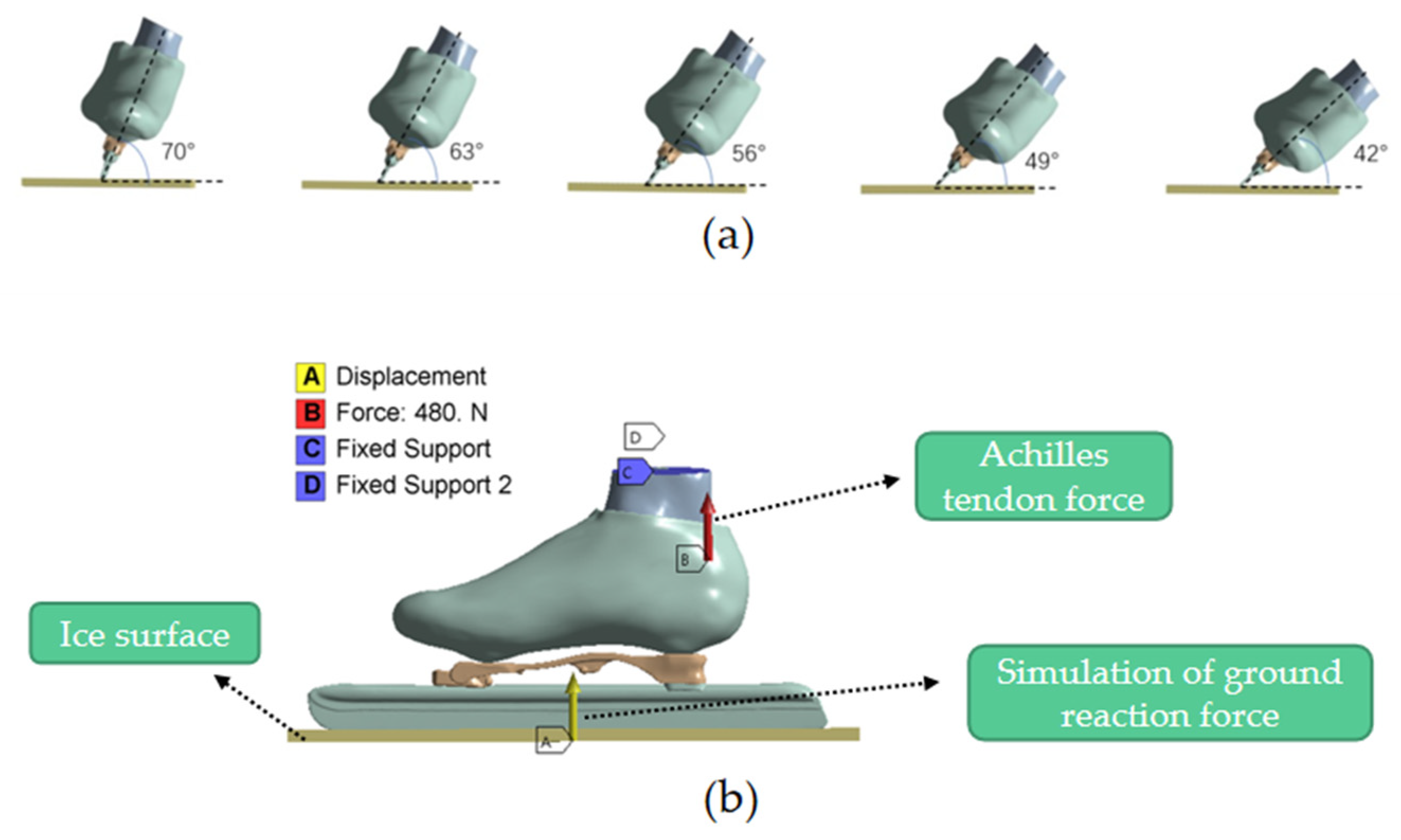

2.4.1. Push-Off Angle Experiment

2.4.2. Boundary and Loading Conditions

3. Results

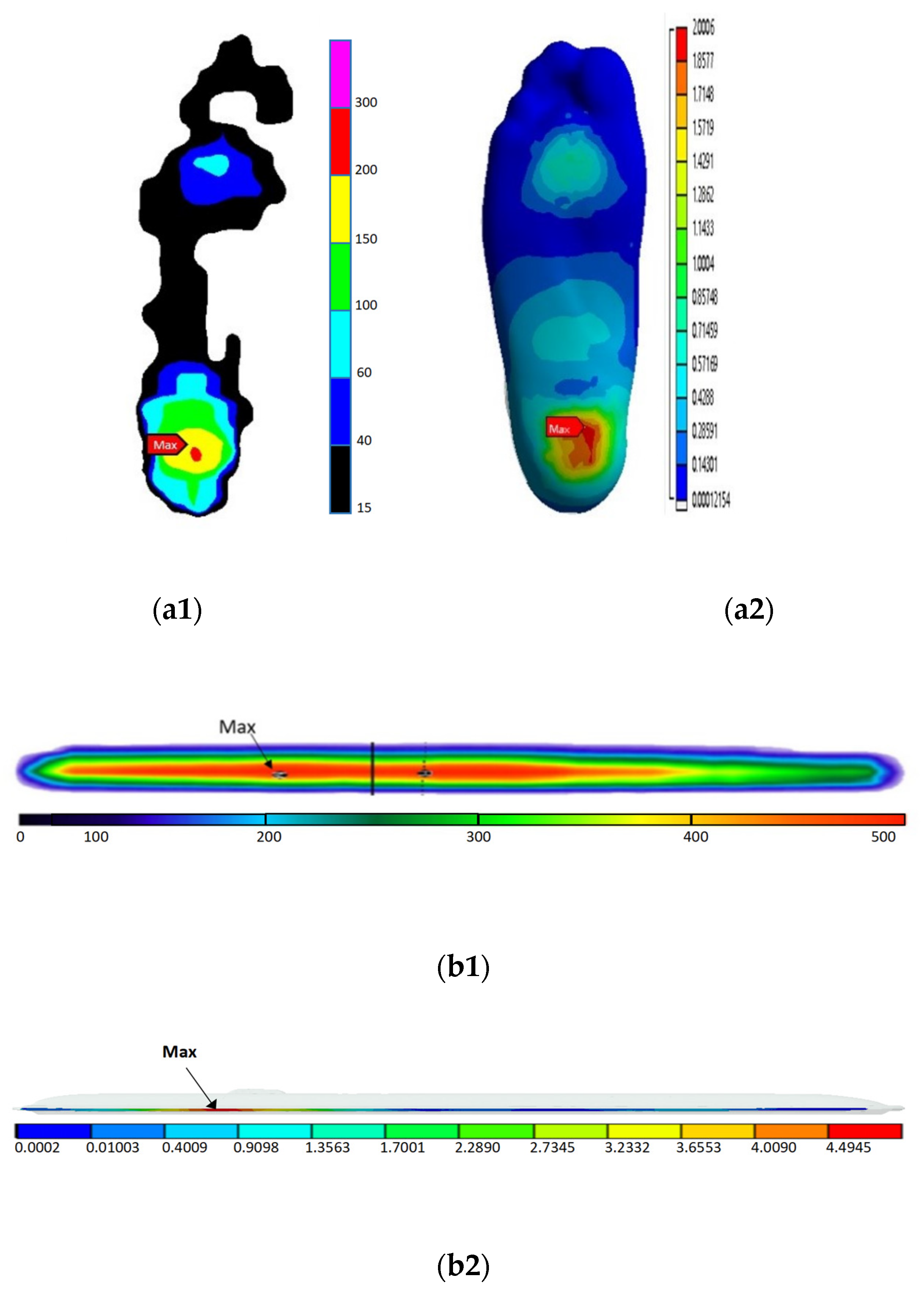

3.1. Model Validation

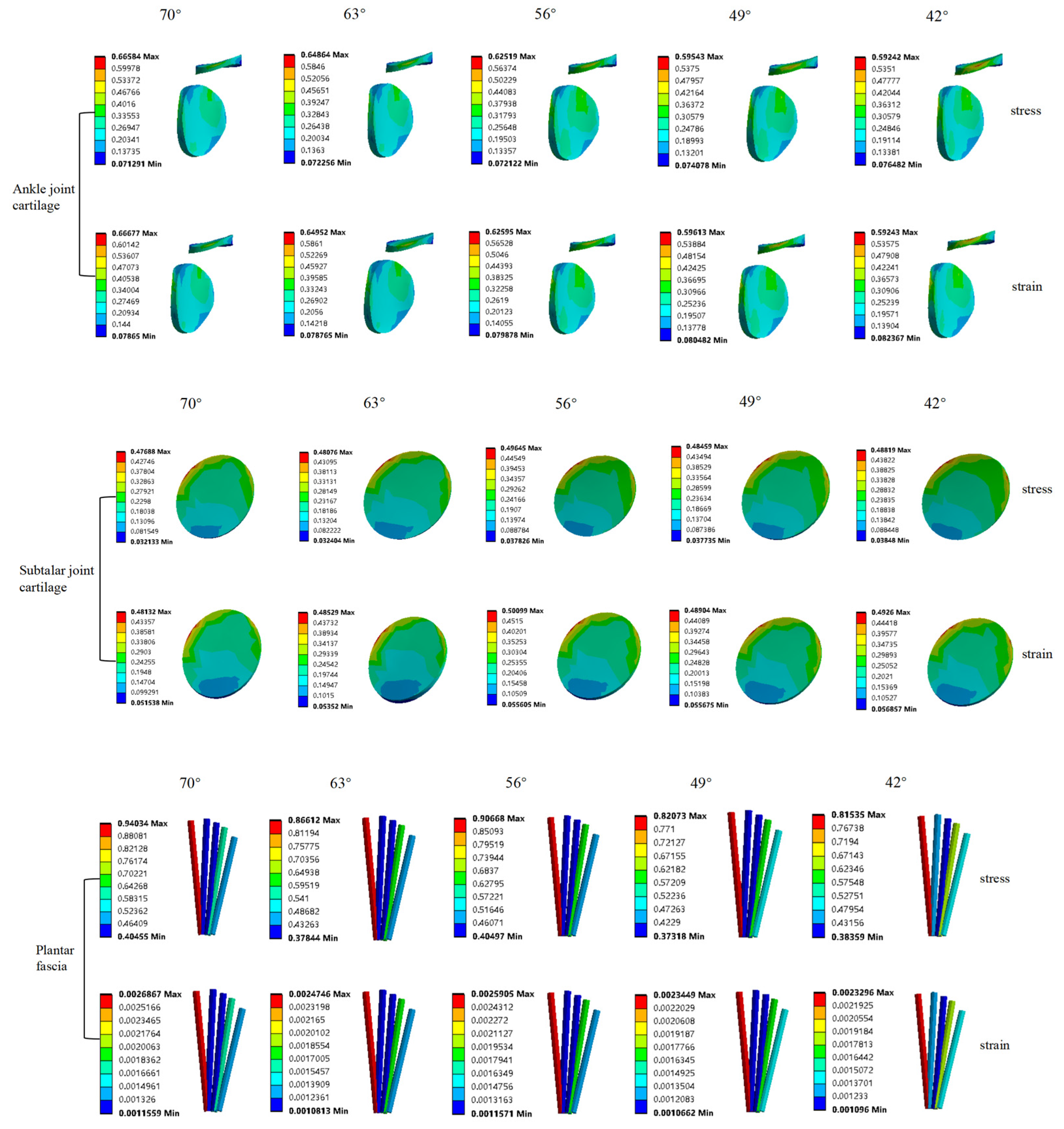

3.2. Effects on Foot Structures of Different Push-Off Angles

4. Discussion

4.1. Validity of the FEM

4.2. Mechanical Response to Stress and Strain on the Foot Structure

4.3. Limitations

4.4. Practical Applications

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Peng, Q.; Li, F.; Liu, H.; Gomez, M.-A. Analysis of Pacing Behaviors on Mass Start Speed Skating. Int. J. Environ. Res. Public Health 2022, 19, 10830. [Google Scholar] [CrossRef] [PubMed]

- Konings, M.J.; Elferink-Gemser, M.T.; Stoter, I.K.; van der Meer, D.; Otten, E.; Hettinga, F.J. Performance Characteristics of Long-Track Speed Skaters: A Literature Review. Sports Med. 2015, 45, 505–516. [Google Scholar] [CrossRef] [PubMed]

- Tomita, Y.; Lizuka, T.; Irisawa, K.; Ilumra, S. Detection of Movement Events of Long-Track Speed Skating Using Wearable Inertial Sensors. Sensors 2021, 21, 3649. [Google Scholar] [CrossRef] [PubMed]

- De Koning, J.J.; van Ingen Schena, G.J. Performance-Determining Factors in Speed Skating; Blackwell Science Ltd.: Oxford, UK, 2000; pp. 232–246. [Google Scholar]

- Li, B.; Liu, C.; Yang, W.; Li, Y. The Science of Skating Faster—The sports biology of speed skating. Sports Sci. 2021, 41, 34–42. [Google Scholar]

- Perez, J.; Guilhem, G.; Hager, R.; Brocherie, F. Mechanical determinants of forward skating sprint inferred from off- and on-ice force-velocity evaluations in elite female ice hockey players. Eur. J. Sport Sci. 2021, 21, 192–203. [Google Scholar] [CrossRef]

- Van der Kruk, E.; Veeger, H.E.J.; van der Helm, F.C.T.; Schwab, A.L. Design and verification of a simple 3D dynamic model of speed skating which mimics observed forces and motions. J. Biomech. 2017, 64, 93–102. [Google Scholar] [CrossRef]

- Noordhof, D.A.; Foster, C.; Hoozemans, M.J.M.; de Koning, J.J. The association between changes in speed skating technique and changes in skating velocity. Int. J. Sports Physiol. Perform. 2014, 9, 68–76. [Google Scholar] [CrossRef]

- Noordhof, D.A.; Foster, C.; Hoozemans, M.J.; de Koning, J.J. Changes in speed skating velocity in relation to push-off effectiveness. Int. J. Sports Physiol. Perform. 2013, 8, 188–194. [Google Scholar] [CrossRef]

- Van Ingen, S.G.J.; de Groot, G.; de Boer, R.W. The control of speed in elite female speed skaters. J. Biomech. 1985, 18, 91–96. [Google Scholar] [CrossRef]

- Zhang, M.; Qu, Y.; Cui, Q.; Liu, H. Application of artificial intelligence system for motion capture in speed skating. Sci. Technol. Eng. 2022, 22, 5674–5680. [Google Scholar]

- Stoter, I.K.; Hettinga, F.J.; Otten, E.; Visscher, C.; Elferink-Gemser, M.T. Changes in technique throughout a 1500-m speed skating time-trial in junior elite athletes: Differences between sexes, performance levels and competitive seasons. PLoS ONE 2020, 15, e0237331. [Google Scholar] [CrossRef]

- Timmer, N.; Veldhuis, L. The impact of skinsuit zigzag tape turbulators on speed skating performance. Appl. Sci. 2021, 11, 988. [Google Scholar] [CrossRef]

- Han, J.S.; Geminiani, E.T.; Micheli, L.J. Epidemiology of Figure Skating Injuries: A Review of the Literature. Sports Health 2018, 10, 532–537. [Google Scholar] [CrossRef] [PubMed]

- Khuyagbaatar, B.; Purevsuren, T.; Park, K.M.; Kim, K.; Kim, T.H. Interjoint coordination of the lower extremities in short-track speed skating. Proc. Inst. Mech. Engineers. Part H J. Eng. Med. 2017, 231, 987–993. [Google Scholar] [CrossRef] [PubMed]

- Andrew, Q.; Lun, V.; McCall, J.; Overend, T. Injuries in Short Track Speed Skating. Am. J. Sports Med. 2003, 31, 507–510. [Google Scholar]

- Fong, D.T.; Hong, Y.; Chan, L.K.; Yung, P.S.; Chan, K.M. A systematic review on ankle injury and ankle sprain in sports. Sports Med. 2007, 37, 73–94. [Google Scholar] [CrossRef]

- Liu, J.J.; Zhu, X.L.; Liu, H. Application of finite element method in biomechanical study on plantar fasciitis. Chin. J. Tissue Eng. Res. 2018, 22, 3900–3906. [Google Scholar]

- Mayer, S.W.; Joyner, P.W.; Almekinders, L.C.; Parekh, S.G. Stress fractures of the foot and ankle in athletes. Sports Health 2014, 6, 481–491. [Google Scholar] [CrossRef]

- Aicale, R.; Tarantino, D.; Maffulli, N. Overuse injuries in sport: A comprehensive overview. J. Orthop. Surg. Res. 2018, 13, 309. [Google Scholar] [CrossRef]

- Bernard, A.A.; Corlett, S.; Thomsen, E.; Bell, N.; McMahon, A.; Richmond, P.; Porter, K.M. Ice skating accidents and injuries. Injury 1988, 19, 191–192. [Google Scholar] [CrossRef]

- Bryant, R.A.; Creamer, M.; O’Donnell, M.; Silove, D.; Mcfarlane, A.C. Heart rate after trauma and the specificity of fear circuitry disorders. Psychol. Med. 2011, 41, 2573–2580. [Google Scholar] [CrossRef] [PubMed]

- Tran, K.N.; Nguyen, N.P.K.; Nguyen, L.T.H.; Shin, H.-M.; Yang, I.-J. Screening for Neuroprotective and Rapid Antidepressant-like Effects of 20 Essential Oils. Biomedicines 2023, 11, 1248. [Google Scholar] [CrossRef] [PubMed]

- Polyák, H.; Galla, Z.; Nánási, N.; Cseh, E.K.; Rajda, C.; Veres, G.; Spekker, E.; Szabó, Á.; Klivényi, P.; Tanaka, M.; et al. The Tryptophan-Kynurenine Metabolic System Is Suppressed in Cuprizone-Induced Model of Demyelination Simulating Progressive Multiple Sclerosis. Biomedicines 2023, 11, 945. [Google Scholar] [CrossRef]

- Zhu, X.L.; Wang, H.C.; Liu, J.X.; Zhao, J.; Shen, Y.F. Analysis on differences in stress distribution of foot and ankle at different push-off angles based on finite element model. Med. Biomech. 2022, 37, 1138–1144. [Google Scholar]

- Zhu, X.L.; Liu, J.J.; Liu, H.; Liu, J.X.; Yang, Y.F.; Wang, H.C. Effects of Midsole Hardness on the Mechanical Response Characteristics of the Plantar Fascia during Running. Bioengineering 2023, 10, 533. [Google Scholar] [CrossRef]

- Ab Rashid, A.M.; Ramlee, M.H.; Gan, H.S.; Rafiq Abdul Kadir, M. Effects of badminton insole design on stress distribution, displacement and bone rotation of ankle joint during single-leg landing: A finite element analysis. Sports Biomech. 2022, 20, 1–22. [Google Scholar] [CrossRef]

- Cheung, J.T.; Zhang, M.; Leung, A.K.; Fan, Y.B. Three-dimensional finite element analysis of the foot during standing—A material sensitivity study. J. Biomech. 2005, 38, 1045–1054. [Google Scholar] [CrossRef]

- Nakamura, S.; Crowninshield, R.D.; Cooper, R.R. An analysis of soft tissue loading in the foot—A preliminary report. Bull Prosthet Res. 1981, 10, 27–34. [Google Scholar]

- Siegler, S.; Block, J.; Schneck, C.D. The mechanical characteristics of the collateral ligaments of the human ankle joint. Foot Ankle 1988, 8, 234–242. [Google Scholar] [CrossRef]

- Simkin, A. Structural Analysis of the Human Foot in Standing Posture; Tel Aviv University: Tel Aviv, Israel, 1982. [Google Scholar]

- Cheung, J.T.; Zhang, M. A 3-dimensional finite element model of the human foot and ankle for insole design. Arch. Phys. Med. Rehabil. 2005, 86, 353. [Google Scholar] [CrossRef]

- de Koning, J.J.; Thomas, R.; Berger, M.; de Groot, G.; van Ingen Schenau, G.J. The start in speed skating: From running to gliding. Med. Sci. Sports Exerc. 1995, 27, 1703–1708. [Google Scholar] [CrossRef] [PubMed]

- Kaartinen, S.; Venojarvi, M.; Lesch, K.J.; Tikkanen, H.; Vartiainen, P.; Stenroth, L. Lower limb muscle activation patterns in ice-hockey skating and associations with skating speed. Sports Biomech. 2021, 12, 1–16. [Google Scholar] [CrossRef] [PubMed]

- van der Kruk, E.; Reijne, M.M.; de Laat, B.; Veeger, D.H.E.J. Push-off forces in elite short-track speed skating. Sports Biomech. 2019, 18, 527–538. [Google Scholar] [CrossRef]

- Guo, T.T.; Xie, H.; Xu, G.H. Finite Element analysis of elastic ankle brace performance. Chin. Tissue Eng. Res. 2023, 27, 1031–1037. [Google Scholar]

- Yamada, H. Strength of biological materials. J. Anat. 1970, 108, 582. [Google Scholar]

- Wu, W.L.; Hsu, H.T.; Chu, I.H.; Tsai, F.H.; Liang, J.M. Selected plantar pressure characteristics associated with the skating performance of national in-line speed skaters. Sports Biomech. 2017, 16, 210–219. [Google Scholar] [CrossRef]

- Goudreault, R. Forward Skating in Ice Hockey: Comparison of EMG Activation Patterns of [sic] at Three Velocities Using a Skate Treadmill. Master’s thesis. McGill University. Montreal. Canada. 2002.

- Oefner, C.; Herrmann, S.; Kebbach, M.; Lange, H.E.; Kluess, D.; Woiczinski, M. Reporting checklist for verification and validation of finite element analysis in orthopedic and trauma biomechanics. Med. Eng. Phys. 2021, 92, 25–32. [Google Scholar] [CrossRef]

| Component | Unit Type | Modulus of Elasticity (MPa) | Poisson’s Ratio | Density (kg·m−3) | Cross-Section (mm−2) |

|---|---|---|---|---|---|

| Bone | SOLID187 | 7300 | 0.3 | 1500 | -- |

| Cartilage | SOLID187 | 1 | 0.4 | -- | -- |

| Soft Tissue | SOLID187 | 1.15 | 0.49 | 937 | -- |

| Ligaments | SPRINGS | 260 | -- | 937 | 18.4 |

| Plantar fascia | LINK180 | 350 | -- | 937 | 290.7 |

| Upper | SOLID187 | 80 | 0.45 | 476 | 5.01 |

| Shoe upper lining | SOLID187 | 23.25 | 0.45 | 613 | 20.38 |

| Knife rest | SOLID187 | 79,000 | 0.33 | 280 | -- |

| Ice Blade | SOLID187 | 210,000 | 0.30 | 7850 | -- |

| Ice surface | SOLID187 | 560 | 0.35 | 915 | -- |

| Support plate | SOLID187 | 17,000 | 0.1 | 5000 | -- |

| EVA cushion | SOLID187 | 4.25 | 0.45 | -- | -- |

| Component | Plantar | Bottom of the Blade | ||

|---|---|---|---|---|

| Measurement | Simulation | Measurement | Simulation | |

| Peak pressure/kPa | 220 | 200 | 496 | 449 |

| Contact area/cm2 | 106.8 | 114.9 | 16.8 | 15.2 |

| Push-Off Angle | 70° | 63° | 56° | 49° | 42° | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Component | Stress/MPa | Strain | Stress/MPa | Strain | Stress/MPa | Strain | Stress/MPa | Strain | Stress/MPa | Strain |

| Calcaneus | 63.591 | 0.015 | 63.602 | 0.015 | 63.566 | 0.015 | 63.536 | 0.015 | 63.507 | 0.015 |

| Talus | 78.036 | 0.018 | 77.197 | 0.018 | 75.411 | 0.018 | 73.823 | 0.017 | 73.616 | 0.017 |

| Metatarsal | 54.167 | 0.013 | 53.154 | 0.012 | 60.441 | 0.012 | 56.617 | 0.012 | 60.546 | 0.012 |

| Ankle joint cartilage | 0.666 | 0.667 | 0.649 | 0.650 | 0.625 | 0.626 | 0.595 | 0.596 | 0.592 | 0.592 |

| Subtalar joint cartilage | 0.477 | 0.481 | 0.481 | 0.485 | 0.496 | 0.501 | 0.485 | 0.489 | 0.488 | 0.493 |

| Plantar fascia | 0.940 | 0.003 | 0.866 | 0.002 | 0.907 | 0.003 | 0.821 | 0.002 | 0.815 | 0.002 |

| Stage | Knee Angle | Push-Off Angle | Injured Structure of Possibility |

|---|---|---|---|

| Pre-stroke | ↑ | ↓ | Talus, ankle joint cartilage, plantar fascia |

| Mid-stroke | ↓ | ↓ | Talus, plantar fascia |

| Post-stroke | ↑ | ↓ | Metatarsal bones |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Wu, Y.; Liu, J.; Zhu, X. Investigation of the Mechanical Response of the Foot Structure Considering Push-Off Angles in Speed Skating. Bioengineering 2023, 10, 1218. https://doi.org/10.3390/bioengineering10101218

Wang H, Wu Y, Liu J, Zhu X. Investigation of the Mechanical Response of the Foot Structure Considering Push-Off Angles in Speed Skating. Bioengineering. 2023; 10(10):1218. https://doi.org/10.3390/bioengineering10101218

Chicago/Turabian StyleWang, Haichun, Yusen Wu, Jingxi Liu, and Xiaolan Zhu. 2023. "Investigation of the Mechanical Response of the Foot Structure Considering Push-Off Angles in Speed Skating" Bioengineering 10, no. 10: 1218. https://doi.org/10.3390/bioengineering10101218

APA StyleWang, H., Wu, Y., Liu, J., & Zhu, X. (2023). Investigation of the Mechanical Response of the Foot Structure Considering Push-Off Angles in Speed Skating. Bioengineering, 10(10), 1218. https://doi.org/10.3390/bioengineering10101218