Abstract

Erosion-corrosion is a predominant failure mechanism in the petrochemical, energy, and offshore engineering sectors, causing substantial economic losses and posing significant threats to equipment safety and personnel well-being. To address this critical issue, the present study employs a systematic approach to examine the current status and estimate the future trends in erosion-corrosion research. By utilizing bibliometric techniques, the study constructs a comprehensive knowledge map to analyze the chronological progress, research institutions, journal distribution, collaborative networks, research hotspots and cutting-edge trends in this field. The bibliometric analysis reveals that research hotspots are primarily focused on the erosion-corrosion mechanism, equipment, materials, coating structure reinforcement, and new process of anticorrosion strategies. These findings suggest an interdisciplinary integration trend and the emergence of intelligent prevention and control methods. By elucidating the evolution and future direction of erosion-corrosion research, this study offers valuable insights for advancing academic progress and technological innovation in this area.

1. Introduction

Erosion-corrosion, which refers to the deterioration of metal surfaces due to the interaction with corrosive fluids under relative motion, has been identified as a significant concern in various industrial practices, including petroleum and chemical industries and offshore engineering. This phenomenon, characterized by the combined effects of mechanical scouring and chemical corrosion, has caused substantial damage and thus has necessitated the development of effective mitigation strategies [1,2,3,4]. According to Kermani et al. [5], 9% of corrosion failures in the petroleum industry were attributed to erosion-corrosion, which significantly hindered the advancement of new technologies and engineering applications. The complexity and destructiveness of erosion-corrosion exceed those of other degradation mechanisms, primarily due to two factors. First, the synergistic interaction between electrochemical corrosion and mechanical erosion leads to the formation of erosion-enhanced corrosion and corrosion-enhanced erosion, with the latter accelerating material degradation [1,6,7,8,9,10,11,12]. Second, the coupling of multiple influencing factors, including material properties [13,14,15,16], discrete phase characteristics [17,18,19,20], and hydrodynamic conditions [21,22], has resulted in nonlinear corrosion thinning and a highly unpredictable corrosion phases, thereby significantly reducing the operational reliability of equipment and pipelines.

Despite the focus on erosion-corrosion research since the mid-to-late 20th century, this phenomenon remains a significant safety concern within the petrochemical and related industry. Two notable incidents highlight the severity of this issue [10,23]. In 2005, a refinery in the United States experienced a series of explosions during the restart of a hydrocarbon isomerization unit. The investigation revealed that, in addition to over-pressurization of hydrocarbons in the distillation tower due to improper operating procedures, severe erosion-corrosion had occurred on the inner wall of the feed pipe. This damage led to the failure of safety valves and auxiliary devices, resulting in 15 fatalities, 180 injuries, and over 1.5 billion U.S. dollars losses [24]. Similarly in an incident in 2015, a pipeline rupture occurred in a refinery in China. The accident report indicated that the supply pipe, which transported raw oil with high concentrations of solid particles over an extended period, experienced local wall thickness reduction exceeding 30%. This condition caused the pipeline to fail and leak approximately 150 tons of raw oil, triggering a localized deflagration. The incident resulted in 3 fatalities and numerous injuries [25]. These cases underscore the persistent risk associated with erosion-corrosion in industrial fields. Erosion-corrosion continues to pose a significant threat, often resulting in substantial economic losses and tragic loss of life.

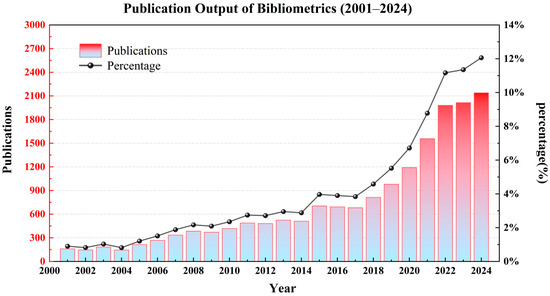

Since its initial proposal in 1964, the bibliometric analysis method has evolved into a systematized tool. Utilizing mathematical and statistical techniques, it reveals the fundamental laws and trends inherent in scientific research [26]. Currently, it has been extensively applied across various disciplines, including computer science [27], engineering [28], medicine [29,30], and social sciences [31,32]. Compared with traditional reviews [33,34,35,36,37,38,39,40,41,42,43], bibliometric analysis has demonstrated several prominent advantages in terms of systematicity, comprehensiveness and objectivity [44,45]. These include the ability to objectively quantify research impact, analyze citation networks, and map the development trends of research fields comprehensively [26]. Moreover, by examining the quantitative characteristics of academic papers, monographs, patents, and the references cited, bibliometrics not only identifies observable patterns in specific research topics [46] but also facilitates the evaluation of research productivity among researchers, institutions, and regions using statistical indices [47]. Figure 1 illustrates the publication data for bibliometrics from the year 2001 to the present within the topic of erosion-corrosion. The data reveal a pronounced trend of rapid growth in the number of publications within this field. Notably, over the past five years, the increase has been particularly great. By the year 2025, the projected publication volume is anticipated to surpass 2500 articles. This trajectory underscores the escalating influence of bibliometrics in academic research and the heightened attention it has garnered. Given these developments, bibliometrics is poised to assume a pivotal role in scientific research evaluation and academic impact analysis.

Figure 1.

Trend of publications in bibliometrics field. (Data Source: Web of Science [48]).

The current focus of studies on corrosion phenomena has primarily centered on the following areas: corrosion of heat exchangers [49], stress corrosion in gas pipeline networks [44], corrosion of urban water supply pipelines [50], and the development of new, efficient corrosion inhibitors [51]. To systematically organize the existing research and elucidate development trends in this field, this study employs bibliometric methods to construct a knowledge map for erosion-corrosion. A comprehensive analysis is conducted across multiple dimensions, including chronological progress, research institutions, journal distribution, collaborative networks, research hotspots, and cutting-edge trends. By tracing the developmental lineage of the erosion-corrosion field and identifying key evolutionary trends and future directions, this study hopes to lay a solid foundation for theoretical advancement and technological innovation in this area.

2. Data Sources and Methodology

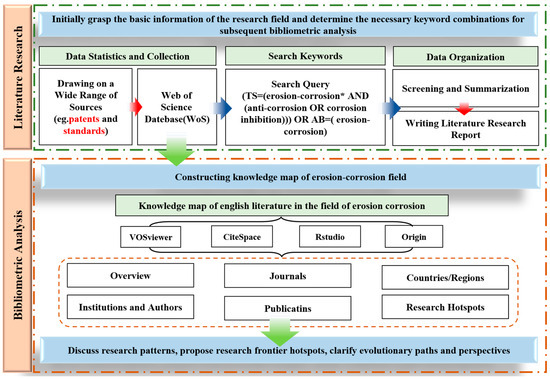

Erosion-corrosion is a transdisciplinary research theme that spans multiple fields, including corrosion science, materials science, and environmental science. It encompasses both in-depth exploration of fundamental theories and the development of applied technologies. Given its complexity and interdisciplinary nature, a systematic analysis of the mechanisms and inhibition strategies of erosion-corrosion is essential to promote scientific progress in this field. The technical approach of this study is delineated in Figure 2, as follows.

Figure 2.

Technical roadmap. ((*) is a wildcard symbol used for truncation, allowing retrieval of all word variants that begin with “erosion-corrosion” (e.g., erosion-corrosive, erosion-corrosion-resistant)).

2.1. Data Collection

Firstly, we summarized and identified the key challenges and research hotspots in the field of erosion-corrosion, drawing on a wide range of sources such as patents and standards. These sources provided important insights that formed the basis for future research directions. Building on this, our aim was to provide a scientific response to the identified challenges and hotspots. To this end, we referred to relevant bibliometric studies. As the Web of Science (WoS) database is widely recognized for its extensive coverage and credibility in scientific research, we selected it as the primary source for our bibliometric analysis.

2.2. Methods and Tools

2.2.1. Multi-Dimensional Analysis Methods

- (1)

- Citation network topology analysis

Citation Analysis, based on graph theory, quantifies the citation relationships between articles. Its core assumption is that highly cited articles represent the core knowledge carriers within a discipline [52]. Citation Count, a metric of academic impact, can be used to objectively evaluate research quality and academic contributions [53]. Additionally, Betweenness Centrality () in cross-institutional collaborative networks helps identify pivotal institutions. BC is calculated using Freeman’s formula [54]:

Here, represents the total number of shortest paths from node to node , and represents the number of these shortest paths that pass-through node . The larger is, the stronger the bridging role of node in the network, and the more significant its impact on academic cooperation and knowledge flow.

- (2)

- Thematic cluster analysis

Thematic Cluster Analysis is a methodology that calculates the relationship between articles based on cosine similarity. This relationship is subsequently utilized to extract thematic labels using the log-likelihood ratio (LLR) algorithm, which identifies research paradigms [55]. The Kleinberg emergence detection model has been introduced to detect emerging research trends [56].

The calculation is performed using the following equation:

In this equation, represents the frequency of occurrence of a feature item within a specified detection time period, while denotes the total frequency of occurrence for all features within that time frame. Additionally, and correspond to the frequency of occurrence of the same feature item and the overall feature frequency, respectively, within a reference time period. When the ratio / is high, it indicates that the feature item has a higher emergence in the research area and may represent an emerging high-priorit

- (3)

- Co-occurrence network analysis

Co-occurrence analysis constructs a keyword association matrix based on the proximity index, assuming that the frequency of co-occurrence follows a power-law distribution of conceptual relevance [57]. The quality of the network’s clustering is evaluated using Modularity ( value). Typically, a value greater than 0.3 indicates a substantial community structure within the network. For example, within the “Hydrogen Embrittlement—erosion-corrosion” thematic network, the value is 0.42, signifying the formation of a cohesive research community in this specific domain [58].

2.2.2. Analytical Tools

This study employs a combination of methodologies to conduct a comprehensive analysis. The primary bibliometric tools utilized include:

- (1)

- CiteSpace (version 6.3) [58] is software developed by Chen. It focuses on revealing research frontiers, knowledge structures, and research hotspots in scientific literature, with the objective of supporting the generation of multiple visualization networks. In this study, for CiteSpace, we used a time slicing of 2001–2024 with one-year intervals, selecting the top 50 nodes per slice based on citation or co-occurrence counts. Pruning was applied using the Pathfinder algorithm and pruning sliced networks to reduce redundant links. The centrality values reported were the raw outputs from CiteSpace for undirected networks (co-citation, keyword co-occurrence, and collaboration networks).

- (2)

- VOSviewer (version 1.6.20) [59], developed by Eck and Waltman, offers capabilities such as managing literature data exported from multiple databases, optimizing network layouts using VOS technology, and generating intuitive clustering diagrams. In this study, For VOSviewer, we set the minimum occurrence threshold of keywords to 5, applied the default association strength normalization, and used default clustering resolution for interpretability.

Additionally, this study utilized RStudio 2024, Origin Pro 2021, and Excel 2019 as auxiliary tools to ensure the accuracy and efficiency of data processing and analysis.

In summary, a comprehensive collection of resources was compiled to establish a solid knowledge base, providing valuable support in identifying the challenges and focal points of erosion-corrosion research. Building on this, bibliometric methods were employed to reveal structural patterns and emerging themes within the field. Integrating CiteSpace, VOSviewer and supporting software ensured the analysis was systematic, accurate and efficient, laying a strong foundation for future research.

3. Results

3.1. Meticulous and Systematic Analysis

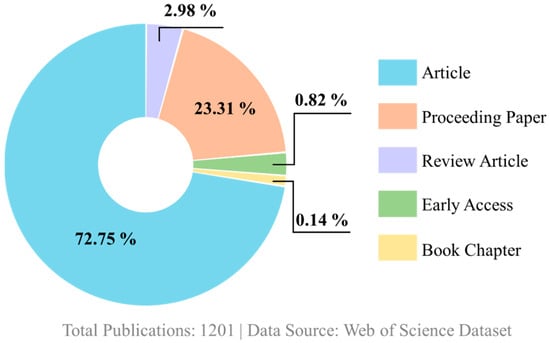

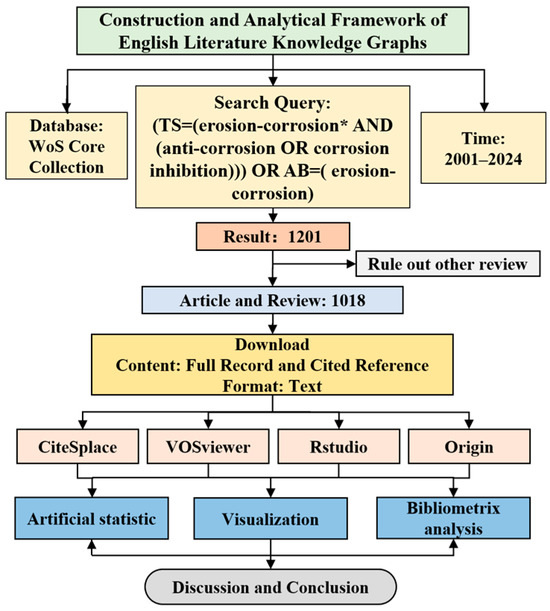

The retrieval of literature data was conducted using the Web of Science (WoS) advanced search tool, which allowed the data to be restricted to the WoS core collection. The search expression used was TS = (erosion-corrosion* AND (anti-corrosion OR corrosion inhibition)) OR AB = (erosion-corrosion). The search was performed for the period from 2001 to 2024, yielding a total of 1201 related publications. The distribution of different types of literature is depicted in Figure 3. This study focuses particularly on two types of literature: articles and review articles. After applying these filters and cleaning the data, a total of 1018 publications were obtained. A multidimensional bibliometric analysis was then conducted using the collected data (including publication year, author, keywords, citations, journal, country, organization, and number of citations). The research framework is illustrated in Figure 4.

Figure 3.

Composition of WoS retrieved publications.

Figure 4.

Bibliometric research content framework for erosion-corrosion. ((*) is a wildcard symbol used for truncation, allowing retrieval of all word variants that begin with “erosion-corrosion” (e.g., erosion-corrosive, erosion-corrosion-resistant)).

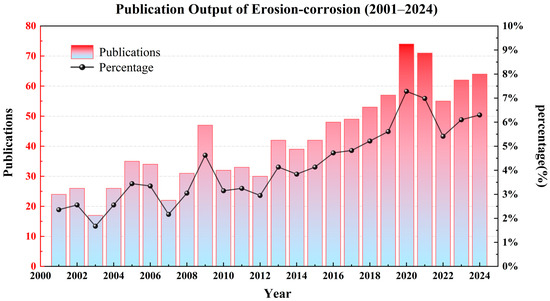

A review of the publications provides insights into the evolution of research activities across various disciplines, geographical regions, and institutional contexts by examining fluctuations in annual publication output [51]. As shown in Figure 5, it illustrates the quantity of publications in the field of erosion-corrosion in the WoS database and the percentage of the total number of publications in this field. These data are drawn from the WoS database for the period from 2001 to 2024. The data demonstrate that erosion-corrosion, a prevalent corrosion failure mechanism in engineering, has consistently attracted considerable research interest. The annual publication rate exceeded 50 articles in most years. Since 2015, the number of articles published in this field has shown a consistent and gradual increase. The significant increase in publications during the period of 2020–2021, with a total over 100 articles, underscores the heightened level of research activity and influence within this domain. It is reasonable to predict that the research fervor surrounding erosion-corrosion will continue, and the potential for future development remains substantial.

Figure 5.

Trend of publications in erosion-corrosion field. (Data Source: Web of Science [48]).

Table 1 presents the distribution of the subject categories. It is important to note that this categorization is based on the default classification categories of the Web of Science. The data show a clear discipline clustering effect in the distribution of erosion-corrosion articles. Among these, materials science is the most prevalent, accounting for 47.2% of the total (482 articles). Metallurgical engineering and engineering machinery are the second and third most prevalent categories, with 311 (30.4%) and 260 (25.4%) articles, respectively. These categories reflect the technical complexity and importance of the problem. Other disciplines, including coatings and thin films, applied physics, and physical chemistry, contribute a smaller percentage of the literature, yet they highlight the necessity for interdisciplinary research.

Table 1.

Distributions of the subject categories.

The study of erosion-corrosion requires a multifaceted approach that integrates the theoretical foundations of materials science and benefits from the interdisciplinary contributions of related fields such as engineering and physical chemistry. Progress in understanding erosion-corrosion mechanisms and in developing prevention and control technologies will be accelerated through multidisciplinary collaborative innovation.

3.2. Journals

The distribution analysis of literature journals is a critical component of academic metrology, as it reveals evolving research hotspots and interdisciplinary development trends. By integrating key performance indicators, including citation metrics and impact factors, this analysis provides a comprehensive overview of scholarly activity [60,61]. Table 2 presents the distribution of publications within the WoS database, highlighting journals that are highly relevant to the field of erosion-corrosion and have high rankings. A statistical analysis of data from research journals in this field since 2000 shows that the majority of these journals are concentrated in the disciplines of mechanical engineering, energy, fuels, electrochemistry, and physical chemistry. The influence of these journals varies, with many having relatively high impact factors.

Table 2.

Distribution of journals in the field of erosion-corrosion.

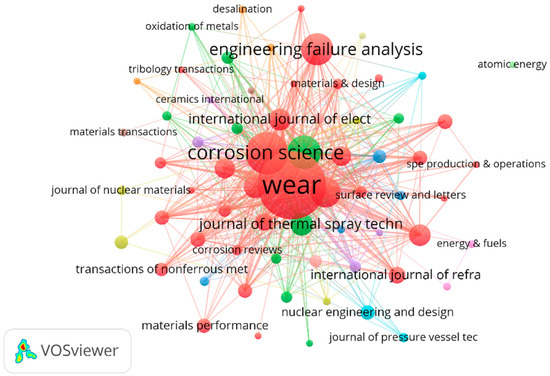

The journals Wear and Corrosion Science are particularly prominent, with both featuring among the journals with over 50 publications, indicating substantial scholarly activity in these areas. Wear has attracted significant attention with 134 publications (13.1%), generating a total of 5413 citations. Its notable Impact Factor of 5.3 highlights its substantial academic reach and influence within the academic community. A review of the published literature in this journal reveals that the majority of the publications are empirical research papers focusing on original studies and reviews related to friction stirring, slurry impact, pipeline transportation, and corrosion-resistant material development. Corrosion Science has achieved significant academic recognition, with 61 published articles and a total of 2653 citations, reflected by an h-index of 168 and an average of 45.5 citations per article. The primary focus of this research is on metallurgical engineering, including the study of electrochemical corrosion and the experimental prevention of corrosion in engineering materials. Together, these two journals have established a significant academic support framework within the domain of erosion-corrosion, thereby fostering the advancement of research in this field.

The visual analysis of Figure 6 provides further confirmation of the data trends in Table 2 by visualizing the differences in the impact of each journal in the dissemination of scientific knowledge. It not only highlights the dominance of Wear and Corrosion Science in the field, but also reflects the continued growth in interest in erosion-corrosion research.

Figure 6.

Distributions of the output in journals.

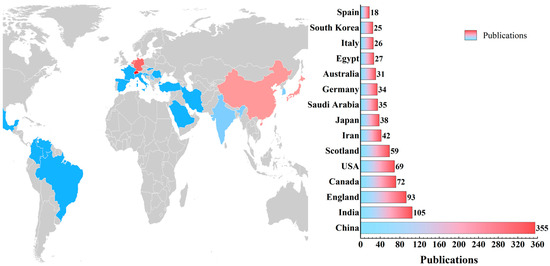

3.3. Countries/Regions

The distribution of publishing countries and regions serves as a reliable indicator of academic literature output, influence, and international cooperation networks in the global context [62,63]. Different countries contribute differently to the progress of erosion-corrosion research. Understanding the countries actively involved in erosion-corrosion research can help researchers identify potential future collaborators and research platforms. A total of 77 countries and regions worldwide have conducted research in the field of erosion-corrosion. As shown in Figure 7, among the top 15 countries and regions in terms of publication numbers, China leads with 355 papers and 8334 citations, indicating its dominant position and crucial role in the field. Other countries and regions with more than 50 publications include India (105 papers, 2281 citations), the United Kingdom (93 papers, 3696 citations), Canada (72 papers, 2816 citations), the United States (69 papers, 2342 citations), and Scotland (59 papers, 1825 citations).

Figure 7.

Distribution of countries in the field of erosion-corrosion. (Data Source: Web of Science [48]).

To further explore the strength of country/region posting relevance in erosion-corrosion, an analysis of the citation strength of different countries’ postings was conducted using CiteSpace. The results are shown in Table 3. The red line indicates the active time period of different countries in the field of erosion-corrosion. The analysis reveals that Scotland has the highest citation strength, with a value of 15.73, indicating its significant academic influence within the field. Japan (12.03), England (9.64), and Mainland China (9.14) also exhibit substantial citation strengths, further validating their importance in erosion-corrosion research. These data highlight the varying contributions of different nations to this research area and provide a basis for establishing international collaborations and refining academic policies.

Table 3.

CiteSpace analysis results: Top 15 countries/Regions by citation strength in the field of erosion-corrosion.

3.4. Institutions and Authors

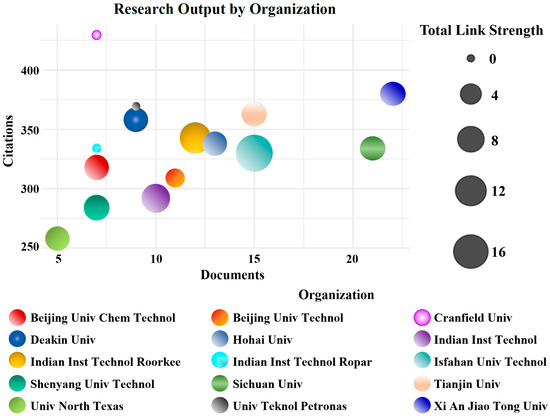

As for the institutional aspect, co-authorship of papers is prevalent in the scientific research process. The dissemination of scholarly literature among various research institutions is a pivotal component in academic metrics, serving as a means to evaluate an institution’s scholarly contributions and their impact [64,65]. A total of 972 institutions are represented in the 1018 articles retrieved, with 68 of these institutions having more than five researchers. Figure 8 illustrates the top 15 research institutions in the field of erosion-corrosion in the WoS database with regard to the number of publications and citations, as derived from CiteSpace. In terms of publications, Xi’an Jiaotong University leads with 22 papers, followed closely by Sichuan University with 21 publications. However, in terms of citations, Cranfield University stands out with a total of seven scholarly articles that have received a total of 430 citations, indicating a significant academic influence.

Figure 8.

Top 15 institutions by publication output in the field of erosion-corrosion.

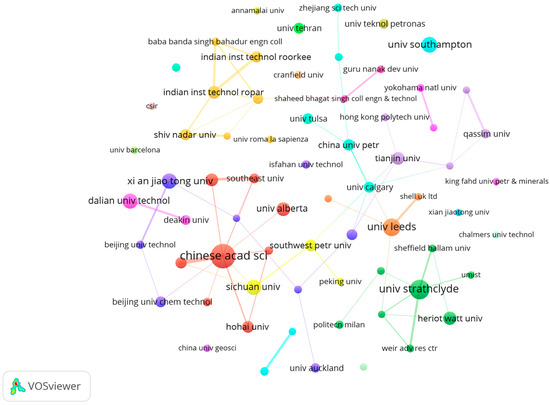

To further explore the collaborative relationships among research organizations, a co-occurrence cluster analysis was conducted using VOSviewer software. The results of this analysis are presented in Figure 9. In this figure, the size of the nodes corresponds to the number of publications from a given country or region, while the thickness of the connections between nodes indicates the strength of collaborative ties between these entities. Distinct colors are used to differentiate clustering groups, with repeated colors highlighting particularly strong collaborative relationships. The analysis reveals that the red cluster is centered around “Chinese Acad Sci”, which includes notable institutions such as “Sichuan Univ” and “Univ Alberta”. The blue cluster, also prominently featuring “Chinese Acad Sci”, encompasses institutions like “Sichuan Univ” and “Southeast Univ”, demonstrating high levels of productivity and core status within the field. The green cluster is characterized by “Xi’an Jiaotong University”, which has a history of frequent collaboration with “Beijing University of Chemical Technology” and other institutions, forming a stable and productive cooperative team. Additionally, institutions such as “Univ Strathclyde” and “Heriot Watt Univ” within the green cluster have established a close and active cooperation network. These findings suggest a pronounced aggregation of research organizations into distinct clusters based on their academic productivity and collaborative networks, highlighting key collaborative hubs within the field of erosion-corrosion research.

Figure 9.

Co-authorship analysis of institutions in the field of erosion-corrosion.

To this end, a bibliometric analysis was conducted using CiteSpace to identify the top ten scholars in terms of publication output and to analyze the chronological distribution of their papers. The analysis encompassed 3054 authors from 972 institutions. The results are presented in Figure 10. A comprehensive analysis of the data reveals that Neville (2001–2021) has published a total of 45 papers, establishing himself as the foremost contributor in terms of publication output. Notably, 29 of these papers were published in Wear journals, garnering a total of 1712 citations, with the most highly cited paper receiving 116 citations. Zheng (2002–2024) has published 37 scholarly papers, including 5 in Wear and Corrosion Science, journals that have garnered significant international recognition. These papers have collectively received 1182 citations, with the most highly cited paper receiving 147 citations. The exceptional performance of leading journals such as Wear and Corrosion Science underscores the pivotal role of research outcomes in this domain for both engineering practice and theoretical advancement. Moreover, three authors—Huang, Xu, and Arora—have emerged as prominent researchers with a high publication frequency in this field since 2015. Their publications serve as essential guides for understanding the frontiers and notable areas of focus in this domain.

Figure 10.

Time series of publications by the top 10 authors.

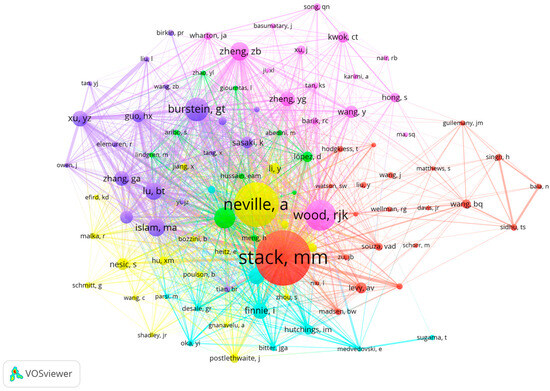

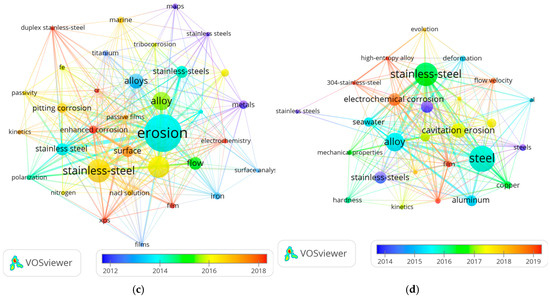

Co-citation authorship analysis refers to the phenomenon where two or more documents are cited simultaneously by other subsequent documents, resulting in the authors of these documents being designated as co-cited authors. Through the analysis of co-citation relationships, it is possible to identify author groups, research hotspots, and knowledge structures within an academic field. In this study, VOSviewer was used to analyze the citation network of authors, with a minimum citation threshold of 30 for inclusion in the analysis. This analysis revealed a network of 96 highly productive authors, as shown in Figure 11. The network is characterized by a total link strength metric, which serves as an indicator of the strength and interaction within the network. Notably, the network comprises six distinct clusters, each distinguished by a unique color. In this study, nodes represent authors, with the size of each node corresponding to the number of published articles. The thickness of the links indicates the frequency of cooperation among the authors.

Figure 11.

Co-citation analysis of highly productive authors in the field of erosion-corrosion. The more co-cited authors there are, the stronger the correlation between authors and the more significant their influence.

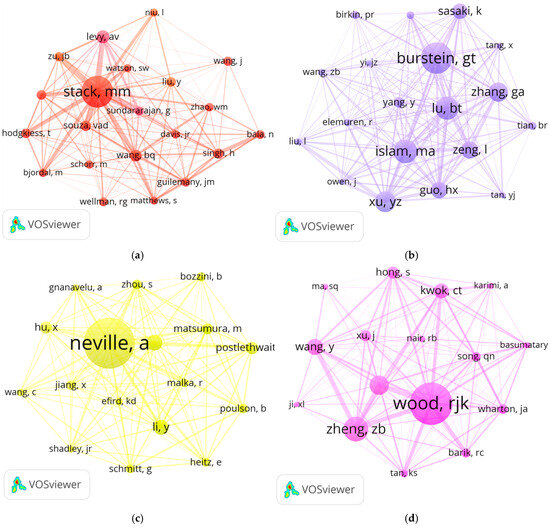

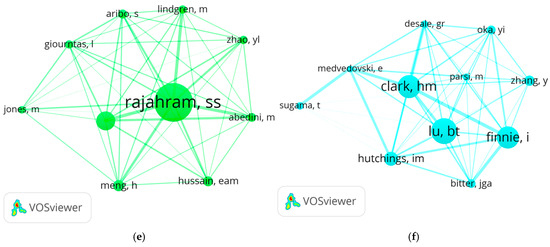

Figure 12 illustrates the specific author collaborations within the six clusters depicted in Figure 11. The red cluster (Figure 12a), led by Stack, focuses on topics such as erosion-corrosion mechanisms and slurry erosion. The purple cluster (Figure 12b), led by Burstein, focuses on electrochemical corrosion and flow-accelerated corrosion mechanisms. The yellow cluster (Figure 12c), centered on Neville, examines the corrosion behavior of pipelines and the corrosion resistance of materials. The pink cluster (Figure 12d), delineated by Wood, emphasizes the efficacy of corrosion-proof coatings, particularly the application of Nickel-Aluminum Bronze (NAB) coatings in High-Velocity Oxy-Fuel (HVOF) spraying. The green cluster (Figure 12e), led by Rajahram, investigates the erosion-corrosion process from the perspective of wear rate and its key influencing factors. The cyan cluster (Figure 12f), represented by Clark, focuses on the development of corrosion protection materials and the utilization of experimental simulation methods.

Figure 12.

VOSviewer clustering map of authors in erosion-corrosion research domain. (a) Focuses on erosion-corrosion mechanisms and slurry erosion. (b) Focuses on electrochemical corrosion and flow-accelerated corrosion mechanisms. (c) Focuses on corrosion resistance of materials. (d) Focuses on corrosion-proof coatings. (e) Focuses on erosion-corrosion process. (f) Focuses on corrosion protection.

3.5. Publications

The number of citations a research article receives is a critical metric for evaluating its scholarly impact. Highly cited literature is defined as scholarly work that ranks in the top 1% of citations within a particular subject area. This high citation frequency can accurately reflect the cutting edge of the discipline and identify research hotspots [66,67]. According to the CiteSpace highly cited literature analysis report, 15 articles with the highest citation counts were identified, and their main contents are presented in Table 4. Notably, all of these articles have garnered at least 50 citations, underscoring their significant scholarly impact. The accompanying table provides a detailed overview of the primary research directions and outcomes of these studies. These findings not only offer a comprehensive summary of the current research landscape but also serve as a valuable source of inspiration for future researchers, guiding their research endeavors.

Table 4.

The top 15 most cited publications based on local citations and global citations.

Specifically, eight of the articles were published in Wear and five in Corrosion Science, which is consistent with Table 2, as these two journals are the most influential and productive sources with high impact factors. A review of the publication dates of the documents revealed that two-thirds of the papers were published after the year 2010, while only one-third were published between the years 2000 and 2010. This finding suggests that research related to erosion-corrosion is undergoing a period of accelerated growth and development.

4. Discussion

4.1. Progress of Erosion-Corrosion Research

Erosion-corrosion is a multifaceted type of corrosion that involves a complex interplay between hydrodynamics and electrochemistry. This research area has evolved in response to industrial needs and technological advancements, shaping its research trajectory over time. As demonstrated by the bibliometric analysis above mentioned, this section elucidates the progress within the field in terms of chronological evolution, disciplinary intersection, geographic distribution, and cooperation patterns.

4.1.1. Chronological Progress

As demonstrated in Figure 5, 2009 and 2020 represent two pivotal years during which the number of publications in the domain of erosion-corrosion underwent a substantial increase. A systematic review and analysis of representative publications from these two periods have been undertaken to reveal the phased evolution of research content and methods in this field.

A total of 47 papers were published in 2009, and the main contents of the key papers are shown in Table 5. The research focused on exploring the erosion-corrosion mechanism and performance under different materials and service conditions. Specifically, the study examined the impact of parameters such as flow velocity, particle concentration, temperature, and flow mode on the material damage mechanism. Concurrently, studies have been conducted that examine the efficacy of corrosion inhibitors in complex environments and the coupling mechanism of cultural and mechanical effects in the erosion-corrosion process.

Table 5.

Key publications on erosion-corrosion in 2009.

In 2020, a total of 76 related papers were published, with the main content of the key papers detailed in Table 6. The research content exhibited a discernible trend toward more profound exploration. The primary research focus was on material protection performance and corrosion prevention technology, with a particular emphasis on the adaptability of alloy materials, such as stainless steel and duplex steel, under harsh conditions, including high-salt and high-velocity flow environments. In the realm of mechanism research, studies have further elucidated the influence mechanisms of fluid dynamics parameters (e.g., shear stress, Reynolds number) on corrosion behavior. Moreover, the advent of advanced experimental techniques, such as high-throughput electrochemical workstations and in situ imaging technologies (e.g., 3D surface profilometers, SEM corrosion tracking), has enabled real-time microscopic observation of corrosion processes. Concurrently, significant advancements were made in numerical simulation based on CFD coupled electrochemical corrosion models during this period. These advancements effectively enabled the prediction of corrosion damage in complex boundary flows and provided a theoretical foundation for quantitative research.

Table 6.

Key publications on erosion-corrosion in 2020.

In recent years, erosion-corrosion research has shown accelerated development, characterized by a steady rise in the number of publications. Studies have focused on understanding corrosion behavior in environments with multiple interacting factors and on creating high-performance protective materials. The creation of high-hardness nanocomposite coatings, such as those made from NiTi, NbC, and TiC, has significantly enhanced material corrosion resistance across various conditions, including seawater, mud, and gas–liquid–solid multiphase flow systems. Research has also uncovered a synergistic relationship between erosion rate, impact angle, particle kinetic energy, and material microstructure. It has been observed that the erosion-corrosion damage mechanism often evolves from being corrosion-dominated to erosion-dominated. Key research findings are summarized in Table 7.

Table 7.

Key publications on erosion-corrosion in the past five years.

Furthermore, in situ electrochemical monitoring techniques, including electrochemical noise (EN) [98,107,108,109], electrochemical impedance spectroscopy (EIS) [80,110,111,112,113], and localized electrochemical methods [114,115,116] (e.g., scanning vibrating electrode technique, SVET), have proven effective in capturing transient corrosion events and informing life prediction models. CFD numerical simulations have also matured, progressing from Reynolds-averaged Navier–Stokes (RANS) models to more detailed large eddy simulation (LES) [117] and direct numerical simulation (DNS) [118,119,120] approaches. More recently, researchers have begun integrating physics-informed neural networks (PINNs) [121] to incorporate physical laws into data-driven models, aiming to accelerate the prediction of localized damage and material failure in real time.

Despite these advancements, significant gaps remain. Multi-scale modeling frameworks that bridge atomic-scale mechanisms (e.g., grain boundary dissolution, localized corrosion pits) with macro-scale phenomena (e.g., pipeline wall thinning, component fatigue) are still under development. The integration of molecular dynamics (MD) and density functional theory (DFT) with CFD remains limited, representing a promising future direction for developing unified, cross-scale predictive models.

4.1.2. Journal Concerns

The distribution of journals in this field indicates its broad reach across various academic disciplines. The predominant proportion of key results in the engineering journal Wear is concentrated within the initial two decades of the 21st century (80.6%), and its total number of citations has reached 5552, with an H-index of 46, thereby reflecting a substantial academic influence. Moreover, of the 134 papers included in the journal, seven have received over 100 citations. These citations are predominantly associated with the effects of erosion-corrosion interactions on marine and offshore materials [122,123,124], the erosion-corrosion of stainless steel, titanium, tantalum, and zirconium [74,125], and the corrosion and synergistic effects in WC-Co-Cr HVOF thermal spray coatings [126]. Table 8 provides a summary of the primary research focuses of these papers.

Table 8.

Highly cited publications (over 100 citations) in Wear.

In comparison to the aforementioned journal, Corrosion Science has slightly fewer articles, with a total of 61 papers. However, it has demonstrated an exponential growth trend in the total number of citations over the past two decades, averaging 45.5 citations per article. This indicates an extremely elevated academic impact. The highly cited literature focuses on the erosion and corrosion of X65 carbon steel elbows at different locations [77] and the erosion and corrosion of HVOF sprayed iron-based amorphous metal coatings under the impact of sand-containing NaCl solutions [71,127]. Previous studies have also investigated the impact of heat treatment on the evolution of microstructure and the erosion-corrosion behavior of nickel-aluminum-bronze alloys and 304 stainless steel in chloride solutions [115,128]. Additionally, the erosion-corrosion of 2205 duplex stainless steel in sandy, flowing seawater [129] and the initiation and propagation processes of flow-accelerated corrosion and erosion-corrosion on steel electrodes have been examined [80]. Table 9 details the specific research topics addressed in the aforementioned studies.

Table 9.

Highly cited publications (over 100 citations) in Corrosion Science.

Furthermore, as illustrated in Figure 6 and outlined in Table 2, prominent journals such as Engineering Failure Analysis, Surface & Coatings Technology, and Tribology International have attained notable success in augmenting the erosion resistance of materials through the implementation of surface modification techniques, including thermal spraying, which have garnered significant attention from the scholarly community [112,131,132,133]. An overview of the core research themes of these papers is presented in Table 10. In sum, these journals have been instrumental in the advancement of the field and its evolution from fundamental theory to practical application.

Table 10.

Key publications published in Engineering Failure Analysis and related journals.

4.1.3. Regional Concerns

The manifestation of erosion-corrosion is subject to variation due to environmental differences across different regions. Consequently, the research priorities for each region are distinct. The geographic distribution of research on erosion-corrosion is characterized in Table 3, which reveals a widespread global presence of such research. Early Scottish studies predominantly focused on corrosion in oilfield production [134]. Among them, Stack published 24 papers, with his most highly cited article conducting a systematic study on the effects of erosion-corrosion on carbon steel subjected to erosion-corrosion in oilfields [135], laying an important foundation for the field. In contrast, Japan has demonstrated a proactive stance in the development of quantitative analysis methodologies for assessing pipeline corrosion and wall thickness thinning. For instance, Takahashi et al. [136] conducted monotonic four-point bending tests using tee pipe specimens with localized wall thinning to investigate the effect of localized wall thinning on the fracture behavior of pipes. Furthermore, they conducted low-cycle fatigue testing and finite element analysis using elbow specimens with localized wall thinning, achieving successful prediction of crack penetration area and crack growth direction [137]. In China, the principal research outcomes in this field have been predominantly concentrated in the last five years, with a mean annual output of over 25 publications. The primary methodologies employed in the study of pipeline corrosion, anti-corrosion materials, and corrosion inhibition included electrochemical experiments and numerical simulations [95,138,139,140,141,142]. Despite the relatively limited number of publications in the United States (see Figure 7), the country has also cooperated extensively with India, China, and other 30 countries. For instance, an exhaustive critical examination of the erosion, corrosion resistance, and erosion-corrosion synergistic effects on Mo-Ti and Ni-Cr-Mo alloyed medium carbon martensitic steels has been conducted in collaboration with Wuhan University [143]. A comprehensive review of the extant literature on erosion-corrosion research reveals a discernible trend of broadening international development.

4.1.4. Institutional Contributions

The prevalence and necessity for cross-disciplinary research on erosion-corrosion are revealed by the characteristics of institutional distribution. Major institutions with robust academic output and a propensity to collaborate are dispersed throughout China, the United Kingdom, Canada, and other countries, exhibiting a multi-core synergistic layout (Figure 9). The Chinese Academy of Sciences serves as the primary node, with affiliated institutions including Xi’an Jiaotong University, Sichuan University, Tianjin University, Beijing University of Chemical Technology, and numerous other domestic universities that occupy a significant position. A notable example is the joint study by Tianjin University, Shanghai Jiao Tong University, and the University of Calgary in Canada, which examined the impact of heat treatment on the microstructure evolution and erosion-corrosion behavior of nickel-aluminum-bronze alloys in chloride solutions [128]. This study serves as a seminal reference for subsequent research in this field. For instance, Luo et al. [144] investigated the synergistic effects of cavitation, erosion, and corrosion on the surface layer of Ni-Al-bronze. Qin et al. [100] investigated the effects of compressive stress on the cavitation, erosion, and corrosion behavior of Ni-Al-bronze alloys.

Concurrently, international research institutions, including the University of Strathclyde and the University of Leeds in the United Kingdom and the University of Alberta in Canada, have exhibited extensive collaborative endeavors. Notably, the University of Leeds and Syncrude Canada Ltd. [145] have engaged in a concerted and methodical evaluation of the erosion-corrosion performance, underscoring the pivotal role of cross-country collaboration in propelling the depth of research. Furthermore, the team conducted a comprehensive assessment of metal matrix composites for erosion-corrosion applications in the oil sands industry, providing substantial support for engineering practice [146].

A comprehensive analysis reveals the establishment of a robust network of collaboration among research institutions, accompanied by the emergence of numerous intersections and linkages in transnational cooperation. These observations suggest a progression in the field of erosion-corrosion research, characterized by an expansion in internationalization and a deepening of multidisciplinary integration.

4.2. Condensation of Research Hotspots

A survey of other related sources—including academic journals, technical standards, and patents—was conducted to identify the primary research areas concerning erosion-corrosion. The results of this survey are illustrated in Figure 13.

Figure 13.

Primary research focus areas.

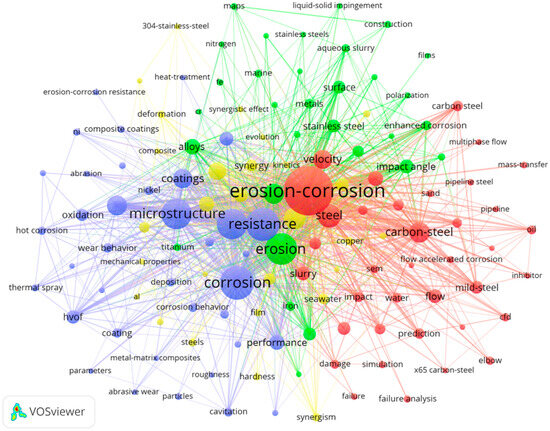

The identification of research hotspots in this field is further refined using bibliometrics. Specifically, the research hotspots of erosion-corrosion from 2001 to 2024 can be identified using the co-occurrence function in VOSviewer, focusing solely on keywords. Keywords serve as proxies for the core content of articles, and keyword frequency analysis can elucidate the research hotspots and cutting-edge topics in the field of corrosion inhibition in pipelines. The analysis is based on the high and low frequency boundary formula proposed by Donohue in 1973 [147]:

where is the boundary line between high and low frequencies and is the number of keywords with frequency 1.

A visual representation of the co-cited keywords was generated using VOSviewer (see Figure 14). This visualization was derived from a total of 138 keywords with more than 10 occurrences. VOSviewer automatically identified four clusters based on their co-occurrences. The use of analogous colors for the representation of keywords within the same cluster facilitates the identification of these terms. To prevent label overlap, some keywords may not display their labels. The thickness of the connecting lines reflects the degree of co-citation between keywords. Moreover, the visualization of co-citations provides insight into the interrelationships among keywords. The proximity of keywords in the visualization indicates their relevance, with greater proximity signifying a stronger connection [148].

Figure 14.

VOSviewer network map for keyword analysis visualization.

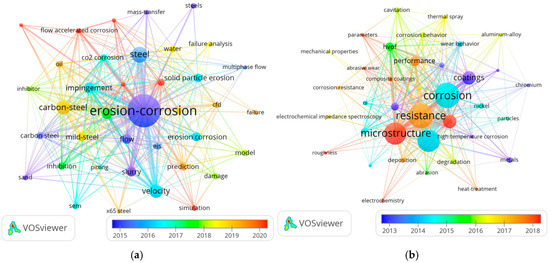

Figure 15 shows the eruption times and contact networks for the keywords of different colored clusters of erosion-corrosion in Figure 14. Figure 15a corresponds to the red cluster. Early studies in this field were based on keywords such as “erosion-corrosion”, “steel”, “solid particle erosion”, “flow”, and “slurry” with a focus on erosion-corrosion behavior in flowing environments. Since 2018, research hotspots have gradually shifted to keywords like “CFD”, “failure analysis”, “carbon steel”, and “X65 steel”, indicating that scholars’ attention has extended from basic mechanisms to engineering applications and failure analysis. This cluster generally reflects the evolution trend of erosion-corrosion in steel materials and actual working conditions. Figure 15b corresponds to the blue cluster. Before 2016, keywords such as “corrosion”, “coatings”, “high-temperature corrosion”, “HVOF”, and “corrosion behavior” dominated, indicating that research primarily focused on the performance of anti-corrosion coatings in high-temperature environments. In the last five years, keywords like “microstructure”, “resistance”, “composite coatings”, and “electrochemistry” have become prominent, indicating that microstructure regulation and electrochemical research have become the focus. This cluster mainly reflects the shift from macroscopic to microscopic research on the properties of protective coatings. As illustrated in Figure 15c, the green cluster encompasses early high-frequency keywords such as “alloys”, “metals”, “iron”, “stainless steel”, “tribocorrosion”, “flow”, and “titanium”. The research was focused on the fundamental corrosion behavior of metallic materials, with specific attention given to “stainless steel”, “tribocorrosion”, “flow”, and “titanium”. Since 2016, the following terms have emerged: “marine”, “surface”, “electrochemistry”, “enhanced corrosion”, and “XPS”. These terms have expanded the scope of research to marine environments and surface analysis techniques, emphasizing the need to enhance corrosion resistance in complex service environments. This cluster reflects the progression of the research process from the study of traditional metal corrosion to the investigation of multi-factor synergistic mechanisms. As illustrated in Figure 15d, the yellow cluster demonstrates a significant increase in keyword frequency between 2014 and 2017. Specifically, there was a notable rise in searches for “stainless steel”, “steel”, “mechanical properties”, “aluminum”, and “deformation”. This trend signifies a heightened emphasis on the mechanical properties and deformation behavior of structural materials. Following 2017, the research focus transitioned to “flow velocity”, “electrochemical corrosion”, “evolution”, and “high temperature”. The terms “high-entropy alloy” and “adaptability of new alloys in complex corrosion environments” are used to emphasize the versatility of novel alloys in intricate corrosion settings. The cluster as a whole demonstrates a transition from the conventional characterization of material properties to the examination of novel material development and service behavior.

Figure 15.

Network map of different clusters of erosion-corrosion keywords. (a) Timeline view of red cluster keywords. (b) Timeline view of blue cluster keywords. (c) Timeline view of green cluster keywords. (d) Timeline view of yellow cluster keywords. The size and color of the nodes represent the frequency of keyword occurrences and the average publication year. The shorter the distance between nodes, the higher the co-occurrence of the keywords.

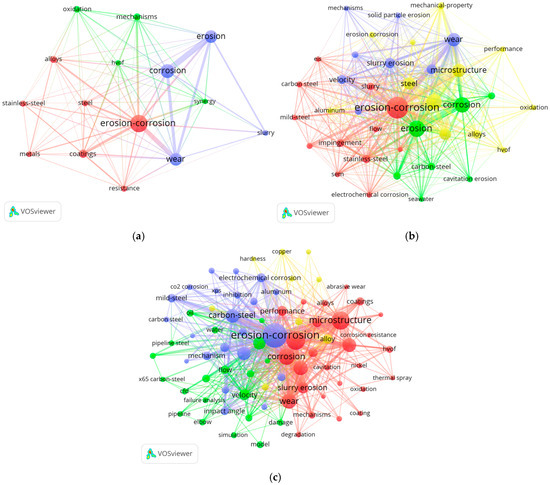

Figure 16 illustrates the outbreak network of keywords across three distinct time periods within the last 24 years. Overall, the research directions and hotspots in the field of erosion-corrosion have expanded significantly. This expansion indicates that the complexity and difficulty of research in this field have increased.

Figure 16.

Keyword co-occurrence network for different time periods. (a) 2001–2008 keyword co-occurrence network. (b) 2009–2016 keyword co-occurrence network. (c) 2017–2024 keyword co-occurrence network.

4.3. Perspective Research Trends

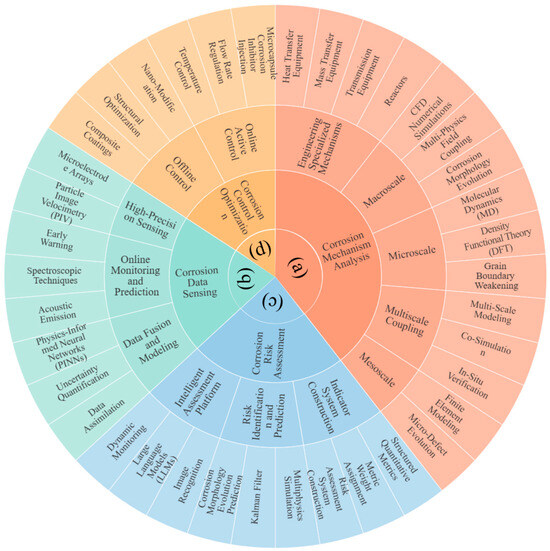

From the bibliometric analysis, it can be seen that erosion-corrosion research has gradually established a multi-mechanism synergistic theoretical framework, covering fluid dynamics, materials science, and electrochemical corrosion, as well as other interdisciplinary fields. In this study, we propose that future research should focus on four key directions: enhancing corrosion mechanisms, developing methodologies for understanding corrosion-related data, evaluating corrosion risk, and optimizing corrosion control measures, as illustrated in Figure 17. These directions aim to transition erosion-corrosion research from empirical studies to a more mechanism-focused and data-driven approach.

Figure 17.

Future research directions in erosion-corrosion. (a) Research directions 1: corrosion mechanism analysis. (b) Research directions 2: corrosion data sensing. (c) Research directions 3: corrosion risk assessment. (d) Research directions 4: corrosion control optimization.

4.3.1. Corrosion Mechanism Analysis

From the previous metrological analysis, the existing literature [149,150,151,152,153,154] shows that research methods for the erosion-corrosion mechanism mainly cover macroscale methods, such as experimental observation, multiphase flow simulation, and CFD. While these methods are important for revealing overall trends and engineering laws of erosion-corrosion, they have limitations. These limitations include long experimental periods, high costs, complex simulation boundary conditions, and difficulty reflecting microscopic corrosion mechanisms. These limitations reduce their overall accuracy and versatility. Therefore, this study analyzes macroscopic, microscopic, mesoscopic, multiscale, and application-specific engineering mechanisms (see Figure 17a) and proposes future research trends to provide ideas for prospective research on industrial corrosion prevention and control.

- (1)

- Macroscale

At the macroscopic scale, corrosion research focuses on the coupled effects of multi-physical fields, including fluid dynamics, heat and mass transfer, and electrochemical reactions. By combining CFD numerical simulations with experimental studies, researchers will investigate the impact of fluid erosion-corrosion on the surface corrosion rate and corrosion morphology of materials. Additionally, macroscopic morphological changes, such as erosion pits and grooves, and their effects on the overall performance of materials will emerge as significant research directions. For example, in marine engineering, understanding the corrosion behavior of seawater piping systems under the influence of multi-physical fields is crucial for ensuring the safe operation of equipment.

- (2)

- Microscale

Currently, research in the field of erosion-corrosion primarily focuses on macroscopic experiments and CFD numerical simulations. Significant progress has been made in understanding the overall flow structure and corrosion characterization. However, there is still a lack of in-depth analysis of the microscale mechanisms.

At the microscopic scale, the generation, merging, and splitting of fluid micro-clusters and vortices not only enhance heat and mass transfer but also thin the passivation film in high shear regions, thereby promoting localized corrosion. In the context of the interplay among heat transfer, mass transfer, transmission, and chemical reactions, the use of Molecular Dynamics (MD), Density Functional Theory (DFT), and other microscopic simulation methods is essential for analyzing interfacial reaction kinetics and corrosion product formation mechanisms at the molecular level. Moreover, examining microstructural changes, such as grain deformation and grain boundary weakening, in response to corrosion behavior will provide a theoretical foundation for the development of high-performance protective coatings and corrosion-resistant materials. For example, molecular dynamics simulations are used to investigate the diffusion behavior of hydrogen atoms in metals, revealing their impact on grain boundary strength.

- (3)

- Mesoscale

Research in mesoscale aims to bridge the gap between microscopic mechanisms and macroscopic behaviors, establishing a seamless connection through multi-scale models. Future research should be grounded in the finite element method and molecular dynamics simulations to quantitatively characterize the processes of stress corrosion crack propagation and corrosion product film formation and evolution. Additionally, there is a need to focus on the evolution of microscopic defects (e.g., cracks, holes, grain boundaries) in corrosive environments and elucidate their impact on overall corrosion rates and failure modes. This research will provide theoretical support for the design of material microstructures and the development of protective coatings, thereby enhancing industrial corrosion prevention and control strategies.

- (4)

- Multi-scale coupling

Future research will prioritize the examination of the coupling effects among macro-, micro-, and meso-scales. The development of a multi-scale corrosion model, spanning from microscopic to macroscopic levels, will be achieved through the synergistic integration of simulations and experimental verifications across each scale. For example, combining molecular dynamics with finite element simulations can quantitatively describe the stress intensity distribution at crack tips. Through in situ monitoring with numerical simulations, the dynamics and evolution laws of crack extension can be revealed, establishing a theoretical foundation for comprehensive protection strategies.

- (5)

- Special mechanism

For engineering applications, constructing a multi-scale coupling model is essential to meet the demands of industrialized applications. Following the development of this model, specialized mechanism research should be conducted on the critical components of various types of equipment. For instance, in heat transfer equipment such as shell-and-tube heat exchangers, it is necessary to deeply explore the synergistic effects of turbulence, pulsation, and wall temperature gradients within the heat transfer tube bundle. Similarly, in mass transfer equipment like packed towers, the multi-coupling mechanisms between liquid film thickness, gas–liquid interfacial tension, and material transfer rates must be analyzed. For transfer equipment, such as centrifugal pumps, fluid–solid chemical coupling models and microscopic wear models should be integrated to quantitatively assess the synergistic degradation effects of erosion-corrosion. In transmission equipment (e.g., centrifugal pumps), the fluid–solid chemical coupling model must be combined with the microscopic wear model to evaluate the combined degradation effects. For reaction equipment, it is crucial to examine the dual driving effects of local flow enhancement due to reaction heat release and changes in chemical conditions on erosion-corrosion behavior.

These studies will provide systematic theoretical support for risk assessment and the design of protective measures in industrial applications.

4.3.2. Corrosion Data Sensing

In the context of corrosion data sensing, a bibliometric analysis reveals the limitations of conventional methods. For instance, as indicated in the extant literature [155,156,157,158], the weightlessness method is characterized by poor data timeliness, limited accuracy, and a narrow scope of application. These issues hinder the capacity to monitor local corrosion dynamics in real time and with precision. Furthermore, the data acquisition process exhibits instability and relies on a singular means of analysis, a limitation that renders it inadequate for predicting complex working conditions. The crux of the matter pertains to the efficacy of data acquisition for the purpose of monitoring the processes of erosion and corrosion. The crux of this matter is the necessity of high-precision, real-time quantification of core parameters. Future research, as illustrated in Figure 17b, will concentrate on the implementation of high-performance sensors, including particle image velocimetry and microelectrode arrays, to capture the dynamic changes in key variables (temperature, position, pressure, flow rate, medium density, and equipment temperature and pressure) during the evolution of corrosion. Multi-point and multi-frequency measurements will enable continuous acquisition of sub-second time-domain and micrometer spatial-domain data during critical phases, thereby reducing uncertainty from environmental disturbances and measurement noise.

On this basis, data assimilation and uncertainty quantification can be used to perform multimodal fusion of experimental observations and CFD numerical simulation results to improve data integrity and reliability. Subsequently, the N-S equations, particle dynamics, and corrosion dynamics equations can be introduced into the deep learning framework with the help of physics-informed neural networks to realize cross-micro–macro-multi-scale feature extraction and residual learning. The deep learning framework has been demonstrated to facilitate the realization of cross-micro-macro multi-scale feature extraction and residual learning. Furthermore, the integration of the spatio-temporal attention mechanism enables the model to not only discern the coupling law between the transient evolution of the flow field and the alteration of the corrosion morphology, but also to dynamically recalibrate the model parameters through online Kalman filtering or recursive least squares. This ensures the uninterrupted precision of the prediction outcomes.

Ultimately, in light of the aforementioned high-precision data and models, online spectral monitoring and acoustic emission technologies are employed for the real-time, in situ observation of equipment hotspot evolution, facilitating the implementation of early warning systems and precision maintenance schedules. This approach enables the establishment of a comprehensive, closed-loop optimization framework that encompasses mechanism identification and operation decision-making. Furthermore, interpretable methods, such as SHapley Additive exPlanations (SHAP), can be employed to analyze the contribution mechanism of key variables to the corrosion rate. It is reasonable to hypothesize that the precise documentation and comprehensive evaluation of high-precision data will establish a substantial theoretical and practical foundation for the subsequent optimization of protection strategies, dynamic prediction, and risk assessment.

4.3.3. Corrosion Risk Assessment

As indicated by the preceding bibliometric analysis, the existing literature [159,160,161,162,163,164] shows that traditional empirical methods and simplified models struggle to accurately represent the nonlinear coupling of key variables in multiphase flow environments, limiting their ability to provide precise risk assessments. Given that the accuracy and reliability of corrosion risk assessment directly affect the safety, economic viability, and rationality of maintenance decisions, it is crucial to develop a data-driven, whole-life risk assessment system, as illustrated in Figure 17c. This system should integrate quantifiable, traceable, and comparable metrics to support quantitative management of identification, prediction, and response.

First, a structured quantitative indicator system should be established to clarify the collection source, timing, and precision of each sub-indicator. The core indicators should encompass metrics such as local corrosion rate and particle concentration, among others. Following normalization, these indicators should be weighted to formulate a unified grading standard. The standard not only facilitates horizontal comparison across pipelines and plants but also enables continuous calibration of weighting with new data.

In the phase of risk identification and prediction, CFD-structural mechanics coupled multiphysics field static simulation is combined with online dynamic monitoring. The former generates a risk heat map with high spatial and temporal resolution, while the latter collects real-time data by deploying sensor arrays of temperature, vibration, and electrochemical noise. The system performs data fusion and state identification by applying Kalman filtering or adaptive Bayesian filtering. In the event that the risk level exceeds a preset threshold, an early warning is automatically triggered. Concurrently, machine learning models founded upon random forests or deep neural networks are utilized to cross-validate historical O&M data and predict long-term future trends in corrosion morphology evolution.

In order to establish a comprehensive and efficient risk assessment framework, coupled with an intelligent decision-making process, it is proposed that an intelligent platform be developed for the assessment of erosion-corrosion risks. This platform would integrate advanced computer vision techniques with large language modeling capabilities. The platform’s functionality encompasses two primary processes. First, it automatically processes online and offline corrosion morphology images to accurately identify features such as pits and cracks. Then, it compares historical cases through semantic search to extract high-similarity precedents. Finally, it integrates mechanism simulation, machine learning prediction, and operation and maintenance strategies (e.g., chemical protection, local reinforcement) to realize multi-scale intelligent management from the microstructure of the metal to the pipeline network in the plant.

4.3.4. Corrosion Control Optimization

In the context of corrosion control optimization, from the previous metrological analysis, the extant literature [141,165,166,167,168,169,170] reveals that traditional methods fall short in accurately addressing the complex and variable conditions of erosion and corrosion. These methods lack the capability for dynamic adjustment and active optimization. Moreover, the conventional approach incurs significant costs in implementation and maintenance. Balancing the safety of equipment with its economic viability is challenging. Consequently, corrosion control strategies need to shift from conventional passive protection measures to active sensing methodologies and intelligent regulation systems. To achieve efficient and sustainable corrosion control, it is essential to integrate multidisciplinary approaches, including material science, fluid mechanics, electrochemistry, and data intelligence. This integration must form a synergistic and optimized technological system at both the off-line and on-line control levels, as illustrated in Figure 17d.

- (1)

- Offline target control technology

Offline target control is based on material and structural optimization. It involves enhancing materials and coatings and optimizing structures to mitigate the risk of erosion-corrosion failure under complex working conditions. This is achieved by establishing a multi-level physical-chemical barrier.

In terms of material selection, a comprehensive analysis is necessary to elucidate the synergistic interplay between mechanical erosion-corrosion and chemical corrosion. In a complex gas–liquid–solid environment, brittle materials demonstrate exceptional resistance to mechanical wear; however, their deficiency in corrosion resistance renders them vulnerable to premature failure in corrosive media. Plastic materials may prove inadequate due to the hardness of their particles, rendering them unable to withstand high-frequency impacts. Consequently, the use of composite materials or composite coatings has emerged as a prevailing option. For instance, the fabrication of composite layered structures or gradient functional coatings can enhance the adaptability of the equipment to the intricacies of the external environment, thereby improving the equipment’s anti-washout and corrosion resistance capabilities.

Furthermore, the use of CFD numerical simulation, visualization experiments, and other macro-techniques has proven effective in identifying areas of uneven flow fields. Through reasonable structural optimization, the impact of particles and liquid on local erosion has been effectively mitigated. Concurrently, at the microscopic level, the implementation of nano-self-organization or microporous array surface modification during the offline stage is instrumental in providing more comprehensive and enduring anti-washout and anti-corrosion protection for the equipment.

- (2)

- Online targeting control technology

Online target control, as a primary means of active corrosion control, must be accorded high priority in practical industrial production. Achieving active intervention and closed-loop optimization of the corrosion process of in-use chemical equipment necessitates precise regulation of the process medium and heat exchange medium flows.

The process media flow control methodology prioritizes the real-time regulation of critical parameters on both the equipment and media sides. The equipment side maintains a stable temperature gradient through zoned temperature control and pulse heating to enhance the interfacial passivation film. Concurrently, segmented differential pressure and pressure pulsation intervene to disrupt the localized steady-state electrolytic layer and mitigate the mechanical stress concentration. In the media field, a multifaceted approach involving the integration of online heat exchange recovery and the injection of fixed-point reflux, split flow, and flow rate pulsation is employed to manipulate the boundary layer structure. This strategy aims to mitigate the occurrence of shear spalling and particle impact.

Heat transfer media flow control functions as a supplement to material flow regulation by coupling a thermal-force-chemical mechanism to further inhibit corrosion. The system incorporates graded insulation and adjustable heat dissipation to ensure a smooth temperature curve. A thermoelectric self-supply unit enables online sensing and actuating devices, thereby providing a stable drive. An intelligent valve group distributes kinetic energy in the flow field in real time, alternating between a high shear zone and a low kinetic energy zone, thus destroying the adhesion of corrosion products. Polymer microcapsules, situated at a fixed point within the high-shear environment, release a corrosion inhibitor, thereby achieving a synergistic effect of kinetic energy and chemical inhibition.

To ensure the responsiveness and accuracy of online control, it is necessary to construct a closed-loop system that combines digital twin and reinforcement learning. The material and energy flows are entered into the CFD-heat conduction-electrochemical multi-field coupling model in real time to predict the evolution of the corrosion front online and generate control suggestions. Concurrently, the temperature, pressure, flow rate, and energy distribution paths are incorporated into the action space of the reinforcement learning intelligences to iteratively optimize the control strategy with the objective of reducing the corrosion rate.

A more profound understanding of the underlying mechanisms governing erosion-corrosion can serve as a foundation for future research endeavors aimed at formulating strategies to more effectively mitigate material degradation. It is anticipated that these strategies will result in a reduction of corrosion rates, an extension of the service life of equipment, and the optimization of operational cycles. By reducing the frequency of unplanned shutdowns and maintenance interventions, it is possible to achieve a substantial reduction in economic losses and enhance overall cost-effectiveness. Whilst the present study does not provide detailed technical solutions, extant literature [81,97,171] demonstrates the efficacy of such approaches in enhancing operational efficiency and reducing financial impact. This forecast underscores the scientific significance and practical economic value of prospective research directions in the domain of erosion-corrosion.

5. Conclusions

The field of erosion-corrosion research is currently experiencing a period of significant growth, as evidenced by a substantial increase in the number of papers published annually and the total number of citations over the past decade. Research in this area generally involves intricate interdisciplinary categories, predominantly encompassing materials science, metallurgical engineering, and engineering equipment, among others. These studies are predominantly disseminated in interdisciplinary journals, such as Wear and Corrosion Science. A total of 77 countries have participated in this research theme, among which China has published 355 articles and collaborated on 63 papers with 29 countries, primarily focusing on anti-corrosion materials research. Keyword co-occurrence analysis reveals that the primary research directions are focused on multi-factor coupling effects, anti-corrosion material research and development, and equipment failure analysis. The objective of this research is to improve the efficiency of equipment failure detection and extend equipment service life.

Furthermore, the erosion-corrosion process has garnered increased attention and recognition due to its close relationship with the flow characteristics of the fluid. The extant research results generally concur; in-depth studies of multiphase, multi-physical fields and multifactor coupling are more conducive to the future development of the field. Finally, material corrosion resistance and equipment service life can be improved in the future through corrosion mechanism enhancement, corrosion data sensing, corrosion risk assessment, and corrosion control optimization. In general, the accurate prediction and targeted suppression of erosion-corrosion are promising strategies for providing sustainable solutions to mitigate the significant economic losses and severe human casualties caused by this phenomenon.

This review offers a comprehensive overview of erosion-corrosion advances that can facilitate researchers’ understanding of erosion-corrosion trends, progress, and the future. It is important to note that this review does not undertake a comprehensive examination of the 1018 articles; rather, it provides a synopsis and an overview of their fundamental concepts. The WoS search formula employed to retrieve all pertinent articles is provided in the text to keep the reader abreast of the current state of the research field.

Author Contributions

Conceptualization, X.T.; methodology, X.T.; software, X.T.; validation, Y.L., B.Q., F.Z. and H.X.; formal analysis, X.T.; investigation, X.T.; resources, G.S., L.C., J.Z. and Z.D.; data curation, X.T.; writing—original draft preparation, X.T.; writing—review and editing, G.S., L.C., J.Z. and Z.D.; supervision, G.S., L.C., J.Z. and Z.D.; project administration, G.S., L.C., J.Z. and Z.D.; funding acquisition, J.Z. and Z.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Key R&D Program of China [Grant No. 2021YFB3301100], the National Natural Science Foundation of China (Grant No. 5220041986), Beijing University of Chemical Technology Interdisciplinary Program [Grant No. XK2023-07]. And The APC was funded by National Key R&D Program of China [Grant No. 2021YFB3301100].

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Zheng, Z.B.; Zheng, Y.G.; Sun, W.H.; Li, J.Q.; Cheng, Y.F. Erosion–corrosion of HVOF-sprayed Fe-based amorphous metallic coating under impingement by a sand-containing NaCl solution. Corros. Sci. 2013, 76, 337–347. [Google Scholar] [CrossRef]

- Gu, J.; Li, L.; Ai, M.; Ye, F.; Wang, Y.; Fu, H. Improvement of solid particle erosion and corrosion resistance using TiAlSiN/Cr multilayer coatings. Surf. Coat. Technol. 2020, 402, 126270. [Google Scholar] [CrossRef]

- Nguyen, Q.B.; Lim, C.Y.H.; Nguyen, V.B.; Tiu, M.S.; Chen, Z. Slurry erosion characteristics and erosion mechanisms of stainless steel. Tribol. Int. 2014, 79, 1–7. [Google Scholar] [CrossRef]

- Yi, J.Z.; Hu, H.X.; Wang, Z.B.; Su, J.Y.; Pan, Y.L. On the critical flow velocity for erosion–corrosion in local eroded regions under liquid-solid jet impingement. Wear 2019, 422–423, 94–99. [Google Scholar] [CrossRef]

- Kermani, M.B.; Harrop, D. The impact of corrosion on the oil and gas industry. Corros. Manag. 1996, 11, 186–190. [Google Scholar] [CrossRef]

- Neville, A.; Wang, C. Erosion–corrosion of engineering steels—Can it be managed by use of chemicals? Wear 2009, 267, 2018–2026. [Google Scholar] [CrossRef]

- Zhang, G.; Dong, H.; Zhang, Y.; Sun, H. Corrosion–erosion wear behaviors of 13Cr24Mn0.44N stainless steel in saline–sand slurry. Tribol. Int. 2010, 43, 891–896. [Google Scholar]

- Zheng, Y.; Yao, Z.; Wei, X.; Zhang, L. The synergistic effect between erosion and corrosion in acidic slurry medium. Wear 1995, 186–187, 555–561. [Google Scholar] [CrossRef]

- Liao, X. Erosion, Factors and Prevention of. In The ECPH Encyclopedia of Mining and Metallurgy; Kuangdi, X., Ed.; Springer Nature: Singapore, 2024; p. 615. [Google Scholar]

- Burstein, G.T.; Sasaki, K. Detecting electrochemical transients generated by erosion–corrosion. Electrochim. Acta 2001, 46, 3675–3683. [Google Scholar] [CrossRef]

- Barik, R.C.; Wharton, J.A.; Wood, R.J.K. Electro-mechanical interactions during erosion–corrosion. Wear 2009, 267, 1900–1908. [Google Scholar] [CrossRef]

- Jiang, X.; Zheng, Y.G.; Ke, W. Effect of flow velocity and entrained sand on inhibition performances of two inhibitors for CO2 corrosion of N80 steel in 3% NaCl solution. Corros. Sci. 2005, 47, 2636–2658. [Google Scholar] [CrossRef]

- Kang, D.H.; Lee, H.W. Study of the correlation between pitting corrosion and the component ratio of the dual phase in duplex stainless steel welds. Corros. Sci. 2013, 74, 396–407. [Google Scholar] [CrossRef]

- Yang, F.F.; Kang, H.; Chen, Z.; Guo, E.; Zeng, Y.; Wang, W.; Wang, T. Electrochemical corrosion mechanisms of nickel–aluminium bronze with different nickel contents using the rotating disc electrode. Corros. Sci. 2019, 161, 108188. [Google Scholar] [CrossRef]

- Zheng, J.; Hu, X.; Pan, C.; Fu, S.; Lin, P.; Chou, K. Effects of inclusions on the resistance to pitting corrosion of S32205 duplex stainless steel. Mater. Corros. 2018, 69, 572–579. [Google Scholar] [CrossRef]

- Ahmed, D.A.; Yerramalli, C.S. Experimental and computational analysis of the erosion behaviour of unidirectional glass fiber epoxy composites. Wear 2020, 462–463, 203525. [Google Scholar] [CrossRef]

- Hutchings, I.M. A model for the erosion of metals by spherical particles at normal incidence. Wear 1981, 70, 269–281. [Google Scholar] [CrossRef]

- Melentiev, R. Physical theories of solid particle erosion and abrasive jet wear. J. Manuf. Process. 2023, 106, 422–452. [Google Scholar] [CrossRef]

- Solnordal, C.B.; Wong, C.Y.; Boulanger, J. An experimental and numerical analysis of erosion caused by sand pneumatically conveyed through a standard pipe elbow. Wear 2015, 336–337, 43–57. [Google Scholar] [CrossRef]

- Takaffoli, M.; Papini, M. Numerical simulation of solid particle impacts on Al6061-T6. Part II: Materials removal mechanisms for impact of multiple angular particles. Wear 2012, 296, 648–655. [Google Scholar] [CrossRef]

- Purandare, Y.P.; Stack, M.M.; Hovsepian, P.E. Velocity effects on erosion–corrosion of CrN/NbN “superlattice” PVD coatings. Surf. Coat. Technol. 2006, 201, 361–370. [Google Scholar] [CrossRef]

- Wei, L.; Pang, X.; Gao, K. Effect of flow rate on localized corrosion of X70 steel in supercritical CO2 environments. Corros. Sci. 2018, 136, 339–351. [Google Scholar] [CrossRef]

- Zadeh, S.A. Erosion-Corrosion. Introduction to Corrosion—Basics and Advances; Singh, A., Ed.; IntechOpen: Rijeka, Croatia, 2023. [Google Scholar]

- Kaszniak, M.U.S. Chemical Safety & Hazard Investigation Board Report: BP Texas Refinery Explosion and Fire; U.S. Chemical Safety and Hazard Investigation Board: Washington, DC, USA, 2007.

- Shenzhen Nanshan District Emergency Management Bureau. Historical Hazardous Chemical Accidents in July [Online]. Shenzhen Nanshan District Emergency Management Bureau, Shenzhen. 2019. Available online: https://www.szns.gov.cn/nsqajj/gkmlpt/content/7/7682/post_7682580.html (accessed on 24 March 2025).

- Garfield, E. “Science Citation Index”—A new dimension in indexing. Science 1964, 144, 649–654. [Google Scholar] [CrossRef]

- Liang, C.; Qiao, S.; Olatosi, B.; Lyu, T.; Li, X. Emergence and evolution of big data science in HIV research: Bibliometric analysis of federally sponsored studies 2000–2019. Int. J. Med. Inform. 2021, 154, 104558. [Google Scholar] [CrossRef]

- Lei, X.; Xie, F.; Wang, J.; Zhang, C. A review of lithium-ion battery state of health and remaining useful life estimation methods based on bibliometric analysis. J. Traffic Transp. Eng. 2024, 11, 1420–1446. [Google Scholar] [CrossRef]

- Lv, J.; Zou, K.; Kang, K. A bibliometric analysis of environmental risk factors in cardiovascular diseases research: A comprehensive perspective using network science tools. Asian J. Surg. 2025, 48, 2405–2406. [Google Scholar] [CrossRef] [PubMed]