Thermal, Mechanical, and Rheological Properties of PLA/PHB Biocomposites Reinforced with Alkaline-Treated Hemp Fibers and Granules

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Elaboration of PLA/PHB/Hemp Biocomposites

2.2.2. Characterization

Thermal Analysis

- Differential scanning calorimetry (DSC)

- −

- ΔHm is the melting enthalpy of the sample (J/g),

- −

- ΔHcc is the cold crystallization enthalpy (J/g),

- −

- is the theoretical melting enthalpy of a 100% crystalline polymer,

- −

- ω is the weight fraction of the polymer in the blend.

- Thermal conductivity

Mechanical Testing

- Dynamic mechanical analysis (DMA)

- Tensile testing

- Flexural testing

Rheological Testing

3. Results and Discussion

3.1. Thermal Analysis

3.1.1. Differential Scanning Calorimetry (DSC)

3.1.2. Thermal Conductivity

3.2. Mechanical Testing

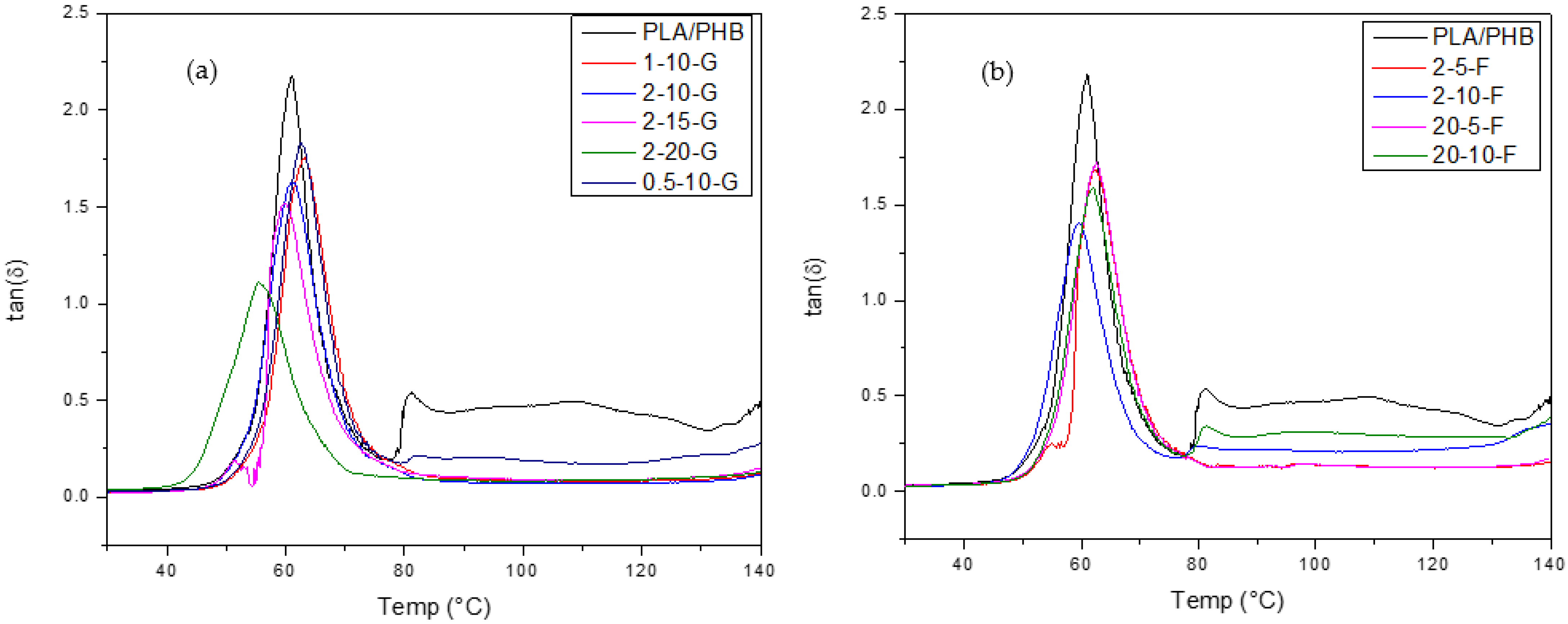

3.2.1. Dynamic Mechanical Analysis (DMA)

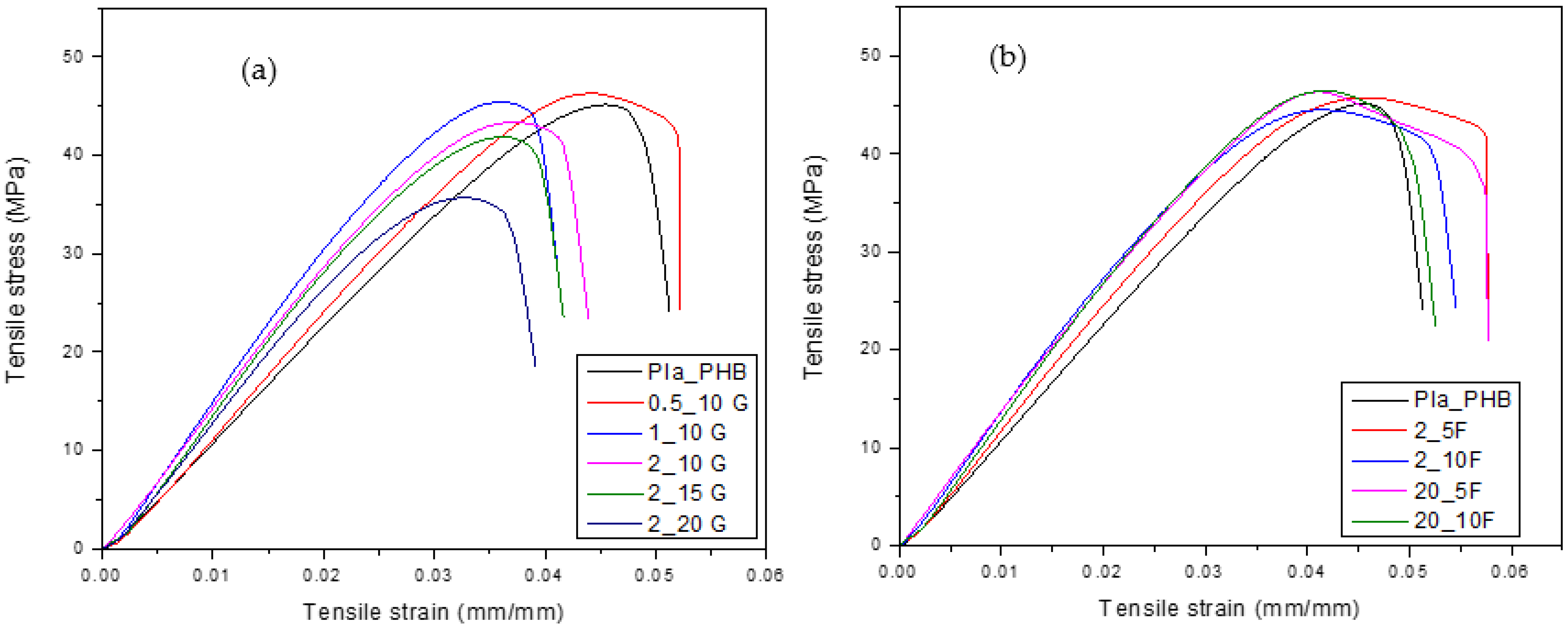

3.2.2. Tensile Testing

3.2.3. Flexural Testing

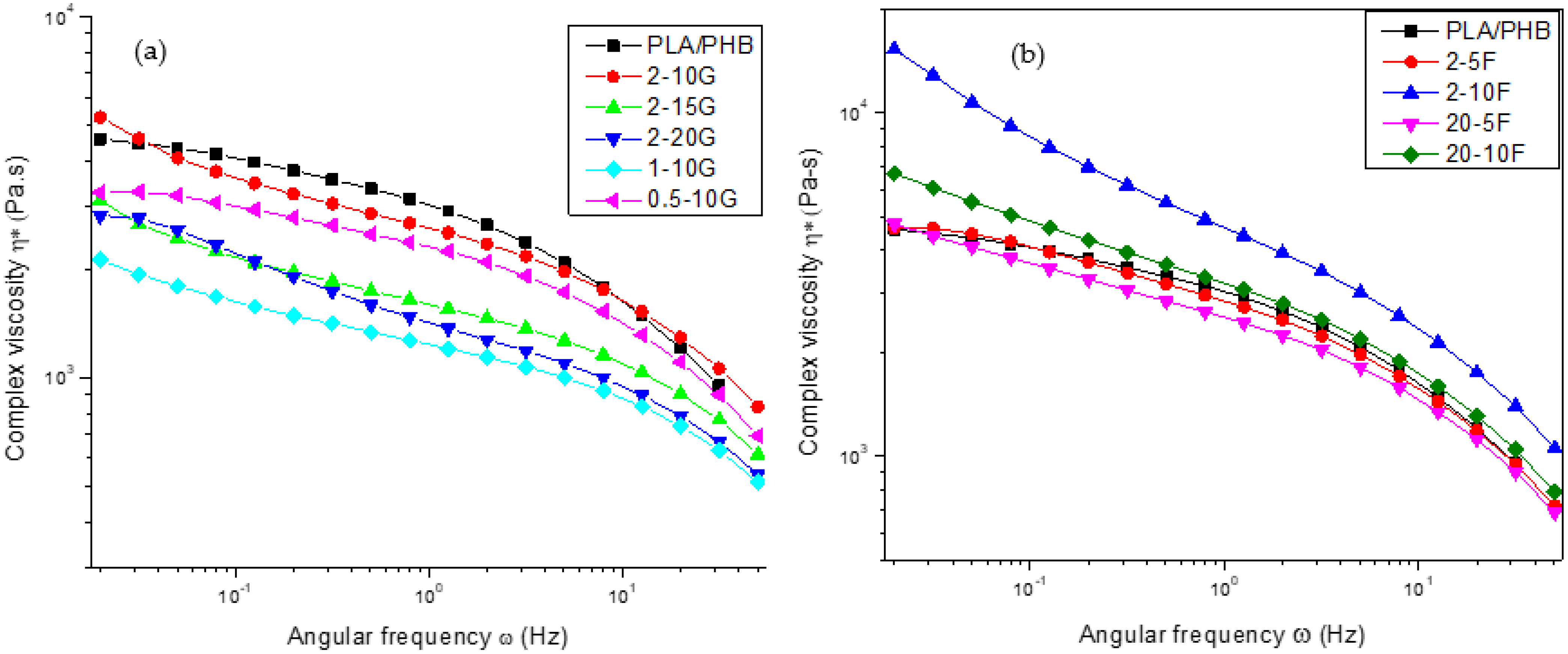

3.3. Rheological Testing

4. Limitations of the Study

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PLA | Polylactic acid |

| PHB | Polyhydroxybutyrate |

| DSC | Differential Scanning Calorimetry |

| DMA | Dynamic Mechanical Analysis |

| DTG | Derivative Thermogravimetry |

| Tg | Glass transition temperature |

| Tc | Cold crystallization temperature |

| Tm | Melting temperature |

| Xc | Degree of crystallinity |

| G′ | Storage modulus |

| G″ | Loss modulus |

| η* | Complex viscosity |

| wt.% | Weight percentage |

References

- Auras, R.; Harte, B.; Selke, S. An overview of polylactides as packaging materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef]

- Wuisman, P.; Smit, T. Bioresorbable polymers: Heading for a new generation of spinal cages. Eur. Spine J. 2006, 15, 133–148. [Google Scholar] [CrossRef]

- Ashothaman, A.; Sudha, J.; Senthilkumar, N. A comprehensive review on biodegradable polylactic acid polymer matrix composite material reinforced with synthetic and natural fibers. Mater. Today Proc. 2023, 80, 2829–2839. [Google Scholar] [CrossRef]

- Middleton, J.C.; Tipton, A.J. Synthetic biodegradable polymers as orthopedic devices. Biomaterials 2000, 21, 2335–2346. [Google Scholar] [CrossRef]

- Vahabi, H.; Rad, E.R.; Parpaite, T.; Langlois, V.; Saeb, M.R. Biodegradable polyester thin films and coatings in the line of fire: The time of polyhydroxyalkanoate (PHA)? Prog. Org. Coat. 2019, 133, 85–89. [Google Scholar] [CrossRef]

- Bugnicourt, E.; Cinelli, P.; Lazzeri, A.; Alvarez, V.A. Polyhydroxyalkanoate (PHA): Review of synthesis, characteristics, processing and potential applications in packaging. Express Polym. Lett. 2014, 8, 791–808. [Google Scholar] [CrossRef]

- Braunegg, G.; Lefebvre, G.; Genser, K.F. Polyhydroxyalkanoates, biopolyesters from renewable resources: Physiological and engineering aspects. J. Biotechnol. 1998, 65, 127–161. [Google Scholar] [CrossRef]

- dos Santos, A.J.; Oliveira Dalla Valentina, L.V.; Hidalgo Schulz, A.A.; Tomaz Duarte, M.A. From obtaining to degradation of PHB: Material properties. Part I. Ing. Cienc. 2017, 13, 269–298. [Google Scholar] [CrossRef]

- Ansari, S.; Fatma, T. Cyanobacterial polyhydroxybutyrate (PHB): Screening, optimization and characterization. PLoS ONE 2016, 11, e0158168. [Google Scholar] [CrossRef]

- Arrieta, M.P.; López, J.; Hernández, A.; Rayón, E. Ternary PLA–PHB–Limonene blends intended for biodegradable food packaging applications. Eur. Polym. J. 2014, 50, 255–270. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Samper, M.D.; López, J.; Jiménez, A. Combined effect of poly (hydroxybutyrate) and plasticizers on polylactic acid properties for film intended for food packaging. J. Polym. Environ. 2014, 22, 460–470. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Castro-López, M.d.M.; Rayón, E.; Barral-Losada, L.F.; López-Vilariño, J.M.; López, J.; González-Rodríguez, M.V. Plasticized poly (lactic acid)–poly (hydroxybutyrate)(PLA–PHB) blends incorporated with catechin intended for active food-packaging applications. J. Agric. Food Chem. 2014, 62, 10170–10180. [Google Scholar] [CrossRef]

- Frone, A.N.; Panaitescu, D.M.; Chiulan, I.; Gabor, A.R.; Nicolae, C.A.; Oprea, M.; Ghiurea, M.; Gavrilescu, D.; Puitel, A.C. Thermal and mechanical behavior of biodegradable polyester films containing cellulose nanofibers. J. Therm. Anal. Calorim. 2019, 138, 2387–2398. [Google Scholar] [CrossRef]

- Frone, A.N.; Batalu, D.; Chiulan, I.; Oprea, M.; Gabor, A.R.; Nicolae, C.-A.; Raditoiu, V.; Trusca, R.; Panaitescu, D.M. Morpho-structural, thermal and mechanical properties of PLA/PHB/cellulose biodegradable nanocomposites obtained by compression molding, extrusion, and 3D printing. Nanomaterials 2019, 10, 51. [Google Scholar] [CrossRef]

- Dong, W.; Ma, P.; Wang, S.; Chen, M.; Cai, X.; Zhang, Y. Effect of partial crosslinking on morphology and properties of the poly (β-hydroxybutyrate)/poly (d, l-lactic acid) blends. Polym. Degrad. Stab. 2013, 98, 1549–1555. [Google Scholar] [CrossRef]

- Mosnáčková, K.; Šišková, A.; Janigová, I.; Kollár, J.; Šlosár, M.; Chmela, Š.; Alexy, P.; Chodák, I.; Bočkaj, J.; Mosnáček, J. Ageing of plasticized poly (lactic acid)/poly (β-hydroxybutyrate) blend films under artificial UV irradiation and under real agricultural conditions during their application as mulches. Chem. Pap. 2016, 70, 1268–1278. [Google Scholar] [CrossRef]

- Mosnáčková, K.; Šlosár, M.; Kollár, J.; Janigová, I.; Šišková, A.; Chmela, Š.; Sikorska, W.; Perďochová, D.; Gálisová, I.; Alexy, P. Ageing of plasticized poly (lactic acid)/poly (3-hydroxybutyrate)/carbon black mulching films during one season of sweet pepper production. Eur. Polym. J. 2019, 114, 81–89. [Google Scholar] [CrossRef]

- Mosnáčková, K.; Opálková Šišková, A.; Kleinová, A.; Danko, M.; Mosnáček, J. Properties and degradation of novel fully biodegradable PLA/PHB blends filled with keratin. Int. J. Mol. Sci. 2020, 21, 9678. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef]

- Mansor, M.; Mastura, M.; Sapuan, S.; Zainudin, A. The environmental impact of natural fiber composites through life cycle assessment analysis. In Durability and Life Prediction in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 257–285. [Google Scholar]

- Garlotta, D. A literature review of poly (lactic acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Dou, Y.; Rodrigue, D. Morphological, thermal and mechanical properties of polypropylene foams via rotational molding. Cell. Polym. 2021, 40, 198–211. [Google Scholar] [CrossRef]

- Xia, K.; Liu, X.; Wang, W.; Yang, X.; Zhang, X. Synthesis of modified starch/polyvinyl alcohol composite for treating textile wastewater. Polymers 2020, 12, 289. [Google Scholar] [CrossRef]

- Righetti, M.C.; Cinelli, P.; Mallegni, N.; Massa, C.A.; Bronco, S.; Stäbler, A.; Lazzeri, A. Thermal, mechanical, and rheological properties of biocomposites made of poly (lactic acid) and potato pulp powder. Int. J. Mol. Sci. 2019, 20, 675. [Google Scholar] [CrossRef]

- Guo, R.; Ren, Z.; Bi, H.; Xu, M.; Cai, L. Electrical and thermal conductivity of polylactic acid (PLA)-based biocomposites by incorporation of nano-graphite fabricated with fused deposition modeling. Polymers 2019, 11, 549. [Google Scholar] [CrossRef] [PubMed]

- Lin, K.; Wang, Z. Multiscale mechanics and molecular dynamics simulations of the durability of fiber-reinforced polymer composites. Commun. Mater. 2023, 4, 66. [Google Scholar] [CrossRef]

- Ferreira, F.; Dufresne, A.; Pinheiro, I.; Souza, D.; Gouveia, R.; Mei, L.; Lona, L. How do cellulose nanocrystals affect the overall properties of biodegradable polymer nanocomposites: A comprehensive review. Eur. Polym. J. 2018, 108, 274–285. [Google Scholar] [CrossRef]

- Arrieta, M.P.; López, J.; Ferrándiz, S.; Peltzer, M.A. Characterization of PLA-limonene blends for food packaging applications. Polym. Test. 2013, 32, 760–768. [Google Scholar] [CrossRef]

- Magagula, S.; Sefadi, J.; Mochane, M.; Mokhothu, T.; Mokhena, T.; Lenetha, G. The effect of alkaline treatment on natural fibers/biopolymer composites. In Surface Treatment Methods of Natural Fibres and Their Effects on Biocomposites; Elsevier: Amsterdam, The Netherlands, 2022; pp. 19–45. [Google Scholar]

- Behera, S.; Gautam, R.K.; Mohan, S. Polylactic acid and polyhydroxybutyrate coating on hemp fiber: Its effect on hemp fiber reinforced epoxy composites performance. J. Compos. Mater. 2022, 56, 929–939. [Google Scholar] [CrossRef]

- Sahbaz Karaduman, N. Experimental investigation of the effect of weave type on the mechanical properties of woven hemp fabric/epoxy composites. J. Compos. Mater. 2022, 56, 1255–1265. [Google Scholar] [CrossRef]

- Al-Itry, R.; Lamnawar, K.; Maazouz, A. Improvement of thermal stability, rheological and mechanical properties of PLA, PBAT and their blends by reactive extrusion with functionalized epoxy. Polym. Degrad. Stab. 2012, 97, 1898–1914. [Google Scholar] [CrossRef]

- Mazzanti, V.; de Luna, M.S.; Pariante, R.; Mollica, F.; Filippone, G. Natural fiber-induced degradation in PLA-hemp biocomposites in the molten state. Compos. Part A Appl. Sci. Manuf. 2020, 137, 105990. [Google Scholar] [CrossRef]

- Nazrin, A.; Sapuan, S.; Zuhri, M.; Ilyas, R.; Syafiq, R.; Sherwani, S. Nanocellulose reinforced thermoplastic starch (TPS), polylactic acid (PLA), and polybutylene succinate (PBS) for food packaging applications. Front. Chem. 2020, 8, 213. [Google Scholar] [CrossRef] [PubMed]

- Ferry, J.D. Viscoelastic Properties of Polymers; John Wiley & Sons: Hoboken, NJ, USA, 1980. [Google Scholar]

- Sodeifian, G.; Nikooamal, H.R.; Yousefi, A.A. Molecular dynamics study of epoxy/clay nanocomposites: Rheology and molecular confinement. J. Polym. Res. 2012, 19, 9897. [Google Scholar] [CrossRef]

| Sample | Hemp Type | Hemp Size (mm) | Hemp Content (wt.%) |

|---|---|---|---|

| PLA/PHB | – | – | 0 |

| PLA/PHB-2–10%-G | Granule | 2 | 10 |

| PLA/PHB-2–15%-G | Granule | 2 | 15 |

| PLA/PHB-2–20%-G | Granule | 2 | 20 |

| PLA/PHB-1–10%-G | Granule | 1 | 10 |

| PLA/PHB-0.5–10%-G | Granule | 0.5 | 10 |

| PLA/PHB-2–5%-F | Fiber | 2 | 5 |

| PLA/PHB-2–10%-F | Fiber | 2 | 10 |

| PLA/PHB-20–5%-F | Fiber | 20 | 5 |

| PLA/PHB-20–10%-F | Fiber | 20 | 10 |

| Sample | Tc (°C) | Tm (°C) | Xc (%) |

|---|---|---|---|

| LA/PHB | 105.2 | 171.5 | 12.8 |

| PLA/PHB-2–10%-G | 102.4 | 170.8 | 15.6 |

| PLA/PHB-2–15%-G | 101.8 | 170.5 | 16.2 |

| PLA/PHB-2–20%-G | 101.1 | 170.7 | 14.9 |

| PLA/PHB-1–10%-G | 100.2 | 170.4 | 17.3 |

| PLA/PHB-0.5–10%-G | 99.6 | 170.3 | 18.1 |

| PLA/PHB-2–5%-F | 99.1 | 170.6 | 19.5 |

| PLA/PHB-2–10%-F | 98.7 | 170.1 | 20.7 |

| PLA/PHB-20–5%-F | 97.9 | 169.8 | 21.2 |

| PLA/PHB-20–10%-F | 97.5 | 169.5 | 22.0 |

| Sample | Thickness (mm) | Thermal Conductivity (W/m·K) at 25 °C | Thermal Conductivity (W/m·K) at 50 °C | Thermal Conductivity (W/m·K) at 75 °C |

|---|---|---|---|---|

| PLA/PHB | 4.45 | 0.135 | 0.168 | 0.127 |

| PLA/PHB-2–10%-G | 4.54 | 0.158 | 0.197 | 0.160 |

| PLA/PHB-2–15%-G | 4.61 | 0.157 | 0.214 | 0.221 |

| PLA/PHB-2–20%-G | 4.69 | 0.190 | 0.215 | 0.188 |

| PLA/PHB-1–10%-G | 4.42 | 0.133 | 0.170 | 0.199 |

| PLA/PHB-0.5–10%-G | 4.44 | 0.119 | 0.175 | 0.134 |

| PLA/PHB-2–5%-F | 4.33 | 0.120 | 0.169 | 0.140 |

| PLA/PHB-2–10%-F | 4.41 | 0.158 | 0.191 | 0.157 |

| PLA/PHB-20–5%-F | 4.32 | 0.113 | 0.169 | 0.136 |

| PLA/PHB-20–10%-F | 4.29 | 0.124 | 0.184 | 0.149 |

| Sample | Young’s Modulus (GPa) | Tensile Strength (MPa) | Strain at Break (%) |

|---|---|---|---|

| PLA/PHB | 1.19 ± 0.05 | 45.1 ± 1.2 | 4.6 ± 0.3 |

| PLA/PHB-2–10%-G | 1.43 ± 0.04 | 42.5 ± 1.0 | 4.9 ± 0.4 |

| PLA/PHB-2–15%-G | 1.56 ± 0.03 | 41.6 ± 0.9 | 3.7 ± 0.2 |

| PLA/PHB-2–20%-G | 1.45 ± 0.06 | 35.2 ± 1.5 | 3.4 ± 0.3 |

| PLA/PHB-1–10%-G | 1.63 ± 0.04 | 45.2 ± 1.1 | 3.7 ± 0.2 |

| PLA/PHB-0.5–10%-G | 1.30 ± 0.05 | 44.6 ± 1.0 | 4.9 ± 0.3 |

| PLA/PHB-2–5%-F | 1.30 ± 0.04 | 43.7 ± 0.8 | 5.4 ± 0.4 |

| PLA/PHB-2–10%-F | 1.43 ± 0.03 | 42.5 ± 1.2 | 4.9 ± 0.3 |

| PLA/PHB-20–5%-F | 1.40 ± 0.06 | 41.0 ± 0.9 | 5.4 ± 0.4 |

| PLA/PHB-20–10%-F | 1.44 ± 0.04 | 44.3 ± 1.3 | 4.7 ± 0.2 |

| Sample | Young’s Modulus (GPa) | Flexural Strength (MPa) | Strain at Break (%) |

|---|---|---|---|

| PLA/PHB | 2.8 ± 0.2 | 125 ± 5 | 5.5 ± 0.4 |

| PLA/PHB-2–10%-G | 3.4 ± 0.3 | 148 ± 6 | 3.6 ± 0.3 |

| PLA/PHB-2–15%-G | 3.6 ± 0.3 | 140 ± 5 | 3.3 ± 0.2 |

| PLA/PHB-2–20%-G | 3.5 ± 0.3 | 130 ± 6 | 3.0 ± 0.2 |

| PLA/PHB-1–10%-G | 2.1 ± 0.2 | 80 ± 4 | 4.0 ± 0.3 |

| PLA/PHB-0.5–10%-G | 3.2 ± 0.2 | 145 ± 5 | 5.0 ± 0.4 |

| PLA/PHB-2–5%-F | 3.4 ± 0.3 | 130 ± 4 | 6.3 ± 0.5 |

| PLA/PHB-2–10%-F | 3.5 ± 0.3 | 145 ± 5 | 5.6 ± 0.4 |

| PLA/PHB-20–5%-F | 3.2 ± 0.3 | 140 ± 5 | 5.3 ± 0.4 |

| PLA/PHB-20–10%-F | 3.1 ± 0.2 | 130 ± 4 | 4.9 ± 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rbihi, Z.; Erchiqui, F.; Rodrigue, D.; Kaddami, H. Thermal, Mechanical, and Rheological Properties of PLA/PHB Biocomposites Reinforced with Alkaline-Treated Hemp Fibers and Granules. ChemEngineering 2025, 9, 122. https://doi.org/10.3390/chemengineering9060122

Rbihi Z, Erchiqui F, Rodrigue D, Kaddami H. Thermal, Mechanical, and Rheological Properties of PLA/PHB Biocomposites Reinforced with Alkaline-Treated Hemp Fibers and Granules. ChemEngineering. 2025; 9(6):122. https://doi.org/10.3390/chemengineering9060122

Chicago/Turabian StyleRbihi, Zainab, Fouad Erchiqui, Denis Rodrigue, and Hamid Kaddami. 2025. "Thermal, Mechanical, and Rheological Properties of PLA/PHB Biocomposites Reinforced with Alkaline-Treated Hemp Fibers and Granules" ChemEngineering 9, no. 6: 122. https://doi.org/10.3390/chemengineering9060122

APA StyleRbihi, Z., Erchiqui, F., Rodrigue, D., & Kaddami, H. (2025). Thermal, Mechanical, and Rheological Properties of PLA/PHB Biocomposites Reinforced with Alkaline-Treated Hemp Fibers and Granules. ChemEngineering, 9(6), 122. https://doi.org/10.3390/chemengineering9060122